From Buildings’ End of Life to Aggregate Recycling under a Circular Economic Perspective: A Comparative Life Cycle Assessment Case Study

Abstract

:1. Introduction

2. Scope and Objectives

- The development of a composite life cycle inventory of primary and secondary data for the demolition of these two buildings.

- The quantification of the potential environmental impacts originating from their end of life.

- The quantification of the potential environmental impacts originating from the production of recycled aggregates when using construction and demolition waste as a resource.

- The comparison of the environmental impacts due to the production of virgin aggregates with those due to the production of recycled aggregates through the treatment of construction and demolition wastes.

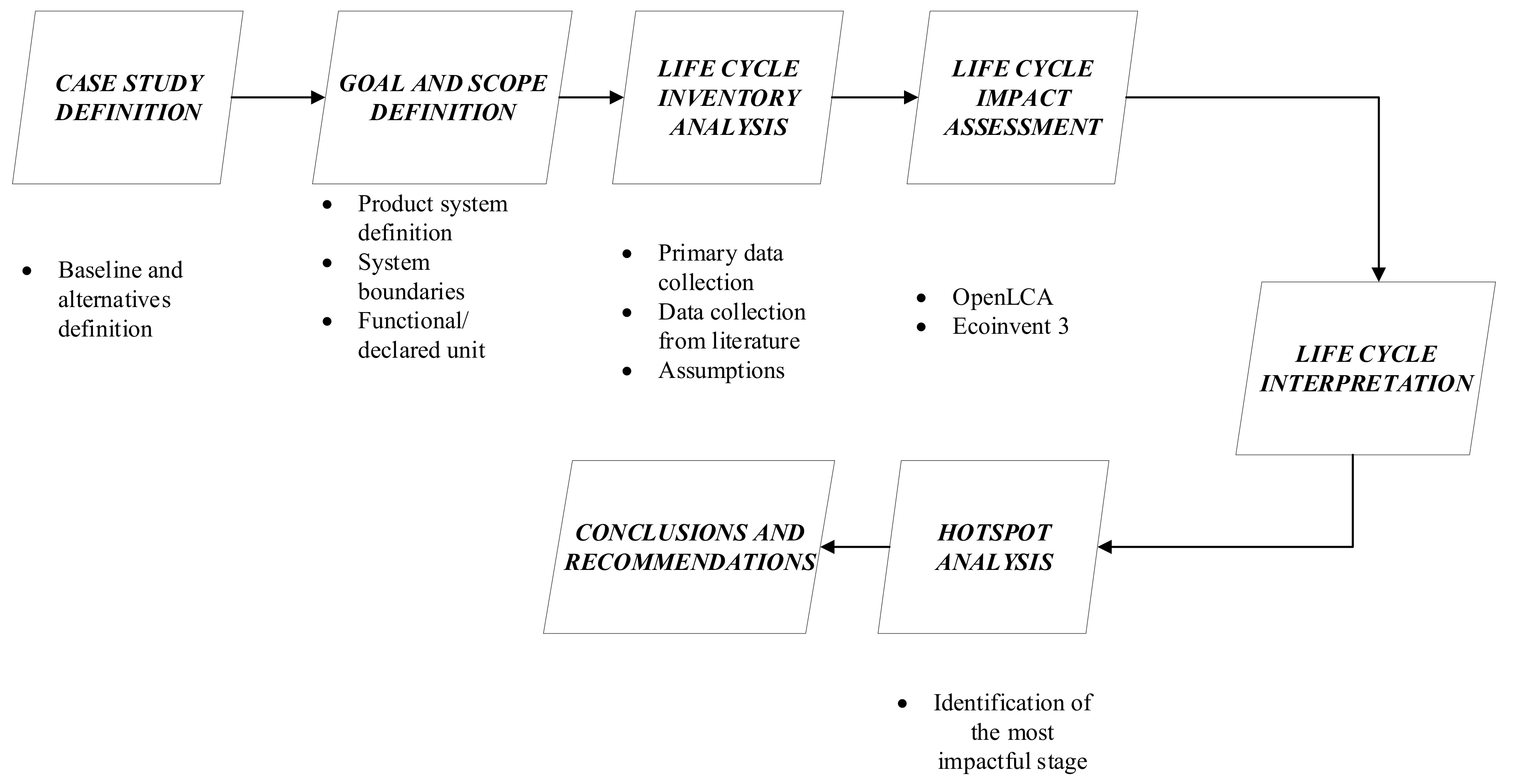

3. Methods

3.1. Life Cycle Assessment

3.2. Life Cycle Impact Assessment Methodology

- Acidification of soil and water (kg SO2 eq.),

- Ozone depletion (kg CFC-11 eq.),

- Eutrophication (kg PO43− eq.),

- Photochemical ozone creation (kg ethylene eq.),

- Air pollution (m3),

- Water pollution (m3),

- Global warming (kg CO2 eq.),

- Depletion of abiotic resources (fossil) (MJ, net calorific value), and

- Depletion of abiotic resources (elements) (kg Sb eq.).

- Consumption of renewable energy resources (MJ),

- Consumption of non-renewable energy resources (MJ),

- Radioactive waste (kg),

- Hazardous waste (kg),

- Non-hazardous waste (kg), and

- Fresh water (m3).

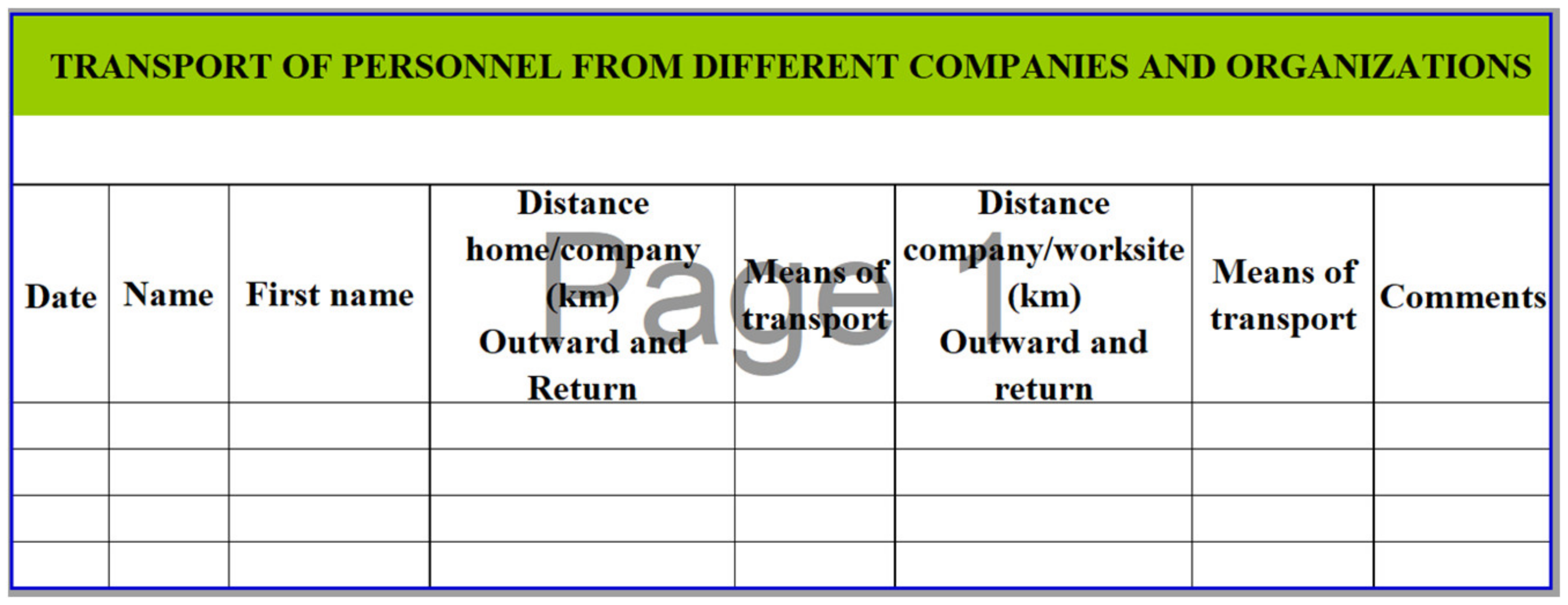

3.3. Data Collection

4. Case Study and Results

4.1. Definition of the Case Study

4.1.1. Demolition Site of Building A

4.1.2. Demolition Site of Building B

4.2. Quantifying the Environmental Impacts of the Buildings’ Demolition and the Production of Recycled and Virgin Aggregates

