1. Introduction

Renewable energy is an energy resource that is naturally replenished over time, such as sunlight, wind, rain, waves, and geothermal heat. Developed countries are increasing their renewable power output to reduce dependence on fossil fuels. Furthermore, higher energy conversion efficiencies have been achieved for solar and wind power generators through continued development. Solar and wind energy are the dominant forms of renewable energy resources owing to the abundant scope for harnessing them. However, wave energy has been drawing considerable research interest as it involves a higher energy density than that of the aforementioned two resources.

Salter [

1] pioneered the wave energy converter (WEC), which transforms kinetic energy of the ocean waves into electrical energy. Since then, various types of WECs have been developed. Surface waves are generated by the friction between wind and surface water and possess high surface energy. Taller waves that last longer have high offshore energy. Therefore, buoys positioned offshore on the surface of the ocean can absorb large quantities of wave energy. However, the cost of laying cables from an offshore location to the land for electricity transmission is high. Furthermore, buoys located on the surface are prone to physical damage. To solve these problems, various types of WECs have been developed, but only a few WEC have achieved commercialization [

2]. One of the most widespread types of WEC are the point absorbers [

3,

4,

5]. The point absorbers consist of a floating body whose oscillating motion (heaving). A long floating body with multiple segments floats parallel with the direction of waves and acts in a similar concept as the point absorber [

6,

7,

8]. In addition, the WEC uses the oscillating water column or terminator [

9,

10,

11,

12,

13,

14] it generates. As the water pressure increases, the air is forced out through the turbine, producing electrical energy.

There is a principle of the various types of PTO system to convert the movement of the buoy by the waves into electrical energy [

15,

16]. Both mechanical and hydraulic PTO can be applied to the three-tether WEC. There are many WEC applied mechanical PTO [

17,

18,

19]. Mechanical PTO generated energy by the wave converter directly into electricity by rotating a generator. Therefore, the Mechanical PTO obtains more energy from wave than hydraulic PTO because of the reduced friction. However, the mechanical PTO undergoes higher load, and reliability of this type of PTO still needs to be proven.

Since wave energy operates at a low frequency, it is advantageous to use a hydraulic pump with a low rated speed [

20,

21,

22,

23]. However, the overall efficiency of hydraulic PTO is about 70% to 80% due to the efficiency of hydraulic pumps and motors [

24]. The fluid flows inside the hydraulic PTO such as the hydraulic pumps and motors, accumulators and this can create hydraulic oil leakage, which can pollute the marine environment [

25]. However, the PTO of InWave WEC prevents this problem due to installation on land.

Numerical studies have been conducted to analyze the efficiency of various WECs [

26,

27,

28,

29,

30,

31]. In this study, considerations of mechanical and hydraulic PTO selection were reviewed and suggested when designing three-tether WEC. The WEC analyzed in this study is a type using three-tether buoy. The WEC developed by INGINE Inc.(Seoul, Korea) is called InWave WEC, is deployed near the onshore to reduce the cost of laying cables and power take-off (PTO) facilities are installed on land to prevent wave-induced damage. The InWave system does not require subsea transmission cables because its power generation unit is installed onshore. In addition, it can be easily maintained because all its components except the buoy itself are installed onshore. However, these aspects are also responsible for its main disadvantage: it generates a smaller wave energy onshore than that offshore. To generate as much energy with InWave as that in the case of offshore WECs, an InWave PTO must be designed that has a higher energy efficiency than that of the existing facilities.

There exist two types of PTOs equipped in WECs: hydraulic and mechanical. The hydraulic PTO stores the energy absorbed by the buoy as hydraulic energy in the accumulator and transmits it to the generator. The mechanical PTO transfers the energy absorbed by the buoy from the waves through a mechanical device to a generator, and it is more efficient than the hydraulic PTO as its mechanism involves only minute energy losses. However, the efficiency of the PTO is not the overall efficiency of the system. The efficiency of PTO means the efficiency of transmitting the power received through the rope to the generator. Because the behavior of the WEC system varies depending on the PTO type, the magnitude of energy absorbed from the buoy movement and the generator’s efficiency must also be considered to analyze the whole system’s efficiency. In this study, simulation studies were conducted to analyze the efficiency of the InWave system when hydraulic and mechanical PTO were applied.

