Risk Management Maturity Model for Logistic Processes

Abstract

1. Introduction

- We have defined assessment areas for risk management maturity, which are essential for logistic processes performance.

- We have introduced a new risk maturity assessment area based on participation in the supply chain–cooperation at risk.

- We propose a 5-grade maturity assessment scale to define the risk assessment maturity achieved by an organization dedicated to logistic processes.

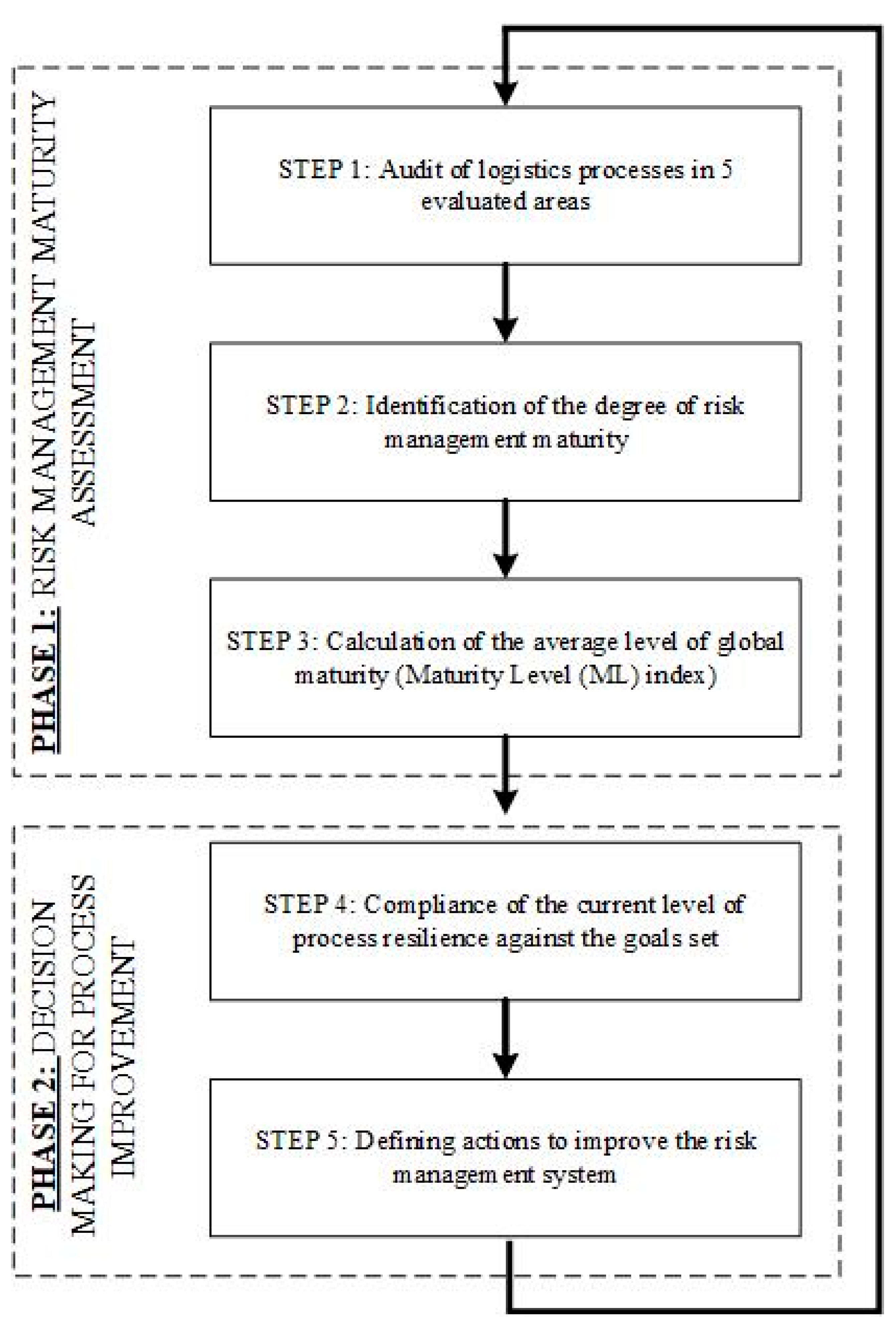

- We introduce a two-stage assessment method to assess the risk based on the global maturity index’s average level.

- Finally, we implement the proposed two-stage assessment method to verify the proposed model’s diagnostic function and determine its labor intensity.

2. Literature Review

2.1. Supply Chain Risk Management

2.2. Organizations’ Maturity Modeling

- The way it operates;

- The possibility of using its resources or previous experience;

- The objectives that can be achieved in the future by setting priorities for actions and identifying the means and ways of their implementation.

