Abstract

This study attempts to examine the impact of corporate sustainability on firm performance by examining the indirect effect of sustainability-oriented supplier partnership and green innovation capabilities of a firm. The data acquired to address the research question is collected from management personnel, officers, and experts in the Ghana manufacturing sector using a list provided by the Association of Ghana Industries. Data acquired are tested for convergent validity and construct reliability and further examine the measurement model. The structural model is examined using partial least square structural equation modeling techniques. The empirical study supports seven (7) out of eight (8) stated hypotheses. Findings indicate that a sustainability-oriented supplier partnership indirectly influences the effect of social sustainability practices on a firm’s performance. In the same view, the outcome revealed that a sustainability-oriented supplier partnership does not positively influence the relationship between environmental, economic sustainability, and firm performance. Green innovation capabilities indirectly influence the effect of social and economic sustainability on firm performance except for environmental sustainability and firm performance. The findings of the study contribute to the literature by providing insights into the indirect effect of supplier–partnership and green innovation capabilities on firm performance, especially in the manufacturing sector.

1. Introduction

The negative effect of firms’ production activities has received significant attention both in practice and academia [1]. Curbing this increasing challenge has lead to the ratification of several policies and promotion of sustainability-oriented frameworks [2]. The transition to sustainable practices is fueled by several factors, such as constant pressures from the organization’s stakeholders and regulatory requirements. These factors serve as the thrust for the adaption and implementation of corporate sustainability practices [3].

Corporate sustainability practices can take diverse dimensions such as economic sustainability practices, social sustainability practices, and environmental practices [4]. The organization needs to perform various sustainability activities to ensure internal and external stakeholders are satisfied. Besides, it is prudent for firms to engage in corporate sustainability practices to build and maintain sustainability core competencies [5]. The practice of sustainability provides firms the necessary leverage to gain entry into new markets and opportunities. Additionally, adopting sustainability practices on a political and tactical level enables firms to comply with regulatory requirements while maintaining a green reputation in the marketplace [6,7]. Inasmuch as corporate sustainability is discussed to impact the performance of firms, the disourse on this relationship is conflicting in some cases.

Therefore, the research adds up to the discourse of the effect of corporate sustainability on firm performance by probing into the role of suppliers and green innovation capabilities of the firm. Ensuring corporate sustainability practices have a significant impact on firm performance requires contribution from diverse stakeholders, especially suppliers. There it is critical to identify and select suppliers with sustainable identity and orientation. Sustainability-oriented supplier–firm relationships/partnerships play a critical role in enriching the sustainability practices of organizations. The interaction among businesses offers firms the knowledge, information, and business acumen to thrive in a green economy. Observing the relevance of sustainability-oriented supplier–buyer networks from a stakeholder theory and social capital perspective, it is acknowledged that focal firms stand the chance to gain sufficient knowledge and resources to augment internal sustainability processes [8]. Additionally, relationship-learning activities are enriched throughout the interaction and collaboration stage between focal firms and suppliers [9]. Having in place a responsible supplier network/ecosystem cannot be underestimated if corporate sustainability practices can contribute towards the performance of firms.

Although the sustainable orientation of firm suppliers is argued to indirectly influence the impact of corporate sustainability on firm performance, for a firm to capitalize on green knowledge and slack resources from sustainability networks, it is required that the particular organization possesses sufficient green innovation capabilities [10,11]. Organizational green innovation capabilities would influence and shape operational processes by reconfiguring and aligning organizational resources needed to convert sustainability practices into overall firm performance [12]. Green innovation capabilities of a firm are argued to have an indirect effect on the impact of corporate sustainability on firm performance. Therefore, the central theme of the study is to examine the impact of corporate sustainability on firm performance through the indirect effect of sustainability-oriented supplier networks and green innovation capabilities. The study is conducted in the Ghanaian manufacturing sector. The economy of Ghana, in recent decades, has witnessed an increase in manufacturing and production activities. The manufacturing and production sector contributes a significant amount to the gross domestic product of the country. Besides contributing to GDP, the sector accounts for a major aspect of employment in the private sector. The success of this sector has attracted several investments and global brands; therefore, it is imperative to address issues of sustainability in the emerging phase before it erodes positive gains in the long run.

2. Hypothesis Development and Conceptual Model

2.1. Corporate Sustainability and Sustainability-Oriented Supply Chain Partnership

Corporate sustainability, as elaborated in earlier sections of the study, is a deliberate approach or strategy by a firm to create long-term stakeholder value through the adoption and implementation of a business strategy that is social, environmental, economic, and ethically sound. Corporate sustainability is rooted in the principle that firms need to deal with short-term gain while mitigating its negative environmental and social effects on the business landscape. As much as corporate sustainability is considered to be a panacea for firm sustainable development, it requires the involvement and commitment of several firms in the business environment, especially in a VUCA landscape [13,14,15]. Achieving a high degree of corporate sustainability requires the firm to cooperate with diverse actors in the business environment.

Firms, in most cases, do not possess all the requisite resources and human capital to sustain their internal sustainability agenda. Therefore, firms form alliances with key partners that possess complementary resources. Having access to complementary resources in the business environment plays a key role in enriching the innovation capabilities and competencies. Sustainable practices and development can be achieved by collaboration with relevant suppliers [16,17,18]. As much as corporate sustainability can be enhanced through a firm–supplier relationship, the overall performance of such an alliance rests on the performance of partners. The success and survival of sustainable supplier–buyer alliance rest on the performance of network members [19,20]. Therefore, partner selection in the formation of such an alliance is considered a critical issue for achieving collective goals [21,22]. The sustainability orientation and capabilities of the partner are essential in the selection process—the firm should identify and select firms that have access to slack resources and knowledge that is prudent to attaining sustainability goals [23,24,25].

However, in recent times, due to firms’ shift in attention from cost-based to more sustainability paradigms, the selection criteria of members for the supply chain network have been affected. The sustainability consciousness of potential partners is considered a critical facet in the selection of the partner process. To achieve a high level of corporate sustainability, firms turn to identify and select suppliers that share similar goals and objectives. Partnering with such firms enables them to gain a competitive advantage in conducting business sustainability practices [26,27]. To be cautious in this cutting-edge and universally competing commercial environment, companies require a potent supply chain association or alliance with tremendous competency in all viewpoints of corporate sustainability [28]. This is because sustainable supply chains can be seen as successful mechanisms that allow the majority of firms to easily revamp sustainable products and services all through their product life cycle [29,30]. According to [31] and [28], the most striking adjustments within the way companies operate with CSR issues and are socially capable is the move of the target from their operations to improving the overall performance of supply chains, customer satisfaction, and loyalty. The sustainability practices of an organization would positively impact its green supply network. The degree to which network actors adhere to network compliance requirements and extend of green knowledge exchange and utilization would impact the performance of such an alliance [32]. In addition, the corporate sustainability practice is identified to positively impact the competitiveness of a firm [33]. The study conceptualizes that the corporate sustainability practice of the firm serves as a thrust on the selection and performance of sustainability-oriented supplier–buyer relations. For the objective of this investigation, corporate sustainability is measured in three dimensions, namely, economic sustainability, environmental sustainability, and social sustainability. Hypotheses 1a–1c attempt to examine the relationship between economic sustainability practices, social sustainability practices, environmental sustainability practices, and sustainability-oriented supplier–buyer partnership performance. Hypotheses are stated below:

Hypotheses 1a (H1a).

