Environmental and Economic Life Cycle Assessment of Recycled Aggregates Concrete in the United Arab Emirates

Abstract

:1. Introduction

2. Methodology

2.1. Goal, Scope, and Functional Unit

2.2. System Boundaries

- The construction, service, and demolition phases of a concrete structure were excluded from the analysis, assuming exposure to a non-aggressive environment throughout its life cycle. According to Knoeri et al. [42], Marinković et al. [11], and Visintin et al. [47], the impacts of these phases for concrete created with NA or RA and exposed to non-aggressive conditions were expected to be similar. As such, their environmental and economic impact were omitted.

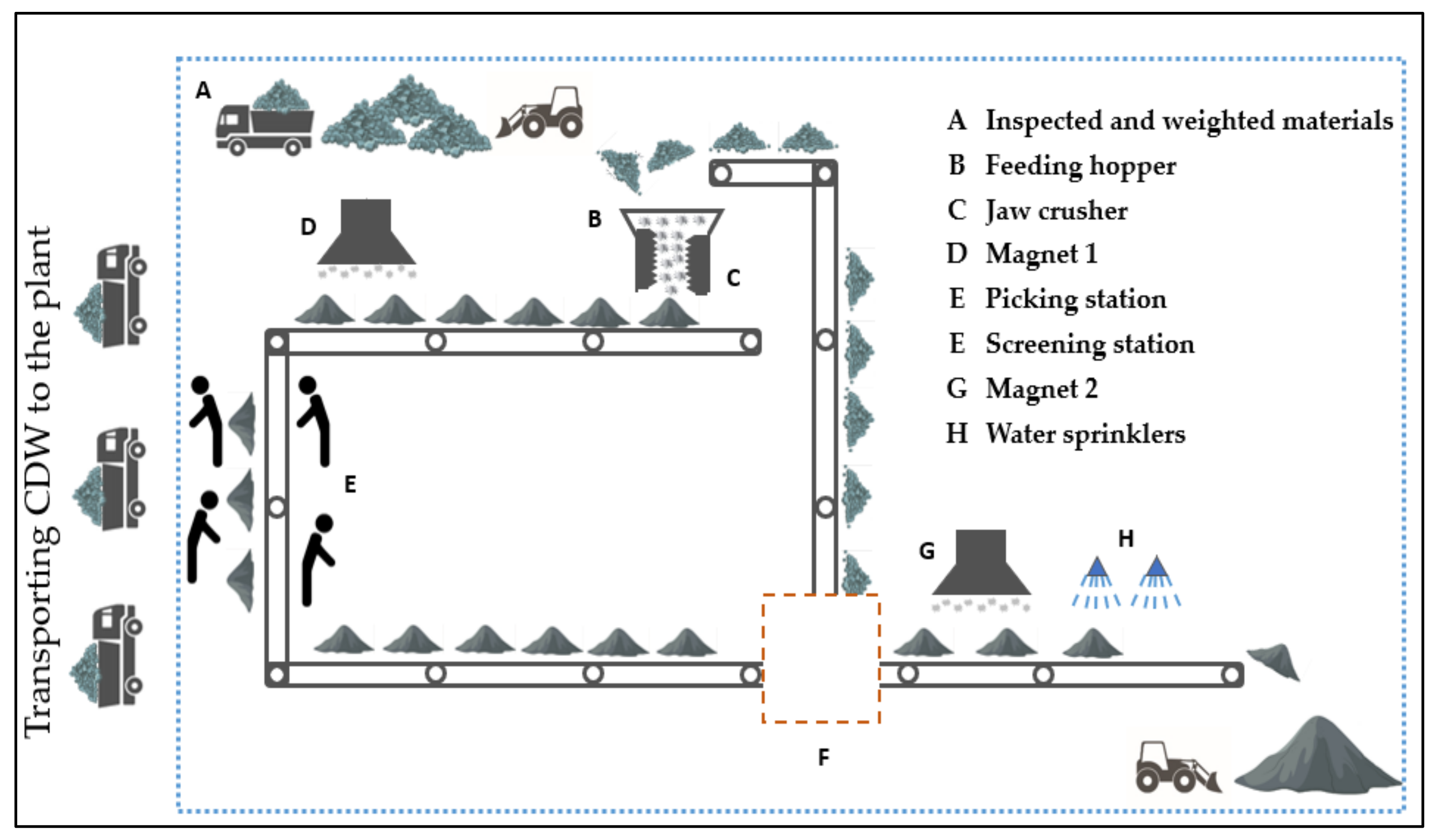

- The recycling plant under consideration in this work has a recovery percentage of the recycled aggregate of 90%. Impurities, including steel, wood, and plastic, among others, are typically forwarded to other recycling facilities for processing. This means that 1 m3 of CDW is completely recycled with no waste being produced.

- Government agencies in the Emirate of Abu Dhabi oblige demolition contractors to send construction and demolition waste (CDW) to the landfill, which is in close proximity (<5 km) to the recycling plant. Thus, the delivery of the CDW from the demolition site to the recycling plant was not considered in the environmental assessment and cost analysis, as it was excluded from the process of manufacturing of RA from CDW and was preliminarily found to have an insignificant impact.