3. Methodology

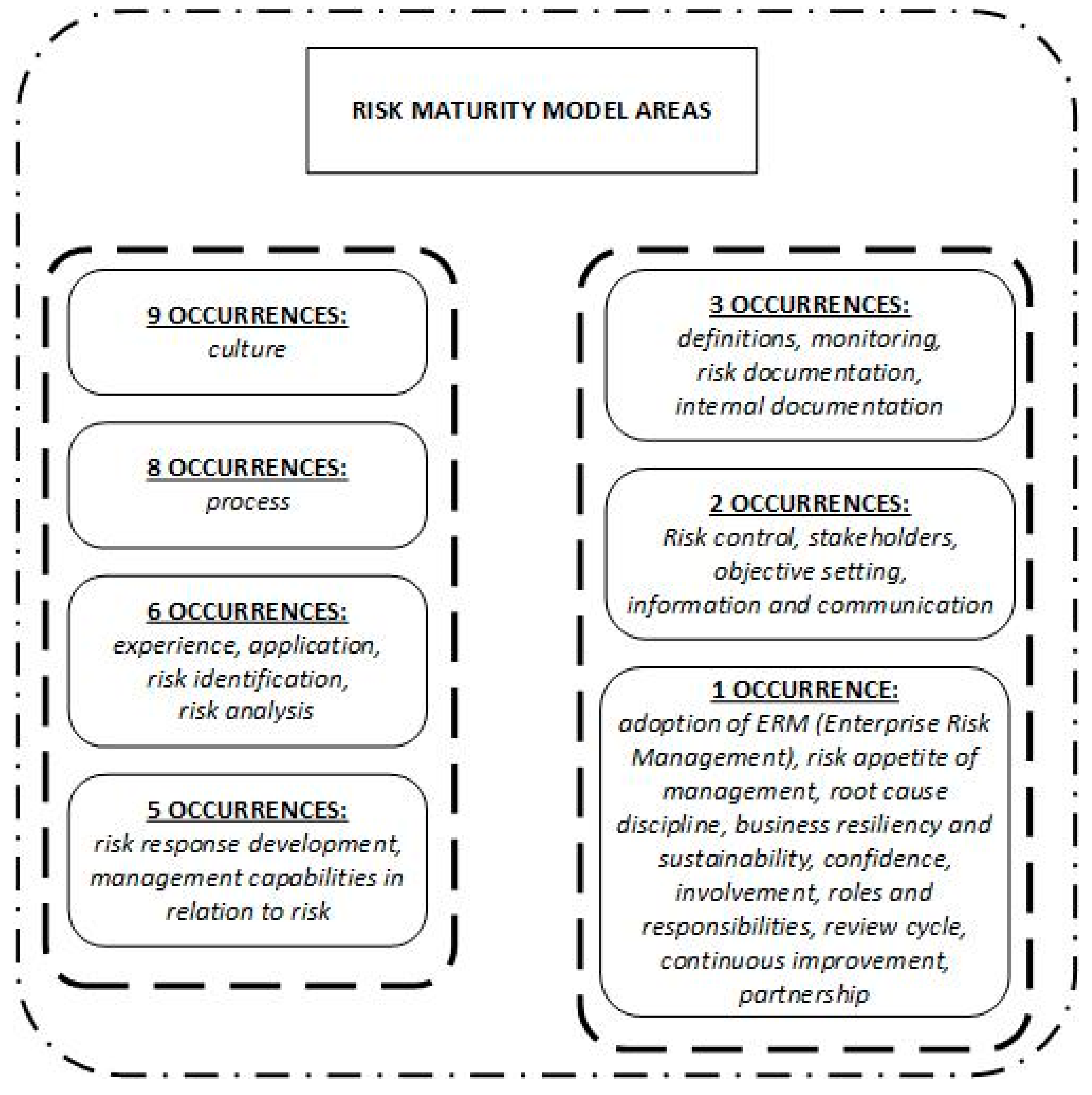

- RQ1. What areas of risk management should be the subject of maturity studies in relation to logistics processes based on classic RMM ERM models?

- RQ2. How to additionally take the inter-organizational nature of logistics processes into account in the risk management maturity study?

- RQ3. How do we identify risk area characteristics at maturity levels?

- RQ4: How should the risk management maturity assessment process be conducted in logistics processes?

- RQ5. Will the developed RMM model’s application affect the risk management maturity assessment performed in the selected organization?

