Thermal-Energy Analysis and Life Cycle GHG Emissions Assessments of Innovative Earth-Based Bamboo Plastering Mortars

Abstract

:1. Introduction

2. Materials and Methods

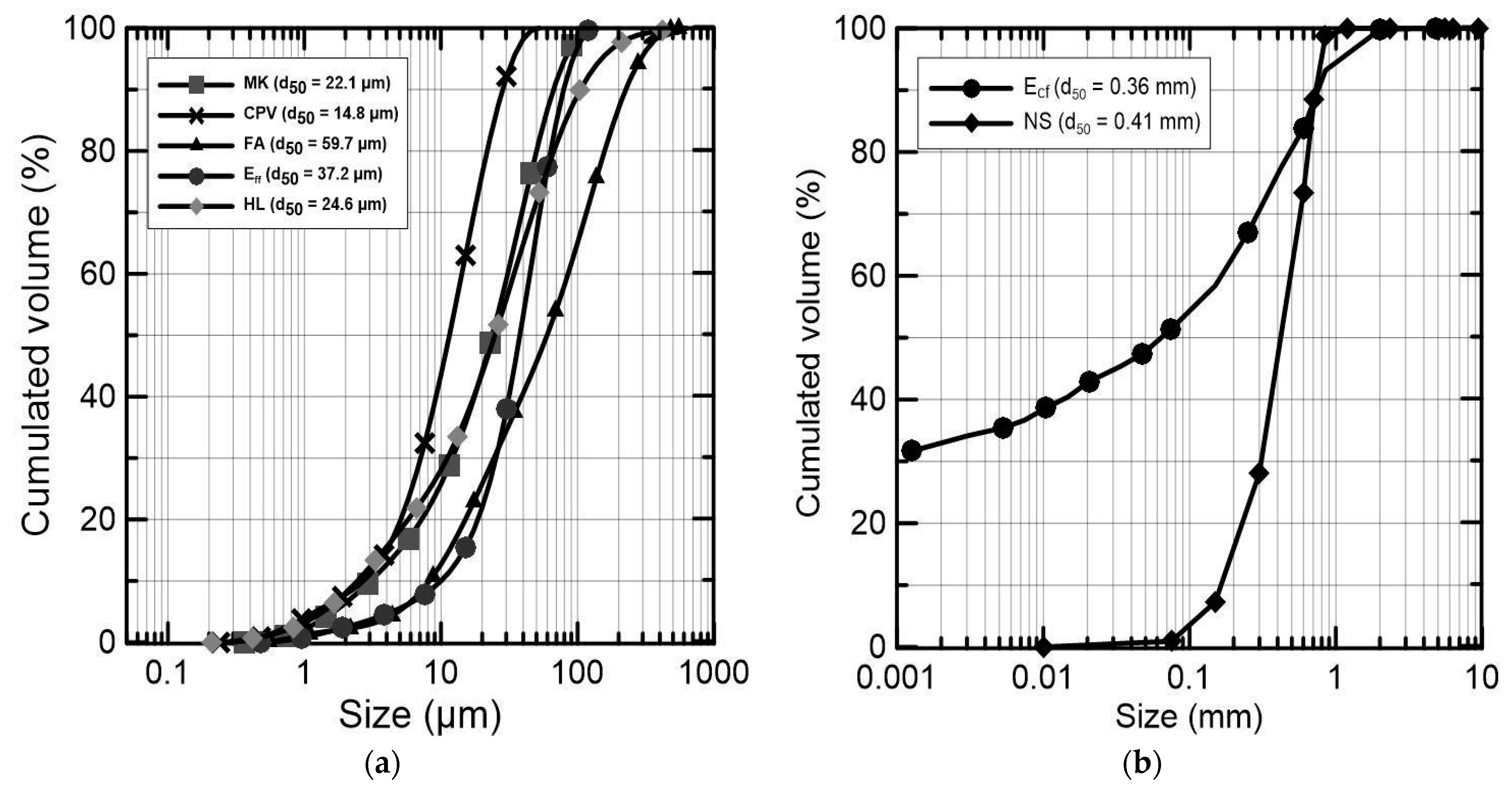

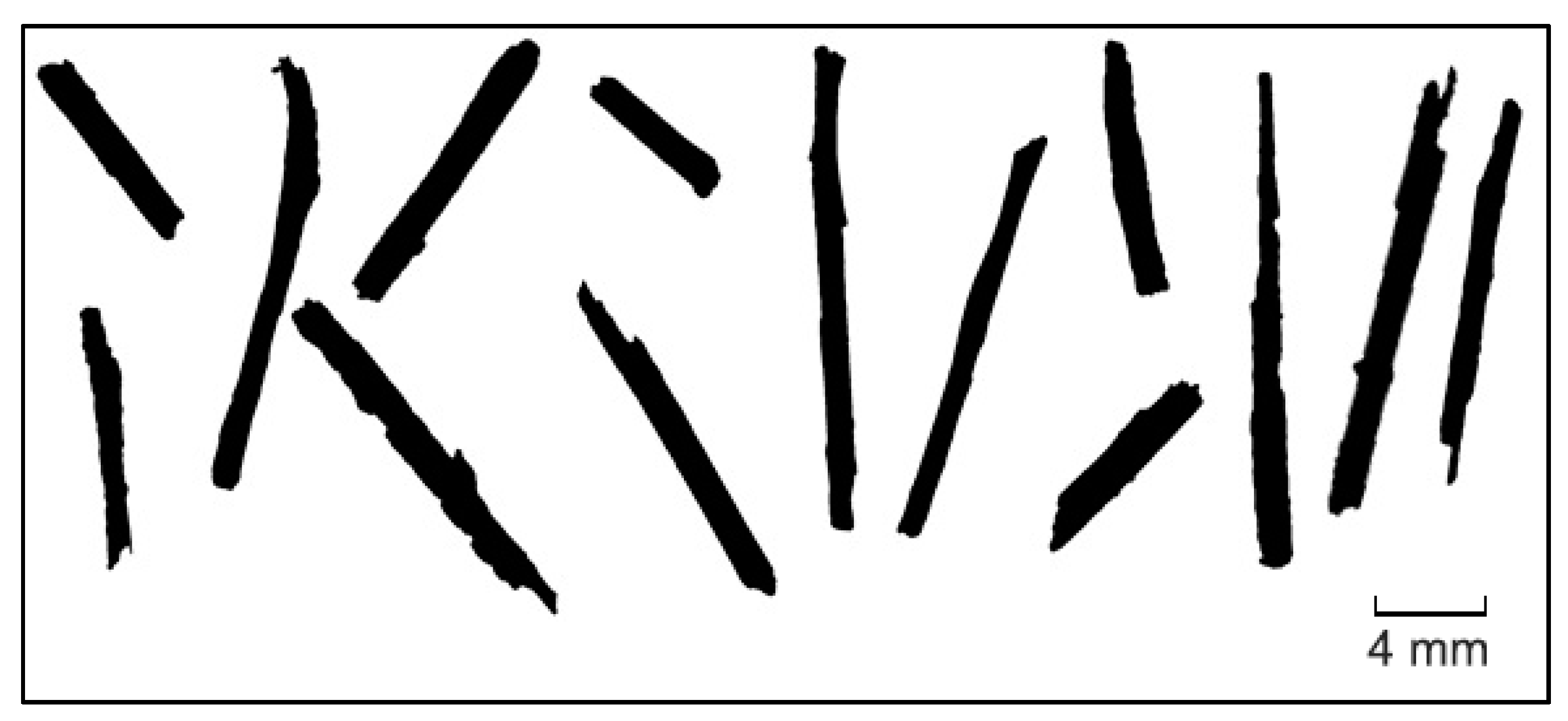

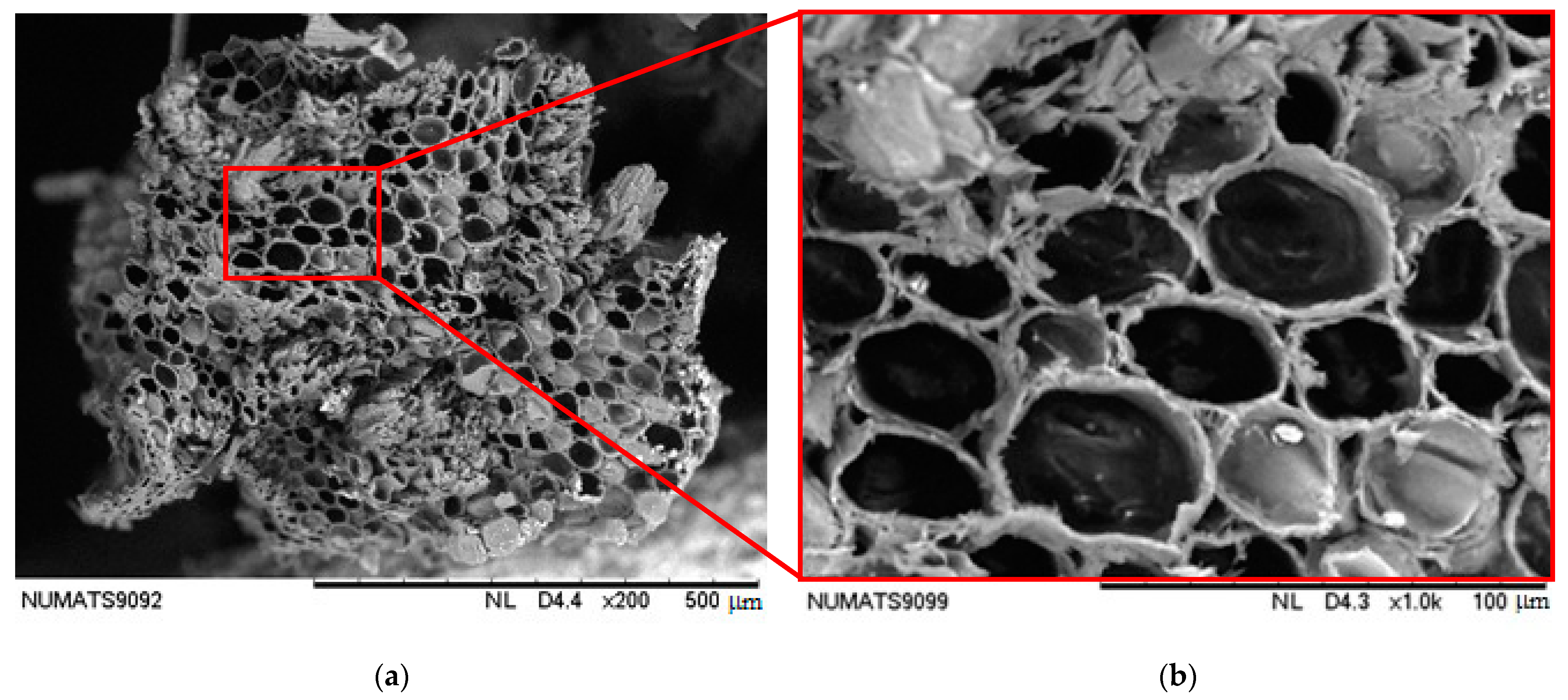

2.1. Materials

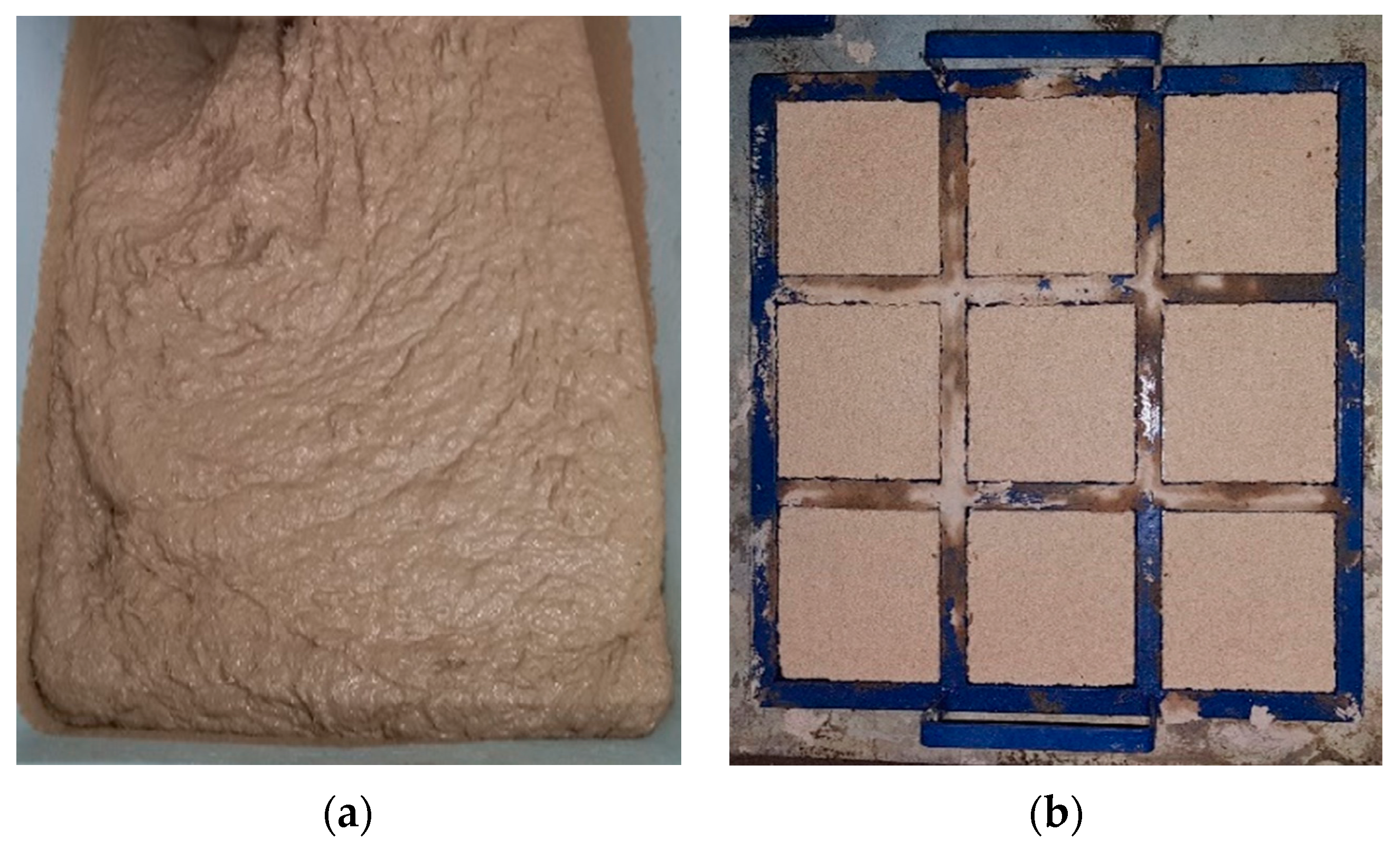

2.2. Mixture Proportions and Production

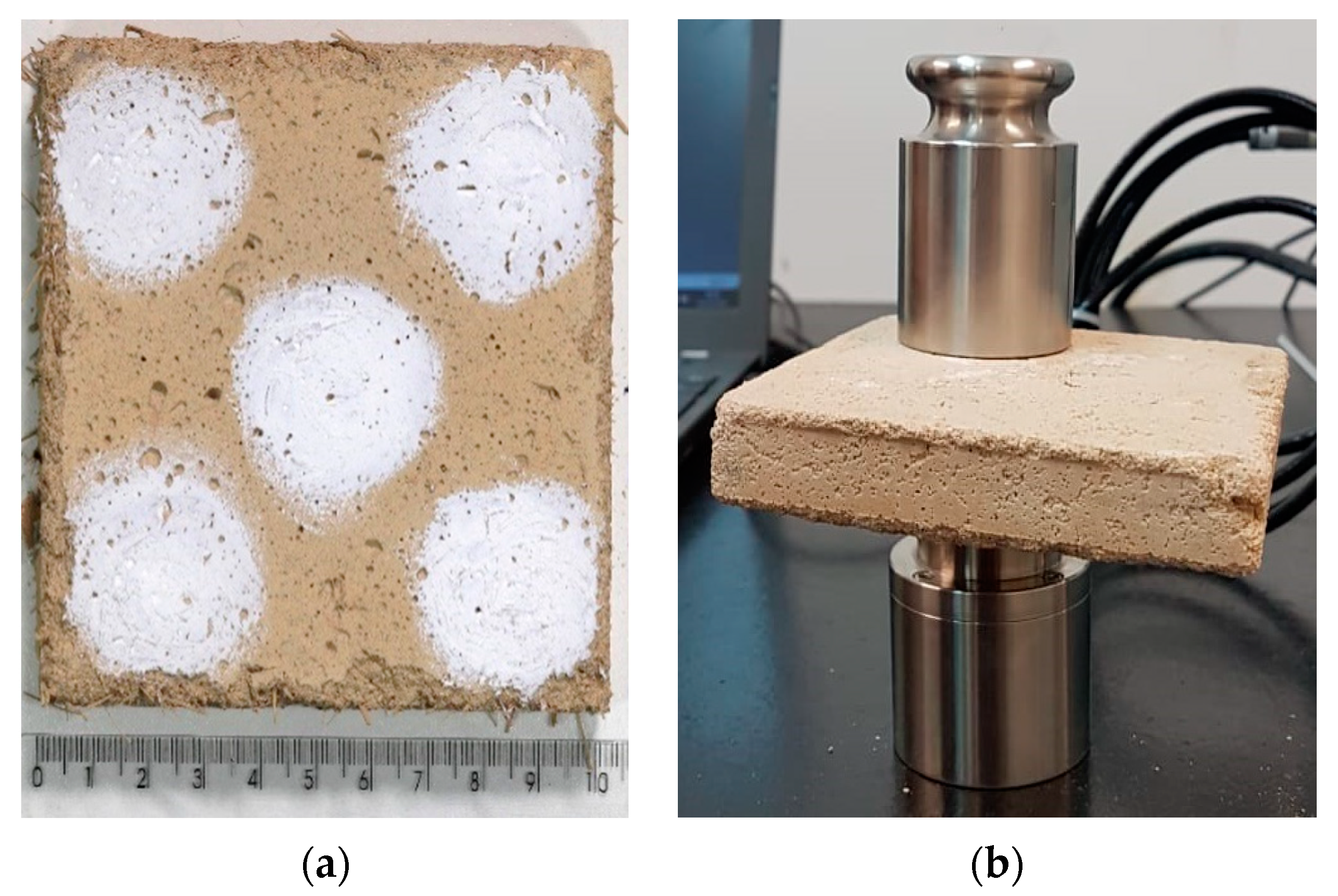

2.3. Characterization of the Mortar

2.4. Life Cycle GHG Emissions Assessment

2.4.1. Definition of the Objective, Scope, and Functional Unit

2.4.2. Life Cycle GHG Emissions Inventory

2.4.3. Bamboo Growth—Biogenic CO2

2.4.4. Carbonation

2.4.5. Sensitivity Analysis

- Service life of EMBs—considering two and three replacements. For the conventional mortar, just one replacement was considered during the building’s service life of 50 years;

