Effects of Seasonal Temperature Variation on Slurry Temperature and Biogas Composition of a Commercial Fixed-Dome Anaerobic Digester Used in Bangladesh

Abstract

:1. Introduction

2. Materials and Methods

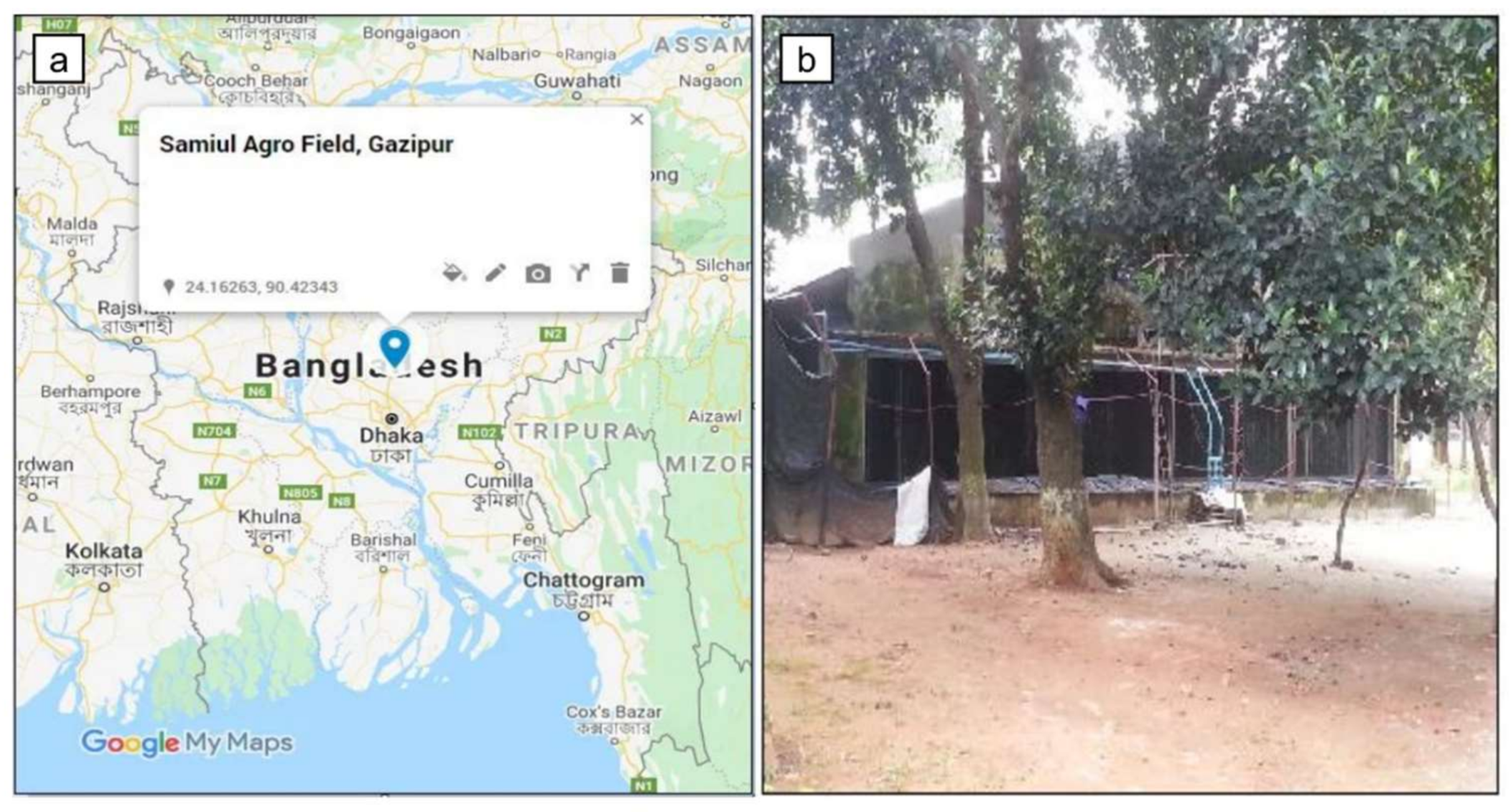

2.1. Experimental Site and Biogas Plant

