Creating Shared Value in BoP Communities with Micro-Manufacturing Factories: A Systematized Literature Review

Abstract

:1. Introduction

“What are the core concepts that need to be taken into consideration for creating shared value with micro-manufacturing factories in communities at the BoP?”

2. Materials and Methods

2.1. Step 1: Planning the Review

2.2. Step 2: Identifying and Evaluating Studies

2.3. Step 3: Extracting and Synthesizing Data

2.4. Step 4: Disseminate the Review Findings

3. Results

3.1. Descriptive Statistics Results

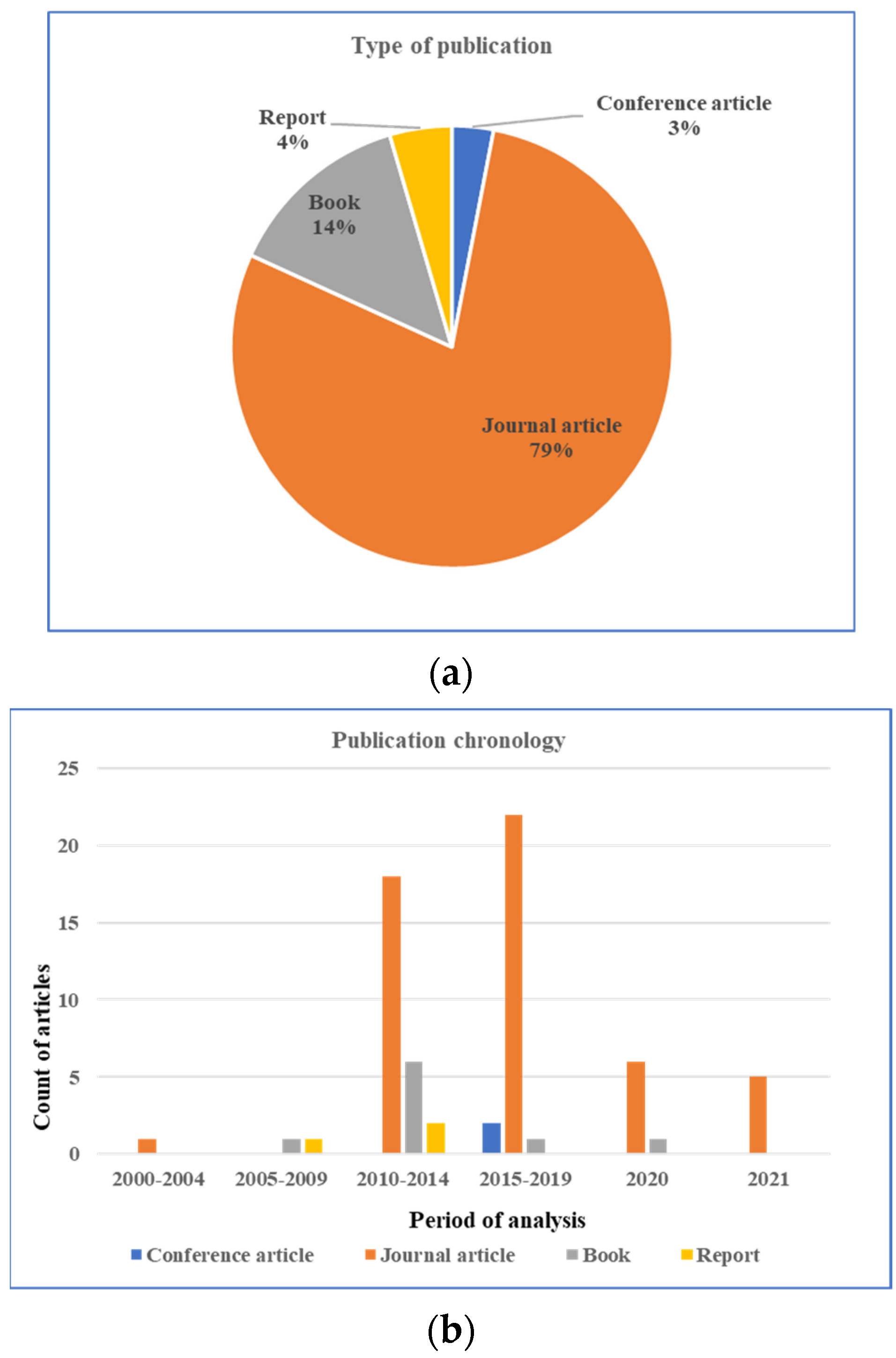

3.1.1. Type of Publication and Citation Data

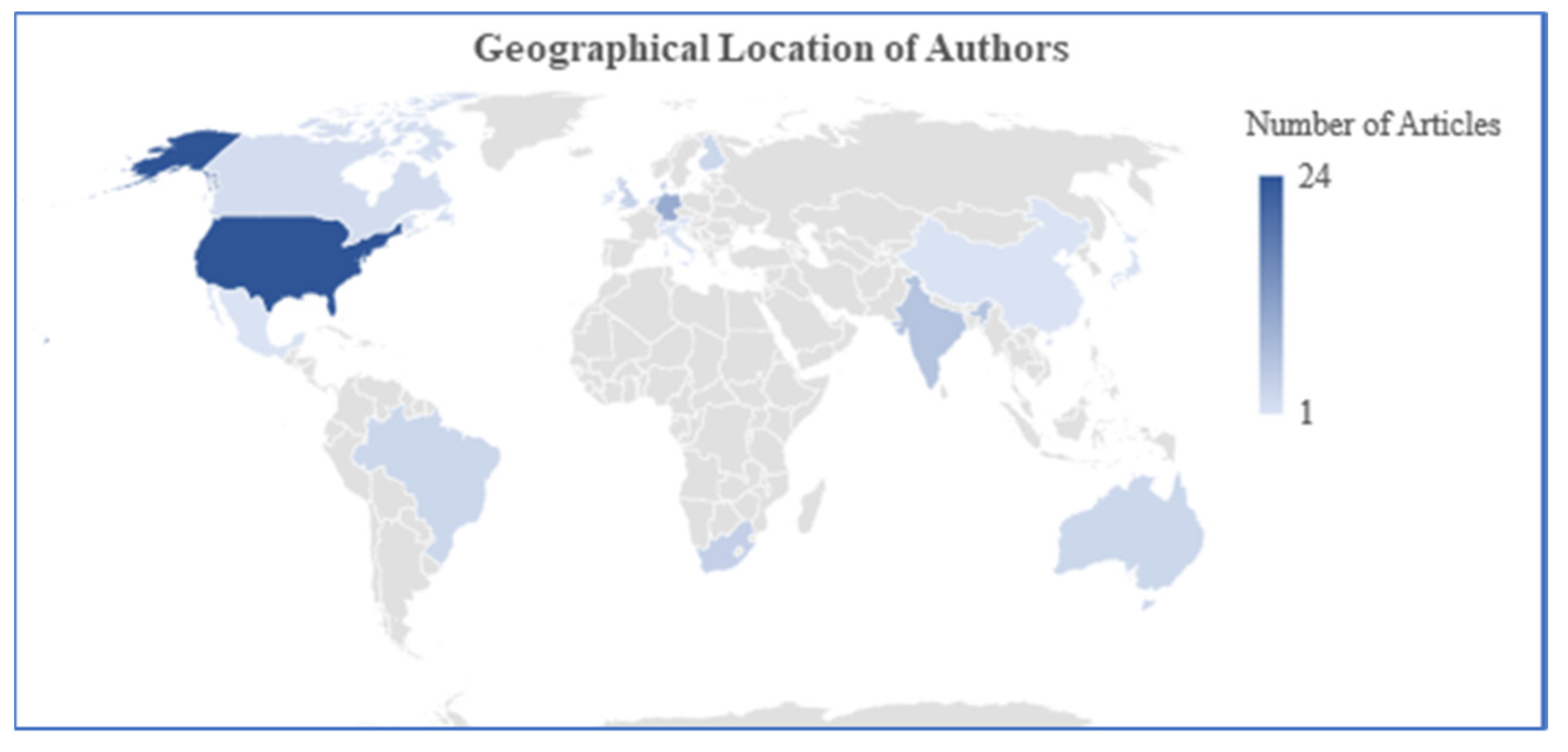

3.1.2. Geographical Location of Authors

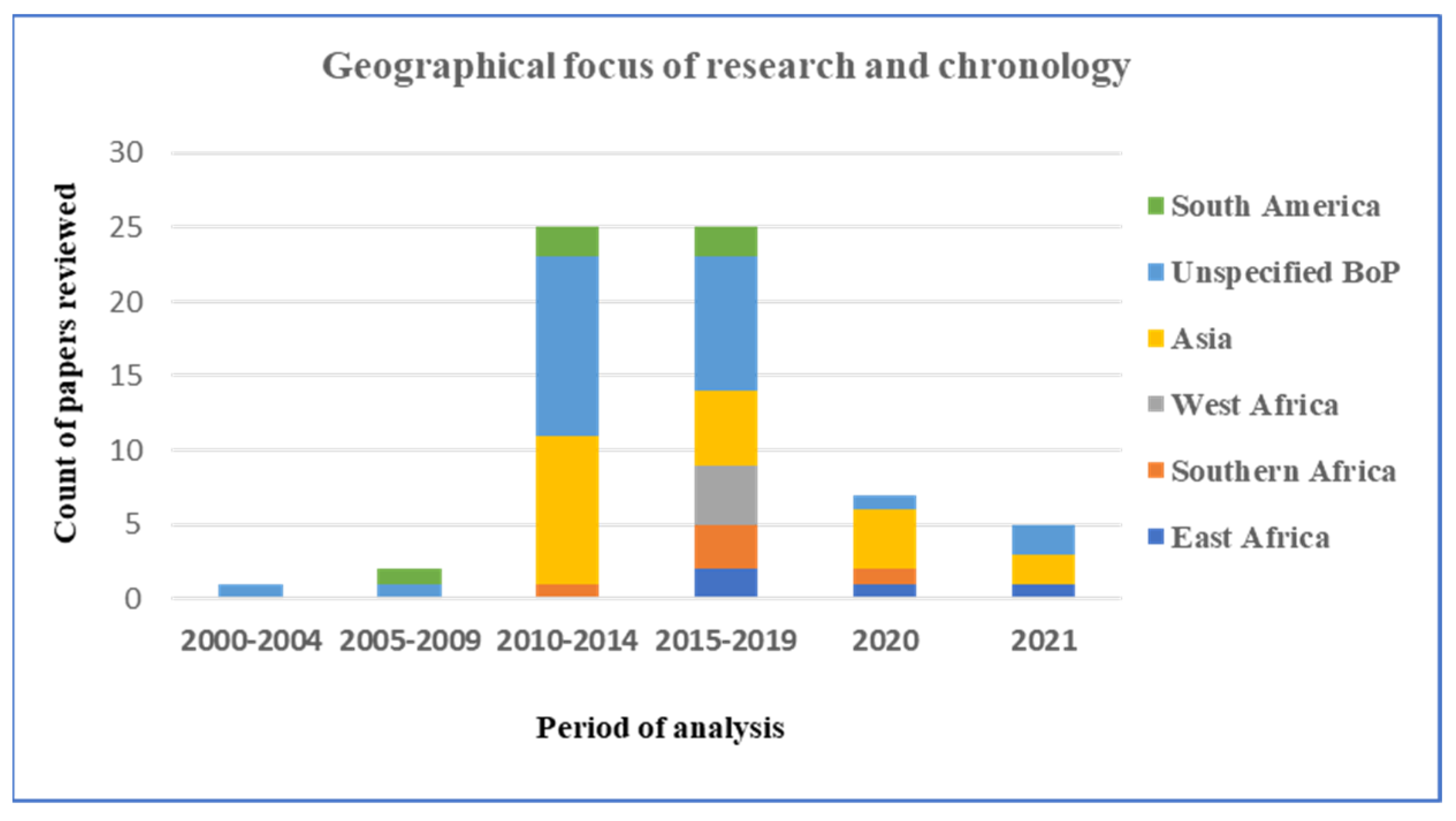

3.1.3. Geographic Focus Areas of the Studies

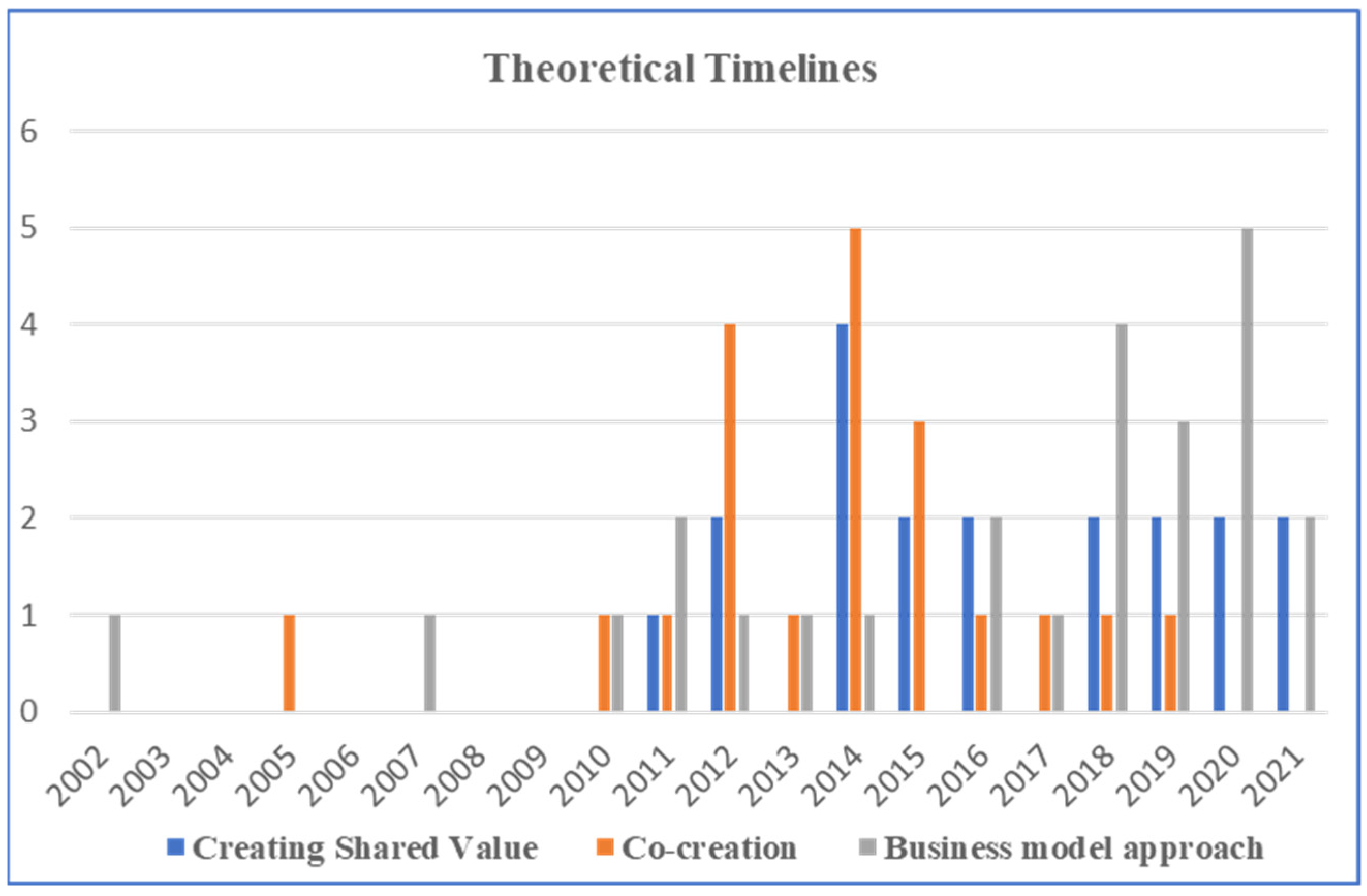

