Exploring Barriers for Circularity in the EU Furniture Industry

Abstract

:1. Introduction

2. Literature Review

2.1. Circular Economy

2.2. Circularity in the Furniture Industry

2.3. Barriers for the Transition to Circularity

- Policy barriers and challenges (in Araujo Galvão et al. [69] labeled “Policy and Regulatory”): Barriers or challenges that result from the policies or behavior of public institutions, including regulatory barriers.

- Market barriers and challenges (in Araujo Galvão et al. [69] labeled “Customer”): Barriers or challenges that result from customer behavior and market preferences.

- Value chain barriers and challenges (in Araujo Galvão et al. [69] not addressed): Barriers or challenges that result from the drivers and dependencies for circularity in the supply chain or value chain

- Technology barriers and challenges (in Araujo Galvão et al. [69] labeled “Technological”): Barriers and challenges of technological nature, including the availability of technologies for recovery of materials.

- Resources barriers and challenges (in Araujo Galvão et al. [69] partly addressed as “Social”): Barriers or challenges related to the organization’s human resources and their competences.

- Awareness barriers and challenges (in Araujo Galvão et al. [69] addressed as “Managerial”): Barriers or challenges resulting from the company’s leadership’s motivation for and stimulation of circularity.

- Business case barriers and challenges (in Araujo Galvão et al. [69] partly addressed as “Financial/Economic”): Barriers or challenges resulting from the balance between costs and benefits of circularity.

3. Research Strategy

3.1. Q-Methodology

- 1.

- Determining the viewpoints on the topic studied (Concours);

- 2.

- Reducing the statements into a manageable set (Q-Set);

- 3.

- Determining participants (P-Set);

- 4.

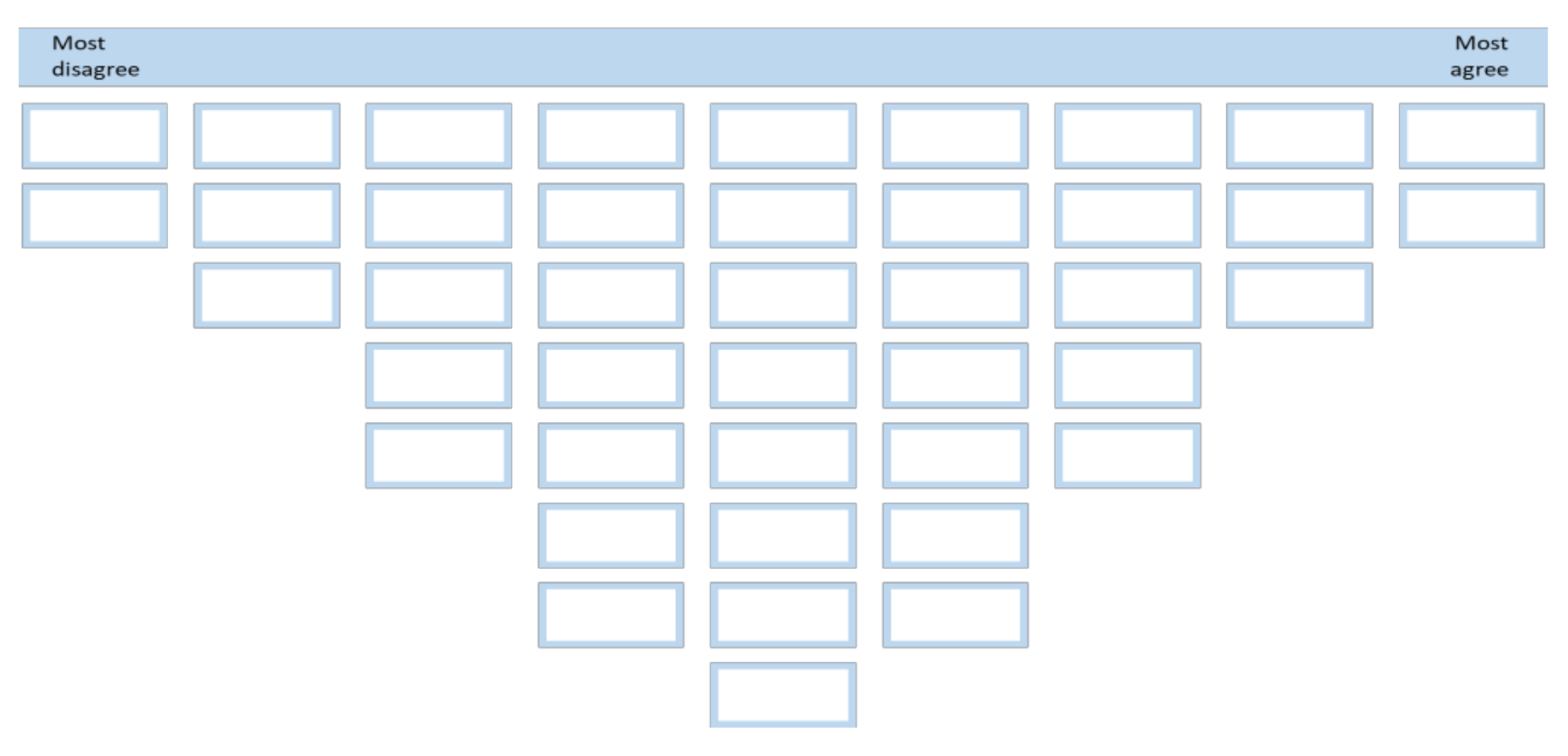

- Sorting the set according to the degree of their agreement with the statements (Q-Sorting);

- 5.

- Analysis and description of the factors found.

3.2. Concours

3.3. Q-Set

3.4. Participants

3.5. Q-Sorting

3.6. Analysis

4. Findings

4.1. Factor Analysis

4.2. Analysing the Factors

4.3. Analysing the Patterns of Barriers

4.3.1. Pattern 1

4.3.2. Pattern 2

4.3.3. Pattern 3

4.3.4. Pattern 4

4.4. Most versus Least Consensus Statements

4.5. Further Analysis

5. Discussion

5.1. Key Findings

- Policy: Barriers or challenges that result from the policies or behavior of public institutions, including regulatory barriers.