2.2. Experiment Period

2.3. Experimental Set-Up and Procedure

2.4. Measurement of Different Parameters

2.5. Statistical Analysis

3. Results and Discussion

3.1. Substrate and Slurry Characteristics

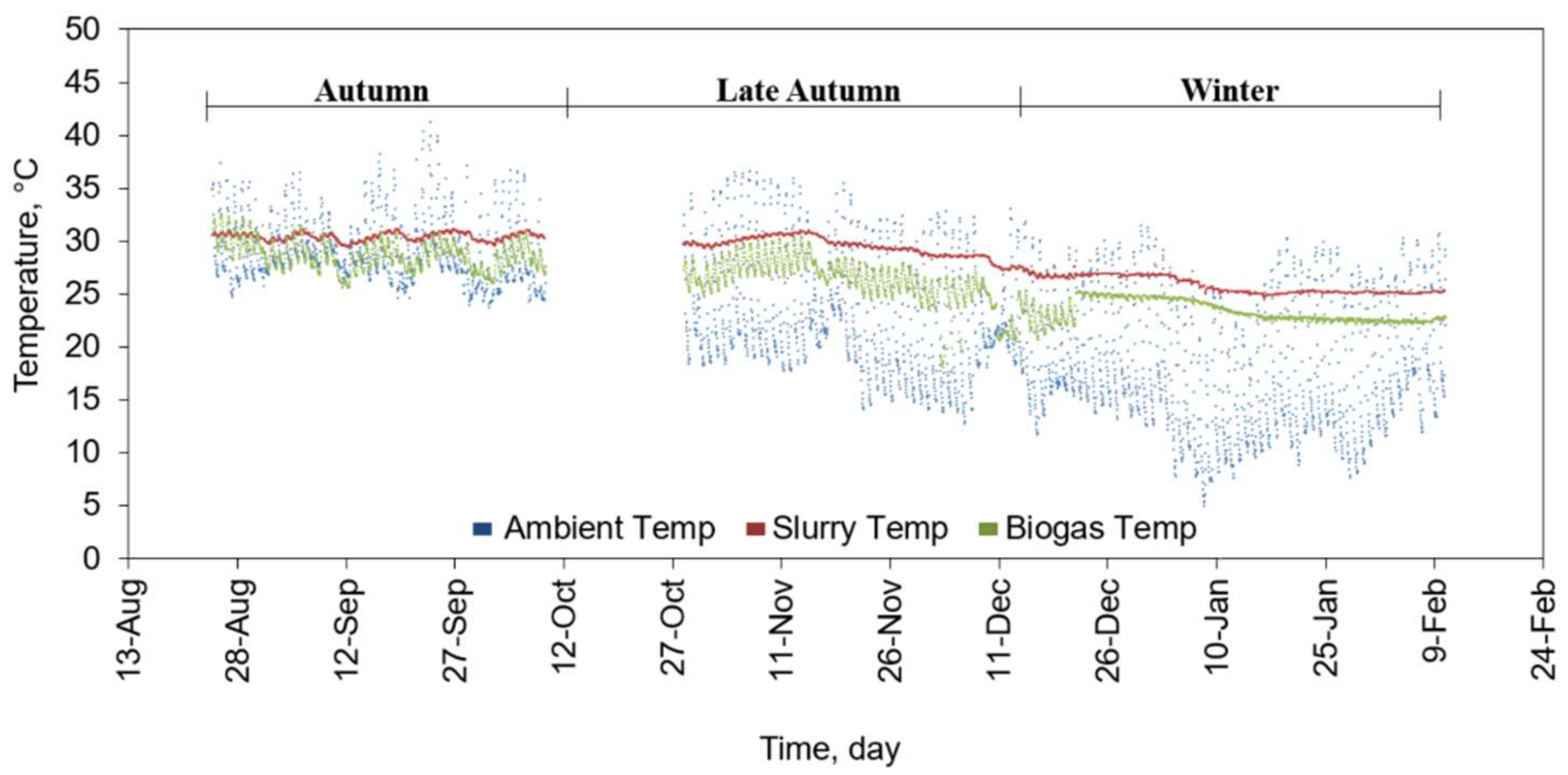

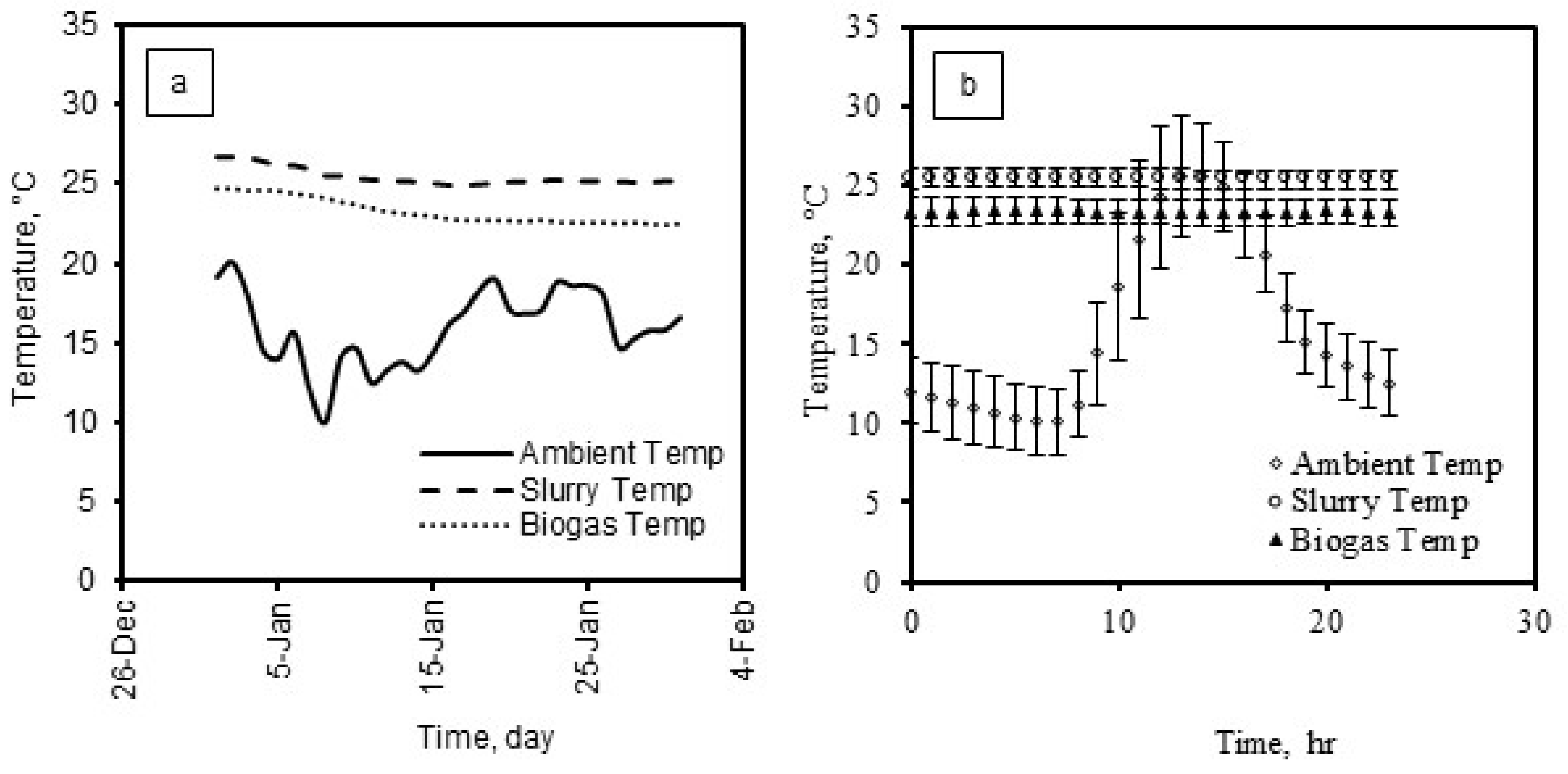