2.3. Life Cycle Inventory Data Analysis

2.3.1. Recycled Aggregates Production

2.3.2. Aggregate Transportation

2.4. Life Cycle Impact Assessment

3. Concrete Mixes

3.1. Materials

3.1.1. Binding Materials

3.1.2. Aggregates

3.1.3. Superplasticizer

3.1.4. Steel Fibers

3.2. Concrete Mixture Proportioning

3.3. Sample Preparation

3.4. Performance Evaluation

4. Results and Discussion

4.1. Slump

4.2. Hardened Concrete Density

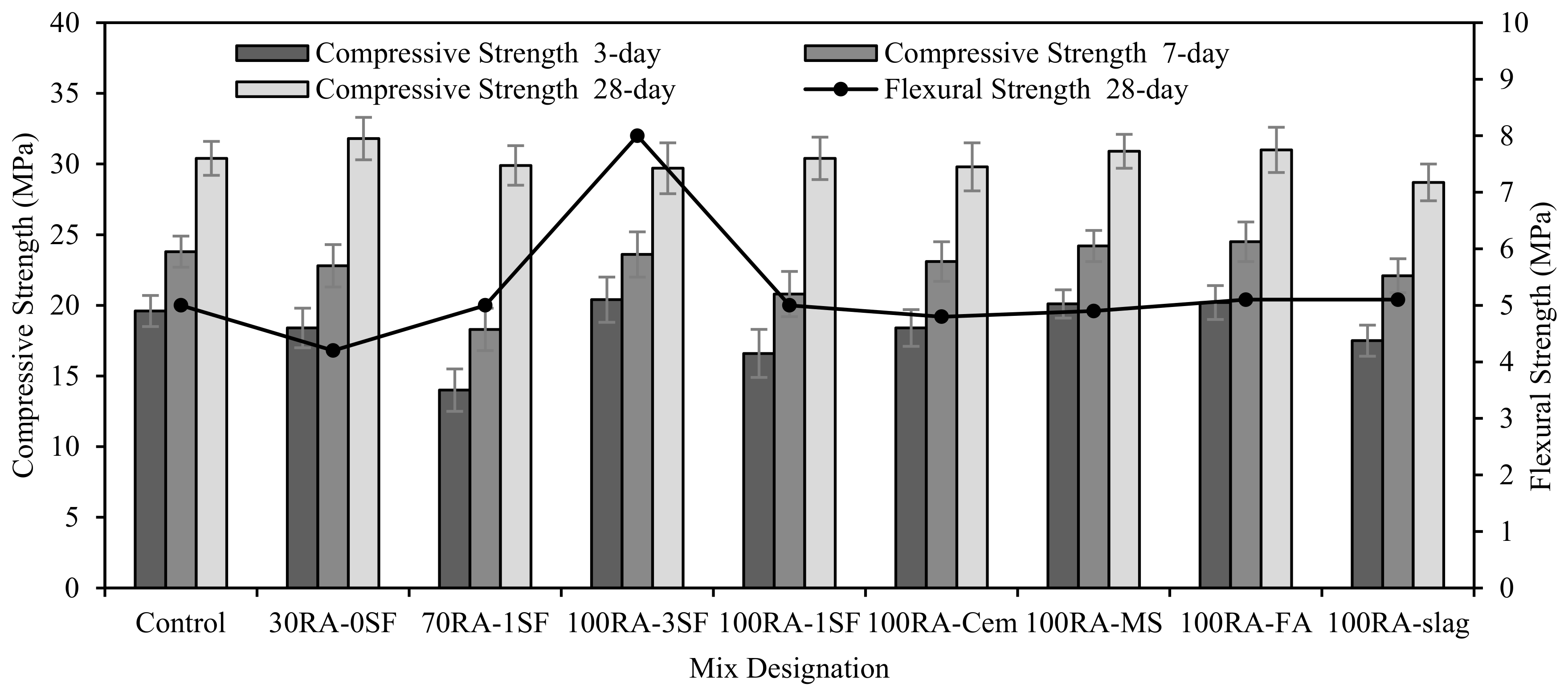

4.3. Compressive Strength

4.4. Flexural Strength

4.5. Life Cycle Impact Assessment

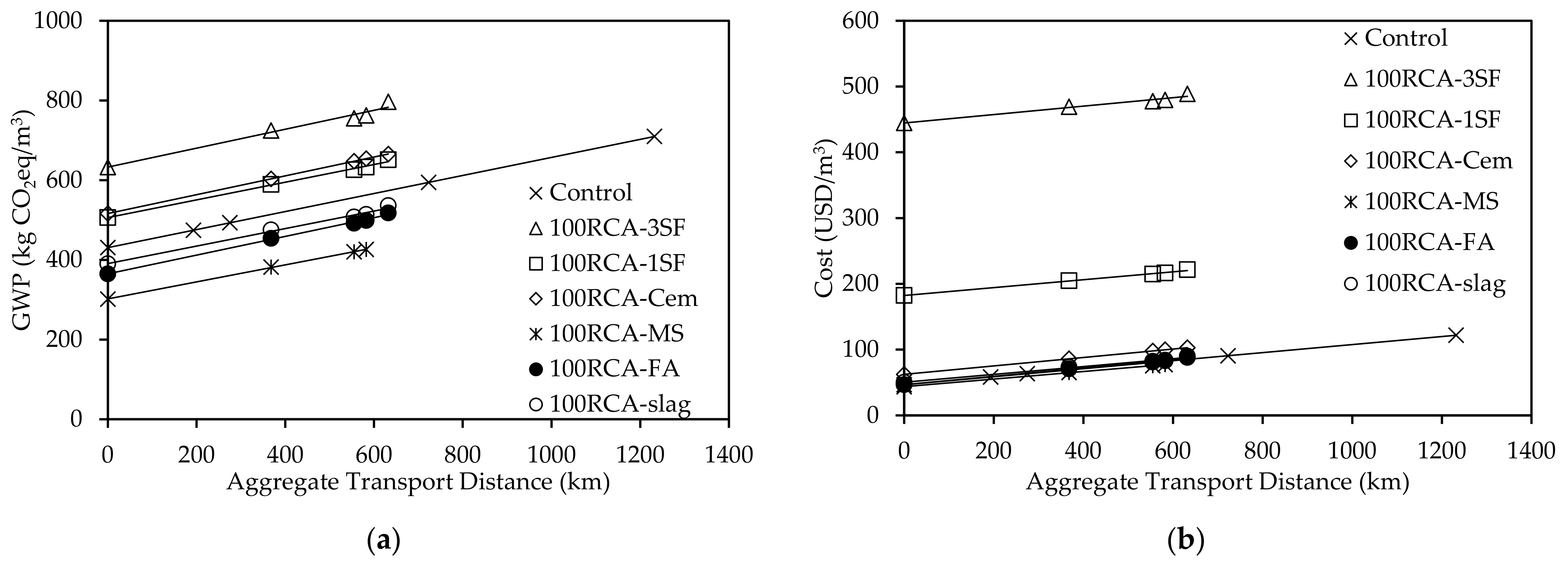

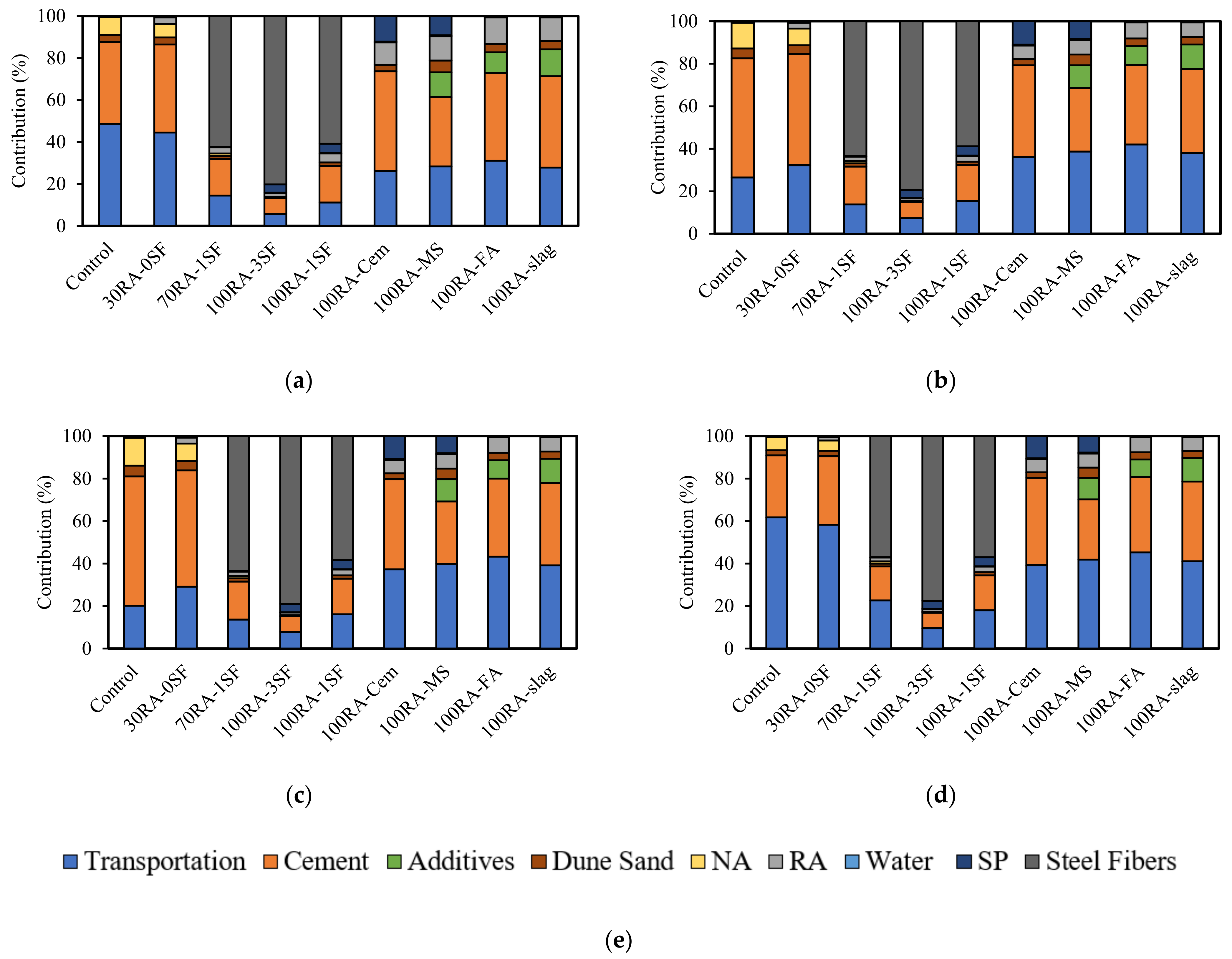

4.5.1. Environmental Impact Assessment

4.5.2. Economic Impact Assessment

4.5.3. Transportation Impact

4.5.4. Ecological Profitability Distance

4.5.5. Discussion and Interpretation

5. Multifunctional Performance Indices

6. Conclusions

- The replacement of NA by 100% RA decreased the slump and density of concrete mixes. Slump values further decreased upon the addition of steel fibers and microsilica, but less reduction was noted when slag and fly ash replaced the cement. The density only increased with steel fiber inclusion.