Economic sustainability practices have a positive impact on the performance of the sustainability-oriented supplier–buyer partnership.

Hypotheses 1b (H1b).

Environmental sustainability practices have a positive impact on the performance of the sustainability-oriented supplier–buyer partnership.

Hypotheses 1c (H1c).

Social sustainability practices have a positive impact on the performance of the sustainability-oriented supplier–buyer partnership.

2.2. Corporate Sustainability and Green Innovation Capabilities of Firm

In recent times, a significant number of studies have been dedicated to investigating the liaison betwixt corporate sustainability and the achievement of the firm. The effect of corporate sustainability practice on the performance of service firms and industries has received lots of attention in academic literature [34,35]. However, there is no consensus on the impact of corporate sustainability on firm performance. Some studies argue that there is a positive and significant relationship between corporate sustainability and firm performance [36]; other studies either report a negative or neutral relationship [37]. The rationale for these discrepancies is rooted in the premise that these studies were conducted in a different geographical location that has a diverse and dynamic business environment. Hence, further studies must be carried out to ascertain the effect of corporate sustainability on firm performance. With the extensive practice of social, economic, and environmental sustainability activities, organizations are able to build and reconfigure their capabilities to enrich the innovation process and capacity of firms. Firms with high capabilities in relation to knowledge, human capital, and technological infrastructure can convert green knowledge and resources to develop and deploy sustainable products and services. The new, improved, green-oriented product opens up firms to novel markets and revenue streams. An increase in customer base, market share, and cash flow is acknowledged to impact the performance of firms in both the short and long run [10,12].

The sustainability practices of an organization shape the organizational culture and practices. Having sustainability-oriented culture and structures shape the direction of a firm’s strategy and further boosts the green innovation competencies [38]. Reconfiguring organization structures and systems towards the fulfillment of the firm’s sustainability strategy enriches the green innovation capabilities of such a particular enterprise. The green innovation capabilities of firms are enhanced by systematically reallocating resources and technical skills towards sustainability projects and activities [39]. The practice of corporate sustainability results in the reconfiguration and alignment of corporate green strategy and policy, which is conceptualized to impact the green innovation capabilities of the focal firm, especially in the manufacturing sector. The various proportions of corporate sustainability practices are postulated to positively impact the green innovation capabilities of a firm. Below are the stated hypotheses:

Hypotheses 2a (H2a).

Economic sustainability practices have a positive impact on the green innovation capabilities of a firm.

Hypotheses 2b (H2b).

Environmental sustainability practices have a positive impact on the green innovation capabilities of a firm.

Hypotheses 2c (H2c).

Social sustainability practices have a positive impact on the green innovation capabilities of a firm.

2.3. Sustainability-Oriented Supplier–Buyer Network, Green Innovation Capabilities, and Firm Performance

Ultimately, studies in supply chain management have ascertained the relevance of supply chain partnerships in achieving supply chain network goals and objectives [40]. The identification and selection of key partners in the supply chain network are crucial to the success or failure of the supply network. Supply chain partnership provides the leverage for firms to gain access to external slack resources, information, and knowledge necessary to augment the innovation capabilities and performance of the focal firm [41,42]. Supply chain partnerships elucidate the elicit benefits such as asymmetrical business model, top-level management support and information, and knowledge sharing and diffusion [39,43]. Reference [44] argues that the link between supply chain partners enhances the channel relationship and consequently impacts the market performance of firms. Drawing lessons from the firm’s social capital perspective, the study conceptualizes that supply chain partnerships enrich the channel and relationship management between supply chain network members. Improved supply chain communication channels boost the internal processes and capacity of firms. The outcome of their study reveals that there is a clear relationship between supply chain partnership and supply chain performance and, consequently, firm performance. However, the significance of supply chain partnership on the non-financial performance of the company is not ascertained. The study contributes to the studies in this domain by examining the impact of a sustainability-oriented supplier network on firm non-financial performance. The partnership nature of the sustainable supply chain network requires constant interaction with buyers, suppliers, and adjacent enterprises to achieve focal firms’ goals and objectives. Shin [42] found that there is a clear link betwixt the performance of supply chain networks and the performance of firms. The competitiveness of firms is improved through collaboration with relevant firms. The collaborative performance of a firm enriches the relational asset of the firm. Lessons from the management literature acknowledge the importance of cooperation and coordination among businesses and their consequence on building the relational and innovative assets of firms. Sustainable supply chain integration ensures supply chain partners achieve a competitive edge in the sustainability landscape by utilizing superior knowledge. From a social capital perspective, network members augment their innovation competence through constant communication and information symmetry. A well-integrated supply chain network affects the performance of firms and is highlighted by the outcome of studies conducted by [45].

Mobilization of these resources enables network members to boost collective and individual performance for the collective good [46,47]. Collective good is acquired through a relationship with suppliers, ties between actors in the procurement ecosystem, and social structure. Information and knowledge exchange between members of such an alliance or network ensures mutual utilization of resources [48,49,50,51]. Utilization of these resources offers firms the requisite platform and leverage to boost internal processes and capabilities. The firm’s capacity for creativity is enhanced through the utilization of external slack resources, skills, and knowledge. The firm’s sustainability innovation capabilities are termed green innovation capabilities in this study. The practices of different aspects of corporate sustainability are argued to impact green organizational processes and competencies. The essence of organizational capabilities has a rippling influence on the green innovation capabilities of the firm. The superior nature of firm green innovation capability has an impact on the quality of products or services a firm offers [52,53]. Firms should endeavor to incorporate eco-friendly activities into their organizational strategy to boost internal innovation capabilities. Having slack resources in place, coupled with internal green capabilities, is argued to influence the business innovation and corporate survival of a particular firm. The forging of green innovation capabilities impacts the green innovation performance of a firm. The innovation performance of firms has a direct consequence on the performance of firms in the manufacturing sector [52,54,55]. Sustainable supply chain partnership enables firms to gain access to untapped social capital and slack resources that are used to augment the internal processes of the focal firm. Gaining the attention of firms in the value chain of focal firm industries enables the firm to gain access to services and information at a low search cost. The quality of tacit and explicit knowledge and information is enriched through constant interaction. Firms can utilize these new resources and skills to develop and offer unique products and services to boost the revenue and overall performance of a firm, especially in the manufacturing sector. Based on the lessons and implications of inter-firm interaction, the risk is managed proactively. Therefore, the study conceptualizes that sustainability-oriented supply chain partnership and the green innovation of firms would impact the performance of the firm.

Hypotheses 3.

The performance of sustainability-oriented supplier–buyer partnership has a positive impact on firm performance.

Hypotheses 4.

Green innovation capabilities of a firm have a positive impact on firm performance.

