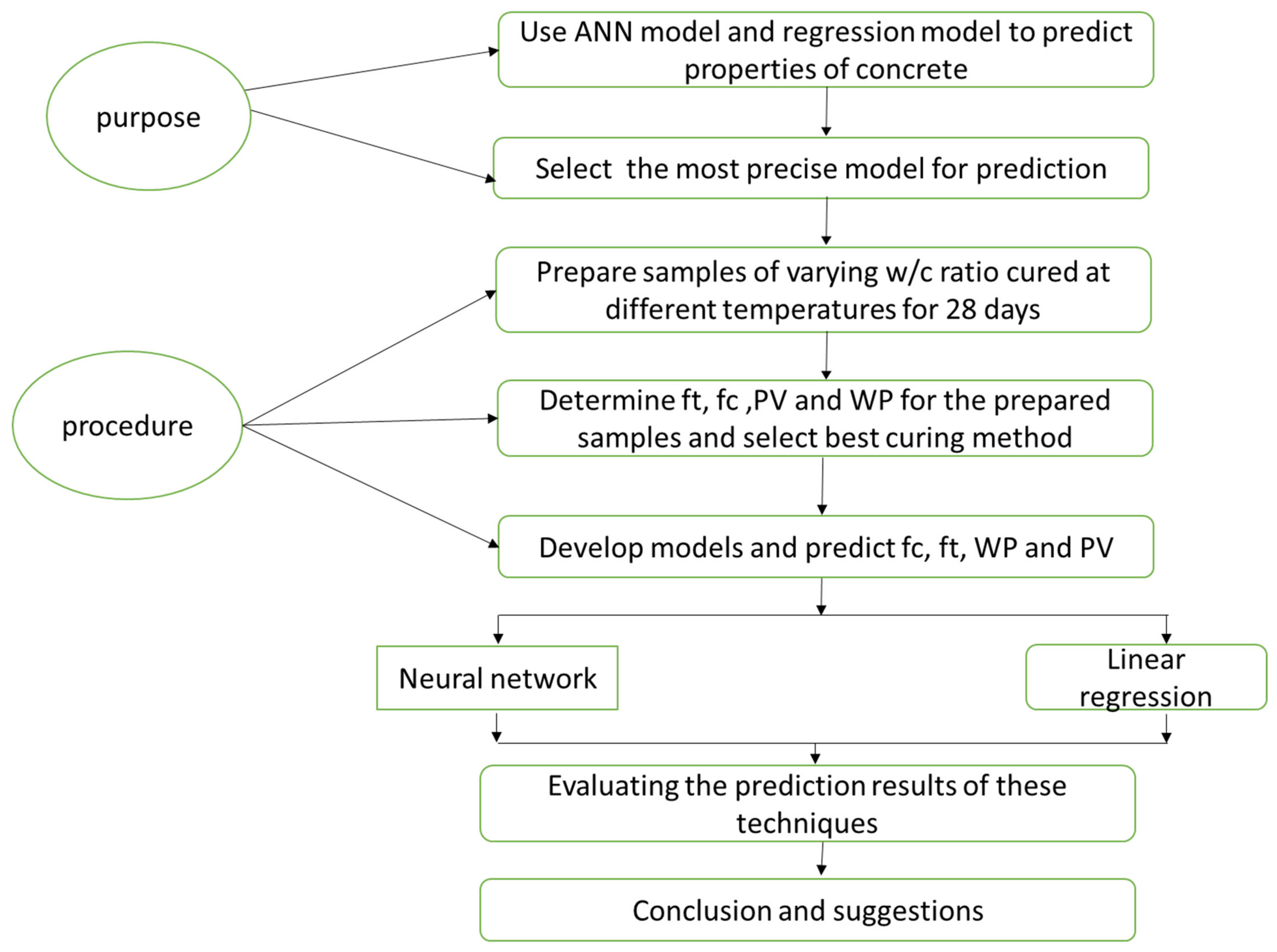

Based on the method adopted in the study, first, the properties of the concrete samples were tested in the laboratory. The test results are discussed subsequently.