- Market: Barriers or challenges that result from customer behavior and market preferences.

- Value chain: Barriers or challenges that result from the drivers and dependencies for circularity in the supply chain or value chain.

- Technology: Barriers and challenges of technological nature, including the availability of technologies for recovery of materials.

- Resources: Barriers or challenges related to the organization’s human resources and their competences.

- Awareness: Barriers or challenges resulting from the company’s leadership’s motivation for and stimulation of circularity.

- Business case: Barriers or challenges resulting from the balance between costs and benefits of circularity.

- Pattern 1. Companies that are well aware of the need to change to circularity, but experience a lack of resources as their main barrier.

- Pattern 2. Companies that experience mostly the policy and business case categories of barriers, such as a high required investment without stimulating subsidies or policies.

- Pattern 3. Companies that experience mostly market related barriers, potentially as a result of competing mainly on price.

- Pattern 4. Companies that experience mostly organization internal, technology, and awareness related barriers.

5.2. Theoretical Contribution and Novelty

5.3. Managerial Implications

6. Conclusions

Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dyllick, T.; Hockerts, K. Beyond the business case for corporate sustainability. Bus. Strategy Environ. 2002, 11, 130–141. [Google Scholar] [CrossRef]

- Meadows, D.H.; Meadows, D.L.; Randers, J.; Behrens, W.W. The Limits to Growth; Universe Books: New York, NY, USA, 1972. [Google Scholar]

- Global Footprint Network World Footprint. 2020. Available online: https://www.footprintnetwork.org/our-work/ecological-footprint/ (accessed on 1 March 2020).

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Homrich, A.; Galvão, G.; Abadia, L.; Carvalho, M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the circular economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef] [Green Version]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- De Jesus, A.; Antunes, P.; Santos, R.; Mendonça, S. Eco-innovation in the transition to a circular economy: An analytical literature review. J. Clean. Prod. 2018, 172, 2999–3018. [Google Scholar] [CrossRef]

- Seuring, S.; Gold, S. Sustainability management beyond corporate boundaries: From stakeholders to performance. J. Clean. Prod. 2013, 56, 1–6. [Google Scholar] [CrossRef]

- Skene, K.R. Circles, spirals, pyramids and cubes: Why the circular economy cannot work. Sustain. Sci. 2018, 13, 479–492. [Google Scholar] [CrossRef]

- European Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. 2008. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008L0098&from=EN (accessed on 22 November 2016).

- Lacy, P.; Rutqvist, J. Waste to Wealth: The Circular Economy Advantage; Palgrave Macmillan: London, UK, 2016. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving’leapfrog development’. Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. [Google Scholar] [CrossRef]

- Preston, F. A Global Redesign? Shaping the Circular Economy; Chatham House: London, UK, 2012. [Google Scholar]

- Van Eik, F. Barriers & Drivers towards a Circular Economy, Acceleratio. 2016. Available online: https://circulareconomy.europa.eu/platform/en/knowledge/barriers-drivers-towards-circular-economy (accessed on 13 April 2021).

- Ritzén, S.; Sandström, G.Ö. Barriers to the circular economy—Integration of perspectives and domains. Procedia CIRP 2017, 64, 7–12. [Google Scholar] [CrossRef]

- Franco, M.A. Circular economy at the micro level: A dynamic view of incumbents’ struggles and challenges in the textile industry. J. Clean. Prod. 2017, 168, 833–845. [Google Scholar] [CrossRef]

- Ormazabal, M.; Prieto-Sandoval, V.; Puga-Leal, R.; Jaca, C. Circular Economy in Spanish SMEs: Challenges and opportunities. J. Clean. Prod. 2018, 185, 157–167. [Google Scholar] [CrossRef]

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: Current awareness, challenges and enablers. Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro de Oliveira, F.; França, S.L.B.; Rangel, L.A.D. Challenges and opportunities in a circular economy for a local productive arrangement of furniture in Brazil. Resour. Conserv. Recycl. 2018, 135, 202–209. [Google Scholar] [CrossRef]

- Jaeger, B.; Upadhyay, A. Understanding barriers to circular economy: Cases from the manufacturing industry. J. Enterp. Inf. Manag. 2020, 33, 729–745. [Google Scholar] [CrossRef]

- Upadhyay, A.; Laing, T.; Kumar, V.; Dora, M. Exploring barriers and drivers to the implementation of circular economy practices in the mining industry. Resour. Policy 2021, 72, 102037. [Google Scholar] [CrossRef]

- Fonseca, L.M.; Domingues, J.P.; Pereira, M.T.; Martins, F.F.; Zimon, D. Assessment of Circular Economy within Portuguese Organizations. Sustainability 2018, 10, 2521. [Google Scholar] [CrossRef] [Green Version]

- García-Quevedo, J.; Jové-Llopis, E.; Martínez-Ros, E. Barriers to the circular economy in European small and medium-sized firms. Bus. Strategy Environ. 2020, 29, 2450–2464. [Google Scholar] [CrossRef]

- De Jesus, A.; Mendonça, S. Lost in Transition? Drivers and Barriers in the Eco-innovation Road to the Circular Economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef] [Green Version]

- Bressanelli, G.; Saccani, N.; Pigosso, D.C.A.; Perona, M. Circular Economy in the WEEE industry: A systematic literature review and a research agenda. Sustain. Prod. Consum. 2020, 23, 174–188. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Chiaroni, D.; Del Vecchio, P.; Urbinati, A. Designing business models in circular economy: A systematic literature review and research agenda. Bus. Strategy Environ. 2020, 29, 1734–1749. [Google Scholar] [CrossRef]

- Frosch, R.A.; Gallopoulos, N.E. Strategies for Manufacturing. Sci. Am. 1989, 261, 144–152. [Google Scholar] [CrossRef]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; Johns Hopkins University Press: Baltimore, MD, USA, 1990; 378p. [Google Scholar]

- Bocken, N.M.P.; Olivetti, E.A.; Cullen, J.M.; Potting, J.; Lifset, R. Taking the Circularity to the Next Level: A Special Issue on the Circular Economy. J. Ind. Ecol. 2017, 21, 476–482. [Google Scholar] [CrossRef]

- McDowall, W.; Geng, Y.; Huang, B.; Barteková, E.; Bleischwitz, R.; Türkeli, S.; Kemp, R.; Doménech, T. Circular Economy Policies in China and Europe. J. Ind. Ecol. 2017, 21, 651–666. [Google Scholar] [CrossRef] [Green Version]

- Ellen MacArthur Foundation (2012). Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1.pdf (accessed on 2 May 2018).