- Electricity grid mix factor—minimum—EFmin—0.130 kgCO2-eq/kWh and maximum—EFmax—0.198 kgCO2-eq/kWh based on González-Mahecha et al. [44];

- Wall’s substrates—concrete wall (U-value of 4.4 W/m2·K) and concrete blocks masonry (U-value of 2.8 W/m2·K)

- Thickness of the plasters—3 and 5 cm;

- Two mixtures (in volume of cement: hydrated lime: sand) of cement-lime plasters—1:3:12 and 1:2:8.

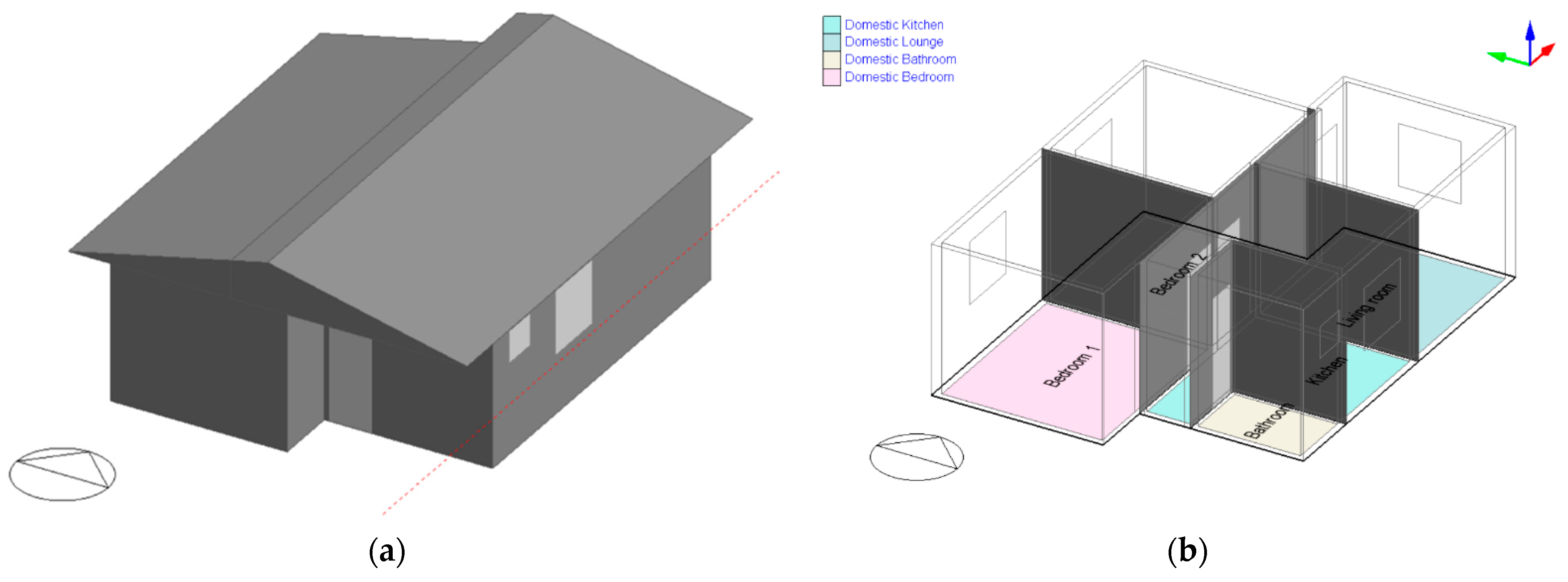

2.5. Thermal-Energy Simulation

3. Results

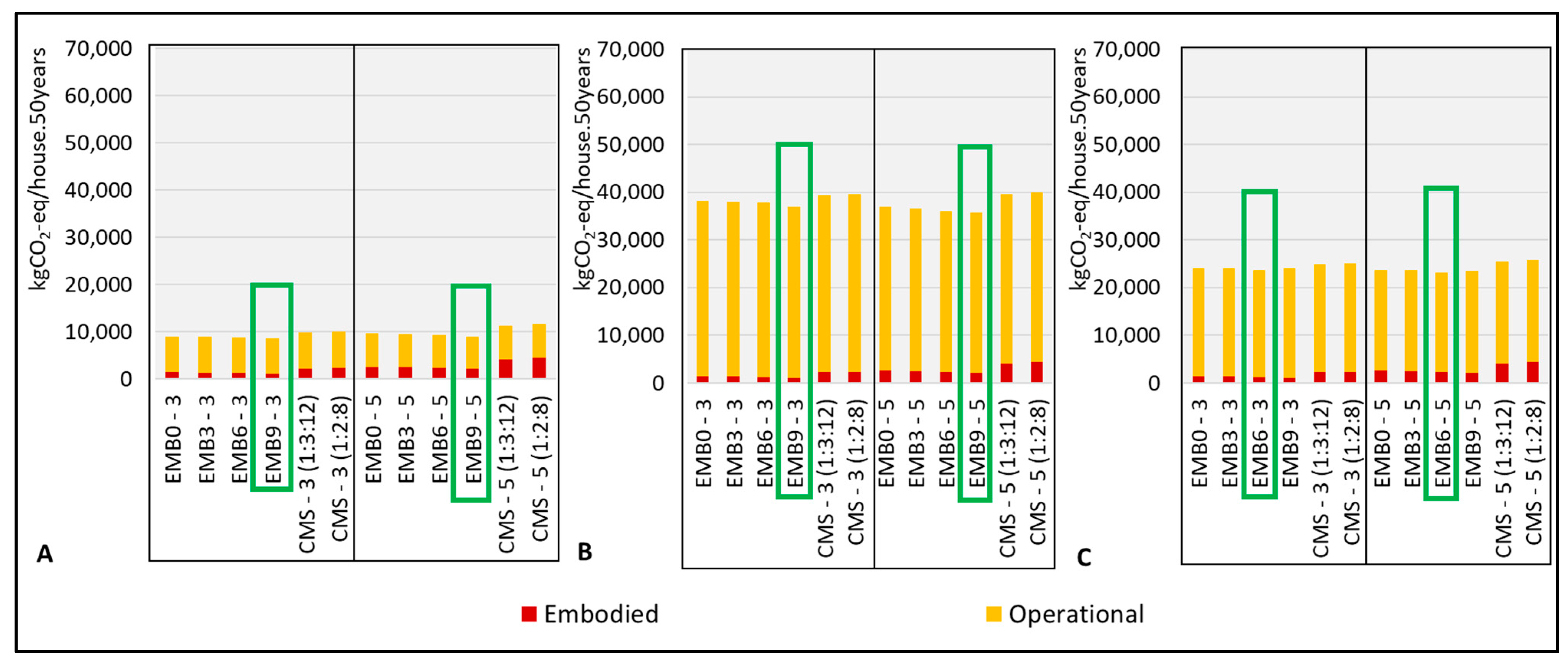

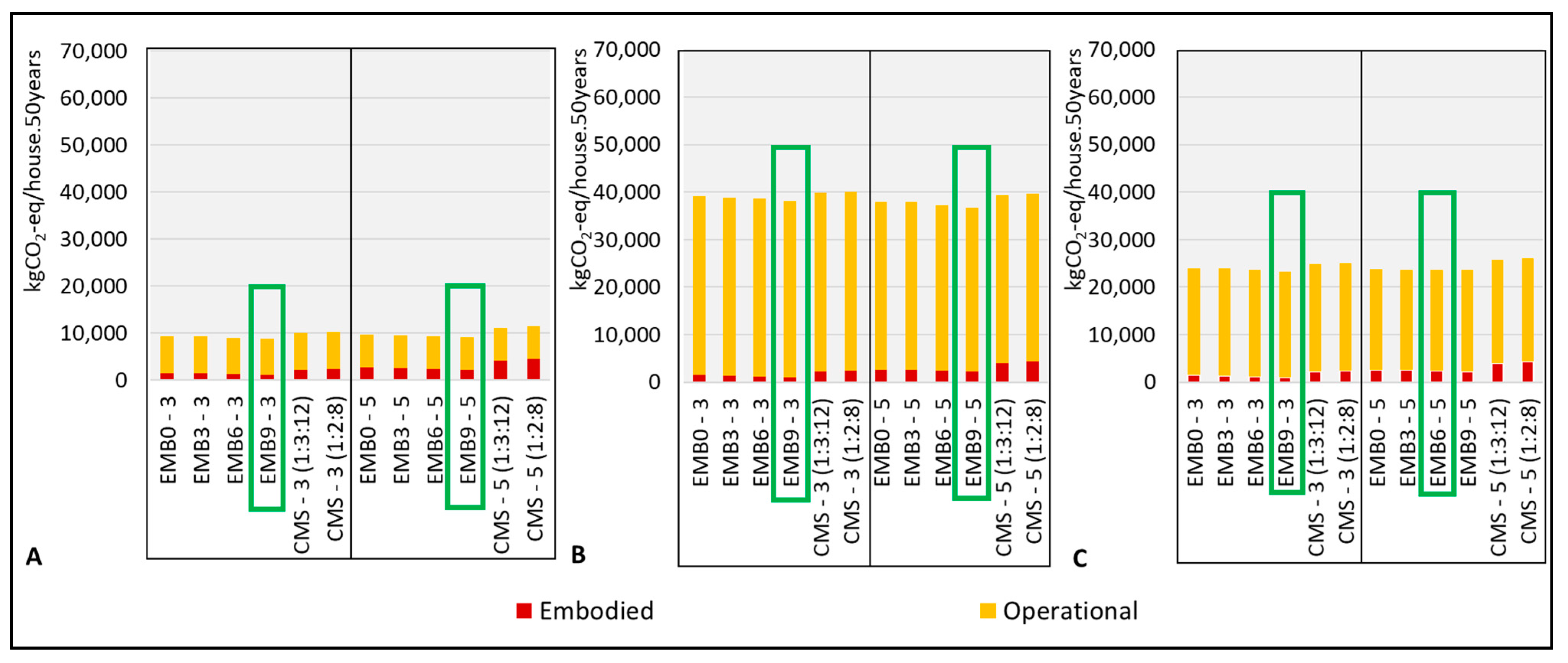

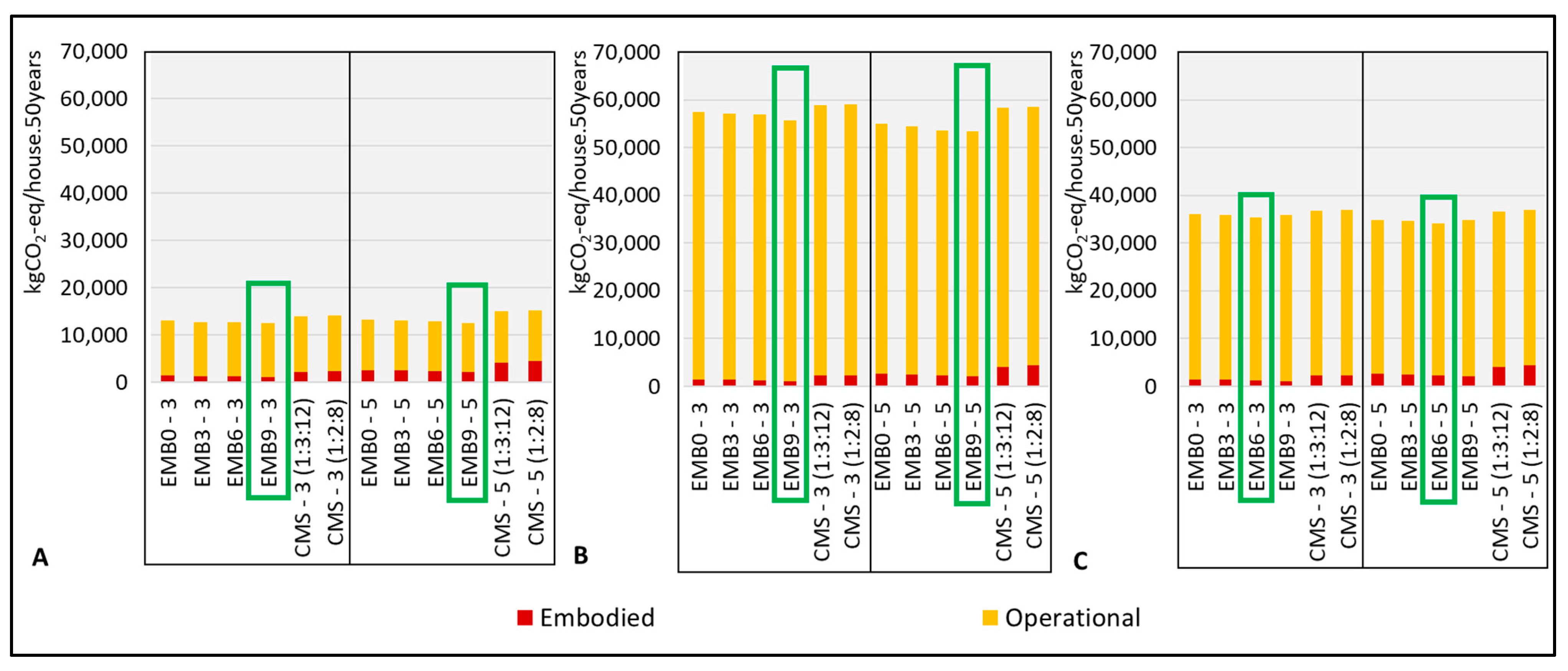

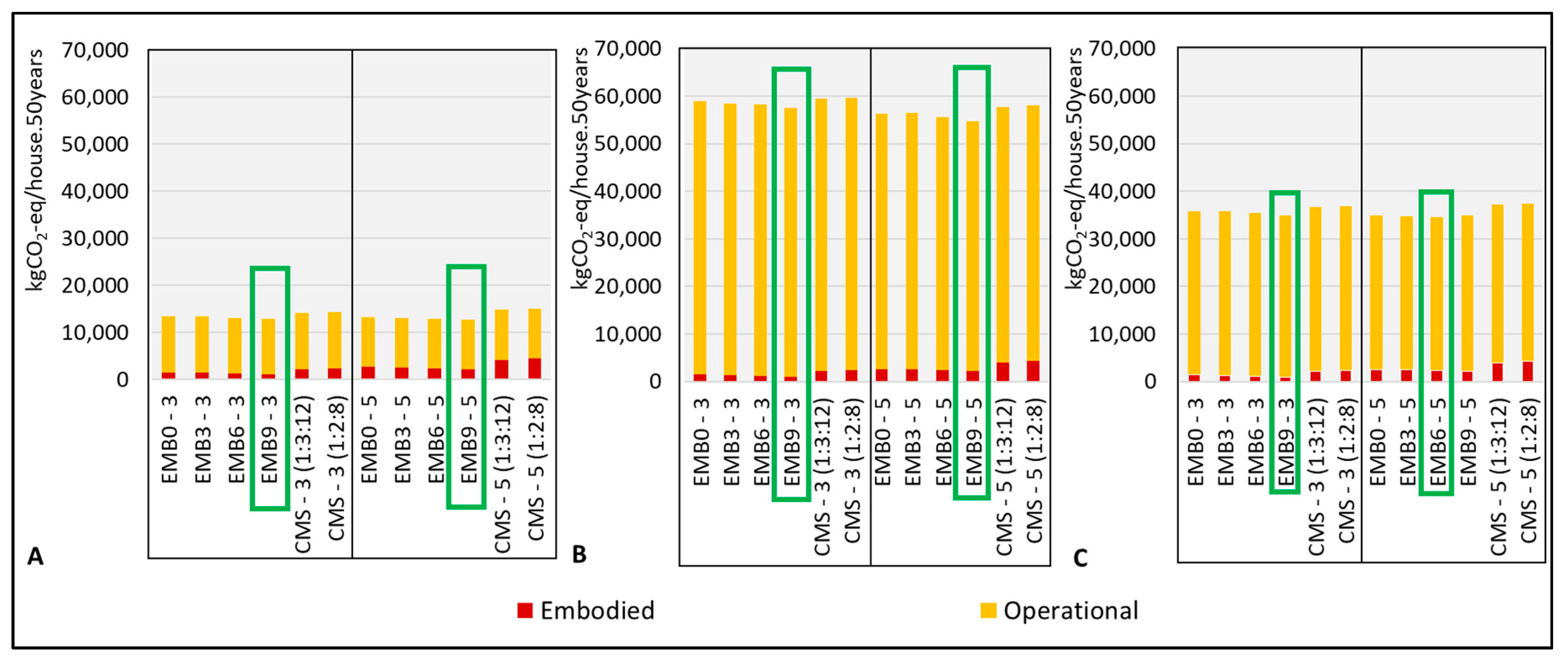

3.1. Total Life Cycle GHG Emissions

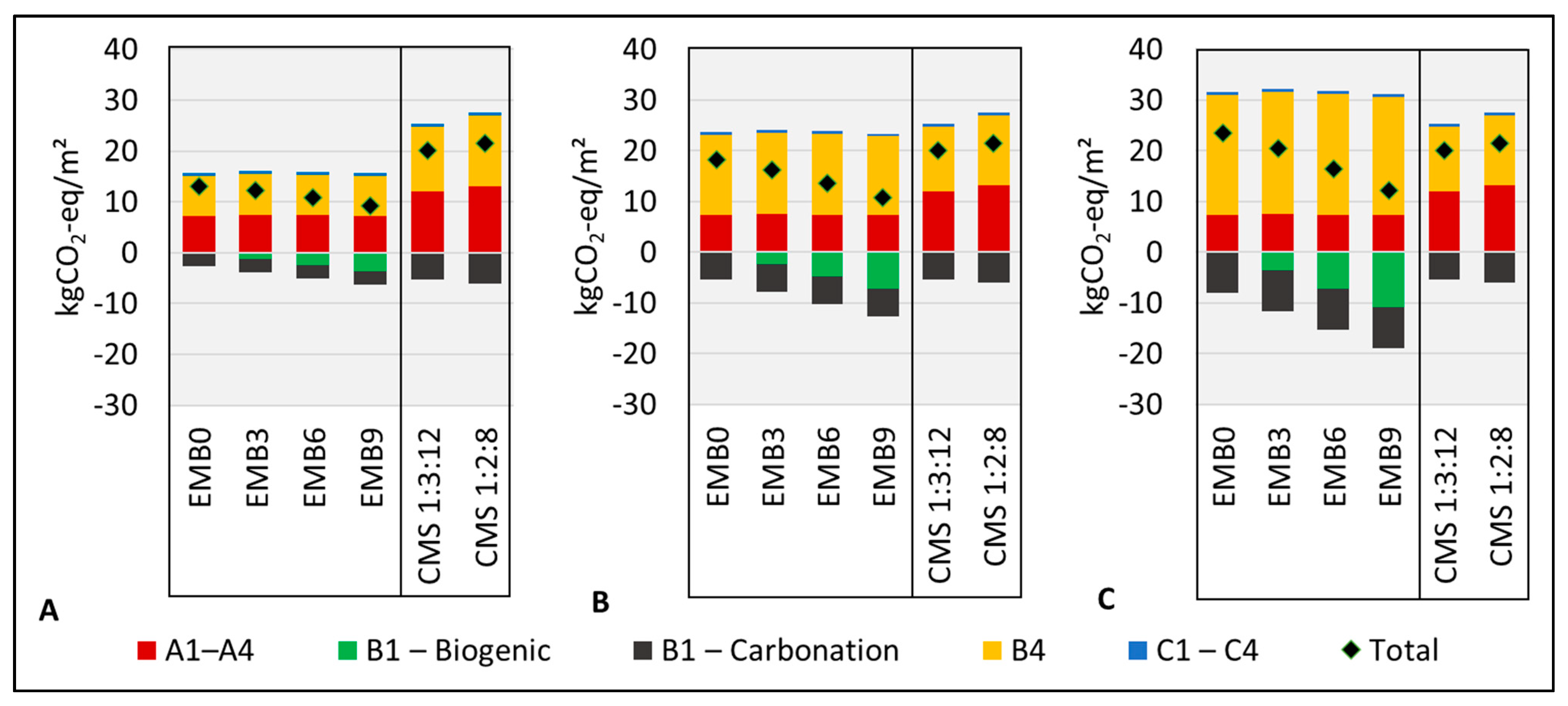

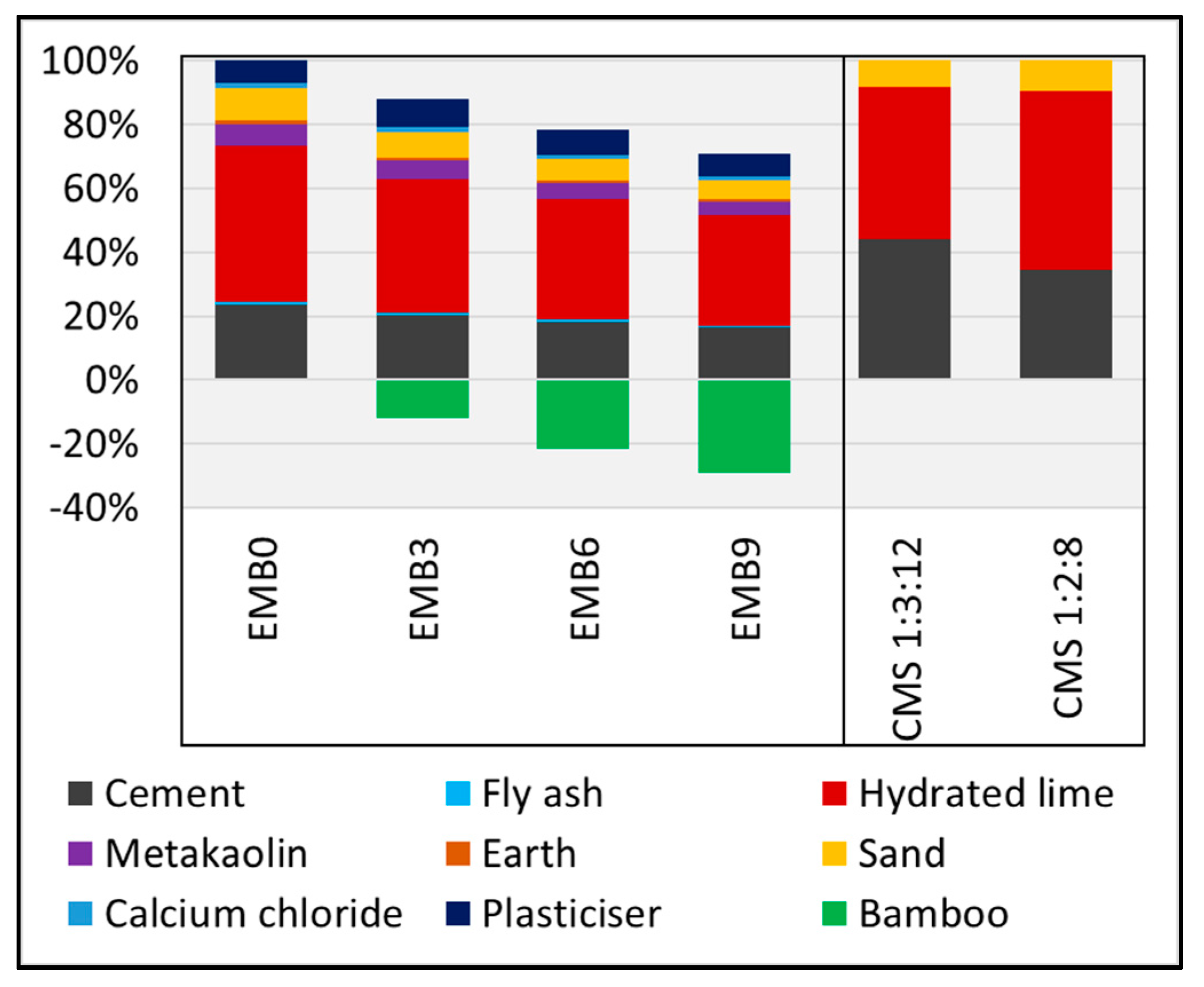

3.2. Embodied GHG Emissions

4. Discussion

5. Conclusions

- The insertion of different percentages of bamboo particles in the beneficial matrix provides a bulk density reduction, thermal conductivity, and an increase in specific heat as in earth mortar matrix thermal properties;

- The EMB shows a smaller carbon footprint than CMS, even when considering different replacement scenarios;

- The use of EMB improves the buildings’ thermal performance with lower energy consumption and GHG emissions;

- The increase of bamboo particles in EMB mixtures decreases its carbon footprint due to a higher carbon stock and a better thermal performance during building operation;

- The greater differences between EMB and CMS occur for the coldest city—Curitiba (temperate/mesothermal climates)—an influence of the higher participation of embodied GHG emissions;

- The number of mortar replacements severely affects the final results.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UNEP—United Nations Environment Programme. 2020 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; UNEP: Nairobi, Kenya, 2020. [Google Scholar]

- UNEP—United Nations Environment Programme. 2019 Global Status Report for Buildings and Construction. Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector; UNEP: Nairobi, Kenya, 2019; p. 41. ISBN 978-92-807-3768-4. Available online: https://www.unep.org/resources/publication/2019-global-status-report-buildings-and-construction-sector (accessed on 20 July 2021).