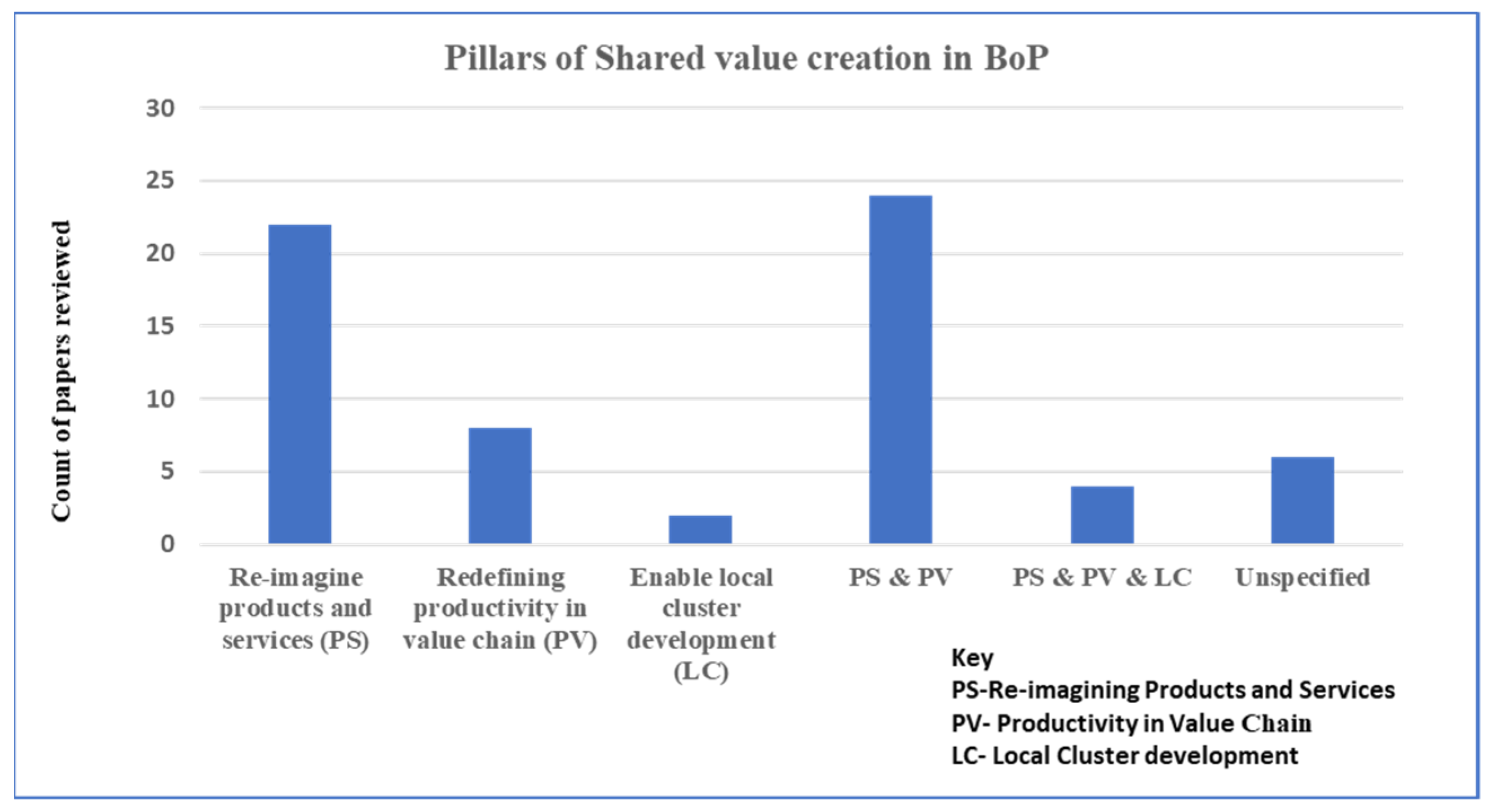

3.2. Content Analysis Results

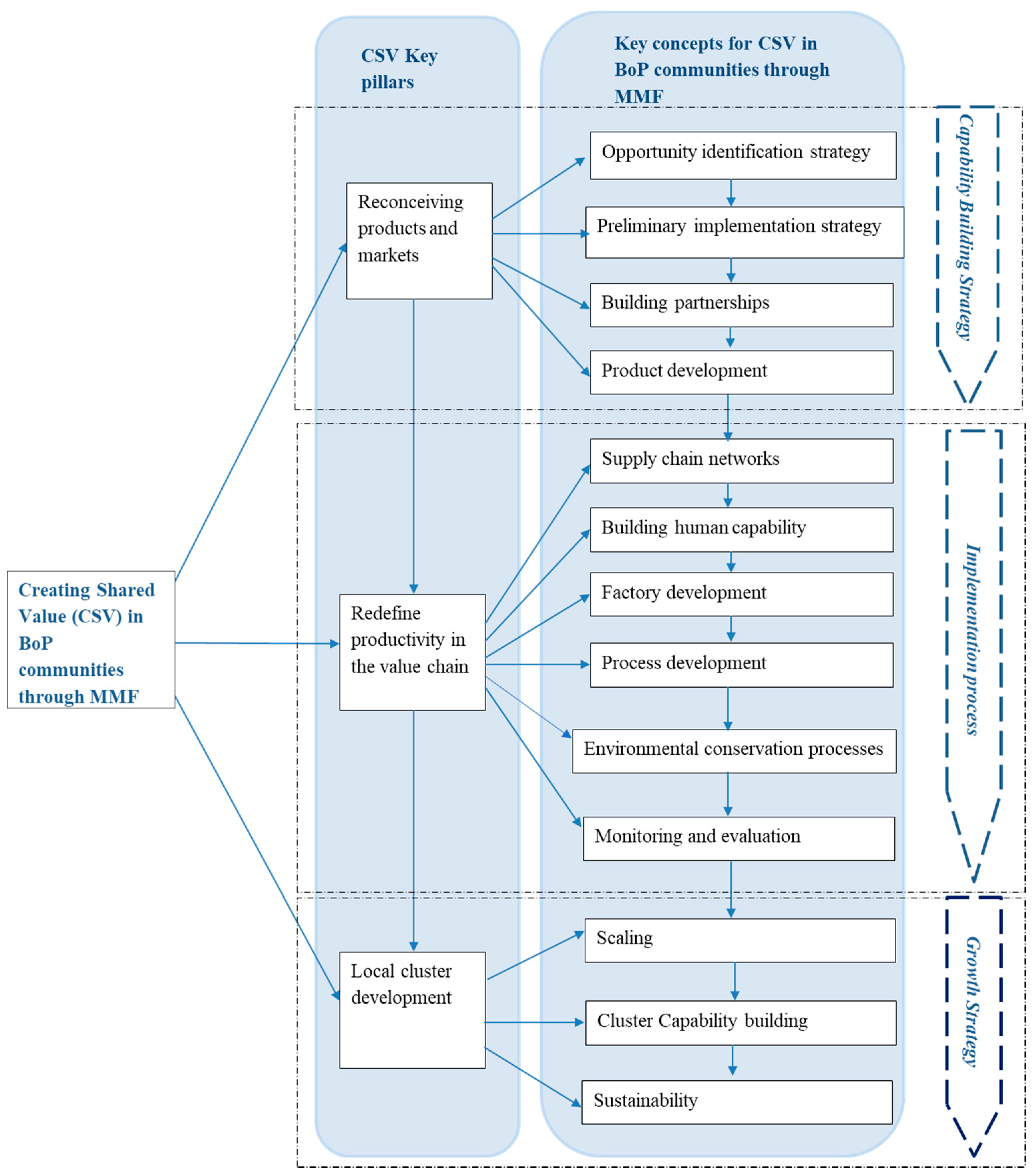

4. Discussion

4.1. Capability Building Strategy

4.2. Implementation Process

4.3. Growth Strategy

4.4. Key Concepts for BoP Manufacturing Shared Value Creation towards a Conceptual Framework

5. Conclusions

6. Future Work and Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prahalad, C.K. The Fortune at the Bottom of the Pyramid, Revised and Updated 5th Anniversary Edition: Eradicating Poverty through Profits; FT Press: Upper Saddle River, NJ, USA, 2009. [Google Scholar]

- London, T. The Base of the Pyramid Promise; Stanford University Press: Redwood City, CA, USA, 2020. [Google Scholar] [CrossRef]

- Arora, S.; Romijn, H. The Empty Rhetoric of Poverty Reduction at the Base of the Pyramid. Organization 2011, 19, 481–505. [Google Scholar] [CrossRef]