- European Environment Agency. Circular economy in Europe—Developing the knowledge base—European Environment Agency. Luxembourg: Publications Office of the European Union. 2016. Available online: https://www.eea.europa.eu/publications/circular-economy-in-europe (accessed on 13 April 2021).

- Mahanty, S.; Boons, F.; Handl, J.; Batista-Navarro, R. Studying the Evolution of the “Circular Economy” Concept Using Topic Modelling. In Proceedings of the 20th International Conference on Intelligent Data Engineering and Automated Learning—IDEAL 2019, Manchester, UK, 14–16 November 2019; Springer: Cham, Switzerland, 2019; pp. 259–270. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Breuer, H.; Fichter, K.; Lüdeke-Freund, F.; Tiemann, I. Sustainability-oriented business model development: Principles, criteria and tools. Int. J. Entrep. Ventur. 2018, 10, 256–286. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2019, 3, 36–61. [Google Scholar] [CrossRef] [Green Version]

- Pieroni, M.P.; McAloone, T.C.; Pigosso, D.C. Business model innovation for circular economy and sustainability: A review of approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.P.; Pigosso, D.C.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 277, 123741. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulena, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Sauvé, S.; Bernard, S.; Sloan, P. Environmental sciences: Sustainable development and circular economy: Alternative concepts for trans-disciplinary research. Environ. Dev. 2016, 17, 48–56. [Google Scholar] [CrossRef] [Green Version]

- Blomsma, F.; Brennan, G. The emergence of circular economy: A new framing around prolonging resource productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Alhawari, O.; Awan, U.; Bhutta, M.K.S.; Ülkü, M. Insights from Circular Economy Literature: A Review of Extant Definitions and Unravelling Paths to Future Research. Sustainability 2021, 13, 859. [Google Scholar] [CrossRef]

- Smol, M.; Marcinek, P.; Koda, E. Drivers and Barriers for a Circular Economy (CE) Implementation in Poland—A Case Study of Raw Materials Recovery Sector. Energies 2021, 14, 2219. [Google Scholar] [CrossRef]

- Barros, M.V.; Salvador, R.; do Prado, G.F.; de Francisco, A.C.; Piekarski, C.M. Circular Economy As A Driver To Sustainable Businesses. Clean. Environ. Syst. 2021, 2, 100006. [Google Scholar] [CrossRef]

- European Furniture Industries Confederation. Sustainable Products Initiative; Position Paper Accompanying Input to Open Public Consultation. 2020. Available online: https://9e2160bf-a0b5-460b-aec7-e9af818978ee.filesusr.com/ugd/a1d93b_42844d7f427b498e8ece1fe643ab5734.pdf (accessed on 22 February 2021).

- Centre for European Policy Studies. The EU Furniture Market Situation and a Possible Furniture Products Initiative. 2014. Available online: https://www.ceps.eu/ceps-publications/eu-furniture-market-situation-and-possible-furniture-products-initiative/ (accessed on 7 June 2021).

- European Environmental Bureau. Circular Economy Opportunities in the Furniture Sector. 2017. Available online: https://eeb.org/library/circular-economy-opportunities-in-the-furniture-sector/ (accessed on 3 November 2020).

- Barbaritiano, M.; Bravi, L.; Savelli, E. Sustainability and quality management in the Italian luxury furniture sector: A circular economy perspective. Sustainability 2019, 11, 3089. [Google Scholar] [CrossRef] [Green Version]

- Hagejärd, S.; Ollár, A.; Femenías, P.; Rahe, U. Designing for Circularity—Addressing Product Design, Consumption Practices and Resource Flows in Domestic Kitchens. Sustainability 2020, 12, 1006. [Google Scholar] [CrossRef] [Green Version]

- EFIC—European Furniture Industries Confederation. The Furniture Sector and Circular Economy 2.0; EFIC—European Furniture Industries Confederation: Brussels, Belgium, 2020. [Google Scholar]

- Achterberg, E.; Hinfelaar, J.; Bocken, N. The Value Hill Business Model Tool: Identifying Gaps and Opportunities in a Circular Network. 2016. Available online: https://www.scienceandenergychallenge.nl/sites/default/files/workshops/attachments/NWO%20Sc4CE%20-%20Workshop%20Business%20Models%20-%20Paper%20on%20Circular%20Business%20Models.pdf (accessed on 6 February 2021).

- Rocha, C.; Camocho, D.; Sampaio, J.; Alexandre, J. Product-Service Development for Circular Economy and Sustainability Course; LNEG—Laboratório Nacional de Energia e Geologia, I.P.: Amodora, Portugal, 2020; ISBN 978-989-675-063-3. [Google Scholar]

- Enel, Symbola. 100 Italian Circular Economy Stories, 38, 128, 158. 2018. Available online: https://www.symbola.net/ricerca/100-italian-circular-economy-stories-la-ricerca-enel-symbola/ (accessed on 5 April 2018).

- World Health Organization. Circular Economy and Health: Opportunities and Risks. 2018. Available online: https://www.euro.who.int/__data/assets/pdf_file/0004/374917/Circular-Economy_EN_WHO_web_august-2018.pdf (accessed on 23 June 2021).

- Pheifer, A.G. Barriers and Enablers to Circular Business Models. 2017. Available online: https://www.circulairondernemen.nl/uploads/4f4995c266e00bee8fdb8fb34fbc5c15.pdf (accessed on 22 February 2021).