4.1. Properties of the Concrete Sample

Table 1 shows the mechanical characteristics and

WP of concrete samples cured for 28 days. It shows different curing methods used at varying temperatures in the current study and their effects on the concrete properties. This was done to choose the best curing method when concreting in a hot climate. Overall, three curing methods are used in this study.

When the w/c is increased, it causes a decrease in ft, fc, and WP, whereas, by increasing the temperature, ft, fc, and PV values are increased. In the first curing method, the concrete is cured by submerging it in water. The results show that, for a w/c of 0.298, the values of fc, ft, and PV are 30.75, 2.94, and 4282, respectively. Similarly, for a w/c of 0.398, the values of fc, ft, and PV are 24.45, 2.57, and 4182. Whereas for a w/c of 0.448, the values of fc, ft, and PV are 20.55, 2.29, and 4142. From these values, a decreasing trend in fc, ft, and PV can be observed with the increase in w/c. Similarly, the increase in the values of concrete properties can be observed when the temperature is increased. In the first method, concrete samples were cured by immersing the samples in water at varying temperatures of 23 °C, 30 °C, 43 °C, and 36 °C. After 28 days, tests were carried out, and fc, ft, PV, and WP were determined. The samples with a w/c of 0.298 gave the highest fc compared to other w/c values. At 43 °C, the fc is observed to be 35.85 Mpa, which is the highest among all alternatives. Further, the value of PV is also the highest (4352 m/s at 43 °C) at a w/c of 0.298, showing superior concrete quality. The maximum tensile strength of 3.23 Mpa is observed at 43 °C at the same w/c. WP value of 16mm is obtained at 30 °C. In comparison, the w/c of 0.398 and 0.448 have lower fc, ft, WP, and PV values. This shows that the sample prepared with a w/c of 0.298 at 43 °C gives superior quality concrete in hot climates such as Rawalpindi.

In the second method, curing is done by covering the concrete with wet burlap. In this method, water is sprayed on the concrete, and burlap blankets are placed over it. The burlap side of the blanket faces down towards the concrete. Burlap is made of natural moisture-absorbing fibers that retain moisture. It also shields the surface of the water from direct exposure to sunlight. Identical samples with the same w/c are prepared that are cured using wet burlap to determine the fc, ft, PV, and WP. In this case, the highest fc (46.75 Mpa) and PV (4372 m/s) were observed at a w/c of 0.298 at 30 °C. The maximum ft (3.95 Mpa) is observed at a w/c of 0.298 at 23 °C. Further, the lowest WP (27 mm) is observed at 0.298 w/c at 30 °C. Based on these results, it can be concluded that superior quality concrete cured using wet burlaps can be obtained at a w/c of 0.298 at 30 °C.

In the third method, curing compounds are used to cure the concrete. Concrete treatment agent SPEC Chen SC 500 is used for curing concrete in this method. SPEC Chen SC 500 is sprinkled over the surface of the concrete. The compound minimizes the evaporation of concrete water, which helps in preventing shrinkage cracking. Afterward, the properties of concrete are determined using similar steps as mentioned in the first two methods. For this technique, the sample prepared with

w/

c of 0.298 at 30 °C gives the maximum

fc (43.95 Mpa),

ft (3.63 Mpa), and

PV (4352 m/s) compared to other

w/

c values. This ratio also gives the lowest

WP value (35 mm). By comparing the results from all methods in

Table 1, it can be concluded that using a

w/

c of 0.298 at an in situ temperature of 30 °C and covering the aggregate with wet burlap, concrete with improved characteristics can be obtained that is best suited for use in hot climates.

4.3. Results and Discussion of the ANN Models

Table 6 lists the predicted properties of concrete prepared under a hot climate using ANNs models. ANNs models were developed to reduce the square error difference between experimental and forecasted values. This was achieved by iterating the hidden neuron weights using the learning algorithm. The scatter plots for all data points of the developed ANN models are presented in

Figure 7,

Figure 8,

Figure 9 and

Figure 10. Accordingly, both the experimental and forecasted data on the scatter plot are observed to be equally spread and closely aligned with the trend line, signifying the accuracy of results in the figures. A combined ANN model was also developed to check the combined effect of

fc,

ft, and

PV.

