Circularity for Electric and Electronic Equipment (EEE), the Edge and Distributed Ledger (Edge&DL) Model

Abstract

:1. Introduction

2. Background

2.1. Circularity and Linearity: System vs. Product Perspecitves

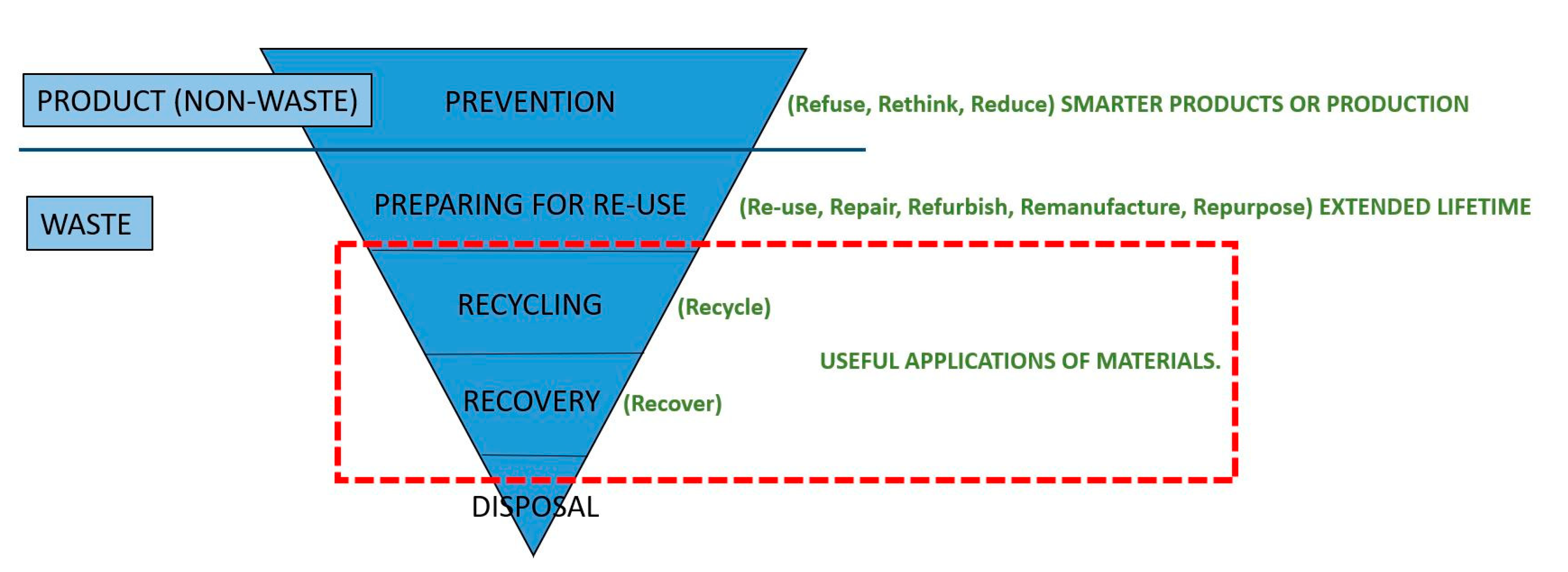

2.2. Circularity vs. Waste

2.3. Contemporary Handling of e-Waste by the WEEE Directive

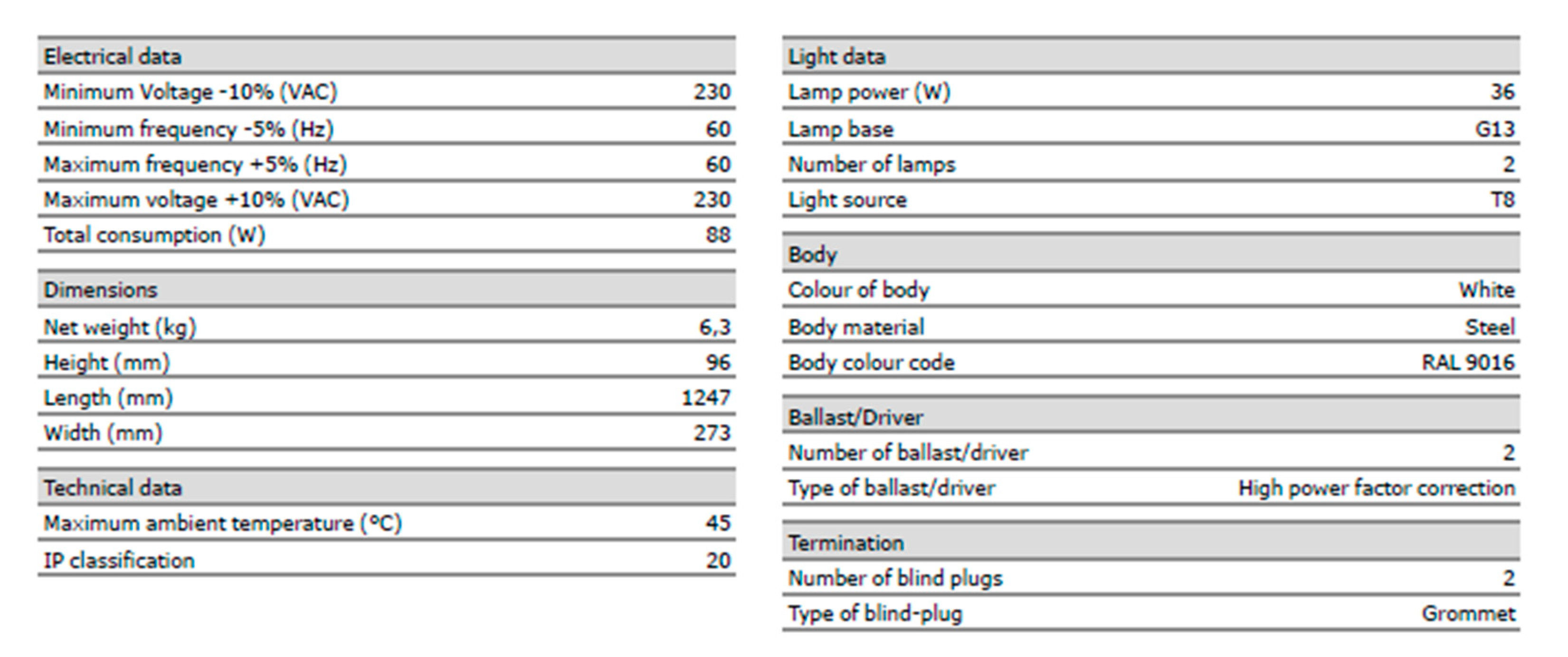

2.4. e-Product Information

3. Methodology

4. Fundamental Principles

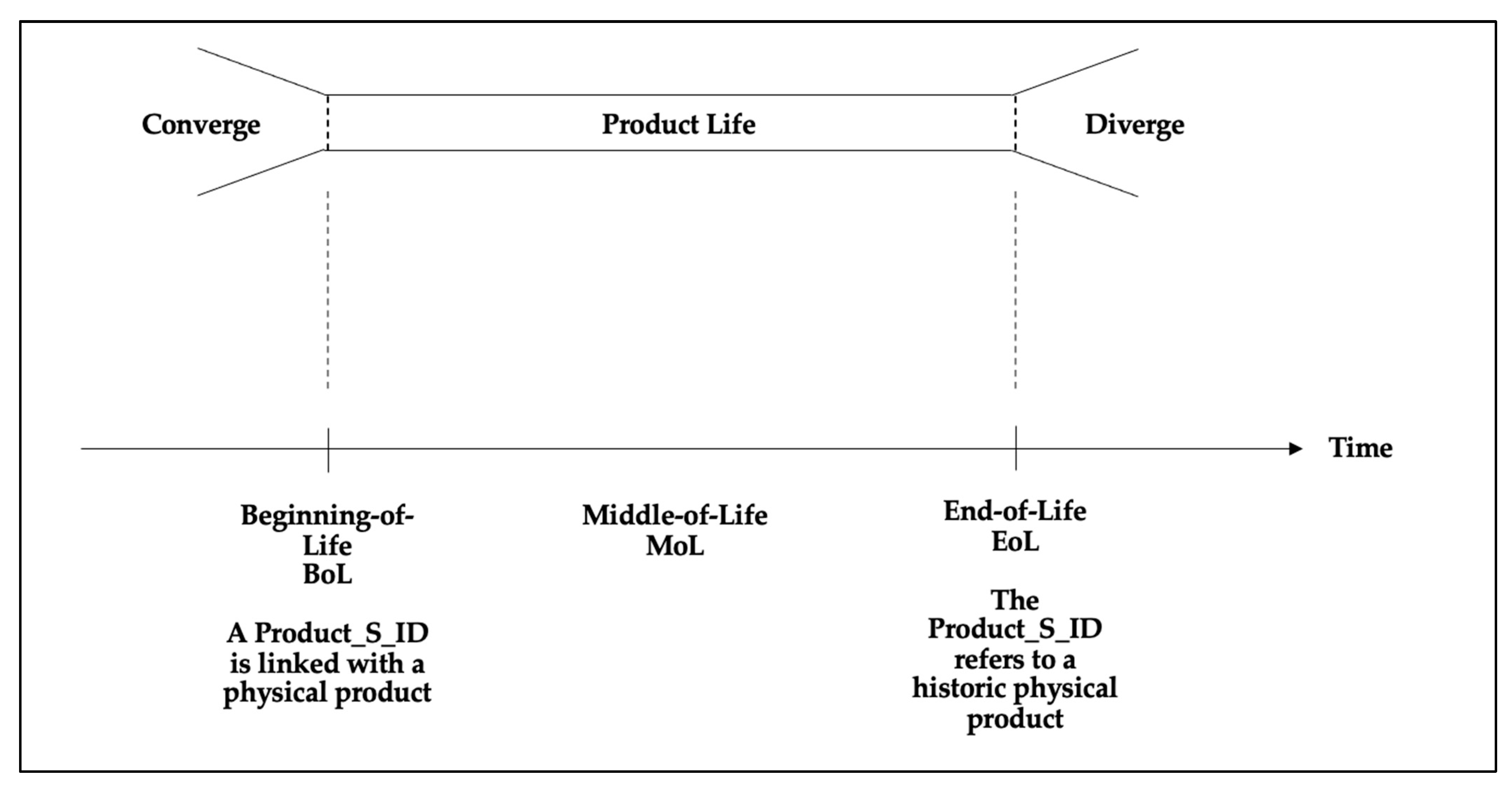

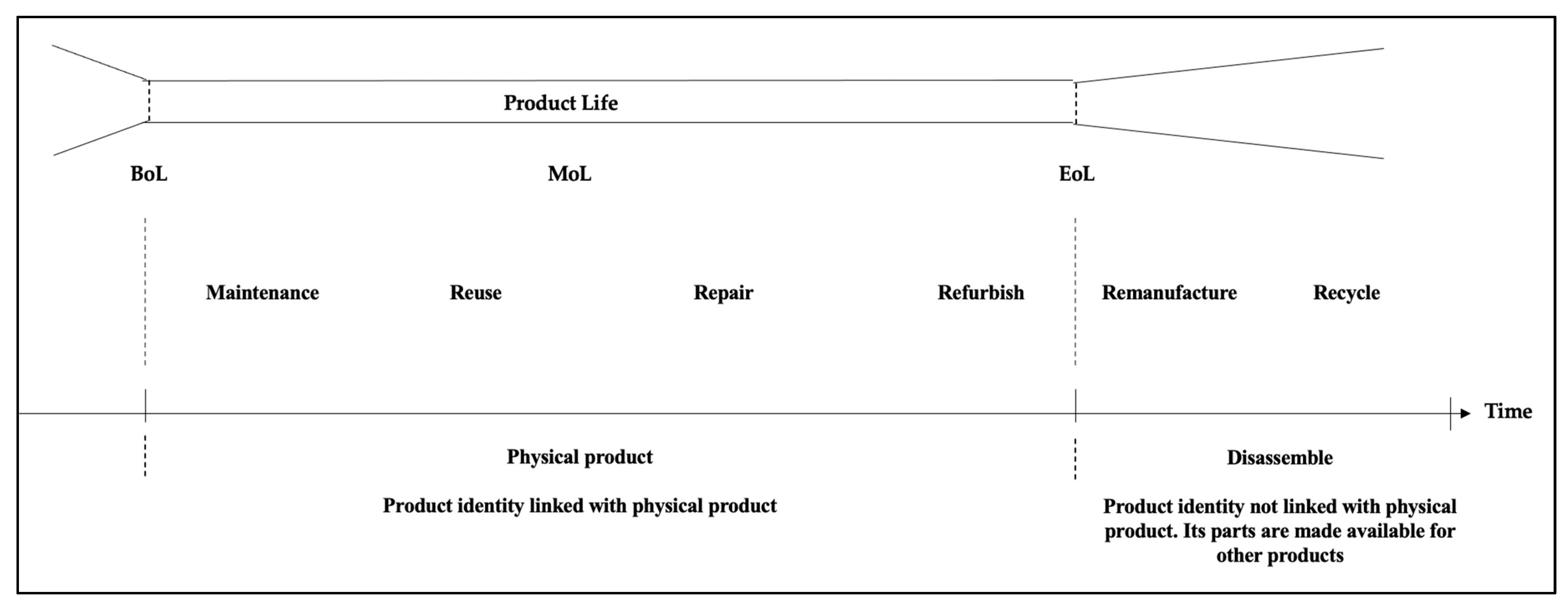

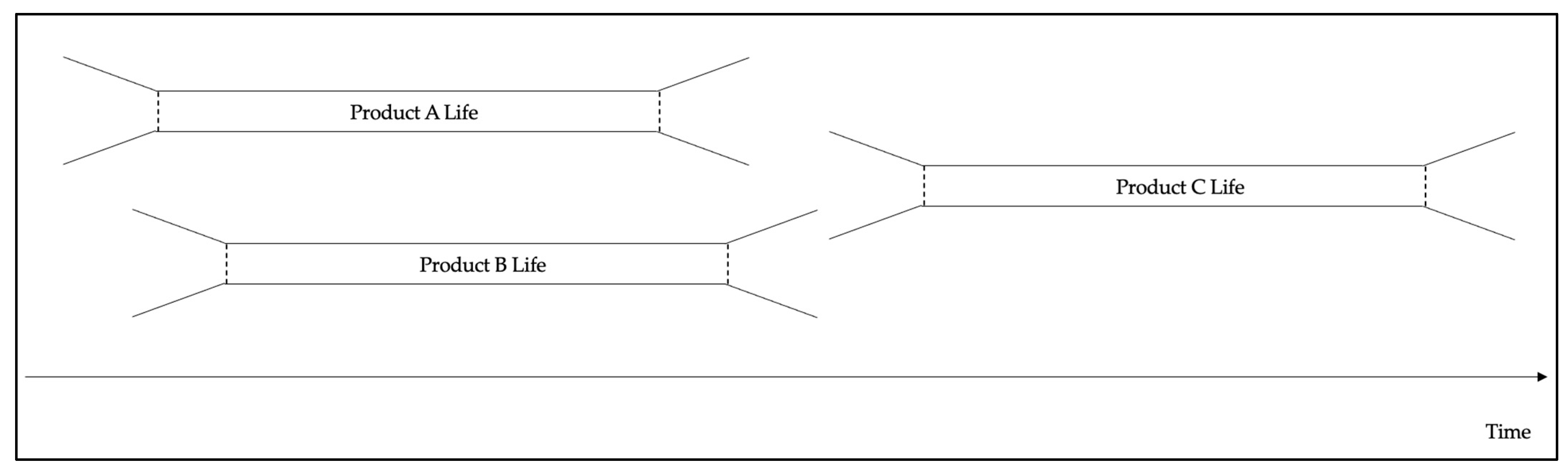