3.2. Seasonal and Diurnal Temperature Variation

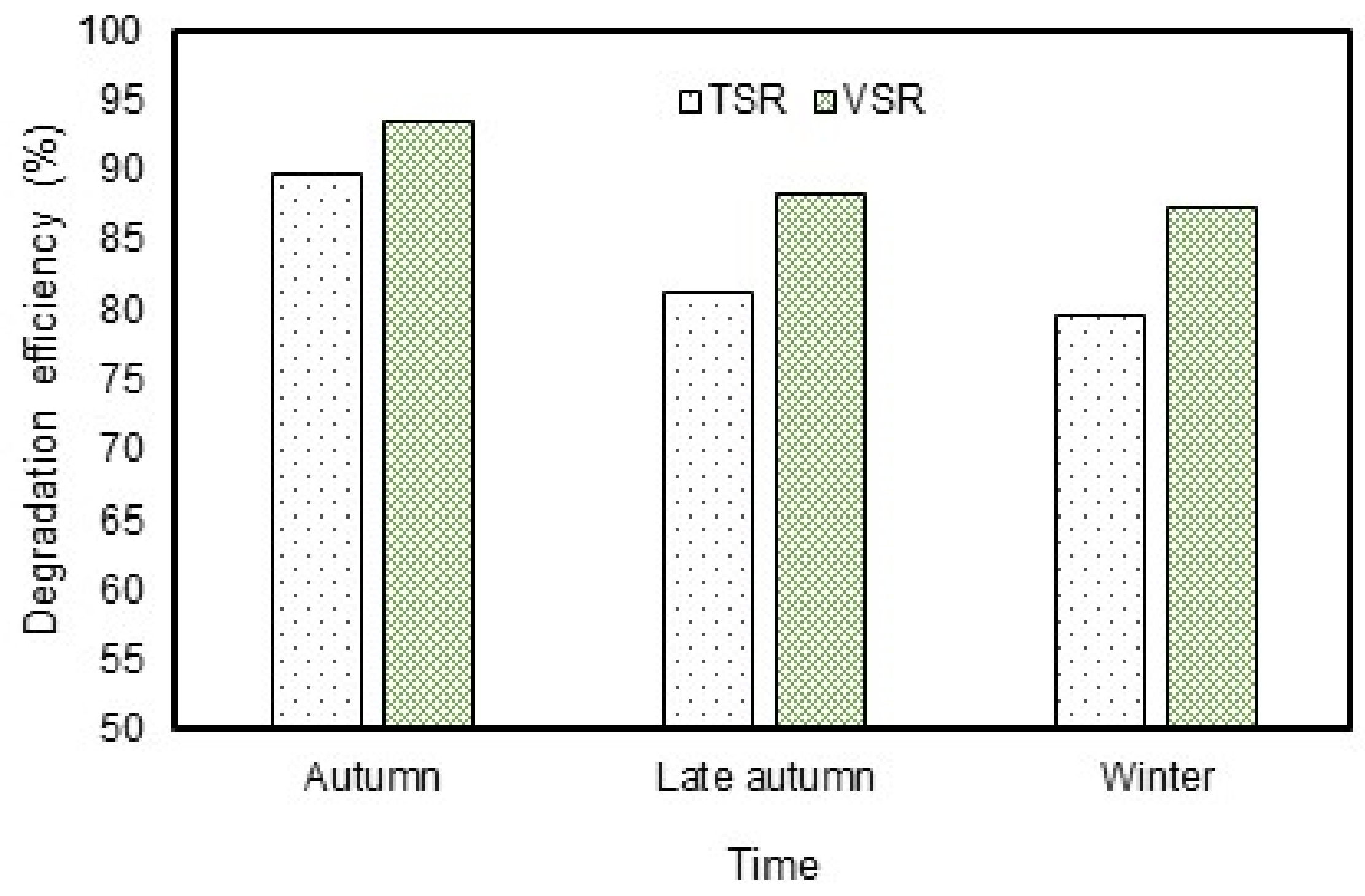

3.3. Effect on Degradation Efficiency

3.4. Seasonal Variation of Gas Composition

3.5. Electricity Production

3.6. Digester Heating

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bangladesh Bureau of Statistics (BBS). Bangladesh Statistics. Available online: http://bbs.portal.gov.bd/sites/default/files/files/bbs.portal.gov.bd/page/a1d32f13_8553_44f1_92e6_8ff80a4ff82e/Bangladesh%20%20Statistics-2018.pdf (accessed on 10 October 2018).