- Shahbazi, S.; Wiktorsson, M.; Kurdve, M.; Jönsson, C.; Bjelkemyr, M. Material efficiency in manufacturing: Swedish evidence on potential, barriers and strategies. J. Clean. Prod. 2016, 127, 438–450. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef] [Green Version]

- Bicket, M.; Guilcher, S.; Hestin, M.; Hudson, C.; Razzini, P.; Tan, A.; ten Brink, P.; van Dijl, E.; Vanner, R.; Watkins, E. Scoping Study to Identify Potential Circular Economy Actions, Priority Sectors, Material Flows and Value Chains; Publications Office of the European Union: Luxembourg, 2014. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Ritala, P.; Mäkinen, S.J. Exploring institutional drivers and barriers of the circular economy: A cross-regional comparison of China, the US, and Europe. Resour. Conserv. Recycl. 2018, 135, 70–82. [Google Scholar] [CrossRef]

- Shi, H.; Peng, S.Z.; Liu, Y.; Zhong, P. Barriers to the implementation of cleaner production in Chinese SMEs: Government, industry and expert stakeholders’ perspectives. J. Clean. Prod. 2008, 16, 842–852. [Google Scholar] [CrossRef]

- Kazancoglu, I.; Sagnak, M.; Kumar Mangla, S.; Kazancoglu, Y. Circular economy and the policy: A framework for improving the corporate environmental management in supply chains. Bus. Strategy Environ. 2021, 30, 590–608. [Google Scholar] [CrossRef]

- Araujo Galvão, G.D.; De Nadae, J.; Clemente, D.H.; Chinen, G.; Carvalho, M. Circular economy: Overview of barriers. Procedia CIRP 2018, 73, 79–85. [Google Scholar] [CrossRef]

- Ormazabal, M.; Prieto-Sandoval, V.; Jaca, C.; Santos, J. An overview of the circular economy among smes in the Basque Country: A multiple case study. J. Ind. Eng. Manag. 2016, 9, 1047–1058. [Google Scholar] [CrossRef] [Green Version]

- Nußholz, J.L.K. Circular business models: Defining a concept and framing an emerging research field. Sustainability 2017, 9, 1810. [Google Scholar] [CrossRef] [Green Version]

- Biondi, V.; Iraldo, F.; Meredith, S. Achieving sustainability through environmental innovation: The role of SMEs. Int. J. Technol. Manag. 2002, 24, 612. [Google Scholar] [CrossRef]

- Brown, S. Political Subjectivity—Application of Q Methodology in Political Science; Yale University Press: New Haven, CT, USA; London, UK, 1980. [Google Scholar]

- Stephenson, W. The Study of Behavior; Q-Technique and Its Methodology; University of Chicago Press: Chicago, IL, USA, 1953. [Google Scholar]

- Angelopulo, G. Q methodology and the measurement of subjectivity in corporate brand perception. S. Afr. J. Bus. Manag. 2009, 40, 21–34. [Google Scholar] [CrossRef] [Green Version]

- Brown, S. Q methodology and qualitative research. Qual. Health Res. 1996, 6, 561–567. [Google Scholar] [CrossRef]

- Watts, S.; Stenner, P. Doing Q methodology: Theory, method and interpretation. Qual. Res. Psychol. 2005, 2, 67–91. [Google Scholar] [CrossRef]

- Dryzek, J.S.; Berejikian, A. Reconstitutive democratic theory. Am. Political Sci. Rev. 1993, 87, 48–60. [Google Scholar] [CrossRef]

- Silvius, G.; Schipper, R. Exploring variety in factors that stimulate project managers to address sustainability issues. Int. J. Proj. Manag. 2020, 38, 353–367. [Google Scholar] [CrossRef]

- Stenner, P.; Stainton Rogers, R. Q Methodology and Qualiquantology: The Example of Discriminating between Emotions; Psychology Press: Hove, UK, 2004; pp. 101–120. [Google Scholar]

- Donner, J.C. Using Q-Sorts in Participatory Processes: An Introduction to the Methodology. In Social Analysis, Selected Tools and Techniques; Social Development Papers, Paper Number 36; Krueger, R.A., Casey, M.A., Donner, J., Kirsch, S., Maack, J.N., Eds.; The World Bank: Washington, DC, USA, 2001. [Google Scholar]

- Schlinger, M. Cues on Q-techniques. J. Advert. Res. 1969, 9(3), 53–60. [Google Scholar]

- McKeown, B.; Thomas, D. Q Methodology; Sage Publications, Inc.: Newbury Park, CA, USA, 1988. [Google Scholar]

- Silvius, G.; Kampinga, M.; Paniagua, S.; Mooi, H. Considering Sustainability in Project Management Decision Making; An investigation using Q-methodology. Int. J. Proj. Manag. 2017, 35, 1133–1150. [Google Scholar] [CrossRef]

- Webler, T.; Danielson, S.; Tuler, S. Using Q Method to Reveal Social Perspectives in Environmental Research; Social and Environmental Research Institute: Greenfield, MA, USA, 2009; Available online: www.serius.org/pubs/Qprimer.pdf (accessed on 22 April 2021).

- Denzine, G. The use of Q Methodology in Student Affairs Research and Practice. Student Affairs Journal Online. 1998. Available online: http://www.sajo.org/denzine040398.html (accessed on 15 January 2017).

- Stainton Rogers, R. Q methodology. In Rethinking Methods in Psychology; Sage Publications: London, UK; Thousand Oaks, CA, USA, 1995; pp. 178–192. [Google Scholar]

- Smolck, P. The Qmethod Software. 2018. Available online: http://schmolck.org/qmethod/ (accessed on 3 April 2018).