3. Methodology

3.1. Data Collection

This research focuses on the manufacturing industry of Ghana—as a growing economy, the manufacturing sector plays a critical role in economic growth and development. The manufacturing industry is a significant contributor to the national GDP. The manufacturing industry of Ghana is made of small, medium, and a few large companies. Products and services from these firms contribute significantly towards local consumption and are export earners. Industries in such a sector thrive on the utilization of superior knowledge to maintain a competitive edge. However, the activities of these firms are becoming increasingly difficult due to the continuous demand for green goods and services. In performing this action, the firm anticipates enriching customer value and obtaining a competitive market edge. The sample of the study comes from a list of firms listed as manufacturers in the Association of Ghana Industry membership list (AGI). The firms selected for the study are mostly located in the Greater Accra Region and Ashanti Region of Ghana. The rationale for selecting these locations is rooted in the fact that most of the manufacturing firms are located in Accra, Tema, and Kumasi. Key informants identified within this sector include production managers, supply chain managers, and top management officials. These individuals are perceived to possess sufficient knowledge and information about the firm’s sustainability practices. Emails were sent to over 500 enterprises identified in the list provided by AGI. The email was sorted to invite and solicit the permission of key informants to participate in the field survey. Out of 500 firms, 321 responded to the mail and expressed willingness to participate in the study.

Summarily, out of the 380 individuals that participated in the survey, a response rate of 243 usable questionnaires, representing 75.7%, was obtained. To address issues of common method bias, responses to questions pertaining to corporate sustainability practices and supply partnership were acquired from supply and production managers. Issues regarding green innovation capabilities and firm performance were solicited from directors of firms, heads of research and development, and marketing/business development managers.

3.2. Measurement Instrument Development

In accordance with studies in the area of management and sustainability, the survey instrument adapted is the questionnaire [56]. The questionnaire attempts to gain information on respondents’ background information and further seeks responses of agreement/disagreement to measure items (statement). The questionnaire is made up of two (2) distinct parts. In addition, questionnaire items are measured on 7-point Likert scales. Each construct is measured using no less than 2 items. To ensure content validity, measurement items are extracted from available literature [57]. In addition, to ensure validity, scales pertaining to independent and dependent variables are included in different sections of the questionnaire to allow control of common method bias [56]. Furthermore, Harman’s (1967) single-factor test is performed to ascertain the non-presence of common method bias. The outcome suggests that common method bias is not an issue with the questionnaire items [58].

In furtherance, to ensure robustness, reliability, and validity of questionnaire and measurement items, extensive pretest was conducted using identified sample. In addition to experts from targeted population, information was collected from academics—these individuals are experts and researched extensively in the sustainability domain. The rationale for conducting pretest is to ensure questionnaire items are accurate and readable with no ambiguities [56,59]. Moreover, the social desirability bias is ascertained, inclusive of common method variance. Preliminary statistics and Cronbach alpha value indicate reliability of the test instrument is at acceptable level.

3.3. Measures

The study utilizes measurement items synthesize from extant literature on corporate sustainability, green supply chain management, and organizational performance. The measurement items are measured on a 7-point Likert scale, with 1—strongly disagree to 7—strongly agree.

3.3.1. Corporate Sustainability

Social Corporate Sustainability Practices. The social corporate sustainability practice (SCSP) measure comprised five items from previous measures. The SCSP assesses a company’s ability to provide career development and training opportunities in green knowledge and innovation. The following are some examples of items (1) my organization has established a secure and healthy work environment; (2) our organization is continuously engaging society in charitable endeavors; (3) our organization views sustainability implementation as a moral duty.

Environmental Corporate sustainability Practices. The environmental corporate sustainability practice (ECSP) [60] is a set of five (5) indicators that assess the influence of a firm’s operations on both its internal and external environments in order to provide resilient environmental goods and services. Examples include: (1) our organization views environmental sustainability practices as a critical tool for success in a green environment; (2) our organization intentionally implements measures to promote the offering of environmental products and services; (3) our firm prefers to work with partners and organizations that have environmental certifications.

Economic Corporate Sustainability Practices. The economic corporate sustainability practice (ECSP) [61] is a set of five (5) elements that assesses a company’s capacity to satisfy its sustainability responsibilities and its triple bottom line. Examples include: (1) our company has gained access to new mark opportunities as a result of supplying green products; (2) income from green practices has a beneficial influence on firm financial performance; (3) sustainability practices are fundamental to our organization’s performance.

3.3.2. Sustainability-Oriented Supply Partnership

The measurement items for sustainability-oriented supplier partnership comprises seven (7) items selected from studies conducted by [42,62]. Examples of measurement items include (1) our organization select and evaluate our partners and suppliers, also on the basis of criteria based on the concept of sustainability partner; (2) our organization promotes and raises awareness for our partners and suppliers to implement “sustainability”; (3) our company benefits from problem-solving with our major suppliers; (4) our company shares sustainability-oriented information with our major suppliers.

3.3.3. Green Innovation Capabilities

The capacity of firm to convert green knowledge and information into green innovative products and services is measured using scaled developed by [63] and used in a study performed by [12]. The measurement items consist of seven (7) scales measuring on a 7-point Likert scale. Examples of measurement items include: (1) our firm is able to recognize valuable, sustainable knowledge; (2) our firm has the ability to utilize newly acquired knowledge; (3) our organization has dedication processes and resources to green innovation; (4) our organization is able to substitute toxic materials for eco-friendly ones.

3.3.4. Firm Performance

Measurement items for organizational performance are measured using items developed and used in studies such as [64]. The measurement items are made up of statements such as (1) our firm has witnessed an overall improvement in stakeholder and user satisfaction; (2) our organization has seen a reduction in the degree of complaints or claims from users; (3) employees in our organization have multiple skills that can be applied to tasks corresponding to other jobs.

3.4. Data Analysis

The study utilizes a partial least square (PLS) structural equation modeling approach—a variance-based, structural equation modeling (SEM)-based technique used to investigate theoretical models. This approach is widely used and accepted in management research [53,54]. PLS-SEM provides robust methods and techniques to assess the reliability and validity of both the outer and inner models of a theoretical construct [55]. The PLS algorithm further enables examining complex theoretical contrast and hypothesized relationships and offers the predictive power needed to predict the effect of corporate sustainability on firm performance whiles assessing the role of sustainability-oriented supplier partnership/network and green innovation capabilities. The PLS-SEM approach and techniques used in this study are in accordance with measures proposed by [53] and as used in the study conducted by [65]. The study utilized SmartPLS version 3.0 in performing related empirical analyses.

3.5. Results

3.5.1. Profile of Respondents

The study utilized data from 243 respondents selected from diverse actors in the manufacturing landscape. Basic information gathered from these individuals revealed that each respondent, on average, serves his or her organization for seven (7) years. These individuals are considered knowledgeable about the information, trends, and changes in the manufacturing ecosystem. Aside from work experience, the individuals surveyed had extensive education, and they had no issues understanding the questionnaire and related items. This, therefore, helps to eliminate any form of inconsistency in answering the questionnaire, which may result in invalid findings. Responses were solicited from diverse individuals from different industrial backgrounds. Respondents were selected from diverse sectors such as agro-processing, cement manufacturing, plastic manufacturing, and the beverage sector. These firms have existed for an average of over 5 years in their respective operations. However, it seems that some of these entities have existed for more than a decade and therefore are considered to be at the leading edge of the sustainability agenda. Table 1 outlines the profile of respondents.