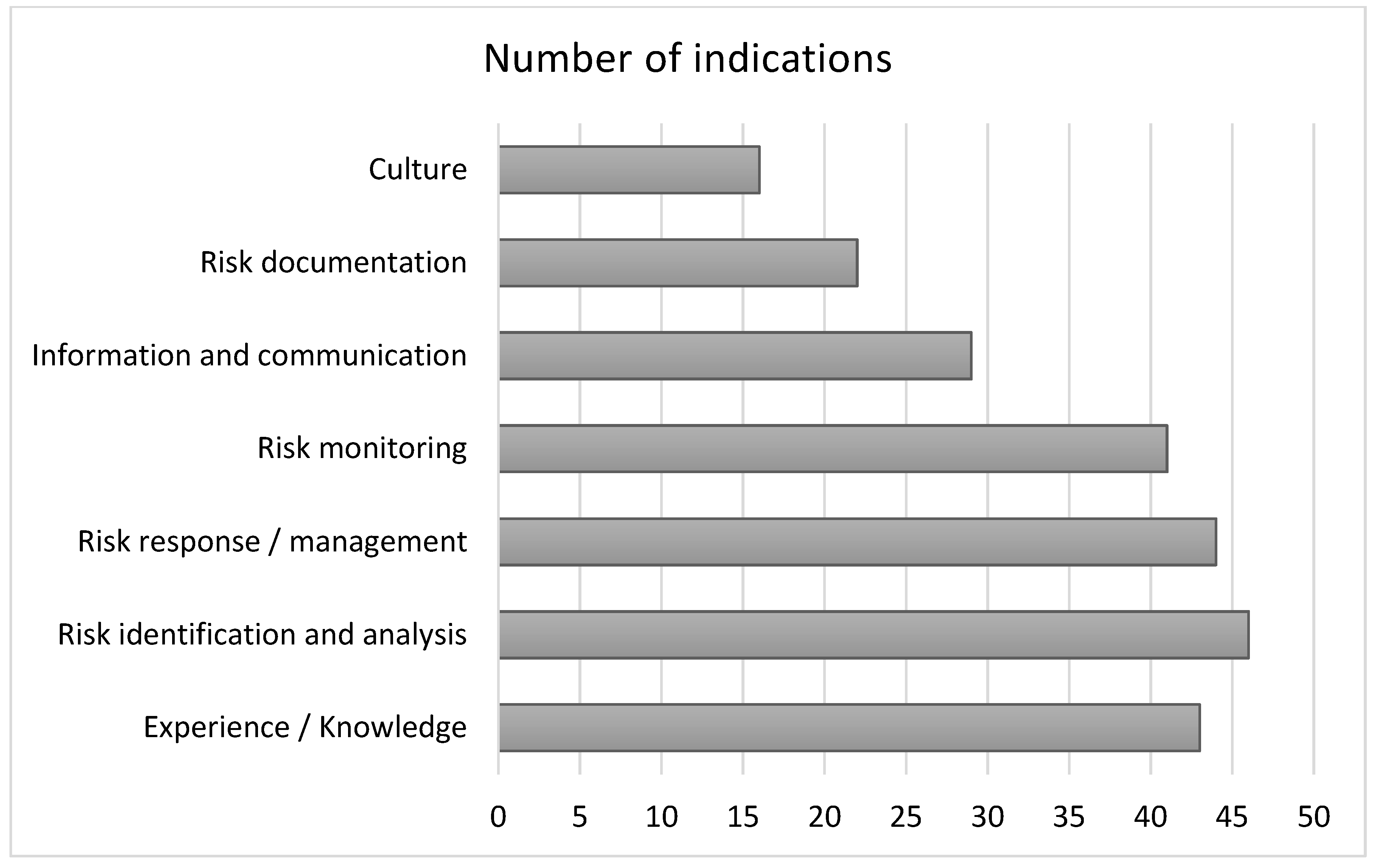

- Experience/knowledge: It should be taken into account that in an interview with logistics managers, the participants stressed the importance of the experience and registered/formalized knowledge of established events.

- Risk identification and analysis: Taking primarily the methods and scope of conducted risk analyses for logistics processes into account.

- Risk process management/Risk response: Determining the degree of use of the results of conducted risk analyses in the process of planning material and information flows, as well as the process management itself, taking into account their limitations and unwanted events.

- Risk monitoring: Understood as monitoring the correctness and effectiveness of logistic processes and achieving the assumed logistic standards.

4. Results and Discussion

- Face-to-face interviews with senior and middle management and with the management board, based on a structured interview aimed at identifying procedures and tools for risk management areas according to the proposed approach;

- Accompanying direct observation carried out between October 2019 and January 2020;

- Document workflow analysis;

- Analysis of the scope of prepared reports and indicators.

- Option 1–traditional core areas of RMM models described in the literature were assessed;

- Option 2–traditional assessment areas have been extended to include the area of cooperation in risk management.