A simulation using subroutine was performed to update the buoy movement and rope tension data at each time step. The buoy movement due to wave was calculated in ocean domain by seaFEM solver and the behavior of rope due to the buoy movement can be computed in subroutine. The reaction force of PTO by the behavior of rope is applied as rope tension. In this simulation, the elasticity of rope is not considered. Subsequently, a numerical model that can compute the rope tension of the PTO according to the buoy movement and simulate the buoy movement due to the tension effect was constructed. Since the real ocean is an irregular wave environment, it is necessary to apply the irregular wave in the installed area to predict the generated power accurately [

32,

33]. However, it is difficult to analyze the detailed behavior of PTO elements in simulations with irregular waves. Since various PTO design variables need to be reviewed, simulations using irregular waves that take a long time to solve are not suitable for simulation for concept design. For example, a 16-core CPU (2.80 Hz, intel i-9) was used to perform the simulation, and it takes about 8000 s to calculate a regular wave case, while it takes about 40,000 s to calculate an irregular wave case. The results obtained in this manuscript with regular waves may be rough compared to the results obtained in irregular waves, but it would be valid and realistic for the current conceptual design phase as in other studies. Various studies have performed simulations applying regular waves in the conceptual design stage of WEC [

34,

35,

36]. The issue on simulation with irregular waves will be dealt with in the future study. The simulations of WEC with irregular waves in the realistic [

37,

38,

39] is usually performed in the next stage of design after the conceptual designs are completed. Therefore, the regular wave was used as boundary condition in this simulation to simplify the analysis of the results, and the characteristics of 30 regular waves were thereby simulated. The numerical model provides information on various factors influencing InWave WEC power generation, namely, the behaviors of the PTO components, rope tension, and buoy movement for both the mechanical as well as hydraulic PTOs. Subsequently, the two PTO types were compared. Specifically, the calculated rope tension values of the two PTOs were analyzed to compare their rope tension utilization rates, and finally the average efficiency of the generator in the two cases was calculated from the efficiency curve of the wave-type generator.

Through simulation, the change of WEC’s efficiency was analyzed when mechanical and hydraulic PTO were installed in InWave. Although the efficiency of hydraulic PTO was smaller than that of mechanical PTO, the whole efficiency of WEC system applied with hydraulic PTO was high. Therefore, even if the PTO efficiency is high, since the entire system’s efficiency is affected depending on the PTO type, it should be calculated considering the energy absorbed from the buoy and the generator’s behavior.