- Dziopa, F.; Ahern, K. A systematic literature review of the applications of Q-technique and its methodology. Methodology 2011, 7, 39–55. [Google Scholar] [CrossRef]

- Cross, R.M. Exploring Attitudes: The Case for Q Methodology. Health Educ. Res. 2005, 20, 206–213. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Category | Identified Barriers/Challenges | References |

|---|---|---|

| Policy | Lack of support from public institutions | [17,18,22,50,64,70] |

| Lack of financial support | [17,22,64,70] | |

| Legal issues with circularity | [21] | |

| Limited sustainable public procurement | [19] | |

| Incoherent policies at different levels | [19,28] | |

| Market | Negative reception of ‘recycled’ products | [17,25,50] |

| Lack of consumer awareness and interest | [17,18,19,21,22,24,70,71] | |

| Price sensitivity of the product | [21] | |

| Lack of incentive to design for end of life (products) | [23,24] | |

| Widespread planned obsolescence in products | [19] | |

| Value chain | Fragmented supply chain | [23,25] |

| Lack of consideration for end-of-life issues | [22] | |

| Lack of market mechanisms for recovery | [19,23] | |

| Low value of raw material/products at end of life | [17,19,21,23] | |

| Non-alignment of power and incentives across the value chain | [19,21,25] | |

| Lack of investment in recycling and recovery infrastructure | [19,23] | |

| Technology | Lack of recycling and recovery technology | [17,18,19,20,22,50,64,67,70] |

| Inadequate information | [17,19,20,22,25,64,70] | |

| Complexity of product | [21,23] | |

| Resources | Lack of technical resources | [17,18,22,25,28,50,64,67,70] |

| Lack of qualified professionals | [17,18,22,50,67,70] | |

| Lack of circular economy knowledge | [19,24,50] | |

| Awareness | Lack of commitment on the part of the organizations’ leaders | [17,67,70,72] |

| Lack of awareness or interest | [23,24] | |

| Business case | Uncertain/unclear business case | [19,23,50] |

| Lack of financial resources | [17,19,22,25,50,64,67,70] |

| Statement | Category | |

|---|---|---|

| P1 | Lack of support from public institutions | Policy |

| P2 | Lack of stimulating subsidies or policies | Policy |

| P3 | Public organizations do not support circularity in their procurement | Policy |

| P4 | Incoherent public policies on circularity and waste | Policy |

| P5 | Laws hinder circularity | Policy |

| P6 | Industry regulations hinder circularity | Policy |

| M1 | Lack of consumer awareness and interest | Market |

| M2 | Customers consider products that are made of recycled materials less desirable | Market |

| M3 | Customers are not interested in circularity | Market |

| M4 | A competitive price in the market leaves no room for investing in circularity | Market |

| M5 | Lack of incentive to design for end of life | Market |

| M6 | No price premium for sustainable products | Market |

| C1 | Lack of consideration of end-of-life issues | Value chain |

| C2 | Lack of market mechanisms for recovery | Value chain |

| C3 | Low value of raw material | Value chain |

| C4 | Difficult to align incentives for circularity across the value chain | Value chain |

| C5 | Lack of know how in the supply chain | Value chain |

| C6 | Lack of recycling and recovery infrastructure | Value chain |

| T1 | Lack of recycling and recovery technology | Technology |

| T2 | Lack of information about the circular aspects of the product | Technology |

| T3 | Unclear whether a used product can be recycled | Technology |

| T4 | Product is too complex to realize circularity | Technology |

| T5 | The product includes different material streams, making it difficult to determine ‘circularity’ | Technology |

| T6 | Limited availability and quality of recycled materials | Technology |

| R1 | Lack of technical resources | Resources |

| R2 | Lack of qualified professionals | Resources |

| R3 | Lack of circular economy knowledge | Resources |

| R4 | Lack of know how in the organization | Resources |

| R5 | Unclear where or how to start | Resources |

| R6 | Lack of creativity in the organization | Resources |

| A1 | Lack of commitment on the part of the organizations’ leaders | Awareness |

| A2 | Lack of interest in the organization | Awareness |

| A3 | Lack of support from the organization’s leadership | Awareness |

| A4 | Difficult to embed circularity in the organization’s culture | Awareness |

| A5 | The organization is facing more urgent issues | Awareness |

| A6 | Lack of support from the organization’s owners | Awareness |

| B1 | Uncertain business case for circularity | Business case |

| B2 | Unclear benefits of circularity | Business case |

| B3 | Lack of financial resources | Business case |

| B4 | High cost of required innovations | Business case |

| B5 | High financial risk of circularity investments | Business case |

| B6 | Regenerating used products is too costly | Business case |

| Question | Answer Categories | Total Sample | |

|---|---|---|---|

| Frequency | Percentage. | ||

| Location of the company | Greece | 6 | 20.0% |

| Italy | 6 | 20.0% | |

| Netherlands | 6 | 20.0% | |

| Slovenia | 6 | 20.0% | |

| Spain | 6 | 20.0% | |

| Age of the company | 1–2 years | 2 | 6.7% |

| 3–5 years | 2 | 6.7% | |

| 6–10 years | 3 | 10.0% | |

| >10 years | 23 | 76.7% | |

| Markets served (multiple answers allowed) | Consumers (B2C) | 19 | 63.3% |

| Businesses (B2B) | 25 | 83.3% | |

| Public organizations (B2P) | 9 | 30.0% | |

| Number of employees | 0–1 employee | 3 | 10.0% |

| 2–5 employees | 3 | 10.0% | |

| 6–20 employees | 9 | 30.0% | |

| 21–50 employees | 2 | 6.7% | |

| 51–250 employees | 9 | 30.0% | |

| >250 employees | 4 | 13.3% | |

| Main materials used (multiple answers allowed) | Ceramics | 1 | 3.3% |

| Fabrics | 7 | 23.3% | |

| Glass | 13 | 43.3% | |

| Metal | 15 | 50.0% | |

| Paper/Carton | 2 | 6.7% | |

| Plastics | 9 | 30.0% | |

| Wood | 28 | 93.3% | |

| Activities performed (mainly) internally (multiple answers allowed) | Design of products | 26 | 86.7% |

| Production of raw materials | 5 | 16.7% | |

| Production products and parts of products | 25 | 83.3% | |

| Assembly of final products | 22 | 73.3% | |

| Transport and logistics | 15 | 50.0% | |

| Activities (mainly) outsourced (multiple answers allowed) | Design of products | 11 | 36.7% |