4.1. Serialized Product Identifiers—CEEE Principle 1

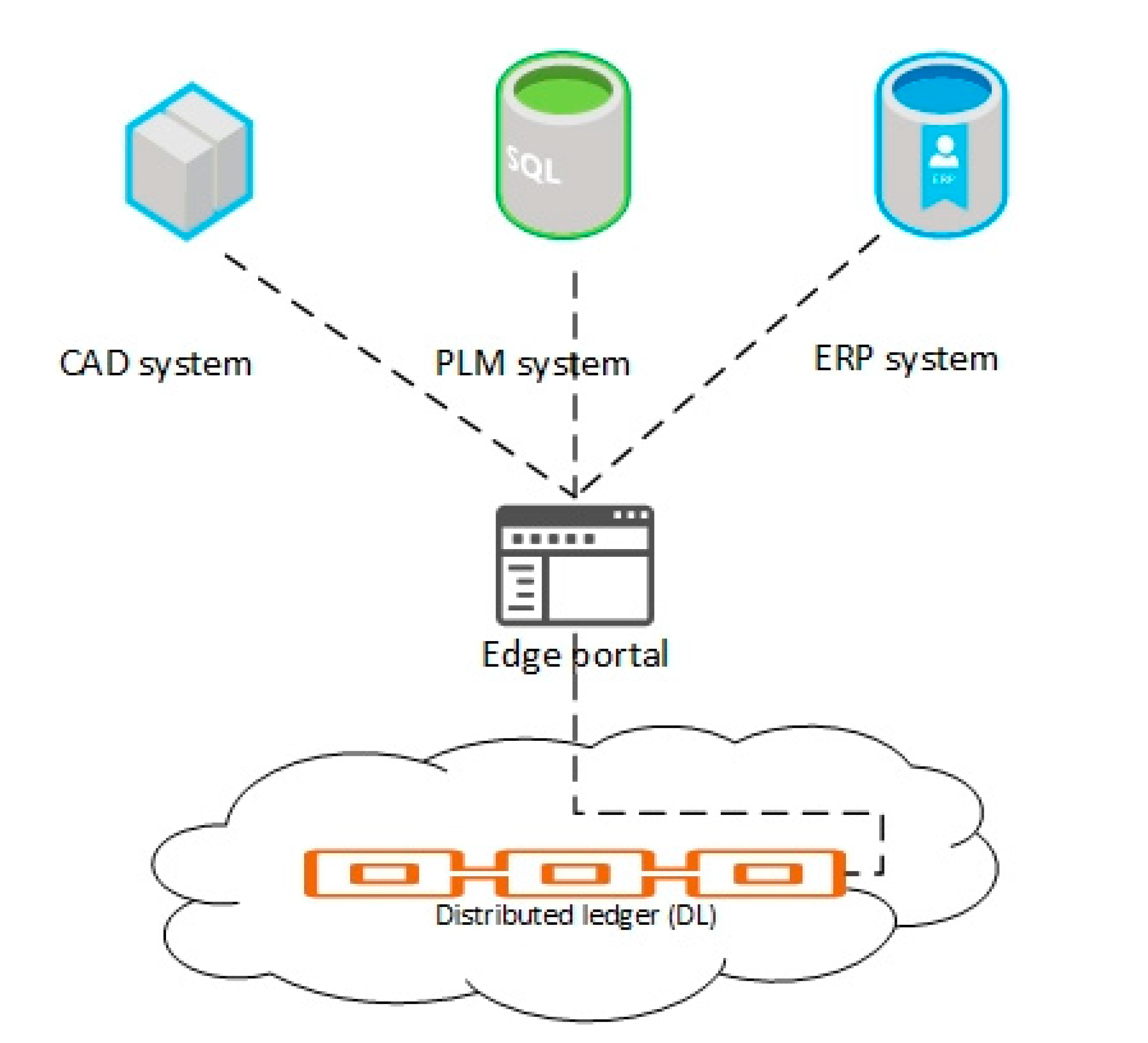

4.2. Edge Data—CEEE-Principles 2

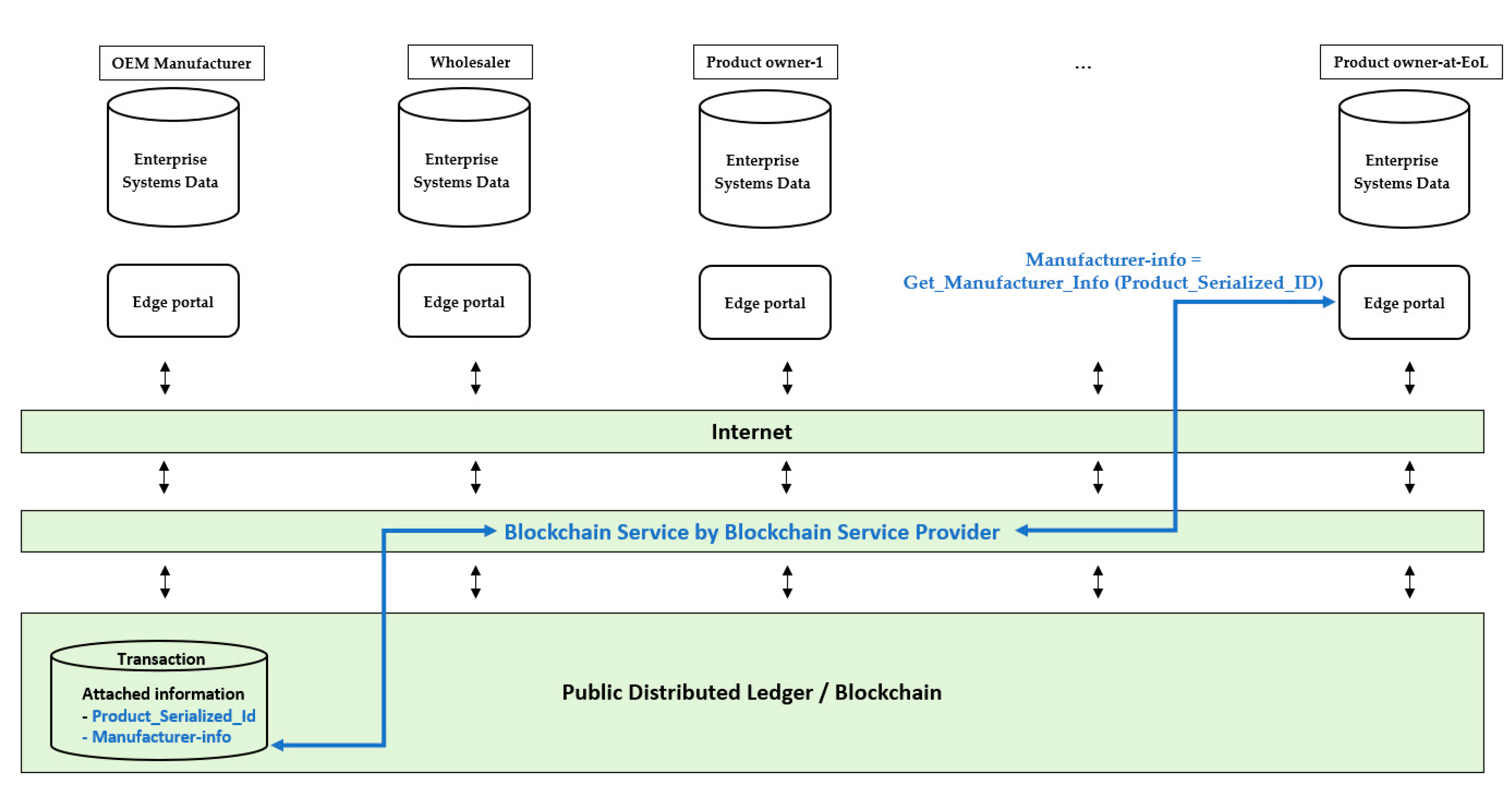

4.3. Public Distributed Ledger/Blockchain—CEEE Principle 3

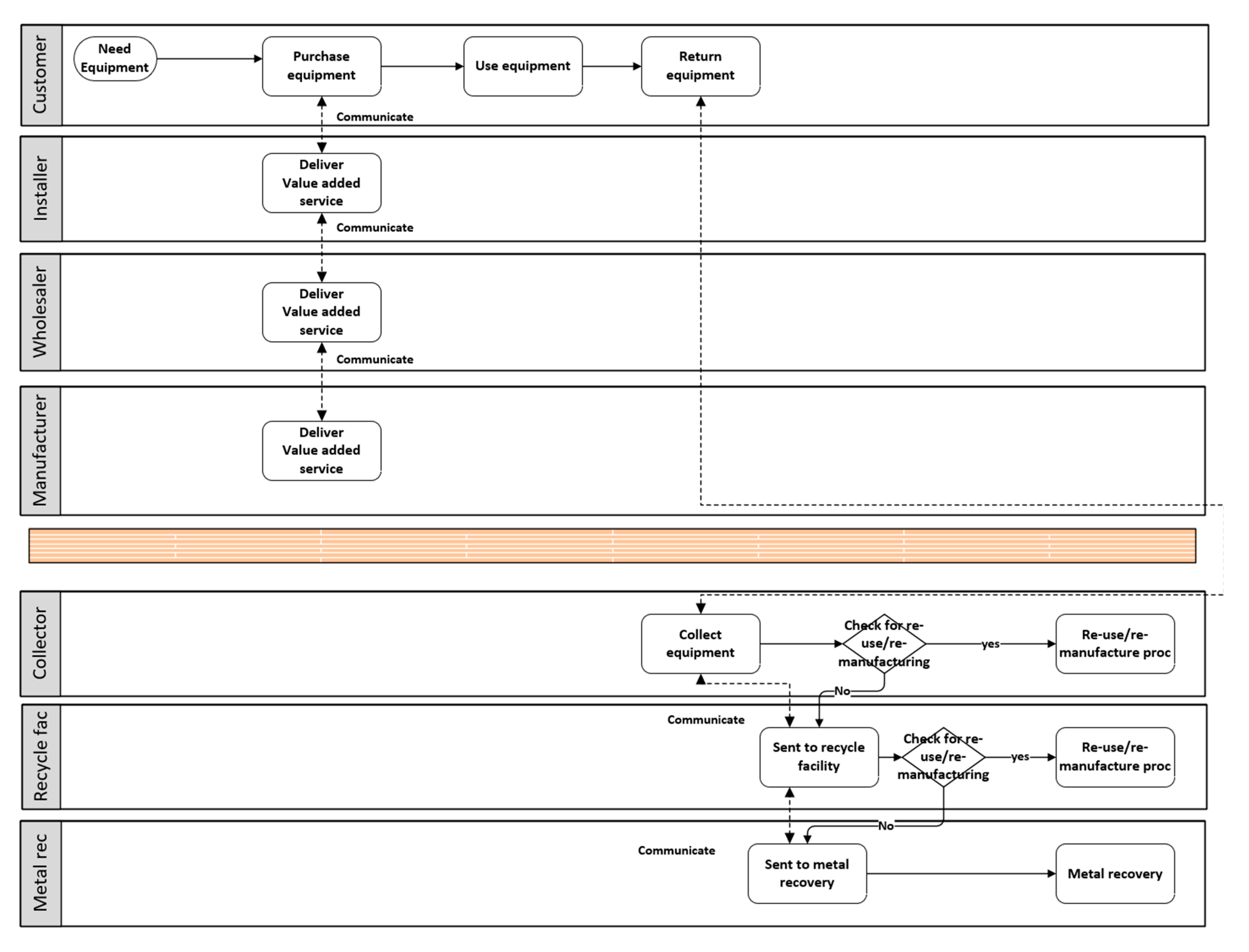

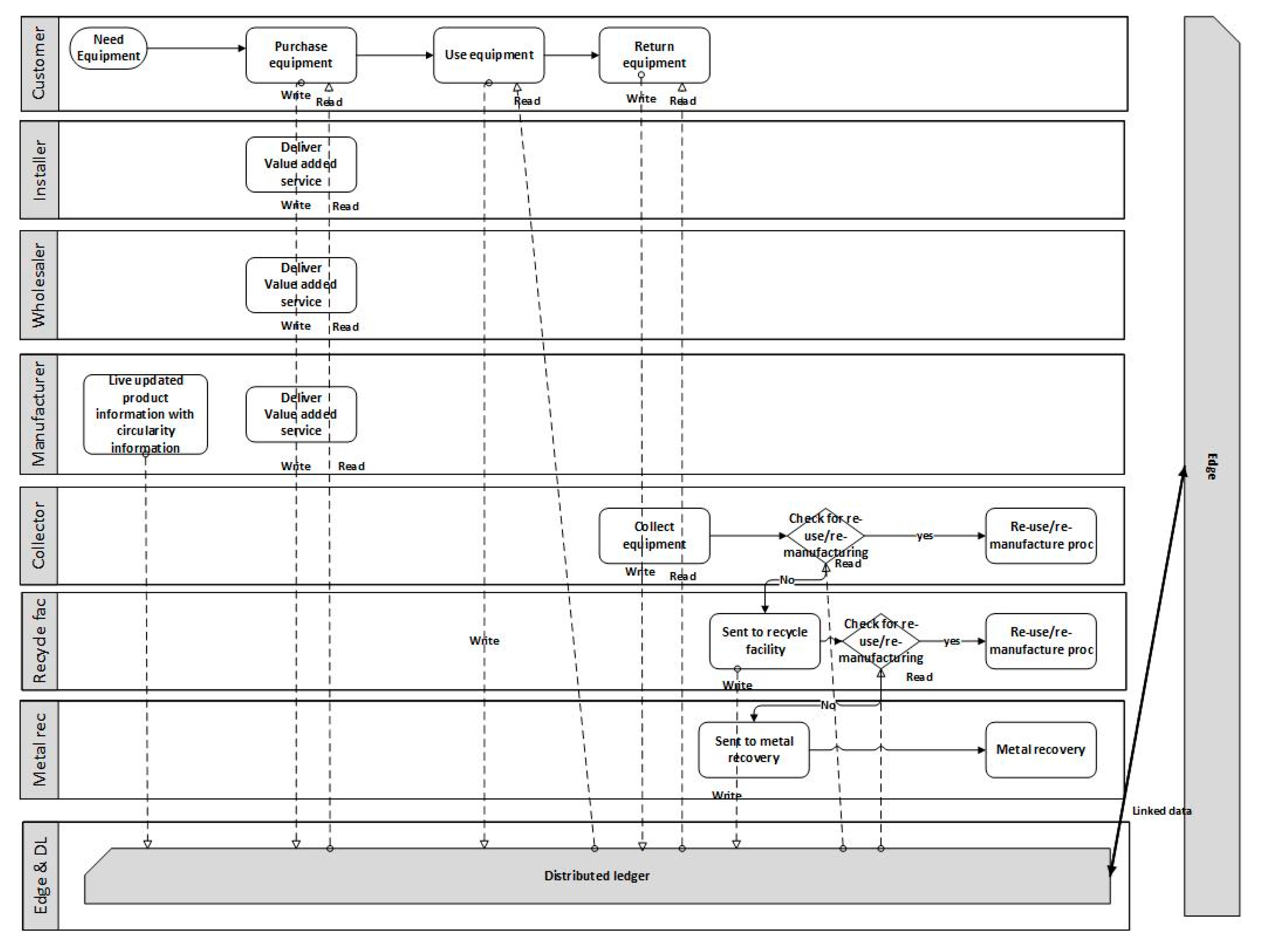

5. Edge&DL, a Conceptual Model for Model for Handling Extended Producer Responsibility (EPR)

5.1. The Product Perspective in Our Case Study

5.2. Circularity Event Example

6. Discussion