WP was not included in the combined ANN model because the tests needed to be carried out after 28 days of curing. For normalization of the values, the variables were preprocessed using the min–max function, as shown in equation 6. In equation 6,

X’ is the normalized value and

X is the observed value, whereas min and max represent the minimum and maximum values of variables [

90].

Table 6.

Results of ANN models for predicting the properties of concrete.

Table 6.

Results of ANN models for predicting the properties of concrete.

| Parameter | ANN Models |

|---|

| WP | fc | ft | PV |

|---|

| Type | MLP | MLP | MLP | MLP |

| Variable normalization | Min–max | Min–max | Min–max | Min–max |

| Hidden layer activation function | Hyperbolic | Hyperbolic | Hyperbolic | Hyperbolic |

| Input/output layer activation function | Linear | Linear | Linear | Linear |

| Number of hidden layers | 1 | 1 | 1 | 1 |

| Number of hidden neurons | 6 | 8 | 4 | 5 |

| Learning algorithm | CGB | CGB | CGB | CGB |

| Error function | Sum-squared | Sum-squared | Sum-squared | Sum-squared |

| R2 | 0.92 | 0.94 | 0.88 | 0.94 |

| RMSE-Training | 3.048 | 2.48 | 0.901 | 17.216 |

| RMSE-Test | 2.834 | 3.17 | 0.913 | 21.847 |

| MAE-Training | 2.603 | 2.13 | 0.869 | 13.778 |

| MAE-Test | 2.388 | 2.75 | 0.884 | 18.224 |

As shown in

Table 6,

R2 values of

WP,

fc,

ft, and

PV are close to 1, showing the prediction accuracy of the model. RMSE and MAE of training and testing models, mentioned in

Table 6, represent the errors in the analyses. For

WP,

fc, and

ft, the values of RMSE and MAE are very small, showing that the model’s predictions are very accurate. However, the values for

PV, MAE, and RMSE are higher, indicating more errors in the results. These errors may be associated with human error in recording the data, the model’s inability to properly analyze the data, or incorrect selection of the number of hidden layers. The activation function provides the output at all nodes. It is a hyperbolic function in ANN models and provides values ranging from −1 to 1.

The layer between input and output layers is known as the hidden layer. In the current ANN model, one hidden layer is used for WP, fc, ft, and PV. It is very important to determine the number of hidden layers because, if too many hidden layers are used, the neurons will remember the data well but will not generalize it properly. On the other hand, if the number of neurons is too low, the neurons will generalize the data well, but the patterns will not be remembered well. Therefore, in this ANN model, six neurons are used for predicting WP, eight for fc, four for ft, and five for PV.

Compared to other published studies, Mai et al. [

87] developed an ANN model to predict the

fc of concrete. Their model showed an

R2 value of 0.9285, and RMSE and MAE as 4.4266 and 3.2971, respectively. In the model developed by Yousif et al. [

91], ANN was used to predict the

PV of concrete that displayed an

R2 value of 0.94. Vineela et al. [

92] developed an ANN model to predict the

ft of concrete where a value of 0.98 was obtained for

R2. For

WP prediction using ANN, Mustafa et al. [

93] developed a model that displayed an

R2 value of 0.98. The current study results are comparable to these relevant studies and show identical results for the ANN model used to predict properties of concrete in hot climates.

The values for both training and testing data sets range from (20, 20) to (80, 80) on the scatter plot in

Figure 7. Each data point represents observed and predicted

WP on the

x-axis and

y-axis, respectively. Compared to the values obtained from the regression model for

WP in the current study, the

R2 of the ANN model (0.92) is superior to that of the regression model (0.87). This shows that the correlation between the testing and training data sets of the ANN model is higher than that of the regression model developed in the current study.

Figure 7.

Scatter plot of water penetration developed using ANN model.

Figure 7.

Scatter plot of water penetration developed using ANN model.

Further, the values of RMSE and MAE for the training regression model are 3.23 and 3.14, which are greater than the ANN model (3.048 and 2.603). The same observations are made for the RMSE and MAE values of the testing data sets of the regression model (4.32, 4.03), which are also higher than the ANN model (2.834, 2.388). This highlights that the ANN model gives more accurate predictions with the least errors. Hence, the ANN model’s prediction capabilities are more accurate compared to the regression model. Similar observations were made by Sarkar and Pandey [

94], who used an ANN model to predict the

WP of concrete and obtained an

R2 value of 0.92.