5. Conclusions and Directions for Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Porter, M.E. Competetive Avantage: Creating and Sustaining Superior Performance; The Free Press: New York, NY, USA, 1985. [Google Scholar]

- Hong, P.; Kwon, H.B.; Roh, J.J. Implementation of strategic green orientation in supply chain. Eur. J. Innov. Manag. 2009, 12, 512–532. [Google Scholar] [CrossRef]

- Fan, Y.; Stevenson, M. A review of supply chain risk management: Definition, theory, and research agenda. Int. J. Phys. Distrib. 2018, 48, 205–230. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M. Supply chain readiness, response and recovery for resilience. Supply Chain Manag. 2016, 21, 709–731. [Google Scholar] [CrossRef]

- Aven, T. On how to conceptualise and describe risk. Reliab. Theory Appl. 2011, 2, 28–37. [Google Scholar] [CrossRef]

- Aven, T. The risk concept-historical and recent development trends. Reliab. Eng. Syst. Safe. 2012, 99, 33–44. [Google Scholar] [CrossRef]

- Aven, T. Risk Analysis, 2nd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2015. [Google Scholar] [CrossRef]

- Aven, T. Risk assessment and risk management: Review of recent advances on their foundation. Eur. J. Oper. Res. 2016, 253, 1–13. [Google Scholar] [CrossRef]

- Bukowski, L. Logistics decision-making based on the maturity assessment of imperfect knowledge. Eng. Manag. Prod. Serv. 2019, 11, 65–79. [Google Scholar] [CrossRef]

- Bukowski, L. Reliable, Secure and Resilient Logistics Networks: Delivering Products in a Risky Environment, Reliable, Secure and Resilient Logistics Networks; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- COSO. Enterprise Risk Management—Integrated Framework Executive Summary; COSO: New York, NY, USA, 2004; Available online: https://www.coso.org/Documents/COSO-ERM-Executive-Summary.pdf (accessed on 21 November 2020).

- Mokgoantle, O.J. Risk Maturity at a Life Insurer; M.Com. (Finance); University of Johannesburg: Johannesburg, South Africa, 2012. [Google Scholar]

- Alcantara, P.; Riglietti, G. Supply Chain Resilience Report 2016; Business Continuity Institute: Zurich, Switzerland, 2016; Available online: https://www.zurich.com.sg/-/media/project/zwp/singapore/docs/corporate-solutions/bcisupplychainresiliencereport2016web.pdf (accessed on 21 November 2020).

- Riglietti, G.; Aguada, L. Supply Chain Resilience Report 2018; Business Continuity Institute: Zurich, Switzerland, 2018; Available online: https://www.thebci.org/uploads/assets/uploaded/c50072bf-df5c-4c98-a5e1876aafb15bd0.pdf (accessed on 21 November 2020).

- Elliott, R.; Thomas, C.; Muhammad, K. Supply Chain Resilience Report 2019; Business Continuity Institute: Zurich, Switzerland, 2019; Available online: https://www.thebci.org/uploads/assets/e5803f73-e3d5-4d78-9efb2f983f25a64d/BCISupplyChainResilienceReportOctober2019SingleLow1.pdf (accessed on 21 November 2020).

- Nowakowski, T.; Scroubelos, G.; Tubis, T.; Werbińska-Wojciechowska, S.; Chlebus, M. Sustainable Supply Chains Versus Safety and Resilience. In Sustainable Logistics and Production in Industry 4.0. EcoProduction (Environmental Issues in Logistics and Manufacturing); Grzybowska, K., Awasthi, A., Sawhney, R., Eds.; Springer: Cham, Switzerland, 2020; pp. 65–87. [Google Scholar]

- Rao, S.; Goldsby, T.J. Supply chain risks: A review and typology. Int. J. Logist. Manag. 2009, 20, 97–123. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B.; Ivanova, M. Disruptions in supply chains and recovery policies: State-of-the art review. IFAC PapersOnLine 2016, 49, 1436–1441. [Google Scholar] [CrossRef]

- Singhal, P.; Agarwal, G.; Mittal, M.L. Supply chain risk management: Review, classification and future research directions. Int. J. Bus. Sci. Appl. Manag. 2010, 6, 15–42. [Google Scholar]

- Ghadge, A.; Dani, S.; Kalawsky, R. Supply chain risk management: Present and future scope. Int. J. Logist. Manag. 2012, 23, 313–339. [Google Scholar] [CrossRef]

- Ceryno, P.S.; Scavarda, L.F.; Klingebiel, K.; Yuzgulec, G. Supply chain risk management: A content analysis approach. Int. J. Ind. Eng. Manag. 2013, 4, 141–150. [Google Scholar]