- Compressive strength results showed a variation in the initial strength and different strength development profiles over time. RA replacement caused a decrease in compressive strength but could be countered by the addition of steel fibers or cement or the replacement of cement by slag, fly ash, or microsilica. This showed that RA can deliver the same concrete compressive strength as that created with NA subject to using certain doses of additives. Flexural strength results showed a similar pattern to the compressive strength. All the mixes recorded similar flexural strength to the control except mix 100RA-3SF, which recorded a 60% increase. This increase was attributed to the bridging effect of the fibers.

- Environmental impact assessment results showed that replacing NA with RA led to lower global warming potential (GWP). Mixes with cement replacement by microsilica, fly ash, and slag had up to 32% lower GWP due to lesser cement being used in the mix compared to the NA-based control mix. Conversely, SF-reinforced mixes recorded an increase in the GWP ranging between 13 and 45%. The contribution of cement to GWP was the highest in all concrete mixes but decreased from over 90% to as low as 67% when SF was incorporated into the mixes.

- Economic impact assessment results showed that the replacement of NA by RA slightly decreased the cost of the mix. The replacement of cement by fly ash, slag, or microsilica had a limited effect on the cost, while the addition of cement was more impactful. In turn, the inclusion of steel fibers increased the cost by at least three times, owing to the expensive cost of the fibers.

- The transportation impact study showed that material transportation was a significant contributor to the environmental and economic burdens of concrete mixes. Transportation contribution came second only to cement. It increased with a larger travel distance and steel fiber inclusion and decreased with RA replacement.

- The ecological profitability distance from an environmental and economic impact standpoint was 378 km from the NA source for mixes created with more cement. In turn, steel fiber-reinforced RA concrete mixes were environmentally favorable over NA-based mixes in one to two zones, but were not economically feasible in any zone. Conversely, mixes created with microsilica, fly ash, and slag were more environmentally and economically advantageous than NA-based concrete mixes across all zones in the UAE.

- Multifunctional performance indexing showed that the mix created with 100% RA and microsilica was optimum for applications concerning slump, compressive strength, environmental and economic impact, and waste reduction. Contrarily, in applications demanding a superior mechanical performance, the mix created with 100% RA and 3% steel fiber volume fraction was most favorable. For applications that required optimizing all individual measures, the mix created with 100% RA and fly ash was deemed most suitable followed by that incorporating 100% RA and microsilica.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, J.; Hua, C.; Liu, C. Considerations for better construction and demolition waste management: Identifying the decision behaviors of contractors and government departments through a game theory decision-making model. J. Clean. Prod. 2019, 212, 190–199. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G.; Arena, U. Life cycle assessment of natural and mixed recycled aggregate production in Brazil. J. Clean. Prod. 2017, 151, 634–642. [Google Scholar] [CrossRef]

- Saghafi, M.; Teshnizi, Z. Recycling value of building materials in building assessment systems. Energy Build. 2011, 43, 3181–3188. [Google Scholar] [CrossRef]

- Eurostat Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Waste_statistics (accessed on 2 December 2020).

- EPA. Sustainable Management of Construction and Demolition Materials. Available online: https://www.epa.gov/smm/sustainable-management-construction-and-demolition-materials (accessed on 2 December 2020).

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; Song, Q. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef] [Green Version]

- SCAD Agriculture & Environment. Available online: https://www.scad.ae (accessed on 5 January 2021).

- Blaisi, N.I. Construction and demolition waste management in Saudi Arabia: Current practice and roadmap for sustainable management. J. Clean. Prod. 2019, 221, 167–175. [Google Scholar] [CrossRef]

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared environmental and economic impact from cradle to gate of concrete with natural and recycled coarse aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Zion Market Research. Construction Aggregates Market by Product Type and by End-User: Global Industry Perspective, Comprehensive Analysis, and Forecast. Available online: https://www.zionmarketresearch.com/report/construction-aggregates-market (accessed on 5 January 2021).

- Xu, L.-Y.; Qian, L.-P.; Huang, B.-T.; Dai, J.-G. Development of artificial one-part geopolymer lightweight aggregates by crushing technique. J. Clean. Prod. 2021, 315, 128200. [Google Scholar] [CrossRef]

- Qian, L.-P.; Wang, Y.-S.; Alrefaei, Y.; Dai, J.-G. Experimental study on full-volume fly ash geopolymer mortars: Sintered fly ash versus sand as fine aggregates. J. Clean. Prod. 2020, 263, 121445. [Google Scholar] [CrossRef]

- Tajra, F.; Elrahman, M.A.; Stephan, D. The production and properties of cold-bonded aggregate and its applications in concrete: A review. Constr. Build. Mater. 2019, 225, 29–43. [Google Scholar] [CrossRef]

- Xu, L.-Y.; Huang, B.-T.; Dai, J.-G. Development of engineered cementitious composites (ECC) using artificial fine aggregates. Constr. Build. Mater. 2021, 305, 124742. [Google Scholar] [CrossRef]

- El-Hassan, H.; Ismail, N.; Al Hinaii, S.; Alshehhi, A.; Al Ashkar, N. Effect of GGBS and curing temperature on microstructure characteristics of lightweight geopolymer concrete. In MATEC Web of Conferences; EDP Sciences: Ulis, France, 2017; Volume 120, p. 03004. [Google Scholar]

- Ismail, N.; El-Hassan, H. Development and Characterization of Fly Ash/Slag-Blended Geopolymer Mortar and Lightweight Concrete. J. Mater. Civ. Eng. 2018, 30, 04018029. [Google Scholar] [CrossRef]

- Hu, D.; You, F.; Zhao, Y.; Yuan, Y.; Liu, T.; Cao, A.; Wang, Z.; Zhang, J. Input, stocks and output flows of urban residential building system in Beijing city, China from 1949 to 2008. Resour. Conserv. Recycl. 2010, 54, 1177–1188. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Use of recycled aggregates arising from construction and demolition waste in new construction applications. J. Clean. Prod. 2019, 236, 117629. [Google Scholar] [CrossRef]

- Rodríguez-Robles, D.; García-González, J.; Juan-Valdés, A.; Morán-del Pozo, J.M.; Guerra-Romero, M.I. Quality Assessment of Mixed and Ceramic Recycled Aggregates from Construction and Demolition Wastes in the Concrete Manufacture According to the Spanish Standard. Materials 2014, 7, 5843–5857. [Google Scholar] [CrossRef] [Green Version]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Klang, A.; Vikman, P.-Å.; Brattebø, H. Sustainable management of demolition waste—An integrated model for the evaluation of environmental, economic and social aspects. Resour. Conserv. Recycl. 2003, 38, 317–334. [Google Scholar] [CrossRef]

- Gayarre, F.L.; López-Colina, C.; Serrano, M.A.; López-Martínez, A. Manufacture of concrete kerbs and floor blocks with recycled aggregate from C&DW. Constr. Build. Mater. 2013, 40, 1193–1199. [Google Scholar] [CrossRef]

- Soutsos, M.N.; Tang, K.; Millard, S.G. Use of recycled demolition aggregate in precast products, phase II: Concrete paving blocks. Constr. Build. Mater. 2011, 25, 3131–3143. [Google Scholar] [CrossRef]

- De Brito, J.; Rui, S. Current status on the use of recycled aggregates in concrete: Where do we go from here? RILEM Tech. Lett. 2016, 1, 1. [Google Scholar] [CrossRef]

- Sormunen, P.; Kärki, T. Recycled construction and demolition waste as a possible source of materials for composite manufacturing. J. Build. Eng. 2019, 24, 100742. [Google Scholar] [CrossRef]

- Devi, S.V.; Gausikan, R.; Chithambaranathan, S.; Jeffrey, J.W. Utilization of recycled aggregate of construction and demolition waste as a sustainable material. Mater. Today Proc. 2021, 45, 6649–6654. [Google Scholar] [CrossRef]