- IPCC —Intergovernmental Panel on Climate Change. Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Cambridge, UK, 2014; Volume 38. [Google Scholar]

- Cellura, M.; Ciulla, G.; Guarino, F.; Longo, S. Redesign of a rural building in a heritage site in Italy: Towards the Net Zero energy target. Buildings 2017, 7, 68. [Google Scholar] [CrossRef] [Green Version]

- Baglivo, C. Dynamic evaluation of the effects of climate change on the energy renovation of a school in a mediterranean climate. Sustainability 2021, 13, 6375. [Google Scholar] [CrossRef]

- Fang, Z.; Li, N.; Li, B.; Luo, G.; Huang, Y. The effect of building envelope insulation on cooling energy consumption in summer. Energy Build. 2014, 77, 197–205. [Google Scholar] [CrossRef]

- Del Rosario, P.; Palumbo, E.; Traverso, M. Environmental product declarations as data source for the environmental assessment of buildings in the context of level(S) and dgnb: How feasible is their adoption? Sustainability 2021, 13, 6143. [Google Scholar] [CrossRef]

- Michalak, J.; Czernik, S.; Marcinek, M.; Michalowski, B. Environmental burdens of external thermal insulation systems. Expanded polystyrene vs. mineral wool: Case study from Poland. Sustainability 2020, 12, 4532. [Google Scholar] [CrossRef]

- Sattler, S.; Österreicher, D. Assessment of sustainable construction measures in building refurbishment-life cycle comparison of conventional and Multi-Active Façade systems in a social housing complex. Sustainability 2019, 11, 4487. [Google Scholar] [CrossRef] [Green Version]

- Ashour, T.; Wieland, H.; Georg, H.; Bockisch, F.J.; Wu, W. The influence of natural reinforcement fibres on insulation values of earth plaster for straw bale buildings. Mater. Des. 2010, 31, 4676–4685. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Bodur, M.N.; Akca, E.; Kapur, S. Thermal isolation and mechanical properties of fibre reinforced mud bricks as wall materials. Constr. Build. Mater. 2007, 21, 901–906. [Google Scholar] [CrossRef]

- Colinart, T.; Vinceslas, T.; Lenormand, H.; De Menibus, A.H.; Hamard, E.; Lecompte, T. Hygrothermal properties of light-earth building materials. J. Build. Eng. 2020, 29, 101134. [Google Scholar] [CrossRef]

- Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Environmental impacts of natural and conventional building materials: A case study on earth plasters. J. Clean. Prod. 2014, 80, 179–186. [Google Scholar] [CrossRef]

- Gomes, M.I.; Faria, P.; Gonçalves, T.D. Earth-based mortars for repair and protection of rammed earth walls. Stabilization with mineral binders and fibers. J. Clean. Prod. 2018, 172, 2401–2414. [Google Scholar] [CrossRef] [Green Version]

- Palumbo, M.; McGregor, F.; Heath, A.; Walker, P. The influence of two crop by-products on the hygrothermal properties of earth plasters. Build. Environ. 2016, 105, 245–252. [Google Scholar] [CrossRef] [Green Version]

- Santos, T.; Faria, P.; Silva, V. Can an earth plaster be efficient when applied on different masonries? J. Build. Eng. 2019, 23, 314–323. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Petrella, A.; Boghetich, A.; Casavola, C.; Pappalettera, G. Hygrothermal properties of clayey plasters with olive fibers. Constr. Build. Mater. 2018, 158, 24–32. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.E.; Magniont, C.; Tribout, C.; Bertron, A. Plant aggregates and fibers in earth construction materials: A review. Constr. Build. Mater. 2016, 111, 719–734. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Luhar, S.; Cheng, T.W.; Luhar, I. Incorporation of natural waste from agricultural and aquacultural farming as supplementary materials with green concrete: A review. Compos. Part B Eng. 2019, 175, 107076. [Google Scholar] [CrossRef]

- Amziane, S.; Sonebi, M. Overview on bio-based building material made with plant aggregate Overview on bio-based building material made with plant aggregate. RILEM Tech. Lett. 2016, 1, 31–38. [Google Scholar] [CrossRef]

- Amziane, S.; Collet, F. Bio-Aggregates Based Building Materials: State-of-the-Art Report of the RILEM Technical Committee 236-BBM; Springer: Heidelberg, Germany, 2017; Volume 23, ISBN 978-94-024-1030-3. [Google Scholar]

- Caldas, L.R.; Saraiva, A.B.; Lucena, A.F.P.; Da Gloria, M.Y.; Santos, A.S.; Filho, R.D.T. Building materials in a circular economy: The case of wood waste as CO2-sink in bio concrete. Resour. Conserv. Recycl. 2021, 166. [Google Scholar] [CrossRef]

- Grazieschi, G.; Asdrubali, F.; Thomas, G. Embodied energy and carbon of building insulating materials: A critical review. Clean. Environ. Syst. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Aste, N.; Della, S.; Cinzia, T.; Rajendra, T.; Adhikari, S.; Rossi, C. Models for Sustainable Development in Emerging African Countries; Springer International Publishing: Heidelberg, Germany, 2020; ISBN 9783030333225. [Google Scholar]

- Faria, P. Argamassas de terra e cal—Características e campos de aplicação. In Proceedings of the V Jorn. FICAL—Fórum Ibérico Da Cal, Lisboa, Portugal, 23–25 May 2016; pp. 277–286, ISBN 978-972-49-2281-2. [Google Scholar]

- Parrella, V.F.; Molari, L. Building retrofitting system based on bamboo-steel hybrid exoskeleton structures: A case study. Sustainability 2021, 13, 5984. [Google Scholar] [CrossRef]

- Agliata, R.; Marino, A.; Mollo, L.; Pariso, P. Historic building energy audit and retrofit simulation with hemp-lime plaster-A case study. Sustainability 2020, 12, 4620. [Google Scholar] [CrossRef]

- Caniato, M.; D’Amore, G.K.O.; Kaspar, J.; Gasparella, A. Sound absorption performance of sustainable foam materials: Application of analytical and numerical tools for the optimization of forecasting models. Appl. Acoust. 2020, 161, 107166. [Google Scholar] [CrossRef]

- Caniato, M.; Cozzarini, L.; Schmid, C.; Gasparella, A. Acoustic and thermal characterization of a novel sustainable material incorporating recycled microplastic waste. Sustain. Mater. Technol. 2021, 28, e00274. [Google Scholar] [CrossRef]

- Binici, H.; Eken, M.; Dolaz, M.; Aksogan, O.; Kara, M. An environmentally friendly thermal insulation material from sunflower stalk, textile waste and stubble fibres. Constr. Build. Mater. 2014, 51, 24–33. [Google Scholar] [CrossRef]

- Quiñones-Bolaños, E.; Gómez-Oviedo, M.; Mouthon-Bello, J.; Sierra-Vitola, L.; Berardi, U.; Bustillo-Lecompte, C. Potential use of coconut fibre modified mortars to enhance thermal comfort in low-income housing. J. Environ. Manag. 2021, 277, 111503. [Google Scholar] [CrossRef] [PubMed]

- Salzer, C.; Wallbaum, H.; Ostermeyer, Y.; Kono, J. Environmental performance of social housing in emerging economies: Life cycle assessment of conventional and alternative construction methods in the Philippines. Int. J. Life Cycle Assess 2017, 22, 1785–1801. [Google Scholar] [CrossRef] [Green Version]

- da Gloria, M.Y.R.; Andreola, V.M.; dos Santos, D.O.J.; Pepe, M.; Toledo Filho, R.D. A comprehensive approach for designing workable bio-based cementitious composites. J. Build. Eng. 2021, 34, 101696. [Google Scholar] [CrossRef]

- Liu, P.; Zhou, Q.; Jiang, N.; Zhang, H.; Tian, J. Fundamental research on tensile properties of phyllostachys bamboo. Results Mater. 2020, 7, 100076. [Google Scholar] [CrossRef]

- Bahtiar, E.T.; Imanullah, A.P.; Hermawan, D.; Nugroho, N. Abdurachman Structural grading of three sympodial bamboo culms (Hitam, Andong, and Tali) subjected to axial compressive load. Eng. Struct. 2019, 181, 233–245. [Google Scholar] [CrossRef]

- Zea Escamilla, E.; Habert, G. Environmental impacts of bamboo-based construction materials representing global production diversity. J. Clean. Prod. 2014, 69, 117–127. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Grabois, T.M.; Caldas, L.R. An Experimental and Environmental Evaluation of Mortars with Recycled Demolition Waste from a Hospital Implosion in Rio de Janeiro. Sustainability 2020, 12, 8945. [Google Scholar] [CrossRef]

- Santos, T.; Almeida, J.; Silvestre, J.D.; Faria, P. Life cycle assessment of mortars: A review on technical potential and drawbacks. Constr. Build. Mater. 2021, 288, 123069. [Google Scholar] [CrossRef]