4.2.1. Goal and Scope

4.2.2. Assumptions Made for the Study

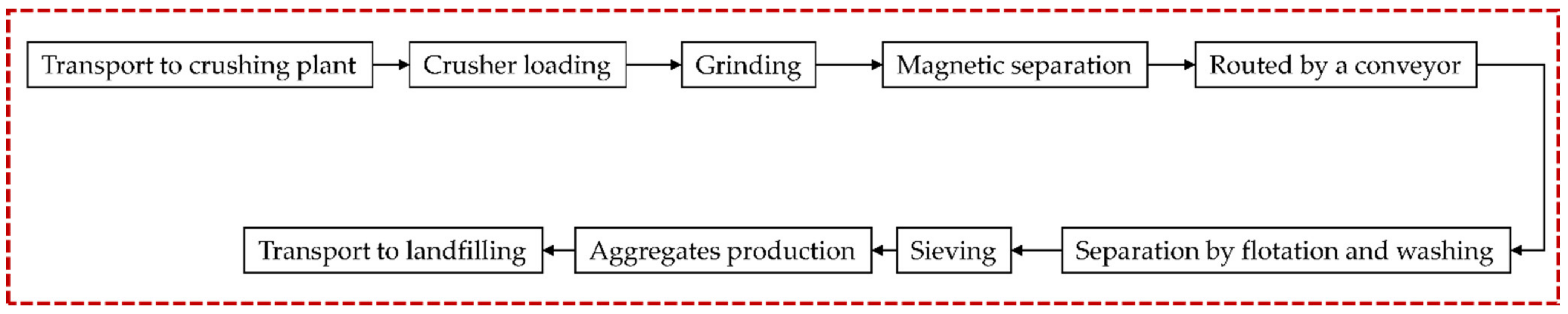

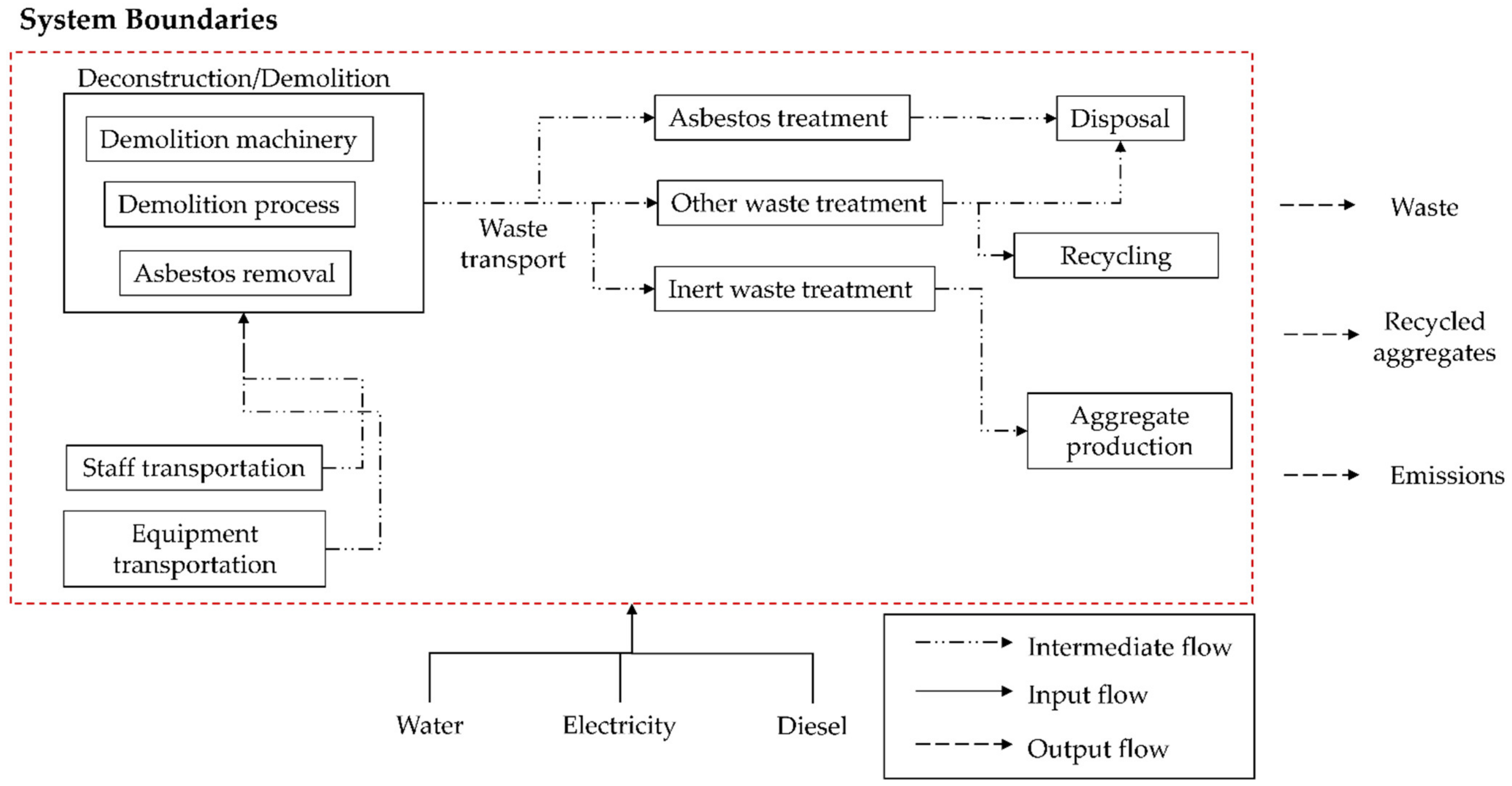

4.2.3. System Boundaries and Functional Unit

- Transport and production of materials used on site (embankments),

- Transport and production of consumables,

- Transport and production of limited use supplies,

- Transport on site and consumption of machinery,

- Transport of staff,

- Transport and treatment of materials from demolition,

- Transport of site installation (site life base for workers),

- Electricity consumption, and

- Water consumption.

- Production of limited use supplies and consumables,

- Construction machinery production,

- The administrative department,

- Production of site installation (site life base for workers), and

- Production of consumables for recycling aggregates process.

- (1)

- “to demolish 1 m2 of floor area of an asbestos building”

- (2)

- “to produce 1 t of aggregate”

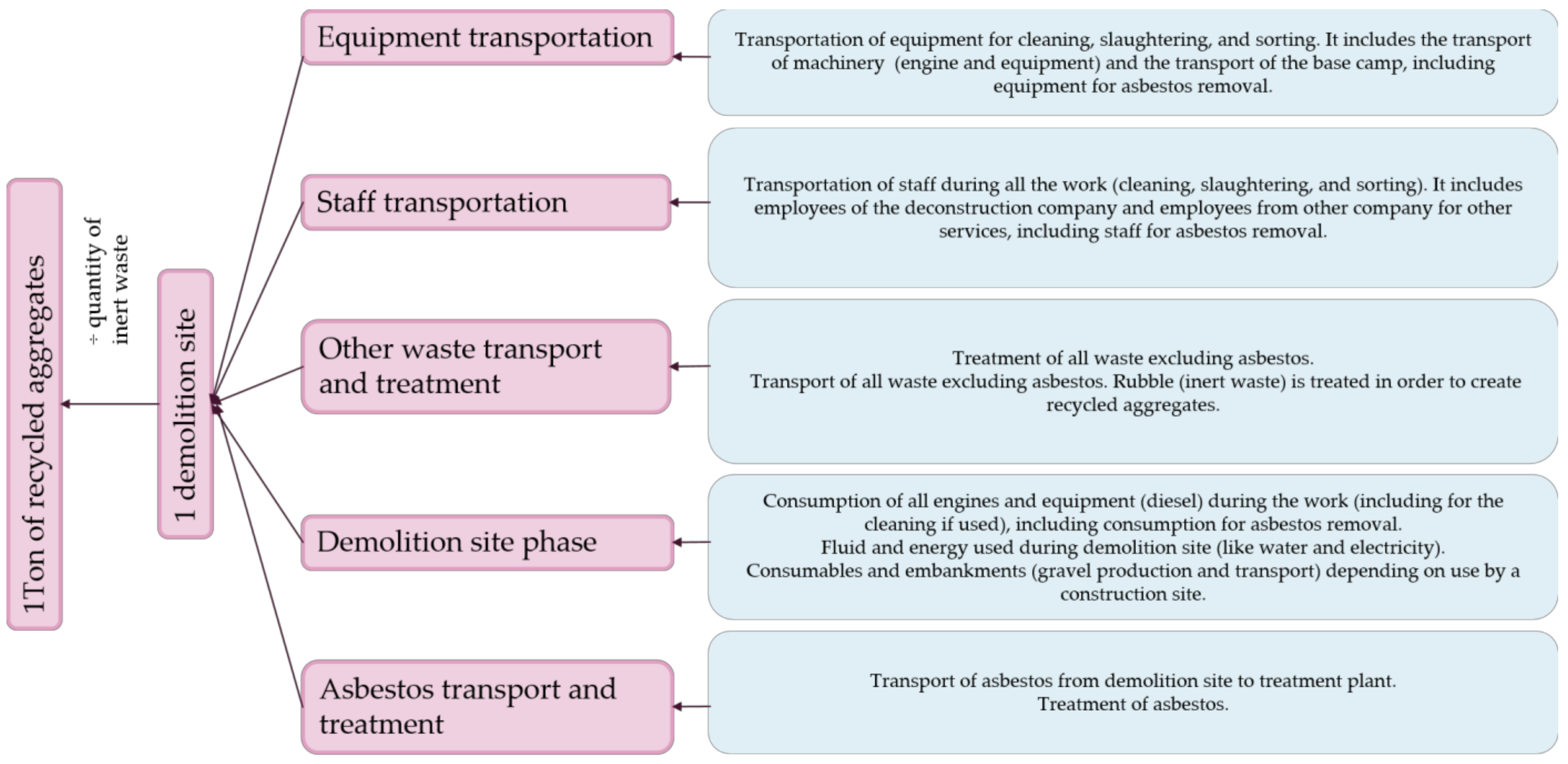

4.2.4. Data and Life Cycle Inventory

- Staff transportation,

- Equipment transportation,

- Asbestos transport and treatment,

- Other waste transport and treatment, and

- Demolition phase.