Table 1.

Profile of respondents.

3.5.2. Descriptive Statistics

The distribution and characteristics of data are outlined in Table 2, including characteristics of data such as mean, standard deviation, kurtosis, and skewness. From the table, it can be seen that respondents, on average, agreed with the statement on the questionnaire. Further examination of the mean and skewness suggested the data had no issues of outliers and thereby required no data transformation.

Table 2.

Descriptive statistics.

3.5.3. Construct Reliability and Validity

The data acquired were tested for construct reliability and validity. The reliability and validity of data acquired were tested using approaches proposed by [66,67]. The construct reliability of data was tested using Cronbach’s alpha and composite reliability techniques. Construct reliability requirement of the data is satisfied because indicators examined obtained 0.7 or higher composite reliability value [68]. Furthermore, construct validity was examined using the average variance extracted approach. The accepted level of average variance extracted is 0.5 or greater. The latent variables observed obtained an average variance extracted (AVE) value greater than 0.5, indicating variables are valid for further analysis [68]. The outcomes of reliability and validity tests are presented in Table 3, Table 4 and Table 5.

Table 3.

Reliability and validity test results.

Table 4.

Discriminant validity.

Table 5.

Outer model.

To augment the validity of data acquired, discriminant validity was performed using discriminant validity as a benchmark, using the discriminant validity approach proposed by [68,69]. In examining discriminant validity, the study seeks to ascertain if latent variables that represent different theoretical viewpoints are statistically different from each other. Although the discriminant validity approach proposed by [68] offers specific insights into the validity of data, the approach is argued to lack sensitivity [70]. Therefore, that to ensure a robust discriminant validity test, [68] argue for the addition of a hetrotrai–monotrait ratio of correlations (HTMT). HTMT is a measure of similarity between latent variables. To establish discriminant validity, variables should have a value less than 1. The outcome of the discriminant test indicates the data acquired are valid and credible for further empirical analysis.

Aside from examining construct validity and reliability, the study examines the relationship between outer model variables and latent variables using indicator loading values as a measurement index. It is suggested that for indicators to be considered to have a high ability to measure the proposed construct, an outer model loading value of 0.5 or higher [66] must be obtained. Examining the outcome of such a test reveals that each indicator has a value either equal to or higher than 0.7, therefore satisfying model validity requirements.

3.5.4. Correlation Analysis

The liaison betwixt environmental sustainability, social sustainability, sustainable supply chain partnership, green innovation capabilities, and firm performance is examined by conducting a correlation test. It is critical to ascertain the connection between the latent variables and firm performance. Although correlation does not equal causality, it still provides some viable insights into the interrelationship between variables. Additionally, the correlation outcome enables the researcher to identify if there is the presence of multicollinearity [71]. The outcome of the study shows an inverse relationship between economic sustainability and environmental sustainability and social sustainability. In addition, all the independent variables examined for the study have some degree of relationship with firm performance (dependent variable). The result for the correlation test is presented in the Table 6 below.

Table 6.

Correlation test outcome.