2. InWave System

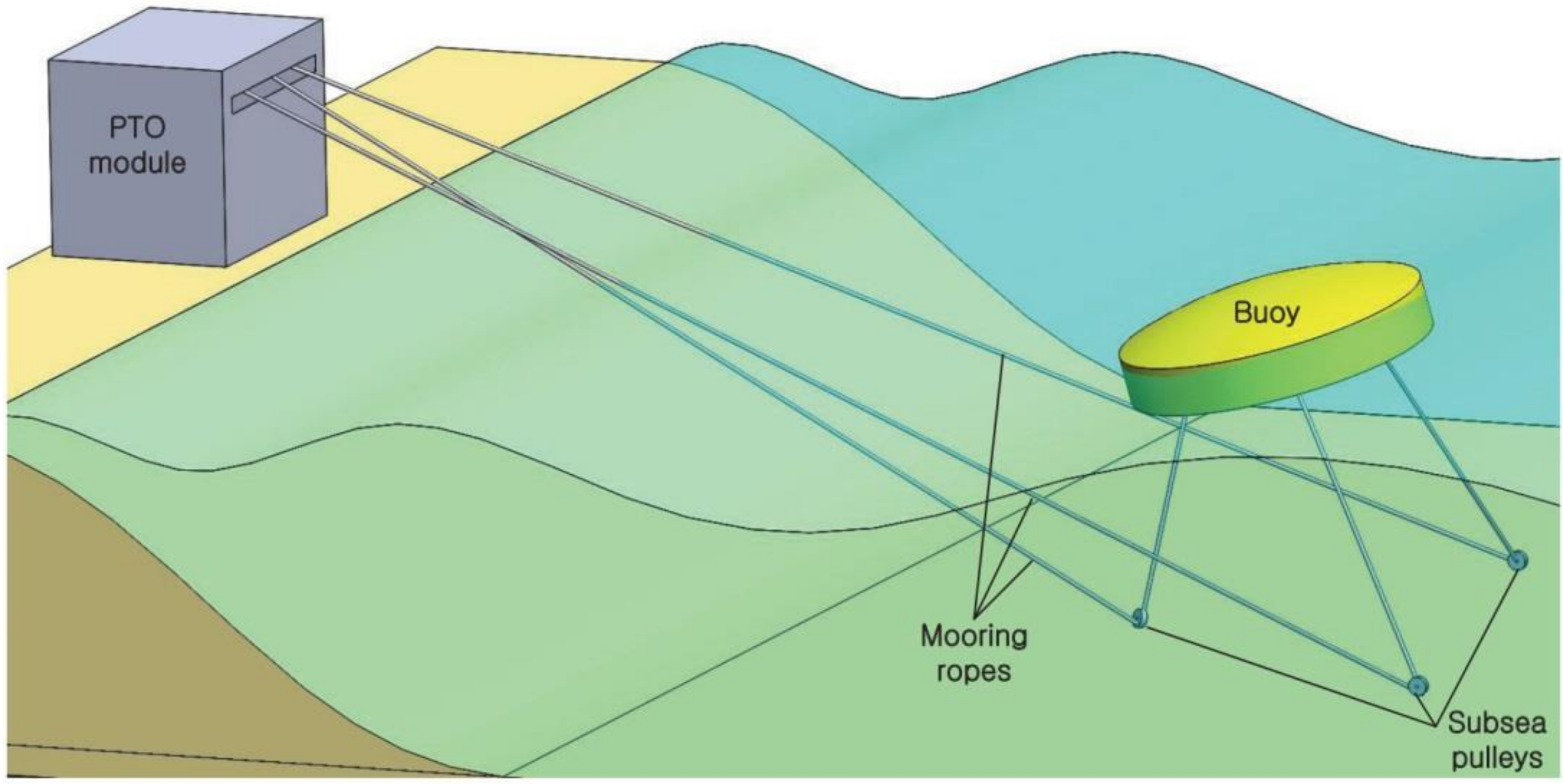

This section details the components and features of the InWave system. The system employs a cylindrical buoy with six degrees of freedom (DoF): surge, sway, heave, roll, pitch, and yaw. There are various types of WECs depending on which mode of motion is utilized to generated power (Point Absorber type–heave, Pelamis type–pitch, Oyster wec type–surge, pitch). These type of WECs are less efficient when the wave direction changes. However, three-tether type of WEC could convert all the 6 DoF into energy: the buoy is moored by a rope at 120° intervals (

Figure 1).

The mooring ropes are wound on rope drums inside the onshore PTO by subsea pulleys anchored to the seabed. As the buoy is elevated by the waves, the rope rotates the rope drum, which transmits power to the generator. As the buoy descends, it rotates anticlockwise, owing to the torque of the counter-weight, and then returns to its original position. The rope drum shaft transmits power to the generator unidirectionally using a ratchet gear or a hydraulic circuit. Thus, the energy generated upon anticlockwise rotation of the rope drum is not transmitted to the generator in the restored state. The variable speed power produced by the generator is stored in the ESS (Energy Storage System) through the inverter and then transmitted to the grid power.

2.1. Mooring Rope

The InWave system transmits the motion of the buoy to the PTO through the rope. The power delivered by the rope is determined by the rope’s line speed and tension. The linear speed depends on the buoy movement, and the rope tension is determined by the torque generator in the mechanical PTO and charging pressure of the accumulator in the hydraulic PTO. If the rope is severed, the energy absorbed by the buoy cannot be transferred to the PTO. In addition, the rope is an important yet nonrecyclable component, the maintenance of which is difficult and requires sea work. Therefore, an appropriate safety design of the rope is important for the economy and efficiency of operation.

The first factor to consider in the safety design is strength. To transmit high power, the rope must be sufficiently strong. The strength of a rope is directly proportional to its thickness. Therefore, WEC designs with high power-generation capacities require thick ropes. On the other hand, thicker ropes are heavier, hence a compromise between thickness and weight should be established. Material plays a key role as well.