- Ouabouch, L.; Pache, G. Risk management in the supply chain: Characterization and empirical analysis. J. Appl. Bus. Res. 2014, 30, 329–340. [Google Scholar]

- Tran, T.H.; Dobrovnik, M.; Kummer, S. Supply chain risk assessment: A content analysis-based literature review. Int. J. Logist. Manag. 2018, 31, 562–591. [Google Scholar] [CrossRef]

- Pournader, M.; Kach, A.; Talluri, S. A Review of the Existing and Emerging Topics in the Supply Chain Risk Management Literature. Decis. Sci. 2020. [Google Scholar] [CrossRef]

- Macdonald, J.R.; Corsi, T.M. Supply chain disruption management: Severe events, recovery, and performance. J. Bus. Logist. 2013, 34, 270–288. [Google Scholar] [CrossRef]

- Ellis, S.C.; Shockley, J.; Henry, R.M. Making sense of supply disruption risk research: A conceptual framework grounded in enactment theory. J. Supply Chain Manag. 2011, 47, 65–96. [Google Scholar] [CrossRef]

- Wagner, S.M.; Bode, C. An empirical examination of supply chain performance along several dimensions of risk. J. Bus. Logist. 2008, 29, 307–325. [Google Scholar] [CrossRef]

- Manuj, I.; Esper, T.L.; Stank, T.P. Supply chain risk management approaches under different conditions of risk. J. Bus. Logist. 2014, 35, 241–258. [Google Scholar] [CrossRef]

- Olson, D.L.; Swenseth, S.R. Trade-offs in supply chain system risk mitigation. Syst. Res. Behav. Sci. 2014, 31, 565–579. [Google Scholar] [CrossRef]

- Talluri, S.; Kull, T.J.; Yildiz, H.; Yoon, J. Assessing the efficiency of risk mitigation strategies in supply chains. J. Bus. Logist. 2013, 34, 253–269. [Google Scholar] [CrossRef]

- Hult, G.T.M.; Craighead, C.W.; Ketchen, D.J. Risk uncertainty and supply chain decisions: A real options perspective. Decis. Sci. 2010, 41, 435–458. [Google Scholar] [CrossRef]

- Käki, A.; Salo, A.; Talluri, S. Disruptions in Supply Networks: A Probabilistic Risk Assessment Approach. J. Bus. Logist. 2015, 36, 273–287. [Google Scholar] [CrossRef]

- Adhitya, A.; Srinivasan, R.; Karimi, I.A. Supply Chain Risk Identification Using a HAZOP-Based Approach. AIChE J. 2009, 55, 1447–1463. [Google Scholar] [CrossRef]

- Saud, Y.E.; Israni, K.; Goddard, J. Bow-Tie diagrams in downtream hazard identification and risk assessment. Process Saf. Prog. 2014, 33, 26–35. [Google Scholar] [CrossRef]

- Peček, B.; Kovačič, A. Methodology of monitoring key risk indicators’, Economic Research-Ekonomska Istrazivanja. Econ. Res. 2019, 32, 3485–3501. [Google Scholar] [CrossRef]

- Wibowo, M.A.; Waluyo, R. Knowledge management maturity in construction companies. Procedia Eng. 2015, 125, 89–94. [Google Scholar] [CrossRef]

- Rudnicka, A. Sustainable supply chain maturity model. Res. Log. Prod. 2017, 7, 201–209. [Google Scholar] [CrossRef]

- Murray-Webster, R.; Williams, G. (Eds.) Risk Management: A Guide for Practitioners; The Stationery Office: Warsaw, Poland, 2010. (In Polish) [Google Scholar]

- Van Looy, A. Business Process Maturity. A Comparative Study on a Sample of Business Process Maturity Models; vom Brocke, J., Liechtenstein, V., Eds.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Business Process Maturity Model (BPMM) Version 1.0. OMG Document Number: Formal/2008-06-01. 2008. Available online: http://www.omg.org/spec/BPMM/1.0/PDF (accessed on 2 November 2020).