- Surendar, M.; Ananthi, G.B.G.; Sharaniya, M.; Deepak, M.S.; Soundarya, T.V. Mechanical properties of concrete with recycled aggregate and M−sand. Mater. Today Proc. 2021, 44, 1723–1730. [Google Scholar] [CrossRef]

- Bhat, A.A.; Kaur, E.P.; Talwar, E.K. A Comparative Study of Concrete Incorporating Recycled Concrete Aggregates and Microsilica (Silica Fume) to Develop a Sustainable Construction Material. Int. J. Eng. Res. Technol. 2018, 7, 193–205. [Google Scholar]

- El-Hassan, H.; Kianmehr, P.; Zouaoui, S. Properties of pervious concrete incorporating recycled concrete aggregates and slag. Constr. Build. Mater. 2019, 212, 164–175. [Google Scholar] [CrossRef]

- Kachouh, N.; El-Hassan, H.; El-Maaddawy, T. The Use of Steel Fibers to Enhance the Performance of Concrete Made with Recycled Aggregate. In Proceedings of the Fifth International Conference on Sustainable Construction Materials and Technologies (SCMT5), London, UK, 15–17 July 2019. [Google Scholar]

- Kachouh, N.; El-Hassan, H.; El-Maaddawy, T. Effect of steel fibers on the performance of concrete made with recycled concrete aggregates and dune sand. Constr. Build. Mater. 2019, 213, 348–359. [Google Scholar] [CrossRef]

- Kachouh, N.; El-Hassan, H.; El-Maaddawy, T. Influence of steel fibers on the flexural performance of concrete incorporating recycled concrete aggregates and dune sand. J. Sustain. Cem. Mater. 2020, 10, 165–192. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Chan, D. Influence of fly ash as a cement addition on the hardened properties of recycled aggregate concrete. Mater. Struct. 2008, 41, 1191–1201. [Google Scholar] [CrossRef]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental evaluation of green concretes versus conventional concrete by means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Yang, Y.; Wang, J.; Hu, S.; Jiao, M.; Ling, Y. Mechanical Properties and Durability of Polypropylene and Steel Fiber-Reinforced Recycled Aggregates Concrete (FRRAC): A Review. Sustainability 2020, 12, 9509. [Google Scholar] [CrossRef]

- Fraj, A.B.; Idir, R. Concrete based on recycled aggregates—Recycling and environmental analysis: A case study of paris’ region. Constr. Build. Mater. 2017, 157, 952–964. [Google Scholar] [CrossRef]

- Shan, X.; Zhou, J.; Chang, V.W.C.; Yang, E.-H. Life cycle assessment of adoption of local recycled aggregates and green concrete in Singapore perspective. J. Clean. Prod. 2017, 164, 918–926. [Google Scholar] [CrossRef]

- Mah, C.M.; Fujiwara, T.; Ho, C. Life cycle assessment and life cycle costing toward eco-efficiency concrete waste management in Malaysia. J. Clean. Prod. 2018, 172, 3415–3427. [Google Scholar] [CrossRef]

- Knoeri, C.; Sanyé-Mengual, E.; Althaus, H.-J. Comparative LCA of recycled and conventional concrete for structural applications. Int. J. Life Cycle Assess. 2013, 18, 909–918. [Google Scholar] [CrossRef] [Green Version]

- ISO 14040. Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: https://www.iso.org/standard/37456.html (accessed on 5 January 2021).

- Ding, T.; Xiao, J.; Tam, V.W.Y. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef]

- Park, W.-J.; Kim, T.; Roh, S.; Kim, R. Analysis of Life Cycle Environmental Impact of Recycled Aggregate. Appl. Sci. 2019, 9, 1021. [Google Scholar] [CrossRef] [Green Version]

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G.; Arena, U. Life cycle assessment of construction and demolition waste management in a large area of São Paulo State, Brazil. Waste Manag. 2019, 85, 477–489. [Google Scholar] [CrossRef] [PubMed]

- Visintin, P.; Xie, T.; Bennett, B. A large-scale life-cycle assessment of recycled aggregate concrete: The influence of functional unit, emissions allocation and carbon dioxide uptake. J. Clean. Prod. 2020, 248, 119243. [Google Scholar] [CrossRef]

- IPCC. IPCC Guidelines for National Greenhouse Gas Inventories (2006). Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/ (accessed on 5 January 2021).

- EFCA. Plasticisers and Superplasticisers Environmental Product Declarations (EPD). Available online: http://www.efca.info/download/plasticisers-and-superplasticisers-epd-2015/ (accessed on 5 January 2021).

- Greenhouse Gas Protocol. GHG Protocol Emission Factors from Cross-Sector Tools. Available online: https://ghgprotocol.org/calculation-tools#cross_sector_tools_id (accessed on 5 January 2021).

- Cembureau. Cembureau Environmental Product Declaration (EPD)—Portland Cement (CEM I). Available online: https://cembureau.eu/ (accessed on 5 January 2021).

- Carbon Solutions. Inventory of Carbon & Energy (ICE) Summary. Available online: https://www.carbonsolution.com/ (accessed on 5 January 2021).

- Kennedy, S.; Lin, P.-Y.; Khalid, A.; Sgouridis, S. CO2 Allocation for Power and Water Production in Abu Dhabi—Masdar Institute Working Paper; Masdar Institute: Abu Dhabi, United Arab Emirates, 2012. [Google Scholar]

- Instytut Techniki Budowlanej. ITB Steel Fibres for Concrete Reinforcement. Available online: https://www.itb.pl/ (accessed on 5 January 2021).

- Zhang, Y.; Liu, M.-h.; Xie, H.-B.; Wang, Y. Assessment of CO2 Emissions and Cost in Fly Ash Concrete; Taylor and Francis: London, UK, 2015; pp. 327–331. [Google Scholar]

- Irish Green Building Council. MRPI Environmental Product Declaration FOR ECOCEM GGBS CEMENT. Available online: https://www.igbc.ie/ (accessed on 5 January 2021).

- Norchem Silica Fume Applications in Sustainability. Available online: https://www.norchem.com/applications-sustainability.html (accessed on 5 January 2021).

- Dong, Y.; Ng, S.T.; Kwan, A.; Wu, S.K. Substituting local data for overseas life cycle inventories—A case study of concrete products in Hong Kong. J. Clean. Prod. 2015, 87, 414–422. [Google Scholar] [CrossRef]

- Shahabian, A.; Fadai, A.; Peruzzi, T. Future of Life-Cycle Assessment in a Smart and/or Sustainable World; IGI Global: Hershey, PA, USA, 2020; pp. 177–207. [Google Scholar]

- Aman, M.M.; Solangi, K.H.; Hossain, M.S.; Badarudin, A.; Jasmon, G.B.; Mokhlis, H.; Bakar, A.H.A.; Kazi, S.N. A review of Safety, Health and Environmental (SHE) issues of solar energy system. Renew. Sustain. Energy Rev. 2015, 41, 1190–1204. [Google Scholar] [CrossRef]

- Al Dhafra Recycling Industries. Available online: http://www.aldhafrarecycling.ae/en/ (accessed on 4 December 2019).

- El-Hassan, H.; Elkholy, S. Performance Evaluation and Microstructure Characterization of Steel Fiber-Reinforced Alkali-Activated Slag Concrete Incorporating Fly Ash. J. Mater. Civ. Eng. 2019, 31, 04019223. [Google Scholar] [CrossRef]

- ASTM C33/C33M-18, Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2018.