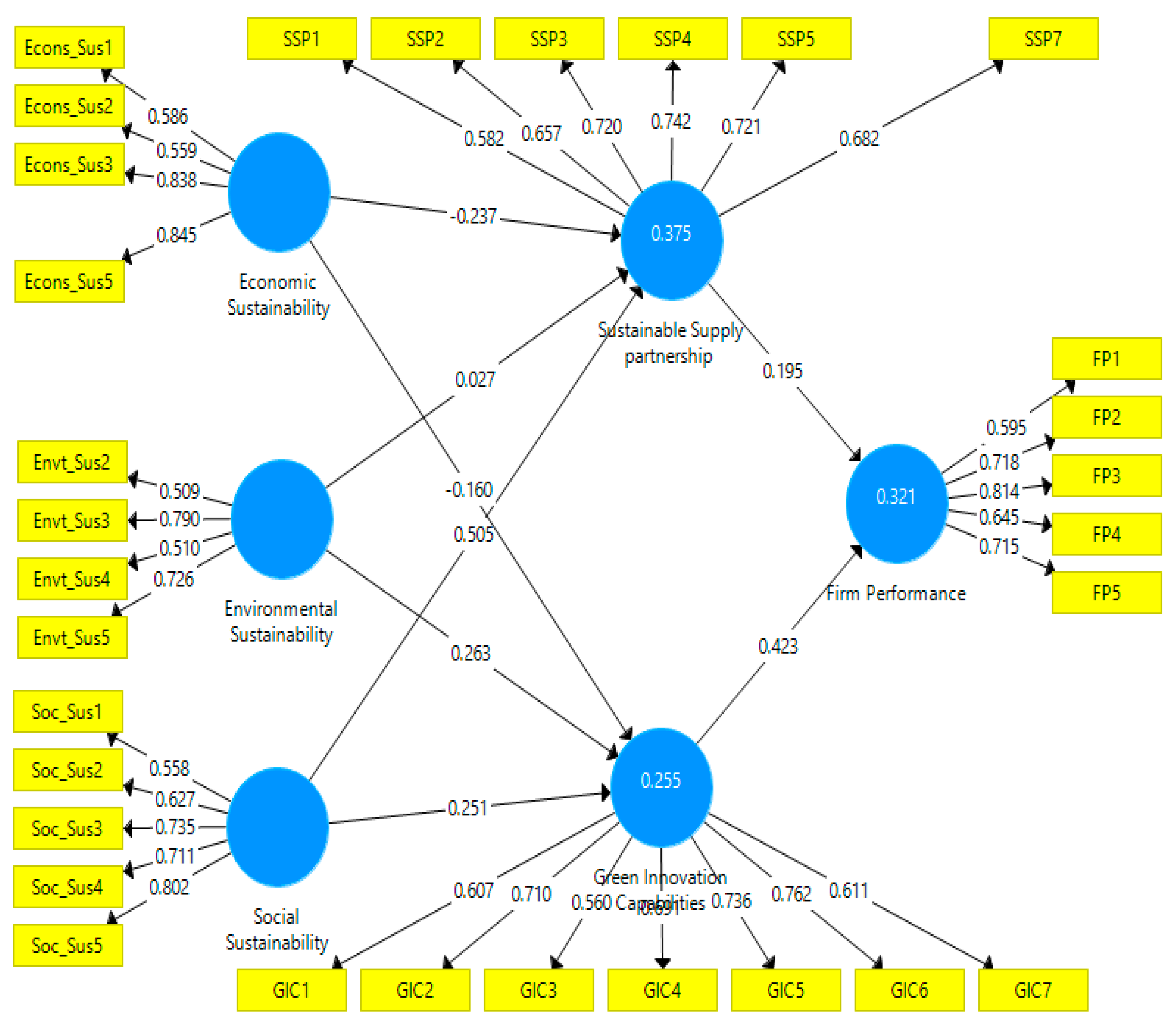

3.5.5. Structural Model Evaluation

The research probes into the influence of corporate sustainability on firm performance and the role of sustainable supplier partnership and green innovation capabilities of a firm. Corporate sustainability is measured in a multidimensional approach, such as environmental sustainability, economic sustainability, and social sustainability. To examine the structural model of the study, partial least square structural equation modeling is performed. The path analysis is conducted to ascertain the extent to which latent variables such as environmental sustainability, social sustainability, and economic sustainability impact sustainable supplier partnership and green innovation capabilities of a manufacturing firm. The path modeling or analysis is conducted following the techniques proposed by [66] and used in studies such as [67]. The outcome of the regression analysis indicates that although different facets of corporate sustainability have an impact on sustainable supplier partnership performance and green innovation capabilities of firms, it can be seen that social sustainability has a significant influence on sustainable supplier partnership and green innovation capabilities at regression coefficients of 0.505 and 0.251, respectively. The regression outcome on the extent of environmental sustainability, social sustainability, and economic sustainability affects the sustainability of supplier partnership of a manufacturing firm, and further, their green innovation capabilities indicate R2 values of 0.375 and 0.255, respectively. Interrogating the regression result indicates social sustainability is pivotal to the performance of a sustainable buyer–supplier network/partnership. However, there is an inverse relationship between economic sustainability and sustainable supplier partnership. The regression outcome indicates that when the level of economic sustainability in buyer–supplier partnership is high, the performance of buyer–supplier partnership is low, and vice versa. Economic asset in buyer–supplier sustainability partnership diminishes the relational outcome of the partnership. Comparatively, the environmental sustainability practice of firms contributes significantly towards green innovation capabilities of firms against the performance of the buyer–supplier sustainability partnership, judging by the regression coefficient between buyer–supplier sustainability partnership and firm performance being 0.195, and green innovation capabilities of firms and firm performance being 0.423. Overall, the variables had an R2 value of 0.321, indicating a percentage ratio of 32%. Although not a very high number, it still demonstrates that these variables can influence the performance of a firm, especially in the manufacturing sector, to a significant extent. The conclusion of the partial least square structural equation modeling is presented in Figure 1.

Figure 1.

Structural model.

3.5.6. Indirect Effect

The study went a step further to examine the indirect effect of buyer–supplier sustainability partnership on the rapport betwixt corporate sustainability scopes and firm performance. According to the outcome of the study, buyer–supplier sustainability partnership indirectly influences the positive liaison between facets of corporate sustainability and firm performance. However, the liaison betwixt environmental sustainability and firm performance is not indirectly influenced by buyer–supplier sustainability partnerships. On the side of green innovation capabilities, it has the ability to influence the rapport betwixt corporate sustainability dimensions (i.e., economic sustainability, environmental sustainability, and social sustainability) and organizational achievement. The conclusion of the indirect test is demonstrated in Table 7 below.

Table 7.

Indirect effect.

3.5.7. Hypotheses Testing

The study set out to examine eight (8) hypotheses. These hypotheses seek to examine the liaison betwixt corporate sustainability and firm performance. They further examine the role of green innovation capabilities and buyer–supplier sustainability partnership. The hypotheses are tested using the t-statistics test. Table 8 outlines the hypotheses test outcome. The benchmark threshold of 1.96 is used to ascertain whether to welcome or dismiss a particular hypothesis. Out of the eight (8) hypotheses, only one (1) is not supported by the research findings.

Table 8.

Hypotheses test outcome.

The resolution to welcome or dismiss particular hypotheses is based on the t-statistics value and p-value. Based on earlier assertion, they indicate that environmental sustainability has no positive relationship with buyer–supplier sustainability partnership. The findings support seven (7) out of the formulated eight (8) hypotheses.

4. Discussion and Implication

The research aims to contribute to the body of literature in the area of corporate sustainability and firm performance by examining the indirect effect of sustainability-oriented supplier partnership/network and green innovation capabilities. The research focuses on the manufacturing sector of Ghana. Firms within this sector are sampled for the study. Sampled firms come from an immense scope of industries spanning pharmaceutical to aluminum product manufacturing. Production activities of these firms impact directly on the environment and society as a whole. The effects of these activities have been a greater concern of government, regulators, and other civic society groups. The data acquired through a field survey are analyzed using partial least square structural equation modeling techniques. A reliability and validity test is conducted to assess the convergent validity of the measurement model. Initial assessment indicates the measurement and structural model is valid and satisfies benchmark indexes outlined as a dimension of this analytical approach. In addition to assessing the structural model, the hypotheses are examined using t-statistics values and p-values. The outcome of the test supports seven (7) out of eight (8) stated hypotheses. The outcome of the study indicates, with the exception of environmental sustainability practice, social and economic sustainability practice has a clear significance on sustainability-oriented supplier partnership or green supplier network. This is in contrast to studies that indicate the relevance of environmental sustainability practices and supply chain network performance. Integrating corporate sustainability practices into supply network sustainability goals and strategies enables one to develop and maintain a green core competence and green portfolio.

Leveraging external green-related knowledge and resources, organizations can enforce the adoption and implementation of sustainability practices. Nonetheless, it is fascinating to notice that environmental sustainability practices that are considered to contribute to the green performance of supplier networks have no effect in this case. The rationale for a low degree of relationship between environmental sustainability practices can be classified as (1) firms adhere to environmental sustainability requirements as a means to earn regulatory and compliance approvals; (2) firms involved in this study are mostly small and medium, with a few large enterprises that do not possess significant network power to dictate the pace at which other network members adopt and abide by sustainability frameworks. The continuous practice of diverse facets of corporate sustainability is found to influence the organization’s green innovation capabilities. Through the extensive and deliberate practice of sustainability, the organization realigns and reconfigures its resources and human capital to take significant advantage of knowledge and resources. Although firms’ innovativeness and competitive edge in most cases rest on the utilization of slack and external knowledge and resources, the availability of these resources alone cannot positively impact their innovation competence. An increase in the practices of sustainability would deliberately affect resource allocation and redistribution in an organization. Sustainability-oriented organizations would make a conscious effort to realign and repurpose their resource and human capital towards the development of green innovation capabilities and competitive advantage. Additionally, the findings of this study are no different. The outcome indicates that the practice of corporate sustainability has a direct and decisive impression on the green innovation capabilities of a firm. This finding supports findings unearthed by [12].

The study findings further revealed there is a clear liaison betwixt sustainability-oriented supply partnership and firm performance. It further emphasizes the positive effect of the green innovation capabilities of an enterprise on firm performance. Sustainability supplier partnership aside, offering firms the leverage to address sustainability issues across entire supply chain networks enables the facilitation of superior knowledge and information through the integration of vertical and horizontal network actors. Sustainable supplier network actors undertake deliberate efforts to ensure network actors adopt, integrate, and make sustainability practice a core foundation of corporate and business level strategy. Through reconfiguration and organization capabilities adjustments, firms are able to allocate significant resources to achieve a green, competitive advantage. Moreover, the firm makes a conscious effort to upgrade human capital and knowledge to boost its green resources. Having access to superior green knowledge and human capital has the propensity to boost the green innovation capabilities of a firm.