4.2.5. Life Cycle inventory of Building A

4.2.6. Life Cycle Inventory of Building B

4.2.7. Data Quality Assessment

4.3. Results Obtained and Discussion

4.3.1. Scale of the Demolition Site

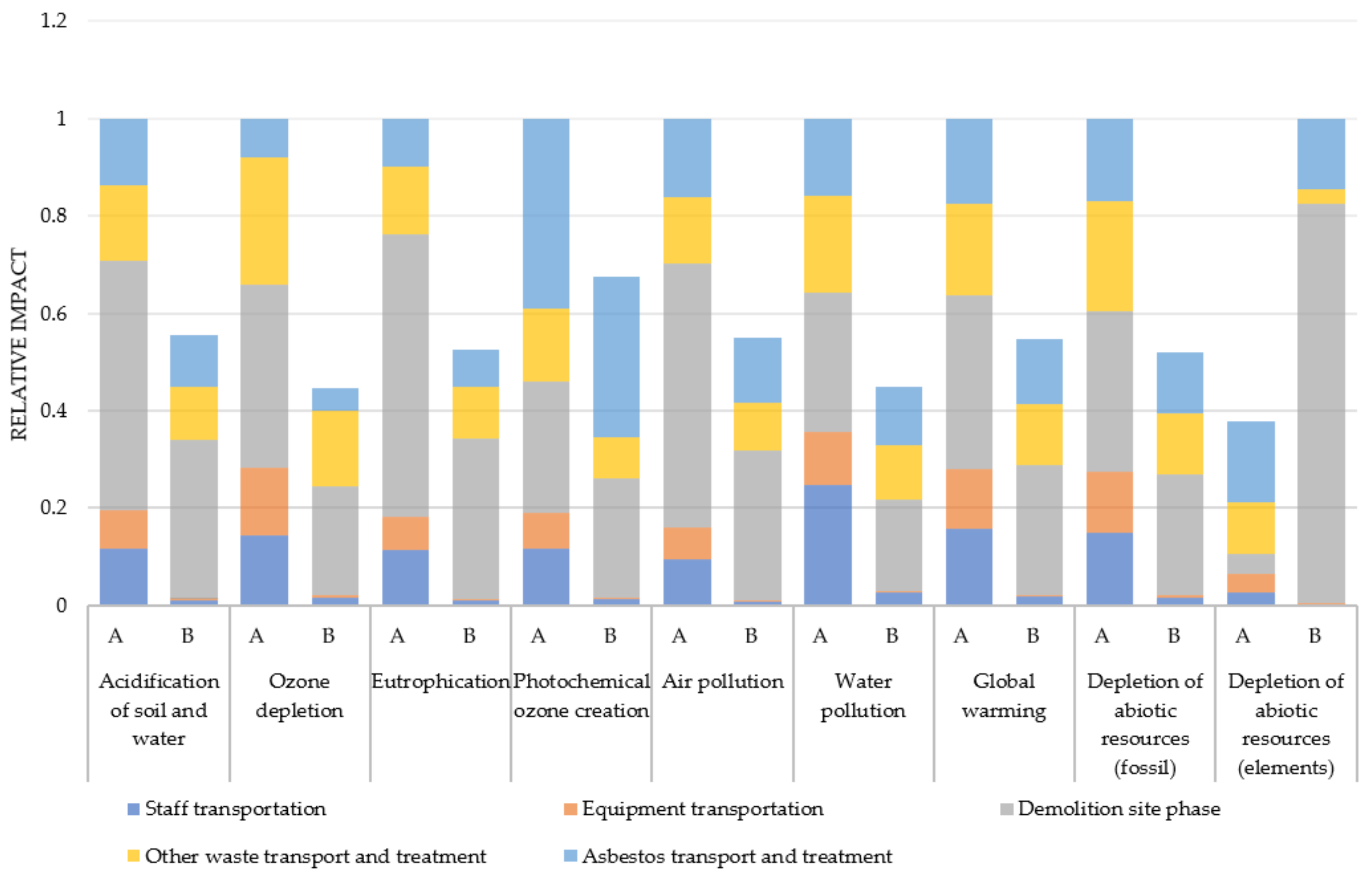

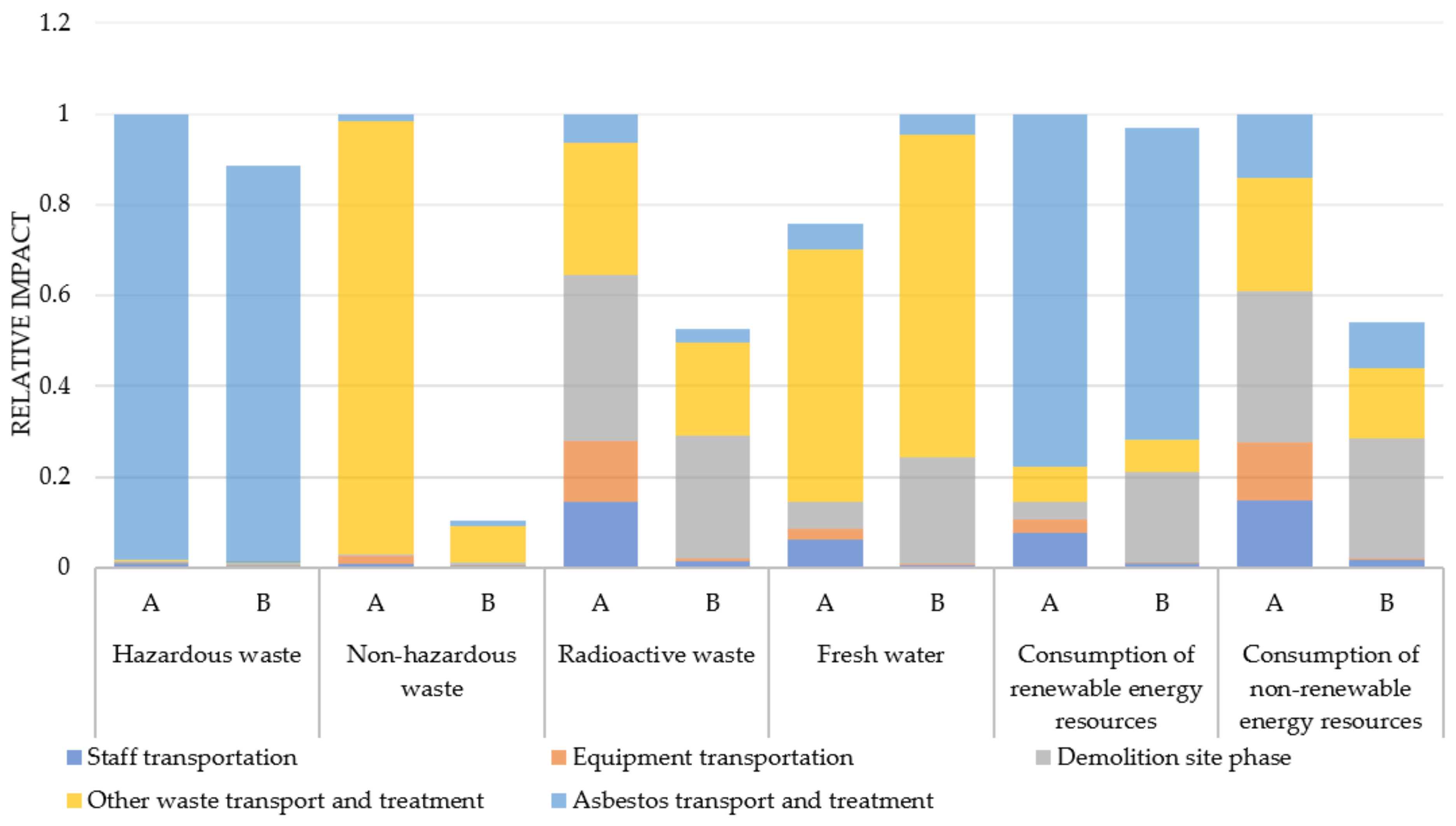

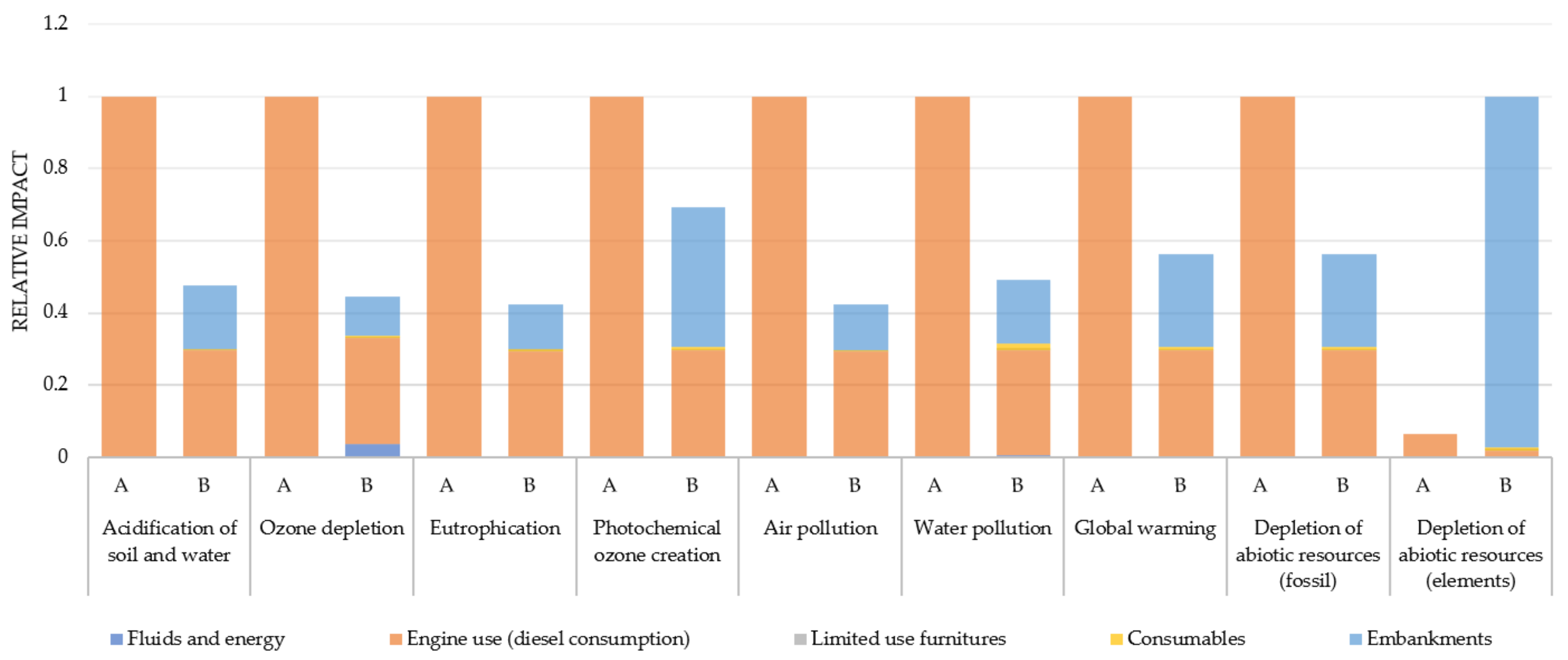

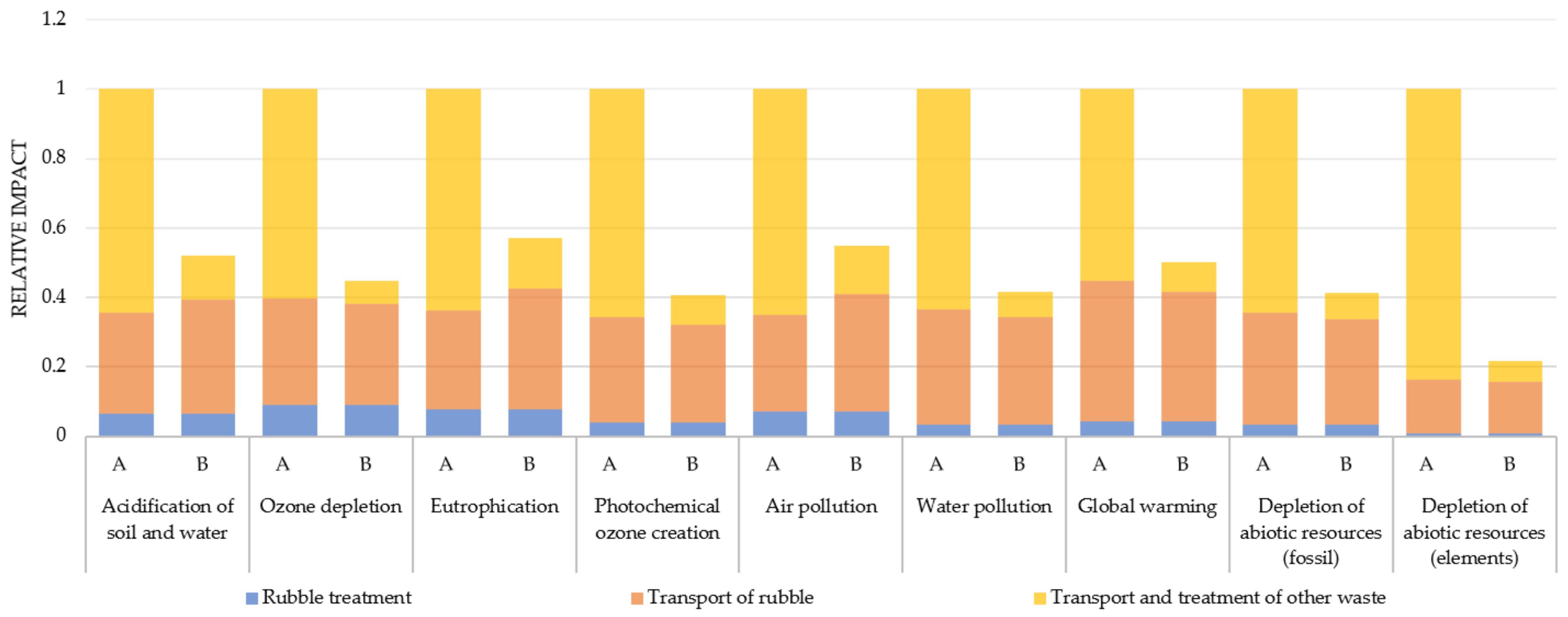

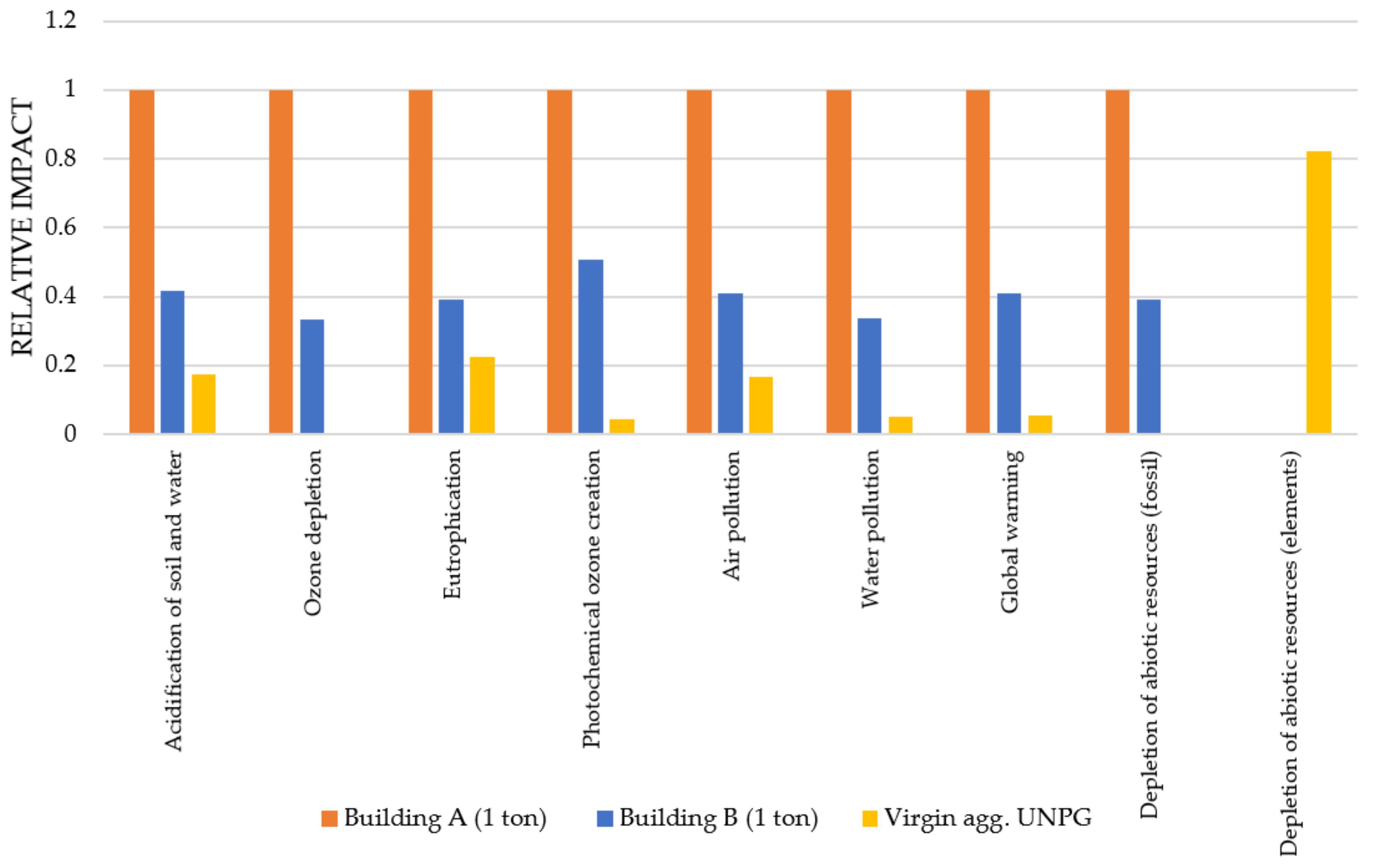

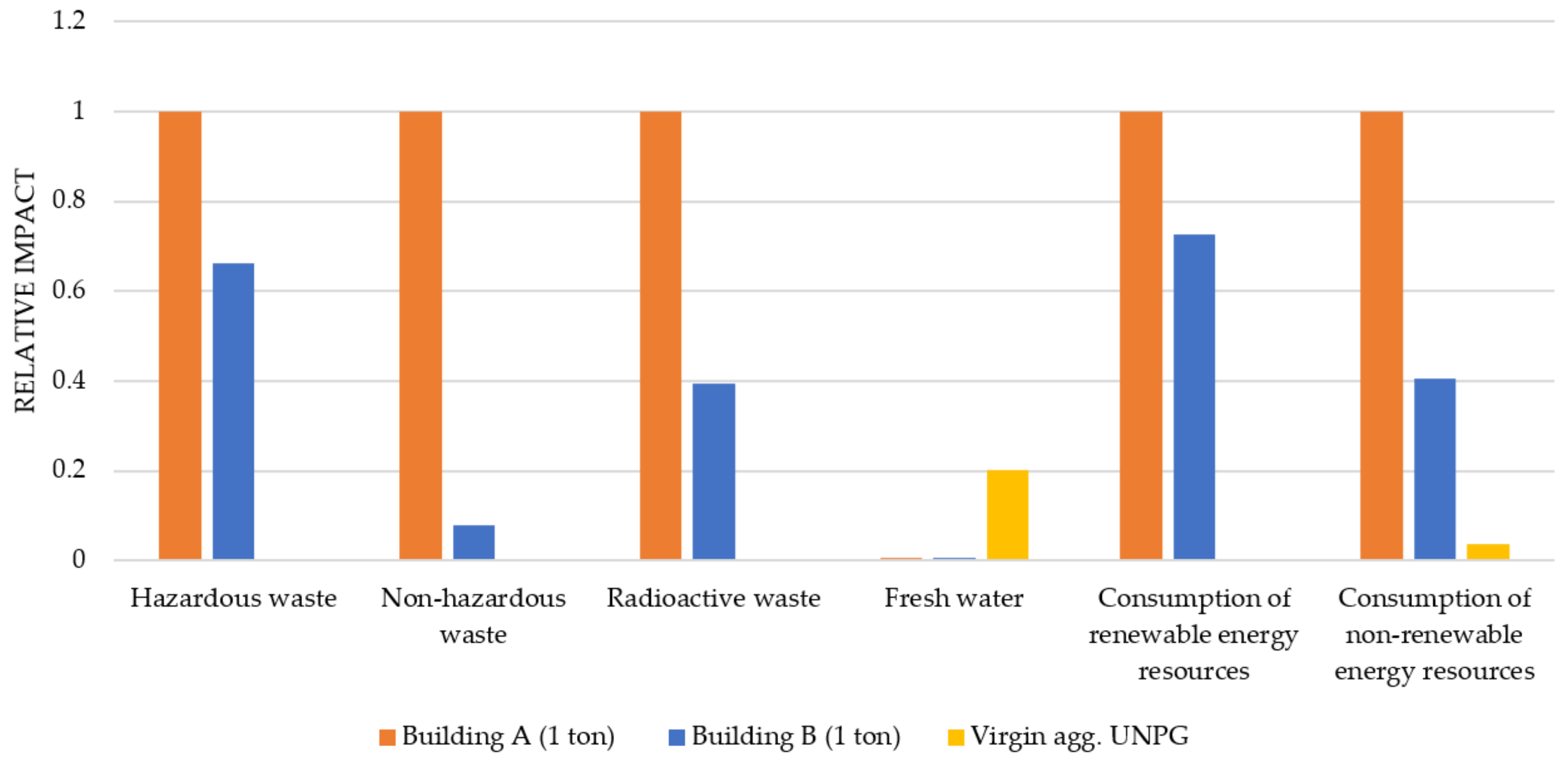

4.3.2. Scale of the Aggregate and Hotspot Analysis and Identification of the Most Relevant Life Cycle Stages