- Seo, D.S.; Choi, H.B. Effects of the old cement mortar attached to the recycled aggregate surface on the bond characteristics between aggregate and cement mortar. Constr. Build. Mater. 2014, 59, 72–77. [Google Scholar] [CrossRef]

- ACI Committee 211.1. Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2009. [Google Scholar]

- El-Hassan, H.; Shehab, E.; Al-Sallamin, A. Effect of Curing Regime on the Performance and Microstructure Characteristics of Alkali-Activated Slag-Fly Ash Blended Concrete. J. Sustain. Cem. Mater. 2021, 10, 289–317. [Google Scholar] [CrossRef]

- El-Hassan, H.; Hussein, A.; Medljy, J.; El-Maaddawy, T. Performance of Steel Fiber-Reinforced Alkali-Activated Slag-Fly Ash Blended Concrete Incorporating Recycled Concrete Aggregates and Dune Sand. Buildings 2021, 11, 327. [Google Scholar] [CrossRef]

- Mesgari, S.; Akbarnezhad, A.; Xiao, J.Z. Recycled geopolymer aggregates as coarse aggregates for Portland cement concrete and geopolymer concrete: Effects on mechanical properties. Constr. Build. Mater. 2020, 236, 117571. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Wang, C.; Zhao, J.; Liu, F.; Fang, C. Study on the optimum initial curing condition for fly ash and GGBS based geopolymer recycled aggregate concrete. Constr. Build. Mater. 2020, 247, 118540. [Google Scholar] [CrossRef]

- El-Hassan, H.; Medljy, J.; El-Maaddawy, T. Properties of Steel Fiber-Reinforced Alkali-Activated Slag Concrete Made with Recycled Concrete Aggregates and Dune Sand. Sustainability 2021, 13, 8017. [Google Scholar] [CrossRef]

- ASTM C143/C143M-20, Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C78/C78M-21, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C39/C39M-21, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C642-13, Standard Test Method for Density, Absorption, and Voids in Hardened Concrete; ASTM International: West Conshohocken, PA, USA, 2013.

- Shahidan, S.; Azmi, M.A.M.; Kupusamy, K.; Zuki, S.S.M.; Ali, N. Utilizing Construction and Demolition (C&D) Waste as Recycled Aggregates (RA) in Concrete. Procedia Eng. 2017, 174, 1028–1035. [Google Scholar] [CrossRef]

- Wagih, A.M.; El-Karmoty, H.Z.; Ebid, M.; Okba, S.H. Recycled construction and demolition concrete waste as aggregate for structural concrete. HBRC J. 2013, 9, 193–200. [Google Scholar] [CrossRef] [Green Version]

- Suda, V.B.R.; Rao, P. Experimental investigation on optimum usage of Micro silica and GGBS for the strength characteristics of concrete. Mater. Today Proc. 2020, 27, 805–811. [Google Scholar] [CrossRef]

- Chrest, A.P. Guide to Using Silica Fume in Precast/Prestressed Concrete Products—PCI Committee on Durability; Precast/Prestressed Concrete Institute: Chicago, IL, USA, 1994; p. 10. [Google Scholar]

- Silva, S.; Evangelista, L.; de Brito, J. Durability and shrinkage performance of concrete made with coarse multi-recycled concrete aggregates. Constr. Build. Mater. 2021, 272, 121645. [Google Scholar] [CrossRef]

- Hassan, R.Y.; Faroun, G.A.; Mohammed, S.K. Mechanical properties of concrete made with coarse and fine recycled aggregates. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Medljy, J.; El-Hassan, H.; El-Maaddawy, T. Effect of Recycled Aggregate and Steel Fibers on the Mechanical Properties of Alkali-Activated Slag/Fly Ash Blended Concrete. ACI Spec. Publ. 2021, 349, 210–223. [Google Scholar]

- Gao, D.; Wang, F. Effects of recycled fine aggregate and steel fiber on compressive and splitting tensile properties of concrete. J. Build. Eng. 2021, 44, 102631. [Google Scholar] [CrossRef]

- Zong, S.; Liu, Z.; Li, S.; Lu, Y.; Zheng, A. Stress-strain behaviour of steel-fibre-reinforced recycled aggregate concrete under axial tension. J. Clean. Prod. 2021, 278, 123248. [Google Scholar] [CrossRef]

- Vaverková, M.D. Landfill Impacts on the Environment—Review. Geosciences 2019, 9, 431. [Google Scholar] [CrossRef] [Green Version]

- MOCCAE News|Media Center|UAE Ministry of Climate Change and Environment Ministry of Climate Change and Environment Issues Resolution on Recycled Aggregates from Construction, Demolition Waste. Available online: https://www.moccae.gov.ae/en/media-center/news/6/2/2019/ministry-of-climate-change-and-environment-issues-resolution-on-recycled-aggregates-from-construction-demolition-waste.aspx?DisableResponsive=1#page=1 (accessed on 5 January 2021).

- Wijayasundara, M.; Mendis, P.; Crawford, R.H. Integrated assessment of the use of recycled concrete aggregate replacing natural aggregate in structural concrete. J. Clean. Prod. 2018, 174, 591–604. [Google Scholar] [CrossRef]

- Jordan, G.; Prevette, S.; Woodward, S. The Performance-Based Management Handbook. Analyzing, Reviewing, and Reporting Performance Data; Oak Ridge Institute for Science and Education: Oak Ridge, TN, USA, 2001; Volume 5. [Google Scholar]

| Scenario | S1 | S2 | S3 | S4 | |

|---|---|---|---|---|---|

| Transported to | Zone 1 | Zone 2 | Zone 3 | Zone 4 | |

| Material | RA | 368 | 555 | 583 | 632 |

| NA | 723 | 275 | 193 | 1232 | |

| Additives | 424 | 220 | 304 | 822 | |

| Material | Cost * in USD/kg | Environmental Impact Category per kg of Material | |||||

|---|---|---|---|---|---|---|---|

| GWP | ODP | AP | EP | POCP | ADP | ||

| kg CO2eq | kg CFC−11eq | kg SO2eq | kg PO4−3 | kg C2H4eq | kg sbeq | ||

| Cement | 0.0756 | 0.898 | 1.21 × 10−10 | 1.48 × 10−3 | 2.211 × 10−4 | 1.42 × 10−4 | 1.1 × 10−6 |

| Dune sand | 0.0052 | - | - | - | - | - | - |

| Natural aggregate | 0.00675 | 0.0052 | - | - | - | - | - |

| Recycled aggregate | 0.0054–0.0081 | 6.67 × 10−4 | - | - | - | - | - |

| Water (per L) | 0.00212 | 0.01258 | - | - | - | - | - |

| Superplasticizer | 1.9278 | 1.88 | 2.30 × 10−10 | 2.92 × 10−3 | 1.03 × 10−3 | 3.12 × 10−4 | 1.1 × 10−6 |

| Steel fibers | 1.62 | 0.771 | 1 × 10−4 | 1.05 × 10−6 | 3.35 × 10−4 | 3.24 × 10−4 | 1.11 × 10−4 |

| Fly ash | 0.0891 | 0.027 | - | - | - | - | - |

| Slag | 0.0756 | 0.0416 | 5.08 × 10−9 | 4.6 × 10−4 | 4.4 × 10−5 | 2.89 × 10−5 | 3.1 × 10−4 |

| Microsilica | 0.3375 | 0.014 | - | - | - | - | - |

| Oxide Compound | Fly Ash (%) | Slag (%) | Microsilica (%) |

|---|---|---|---|

| CaO | 3.3 | 42.0 | 0.2 |

| SiO2 | 48.0 | 34.7 | 97.8 |

| Al2O3 | 23.1 | 14.4 | 0.2 |

| MgO | 1.5 | 6.9 | 0.5 |

| Fe2O3 | 12.5 | 0.8 | 0.5 |

| Na2O | 0.0 | 0.0 | 0.2 |

| K2O | 0.0 | 0.0 | 0.2 |

| Loss on ignition | 1.1 | 1.1 | 0.0 |

| Others | 10.5 | 0.2 | 0.4 |

| Material | Property | ||||||

|---|---|---|---|---|---|---|---|

| Dry-Rodded Density (kg/m3) | Absorption (%) | Los Angeles Abrasion (%) | Surface Area (cm2/g) | Soundness (MgSO4) (%) | Specific Gravity | Fineness Modulus | |

| ASTM Standard | C29 | C127 | C131 | C136 | C88 | C127 | C136 |

| NA | 1635 | 0.62 | 16.0 | 2.49 | 1.20 | 2.82 | 6.82 |

| RA | 1563 | 6.63 | 32.6 | 2.50 | 2.78 | 2.63 | 7.44 |

| Dune Sand | 1663 | - | - | 116.8 | - | 2.77 | 1.45 |

| Mix Designation | Weight (kg/m3) | Volume (m3) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Binder | Aggregates | Water | SP | Steel Fibers | |||||