The second factor is the lifespan of the rope, which is determined by the diameter of the rope drum and thickness of the rope. To produce ropes that can last long, rope drums with large diameters must be used.

However, at a constant rope speed, the rotational speed of the shaft decreases as the diameter of the rope drum increases. When the rotational speed of the rope drum, a gearbox with a high ratio should be required because the generator cannot operate at rated speed. The challenges resulting from a slow shaft speed are explained in the subsequent section.

2.2. Generator

The parameters of the operating conditions required to be met to ensure safe and efficient operation of a generator in the manufacturer’s specifications are appropriate rated current, voltage, torque, and rotational speed. If these specifications are not met, the generator may not perform efficiently, or it may fail altogether. Therefore, for the stable operation of a generator, the PTO design must conform to the generator rated value; alternatively, a generator suited to the PTO must be selected.

A generator is a machine that can be fabricated easily using commercial components with various specifications. Based on the generator’s capacity, the PTO can either have a low-rated velocity—high-rated torque or a high-rated velocity—low-rated torque configuration. Because the rope drum of the InWave WEC rotates at a low speed (<10 rpm), the power cannot be directly transmitted to the generator. The mechanical PTO uses a gearbox to accelerate the slow rope drum to enable power transmission to the generator. A generator with a low-rated velocity is suitable for this purpose; however, it has a large moment of inertia, which warrants a large torque to rotate the shaft. Additionally, because the tension caused by inertia is proportional to the square of the gear ratio, selecting a generator with suitable specifications is critical. A generator is highly efficient when it is operated below the rated torque and velocity conditions. Therefore, the generator for the intended purpose must be selected by analyzing the operating conditions suitable for the characteristics of the most frequent type of wave in the installation area. However, tall waves cause the buoy to transmit excess rotational speed to the generator, which damages the generator. Damage to the generator not only increases maintenance costs, but also WEC could not generate electricity. In addition, in mechanical PTO, it is complicated to replace the generator only when the movement of the buoy must be stopped. In addition, high energy conversion efficiency can only be achieved for moments close to the rated velocity.

In the hydraulic PTO, the power transmitted from the rope drum is stored in the accumulator and then released, and this PTO is therefore free from the above-mentioned disadvantages. Power from this PTO can be transmitted to the generator at a constant speed through the variable displacement of the hydraulic motor and accumulator control.

3. Numerical Model

The commercial package seaFEM, which can be employed to analyze floating bodies in the marine environment, was used to simulate the WEC behavior. SeaFEM includes a state-of-the-art radiation and diffraction BEM and FEM solver, enabling frequency domain and direct time-domain analyses of the dynamic response of the structure [

41]. The buoy’s motion was simulated in the time-domain using the FEM solver. The radiation and diffraction problems are solved based on potential flow theory. The seaFEM provides the forces and moments acting over the buoy and movements, velocities, and accelerations referred to the gravity center of the buoy. In this study, the PTO behavior was expressed only by a mathematical model. The movements of the rope and the behavior of PTO components were calculated using the movements data of the buoy provided by the seaFEM solver. For each time step, seaFEM transfers the buoy’s 6-DoF motion to the mathematical model (PTO model), which in turn calculates the linear velocity of the rope and simulates the behavior of the PTO components. The rope tension calculated in mathematical model (subroutine) was returned to seaFEM as external load applying on the floating body (connection points). The model equations used in this simulation are detailed in the next section.

3.1. Rope Vector

The magnitude and direction vector of the tension were calculated to simulate the behavior of a buoy under rope tension. First, the direction vector was calculated from the position of the point on the buoy, to which the rope was tethered, and the position of the subsea pulley. SeaFEM provides information on the wave-induced buoy movement as 6 DoF (surge, sway, heave, roll, pitch, yaw) of the buoy’s central coordinates. The mooring point’s position coordinates were calculated using the translational and rotational matrices of the relative position vector between the buoy center and mooring point.

Equation (1) represents the rotational matrix.

The connection point coordinates of the (

i + 1)th time step by rotation are expressed as follows.

In Equation (3),

dR is the displacement caused by rotation during one time step.