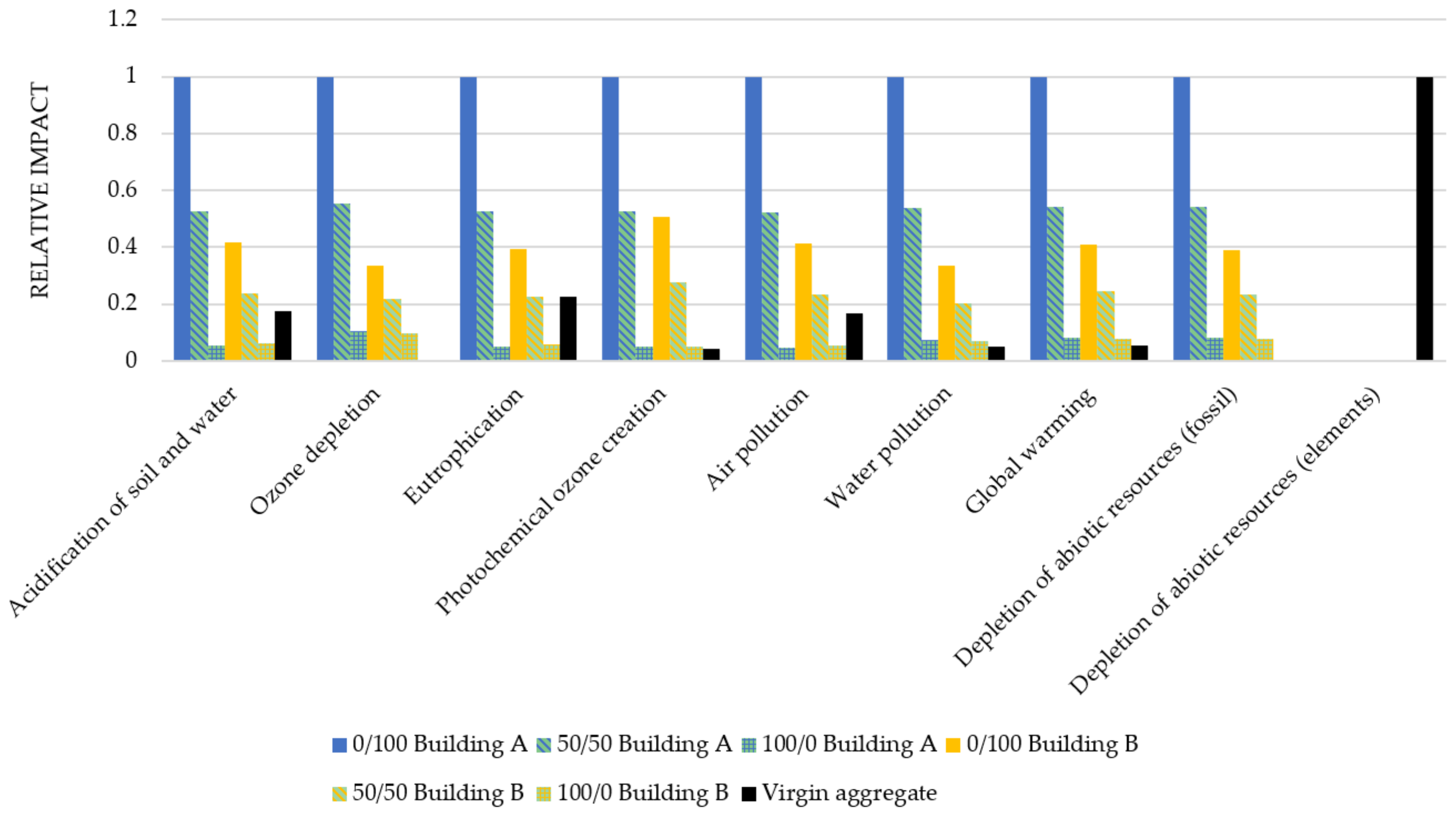

4.3.3. Sensitivity Analysis on Different Allocation Approaches

- 0/100 approach: With this kind of method, demolishing buildings is prompted (only by integrating avoided impacts) in order to produce recycled aggregates. However, the big impact of the recycled aggregate is not encouraging the use. Thus, this approach could be relevant to limit the act of demolishing and limit new constructions as it is joined with regulation of the extraction of virgin aggregates.

- 50/50 approach: This method is a compromise between the previous and the following approaches. It fairly distributes the impact of demolishing on the old building and the recycled aggregate. This method does not currently permit the promotion of the use of recycled aggregate because the impact is still more severe than one for virgin aggregate in some demolition site. Nonetheless, it could permit selecting only more efficient demolishing.