Examining the indirect effect reveals sustainability-oriented partnership and green innovation capabilities can indirectly influence the connection betwixt the facets of sustainability practice (economic, social, and environmental sustainability practices) and the performance of the firm. The outcome of the study indicates that sustainability supplier partners can positively influence the relationship between social sustainability practices and firm performances. However, it fails to influence the rapport betwixt environmental sustainability hones and economic sustainability hones and organizational achievement. The rationale for these happenings can be attributed to diverse factors, including the VUCA nature of the business environment within which firms operate and the additional network position of firms in their respective supply networks. Furthermore, the green innovation capabilities indirectly influence the positive and significant effect of economic sustainability practices, and social sustainability hones on firm performance. Regardless, it fails to impact the liaison betwixt environmental sustainability practices and firm performance. Firms must endeavor to continuously enrich their green innovation capabilities if they want to maintain their competitive advantage and growth in the business landscape.

Implication for Public Institutions

Inasmuch as the study highlights the implication for research and practice, it further provides insights into implications for public institutions to ensure the micro sustainability gains firms enjoy in industrial sectors translate into macro gains regarding sustainability outcomes. According to the findings of the study, corporate sustainability practices have a significant impact on the sustainability-oriented supplier partnership and green innovation capabilities of a firm. Therefore, it is prudent for regulatory stakeholders and public agencies to draft a collaboration framework to foster the transfer of information and superior knowledge to various expect of economy. Having in place a proper framework would serve as a guide to appropriate stakeholders such as regulatory institutions, civil society organisations service providers, heads and managers of organizations, purchasing officials, and the officials in charge of sustainability and climate change activities in public space.

The study advocate for continuous inter-sectoral education programs, conferences, and workshops to enable individuals to gain insights into the experience and expertise of sustainability professionals; collaboration is critical for achieving regulatory compliance—compliance management, in most cases, is at the purview of public institutions. In addition, the outcome can be adopted in the public sector to address issues of inefficiencies that negatively impact the sustainability outcome of such agencies. The study advocates for continuous interaction between parasternal departments and the private sector in the interest of citizens’ immediate and long-term welfare.

5. Conclusions and Further Research

The research aims to investigate the impact of corporate sustainability hones on firm performance by examining the indirect effect of sustainability-oriented supplier partnership and the green innovation capabilities of a firm. The data acquired to address the research question were collected from management personnel and officers in the Ghana manufacturing sector using a list provided by the Association of Ghana Industries. These firms were selected across multiple industries and can be classified as small, medium, and large enterprises, respectively. Data acquired were tested for convergent validity and construct reliability. The structural model was examined using partial least square structural equation modeling techniques. The outcome of the empirical study supports seven (7) out of eight (8) stated hypotheses. The outcome of the study indicates that sustainability-oriented supplier partnership indirectly influences the effect of social sustainability practices on a firm’s performance.

In the same view, the outcome revealed that a sustainability-oriented supplier partnership does not positively influence the liaison between environmental and economic sustainability practices and firm performance. In addition, the outcome revealed that green innovation capabilities indirectly influence the effect of social and economic sustainability honing on firm performance except for environmental sustainability and firm performance. Although the study makes some interesting input to the erudite work in the area of corporate sustainability, some shortcomings limit the generalization of research findings. Further research should be conducted using firms and informants outside the manufacturing sector to ascertain if findings cut across the diverse economic landscape. Although this study focuses on the non-financial performance of firms, it would be interesting to conduct a study that examines both financial and non-financial performance longitudinally. In addition, future studies should consider the effect of sustainability mobility coupled with other condition process variables to examine the effect of corporate sustainability practices on organizational performance.

Author Contributions

Writing of original draft, M.F.F.; conceptualization and supervision, Y.M.; conceptualization, revision, and editing, S.S.A.-Y.; data analysis and interpretation; M.A.H.; review and editing, M.A.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in this article.

Acknowledgments

The authors also thank the journal editor and anonymous reviewers for their guidance and constructive suggestions. We are also grateful to Margaret T. Frempong and Anthony Fosu for their support and advice.

Conflicts of Interest

The authors declare no potential conflict of interest with respect to the research, authorship, and/or publication of this article.

References

- Clayton, A.M.H.; Radcliffe, N.J. Sustainability: A Systems Approach, 1st ed.; Routledge: London, UK, 2018; pp. 221–245. [Google Scholar]

- Mindess, S. Sustainability of Concrete. In Developments in the Formulation and Reinforcement of Concrete, 2nd ed.; Woodhead Publishing: Cambridge, UK, 2019; pp. 3–17. [Google Scholar]

- Hisjam, M.; Guritno, A.D.; Supriyatno, N.; Tandjung, S.D. A Sustainable Partnership Model among Supply Chain Players in Wooden Furniture Industry Using Goal Programming. Agric. Agric. Sci. Procedia 2015, 3, 154–158. [Google Scholar] [CrossRef] [Green Version]

- Maignan, I.; Hillebrand, B.; McAlister, D.T. Managing Socially-Responsible Buying: How to Integrate Non-Economic Criteria into the Purchasing Process. Eur. Manag. J. 2002, 20, 641–648. [Google Scholar] [CrossRef]

- Annunziata, E.; Pucci, T.; Frey, M.; Zanni, L. The Role of Organizational Capabilities in Attaining Corporate Sustainability Practices and Economic Performance: Evidence from Italian Wine Industry. J. Clean. Prod. 2018, 171, 1300–1311. [Google Scholar] [CrossRef]

- Maji, S.G.; Laskar, N. Corporate Sustainability Performance and Firm Performance: Evidence from India and South Korea. Int. J. Corp. Strateg. Soc. Responsib. 2017, 1, 118. [Google Scholar] [CrossRef]

- Xiao, C.; Wang, Q.; van der Vaart, T.; van Donk, D.P. When Does Corporate Sustainability Performance Pay off? The Impact of Country-Level Sustainability Performance. Ecol. Econ. 2018, 146, 325–333. [Google Scholar] [CrossRef]

- Cheung, M.S.; Myers, M.B.; Mentzer, J.T. The Value of Relational Learning in Global Buyer-Supplier Exchanges: A Dyadic Perspective and Test of the Pie-Sharing Premise. Strateg. Manag. J. 2011, 32, 1061–1082. [Google Scholar] [CrossRef]

- Saelens, B.E.; Sallis, J.F.; Black, J.; Chen, D. Neighborhood Environment Walkability Survey (NEWS) & Neighborhood Environment Walkability Survey—NEWS-A. Meas. Instrum. Database Soc. Sci. 2003, 93, 1552–1558. [Google Scholar]

- Wang, F.; Chen, K. Do Product Imitation, and Innovation Require Different Patterns of Organizational Innovation? Evidence from Chinese Firms. J. Bus. Res. 2020, 106, 60–74. [Google Scholar] [CrossRef]

- Camisón, C.; Villar-López, A. Organizational Innovation as an Enabler of Technological Innovation Capabilities and Firm Performance. J. Bus. Res. 2014, 67, 2891–2902. [Google Scholar] [CrossRef]