- Bangladesh Power Development Board (BPDB). Annual Report 2018–2019. Available online: https://www.bpdb.gov.bd/bpdb_new/resourcefile/annualreports/annualreport_1574325376_Annual_Report_2018-19.pdf (accessed on 10 October 2019).

- International Energy Agency (IEA). World Energy Statistics Report 2018. Available online: https://www.iea.org/ (accessed on 5 April 2021).

- Bangladesh Power Development Board. BPDB Key Statistics. 2021. Available online: https://bd.bpdb.gov.bd/bpdb_new/index.php/site/page/13e9-2cc0-ce41-9c09-088d-94d5-f546-04a6-b4fa-1d18. (accessed on 10 October 2020).

- Shetol, H.; Rahman, M.M.; Sarder, R.; Hossain, M.I.; Riday, F.R. Present status of Bangladesh gas fields and future development: A review. J. Nat. Gas Geosci. 2019, 4, 347–354. [Google Scholar] [CrossRef]

- Arikan, O.A.; Mulbry, W.; Lansing, S. Effect of temperature on methane production from field-scale anaerobic digesters treating dairy manure. Waste Manag. 2015, 43, 108–113. [Google Scholar] [CrossRef]

- Nandi, R.; Saha, C.K.; Sarker, S.; Huda, M.S.; Alam, M.M. Optimization of reactor temperature for continuous anaerobic digestion of cow manure: Bangladesh perspective. Sustainability 2020, 12, 8772. [Google Scholar] [CrossRef]

- Rahman, A.; Møller, H.B.; Saha, C.; Alam, M. The Effect of Temperature on the Anaerobic Co-Digestion of Poultry Droppings and Sugar Mill Press Mud. Biofuels 2019. [Google Scholar] [CrossRef]

- Nasir, I.M.; Ghazi, T.I.M.; Omar, R. Anaerobic digestion technology in livestock manure treatment for biogas production: A review. Eng. Life Sci. 2012, 12, 258–269. [Google Scholar] [CrossRef]

- Im, S.; Petersen, S.O.; Lee, D.; Kim, D.H. Effects of storage temperature on CH4 emissions from cattle manure and subsequent biogas production potential. Waste Manag. 2020, 101, 35–43. [Google Scholar] [CrossRef]

- Schmidt, T.; Harris, P.; Lee, S.; McCabe, B.K. Investigating the impact of seasonal temperature variation on biogas production from covered anaerobic lagoons treating slaughterhouse wastewater using lab scale studies. J. Environ. Chem. Eng. 2019, 7, 103077. [Google Scholar] [CrossRef]

- Barik, D.; Murugan, S. Assessment of sustainable biogas production from de-oiled seed cake of karanja-an organic industrial waste from biodiesel industries. Fuel 2015, 148, 25–31. [Google Scholar] [CrossRef]

- Rahman, A.; Saha, C.; Ward, A.J.; Møller, H.B.; Alam, M. Anaerobic Co-Digestions of Agro-Industrial Waste Blends Using Mixture Design. Biomass Bioenergy 2019, 122, 156–164. [Google Scholar] [CrossRef]

- Rahman, A.; Møller, H.B.; Alam, M. Assessing the Energy Potential of Agricultural Residues and an Approach to Meet the Rural Energy Demand: The Bangladesh Perspective. Biomass Convers. Biorefin. 2018, 8, 925–934. [Google Scholar] [CrossRef]

- Talukder, M.F.S.I. Impact Assessment of Biogas Plants: A Case Study in Bangladesh. Master’s Thesis, Energy and Environmental Management, International Institute of Management, University of Flensburg, Flensburg, Germany, 2010. [Google Scholar]

- GEKH. Survey Report on Biogas Plants in Bangladesh by Green Energy Knowledge Hub; Bangladesh Agricultural University: Mymensingh, Bangladesh, 2016. [Google Scholar]

- Nandi, R.; Saha, C.K.; Huda, M.S.; Alam, M.M. Effect of Mixing on Biogas Production from Cowdung. Eco Friendly Agric. J. 2017, 10, 7–13. [Google Scholar]

- Islam, A.R.M.T.; Shen, S.; Hu, Z.; Rahman, M.A. Drought Hazard Evaluation in Boro Paddy Cultivated Areas of Western Bangladesh at Current and Future Climate Change Conditions. Adv. Meteorol. 2017, 2017, 3514381. [Google Scholar] [CrossRef]

- Khatun, M.A.; Rashid, M.B.; Hygen, H.O. Climate of Bangladesh. MET Report. Available online: https://www.met.no/publikasjoner/met-report/met-report-2016/_/attachment/download/b50e3f06-4485-4f34-b642-0a1e86f12c7d:a483b63367b0f087f3bd9410e135a5e0837d1927/MET-report-08-2016.pdf (accessed on 31 May 2016).