| Cement | Additive * | Dune Sand | NA | RA | |||||

| Control | 470 | 0 | 600 | 1150 | 0 | 230 | 0 | 0 | 1.01 |

| 30RA-0SF ** | 470 | 0 | 545 | 791 | 339 | 230 | 0 | 0 | 1.01 |

| 70RA-1SF ** | 470 | 0 | 575 | 339 | 731 | 230 | 0 | 78 | 1.01 |

| 100RA-3SF | 470 | 0 | 570 | 0 | 1130 | 230 | 9.6 | 234 | 1.05 |

| 100RA-1SF | 480 | 0 | 650 | 0 | 1090 | 180 | 4.8 | 78 | 1.02 |

| 100RA-Cem | 560 | 0 | 525 | 0 | 1180 | 170 | 5.6 | 0 | 1.01 |

| 100RA-MS | 325 | 26 | 800 | 0 | 1060 | 180 | 3.5 | 0 | 1.01 |

| 100RA-FA | 400 | 80 | 550 | 0 | 1130 | 200 | 0 | 0 | 1.01 |

| 100RA-Slag | 425 | 125 | 550 | 0 | 1030 | 210 | 0 | 0 | 1.00 |

| Mix Designation | Slump (mm) | % Change | Density (kg/m3) | % Change |

|---|---|---|---|---|

| Control | 150 | - | 2617 | - |

| 30RA-0SF * | 135 | −10.0 | 2560 | −2.2 |

| 70RA-1SF * | 100 | −33.3 | 2527 | −3.4 |

| 100RA-3SF | 100 | −33.3 | 2600 | −0.6 |

| 100RA-1SF | 120 | −20.0 | 2450 | −6.4 |

| 100RA-Cem | 136 | −9.3 | 2378 | −9.1 |

| 100RA-MS | 100 | −33.3 | 2390 | −8.7 |

| 100RA-FA | 125 | −16.7 | 2375 | −9.2 |

| 100RA-Slag | 128 | −14.7 | 2395 | −8.5 |

| Mix Designation | Environmental Category | |||||

|---|---|---|---|---|---|---|

| GWP (kg CO2eq) | ODP (kg CFC−11eq) | AP (kg SO2eq) | EP (kg PO4−3) | POCP (kg C2H4eq) | ADP (kg sbeq) | |

| Control | 430.8 | 5.7 × 10−8 | 0.7 | 0.10 | 0.07 | 0.00 |

| 30RA-0SF | 429.3 | 5.7 × 10−8 | 0.7 | 0.10 | 0.07 | 0.00 |

| 70RA-1SF | 487.3 | 7.8 × 10−3 | 0.7 | 0.13 | 0.09 | 0.01 |

| 100RA-3SF | 624.2 | 2.3 × 10−2 | 0.7 | 0.19 | 0.15 | 0.03 |

| 100RA-1SF | 503.2 | 7.8 × 10−3 | 0.7 | 0.14 | 0.09 | 0.01 |

| 100RA-Cem | 516.3 | 6.9 × 10−8 | 0.8 | 0.13 | 0.08 | 0.00 |

| 100RA-MS | 301.8 | 4.0 × 10−8 | 0.5 | 0.08 | 0.05 | 0.00 |

| 100RA-FA | 364.6 | 4.8 × 10−8 | 0.6 | 0.09 | 0.06 | 0.00 |

| 100RA-Slag | 390.2 | 6.9 × 10−7 | 0.7 | 0.10 | 0.06 | 0.04 |

| Mix Designation | Component | |||||||

|---|---|---|---|---|---|---|---|---|

| Cement | Additive * | Dune Sand | NA | RA | Water | SP | Steel Fibers | |

| Control | 97.96 | 0.00 | 0.00 | 1.36 | 0.00 | 0.67 | 0.00 | 0.00 |

| 30RA-0SF | 98.32 | 0.00 | 0.00 | 0.96 | 0.05 | 0.67 | 0.00 | 0.00 |

| 70RA-1SF | 86.60 | 0.00 | 0.00 | 0.36 | 0.10 | 0.59 | 0.00 | 12.34 |

| 100RA-3SF | 67.62 | 0.00 | 0.00 | 0.00 | 0.12 | 0.46 | 2.89 | 28.90 |

| 100RA-1SF | 85.66 | 0.00 | 0.00 | 0.00 | 0.14 | 0.45 | 1.79 | 11.95 |

| 100RA-Cem | 97.39 | 0.00 | 0.00 | 0.00 | 0.15 | 0.41 | 2.04 | 0.00 |

| 100RA-MS | 98.87 | 0.12 | 0.00 | 0.00 | 0.24 | 0.77 | 0.00 | 0.00 |

| 100RA-FA | 98.51 | 0.59 | 0.00 | 0.00 | 0.21 | 0.69 | 0.00 | 0.00 |

| 100RA-Slag | 97.81 | 1.33 | 0.00 | 0.00 | 0.18 | 0.68 | 0.00 | 0.00 |

| Mix Designation | Binder | Aggregate | Water | SP | SF | Total Cost (USD/m3) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement | Additive * | Dune Sand | NA | RA (Lower) | RA (Upper) | Lower | Upper | ||||

| Control | 35.5 | 0.0 | 3.0 | 7.6 | 0.0 | 0.0 | 0.5 | 0.0 | 0.0 | 46.6 | 46.6 |

| 30RA-0SF | 35.5 | 0.0 | 2.8 | 5.3 | 1.8 | 2.8 | 0.5 | 0.0 | 0.0 | 46.0 | 46.9 |

| 70RA-1SF | 35.5 | 0.0 | 3.0 | 2.3 | 4.0 | 5.9 | 0.5 | 0.0 | 126.4 | 171.6 | 173.6 |

| 100RA-3SF | 35.5 | 0.0 | 2.6 | 0.0 | 6.1 | 9.2 | 0.5 | 18.5 | 379.1 | 442.2 | 445.3 |

| 100RA-1SF | 36.3 | 0.0 | 3.4 | 0.0 | 5.9 | 8.8 | 0.4 | 9.3 | 126.4 | 181.6 | 184.5 |

| 100RA-Cem | 42.3 | 0.0 | 2.7 | 0.0 | 6.4 | 9.6 | 0.4 | 10.8 | 0.0 | 62.6 | 65.8 |

| 100RA-MS | 24.6 | 8.8 | 4.2 | 0.0 | 5.7 | 8.6 | 0.4 | 0.0 | 0.0 | 43.6 | 46.5 |

| 100RA-FA | 30.2 | 7.1 | 2.9 | 0.0 | 6.1 | 9.2 | 0.4 | 0.0 | 0.0 | 46.7 | 49.8 |

| 100RA-Slag | 32.1 | 9.5 | 2.9 | 0.0 | 5.6 | 8.3 | 0.4 | 0.0 | 0.0 | 50.4 | 53.2 |

| Environmental Impact of Transportation | Cost of Transportation | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mix | RA | NA | SF | Additives * | Trans. GWP | Total ** | RA | NA | SF | Additives * | Trans. Cost | Total *** |

| Zone 1 | ||||||||||||

| Control | 0.0 | 163.6 | 0.0 | 0.0 | 163.6 | 594.4 | 0.0 | 44.1 | 0.0 | 0.0 | 44.1 | 90.7 |

| 30RA-0SF | 25.0 | 114.5 | 0.0 | 0.0 | 139.5 | 568.8 | 6.7 | 30.9 | 0.0 | 0.0 | 37.6 | 83.6 |

| 70RA-1SF | 53.9 | 49.1 | 5.8 | 0.0 | 108.8 | 596.1 | 14.5 | 13.2 | 1.6 | 0.0 | 29.3 | 200.9 |

| 100RA-3SF | 83.3 | 0.0 | 17.3 | 0.0 | 100.6 | 724.8 | 22.5 | 0.0 | 4.7 | 0.0 | 27.2 | 469.5 |

| 100RA-1SF | 80.3 | 0.0 | 5.8 | 0.0 | 86.1 | 589.3 | 21.7 | 0.0 | 1.6 | 0.0 | 23.3 | 204.8 |

| 100RA-Cem | 87.0 | 0.0 | 0.0 | 0.0 | 93.6 | 603.3 | 23.5 | 0.0 | 0.0 | 0.0 | 25.3 | 86.1 |