| Production of raw materials | 25 | 83.3% | |

| Production products and parts of products | 8 | 26.7% | |

| Assembly of final products | 6 | 20.0% | |

| Transport and logistics | 13 | 43.3% | |

| Supply chain | Locally/Nationally | 12 | 40.0% |

| Elsewhere in Europe | 12 | 40.0% | |

| Europe and mainly Asia | 2 | 6.7% | |

| Europe and mainly Africa | 0 | 0.0% | |

| Europe and mainly North America | 0 | 0.0% | |

| Europe and mainly South America | 0 | 0.0% | |

| Globally | 4 | 13.3% | |

| Familiarity with circularity | Basic understanding | 14 | 46.7% |

| Some familiarity | 3 | 10.0% | |

| Familiar and some application | 13 | 43.3% | |

| Factor 1 | Factor 2 | Factor 3 | Factor 4 | |

|---|---|---|---|---|

| Eigenvalues | 4.4936 | 3.6709 | 2.638 | 2.4731 |

| % Explained Variance | 15 | 12 | 9 | 8 |

| Number of Defining Variables | 7 | 5 | 8 | 3 |

| Average Reliability Coefficient | 0.800 | 0.800 | 0.800 | 0.800 |

| Composite Reliability | 0.966 | 0.952 | 0.970 | 0.923 |

| Standard Error of Factor Z-Scores | 0.186 | 0.218 | 0.174 | 0.277 |

| Participant # | Factor 1 | Factor 2 | Factor 3 | Factor 4 |

|---|---|---|---|---|

| 1 | 0.3942 | 0.0544 | 0.4505X | 0.1731 |

| 2 | 0.2779 | −0.2017 | 0.1639 | −0.0847 |

| 3 | 0.3068 | −0.091 | −0.3654X | 0.166 |

| 4 | 0.4689 | 0.4894 | −0.2264 | −0.2902 |

| 5 | 0.1063 | 0.4418X | 0.317 | −0.3274 |

| 6 | 0.274 | 0.1132 | 0.4125X | 0.0409 |

| 7 | 0.1375 | 0.0517 | 0.0393 | 0.4155X |

| 8 | 0.3646 | 0.157 | 0.5341X | 0.0506 |

| 9 | 0.5285X | −0.2681 | 0.0734 | 0.2087 |

| 10 | 0.3467 | 0.2139 | 0.7065X | 0.0113 |

| 11 | 0.4820X | −0.3094 | −0.0622 | −0.2529 |

| 12 | 0.5661X | −0.1583 | 0.065 | 0.2565 |

| 13 | 0.2519 | −0.4285 | −0.2911 | 0.4888 |

| 14 | 0.3483X | −0.2136 | 0.2694 | 0.264 |

| 15 | 0.4872 | −0.4382 | −0.159 | 0.3718 |

| 16 | 0.3224 | −0.2366 | 0.4369X | 0.1225 |

| 17 | 0.2101 | 0.5893X | 0.1564 | −0.3117 |

| 18 | 0.3194 | −0.3556X | −0.0322 | −0.064 |

| 19 | 0.6827X | −0.3593 | −0.1319 | −0.152 |

| 20 | 0.2784 | 0.265 | 0.0001 | −0.4041X |

| 21 | 0.4526X | −0.1162 | −0.1626 | −0.1961 |

| 22 | 0.6288X | −0.1838 | −0.0051 | −0.4992 |

| 23 | 0.2619 | −0.0724 | 0.0886 | −0.2344 |

| 24 | 0.1447 | 0.1093 | 0.3002X | 0.1269 |

| 25 | 0.4386 | −0.1002 | −0.3122 | −0.5560X |

| 26 | 0.3646 | 0.3836 | −0.5410X | 0.0167 |

| 27 | 0.1634 | 0.7563X | −0.147 | 0.3057 |

| 28 | 0.238 | 0.7724X | −0.0008 | 0.3488 |

| 29 | 0.478 | 0.3757 | −0.2436 | 0.4756 |

| 30 | 0.4622 | 0.4733 | −0.3762 | 0.0878 |

| Factor 1 | Factor 2 | Factor 3 | Factor 4 | |

|---|---|---|---|---|

| Factor 1 | 1 | −0.1323 | 0.2025 | −0.3847 |

| Factor 2 | −0.1323 | 1 | 0.1378 | −0.026 |

| Factor 3 | 0.2025 | 0.1378 | 1 | 0.0875 |

| Factor 4 | −0.3847 | −0.026 | 0.0875 | 1 |

| Factor 1 | Factor 2 | Factor 3 | Factor 4 | |

|---|---|---|---|---|

| Policy | 0.107 | 0.350 | −0.345 | 0.047 |

| Market | 0.030 | −0.075 | 0.918 | −0.547 |

| Value chain | 0.033 | −0.337 | −0.015 | 0.077 |

| Technology | 0.003 | −0.120 | −0.160 | 0.707 |

| Resources | 0.660 | −0.297 | −0.178 | −1.043 |

| Awareness | −0.963 | 0.040 | 0.267 | 1.000 |

| Business case | 0.130 | 0.438 | −0.487 | −0.245 |

| Statement | Category | Q-Sort Value | Average z-Score | |

|---|---|---|---|---|

| 28 | Lack of technical resources | Resources | 4 | 1.29 * |

| 35 | Public organizations do not support circularity in their procurement | Policy | 3 | 1.27 |

| 41 | Unclear where or how to start | Resources | 3 | 1.01 * |

| 1 | High cost of required innovations | Business case | 3 | 1.01 |

| 37 | The organization is facing more urgent issues | Awareness | 2 | 0.96 |

| 33 | Limited availability and quality of recycled materials | Technology | 2 | 0.91 |

| 10 | Lack of incentive to design for end of life | Market | 1 | 0.83 * |

| 25 | Lack of recycling and recovery infrastructure | Value chain | 1 | 0.60 * |

| 12 | A competitive price in the market leaves no room for investing in circularity | Market | 1 | 0.57 * |

| 9 | Lack of financial resources | Business case | 0 | 0.50* |

| 19 | Lack of information about the circular aspects of the product | Technology | 0 | 0.46 |

| 6 | Lack of consideration of end-of-life issues | Value chain | −1 | −0.82 |

| 13 | Difficult to embed circularity in the organization’s culture | Awareness | −1 | −0.91 * |