- Bangladesh Climate Data Portal. Available online: http://bmd.wowspace.org/team/homex.php (accessed on 5 April 2021).

- Hubert, C.; Steiniger, B.; Schaum, C.; Michel, M.; Spallek, M. Variation of the Digester Temperature in the Annual Cycle–Using the Digester As Heat Storage. Water Pract. Technol. 2019, 14, 471–481. [Google Scholar] [CrossRef] [Green Version]

- Kalia, A.; Kanwar, S. Long-Term Evaluation of a Fixed Dome Janata Biogas Plant in Hilly Conditions. Bioresour. Technol. 1998, 65, 61–63. [Google Scholar] [CrossRef]

- Ihara, I.; Yano, K.; Andriamanohiarisoamanana, F.J.; Yoshida, G.; Yuge, T.; Yuge, T.; Tangtaweewipat, S.; Umetsu, K. Field Testing of a Small-Scale Anaerobic Digester With Liquid Dairy Manure and Other Organic Wastes at an Urban Dairy Farm. J. Mater. Cycles Waste Manag. 2020, 22, 1382–1389. [Google Scholar] [CrossRef]

- Castano, J.M.; Martin, J.F.; Ciotola, R. Performance of a small-scale, variable temperature fixed dome digester in a temperate climate. Energies 2014, 7, 5701–5716. [Google Scholar] [CrossRef] [Green Version]

- Terradas-Ill, G.; Pham, C.H.; Triolo, J.M.P.; Martí-Herrero, J.; Sommer, S.G. Thermic Model to Predict Biogas Production in Unheated Fixed-Dome Digesters Buried in the Ground. Environ. Sci. Technol. 2014, 48, 3253–3262. [Google Scholar] [CrossRef] [PubMed]

- APHA. Standard Methods for the Examination of Waste Water, 23rd ed.; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- Nasrin, T.; Saha, C.K.; Nandi, R.; Huda, M.S.; Alam, M.M. Kinetic study and optimization of total solids for anaerobic digestion of kitchen waste: Bangladesh perspective. Water Sci. Technol. 2021, 84, 1136–1145. [Google Scholar] [CrossRef]

- Zinder, S.H. Physiological Ecology of Methanogens. In Methanogenesis. Chapman & Hall Microbiology Series (Physiology/Ecology/Molecular Biology/Biotechnology); Ferry, J.G., Ed.; Springer: Boston, MA, USA, 1993. [Google Scholar] [CrossRef]

- Sarker, S.; Lamb, J.J.; Hjelme, D.R.; Lien, K.M. A Review of the Role of Critical Parameters in the Design and Operation of Biogas Production Plants. Appl. Sci. 2019, 9, 1915. [Google Scholar] [CrossRef] [Green Version]

- Kalia, A.K.; Kanwar, S.S. Temperature Profiles of Biogas Plants Operating under Hilly Conditions. Biol. Wastes 1989, 30, 217–224. [Google Scholar] [CrossRef]

- Wang, S.; Ma, F.; Ma, W.; Wang, P.; Zhao, G.; Lu, X. Influence of temperature on biogas production efficiency and microbial community in a two-phase anaerobic digestion system. Water 2019, 11, 133. [Google Scholar] [CrossRef] [Green Version]

- Guo, P.; Zhou, J.; Ma, R.; Yu, N.; Yuan, Y. Biogas production and heat transfer performance of a multiphase flow digester. Energies 2019, 12, 1960. [Google Scholar] [CrossRef] [Green Version]

- Browne, J.D.; Gilkinson, S.R.; Frost, J.P. The Effects of Storage Time and Temperature on Biogas Production from Dairy Cow Slurry. Biosyst. Eng. 2015, 129, 48–56. [Google Scholar] [CrossRef]