- Simanis, E.; Hart, S. The Base of the Pyramid Protocol: Toward Next Generation BoP Strategy. Innov. Technol. Governance Glob. 2008, 3, 57–84. [Google Scholar] [CrossRef]

- Cañeque, F.; Hart, S. Base of the Pyramid 3.0: Sustainable Development through Innovation and Entrepreneurship; Greenleaf: New York, NY, USA, 2015. [Google Scholar]

- Van Der Merwe, M.D.; Grobbelaar, S.S.; Schutte, C.S.L.; Von Leipzig, K.H. Toward an Enterprise Growth Framework for Entering the Base of the Pyramid Market: A Systematic Review. Int. J. Innov. Technol. Manag. 2018, 15, 1850035. [Google Scholar] [CrossRef]

- Porter, M.E.; Kramer, M.R. Creating Shared Value How to Reinvent Capitalism-and Unleash a Wave of Innovation and Growth. Harv. Bus. Rev. 2011, 89, 323–346. [Google Scholar] [CrossRef]

- Khurshid, H.; Snell, R.S. Examining Mechanisms for Creating Shared Value by Asian Firms. J. Bus. Res. 2021, 129, 122–133. [Google Scholar] [CrossRef]

- Ueda, K.; Takenaka, T.; Váncza, J.; Monostori, L. Value Creation and Decision-Making in Sustainable Society. CIRP Ann.-Manuf. Technol. 2009, 58, 681–700. [Google Scholar] [CrossRef]

- Okpara, J.; Wynn, P. Determinants of Small Business Growth Constraints in Sub-Saharan African Economy. S.A.M. Adv. Manag. 2007, 72, 24–35. [Google Scholar]

- Fox, S. Moveable Factories: How to Enable Sustainable Widespread Manufacturing by Local People in Regions without Manufacturing Skills and Infrastructure. Technol. Soc. 2015, 42, 49–60. [Google Scholar] [CrossRef]

- Madyira, D.M. Development of Container Based Community Factories. In Proceedings of the 7th International Conference on Aproppriate Technology, Victoria Falls, Zimbabwe, 23–26 November 2016. [Google Scholar]

- Chihambakwe, Z.J.; Oosthuizen, G.A.; Matope, S.; Uheida, E.H. A Conceptual Framework to Create Shared Value in Base of the Pyramid Communities with Micro-Containerised Factories. Procedia Manuf. 2019, 33, 160–167. [Google Scholar] [CrossRef]

- Grant, M.J.; Booth, A. A Typology of Reviews: An Analysis of 14 Review Types and Associated Methodologies. Health Inform. Libr. J. 2009, 26, 91–108. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. BMJ 2009, 339, 332–336. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Krippendorff, K. Reliability in Content Analysis Some Common Misconceptions and Recommendations. Hum. Commun. Res. 2004, 30, 411–433. [Google Scholar] [CrossRef]

- Holt, D.; Littlewood, D. Informal Economy Entrepreneurs from Sub-Saharan Africa Observations from Kenya. In Routledge Companion to Business in Africa; Routledge: Oxfordshire, UK, 2014. [Google Scholar]