7. Conclusions, Limitations and Directions for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 4R | Reduce, Reuse, Remanufacture and Recycle |

| 5R | Refuse, Reduce, Reuse, Repurpose and Recycle |

| BCoT | Blockchain of Things |

| BIM | Building Information Modeling |

| BoL | Beginning of Life |

| BOM | Bill of Material |

| CE | Circular Economy |

| CEEE | Circular Electric and Electronic Equipment |

| CPS | Cyber-Physical Systems |

| DL | Distributed Ledger |

| EDI | Electronic Data Interchange |

| EEE | Electric and Electronic Equipment |

| EMS | Environmental Management System |

| EoL | End of Life |

| EPR | Extended Producer Responsibility |

| ERP | Enterprise Resource Planning |

| FAIR | Findable, Accessible, Interoperable and Reusable |

| GDSN | Global Data Synchronization Network |

| GS1 | Global Standard 1 |

| GSCM | Green Supply Chain Management |

| GSMA | Global System for Mobile Communications |

| IMEI | International Mobile Equipment Identity |

| IS | Information Systems |

| LCA | Life Cycle Assessment |

| MFA | Material Flow Analysis |

| MoL | Middle of Life |

| PD | Product Development |

| PDCA | Plan, Do, Check, Act |

| PLM | Product Lifecycle Management |

| PPP | Polluter Pays Principle |

| PRO | Producer Responsibility Organization |

| RSC | Reverse Supply Chain |

| SC | Supply Chain |

| SCM | Supply Chain Management |

| SFA | Substance Flow Analysis |

| SGTIN | Serialized Global Trade Item Number |

| SOA | Service-Oriented Software |

| SSCM | Sustainable Supply Chain Management |

| WEEE | Waste Electric and Electronic Equipment |

Appendix A

References

- Brundtland, G. Our Common Future; The World Commission on Environment and Development: New York, NY, USA, 1987. [Google Scholar]