The position of the mooring point in the global coordinate system considering the buoy’s central displacement (

dx,

dy,

dz) is expressed as follows.

The ith length of the rope

, the speed of the rope

, and acceleration of the rope

is calculated as follows.

The rotational speed of the shaft according to the rope drum diameter can be calculated from the linear velocity and acceleration of the rope. The rotating body and the generator are rotated by the rope drum, generating rope tension. On one hand, underestimating the tension would yield less than the expected power, resulting in unexpected damages to the rope and generator of the WEC system. On the other hand, overestimating the rope tension would result in unnecessarily advanced WEC configurations and consequently high installation costs. Therefore, the rope tension must be accurately predicted to reasonably evaluate the economic feasibility and stability of the WEC. The equations for modeling the behavior of components and calculating the rope tension are presented in the next section.

3.2. Mechanical Power Take-Off (PTO)

The factors that induce tension in the rope can be classified as counter mass, moment of inertia, and generator torque. First, the counter mass applies tension in the rope both on the generation and restoration states. In this case. the rope tension can be calculated from the value of the counter mass, acceleration due to gravity, and linear acceleration of the rope.

The ith rope tension from the counter mass (

) is expressed as follows.

The moment of inertia of the rotating components in the PTO induces tension in the rope. The rotating elements in the mechanical PTO are the rope drum, gear, and generator, and they generate a tension proportional to the square of the gear ratio in the rope. This rope tension is expressed as in Equation (10).

where J2 is the moment of inertia about the elements influenced by the gearbox such as the generator shaft, flywheel to smooth the velocity of generator also the moment of inertia of generator. The last rope tension-inducing factor is the generator torque. The generator rotates when the power transmitted equals the torque generated. The generator torque can be set by the user. It can be expressed as a constant, curve, or function. If the initial generator torque equals the rated torque, a high impact load is generated at the initial generation.

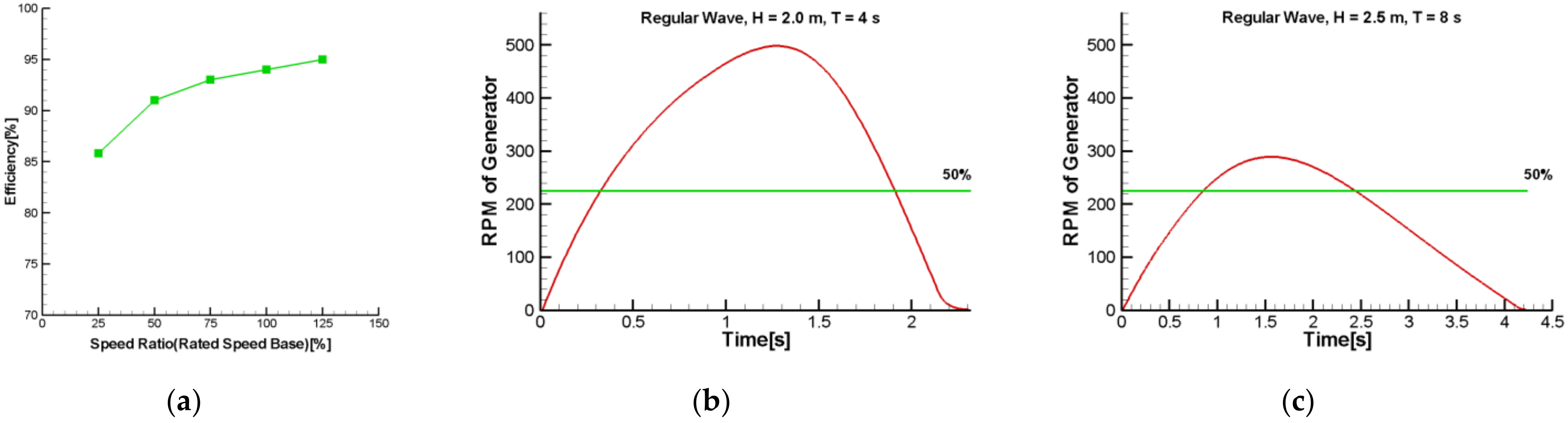

Figure 2 illustrates the torque curve, in which the torque is increased by increasing the rotational speed. If the generator rotates over the rated speed in the rated torque condition, it will produce over-electricity and cause damage to the generator. Therefore, to avoid the situation, the rated torque should be reduced if the generator speed exceeds the rated speed.