- 100/0 approach: This approach is the method where recycled aggregate is the most competitive. It incites the use of recycled aggregates under the condition that global warming is not the only indicator focused on. Nevertheless, it does not limit demolishing.

5. Summary and Conclusions

- Concerning recycled aggregate production, the maximum impact was measured by allocating all the impacts of the end of life of the building. Comparison between building A and building B was similar as for the end-of-life scale (i.e., building B was less impacting than building A). For flow indicators, observations were almost the same. Impacts of recycled aggregates were higher than those of virgin aggregates for all indicators except for depletion of abiotic resources (elements) and ozone depletion (this one was not computed for virgin aggregate). Consequently, recycled aggregates are not competitive with this allocation method.

- On both scales, hotspot analysis highlighted that all parts of the end of life were impacting but demolition phase and transport and treatment of waste were predominant. For example, demolition site phase and transport and treatment of waste both corresponded to about 35% for building A and the global warming indicator. This is mainly due to fuel consumption of building machinery and transport of waste. Moreover, the big variation of impact between both buildings was due to the quantity of other waste (without rubble) produced by demolition. Hence, it reinforces the aspect of the typology of the building and economy of scale.

- Previously, we observed that recycled aggregates are not competitive with virgin aggregates when all impacts of the building’s end of life are allocated to the production of recycled aggregates. In order to know at which level of allocation becomes competitive, a sensitivity analysis with different allocation approaches was carried out. Conclusions were quite mixed because with the most favorable allocation (which consisted of taking into account only transport and treatment of inert waste for impact of recycled aggregate), recycled aggregate was not significantly the least impacting for all indicators, especially global warming. Those observations highlight the interest of the multicriteria aspect of life cycle assessment.

- The optimization of the treatment processes of the C&Dw is a crucial activity within an advanced waste management since it was seen that the asbestos treatment is very impactful in the hotspot analysis.

- The optimization of the geolocation of the demolition sites and the treatment plant is essential as well. Therefore, the transport stage was also significantly impactful and thus, careful planning of the transport routes has to be undertaken before the demolition of any building.

- It was also shown that the sustainability implications of the demolition of buildings and the subsequent production of recycled aggregates using C&Dw under the umbrella of circular economy is an aspect that is highly location-, context-, and case-sensitive.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Life Cycle Inventory of Process of Recycling Aggregate, of Building A and Building B

Appendix B. Information about Collection of Data

| Ecoinvent®-Flow Name | Quantity | Information | Provider |

|---|---|---|---|

| diesel, burned in building machine | 2.75 MJ | Loading into crusher | Cutoff, U—GLO |

| tap water | 67.7 kg | Flotation separation and washing | Market, Cutoff, U—Europe without Switzerland |

| transport, freight, lorry > 32 metric ton, EURO4 | 0.1 t.km | Internal transport | Cutoff, U—RER |

| electricity, medium voltage | 1.5 kWh | For all stage needing electricity | Market, Cutoff, U—FR |

| Asbestos, Transportation and Treatment | |||

| Ecoinvent®-Flow Name | Quantity | Information | Provider |

| hazardous waste, for underground deposit | 9 t | Treatment of asbestos waste | Cutoff, U—RoW |

| transport, freight, lorry 16–32 metric ton, EURO5 | 2295 t.km | Transport of asbestos waste | Cutoff, U—RER |

| Waste, Transportation and Disposal | |||

| Ecoinvent®-Flow Name | Quantity | Information | Provider |

| inert waste, for final disposal | 112 t | Treatment of all waste except inert waste which could be recycled | Cutoff, U—RoW |

| process of treatment (Table A1) | 276 t | Recycling treatment for Inert waste | |

| transport, freight, lorry 16–32 metric ton, EURO5 | 4125 t.km | Transport of waste to treatment plants | Cutoff, U—RER |

| transport, freight, lorry 7.5–16 metric ton, EURO5 | 4635 t.km | Transport of waste to treatment plants | Cutoff, U—RER |

| Demolition Site Phase | |||

| Ecoinvent®-flow Name | Quantity | Information | Provider |

| diesel, burned in building machine | 49,466.3 MJ | Use of construction machinery | Cutoff, U—GLO |

| tap water | 500 kg | Water consumption during demolition site | Market, Cutoff, U—Europe without Switzerland |

| Equipment Transportation | |||

| Ecoinvent®-Flow Name | Quantity | Information | Provider |

| transport, freight, lorry > 32 metric ton, EURO5 | 14,792 t.km | Transport of heavy machinery | Cutoff, U—RER |

| transport, freight, lorry 16–32 metric ton, EURO5 | 1514.088 t.km | Transport of machinery and installation site | Cutoff, U—RER |

| Staff Transportation | |||

| Ecoinvent®-Flow Name | Quantity | Information | Provider |

| transport, passenger car, medium size, diesel, EURO 5 | 2580 km | Transport of staff including staff for asbestos removal | Cutoff, U—RER |

| transport, passenger car, small size, diesel, EURO 5 | 1332 km | Transport of staff | Cutoff, U—RER |

| transport, passenger train | 720 p.km | Transport of staff | Cutoff, U—FR |

| Asbestos, Transportation and Treatment | |||

| Ecoinvent®-Flow Name | Quantity | Information | Provider |

| hazardous waste, for underground deposit | 146.08 t | Treatment of asbestos waste | Cutoff, U—RoW |

| transport, freight, lorry 16–32 metric ton, EURO4 | 3229.4 t.km | Transport of asbestos from building | Cutoff, U—RER |

| transport, freight, lorry 16–32 metric ton, EURO4 | 1130.08 t.km | Transport of asbestos from asphalt | Cutoff, U—RER |

| Waste, Transportation and Disposal | |||

| Ecoinvent®-Flow Name | Quantity | Information | Provider |

| inert waste, for final disposal | 155.92 t | Ordinary industrial waste which is landfilled | Cutoff, U—RoW |

| transport, freight, lorry 7.5–16 metric ton, EURO4 | 1247.2 t.km | Transport of ordinary industrial waste to treatment plant | Cutoff, U—RER |

| wood chips, from post-consumer wood, measured as dry mass | 51.04 t | Treatment of wood | treatment, sorting and shredding Cutoff, U—RoW |

| transport, freight, lorry 16–32 metric ton, EURO4 | 468.07 t.km | Transport of wood to the treatment plant | Cutoff, U—RER |

| waste reinforcement steel | 45.84 t | Treatment of shear iron and cast iron, they are recycled | Treatment, recycling Cutoff, U—RoW |

| transport, freight, lorry 16–32 metric ton, EURO4 | 435.48 t.km | Transport of shear iron and cast iron | Cutoff, U—RER |

| process of treatment (Table A1) | 6738 t | Recycling treatment for Inert waste | |

| transport, freight, lorry 16–32 metric ton, EURO4/6000 | 131,795.28 t.km | Transport of inert waste to recycling plant | Cutoff, U—RER |

| Demolition Site Phase | |||

| Ecoinvent®-Flow Name | Quantity | Information | Provider |

| diesel, burned in building machine | 353,398 MJ | Use of construction machinery | Cutoff, U—GLO |

| gravel, crushed | 20.89274 t | Consumable | Gravel production Cutoff, U—RoW |

| transport, passenger car, large size, diesel, EURO 4 | 2164 km | Transport of consumable (other than gravel) | Cutoff, U—RER |

| transport, freight, lorry 16–32 metric ton, EURO4 | 115.417 t.km | Transport of consumable | Cutoff, U—RER |

| electricity, medium voltage | 29,639 MJ | Electricity used during demolition site | Market, Cutoff, U—FR |

| tap water | 37,000 kg | Water consumption during demolition site | Market, Cutoff, U—Europe without Switzerland |

| gravel, crushed | 2522.22 t | For embankments | Gravel production Cutoff, U—RoW |

| transport, freight, lorry > 32 metric ton, EURO4 | 27,514.4 t | Transport of gravel for embankments | Cutoff, U—RER |

| transport, passenger car, large size, diesel, EURO 4 | 57 km | Transport of other elements | Cutoff, U—RER |

| Equipment Transportation | |||

| Ecoinvent®-Flow Name | Quantity | Information | Provider |

| transport, freight, lorry > 32 metric ton, EURO4 | 840 t.km | Transport of heavy machinery | Cutoff, U—RER |

| transport, freight, lorry 7.5–16 metric ton, EURO4 | 67.8 t.km | Transport of medium machinery | Cutoff, U—RER |

| transport, freight, lorry 3.5–7.5 metric ton, EURO4 | 53.6556 t.km | Transport of light machinery | Cutoff, U—RER |

| transport, freight, lorry 16–32 metric ton, EURO4 | 4415.77 t.km | Transport of heavy machinery | Cutoff, U—RER |

| transport, freight, lorry 16–32 metric ton, EURO4 | 188.6 t.km | Transport of installation site | Cutoff, U—RER |

| Staff Transportation | |||

| Ecoinvent®-Flow Name | Quantity | Information | Provider |

| transport, passenger car, large size, diesel, EURO 4 | 6268 km | Transport of staff for various services | Cutoff, U—RER |

| transport, freight, lorry 16–32 metric ton, EURO4 | 45.475 t.km | Transport of staff for various services | Cutoff, U—RER |

| transport, freight, lorry 7.5–16 metric ton, EURO4 | 47.6 t.km | Transport of staff from enterprise to site | Cutoff, U—RER |

| transport, passenger car, large size, diesel, EURO 4 | 3934 km | Transport of staff from enterprise to site | Cutoff, U—RER |

| transport, passenger car, small size, diesel, EURO 4 | 812 km | Transport of staff from enterprise to site | Cutoff, U—RER |