- Caldas, L.R.; Paiva, R.D.L.M.; de Martins, A.P.S.; Toledo Filho, R.D. Argamassas De Terra Versus Convencionais: Avaliação Do Desempenho Ambiental Considerando O Ciclo De Vida. Mix Sustentável 2020, 6, 115–128. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T. Embodied GHG emissions of buildings—The hidden challenge for effective climate change mitigation. Appl. Energy 2019, 258, 114107. [Google Scholar] [CrossRef]

- González Mahecha, R.E.; Caldas, L.R.; Garaffa, R.; Lucena, A.F.P.; Szklo, A.; Toledo Filho, R.D. Constructive systems for social housing deployment in developing countries: A case study using dynamic life cycle carbon assessment and cost analysis in Brazil. Energy Build. 2020, 227, 110395. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas. Soil Samples—Preparation for compactation and Characterization Tests; NBR. 6457; ABNT: Rio de Janeiro, Brazil, 1986. [Google Scholar]

- Associação Brasileira de Normas Técnicas. Aggregates—Sieve Analysis of Fine and Coarse Aggregates; NBR NM. 248; ABNT: Rio de Janeiro, Brazil, 2003. [Google Scholar]

- Restrepo, A.; Becerra, R.; Tibaquirá, J.E.G. Energetic and carbon footprint analysis in manufacturing process of bamboo boards in Colombia. J. Clean. Prod. 2016, 126, 563–571. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas. Fine Aggregate—Determination of the Bulk Specific Gravity and Apparent Specific Gravity; NBR NM 52; ABNT: Rio de Janeiro, Brazil, 2009. [Google Scholar]

- Associação Brasileira de Normas Técnicas. Coarse Aggregate—Determination of Total Moisture Content—Test Method; NBR 9939; ABNT: Rio de Janeiro, Brazil, 2011. [Google Scholar]

- American Association of State and Highway Transportation Officials. Method of Test for Determining Aggregate Shape Properties by Means of Digital Image Analysis; TP 81; AASHTO: Washington, DC, USA, 2017. [Google Scholar]

- Masad, E.A. Aggregate imaging system (AIMS): Basics and applications. Performing Organization Code Project 5-1707-01; Type Rep. Period Cover. Unclassif.; Texas Transportation Institute, Texas A & M University System: College Station, TX, USA, 2005; p. 58. [Google Scholar]

- Cirilo, F.; Melo, A.T.S. Comparativo de Desempenho Ambiental entre Argamassa Industrializada e Argamassa Virada em Obra; VI Congressso Brasileiro sobre Gestão do Ciclo de Vida: Brasilia, Brazil, 2018; p. 6. [Google Scholar]

- Caldas, L.R.; Carvalho, M.T.M.; Toledo Filho, R.D. Avaliação de estratégias para a mitigação dos impactos ambientais de revestimentos argamassados no Brasil. Ambient. Construído 2020, 20, 343–362. [Google Scholar] [CrossRef]

- ISO. 12571. Hygrothermal Performance of Building Materials and Products—Determination of Hygroscopic Sorption Properties; International Organization for Standardization: Geneva, Switzerland, 2013; p. 18. [Google Scholar]

- Rode, C.; Peuhkuri, R.H.; Hansen, K.K.; Time, B.; Svennberg, K.; Arfvidsson, J.; Ojanen, T. NORDTEST Project on Moisture Buffer Value of Materialsals. In Proceedings of the AIVC Conference ‘Energy Performance Regulation’: Ventilation in Relation to the Energy Performance of Buildings, Brussels, Belgium, 1 January 2005; pp. 47–52. [Google Scholar]

- Associação Brasileira de Normas Técnicas. Mortars Applied on Walls and Ceilings—Determination of the Specific Gravity in the Hardened Stage; NBR. 13280; ABNT: Rio de Janeiro, Brazil, 2005. [Google Scholar]

- C-THERM TECHNOLOGIES. Simplifying Thermal Conductivity (k)—Equipment Manual. Available online: https://ctherm.com/thermal-conductivity-instruments/tci-thermal-conductivity-analyzer/ (accessed on 30 July 2021).

- Paiva, R.L.M. Hygrothermal Properties, Biological Durability and Life Cycle Assessment of Earth Mortars with Bamboo Particles. Ph.D. Thesis, Federal University of Rio de Janeiro/PEC/COPPE, Rio de Janeiro, Brazil, 2020. Document in Portuguese. pp. 1–176. [Google Scholar]

- Savastano, H.J. Materiais à Base de Cimento Reforçado Com Fibra Vegetal: Reciclagem de Resíduos Para a Construção de Baixo Custo. Ph.D. Thesis, University of São Paulo, São Paulo, Brazil, 2000. Document in Portuguese. pp. 1–152. [Google Scholar]

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas. Thermal Performance in Buildings Part 2: Calculation Methods of Thermal Transmittance, Thermal Capacity, Thermal Delay and Solar Heat Factor of Elementes and Components of Buildings; NBR. 15220-2; ABNT: Rio de Janeiro, Brazil, 2005. [Google Scholar]

- ISO. 14040. Environmental Management–Life Cycle Assessment—Principles and Framework; European Committee for Standardization: Brussels, Belgium, 2006; p. 20. ISBN 0 580 48993 0. [Google Scholar]

- EN CEN. 15804:2012 + A2:2019—Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products; European Committee for Standardization: Brussels, Belgium, 2012; p. 72. [Google Scholar]

- Caldas, L.R.; Saraiva, A.B.; Andreola, V.M.; Dias Toledo Filho, R. Bamboo bio-concrete as an alternative for buildings’ climate change mitigation and adaptation. Constr. Build. Mater. 2020, 263, 120652. [Google Scholar] [CrossRef]

- PD CEN ISO/TS 14067. Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification and Communication; European Committee for Standardization: Brussels, Belgium, 2014; p. 52. [Google Scholar]

- Dolezal, F.; Hill, C.A.S.; Escamilla, E.Z. Comparative assessment for biogenic carbon accounting methods in carbon footprint of products: A review study for construction materials based on forest products. iForest 2017, 10, 815–823. [Google Scholar] [CrossRef] [Green Version]

- Guest, G.; Cherubini, F.; Strømman, A.H. Global Warming Potential of Carbon Dioxide Emissions from Biomass Stored in the Anthroposphere and Used for Bioenergy at End of Life. J. Ind. Ecol. 2012, 17, 20–30. [Google Scholar] [CrossRef]

- Pittau, F.; Krause, F.; Lumia, G.; Habert, G. Fast-growing bio-based materials as an opportunity for storing carbon in exterior walls. Build. Environ. 2018, 129, 117–129. [Google Scholar] [CrossRef]

- Lagerblad, B. Carbon Dioxide Uptake during Concrete Life Cycle: State of the Art; Swedish Cement and Concrete Research Institute: Stockholm, Sweden, 2005; ISBN 91-976070-0-2. [Google Scholar]

- Invidiata, A.; Ghisi, E. Impact of climate change on heating and cooling energy demand in houses in Brazil. Energy Build. 2016, 130, 20–32. [Google Scholar] [CrossRef]

- Triana, M.A.; Lamberts, R.; Sassi, P. Should we consider climate change for Brazilian social housing? Assessment of energy efficiency adaptation measures. Energy Build. 2018, 158, 1379–1392. [Google Scholar] [CrossRef] [Green Version]

- Hashemi, A. ScienceDirect Effects of thermal insulation on thermal comfort in low-income tropical housing. Energy Procedia 2017, 134, 815–824. [Google Scholar] [CrossRef] [Green Version]

- Rosse, L.; Yassin, M.; Da Gloria, R.; Pittau, F.; Maria, V.; Habert, G.; Toledo, R.D. Environmental impact assessment of wood bio-concretes: Evaluation of the influence of different supplementary cementitious materials. Constr. Build. Mater. 2021, 268, 121146. [Google Scholar] [CrossRef]

- Wang, Y.; Fukuda, H. Timber Chips as the Insulation Material for Energy Saving in Prefabricated Offices. Sustainability 2016, 8, 587. [Google Scholar] [CrossRef] [Green Version]

- Margani, G.; Evola, G.; Tardo, C.; Marino, E.M. Energy, Seismic, and Architectural Renovation of RC Framed Buildings with Prefabricated Timber Panels. Sustainability 2020, 12, 4845. [Google Scholar] [CrossRef]

- Valluzzi, M.R.; Saler, E.; Vignato, A.; Salvalaggio, M.; Croatto, G.; Dorigatti, G.; Turrini, U. Nested Buildings: An Innovative Strategy for the Integrated Seismic and Energy Retrofit of Existing Masonry Buildings with CLT Panels. Sustainability 2021, 13, 1188. [Google Scholar] [CrossRef]

- Tinsley, J.; Pavía, S. Thermal performance and fi tness of glacial till for rammed earth construction. J. Build. Eng. 2019, 24, 100727. [Google Scholar] [CrossRef]

- José, M.; Fiorito, F. Performance assessment of earth constructions under the Chilean energy rating system software. Procedia Eng. 2017, 180, 502–509. [Google Scholar] [CrossRef]