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Masi, D.; Day, S.; Godsell, J. Supply Chain Configurations in the Circular Economy: A Systematic Literature Review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef] [Green Version]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Holuszko, M.; Espinosa, D.C.R. E-waste: An overview on generation, collection, legislation and recycling practices. Resour. Conserv. Recycl. 2017, 122, 32–42. [Google Scholar] [CrossRef]

- Forti, V.; Balde, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential; United Nations University: New York, NY, USA, 2020. [Google Scholar]

- Islam, M.; Huda, N. Reverse logistics and closed-loop supply chain of Waste Electrical and Electronic Equipment (WEEE)/E-waste: A comprehensive literature review. Resour. Conserv. Recycl. 2018, 137, 48–75. [Google Scholar] [CrossRef]

- Bressanelli, G.; Saccani, N.; Pigosso, D.C.A.; Perona, M. Circular Economy in the WEEE industry: A systematic literature review and a research agenda. Sustain. Prod. Consum. 2020, 23, 174–188. [Google Scholar] [CrossRef]

- Andersen, T. A comparative study of national variations of the European WEEE directive: Manufacturer’s view. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef]

- Zeiss, R.; Ixmeier, A.; Recker, J.; Kranz, J. Mobilising information systems scholarship for a circular economy: Review, synthesis, and directions for future research. Inf. Syst. J. 2021, 31, 148–183. [Google Scholar] [CrossRef]

- Diedler, S.; Hobohm, J.; Batinic, B.; Kalverkamp, M.; Kuchta, K. WEEE data management in Germany and Serbia. Glob. NEST J. 2018, 20, 751–757. [Google Scholar]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Carter, C.R.; Hatton, M.R.; Wu, C.; Chen, X. Sustainable supply chain management: Continuing evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2019, 50, 122–146. [Google Scholar] [CrossRef]

- Rodhain, F. Electronic Waste Dumped in the Global South: Ethical Issues in Practices and Research. In The Path of Ethics In Research in Laos and Mekong Countries; French National Research Agency: Paris, France, 2018; pp. 95–101. [Google Scholar]

- Geissdoerfer, M.; Morioka, S.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Nabil Nasr, J.R.; Stefan, B.; Stefanie, H.; Brian, H.; Cory, K.; Nadia von Gries, R.P. Re-defining Value—The Manufacturing Revolution. Remanufacturing, Refurbishment, Repair and Direct Reuse in the Circular Economy. In A Report of the International Resource Panel; United Nations Environment Programme: Nairobi, Kenya, 2018. [Google Scholar]

- MacArthur, E. Towards the circular economy. J. Ind. Ecol. 2013, 2, 23–44. [Google Scholar]

- Braungart, M. Creating Desired Futures, in Cradle-to-Cradle Design: Creating Healthy Emissions—A Strategy for Eco-Effective Product and System Design; Michael, S., Ed.; Birkhäuser: Basel, Switzerland, 2012; pp. 247–271. [Google Scholar]

- Sharpe, R.; Goodall, P.A.; Neal, A.; Conway, P.P.; West, A.A. Cyber-Physical Systems in the re-use, refurbishment and recycling of used Electrical and Electronic Equipment. J. Clean. Prod. 2018, 170, 351–361. [Google Scholar] [CrossRef] [Green Version]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.A.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- EFNMS. The European Federation of National Maintenance Societies. 2021. Available online: https://www.efnms.eu/about-us/what-does-efnms-stand-for/ (accessed on 30 August 2021).

- Guide, V.D.R.; Jayaraman, V.; Srivastava, R.; Benton, W.C. Supply-Chain Management for Recoverable Manufacturing Systems. Interfaces 2000, 30, 125–142. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain–Policy Report; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017. [Google Scholar]

- European Commission. Circular Economy Closing the Loop; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- European Commission. Revised Waste Framework Directive; 2008/98/EC; European Commission: Brussels, Belgium, 2008. [Google Scholar]

- Andersen, T.; Jæger, B.; Mishra, A. Circularity in Waste Electrical and Electronic Equipment (WEEE) Directive. Comparison of a Manufacturer’s Danish and Norwegian Operations. Sustainability 2020, 12, 5236. [Google Scholar] [CrossRef]

- Lawrenz, S.; Nippraschk, M.; Wallat, P.; Rausch, A.; Goldmann, D.; Lohrengel, A. Is it all about Information? The Role of the Information Gap between Stakeholders in the Context of the Circular Economy. Procedia CIRP 2021, 98, 364–369. [Google Scholar] [CrossRef]

- Polat, O.; Capraz, O.; Gungor, A. Modelling of WEEE recycling operation planning under uncertainty. J. Clean. Prod. 2018, 180, 769–779. [Google Scholar] [CrossRef]

- Krook, J.; Svensson, N.; Eklund, M. Landfill mining: A critical review of two decades of research. Waste Manag. 2012, 32, 513–520. [Google Scholar] [CrossRef]

- Zhang, L.; Geng, Y.; Zhong, Y.; Dong, H.; Liu, Z. A bibliometric analysis on waste electrical and electronic equipment research. Environ. Sci. Pollut. Res. 2019, 26, 21098–21108. [Google Scholar] [CrossRef]

- Cesaro, A.; Marra, A.; Kuchta, K.; Belgıorno, V.; Van Hullebusch, E.D. WEEE management in a circular economy perspective: An overview. Glob. NEST J. 2018, 20, 743–750. [Google Scholar]

- European Commission. Waste Electrical and Electronic Equipment Directive; [WEEE] 2002/96/EC; European Commission: Brussels, Belgium, 2002. [Google Scholar]

- European Commission. Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on waste electrical and electronic equipment (WEEE). Off. J. Eur. Union 2012, 197, 38–71. [Google Scholar]

- OECD. Extended Producer Responsibility. 2017. Available online: http://www.oecd.org/env/tools-evaluation/extendedproducerresponsibility.htm (accessed on 30 August 2021).