| 20 | Lack of interest in the organization | Awareness | −2 | −1.21 * |

| 40 | Unclear benefits of circularity | Business case | −2 | −1.34 * |

| 27 | Lack of support from the organization’s owners | Awareness | −3 | −1.52 * |

| 5 | Lack of commitment on the part of the organizations’ leaders | Awareness | −4 | −1.75 * |

| 42 | Unclear whether a used product can be recycled | Technology | −4 | −2.31 * |

| Statement | Category | Q-Sort Value | Average z-Score | |

|---|---|---|---|---|

| 17 | Lack of stimulating subsidies or policies | Policy | 4 | 1.96 * |

| 1 | High cost of required innovations | Business case | 3 | 1.84 * |

| 39 | Uncertain business case for circularity | Business case | 3 | 1.45 * |

| 3 | Industry regulations hinder circularity | Policy | 2 | 0.81 * |

| 20 | Lack of interest in the organization | Awareness | 1 | 0.41 |

| 8 | Lack of creativity in the organization | Resources | 0 | 0.25 * |

| 9 | Lack of financial resources | Business case | −1 | −0.61 * |

| 23 | Lack of market mechanisms for recovery | Value chain | −2 | −0.89 * |

| 35 | Public organizations do not support circularity in their procurement | Policy | −2 | −1.03 |

| 34 | Product is too complex to realize circularity | Technology | −2 | −1.13 * |

| 31 | No price premium for sustainable products | Market | −3 | −1.25 * |

| 22 | Lack of know how in the supply chain | Value chain | −4 | −1.43 * |

| 12 | A competitive price in the market leaves no room for investing in circularity | Market | −4 | −1.85 * |

| Statement | Category | Q-Sort Value | Average z-Score | |

|---|---|---|---|---|

| 12 | A competitive price in the market leaves no room for investing in circularity | Market | 4 | 2.45 * |

| 37 | The organization is facing more urgent issues | Awareness | 3 | 1.48 |

| 32 | Difficult to align incentives for circularity across the value chain | Value chain | 3 | 1.34 * |

| 14 | Customers are not interested in circularity | Market | 2 | 0.95 * |

| 35 | Public organizations do not support circularity in their procurement | Policy | 1 | 0.66 |

| 1 | High cost of required innovations | Business case | 1 | 0.49 |

| 28 | Lack of technical resources | Resources | 1 | 0.36 * |

| 13 | Difficult to embed circularity in the organization’s culture | Awareness | 0 | 0.11 * |

| 18 | Lack of support from the organization’s leadership | Awareness | 0 | 0.09 * |

| 2 | Incoherent public policies on circularity and waste | Policy | −1 | −0.5 |

| 20 | Lack of interest in the organization | Awareness | −1 | −0.52 * |

| 26 | Lack of recycling and recovery technology | Technology | −3 | −1.61 * |

| Statement | Category | Q-Sort Value | Average z-Score | |

|---|---|---|---|---|

| 34 | Product is too complex to realize circularity | Technology | 4 | 1.95 * |

| 38 | The product includes different material streams, making it difficult to determine ‘circularity’ | Technology | 4 | 1.83 * |

| 5 | Lack of commitment on the part of the organizations’ leaders | Awareness | 3 | 1.82 * |

| 18 | Lack of support from the organization’s leadership | Awareness | 3 | 1.29 * |

| 20 | Lack of interest in the organization | Awareness | 3 | 1.2 |

| 40 | Unclear benefits of circularity | Business case | 2 | 1.09 * |

| 27 | Lack of support from the organization’s owners | Awareness | 2 | 0.93 * |

| 29 | Laws hinder circularity | Policy | 1 | 0.53 * |

| 39 | Uncertain business case for circularity | Business case | 1 | 0.13 |

| 35 | Public organizations do not support circularity in their procurement | Policy | −1 | −0.33 |

| 1 | High cost of required innovations | Business case | −1 | −0.41 * |

| 12 | A competitive price in the market leaves no room for investing in circularity | Market | −1 | −0.42 * |

| 36 | Regenerating used products is too costly | Business case | −2 | −0.66 * |

| 10 | Lack of incentive to design for end of life | Market | −2 | −1.03 * |

| 14 | Customers are not interested in circularity | Market | −3 | −1.50 * |

| Statement | Category | Factor 1 | Factor 2 | Factor 3 | Factor 4 | |

|---|---|---|---|---|---|---|

| 6 | Lack of consideration of end-of-life issues | Value chain | −1 | 0 | 0 | 0 |

| 33 | Limited availability and quality of recycled materials | Technology | 2 | 0 | 1 | 0 |

| 11 | Lack of support from public institutions | Policy | 2 | 1 | 0 | 0 |

| 15 | Customers consider products that are made of recycled materials less desirable | Market | −1 | −2 | −2 | 0 |

| 2 | Incoherent public policies on circularity and waste | Policy | 0 | 1 | −1 | 1 |

| 25 | Lack of recycling and recovery infrastructure | Value chain | 1 | 0 | 0 | −1 |

| 21 | Lack of know how in the organization | Resources | 2 | 0 | 2 | 1 |

| 19 | Lack of information about the circular aspects of the product | Technology | 0 | −1 | −2 | 0 |

| 32 | Difficult to align incentives for circularity across the value chain | Value chain | 0 | 1 | 3 | 0 |

| 38 | The product includes different material streams, making it difficult to determine ‘circularity’ | Technology | 0 | 1 | 1 | 4 |

| Statement | Category | Factor 1 | Factor 2 | Factor 3 | Factor 4 | |

|---|---|---|---|---|---|---|

| 12 | A competitive price in the market leaves no room for investing in circularity | Market | 1 | −4 | 4 | −1 |

| 42 | Unclear whether a used product can be recycled | Technology | −4 | 2 | 2 | 1 |

| 5 | Lack of commitment on the part of the organizations’ leaders | Awareness | −4 | 1 | 1 | 3 |

| 9 | Lack of financial resources | Business case | 0 | −1 | −4 | −4 |

| 24 | Lack of qualified professionals | Resources | 2 | 2 | −3 | −3 |

| 10 | Lack of incentive to design for end of life | Market | 1 | 4 | 4 | −2 |

| 34 | Product is too complex to realize circularity | Technology | −1 | −2 | −1 | 4 |