Different ANN models were tried by varying the number of hidden layers, activation function, and neurons in the current study. The accuracies for all models were estimated and recorded. It was observed that the maximum accuracy is given by the activation function with one hidden layer. Some minor errors were observed in the model values. At least two hidden layers are required in combined ANN models due to the higher complexity within the problem. A maximum of seven neurons has been used in the developed models, while the minimum number is three. For example, seven neurons are used to predict fc, while three neurons are used for predicting ft. The neurons connect the input and output variables. Thus, the variables with greater correlation will necessitate more neurons. The number of neurons does not significantly affect the processing time, nor does it require some special computational package.

ANN models displayed superior results than the quadratic regression models. In all cases, the value of

R2 for the ANN model is greater than the values obtained by the regression model. Scatter plots of ANN models for determining

fc,

ft, and

PV are shown in

Figure 8,

Figure 9 and

Figure 10. The ANN models have fewer variations compared to the regression models. There is a large difference between the accuracy of ANN and the regression models for

fc,

ft, and

PV, where ANN models show superior predictions. Further, the scatter plots for these parameters in the regression models are impractical as they display more predicted values to be out of range.

The combined ANN model of

fc,

ft,

and PV shows a higher prediction accuracy for determining all the parameters, as shown in

Table 7. Furthermore,

R2, RMSE, and MAE values for the combined model are improved in comparison to the previous ANN models. For

fc, the data on the scatter plot are spread widely but equally around the trend line, as shown in

Figure 11, highlighting data accuracy. The corresponding

R2 value is 0.96, which is close to one, indicating more reliability. The

ft data on the scatter plot follow a similar trend as shown in

Figure 12, with an

R2 value of 0.95. Similarly, for

PV data the

R2 value is 0.9. The closer concentration around the trendline for the values of

fc,

ft, and

PV represents higher accuracy of the combined ANN model for determining the characteristics of concrete prepared in a hot climate.

The values for

fc of the concrete in the training and testing data sets range from (20, 20) to (80, 80) on the scatter plot and display a positive correlation, as shown in

Figure 8. In comparison to the regression model, the

R2 value has improved from 0.93 in the regression model to 0.94 in the ANN model. Thus, the ANN model gives a superior performance in both training and testing phases. In comparison to other studies, Abuodeh et al. [

95] used a back-propagation neural network model to predict the

fc of concrete where the

R2 value of 80.1 is obtained. In comparison, the current study shows superior results.

Figure 8.

Scatter plot of compressive strength established using ANN model.

Figure 8.

Scatter plot of compressive strength established using ANN model.

Figure 9 shows the

ft predictions using the ANN model. The training and testing data sets range from (2, 1.5) to (6.8, 6.8) on the scatter plot in

Figure 9, displaying a positive correlation. In comparison to the

R2 value of the regression model (0.835), there is an improvement in the value of

R2 of the ANN model (0.88). Further, the correlation between training and testing data sets of the ANN model is improved in comparison to the regression model. However, the RMSE values for the training and testing data sets of the regression model were 0.318 and 0.362, compared to 0.901 and 0.913 for ANN. Thus, compared to the regression model, the ANN model has more RMSE error value for

ft prediction, but high

R2. In comparison to published studies, Gülbandılar and Koçak [

96] predicted the

ft of concrete using the ANN model and obtained an

R2 value of 0.90, which is very close to the findings of the current study.

Figure 9.

Scatter plot of split tensile strength using ANN model.

Figure 9.

Scatter plot of split tensile strength using ANN model.

Figure 10 shows the values for

PV using the ANN model. The scatter plot in

Figure 10 shows that the training and testing data sets range from (41, 41) to (45, 45), showing a positive correlation. In comparison, the

R2 value of the regression model is very low (0.66) compared to the ANN model (0.94). Thus, there is a weak correlation between testing and training data sets in regression model when compared to the ANN model. The values of RMSE and MAE further support this. These are 71.819 and 59.754 for the regression model and 21.847 and 18.224 for the ANN model. Thus, the ANN model has less error and a high correlation between testing and training data sets compared to the regression model. Therefore, the ANN model is more accurate in predicting

PV. In comparison to published studies, Trtnik et al. [

14] developed an ANN model to predict the

PV of concrete where the

R2 value of 0.84 was obtained. The current ANN model shows superior results. As discussed in

Section 4.3, a combined ANN model was also developed in the current study. This model combines all the previously developed ANN models to improve the predictions. The combined ANN model uses a CGB learning algorithm with one hidden layer and nine neurons.