- Aboelmaged, M.; Hashem, G. Absorptive Capacity and Green Innovation Adoption in SMEs: The Mediating Effects of Sustainable Organisational Capabilities. J. Clean. Prod. 2019, 220, 853–863. [Google Scholar] [CrossRef]

- Engert, S.; Rauter, R.; Baumgartner, R.J. Exploring the Integration of Corporate Sustainability into Strategic Management: A Literature Review. J. Clean. Prod. 2016, 112, 2833–2850. [Google Scholar] [CrossRef]

- Atkinson, G.; Dietz, S.; Neumayer, E. Handbook of Sustainable Development. In European Review of Agricultural Economics, 2nd ed.; Oxford University Press: Oxford, UK, 2007; Volume 42, pp. 535–537. [Google Scholar]

- Zimek, M.; Baumgartner, R.J. Corporate Sustainability Activities and Sustainability Performance of First and Second Order. In Proceedings of the 18th conference of the European Roundtable for Sustainable Consumption and Production Society (ERSCP 2017), Skiathos, Greece, 1–5 October 2017. [Google Scholar]

- Formentini, M.; Taticchi, P. Corporate Sustainability Approaches and Governance Mechanisms in Sustainable Supply Chain Management. J. Clean. Prod. 2016, 112, 1920–1933. [Google Scholar] [CrossRef] [Green Version]

- Bansal, P.; Song, H.C. Similar but Not the Same: Differentiating Corporate Sustainability from Corporate Responsibility. Acad. Manag. Ann. 2017, 11, 105–149. [Google Scholar] [CrossRef]

- Chesborugh, H.; Brunswicker, S. Managing Open Innovation in Large Firms, 1st ed.; Fraunhofer: Munich, Germany, 2013; pp. 6–44. [Google Scholar]

- Grusky, D.; Granovetter, M.S. The Strength of Weak Ties. In Inequality in the 21st Century, 1st ed.; Routledge: London, UK, 2018; pp. 249–252. [Google Scholar]

- Burt, R.S. Network-Related Personality and the Agency Question: Multirole Evidence from a Virtual World. Am. J. Sociol. 2012, 118, 543–591. [Google Scholar] [CrossRef] [Green Version]

- Kauser, S.; Shaw, V. The Influence of Behavioural and Organisational Characteristics on the Success of International Strategic Alliances. Int. Mark. Rev. 2004, 21, 17–52. [Google Scholar] [CrossRef]

- Lv, B.; Qi, X. Research on Partner Combination Selection of the Supply Chain Collaborative Product Innovation Based on Product Innovative Resources. Comput. Ind. Eng. 2019, 128, 245–253. [Google Scholar] [CrossRef]

- Shevtshenko, E.; Mahmood, K.; Karaulova, T. Enhancing the Partner Selection Process in a Sustainable Partner Network. IFAC-PapersOnLine 2019, 13, 2425–2430. [Google Scholar] [CrossRef]

- Demirkan, H.; Cheng, H.K. The Risk and Information Sharing of Application Services Supply Chain. Eur. J. Oper. Res. 2008, 187, 765–784. [Google Scholar] [CrossRef]

- Lee, L.H.; Wong, T.N.; Sun, Z. An Agent-Based Framework for Partner Selection with Sustainability Considerations. IFAC Proc. Vol. 2013, 46, 168–173. [Google Scholar] [CrossRef]

- Alvarez, G.; Pilbeam, C.; Wilding, R. Nestlé Nespresso AAA Sustainable Quality Program: An Investigation into the Governance Dynamics in a Multi-Stakeholder Supply Chain Network. Supply Chain Manag. 2010, 15, 165–182. [Google Scholar] [CrossRef]

- Mangla, S.K.; Sharma, Y.K.; Patil, P.P.; Yadav, G.; Xu, J. Logistics and Distribution Challenges to Managing Operations for Corporate Sustainability: Study on Leading Indian Diary Organizations. J. Clean. Prod. 2019, 238, 117620. [Google Scholar] [CrossRef]

- Kogg, B.; Mont, O. Environmental and Social Responsibility in Supply Chains: The Practise of Choice and Inter-Organisational Management. Ecol. Econ. 2012, 83, 154–163. [Google Scholar] [CrossRef]

- Klassen, R.D.; Vereecke, A. Social Issues in Supply Chains: Capabilities Link Responsibility, Risk (Opportunity), and Performance. Int. J. Prod. Econ. 2012, 140, 103–115. [Google Scholar] [CrossRef]

- Tidy, M.; Wang, X.; Hall, M. The Role of Supplier Relationship Management in Reducing Greenhouse Gas Emissions from Food Supply Chains: Supplier Engagement in the UK Supermarket Sector. J. Clean. Prod. 2016, 112, 3294–3305. [Google Scholar] [CrossRef] [Green Version]

- Cruz, J.M.; Wakolbinger, T. Multiperiod Effects of Corporate Social Responsibility on Supply Chain Networks, Transaction Costs, Emissions, and Risk. Int. J. Prod. Econ. 2008, 116, 61–74. [Google Scholar] [CrossRef]

- Golicic, S.L.; Smith, C.D. A Meta-Analysis of Environmentally Sustainable Supply Chain Management Practices and Firm Performance. J. Supply Chain Manag. 2013, 49, 78–95. [Google Scholar] [CrossRef]

- Das, D. The Impact of Sustainable Supply Chain Management Practices on Firm Performance: Lessons from Indian Organizations. J. Clean. Prod. 2018, 203, 179–196. [Google Scholar] [CrossRef]

- Laskar, N. Impact of Corporate Sustainability Reporting on Firm Performance: An Empirical Examination in Asia. J. Asia Bus. Stud. 2018, 12, 571–593. [Google Scholar] [CrossRef]

- Gupta, A.K.; Gupta, N. Effect of Corporate Environmental Sustainability on Dimensions of Firm Performance towards Sustainable Development: Evidence from India. J. Clean. Prod. 2020, 253, 119948. [Google Scholar] [CrossRef]

- Goyal, P.; Rahman, Z.; Kazmi, A.A. Corporate Sustainability Performance and Firm Performance Research: Literature Review and Future Research Agenda. Manag. Decis. 2013, 51, 361–379. [Google Scholar] [CrossRef]

- Linnenluecke, M.K.; Griffiths, A. Corporate Sustainability and Organizational Culture. J. World Bus. 2010, 45, 357–366. [Google Scholar] [CrossRef]

- Yang, Z.; Lin, Y. The Effects of Supply Chain Collaboration on Green Innovation Performance: An Interpretive Structural Modeling Analysis. Sustain. Prod. Consum. 2020, 23, 1–10. [Google Scholar] [CrossRef]

- Youn, S.; Yang, M.G.; Hong, P.; Park, K. Strategic Supply Chain Partnership, Environmental Supply Chain Management Practices, and Performance Outcomes: An Empirical Study of Korean Firms. J. Clean. Prod. 2013, 56, 121–130. [Google Scholar] [CrossRef]

- Chu, S.H.; Yang, H.; Lee, M.; Park, S. The Impact of Institutional Pressures on Green Supply Chain Management and Firm Performance: Top Management Roles and Social Capital. Sustainability 2017, 9, 764. [Google Scholar] [CrossRef] [Green Version]