- Hahn, R.; Gold, S. Resources and Governance in “Base of the Pyramid”-Partnerships: Assessing Collaborations between Businesses and Non-Business Actors. J. Bus. Res. 2014, 67, 1321–1333. [Google Scholar] [CrossRef]

- Schuster, T.; Holtbrügge, D. Benefits of Cross-Sector Partnerships in Markets at the Base of the Pyramid. Bus. Strateg. Environ. 2014, 23, 188–203. [Google Scholar] [CrossRef]

- Karnani, A. Fighting Poverty Together: Rethinking Strategies for Business, Governments, and Civil Society to Reduce Poverty; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Arnold, M.G. Inclusive Value Creation for Sustainability of Frugal Innovations in the Base of the Pyramid Low-Income Contexts. J. Contemp. Manag. 2018, 15, 218–244. [Google Scholar]

- Varga, V.; Rosca, E. Driving Impact through Base of the Pyramid Distribution Models: The Role of Intermediary Organizations. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 492–513. [Google Scholar] [CrossRef]

- Hossain, M. Frugal Innovation and Sustainable Business Models. Technol. Soc. 2021, 64, 101508. [Google Scholar] [CrossRef]

- London, T.; Sheth, S.; Hart, S. A Roadmap for the Base of the Pyramid Domain: Re-Energizing for the Next Decade; William Davidson Institute at the University of Michigan: Ann Arbor, MI, USA, 2014. [Google Scholar]

- Angeli, F.; Jaiswal, A.K. Competitive Dynamics between MNCs and Domestic Companies at the Base of the Pyramid: An Institutional Perspective. Long Range Plan. 2015, 48, 182–199. [Google Scholar] [CrossRef]

- Marconatto, D.A.B.; Barin-Cruz, L.; Pozzebon, M.; Poitras, J.E. Developing Sustainable Business Models within BOP Contexts: Mobilizing Native Capability to Cope with Government Programs. J. Clean. Prod. 2016, 129, 735–748. [Google Scholar] [CrossRef]

- Dembek, K.; York, J. Applying a Sustainable Business Model Lens to Mutual Value Creation with Base of the Pyramid Suppliers. Bus. Soc. 2020. [Google Scholar] [CrossRef]

- Goldsmith, A.A. Profits and Alms: Cross-Sector Partnerships for Global Poverty Reduction. Public Adm. Dev. 2011, 31, 15–24. [Google Scholar] [CrossRef]

- Rahdari, A.; Sepasi, S.; Moradi, M. Achieving Sustainability through Schumpeterian Social Entrepreneurship: The Role of Social Enterprises. J. Clean. Prod. 2016, 137, 347–360. [Google Scholar] [CrossRef]

- Jäger, U.; Symmes, F.; Cardoza, G. Scaling Strategies for Social Entrepreneurs A Amrket Approach; Palgrave Macmillan: London, UK, 2020. [Google Scholar] [CrossRef]

- Prahalad, C.K.; Hammond, A. Serving the World’s Poor, Profitably. Harv. Bus. Rev. 2002, 80, 48. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karnani, A. Fortune at the Bottom of the Pyramid: A Mirage How the Private Sector Can Help Alleviate Poverty. Business 2007, 40, 1035. [Google Scholar]

- Filard, F.; Barros, F.D.; Fischmann, A.A. Business Strategies for the Bottom of the Pyramid: Multiple Case Studies of Large Companies in the Pacified Communities of Rio de Janeiro. RAUSP Manag. J. 2018, 53, 63–73. [Google Scholar] [CrossRef]

- Dembek, K.; Sivasubramaniam, N.; Chmielewski, D.A. A Systematic Review of the Bottom/Base of the Pyramid Literature: Cumulative Evidence and Future Directions. J. Bus. Ethics 2019, 165, 365–382. [Google Scholar] [CrossRef]

- Varadarajan, R.; Kaul, R. Doing Well by Doing Good Innovations: Alleviation of Social Problems in Emerging Markets through Corporate Social Innovations. J. Bus. Res. 2018, 86, 225–233. [Google Scholar] [CrossRef]

- Panapanaan, V.; Bruce, T.; Virkki-Hatakka, T.; Linnanen, L. Analysis of Shared and Sustainable Value Creation of Companies Providing Energy Solutions at the Base of the Pyramid (BoP). Bus. Strateg. Environ. 2016, 25, 293–309. [Google Scholar] [CrossRef]

- Spitzeck, H.; Chapman, S. Creating Shared Value as a Differentiation Strategy—The Example of BASF in Brazil. Corp. Gov. 2012, 12, 499–513. [Google Scholar] [CrossRef] [Green Version]

- Desa, G.; Koch, J.L. Scaling Social Impact: Building Sustainable Social Ventures at the Base-of-the-Pyramid. J. Soc. Entrep. 2014, 5, 146–174. [Google Scholar] [CrossRef]

- Albert, P.J.; Werhane, P.; Rolph, T. (Eds.) Global Poverty Alleviation: A Case Book; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Tashman, P.; Marano, V. Dynamic Capabilities and Base of the Pyramid Business Strategies. J. Bus. Ethics 2010, 89 (Suppl. 4), 495–514. [Google Scholar] [CrossRef]

- Kasturi Rangan, V.; Chu, M.; Petkoski, D. The Globe: Segmenting the Base of the Pyramid. Harv. Bus. Rev. 2011, 89, 3–8. [Google Scholar]