| 28 | Lack of technical resources | Resources | 4 | −3 | 1 | −3 |

| 4 | Lack of circular economy knowledge | Resources | 4 | −1 | 2 | −2 |

| 7 | Lack of consumer awareness and interest | Market | −1 | 3 | 3 | −1 |

| Question | Answer Categories | Total P-Set | Factor 1 | Factor 2 | Factor 3 | Factor 4 |

|---|---|---|---|---|---|---|

| Location of the company | Greece | 20.0% | 42.9% | 0.0% | 12.5% | 33.3% |

| Italy | 20.0% | 42.9% | 0.0% | 25.0% | 33.3% | |

| Netherlands | 20.0% | 0.0% | 20.0% | 37.5% | 0.0% | |

| Slovenia | 20.0% | 0.0% | 40.0% | 12.5% | 33.3% | |

| Spain | 20.0% | 14.3% | 40.0% | 12.5% | 0.0% | |

| Age of the company | 1–2 years | 6.7% | 0.0% | 0.0% | 12.5% | 0.0% |

| 3–5 years | 6.7% | 0.0% | 40.0% | 0.0% | 0.0% | |

| 6–10 years | 10.0% | 0.0% | 20.0% | 12.5% | 33.3% | |

| >10 years | 76.7% | 100.0% | 40.0% | 75.0% | 66.7% | |

| Markets served | Consumers (B2C) | 63.3% | 57.1% | 60.0% | 62.5% | 100.0% |

| Businesses (B2B) | 83.3% | 100.0% | 80.0% | 87.5% | 100.0% | |

| Public organizations (B2P) | 30.0% | 42.9% | 40.0% | 25.0% | 33.3% | |

| Number of employees | 0–1 employee | 10.0% | 0.0% | 0.0% | 12.5% | 33.3% |

| 2–5 employees | 10.0% | 0.0% | 20.0% | 12.5% | 0.0% | |

| 6–20 employees | 30.0% | 57.1% | 40.0% | 12.5% | 66.7% | |

| 21–50 employees | 6.7% | 14.3% | 0.0% | 0.0% | 0.0% | |

| 51–250 employees | 30.0% | 14.3% | 20.0% | 50.0% | 0.0% | |

| >250 employees | 13.3% | 14.3% | 20.0% | 12.5% | 0.0% | |

| Main materials used | Ceramics | 3.3% | 0.0% | 20.0% | 0.0% | 0.0% |

| Fabrics | 23.3% | 14.3% | 60.0% | 12.5% | 33.3% | |

| Glass | 43.3% | 42.9% | 40.0% | 37.5% | 66.7% | |

| Metal | 50.0% | 57.1% | 60.0% | 50.0% | 66.7% | |

| Paper/Carton | 6.7% | 14.3% | 0.0% | 12.5% | 0.0% | |

| Plastics | 30.0% | 28.6% | 40.0% | 25.0% | 66.7% | |

| Wood | 93.3% | 100.0% | 80.0% | 87.5% | 100.0% | |

| Activities (performed mainly internal) | Design of products | 86.7% | 100.0% | 100.0% | 87.5% | 33.3% |

| Production of raw materials | 16.7% | 0.0% | 40.0% | 12.5% | 0.0% | |

| Production products and parts of products | 83.3% | 85.7% | 100.0% | 75.0% | 66.7% | |

| Assembly of final products | 73.3% | 71.4% | 80.0% | 62.5% | 66.7% | |

| Transport and logistics | 50.0% | 14.3% | 40.0% | 62.5% | 66.7% | |

| Activities (mainly outsourced) | Design of products | 36.7% | 57.1% | 40.0% | 25.0% | 66.7% |

| Production of raw materials | 83.3% | 100.0% | 80.0% | 75.0% | 100.0% | |

| Production products and parts of products | 26.7% | 14.3% | 20.0% | 25.0% | 33.3% | |

| Assembly of final products | 20.0% | 28.6% | 40.0% | 12.5% | 33.3% | |

| Transport and logistics | 43.3% | 85.7% | 40.0% | 25.0% | 33.3% | |

| Supply chain | Locally/Nationally | 40.0% | 42.9% | 40.0% | 50.0% | 33.3% |

| Elsewhere in Europe | 40.0% | 14.3% | 60.0% | 37.5% | 66.7% | |

| Europe and mainly Asia | 6.7% | 14.3% | 0.0% | 12.5% | 0.0% | |

| Globally | 13.3% | 28.6% | 0.0% | 0.0% | 0.0% | |

| Familiarity with circularity | Basic understanding | 46.7% | 85.7% | 40.0% | 37.5% | 66.7% |

| Some familiarity | 10.0% | 0.0% | 20.0% | 0.0% | 0.0% | |

| Familiar and some application | 43.3% | 14.3% | 40.0% | 62.5% | 33.3% |

| Implications | Industry-specific contextualized research on CE barriers. Focus on business insights related to CE. Four patterns of subjective arguments for avoiding the adoption of CE practices exist at present. Solutions should focus on assessing financial risks, introducing circular offerings in markets, and fostering internal changes in the organizations. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silvius, G.; Ismayilova, A.; Sales-Vivó, V.; Costi, M. Exploring Barriers for Circularity in the EU Furniture Industry. Sustainability 2021, 13, 11072. https://doi.org/10.3390/su131911072

Silvius G, Ismayilova A, Sales-Vivó V, Costi M. Exploring Barriers for Circularity in the EU Furniture Industry. Sustainability. 2021; 13(19):11072. https://doi.org/10.3390/su131911072

Chicago/Turabian StyleSilvius, Gilbert, Aydan Ismayilova, Vicente Sales-Vivó, and Micol Costi. 2021. "Exploring Barriers for Circularity in the EU Furniture Industry" Sustainability 13, no. 19: 11072. https://doi.org/10.3390/su131911072

APA StyleSilvius, G., Ismayilova, A., Sales-Vivó, V., & Costi, M. (2021). Exploring Barriers for Circularity in the EU Furniture Industry. Sustainability, 13(19), 11072. https://doi.org/10.3390/su131911072