| 100RA-MS | 78.1 | 0.0 | 0.0 | 1.9 | 80.0 | 381.8 | 21.1 | 0.0 | 0.0 | 0.5 | 21.6 | 65.2 |

| 100RA-FA | 83.3 | 0.0 | 0.0 | 5.9 | 89.2 | 453.8 | 22.5 | 0.0 | 0.0 | 1.6 | 24.1 | 70.8 |

| 100RA-Slag | 75.9 | 0.0 | 0.0 | 9.2 | 85.1 | 475.3 | 20.5 | 0.0 | 0.0 | 2.5 | 23.0 | 73.4 |

| Zone 2 | ||||||||||||

| Control | 0.0 | 62.2 | 0.0 | 0.0 | 62.2 | 493.0 | 0.0 | 16.8 | 0.0 | 0.0 | 16.8 | 63.4 |

| 30RA-0SF | 37.7 | 43.6 | 0.0 | 0.0 | 81.3 | 510.6 | 10.2 | 11.8 | 0.0 | 0.0 | 22.0 | 68.0 |

| 70RA-1SF | 81.3 | 18.7 | 1.7 | 0.0 | 101.7 | 589.0 | 21.9 | 5.0 | 0.5 | 0.0 | 27.4 | 199.0 |

| 100RA-3SF | 125.6 | 0.0 | 5.2 | 0.0 | 130.8 | 755.0 | 33.9 | 0.0 | 1.4 | 0.0 | 35.3 | 477.6 |

| 100RA-1SF | 121.2 | 0.0 | 1.7 | 0.0 | 122.9 | 626.1 | 32.7 | 0.0 | 0.5 | 0.0 | 33.2 | 214.7 |

| 100RA-Cem | 131.2 | 0.0 | 0.0 | 0.0 | 133.2 | 647.5 | 35.4 | 0.0 | 0.0 | 0.0 | 35.9 | 98.0 |

| 100RA-MS | 117.8 | 0.0 | 0.0 | 0.6 | 118.4 | 420.1 | 31.8 | 0.0 | 0.0 | 0.2 | 32.0 | 75.6 |

| 100RA-FA | 125.6 | 0.0 | 0.0 | 1.8 | 127.4 | 492.0 | 33.9 | 0.0 | 0.0 | 0.5 | 34.4 | 81.1 |

| 100RA-Slag | 114.5 | 0.0 | 0.0 | 2.8 | 117.3 | 507.5 | 30.9 | 0.0 | 0.0 | 0.8 | 31.7 | 82.1 |

| Zone 3 | ||||||||||||

| Control | 0.0 | 43.6 | 0.0 | 0.0 | 43.6 | 474.4 | 0.0 | 11.8 | 0.0 | 0.0 | 11.8 | 58.4 |

| 30RA-0SF | 39.6 | 30.5 | 0.0 | 0.0 | 70.1 | 499.4 | 10.7 | 8.2 | 0.0 | 0.0 | 18.9 | 64.9 |

| 70RA-1SF | 85.3 | 13.1 | 2.2 | 0.0 | 100.6 | 587.9 | 23.0 | 3.5 | 0.6 | 0.0 | 27.1 | 198.7 |

| 100RA-3SF | 131.8 | 0.0 | 6.7 | 0.0 | 138.5 | 762.7 | 35.6 | 0.0 | 1.8 | 0.0 | 37.4 | 479.7 |

| 100RA-1SF | 127.2 | 0.0 | 2.2 | 0.0 | 129.4 | 632.6 | 34.3 | 0.0 | 0.6 | 0.0 | 34.9 | 216.4 |

| 100RA-Cem | 137.7 | 0.0 | 0.0 | 0.0 | 140.3 | 654.0 | 37.2 | 0.0 | 0.0 | 0.0 | 37.9 | 99.8 |

| 100RA-MS | 123.7 | 0.0 | 0.0 | 0.74 | 124.4 | 426.2 | 33.4 | 0.0 | 0.0 | 0.2 | 33.6 | 77.2 |

| 100RA-FA | 131.8 | 0.0 | 0.0 | 2.28 | 134.1 | 498.7 | 35.6 | 0.0 | 0.0 | 0.6 | 36.2 | 83.0 |

| 100RA-Slag | 120.2 | 0.0 | 0.0 | 3.55 | 123.8 | 513.9 | 32.4 | 0.0 | 0.0 | 1.0 | 33.4 | 83.8 |

| Zone 4 | ||||||||||||

| Control | 0.0 | 278.8 | 0.0 | 0.0 | 278.8 | 709.6 | 0.0 | 75.3 | 0.0 | 0.0 | 75.3 | 121.9 |

| 30RA-0SF | 42.9 | 195.2 | 0.0 | 0.0 | 238.1 | 667.4 | 11.6 | 52.7 | 0.0 | 0.0 | 64.3 | 110.3 |

| 70RA-1SF | 92.5 | 83.6 | 9.9 | 0.0 | 186.0 | 673.3 | 25.0 | 22.6 | 2.7 | 0.0 | 50.3 | 221.9 |

| 100RA-3SF | 143.0 | 0.0 | 29.6 | 0.0 | 172.6 | 796.8 | 38.6 | 0.0 | 8.0 | 0.0 | 46.6 | 488.9 |

| 100RA-1SF | 138.0 | 0.0 | 9.9 | 0.0 | 147.9 | 651.1 | 37.3 | 0.0 | 2.7 | 0.0 | 40.0 | 221.5 |

| 100RA-Cem | 149.4 | 0.0 | 0.0 | 0.0 | 160.8 | 665.7 | 40.3 | 0.0 | 0.0 | 0.0 | 43.4 | 102.9 |

| 100RA-MS | 134.2 | 0.0 | 0.0 | 3.3 | 137.5 | 439.3 | 36.2 | 0.0 | 0.0 | 0.9 | 37.1 | 80.7 |

| 100RA-FA | 143.0 | 0.0 | 0.0 | 10.1 | 153.1 | 517.8 | 38.6 | 0.0 | 0.0 | 2.7 | 41.3 | 88.1 |

| 100RA-Slag | 130.4 | 0.0 | 0.0 | 15.8 | 146.2 | 536.4 | 35.2 | 0.0 | 0.0 | 4.3 | 39.5 | 89.9 |