- Vanegas, C.; Bartlett, J. Anaerobic Digestion of Laminaria Digitata: The Effect of Temperature on Biogas Production and Composition. Waste Biomass Valorization 2012, 4, 509–515. [Google Scholar] [CrossRef]

- Choudhury, A.; Shelford, T.; Felton, G.; Gooch, C.; Lansing, S. Evaluation of Hydrogen Sulfide Scrubbing Systems for Anaerobic Digesters on Two U.S. Dairy Farms. Energies 2019, 12, 4605. [Google Scholar] [CrossRef] [Green Version]

- Zulkefli, N.N.; Masdar, M.S.; Jahim, J.; Harianto, E. Overview of H2S removal technologies from biogas production. Int. J. Appl. Eng. Res. 2016, 11, 10060–10066. [Google Scholar]

- Jung, H.; Kim, J.; Lee, C. Temperature effects on methanogenesis and sulfidogenesis during anaerobic digestion of sulfur-rich macroalgal biomass in sequencing batch reactors. Microorganisms 2019, 7, 682. [Google Scholar] [CrossRef] [Green Version]

- Saha, C.K.; Rahman, M.; Moller, H.B.; Alam, M.M. Biogas production from animal manure and poultry litter in Bangladesh. In Proceedings of the 4th CIGR - International Conference of Agricultural Engineering (CIGR-AgEng2016): Automation, Environment and Food Safety, Aarhus, Denmark, 26–29 June 2016. [Google Scholar]

- Guo, J.; Dong, R.; Clemens, J.; Wang, W. Performance Evaluation of a Completely Stirred Anaerobic Reactor Treating Pig Manure at a Low Range of Mesophilic Conditions. Waste Manag. 2013, 33, 2219–2224. [Google Scholar] [CrossRef]

- Haghighatafshar, S.; Kjerstadius, H.; Jansen, J.L.C.; Davidsson, Å. Management of hydrogen sulfide in anaerobic digestion of enzyme pretreated marine macro-algae. Vatten–J. Water Manag. Res. 2012, 68, 265–273. [Google Scholar]

- Lansing, S.A.; Klavon, K.H.; Mulbry, W.W.; Moss, A.R. Design and validation of field-scale anaerobic digesters treating dairy manure for small farms. Trans. Asabe 2015, 58, 441–449. [Google Scholar] [CrossRef]

- Spyridonidis, A.; Vasiliadou, I.A.; Akratos, C.S.; Stamatelatou, Κ. Performance of a full-scale biogas plant operation in greece and its impact on the circular economy. Water 2020, 12, 3074. [Google Scholar] [CrossRef]

- Shende, A.D.; Pophali, G.R. Anaerobic Treatment of Slaughterhouse Wastewater: A Review. Environ. Sci. Pollut. Res. 2021, 28, 35–55. [Google Scholar] [CrossRef]

- Kavuma, C. Variation of Methane and Carbon Dioxide Yield in a Biogas Plant. Master’s Thesis, Royal Institute of Technology, Stockholm, Sweden, 2013. [Google Scholar]

- Knight, L.; Presnell, S. Death by sewer gas: Case report of a double fatality and review of the literature. Am. J. Forensic. Med. Pathol. 2005, 26, 181–185. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Tan, Y.; Zhang, X. Using a Hybrid Heating System to Increase the Biogas Production of Household Digesters in Cold Areas of China: An Experimental Study. Appl. Therm. Eng. 2016, 103, 1299–1311. [Google Scholar] [CrossRef]

- Liu, J.; Li, W.Z.; Chen, S.W. Heating mode of biogas plant in alpine region based on underground water source heat pump. Trans. Chin. Soc. Agric. Eng. 2013, 29, 163–169. [Google Scholar]

- Gaballah, E.S.; Abdelkader, T.K.; Luo, S.; Yuan, Q.; Abomohra, A.E.F. Enhancement of biogas production by integrated solar heating system: A pilot study using tubular digester. Energy 2020, 193, 116758. [Google Scholar] [CrossRef]

- Dong, F.; Lu, J. Using Solar Energy to Enhance Biogas Production from Livestock Residue – A Case Study of the Tongren Biogas Engineering Pig Farm in South China. Energy 2013, 57, 759–765. [Google Scholar] [CrossRef]