References

- LWARB. London’s Circular Economy Route Map; London Waste and Recycling Board: London, UK, 2017. [Google Scholar]

- Republica Portuguesa. Leading the Transition—Action Plan for Circular Economy in Portugal: 2017–2020; Portuguese Council of Ministers: Lisbon, Portugal, 2017; pp. 1–62. [Google Scholar]

- Circular Flanders (Vlaanderen Circulair). CIRCULAR FLANDERS Together towards a Circular Economy; Circular Flanders: Mechelen, Belgium, 2017. [Google Scholar]

- Mantalovas, K.; di Mino, G.; Carrion, A.J.D.B.; Keijzer, E.; Kalman, B.; Parry, T.; Presti, D.L. European National Road Authorities and Circular Economy: An Insight into Their Approaches. Sustainability 2020, 12, 7160. [Google Scholar] [CrossRef]

- Mercante, I.T.; Bovea, M.D.; Ibáñez-Forés, V.; Arena, A.P. Life cycle assessment of construction and demolition waste management systems: A Spanish case study. Int. J. Life Cycle Assess. 2011, 17, 232–241. [Google Scholar] [CrossRef]

- Sala, S.; Farioli, F.; Zamagni, A. Life cycle sustainability assessment in the context of sustainability science progress (part 2). Int. J. Life Cycle Assess. 2012, 18, 1686–1697. [Google Scholar] [CrossRef]

- ISO 14044. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006; Volume 2006, pp. 652–668. [Google Scholar]

- Council of the European Union. Council decision of 19 December 2002 establishing criteria and procedures for the acceptance of waste at landfills pursuant to Article 16 of and Annex II to Directive 1999/31/EC. Off. J. Eur. Communities 2003, 4646, 27–49. [Google Scholar]

- The European Parliament. Regulation (EC) No 2150/2002 of the European Parliament and of the Council on Waste Statistics. Off. J. Eur. Communities 2002, 2150, 1–36. [Google Scholar]

- European Commission. Taking Sustainable Use of Resources Forward: A Thematic Strategy on the Prevention and Recycling of Waste; COM 666 Final; European Commission: Brussel, Belgium, 2005. [Google Scholar]

- Butera, S.; Christensen, T.H.; Astrup, T.F. Life cycle assessment of construction and demolition waste management. Waste Manag. 2015, 44, 196–205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- European Commission. Decision of the European Parliament and of the Council on a General Union Environment Action Programme to 2030; COM(2020) 652 Final; European Commission: Brussel, Belgium, 2020. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions—The Green Deal; COM(2019) 640 Final; European Commission: Brussell, Belgium, 2019. [Google Scholar]

- European Commision. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions—A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; COM(2020) 98 Final; European Commission: Brussel, Belgium, 2020. [Google Scholar]

- Deloitte and Bre. Construction and Demolition Waste Management in France. 2015. Available online: https://ec.europa.eu/environment/pdf/waste/studies/deliverables/CDW_France_Factsheet_Final.pdf (accessed on 8 May 2021).

- International Organization for Standardization. EN ISO 14040:2006: Environmental Management—Life Cycle Assessment—Principles and Framework; Elsevier Ltd.: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Leite, F.D.C.; Motta, R.D.S.; Vasconcelos, K.L.; Bernucci, L. Laboratory evaluation of recycled construction and demolition waste for pavements. Constr. Build. Mater. 2011, 25, 2972–2979. [Google Scholar] [CrossRef]

- Hackenhaar, I.C.; Waskow, R.P.; Tubino, R.; Passuello, A. Life Cycle Assessment applied to construction and demolition waste treatment: Proposal of a Brazilian scenario. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012054. [Google Scholar] [CrossRef]

- Blengini, G.A.; di Carlo, T. The changing role of life cycle phases, subsystems and materials in the LCA of low energy buildings. Energy Build. 2010, 42, 869–880. [Google Scholar] [CrossRef]

- Blengini, G.A.; Garbarino, E. Resources and waste management in Turin (Italy): The role of recycled aggregates in the sustainable supply mix. J. Clean. Prod. 2010, 18, 1021–1030. [Google Scholar] [CrossRef]

- Blengini, G.A. Life cycle of buildings, demolition and recycling potential: A case study in Turin, Italy. Build. Environ. 2009, 44, 319–330. [Google Scholar] [CrossRef]

- Ortiz, O.; Pasqualino, J.; Castells, F. Environmental performance of construction waste: Comparing three scenarios from a case study in Catalonia, Spain. Waste Manag. 2010, 30, 646–654. [Google Scholar] [CrossRef] [PubMed]

- Kulik, M. A visual Life Cycle Analysis for architects and policymakers: Comparing standard building structure materials with bamboo for China’s plan to house 400 million people in cities in 20 years. Creat. Commons 2013, 2, 87. [Google Scholar]

- Teng, Y.; Pan, W.; Li, K. Comparing Life Cycle Assessment Databases for Estimating Carbon Emissions of Prefabricated Buildings. In Construction Research Congress (CRC) 2018; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2018. [Google Scholar] [CrossRef]

- Pourkhorshidi, S.; Sangiorgi, C.; Torreggiani, D.; Tassinari, P. Using Recycled Aggregates from Construction and Demolition Waste in Unbound Layers of Pavements. Sustainability 2020, 12, 9386. [Google Scholar] [CrossRef]

- Lancieri, F.; Marradi, A.; Mannucci, S. C&D waste for road construction: Long time performance of roads constructed using recycled aggregate for unbound pavement layers. WIT Trans. Ecol. Environ. 2006, 92, 559–569. [Google Scholar] [CrossRef] [Green Version]

- Mantalovas, K.; di Mino, G. Integrating Circularity in the Sustainability Assessment of Asphalt Mixtures. Sustainability 2020, 12, 594. [Google Scholar] [CrossRef] [Green Version]

- Mantalovas, K.; di Mino, G. The Sustainability of Reclaimed Asphalt as a Resource for Road Pavement Management through a Circular Economic Model. Sustainability 2019, 11, 2234. [Google Scholar] [CrossRef] [Green Version]

- Mantalovas, K.; di Mino, G.; Inzerillo, L.; Roberts, R. Exploiting 3D Modelling and Life Cycle Assessment to Improve the Sustainability of Pavement Management; Springer International Publishing: Cham, Switzerland, 2021; Volume 178. [Google Scholar] [CrossRef]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M. Circular Economy on Construction and Demolition Waste: A Literature Review on Material Recovery and Production. Materials 2020, 13, 2970. [Google Scholar] [CrossRef] [PubMed]

- EM Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition. Available online: https://ellenmacarthurfoundation.org/towards-a-circular-economy-business-rationale-for-an-accelerated-transition, (accessed on 20 August 2021).

- Manosalvas-Paredes, M.; Roberts, R.; Barriera, M.; Mantalovas, K. Towards More Sustainable Pavement Management Practices Using Embedded Sensor Technologies. Infrastructures 2019, 5, 4. [Google Scholar] [CrossRef] [Green Version]

- Mantalovas, K.; Carrión, A.J.D.B.; Planche, J.P.; Porot, L.; Pouget, S.; Williams, C.; Presti, D.L. Interpreting Life Cycle Assessment results of bio-asphalt pavements for more informed decision-making. In Pavement, Roadway, and Bridge Life Cycle Assessment 2020, Proceedings of the International Symposium on Pavement. Roadway, and Bridge Life Cycle Assessment 2020 LCA 2020, Sacramento, CA, USA, 3–6 June 2020; LCA 2020: Sacramento, CA, USA, 2020. [Google Scholar]

- Mantalovas, K. Increasing the Circularity of Asphalt Mixtures: Integrated Sustainability and Circularity Assessment as a Progress Monitoring Tool towards More Circular and Sustainable Asphalt Pavements Increasing the Circularity of Asphalt Mixtures: Integrated Sustain. Ph.D. Thesis, University of Palermo, Palermo, Italy, 2021. [Google Scholar]

- AFNOR. EN 15804:2012—Standards Publication Sustainability of construction works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products; AFNOR: Paris, France, 2012. [Google Scholar]

- AFNOR. EN 15643-2:2011—Sustainability of Construction Works—Assessment of Buildings—Part 2: Framework for the Assessment of Environmental Performance; AFNOR: Paris, France, 2011; pp. 1–36. [Google Scholar]

- Getas, F. Recommandations sur la Mise en Place d’une Economie Circulaire Autour des Chantiers de Déconstruction par une Approche d’Analyse de Cycle de Vie. Master’s Thesis, Université de Technologie de Troyes, Troyes, France, 2016. [Google Scholar]

- Desbois, T.; Yazoghli-Marzouk, O.; Feraille, A. LCA of construction and demolition waste recycling: Case study of production phase. In Proceedings of the International Symposium on Pavement, Roadway, and Bridge Life Cycle Assessment 2020, Online, 12–15 January 2021. [Google Scholar]

- UNPG. Module D’information Environnemental de la Production de Granulat Recycle, mai 2011. Available online: https://www.unpg.fr/accueil/dossiers/environnement/analyse-de-cycle-de-vie-des-granulats/ (accessed on 2 July 2021).