Figure 2 shows the shape of the torque curve applied in this study.

The technician can adjust the torque curve of the generator as per the requirement. Although the torque curve affects the behavior of both the generator and buoy, the numerical analysis in this study was performed with only one torque curve. The

ith rope tension due to the generator torque is expressed as follows.

3.3. Hydraulic PTO

The hydraulic PTO uses the same rope drum and counter-weight as the mechanical one does. In addition, it uses a hydraulic circuit for energy transfer.

Figure 3 shows a schematic of the hydraulic PTO. This section details the energy transfer process of the PTO mechanism and rope tension calculation.

As the buoy is lifted by the waves, the rope rotates the rope drum and the hydraulic pump in the same shaft, which charges the accumulator. The accumulator transmits the stored power to the generator through a hydraulic motor, producing electricity. The accumulators alternately charge, standby, and release energy to deliver energy to the generator, causing the generator to rotate continuously. The charging, standby, and discharge processes can be controlled by installing solenoid valves and pressure sensors at the inlet and outlet of the accumulator.

As with the mechanical PTO, the hydraulic mechanism is also divided into restoration and power-generation states. The counter mass applies tension on the rope in both the states, whereas the accumulator applies tension only in the power-generation state.

The rope tension required to fill the accumulator with the operating oil is expressed as follows.

All parameters except for the internal pressure of the accumulator are kept constant. The internal pressure, and consequently the rope tension, increases as the operating oil is filled. To reflect this trend in the simulation, the filling flow rate was calculated according to the rotational displacement of the rope drum for each time step. The buoy was subjected to rope tension according to the pressure gradient inside the accumulator.

The rope tension induced by the internal pressure gradient of the accumulator is derived using Equations (13)–(16).

6. Conclusions

In this study, a seaFEM model was constructed to analyze the behaviors of the mechanical and hydraulic PTO and design a PTO for the InWave WEC. To calculate the energy input required by the PTO, the tension of the rope transferring kinetic energy from the buoy movement was calculated. In addition, the behavior of the generator was analyzed to calculate the average efficiency according to the generator operation status.

The buoy motion was simulated under the wave conditions of 0.5–3.0 m (height) and 4–12 s (period) (CASE30). Thus, the behavior of the main components was simulated, and the average availability of rope tension was calculated.

The effective tension converted into electrical energy is relatively similar from 2.0–3.0 m, but the longer the cycle, the larger the effective tension in the hydraulic PTO. In the mechanical PTO, the wave-induced buoy motion directly affects the rope tension and generator behavior. Therefore, the rotation of the rope drum must be maintained under a condition conducive to generator operation. However, in the hydraulic PTO, if a small degree of movement in the buoy can generate sufficient buoyancy, the buoy will absorb the energy and transfer it to the accumulator of the PTO. In addition, the hydraulic PTO has a higher energy conversion efficiency than that of the mechanical PTO because its generator can operate at the rated speed for a long time.

The mechanical PTO presented in this study is an initial model of InWave WEC. By constructing and operating InWave WEC (mechanical PTO) on a real scale, the limitations of mechanical PTO were confirmed. Therefore, hydraulic PTO was designed as shown in

Figure 3 to design WEC with higher efficiency. Although the efficiency of hydraulic PTO is low, it was confirmed in this study that it can produce more electricity than WEC installed with mechanical PTO. WECs equipped with mechanical PTO, which were previously presented in other research, can expect higher electricity production if mechanical PTO is changed to hydraulic PTO like the InWave model. However, depending on the characteristics of the wave, mechanical PTO may be more appropriate, so it is necessary to review both mechanical and hydraulic PTO.

However, the total energy-conversion efficiency of the WEC system is affected by the rope tension and generator efficiency, as well as the efficiency of the friction and hydraulic-circuit components. Therefore, it is necessary to construct a more inclusive numerical model. In future research, a numerical model considering the detailed design should be designed and the corresponding PTO characteristics under irregular wave conditions should be analyzed.