- Ali, Z.; Gongbing, B.; Mehreen, A. Supply Chain Network and Information Sharing Effects of SMEs’ Credit Quality on Firm Performance: Do Strong Tie and Bridge Tie Matter? J. Ent. Inf. Manag. 2019, 32, 714–734. [Google Scholar] [CrossRef]

- Shin, N.; Park, S.H.; Park, S. Partnership-Based Supply Chain Collaboration: Impact on Commitment, Innovation and Firm Performance. Sustainability 2019, 11, 449. [Google Scholar] [CrossRef] [Green Version]

- Chen, I.J.; Paulraj, A. Understanding Supply Chain Management: Critical Research and a Theoretical Framework. Int. J. Prod. Res. 2004, 42, 131–163. [Google Scholar] [CrossRef]

- Kim, D.; Cavusgil, S.T.; Calantone, R.J. Information System Innovations, and Supply Chain Management: Channel Relationships and Firm Performance. J. Acad. Mark. Science. 2006, 34, 40–54. [Google Scholar] [CrossRef]

- Lii, P.; Kuo, F.I. Innovation-Oriented Supply Chain Integration for Combined Competitiveness and Firm Performance. Int. J. Prod. Econ. 2016, 174, 142–155. [Google Scholar] [CrossRef]

- Crowston, K.; Jullien, N.; Ortega, F. Sustainability of Open Collaborative Communities: Analyzing Recruitment Efficiency. Technol. Innov. Manag. Rev. 2013, 646, 1–7. [Google Scholar] [CrossRef]

- Sandler, T.; Hartley, K. Economics of Alliances: The Lessons for Collective Action. J. Econ. Lit. 2001, 39, 869–896. [Google Scholar] [CrossRef] [Green Version]

- Gulati, R. Network Location and Learning: The Influence of Network Resources and Firm Capabilities on Alliance Formation. Strateg. Manag. J. 1999, 20, 397–420. [Google Scholar] [CrossRef]

- Inkpen, A.C.; Tsang, E.W.K. Social Capital Networks and Transfer Knowledge. Acad. Manag. Rev. 2011, 30, 20. [Google Scholar] [CrossRef] [Green Version]

- Burt, R.S. The Network Structure of Social Capital. Res. Organ. Behav. 2000, 22, 345–423. [Google Scholar] [CrossRef]

- Krause, J.; Croft, D.P.; James, R. Social Network Theory in the Behavioural Sciences: Potential Applications. Behav. Ecol. Sociobiol. 2007, 62, 15–27. [Google Scholar] [CrossRef]

- Monga, C.; Lin, J.Y.; Lee, K.; Juma, C.; Mathews, J. Innovation Capabilities for Sustainable Development in Africa. In The Oxford Handbook of Africa and Economics, 1st ed.; Monga, C., Lin, J.Y., Eds.; Oxford University Press: Oxford, UK, 2014; Volume 2, pp. 551–580. [Google Scholar]

- Tseng, F.C.; Fan, Y.J. Exploring the Influence of Organizational Ethical Climate on Knowledge Management. J. Bus. Ethics 2011, 101, 325–342. [Google Scholar] [CrossRef]

- Weng, H.H.R.; Chen, J.S.; Chen, P.C. Effects of Green Innovation on Environmental and Corporate Performance: A Stakeholder Perspective. Sustainability 2015, 7, 4997–5026. [Google Scholar] [CrossRef] [Green Version]

- Zailani, S.; Govindan, K.; Iranmanesh, M.; Shaharudin, M.R.; Chong, Y.S. Green Innovation Adoption in Automotive Supply Chain: The Malaysian Case. J. Clean. Prod. 2015, 108, 1115–1122. [Google Scholar] [CrossRef]

- Krishnan, R.; Martin, X.; Noorderhaven, N. When Does Trust Matter? J. Acad. Manag. 2006, 49, 894–917. [Google Scholar] [CrossRef]

- Nunnally, J.C.; Bernstein, I.H. The Assessment of Reliability. J. Sci. Res. 1994, 3, 248–292. [Google Scholar]

- Aguirre-Urreta, M.I.; Hu, J. Detecting Common Method Bias, Performance of the Harman’s Single-Factor Test. J. Data Adv. Inf. Syst. 2019, 50, 45–70. [Google Scholar] [CrossRef]

- DeVellis, R.F. Scale Development: Theory and Applications, Applied Social Research Methods; Sage Publications: Thousand Oaks, CA, USA, 2003. [Google Scholar]

- Adebambo, H.; Ashari, N.; Nordin, N. An Empirical Study on the Influence of Sustainable Environmental Manufacturing Practice on Firm Performance. J. Sustain. Sci. Manag. 2015, 10, 42–51. [Google Scholar]

- Nastja, T.; Stefan, B.; Blaz, S. Corporate Sustainability and Economic Performance in Small and Medium Sized Enterprises. J. Clean. Prod. 2015, 108, 603–612. [Google Scholar]

- Baah, C.; Jin, Z. Sustainable Supply Chain Management and Organizational Performance: The Intermediary Role of Competitive Advantage. J. Manag. Sustain. 2019, 9, 119. [Google Scholar] [CrossRef] [Green Version]

- Kemp, R.; Pearson, P. MEI Project about Measuring Eco-Innovation. J. Sci. Technol. Inf. 2008, 2, 85–95. [Google Scholar]

- Bou-Llusar, J.C.; Camison-Zornoza, C.; Escrig-Tena, A.B. Measuring the Relationship between Firm Perceived Quality and Customer Satisfaction and its Influence on Purchase Intensions. Total Qual. Manag. 2001, 12, 719–734. [Google Scholar] [CrossRef]

- Albort-Morant, G.; Leal-Millán, A.; Cepeda-Carrión, G. The Antecedents of Green Innovation Performance: A Model of Learning and Capabilities. J. Bus. Res. 2016, 69, 4912–4917. [Google Scholar] [CrossRef]

- Hair, J.F.; Sarstedt, M.; Hopkins, L.; Kuppelwieser, V.G. Partial Least Squares Structural Equation Modeling (PLS-SEM): An Emerging Tool in Business Research. Eur. Bus. Rev. 2014, 26, 106–121. [Google Scholar] [CrossRef]

- Shmueli, G.; Sarstedt, M.; Hair, J.F.; Cheah, J.-H.; Ting, H.; Vaithilingam, S.; Ringle, C.M. European Journal of Marketing Predictive Model Assessment in PLS-SEM: Guidelines for Using PLSpredict Article Information. Eur. J. Mark. 2019, 53, 2322–2347. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A New Criterion for Assessing Discriminant Validity in Variance-Based Structural Equation Modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef] [Green Version]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Rönkkö, M.; Evermann, J. A Critical Examination of Common Beliefs About Partial Least Squares Path Modeling. Organ. Res. Methods 2013, 16, 425–448. [Google Scholar] [CrossRef]

- Nikolić, D.; Mureşan, R.C.; Feng, W.; Singer, W. Scaled Correlation Analysis: A Better Way to Compute a Cross-Correlogram. Eur. J. Neurosci. 2012, 35, 742–762. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).