| Zone | Mix | Individual Performance Criterion (Wi) | |||||

|---|---|---|---|---|---|---|---|

| Environ. | Cost | Waste | Slump | f’c | fr | ||

| Zone 1 | Control | 0.63 | 0.71 | 0.10 | 1.00 | 0.96 | 0.63 |

| 30RA-0SF | 0.66 | 0.77 | 0.14 | 0.90 | 1.00 | 0.53 | |

| 70RA-1SF | 0.63 | 0.32 | 0.33 | 0.67 | 0.94 | 0.63 | |

| 100RA-3SF | 0.52 | 0.14 | 1.00 | 0.67 | 0.93 | 1.00 | |

| 100RA-1SF | 0.63 | 0.32 | 1.00 | 0.80 | 0.96 | 0.63 | |

| 100RA-Cem | 0.62 | 0.75 | 1.00 | 0.91 | 0.94 | 0.60 | |

| 100RA-MS | 1.00 | 1.00 | 1.00 | 0.67 | 0.97 | 0.61 | |

| 100RA-FA | 0.83 | 0.93 | 1.00 | 0.83 | 0.97 | 0.64 | |

| 100RA-Slag | 0.80 | 0.91 | 1.00 | 0.85 | 0.90 | 0.64 | |

| Zone 2 | Control | 0.84 | 1.00 | 0.10 | 1.00 | 0.96 | 0.63 |

| 30RA-0SF | 0.81 | 0.92 | 0.14 | 0.90 | 1.00 | 0.53 | |

| 70RA-1SF | 0.70 | 0.32 | 0.33 | 0.67 | 0.94 | 0.63 | |

| 100RA-3SF | 0.55 | 0.13 | 1.00 | 0.67 | 0.93 | 1.00 | |

| 100RA-1SF | 0.66 | 0.29 | 1.00 | 0.80 | 0.96 | 0.63 | |

| 100RA-Cem | 0.64 | 0.63 | 1.00 | 0.91 | 0.94 | 0.60 | |

| 100RA-MS | 1.00 | 0.81 | 1.00 | 0.67 | 0.97 | 0.61 | |

| 100RA-FA | 0.84 | 0.76 | 1.00 | 0.83 | 0.97 | 0.64 | |

| 100RA-Slag | 0.82 | 0.75 | 1.00 | 0.85 | 0.90 | 0.64 | |

| Zone 3 | Control | 0.88 | 1.00 | 0.10 | 1.00 | 0.96 | 0.63 |

| 30RA-0SF | 0.84 | 0.89 | 0.14 | 0.90 | 1.00 | 0.53 | |

| 70RA-1SF | 0.71 | 0.29 | 0.33 | 0.67 | 0.94 | 0.63 | |

| 100RA-3SF | 0.55 | 0.12 | 1.00 | 0.67 | 0.93 | 1.00 | |

| 100RA-1SF | 0.66 | 0.27 | 1.00 | 0.80 | 0.96 | 0.63 | |

| 100RA-Cem | 0.64 | 0.57 | 1.00 | 0.91 | 0.94 | 0.60 | |

| 100RA-MS | 1.00 | 0.73 | 1.00 | 0.67 | 0.97 | 0.61 | |

| 100RA-FA | 0.84 | 0.68 | 1.00 | 0.83 | 0.97 | 0.64 | |

| 100RA-Slag | 0.82 | 0.68 | 1.00 | 0.85 | 0.90 | 0.64 | |

| Zone 4 | Control | 0.61 | 0.68 | 0.10 | 1.00 | 0.96 | 0.63 |

| 30RA-0SF | 0.64 | 0.74 | 0.14 | 0.90 | 1.00 | 0.53 | |

| 70RA-1SF | 0.64 | 0.37 | 0.33 | 0.67 | 0.94 | 0.63 | |

| 100RA-3SF | 0.54 | 0.17 | 1.00 | 0.67 | 0.93 | 1.00 | |

| 100RA-1SF | 0.66 | 0.37 | 1.00 | 0.80 | 0.96 | 0.63 | |

| 100RA-Cem | 0.64 | 0.78 | 1.00 | 0.91 | 0.94 | 0.60 | |

| 100RA-MS | 1.00 | 1.00 | 1.00 | 0.67 | 0.97 | 0.61 | |

| 100RA-FA | 0.85 | 0.94 | 1.00 | 0.83 | 0.97 | 0.64 | |

| 100RA-Slag | 0.82 | 0.93 | 1.00 | 0.85 | 0.90 | 0.64 | |

| Zone | Mix | Multifunctional Performance Indices | |||||

|---|---|---|---|---|---|---|---|

| PI-1 | PI-2 | PI-3 | PI-4 | PI-5 | PI-6 | ||

| Zone 1 | Control | 4.5 | 6.7 | 6.6 | 96.0 | 64.0 | 6.6 |

| 30RA-0SF | 7.2 | 9.8 | 10.1 | 75.9 | 56.2 | 8.5 | |

| 70RA-1SF | 6.7 | 6.7 | 6.5 | 62.9 | 62.9 | 6.5 | |

| 100RA-3SF | 7.1 | 7.1 | 6.8 | 100.0 | 100.0 | 11.0 | |

| 100RA-1SF | 20.0 | 24.0 | 23.6 | 76.8 | 64.0 | 23.7 | |

| 100RA-Cem | 46.5 | 63.2 | 61.0 | 81.9 | 60.2 | 58.8 | |

| 100RA-MS | 100.0 | 100.0 | 100.0 | 63.7 | 63.7 | 98.4 | |

| 100RA-FA | 77.9 | 97.3 | 97.6 | 83.2 | 66.5 | 100.0 | |

| 100RA-Slag | 73.0 | 93.5 | 86.8 | 78.9 | 61.6 | 88.9 | |

| Zone 2 | Control | 10.3 | 15.5 | 15.3 | 96.0 | 64.0 | 15.1 |

| 30RA-0SF | 13.1 | 17.7 | 18.2 | 75.9 | 56.2 | 15.2 | |

| 70RA-1SF | 9.1 | 9.1 | 8.8 | 62.9 | 62.9 | 8.7 | |

| 100RA-3SF | 8.9 | 8.9 | 8.6 | 100.0 | 100.0 | 13.6 | |

| 100RA-1SF | 23.7 | 28.5 | 28.0 | 76.8 | 64.0 | 27.8 | |

| 100RA-Cem | 49.3 | 67.1 | 64.7 | 81.9 | 60.2 | 61.7 | |

| 100RA-MS | 100.0 | 100.0 | 100.0 | 63.7 | 63.7 | 97.3 | |

| 100RA-FA | 78.8 | 98.4 | 98.8 | 83.2 | 66.5 | 100.0 | |

| 100RA-Slag | 76.1 | 97.4 | 90.5 | 78.9 | 61.6 | 91.6 | |

| Zone 3 | Control | 12.1 | 18.1 | 17.8 | 96.0 | 64.0 | 17.7 |

| 30RA-0SF | 14.5 | 19.6 | 20.2 | 75.9 | 56.2 | 16.8 | |

| 70RA-1SF | 9.4 | 9.4 | 9.1 | 62.9 | 62.9 | 9.1 | |

| 100RA-3SF | 9.1 | 9.1 | 8.7 | 100.0 | 100.0 | 13.8 | |

| 100RA-1SF | 24.1 | 28.9 | 28.4 | 76.8 | 64.0 | 28.2 | |

| 100RA-Cem | 49.7 | 67.5 | 65.1 | 81.9 | 60.2 | 62.0 | |

| 100RA-MS | 100.0 | 100.0 | 100.0 | 63.7 | 63.7 | 97.1 | |

| 100RA-FA | 78.9 | 98.6 | 98.9 | 83.2 | 66.5 | 100.0 | |

| 100RA-Slag | 76.5 | 97.9 | 90.9 | 78.9 | 61.6 | 91.9 | |

| Zone 4 | Control | 4.1 | 6.2 | 6.1 | 96.0 | 64.0 | 6.0 |

| 30RA-0SF | 6.8 | 9.2 | 9.5 | 75.9 | 56.2 | 7.9 | |

| 70RA-1SF | 7.8 | 7.8 | 7.6 | 62.9 | 62.9 | 7.5 | |

| 100RA-3SF | 9.1 | 9.1 | 8.7 | 100.0 | 100.0 | 13.8 | |

| 100RA-1SF | 24.3 | 29.1 | 28.7 | 76.8 | 64.0 | 28.4 | |

| 100RA-Cem | 50.3 | 68.3 | 65.9 | 81.9 | 60.2 | 62.5 | |

| 100RA-MS | 100.0 | 100.0 | 100.0 | 63.7 | 63.7 | 96.9 | |

| 100RA-FA | 79.1 | 98.9 | 99.2 | 83.2 | 66.5 | 100.0 | |

| 100RA-Slag | 77.1 | 98.7 | 91.7 | 78.9 | 61.6 | 92.4 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alzard, M.H.; El-Hassan, H.; El-Maaddawy, T. Environmental and Economic Life Cycle Assessment of Recycled Aggregates Concrete in the United Arab Emirates. Sustainability 2021, 13, 10348. https://doi.org/10.3390/su131810348

Alzard MH, El-Hassan H, El-Maaddawy T. Environmental and Economic Life Cycle Assessment of Recycled Aggregates Concrete in the United Arab Emirates. Sustainability. 2021; 13(18):10348. https://doi.org/10.3390/su131810348

Chicago/Turabian StyleAlzard, Mohammed H., Hilal El-Hassan, and Tamer El-Maaddawy. 2021. "Environmental and Economic Life Cycle Assessment of Recycled Aggregates Concrete in the United Arab Emirates" Sustainability 13, no. 18: 10348. https://doi.org/10.3390/su131810348