- Juchniewicz, M. Project maturity of an organization as a tool to improve project management processes. In Modern Concepts of Production, Quality and Logistics Management; Lachiewicz, S., Matejun, M., Eds.; Lodz: Publ. House of Lodz University of Technology: Lodz, Poland, 2010; pp. 287–305. (In Polish) [Google Scholar]

- Chrapko, M. CMMI Improvement of Processes in Organization; Polish Scientific Publishers PWN: Warsaw, Poland, 2010; (In Polish). [Google Scholar] [CrossRef]

- Lee, D.; Gu, J.W.; Jung, H.W. Process maturity models: Classification by application sectors and validities studies. J. Softw. Evol. Proc. 2019, 31, 1–30. [Google Scholar] [CrossRef]

- Helgesson, Y.Y.L.; Host, M.; Weyns, K. A review of methods for evaluation and maturity models for process improvement. J. Softw. Maint. Evol. R. 2012, 24, 436–454. [Google Scholar] [CrossRef]

- Pino, F.J.; Baldassarre, M.D.; Piattini, M.; Vissaggio, G. Harmonizing maturity levels from CMMI_DEV and ISO_IEC 15504. J. Softw. Evol. Proc. 2010, 22, 279–296. [Google Scholar] [CrossRef]

- Albu, E.; Panzar, C. A new tool for assessing maturity alignment: The Enterprise Maturity Matrix. Perform. Improv. 2010, 49, 35–47. [Google Scholar] [CrossRef]

- Kosieradzka, A.; Smagowicz, J. Concept of maturity model of organization in the area of public crisis management. Sci. Notebooks Silesian Univ. Technol. Ser. Org. Manag. 2018, 128, 217–230. (In Polish) [Google Scholar]

- Cheshmberah, M.; Beheshtikia, S. Supply chain management maturity: An all-encompassing literature review on models, dimensions and approaches. LogForum 2020, 16, 103–116. [Google Scholar]

- Scott, S.H. Supply Chain Management Maturity Level Assessment. Defense ARJ 2017, 24. [Google Scholar] [CrossRef]

- Correia, E.; Calvalho, H.; Azevedo, S.G.; Govindan, K. Maturity models in supply chain sustainability: A systematic literature review. Sustainability 2017, 9, 64. [Google Scholar] [CrossRef]

- Facchini, F.; Oleśków-Szłapka, J.; Ranieri, L.; Urbinati, A. A maturity model for logistics 4.0: An empirical analysis and a roadmap for future research. Sustainability 2020, 12, 86. [Google Scholar] [CrossRef]

- Hofman, W. Data sharing requirements of supply—And logistics innovations—Towards a maturity model. In Proceedings of the ILS 2016—6th International Conference on Information Systems, Logistics and Supply Chain, Bordeaux, France, 1–4 June 2016; pp. 1–8. [Google Scholar]

- Kasse, T.; Johansen, J. Maturity differences between customer and supplier - challenges, problems, and possible solutions. J. Softw. Evol. Proc. 2014, 26, 295–305. [Google Scholar] [CrossRef]

- Netland, T.; Alfnes, E.; Fauske, H. How mature is your supply chain? A supply chain maturity assessment test. In Proceedings of the 14th International EurOMA Conference “Managing Operations in an Expanding Europe”, Ankara, Turkey, 17–20 June 2007; pp. 1–10. Available online: https://www.sintef.no/project/SMARTLOG/Publikasjoner/2007/Netland%20etal%20_2007_%20How%20mature%20is%20your%20supply%20chain.pdf (accessed on 2 November 2020).

- Zou, P.X.W.; Chen, Y.; Chan, T.Y. Understanding and improving your risk management capability: Assessment model for construction organizations. J. Constr. Eng. Manag. 2010, 136, 854–863. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Lima, G.B.A.; de Mattos Nascimento, D.L.; Neto, J.V.; de Oliveira, R.A.M. Guidelines to Risk Management Maturity in Construction Projects. Braz. J. Oper. Prod. Manag. 2016, 13, 372–385. [Google Scholar] [CrossRef]

- Sawalha, I.H.S. Collaboration in crisis and emergency management: Identifying the gaps in the case of storm “Alexa”. J. Bus. Contin. Emer. Plan. 2014, 7, 312–323. [Google Scholar] [PubMed]

- Christopher, M. Logistics and Supply Chain Management: Strategies for Reducing Costs and Improving Service; Financial Times—Prentice Hall: London, UK, 1998. [Google Scholar]

| Areas | Poor–1 | Basic–2 | Good–3 | Satisfactory–4 | Excellent–5 |

|---|---|---|---|---|---|

| Knowledge | Lack of systematic knowledge about the operation of logistic processes and occurring disturbances. The employees rely solely on their own experience. Lack of knowledge of the organization about risks in logistics systems. | Logistics process managers have the knowledge gained from their team about critical logistics operations and the associated risks. However, this knowledge is not formally recorded in the system. | Based on collected reports about logistic operations, managers report the most significant adverse events to the system. | A knowledge base of adverse events is established, taking into account the causes, effects, dates of occurrence, associated factors, and critical logistic operations (in particular their time and space relationships and resources). | The knowledge base is regularly updated based on current observations and events. The company also registers in the system sectoral, process, and technical knowledge derived from benchmarking analyses. The knowledge is acquired based on developed reporting tools. The knowledge comes not only from the company’s own experience but also from other external entities. Defined knowledge management principles. |