- Axaopoulos, P.; Panagakis, P.; Tsavdaris, A.; Georgakakis, D. Simulation and Experimental Performance of a Solar-Heated Anaerobic Digester. Sol. Energy 2001, 70, 155–164. [Google Scholar] [CrossRef]

- Han, R.; Hagos, K.; Ji, X.; Zhang, S.; Chen, J.; Yang, Z.; Lu, X.; Wang, C. Review on Heat-Utilization Processes and Heat-Exchange Equipment in Biogas Engineering. J. Renew. Sustain. Energy 2016, 8, 032701. [Google Scholar] [CrossRef]

- Lantz, M. The Economic Performance of Combined Heat and Power from Biogas Produced from Manure in Sweden – A Comparison of Different CHP Technologies. Appl. Energy 2012, 98, 502–511. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Capacity of the digester (m3) | 350 |

| Digester type | Fixed dome |

| Feedstock | Poultry droppings |

| Population (no. of birds) | 60,000 |

| Waste produced (kg/d) | 12,000 |

| Waste fed into the digester (kg/d) | 3000 |

| Date | Substrate | Slurry | ||||

|---|---|---|---|---|---|---|

| TS (%) | VS (%) | pH | TS (%) | VS (%) | pH | |

| 24-08-17 | 17.08 | 10.78 | 5.95 | 1.02 | 0.44 | 7.09 |

| 14-09-17 | 6.45 | 4.26 | 6.27 | 0.83 | 0.33 | 7.63 |

| 09-10-17 | 10.54 | 6.65 | 7.65 | 1.29 | 0.52 | 8.04 |

| 01-11-17 | 6.25 | 4.18 | 7.46 | 1.25 | 0.51 | 7.95 |

| 14-12-17 | 6.5 | 4.12 | 6.39 | 1.15 | 0.46 | 6.96 |

| 04-01-18 | 10.16 | 6.63 | 6.54 | 1.13 | 0.47 | 6.83 |

| 10-02-18 | 10.27 | 6.88 | 6.82 | 3.03 | 1.24 | 5.96 |

| Name of the Season | Ambient Temperature (°C) (Mean ± SD) | Slurry Temperature (°C) (Mean ± SD) |

|---|---|---|

| Autumn | 29.05 ± 3.07 a | 30.38 ± 0.38 a |

| Late autumn | 22.90 ± 5.47 b | 29.36 ± 0.96 a |

| Winter | 17.64 ± 6 c | 25.76 ± 0.78 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabbir, A.S.M.Y.B.; Saha, C.K.; Nandi, R.; Zaman, M.F.U.; Alam, M.M.; Sarker, S. Effects of Seasonal Temperature Variation on Slurry Temperature and Biogas Composition of a Commercial Fixed-Dome Anaerobic Digester Used in Bangladesh. Sustainability 2021, 13, 11096. https://doi.org/10.3390/su131911096

Sabbir ASMYB, Saha CK, Nandi R, Zaman MFU, Alam MM, Sarker S. Effects of Seasonal Temperature Variation on Slurry Temperature and Biogas Composition of a Commercial Fixed-Dome Anaerobic Digester Used in Bangladesh. Sustainability. 2021; 13(19):11096. https://doi.org/10.3390/su131911096

Chicago/Turabian StyleSabbir, A. S. M. Younus Bhuiyan, Chayan Kumer Saha, Rajesh Nandi, Md. Forid Uz Zaman, Md. Monjurul Alam, and Shiplu Sarker. 2021. "Effects of Seasonal Temperature Variation on Slurry Temperature and Biogas Composition of a Commercial Fixed-Dome Anaerobic Digester Used in Bangladesh" Sustainability 13, no. 19: 11096. https://doi.org/10.3390/su131911096

APA StyleSabbir, A. S. M. Y. B., Saha, C. K., Nandi, R., Zaman, M. F. U., Alam, M. M., & Sarker, S. (2021). Effects of Seasonal Temperature Variation on Slurry Temperature and Biogas Composition of a Commercial Fixed-Dome Anaerobic Digester Used in Bangladesh. Sustainability, 13(19), 11096. https://doi.org/10.3390/su131911096