- Osterwalder, A.; Pigneur, Y.; Clark, T. Business Model Generation: A Handbook for Visionaries, Game Changers and Challengers; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Biswas, A.K.; Tortajada, C.; Joshi, Y.K.; Gupta, A. Creating Shared Value: Impacts of Nestlé in Moga, India; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Rodrigues, J.; Baker, G.A. Grameen Danone Foods Limited (GDF). Int. Food Agribus. Manag. Rev. 2012, 15, 127–158. [Google Scholar]

- Knuckles, J. Business Models for Mini-Grid Electricity in Base of the Pyramid Markets. Energy Sustain. Dev. 2016, 31, 67–82. [Google Scholar] [CrossRef]

- Peerally, J.A.; De Fuentes, C.; Figueiredo, P.N. Inclusive Innovation and the Role of Technological Capability-Building: The Social Business Grameen Danone Foods Limited in Bangladesh. Long Range Plann. 2019, 52, 101843. [Google Scholar] [CrossRef]

- Prahalad, C.K. The Fortune at the Bottom of the Pyramid: Eradicating Poverty Through Profits. Enabling Dignity and Choice Through Markets. McKinsey Brief. Notes Ser. 2005, 36, 52–74. [Google Scholar]

- Leke, A.; Chironga, M.; Desvaux, G. Africa’s Business Revolution: How to Succeed in the World’s Next Big Growth Market; Harvard Business Review Press: Boston, MA, USA, 2018. [Google Scholar]

- Prahalad, C.K. Bottom of the Pyramid as a Source of Breakthrough Innovations. J. Prod. Innov. Manag. 2012, 29, 6–12. [Google Scholar] [CrossRef]

- Chopra, S.K.; Narayana, M.G.P.L. Meeting Bottom of the Pyramid (BOP) Needs by Engineering Sustainable Solutions. In Proceedings of the 2012 IEEE Conference on Technology and Society in Asia, Singapore, 27–29 October 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Lashitew, A.A.; Bals, L.; van Tulder, R. Inclusive Business at the Base of the Pyramid: The Role of Embeddedness for Enabling Social Innovations. J. Bus. Ethics 2018, 162, 421–448. [Google Scholar] [CrossRef] [Green Version]

- Brix-asala, C.; Hahn, R.; Seuring, S. Reverse Logistics and Informal Valorisation at the Base of the Pyramid: A Case Study on Sustainability Synergies and Trade-Offs. Eur. Manag. J. 2016, 34, 414–423. [Google Scholar] [CrossRef]

- Plambeck, E.L.; Ramdas, K. Alleviating Poverty by Empowering Women through Business Model Innovation: Manufacturing & Service Operations Management Insights and Opportunities. Manuf. Serv. Oper. Manag. 2020, 22, 123–134. [Google Scholar] [CrossRef] [Green Version]

- Prasad, S.; Jaffe, J.; Bhattacharyya, K.; Jasmine, T.; Marshall, D. Value Supply Chains at the Base of the Pyramid: Studies of Past and Present Textile Networks. J. Humanit. Logist. Supply Chain Manag. 2017, 7, 304–323. [Google Scholar] [CrossRef]

- Reiner, G.; Gold, S.; Hahn, R. Wealth and Health at the Base of the Pyramid: Modelling Trade-Offs and Complementarities for Fast Moving Dairy Product Case. Int. J. Prod. Econ. 2015, 170, 413–421. [Google Scholar] [CrossRef]

- Gold, S.; Hahn, R.; Seuring, S. Sustainable Supply Chain Management in “Base of the Pyramid” Food Projects-A Path to Triple Bottom Line Approaches for Multinationals? Int. Bus. Rev. 2013, 22, 784–799. [Google Scholar] [CrossRef]

- Rosca, E.; Agarwal, N.; Brem, A. Women Entrepreneurs as Agents of Change: A Comparative Analysis of Social Entrepreneurship Processes in Emerging Markets. Technol. Forecast. Soc. Chang. 2020, 157, 120067. [Google Scholar] [CrossRef]

- Hossain, M.; Sarkar, S. Frugal Entrepreneurship: Profiting with Inclusive Growth. IEEE Trans. Eng. Manag. 2021, 1–14. [Google Scholar] [CrossRef]

- Schleinkofer, U.; Dazer, M.; Lucan, K.; Mannuß, O.; Bertsche, B.; Bauernhansl, T. Framework for Robust Design and Reliability Methods to Develop Frugal Manufacturing Systems. Procedia CIRP 2019, 81, 518–523. [Google Scholar] [CrossRef]

- Nittapaipapon, N.; Atchattabhan, T. Creating Shared Value Embedded an Inclusive Business Model: A Case Study. Asian J. Bus. Manag. 2016, 4, 56–64. [Google Scholar]

- London, T.; Anupindi, R.; Sheth, S. Creating Mutual Value: Lessons Learned from Ventures Serving Base of the Pyramid Producers. J. Bus. Res. 2010, 63, 582–594. [Google Scholar] [CrossRef]

- Jacob, S.; Pin, K. Improving Lives in the Base of Pyramid, Profitably. Soc. Sp. 2011, 2011, 48–53. [Google Scholar]

- Moellmann, J.; Thomas, V.M. Social Enterprise Factory Location and Allocation Model: Small Scale Manufacturing for East Africa. Socioecon. Plann. Sci. 2019, 68, 100694. [Google Scholar] [CrossRef]

- Sinkovics, N.; Sinkovics, R.R.; Yamin, M. The Role of Social Value Creation in Business Model Formulation at the Bottom of the Pyramid—Implications for MNEs? Int. Bus. Rev. 2014, 23, 692–707. [Google Scholar] [CrossRef]