- Palme, M.; Guerra, J.; Alfaro, S. Thermal Performance of Traditional and New Concept Houses in the Ancient Village of San Pedro De Atacama and Surroundings. Sustainability 2014, 6, 3321–3337. [Google Scholar] [CrossRef] [Green Version]

- Bahramian, M.; Yetilmezsoy, K. Life cycle assessment of the building industry: An overview of two decades of research (1995–2018). Energy Build. 2020, 219, 109917. [Google Scholar] [CrossRef]

- Santos, T.; Nunes, L.; Faria, P. Production of eco-efficient earth-based plasters: Influence of composition on physical performance and bio-susceptibility. J. Clean. Prod. 2018, 167, 55–67. [Google Scholar] [CrossRef] [Green Version]

- WBCSD. Decarbonizing Construction—Guidance for Investors and Developers to Reduce Embodied Carbon; WBCSD: Geneva, Switzerland, 2021; p. 76. [Google Scholar]

- Caldas, L.R.; Toledo Filho, R.D. Avaliação do Ciclo de Vida de materiais cimentícios utilizados no Brasil: Estudo para o bloco de concreto e diferentes argamassas. LALCA Rev. Latino-Americana Avaliação Ciclo Vida 2019, 2, 34–61. [Google Scholar] [CrossRef]

- Qin, J.; Jiang, J.; Tao, Y.; Zhao, S.; Zeng, W.; Shi, Y.; Lu, T.; Guo, L.; Wang, S.; Zhang, X.; et al. Sunlight tracking and concentrating accelerated weathering test applied in weatherability evaluation and service life prediction of polymeric materials: A review American Society of Testing Materials. Polym. Test. 2021, 93, 106940. [Google Scholar] [CrossRef]

- Silva, A.; Brito, J. De Service life of building envelopes: A critical literature review. J. Build. Eng. 2021, 44, 102646. [Google Scholar] [CrossRef]

- Gursel, A.P.; Maryman, H.; Ostertag, C. A life-cycle approach to environmental, mechanical, and durability properties of “green” concrete mixes with rice husk ash. J. Clean. Prod. 2016, 112, 823–836. [Google Scholar] [CrossRef]

- Petek Gursel, A.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Gettu, R.; Patel, A.; Rathi, V.; Prakasan, S.; Basavaraj, A.S.; Palaniappan, S.; Maity, S. Influence of supplementary cementitious materials on the sustainability parameters of cements and concretes in the Indian context. Mater. Struct. Constr. 2019, 52, 10. [Google Scholar] [CrossRef]

- Paiva, R.L.M.; Martins, A.P.S.; Caldas, L.R.; Reales, O.A.M.; Filho, R.D.T. Earth-based mortars: Mix design, mechanical characterization and environmental performance assessment. In Proceedings of the 4th International Conference on Bio-Based Building Materials (ICBBM 2021), Barcelona, Spain, 16–18 June 2021; pp. 362–367. [Google Scholar]

- Caldas, L.R.; Toledo Filho, R.D. Avaliação ambiental do sistema construtivo de alvenaria de blocos de solo-cimento considerando diferentes especificações de projeto. Gestão Tecnol. Proj. 2021, 16, 149–172. [Google Scholar] [CrossRef]

- Arrigoni, A.; Beckett, C.T.S.; Ciancio, D.; Pelosato, R.; Dotelli, G.; Grillet, A.C. Rammed Earth incorporating Recycled Concrete Aggregate: A sustainable, resistant and breathable construction solution. Resour. Conserv. Recycl. 2018, 137, 11–20. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Earth construction: Lessons from the past for future eco-efficient construction. Constr. Build. Mater. 2012, 29, 512–519. [Google Scholar] [CrossRef] [Green Version]

| Hydrated Lime (HL) | Portland Cement (CPV) | Metakaolin (MK) | Fly Ash (FA) | Earth (E) | |

|---|---|---|---|---|---|

| True Density (kg/m3) | 2530 | 3010 | 2690 | 1940 | 2680 |

| Oxide composition by mass (wt.%) | |||||

| CaO | 64.66 | 57.04 | 0.14 | 1.81 | 3.99 |

| SiO2 | 3.09 | 22.06 | 44.90 | 52.33 | 51.30 |

| Al2O3 | - | 10.44 | 44.42 | 33.15 | 26.07 |

| Fe2O3 | 0.33 | 1.73 | 4.88 | 4.82 | 10.76 |

| SO3 | 0.61 | 3.87 | 1.45 | 1.86 | 1.27 |

| K2O | 0.30 | 0.54 | 1.42 | 3.46 | 4.41 |

| MgO | 30.97 | - | - | - | - |

| Sc2O3 | - | 3.58 | - | - | - |

| TiO2 | - | - | 1.37 | 1.14 | 1.75 |

| P2O5 | - | - | 0.93 | 0.76 | - |

| EMB | NS | BP | Wt | SP |

|---|---|---|---|---|

| EMB0 | 1149.65 | - | 306.57 | 9.23 |

| EMB3 | 1070.15 | 15 | 319.06 | 13.85 |

| EMB6 | 990.65 | 30 | 328.31 | 13.85 |

| EMB9 | 911.15 | 45 | 337.57 | 13.85 |

| Mortar | Bulk Density (ρb) | Thermal Conductivity (k) | Specific Heat (Sh) |

|---|---|---|---|

| (kg/m³) | (W/m·K) | (J/kg·K) | |

| EMB0 | 1704.13 ± 1.26 | 0.62 ± 0.07 | 897.37 ± 13.26 |

| EMB3 | 1634.72 ± 0.50 | 0.55 ± 0.10 | 910.68 ± 14.86 |

| EMB6 | 1529.67 ± 0.71 | 0.49 ± 0.08 | 967.00 ± 15.82 |

| EMB9 | 1471.80 ± 0.77 | 0.43 ± 0.15 | 1003.34 ± 14.16 |

| CMS | 1465.48 ± 0.52 | 0.94 ± 0.10 | 1164.87 ± 25.59 |

| Wall Substrate | Options 1 | Total Wall Thickness (mm) | U-Value (W/m2·K) | Thermal Capacity (kJ/m2·K) |

|---|---|---|---|---|

| Concrete wall | EMB0—3 | 13 | 3.62 | 285.88 |

| EMB3—3 | 13 | 3.55 | 284.66 | |

| EMB6—3 | 13 | 3.47 | 284.38 | |

| EMB9—3 | 13 | 3.36 | 284.30 | |

| CMS—3 | 13 | 3.86 | 291.21 | |

| EMB0—5 | 15 | 3.25 | 316.46 | |

| EMB3—5 | 15 | 3.14 | 314.44 | |

| EMB6—5 | 15 | 3.04 | 313.96 | |

| EMB9—5 | 15 | 2.91 | 313.84 | |

| CMS—5 | 15 | 3.56 | 325.35 | |

| Concrete block masonry | EMB0—3 | 17 | 2.65 | 204.18 |

| EMB3—3 | 17 | 2.61 | 202.96 | |

| EMB6—3 | 17 | 2.56 | 202.68 | |

| EMB9—3 | 17 | 2.51 | 202.60 | |

| CMS—3 | 17 | 2.77 | 209.51 | |

| EMB0—5 | 19 | 2.44 | 234.76 | |

| EMB3—5 | 19 | 2.38 | 232.74 | |

| EMB6—5 | 19 | 2.32 | 232.26 | |

| EMB9—5 | 19 | 2.24 | 232.14 | |

| CMS—5 | 19 | 2.62 | 243.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paiva, R.d.L.M.; Caldas, L.R.; Martins, A.P.d.S.; de Sousa, P.B.; de Oliveira, G.F.; Toledo Filho, R.D. Thermal-Energy Analysis and Life Cycle GHG Emissions Assessments of Innovative Earth-Based Bamboo Plastering Mortars. Sustainability 2021, 13, 10429. https://doi.org/10.3390/su131810429

Paiva RdLM, Caldas LR, Martins APdS, de Sousa PB, de Oliveira GF, Toledo Filho RD. Thermal-Energy Analysis and Life Cycle GHG Emissions Assessments of Innovative Earth-Based Bamboo Plastering Mortars. Sustainability. 2021; 13(18):10429. https://doi.org/10.3390/su131810429

Chicago/Turabian StylePaiva, Rayane de Lima Moura, Lucas Rosse Caldas, Adriana Paiva de Souza Martins, Patricia Brandão de Sousa, Giulia Fea de Oliveira, and Romildo Dias Toledo Filho. 2021. "Thermal-Energy Analysis and Life Cycle GHG Emissions Assessments of Innovative Earth-Based Bamboo Plastering Mortars" Sustainability 13, no. 18: 10429. https://doi.org/10.3390/su131810429

APA StylePaiva, R. d. L. M., Caldas, L. R., Martins, A. P. d. S., de Sousa, P. B., de Oliveira, G. F., & Toledo Filho, R. D. (2021). Thermal-Energy Analysis and Life Cycle GHG Emissions Assessments of Innovative Earth-Based Bamboo Plastering Mortars. Sustainability, 13(18), 10429. https://doi.org/10.3390/su131810429