| Risk identification and analysis | Lack of identification of undesirable event to the successful operation of logistics processes. No risk assessment, even for the critical delivery processes. | In the case of undesirable events in critical logistic operations, the risk of their occurrence shall be determined using qualitative tools. The results are communicated to the management board only. | Risk identification and analysis of logistic processes carried out at the request of the management board. Only a small team of logistics specialists is involved in the performed analyses. Quality tools are mainly used. The results are communicated to the management board and logistics managers. | Risk analysis is carried out for all logistics processes regularly but at considerable intervals. An evaluation carried out using quantitative and qualitative tools. The results are communicated to the management board and selected managers (not only from the logistics area). | A risk assessment carried out on a systematic basis (periodic update of the results obtained). The assessment uses the knowledge of managers from different areas—a team composed of specialists from different areas of the company. The use of advanced quantitative and qualitative risk assessment tools. Assessment results are distributed to all units of the organization. |

| Risk response | Lack of identification of the critical logistics processes. Lack of consideration of occurring limitations or undesired events in the planning processes performance. | Identified operations that are critical to the correct completion of delivery processes. Modes of emergency execution of critical operations have been identified in the case of undesired events occurrence. | The results of the conducted analysis are used to plan high-risk logistics processes. Lack of prevention and mitigation actions. Lack of improvement of logistic processes based on the existing risk identification. | Preventive procedures and scenarios are developed for events with the highest risk level. When planning logistic activities, managers use their knowledge about adverse events and their occurrence possibility. | The results of the risk assessment are the basis for planning logistics activities. For events with an unacceptable level of risk indicator, preventive measures are developed (reducing the probability of their occurrence), as well as scenarios for dealing with their consequences (reducing the effects of the event occurrence). Based on the results of risk analysis, logistic processes are improved in accordance with the PDCA cycle (Plan-Do-Check_Act). |

| Risk monitoring | Lack of a system of logistic indicators to monitor the efficiency and effectiveness of performed processes. | Fundamental logistic indicators that monitor the performance of processes and the results obtained. Lack of use of logistic indicators in the assessment of hazards to the execution of delivery processes. | Fundamental logistic indicators to monitor the efficiency and effectiveness of performed processes, calculated regularly for reporting purposes, and at the management board’s request. Set standards for indicators to inform about deviations from planned effects achievement level. | A formalized (integrated with the IT system) system of indicators monitoring the correctness and effectiveness of the implementation of logistic processes and their compliance with the set standards (logistic service standards). Risk analysis in the case of long-term or significant deviations occurrence. | A comprehensive system of indicators monitoring the correctness and effectiveness of logistic processes, determined regularly based on data reported to the system. Regular analysis and interpretation of deviations from the assumed logistic standards. Exchange of information between departments on significant deviations affecting supply processes and other company processes. Indicators play the role of guards of process correctness. |

| Cooperation at risk | Lack of exchange of information on adverse events within the company and with business partners. | For critical events, cooperation between functional areas following the guidelines of the management board. | Sharing information on adverse events with other functional areas of the company. Internal cooperation in planning high-risk processes. Information on disruptions to business partners. | Sharing information on adverse events within the company and with strategic partners. Developed emergency scenarios for high-risk adverse events, prepared together with strategic partners. | Information integration of risks within the company and with business partners. Cooperation with partners in the supply chain in the area of risk reduction. Joint development of preventive measures. Jointly developed emergency response scenarios taking into account the potential and accepted ranges of deviations by partners in the supply chain and distribution channels. Coordinated responses to the occurrence of adverse events. |

| Maturity Level | Characteristics |

|---|---|

| Level 1: Ad hoc risk management | There are no activities aimed at identifying risks in the area of logistic systems performance; no preventive actions, and no reduction of the effects of supply disruptions. Lack of risk management rules and procedures in logistic systems operation, due to the occurrence of undesired events, deliveries are executed in a chaotic manner (“ad hoc” management). |

| Level 2: Critical events in logistic system management | Developed and implemented procedures for managing critical events in logistic systems. Other possible disruptions are identified, but there are no systematically applied solutions for risk assessment and logistic process performance management. Lack of use of available IT (information technology) tools to gather knowledge and monitor the current implementation of delivery processes. Possible risk reduction is limited to a given logistic process and results from particular logistic managers’ initiative. The competence and commitment of employees determine the success of an organization. |