- Ansari, S.; Munir, K.; Gregg, T. Impact at the “Bottom of the Pyramid”: The Role of Social Capital in Capability Development and Community Empowerment. J. Manag. Stud. 2012, 49, 813–842. [Google Scholar] [CrossRef]

- Carlson, E.; Koch, J. Building a Successful Social Venture: A Guide for Social Entrepreneurs; Berrett-Koehler Publishers: Oakland, CA, USA, 2017. [Google Scholar]

- Armstong, R.M.; Grobbelaar, S. Toward the Development of Sustainable Business Models for Social Enterprises. In Proceedings of the SAIIE29, Spier, Stellenbosch, South Africa, 24–26 October 2018; pp. 549–561. [Google Scholar]

- Raghubanshi, G.; Venugopal, S.; Saini, G.K. Fostering Inclusive Social Innovation in Subsistence Marketplaces through Community-Level Alliances: An Institutional Work Perspective. Ind. Mark. Manag. 2021, 97, 21–34. [Google Scholar] [CrossRef]

- Azmat, F.; Ferdous, A.S.; Couchman, P. Understanding the Dynamics Between Social Entrepreneurship and Inclusive Growth in Subsistence Marketplaces. J. Public Policy Mark. JPP&M 2015, 34, 252. [Google Scholar] [CrossRef]

- Onwuegbuzie, H.N.; Mafimisebi, O.P. Global Relevance of Scaling African Indigenous Entrepreneurship. Technol. Forecast. Soc. Chang. 2021, 166, 120629. [Google Scholar] [CrossRef]

- Siebold, N.; Günzel-Jensen, F.; Müller, S. Balancing Dual Missions for Social Venture Growth: A Comparative Case Study. Entrep. Reg. Dev. 2019, 31, 710–734. [Google Scholar] [CrossRef]

- Jenkins, B. Expanding Economic Opportunity: The Role of Large Firms. Corporate Social Responsibility Initiative Report No. 17; Harvard University: Cambridge, MA, USA, 2007. [Google Scholar]

- Gaertner, K.; Ishikawa, E. Shared Prosperity through Inclusive Business: How Successful Companies Reach the Base of the Pyramid; International Finance Corporation: Washington, DC, USA, 2014. [Google Scholar] [CrossRef] [Green Version]

| Keywords | Search Strings | Science Direct Results | Scopus Results | Web of Science Results | Google Scholar Results |

|---|---|---|---|---|---|

| Shared value creation, base of the pyramid | “Shared value creation” AND “base of the pyramid” | 8 | 3 | 7 | 245 |

| Shared value creation, factories | “Shared value creation” AND “factories” | 12 | 9 | 11 | 343 |

| Base of the pyramid, Manufacturing factories | “Base of the pyramid” AND “manufacturing factories” | 2 | 1 | 9 | 11 |

| Base of the pyramid, factories | “Base of the pyramid” AND “factories” | 173 | 6 | 15 | 2390 |

| Base of the pyramid, container factories | “Base of the pyramid” AND “container factories” | 0 | 0 | 0 | 2 |

| Shared value creation, base of the pyramid, factories | “Shared value creation” AND “base of the pyramid” AND “factories” | 3 | 1 | 1 | 56 |

| Innovation, base of the pyramid, factories | “Innovation” AND “base of the pyramid” AND “factories” | 89 | 0 | 1 | 1570 |

| TOTAL | 287 | 20 | 44 | 4617 |

| Research Themes | Inclusion Criteria | Exclusion Criteria |

|---|---|---|

| BoP communities |

|

|

| Creating shared value |

|

|

| Micro-manufacturing |

|

|

| Category | Analysis | Information Extracted |

|---|---|---|

| Conceptual aspects | Descriptive statistics |

|

| Empirical aspects | Content Analysis |

|

| Significance and conclusions | Significance and Conclusions |

|

| CSV KeyPillars | MSV Strategies | Key Aspects | Activity Description | Key Questions to Be Addressed |

|---|---|---|---|---|

| Key Pillar 1: Reconceiving products and markets | Capability building strategy |

|

|

|

|

|

| ||

|

|

| ||

|

|

| ||

| Key pillar 2: Redefine productivity in the value chain | Implementation process |

|

|

|

|

|

| ||

|

|

| ||

|

|

| ||

|

|

| ||

|

|

| ||

| Key pillar 3: Local cluster development | Growth strategy |

|

|

|

|

|

| ||

|

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chihambakwe, Z.J.; Grobbelaar, S.S.; Matope, S. Creating Shared Value in BoP Communities with Micro-Manufacturing Factories: A Systematized Literature Review. Sustainability 2021, 13, 10289. https://doi.org/10.3390/su131810289

Chihambakwe ZJ, Grobbelaar SS, Matope S. Creating Shared Value in BoP Communities with Micro-Manufacturing Factories: A Systematized Literature Review. Sustainability. 2021; 13(18):10289. https://doi.org/10.3390/su131810289

Chicago/Turabian StyleChihambakwe, Zviemurwi J., Sara S. (Saartjie) Grobbelaar, and Stephen Matope. 2021. "Creating Shared Value in BoP Communities with Micro-Manufacturing Factories: A Systematized Literature Review" Sustainability 13, no. 18: 10289. https://doi.org/10.3390/su131810289

APA StyleChihambakwe, Z. J., Grobbelaar, S. S., & Matope, S. (2021). Creating Shared Value in BoP Communities with Micro-Manufacturing Factories: A Systematized Literature Review. Sustainability, 13(18), 10289. https://doi.org/10.3390/su131810289