- Fleckinger, P.; Glachant, M. The organization of extended producer responsibility in waste policy with product differentiation. J. Environ. Econ. Manag. 2010, 59, 57–66. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Gu, Y.; Li, L.; Liu, T.; Wu, Y.; Zuo, T. Operating models and development trends in the extended producer responsibility system for waste electrical and electronic equipment. Resour. Conserv. Recycl. 2017, 127, 159–167. [Google Scholar] [CrossRef]

- Cooper, M.C.; Lambert, D.M.; Pagh, J.D. Supply Chain Management: More Than a New Name for Logistics. Int. J. Logist. Manag. 1997, 8, 1. [Google Scholar] [CrossRef]

- Daugherty, P.J.; Myers, M.B.; Richey, R.G. Information Support for reverse logistics: The influence of relationship commitment. J. Bus. Logist. 2002, 23, 85–106. [Google Scholar] [CrossRef]

- Shi, X.; Li, L.X.; Yang, L.; Li, Z.; Choi, J.Y. Information flow in reverse logistics: An industrial information integration study. Inf. Technol. Manag. 2012, 13, 217–232. [Google Scholar] [CrossRef]

- Madenas, N.; Tiwari, A.; Turner, C.J.; Woodward, J. Information flow in supply chain management: A review across the product lifecycle. CIRP J. Manuf. Sci. Technol. 2014, 7, 335–346. [Google Scholar] [CrossRef]

- Kurilova-Palisaitiene, J.; Lindkvist, L.; Sundin, E. Towards Facilitating Circular Product Life-Cycle Information Flow via Remanufacturing. Procedia CIRP 2015, 29, 780–785. [Google Scholar] [CrossRef]

- ISO. ISO 14001, in Environmental Management Systems—Requirements with Guidance for Use; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Mazzi, A.; Toniolo, S.; Catto, S.; De Lorenzi, V.; Scipioni, A. The combination of an Environmental Management System and Life Cycle Assessment at the territorial level. Environ. Impact Assess. Rev. 2017, 63, 59–71. [Google Scholar] [CrossRef]

- Daniels, P.L.; Moore, S. Approaches for Quantifying the Metabolism of Physical Economies: Part I: Methodological Overview. J. Ind. Ecol. 2001, 5, 69–93. [Google Scholar] [CrossRef]

- Ahlroth, S.; Nilsson, M.; Finnveden, G.; Hjelm, O.; Hochschorner, E. Weighting and valuation in selected environmental systems analysis tools—Suggestions for further developments. J. Clean. Prod. 2011, 19, 145–156. [Google Scholar] [CrossRef]

- Bicalho, T.; Sauer, I.; Rambaud, A.; Altukhova, Y. LCA data quality: A management science perspective. J. Clean. Prod. 2017, 156, 888–898. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N. Material flow analysis (MFA) as a strategic tool in E-waste management: Applications, trends and future directions. J. Environ. Manag. 2019, 244, 344–361. [Google Scholar] [CrossRef]

- Kurniadi, K.A.; Ryu, K. Maintaining Sustainability in Reconfigurable Manufacturing Systems Featuring Green-BOM. Int. J. Precis. Eng. Manuf. Technol. 2020, 7, 755–767. [Google Scholar] [CrossRef]

- Bogers, M. The open innovation paradox: Knowledge sharing and protection in R&D collaborations. Eur. J. Innov. Manag. 2011, 14, 93–117. [Google Scholar] [CrossRef]

- Davies, I.; Green, P.F.; Rosemann, M.; Indulska, M.; Gallo, S. How do practitioners use conceptual modeling in practice? Data Knowl. Eng. 2006, 58, 358–380. [Google Scholar] [CrossRef] [Green Version]

- Parajuly, K.; Wenzel, H. Product Family Approach in E-Waste Management: A Conceptual Framework for Circular Economy. Sustainability 2017, 9, 768. [Google Scholar] [CrossRef] [Green Version]

- Song, X.; Wang, J.; Yang, J.; Lu, B. An updated review and conceptual model for optimizing WEEE management in China from a life cycle perspective. Front. Environ. Sci. Eng. 2017, 11, 3. [Google Scholar] [CrossRef]

- Moody, D.L. Theoretical and practical issues in evaluating the quality of conceptual models: Current state and future directions. Data Knowl. Eng. 2005, 55, 243–276. [Google Scholar] [CrossRef]

- Norway, G. Guideline for Unique Identification of Products with SGTIN; The Global Language Business: Boston, MA, USA, 2018. [Google Scholar]

- Nnorom, I.; Osibanjo, O. Toxicity characterization of waste mobile phone plastics. J. Hazard. Mater. 2009, 161, 183–188. [Google Scholar] [CrossRef]

- Goltsos, T.E.; Syntetos, A.A.; Van Der Laan, E. Forecasting for remanufacturing: The effects of serialization. J. Oper. Manag. 2019, 65, 447–467. [Google Scholar] [CrossRef]

- Gerbert, P. Industry 4.0—The Future of Productivity and Growth in Manufacturing Industries; The Boston Consulting Group: Boston, MA, USA, 2015. [Google Scholar]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-based Production Systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Bodkhe, U.; Tanwar, S.; Parekh, K.; Khanpara, P.; Tyagi, S.; Kumar, N.; Alazab, M. Blockchain for Industry 4.0: A Comprehensive Review. IEEE Access 2020, 8, 79764–79800. [Google Scholar] [CrossRef]

- Kembro, J.; Näslund, D.; Olhager, J. Information sharing across multiple supply chain tiers: A Delphi study on antecedents. Int. J. Prod. Econ. 2017, 193, 77–86. [Google Scholar] [CrossRef]

- Fawcett, S.E.; Osterhaus, P.; Magnan, G.M.; Brau, J.C.; McCarter, M.W. Information sharing and supply chain performance: The role of connectivity and willingness. Supply Chain Manag. Int. J. 2007, 12, 358–368. [Google Scholar] [CrossRef] [Green Version]

- Prajogo, D.; Olhager, J. Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration. Int. J. Prod. Econ. 2012, 135, 514–522. [Google Scholar] [CrossRef]

- Jannes, K.; Lagaisse, B.; Joosen, W. The Web Browser as Distributed Application Server: Towards Decentralized Web Applications in the Edge. In Proceedings of the 2nd International Workshop on Edge Systems, Analytics and Networking, Dresden, Germany, 25 March 2019; pp. 7–11. [Google Scholar]

- Nakamoto, S. Bitcoin: A peer-to-peer electronic cash system. Decentralized Bus. Rev. 2019, 1, 21260. [Google Scholar]

- Wang, Y.; Singgih, M.; Wang, J.; Rit, M. Making sense of blockchain technology: How will it transform supply chains? Int. J. Prod. Econ. 2019, 211, 221–236. [Google Scholar] [CrossRef]

- Wang, X.V.; Wang, L. WRCloud: A Novel WEEE Remanufacturing Cloud System. Procedia CIRP 2015, 29, 786–791. [Google Scholar] [CrossRef]