| Level 3: Selective organizational risk management | Risk management procedures and rules have been developed but are not implemented in a systemically sound manner. They are known only to a small group of logistic specialists. Risk assessment is supported by information from the IT system (ERP (Enterprise Resource System), WMS (Warehouse Management System)). No continuous monitoring of risks. Delivery risk assessment results support management processes, but only in selected cases. The principles of cross-departmental cooperation (of particular functional areas in the company) are defined in case of undesired events (with a high level of risk) in particular processes occurrence. Qualitative methods are used to identify and assess logistic risk. |

| Level 4: Cross-functional supply risk management | Risk assessment and management procedures in the logistic system have been developed and implemented systematically. The risk assessment involves representatives of the logistics department and the departments cooperating in handling material and information flows in the company. The company collects information on undesirable events systemically occurring in the delivery process and uses it in the planning processes. Selected business partners are involved in risk management processes. In addition to qualitative methods, basic quantitative methods are included in risk identification and assessment. Risk monitoring is based on a defined system of logistic indicators. |

| Level 5: Integrated supply risk management | Full implementation of all assumed supply risk management tools in a fully integrated system. A system for gathering and using the information following the concept of a learning organization. Continuous improvement of logistics processes based on risk assessment. Full use of the knowledge and experience of logistics staff and external information from supply chain partners. Risk management system based on integration with business partners. Integration of the risk management system with the so-called core business objectives and company management strategy. |

| Area | Characteristics of the Area in the Analyzed Company |

|---|---|

| Knowledge | In the case of an adverse event that occurred in supply processes, managers collect information from team members on the causes of the event and determine the consequences of its occurrence. Undesirable events, which are the most important in their assessment, are recorded in a shared spreadsheet with the date of occurrence. |

| Risk assessment | Risk identification and analysis is prepared for every request of the company management. However, the analysis is prepared by a small team of the CEO’s closest associates. Based on the information entered by logistics specialists into the spreadsheet, the logistics director determines critical events. These are registered cases with many repetitions or effects that significantly affect the company’s market position. For critical events, managers must periodically prepare a risk analysis based on their observations and knowledge. Information on the identified risks is communicated to the management board and selected managers. |

| Process risk management | For critical events, particularly for which the consequences determine an enterprise’s competitive position, logistic managers are required to develop emergency procedures. These actions are primarily aimed at maintaining the continuity of the company’s operations and a quick return to the declared level of logistical service. |

| Cooperation at risk | Prepared scenarios for emergency procedures assume integration of activities of selected functional areas. For this reason, information on critical events is placed in spreadsheets to which managers of all functional areas have access. However, the cooperation procedure applies only to events critical to the company’s operations. |

| Risk monitoring | Information on critical events is communicated only to selected managers and only for the management board’s explicit indication. No exchange of information on adverse events with contractors, even those with whom the company cooperates in partnership relations. |

| Option 1 | Option 2 | |||

|---|---|---|---|---|

| Area | Weights for Area | Maturity Level | Weights for Area | Maturity Level |

| Knowledge | 0.2 | 3 | 0.1 | 3 |

| Risk assessment | 0.3 | 3 | 0.3 | 3 |

| Process risk management | 0.3 | 2 | 0.3 | 2 |

| Risk monitoring | 0.2 | 3 | 0.1 | 3 |

| Cooperation at risk | - | - | 0.2 | 1 |

| ML indicator | 2.7 | 2.3 | ||

| CHANGE MANAGEMENT | Risk Assessment | Risk Process Management |

| AS–IS ANALYSIS | ||

| No exchange of information on adverse events occurring in the supply chain | Process emergency procedures designed for critical events only | |

| TO–BE SCENARIO | ||

| Step 1: Cooperation between departments within the company to reduce the impact and likelihood of adverse events occurrence | Step 1: Use of risk analysis results for planning vulnerable processes | |

| Step 2: Transmission of the information on potential disruptions in supply/orders to business partners | Step 2: Development of preventive procedures and management scenarios for identified adverse events | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tubis, A.A.; Werbińska-Wojciechowska, S. Risk Management Maturity Model for Logistic Processes. Sustainability 2021, 13, 659. https://doi.org/10.3390/su13020659

Tubis AA, Werbińska-Wojciechowska S. Risk Management Maturity Model for Logistic Processes. Sustainability. 2021; 13(2):659. https://doi.org/10.3390/su13020659

Chicago/Turabian StyleTubis, Agnieszka A., and Sylwia Werbińska-Wojciechowska. 2021. "Risk Management Maturity Model for Logistic Processes" Sustainability 13, no. 2: 659. https://doi.org/10.3390/su13020659

APA StyleTubis, A. A., & Werbińska-Wojciechowska, S. (2021). Risk Management Maturity Model for Logistic Processes. Sustainability, 13(2), 659. https://doi.org/10.3390/su13020659