Table 7 shows the results of the combined ANN model for predicting the properties of concrete. The

R2 values of

fc,

ft, and

PV obtained through this model are above 0.9, reflecting higher prediction accuracy.

Figure 10.

Scatter plot of pulse velocity for concrete using ANN model.

Figure 10.

Scatter plot of pulse velocity for concrete using ANN model.

In comparison to other studies, Yue et al. [

97] developed an ANN model to predict

fc,

ft, elastic modulus, and concrete slump. The resulting

values obtained for these properties were above 0.94. The current study shows similar results for

fc and

ft. In the current study, the

R2 values of the combined ANN model are higher than the individual ANN models of

fc,

ft, and

PV. Thus, the combined ANN model has improved prediction accuracy in comparison to individual ANN models. Therefore, the combined ANN model should be used for forecasting characteristics of concrete with more accuracy.

As shown in

Figure 11, the values for both training and testing data sets range from (20, 20) to (80, 80) on the scatter plot, showing a positive correlation.

Figure 11 shows the predicted

fc values using the combined ANN model.

R2 of

fc for the combined ANN model is 0.96, which is improved in comparison to the initial ANN model (0.94). This shows that the combined ANN model has a better correlation between testing and training data set models than the individual models. The value of RMSE and MAE for the combined ANN model for the testing data sets are 3.287 and 2.771, which are improved in comparison to the individual ANN (3.17 and 2.75). The errors in both combined and individual models remain the same. Hence, the combined ANN model is better at predicting the

fc of concrete with the same errors. In comparison to other studies, Uchechukwu and Austin [

98] obtained an

R2 value of 0.97 for

fc. The current study has nearly similar results.

Figure 11.

Scatter plot of compressive strength developed using combined ANN model.

Figure 11.

Scatter plot of compressive strength developed using combined ANN model.

Figure 12 shows the

ft values obtained from the combined ANN model. As shown in

Figure 12, the training data set ranges from (1.6, 1.6) to (6.6, 6.7) on the scatter plot for predicting the

ft of concrete using the combined ANN model. The testing data set ranges from (1.6, 1.5) to (6.5, 6.5) on the scatter plot, showing a positive correlation.

Figure 12.

Scatter plot of split tensile strength developed using combined ANN model.

Figure 12.

Scatter plot of split tensile strength developed using combined ANN model.

The R2 value for ft using the combined ANN model is 0.95, compared to 0.88 for the individual ANN model, showing superior performance. The values of RMSE and MAE for the testing data sets of the combined ANN model are 0.805 and 0.784, compared to 0.913 and 0.884 for the individual ANN model. This shows that the individual ANN models have more errors than the combined ANN model. The combined ANN model has a high R2 value, better correlation between training and testing data sets, and fewer errors. Therefore, the combined model is more suitable for predicting the ft of concrete.

In this study, regression models, ANN models, and a combined ANN model for predicting the properties of concrete were developed. The models were used to predict concrete properties (

fc,

ft,

PV, and

WP) when prepared in hot climates. In the studies by Nikoo et al. [

99], an

R2 value of 0.899 was obtained when predicting the

fc of concrete. In comparison, the current model gives a value of 0.96, showing better performance and increased reliability for both testing and training models. In another study by Nikoo et al. [

100],

R2 values of 0.880, 0.993, and 0.946 were for training, validation, and testing phases when determining concrete strength. In comparison, the values obtained in this study are higher. Similarly, Ray et al. [

101] determined the value of

R2 for

ft to be 0.958, which is the same as the current study, thus validating the results. Further, Yousif et al. [

91] determined the

R2 for

PV to be 0.93, whereas the current combined ANN model gave a value of 0.97, showing superior performance. Therefore, based on the above comparisons, the combined ANN model developed in the current study is better at predicting the properties of concrete and is recommended to be used for such purposes.