- Ben Fraj, A.; Idir, R. Concrete based on recycled aggregates—Recycling and environmental analysis: A case study of Paris’ region. Constr. Build. Mater. 2017, 157, 952–964. [Google Scholar] [CrossRef]

- Zampori, L.; Saouter, E.; Castellani, V.; Schau, E.; Cristobal, J.; Sala, S. Guide Forinterpreting Life Cycle Assessment Result; Publications Office of the European Union: Luxembourg, 2016; p. 60. [Google Scholar] [CrossRef]

| Data Quality Requirements | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Data | Type | Source | Technological | Geographical | Time-Related | Completeness | Methodological Appropriateness and Consistency | Parameter Uncertainty | Resulting Data Quality Rating (DQR) |

| Fuel consumption (demolition phase) | Primary | Reported data and ecoinvent® | 1 | 4 | 4 | 3 | 2 | 2 | 2.67 |

| Water consumption (demolition phase) | Primary | Reported data and ecoinvent® | 3 | 3 | 3 | 2 | 2 | 1 | 2.33 |

| Electricity consumption (demolition phase) | Primary | Reported data and ecoinvent® | 3 | 2 | 3 | 2 | 2 | 1 | 2.17 |

| Consumables (gravel) | Primary | Reported data and ecoinvent® | 4 | 4 | 4 | 2 | 3 | 1 | 3.00 |

| Means of transport and distances (staff, materials) | Primary | Reported data and ecoinvent® | 2 | 3 | 4 | 2 | 2 | 1 | 2.33 |

| Disposal and other waste processing | Secondary | Reported quantity, assumption for the treatment | 4 | 4 | 4 | 1 | 2 | 4 | 3.17 |

| Internal transport (production plant) | Secondary | Amor Ben Fraj, Rachida Idir 2017, and ecoinvent® | 2 | 3 | 4 | 3 | 1 | 3 | 2.67 |

| Water consumption (production plant) | Secondary | Amor Ben Fraj, Rachida Idir 2017, and ecoinvent® | 3 | 3 | 3 | 3 | 1 | 3 | 2.67 |

| Fuel consumption (production plant) | Secondary | Amor Ben Fraj, Rachida Idir 2017, and ecoinvent® | 1 | 4 | 4 | 3 | 1 | 3 | 2.67 |

| Electricity consumption (production plant) | Secondary | Amor Ben Fraj, Rachida Idir 2017, and ecoinvent® | 3 | 2 | 3 | 3 | 1 | 3 | 2.50 |

| TOTAL AVERAGE | 2.62 | ||||||||

| Impact Category | Reference Unit | Building A (for 1 m2) | Building B (for 1 m2) |

|---|---|---|---|

| Acidification of soil and water | kg SO2 eq | 2.24 × 10−1 | 1.24 × 10−1 |

| Ozone depletion | kg CFC-11 eq. | 7.28 × 10−6 | 3.25 × 10−6 |

| Eutrophication | kg PO43− eq. | 4.28 × 10−2 | 2.25 × 10−2 |

| Photochemical ozone creation | kg ethylene eq. | 1.13 × 10−2 | 7.61 × 10−3 |

| Air pollution | m3 | 1.96 × 102 | 1.07 × 102 |

| Water pollution | m3 | 2.75 × 104 | 1.24 × 104 |

| Global warming | kg CO2 eq. | 4.22 × 101 | 2.31 × 101 |

| Depletion of abiotic resources (fossil) | MJ, net calorific value | 6.59 × 102 | 3.44 × 102 |

| Depletion of abiotic resources (elements) | kg Sb eq. | 3.38 × 10−9 | 8.91 × 10−9 |

| Flow Category | Reference Unit | Building A (for 1 m2) | Building B (for 1 m2) |

|---|---|---|---|

| Consumption of renewable energy resources | MJ | 3.20 × 101 | 3.10 × 101 |

| Consumption of non-renewable energy resources | MJ | 7.01 × 102 | 3.79 × 102 |

| Radioactive waste | kg | 4.19 × 10−3 | 2.21 × 10−3 |

| Hazardous waste | kg | 3.11 × 101 | 2.75 × 101 |

| Non-hazardous waste | kg | 3.95 × 102 | 4.11 × 101 |

| Fresh water | m3 | 9.33 × 10−2 | 1.23 × 10−1 |

| Impact Category | Reference Unit | Building A (for 1 ton) | Building B (for 1 ton) | Virgin Aggregate UNPG |

|---|---|---|---|---|

| Acidification of soil and water | kg SO2 eq. | 2.43 × 10−1 | 1.01 × 10−1 | 4.23 × 10−2 |

| Ozone depletion | kg CFC-11 eq. | 7.91 × 10−6 | 2.64 × 10−6 | //// |

| Eutrophication | kg PO43− eq. | 4.66 × 10−2 | 1.83 × 10−2 | 1.05 × 10−2 |

| Photochemical ozone creation | kg ethylene eq. | 1.22 × 10−2 | 6.20 × 10−3 | 5.17 × 10−4 |

| Air pollution | m3 | 2.13 × 102 | 8.75 × 101 | 3.54 × 101 |

| Water pollution | m3 | 2.99 × 104 | 1.01 × 104 | 1.48 × 103 |

| Global warming | kg CO2 eq. | 4.59 × 101 | 1.88 × 101 | 2.42 × 100 |

| Depletion of abiotic resources (fossil) | MJ, net calorific value | 7.17 × 102 | 2.80 × 102 | 3.16 × 100 |

| Depletion of abiotic resources (elements) | kg Sb eq. | 3.67 × 10−9 | 7.25 × 10−9 | 5.69 × 10−6 |

| Flow Category | Reference Unit | Result Building A | Result Building B | Virgin Aggregate |

|---|---|---|---|---|

| Consumption of renewable energy resources | MJ | 3.48 × 101 | 2.53 × 101 | 0.00 × 100 |

| Consumption of non-renewable energy resources | MJ | 7.62 × 102 | 3.09 × 102 | 2.89 × 101 |

| Radioactive waste | kg | 4.56 × 10−3 | 1.80 × 10−3 | 0.00 × 100 |

| Hazardous waste | kg | 3.38 × 101 | 2.24 × 101 | 0.00 × 100 |

| Non-hazardous waste | kg | 4.29 × 102 | 3.35 × 101 | 0.00 × 100 |

| Fresh water | m3 | 1.01 × 10−1 | 1.00 × 10−1 | 2.91 × 100 |

| Allocation Approach | Part of the Impact Allocated to the Building Deconstructed | Part of the Impact Allocated to the Recycled Aggregate | ||||

|---|---|---|---|---|---|---|

| Transport of Rubble to Treatment Plant | Treatment of Rubble | Other Impacts * | Transport of Rubble to Treatment Plant | Treatment of Rubble | Other Impacts * | |

| 0/100 | 0% | 0% | 0% | 100% | 100% | 100% |

| 50/50 | 0% | 0% | 50% | 100% | 100% | 50% |

| 100/0 | 0% | 0% | 100% | 100% | 100% | 0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lachat, A.; Mantalovas, K.; Desbois, T.; Yazoghli-Marzouk, O.; Colas, A.-S.; Di Mino, G.; Feraille, A. From Buildings’ End of Life to Aggregate Recycling under a Circular Economic Perspective: A Comparative Life Cycle Assessment Case Study. Sustainability 2021, 13, 9625. https://doi.org/10.3390/su13179625

Lachat A, Mantalovas K, Desbois T, Yazoghli-Marzouk O, Colas A-S, Di Mino G, Feraille A. From Buildings’ End of Life to Aggregate Recycling under a Circular Economic Perspective: A Comparative Life Cycle Assessment Case Study. Sustainability. 2021; 13(17):9625. https://doi.org/10.3390/su13179625

Chicago/Turabian StyleLachat, Ambroise, Konstantinos Mantalovas, Tiffany Desbois, Oumaya Yazoghli-Marzouk, Anne-Sophie Colas, Gaetano Di Mino, and Adélaïde Feraille. 2021. "From Buildings’ End of Life to Aggregate Recycling under a Circular Economic Perspective: A Comparative Life Cycle Assessment Case Study" Sustainability 13, no. 17: 9625. https://doi.org/10.3390/su13179625

APA StyleLachat, A., Mantalovas, K., Desbois, T., Yazoghli-Marzouk, O., Colas, A.-S., Di Mino, G., & Feraille, A. (2021). From Buildings’ End of Life to Aggregate Recycling under a Circular Economic Perspective: A Comparative Life Cycle Assessment Case Study. Sustainability, 13(17), 9625. https://doi.org/10.3390/su13179625