- Wang, X.V.; Wang, L. Digital twin-based WEEE recycling, recovery and remanufacturing in the background of Industry 4. Int. J. Prod. Res. 2018, 57, 3892–3902. [Google Scholar] [CrossRef]

- Magrini, C.; Nicolas, J.; Berg, H.; Bellini, A.; Paolini, E.; Vincenti, N.; Campadello, L.; Bonoli, A. Using Internet of Things and Distributed Ledger Technology for Digital Circular Economy Enablement: The Case of Electronic Equipment. Sustainability 2021, 13, 4982. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S.; Guo, J.; Du, Y.; Cheng, S.; Li, X. A Summary of Research on Blockchain in the Field of Intellectual Property. Procedia Comput. Sci. 2019, 147, 191–197. [Google Scholar] [CrossRef]

- Magal, S.; Word, J. Essentials of Business Processes and Information Systems; Wiley Publishing: Hoboken, NJ, USA, 2009. [Google Scholar]

- Boccaletti, S.; Bianconi, G.; Criado, R.; del Genio, C.; Gomez-Gardenes, J.; Romance, M.; Sendiña-Nadal, I.; Wang, Z.; Zanin, M. The structure and dynamics of multilayer networks. Phys. Rep. 2014, 544, 1–122. [Google Scholar] [CrossRef] [Green Version]

- Bortolini, M.; Galizia, F.G.; Mora, C. Reconfigurable manufacturing systems: Literature review and research trend. J. Manuf. Syst. 2018, 49, 93–106. [Google Scholar] [CrossRef]

- European Commission. Statistics for the European Union’s (EU) manufacturing sector. In Annual Detailed Enterprise Statistics for Industry; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Klievink, B.; Van Stijn, E.; Hesketh, D.; Aldewereld, H.; Overbeek, S.; Heijmann, F.; Tan, Y.H. Enhancing visibility in international supply chains: The data pipeline concept. Int. J. Electron. Gov. Res. 2012, 8, 14–33. [Google Scholar] [CrossRef] [Green Version]

- Sheffi, Y. Balancing Green: When to Embrace Sustainability in a Business (And When Not to); MIT Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Gligoric, N.; Krco, S.; Hakola, L.; Vehmas, K.; De, S.; Moessner, K.; Jansson, K.; Polenz, I.; Van Kranenburg, R. SmartTags: IoT Product Passport for Circular Economy Based on Printed Sensors and Unique Item-Level Identifiers. Sensors 2019, 19, 586. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhang, P.; Tao, F.; Liu, Y.; Zuo, Y. Consensus aware manufacturing service collaboration optimization under blockchain based Industrial Internet platform. Comput. Ind. Eng. 2019, 135, 1025–1035. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.V.; Gao, L.; Váncza, J. A cloud-based approach for WEEE remanufacturing. CIRP Ann. 2014, 63, 409–412. [Google Scholar] [CrossRef] [Green Version]

- Lu, R.; Li, X.; Liang, X.; Shen, X.; Lin, X. GRS: The green, reliability, and security of emerging machine to machine communications. IEEE Commun. Mag. 2011, 49, 28–35. [Google Scholar] [CrossRef]

- Damianou, A.; Angelopoulos, C.M.; Katos, V. An Architecture for Blockchain over Edge-enabled IoT for Smart Circular Cities. In Proceedings of the 15th International Conference on Distributed Computing in Sensor Systems (DCOSS), Santorini Island, Greece, 29–31 May 2019; pp. 465–472. [Google Scholar]

- Demestichas, K.; Daskalakis, E. Information and Communication Technology Solutions for the Circular Economy. Sustainability 2020, 12, 7272. [Google Scholar] [CrossRef]

| Action | Description | Dis-Assembly Required | Action Type (MoL, EoL, Waste) |

|---|---|---|---|

| Maintenance | Activities to keep an e-product in the desired operating condition [20,21] | No | MoL |

| Reuse | Use the e-product again for the same purpose as when it was manufactured [16] | No | MoL |

| Repair | Fix a fault or replace defective components to make it fully functional as when it was manufactured [16] | No | MoL |

| Refurbish | Modification to make it fully functional as when it was manufactured [16] | No | MoL |

| Remanufacture | Industrial process to transform e-products or their parts into products that are as functional as original manufactured products [16,22] | Yes | EoL |

| Recycle | Operations for reprocessing products, not necessarily for the original purpose [17,18] | Yes | EoL |

| Collect waste | PROs collect e-waste after EoL [17,18] | No | Waste |

| Recovery of energy | Burning and using the heat [17,18] | No | Waste |

| Placement in landfill | Transport and digging [17,18] | No | Waste |

| # | Category |

|---|---|

| 1 | Temperature exchange equipment |

| 2 | Screens, monitors, and equipment containing screens having a surface greater than 100 cm2 |

| 3 | Lamps |

| 4 | Large equipment (any external dimension more than 50 cm) |

| 5 | Small equipment (no external dimension more than 50 cm) |

| 6 | Small IT and telecommunication equipment (no external dimension more than 50 cm) |

| Company | Title of Interviewee/Stakeholder | Type |

|---|---|---|

| Original Equipment Manufacturer (OEM) | Product manager Product manager Head of product management Product Engineer | Phone/E-mail |

| Reverse Supply Chain Actor 1: EEE-installer | Representative from the EEE-installer | Phone |

| Reverse Supply Chain Actor 2: Waste collector | Representative from the waste collector | Phone |

| Reverse Supply Chain Actor 3: Recycle facility | Representative from the recycle facility | Phone |

| Blockchain as a service company | Business manager, CEO | E-mail with conceptual model Zoom meeting |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andersen, T.; Jæger, B. Circularity for Electric and Electronic Equipment (EEE), the Edge and Distributed Ledger (Edge&DL) Model. Sustainability 2021, 13, 9924. https://doi.org/10.3390/su13179924

Andersen T, Jæger B. Circularity for Electric and Electronic Equipment (EEE), the Edge and Distributed Ledger (Edge&DL) Model. Sustainability. 2021; 13(17):9924. https://doi.org/10.3390/su13179924

Chicago/Turabian StyleAndersen, Terje, and Bjørn Jæger. 2021. "Circularity for Electric and Electronic Equipment (EEE), the Edge and Distributed Ledger (Edge&DL) Model" Sustainability 13, no. 17: 9924. https://doi.org/10.3390/su13179924

APA StyleAndersen, T., & Jæger, B. (2021). Circularity for Electric and Electronic Equipment (EEE), the Edge and Distributed Ledger (Edge&DL) Model. Sustainability, 13(17), 9924. https://doi.org/10.3390/su13179924