1. Introduction

The economic sector of outdoor sporting activities is part of a constantly growing segment of the European economy [

1]. An increase in sales of 3% was achieved in 2017, with individual segments such as climbing equipment generating even higher sales growth of more than 4% [

1]. As the business surrounding mountain sports grows, so too does the demand for sustainable outdoor products [

2,

3]. Mountain sports are affected by climate change in a way which few other sports are. Melting glaciers, less snowfall in many regions and rock fall due to thawing permafrost are all having a direct impact on athletes and the business surrounding mountain sports [

4,

5,

6].

The efforts of producers to reduce their impact on the environment have so far focused mainly on apparel production [

7,

8]. However, a company carbon footprint analysis conducted by the Mammut Sports Group AG (hereafter Mammut), a multinational mountaineering company based in Seon (Switzerland), revealed that hardware accounts for the largest share (47%, 26.9 t CO

2-eq.) of greenhouse gas (GHG) emissions [

9]. Hardware includes all products that cannot be classified as textiles or shoes [

9]. At 41% (11 t CO

2-eq.), climbing ropes produced in the Czech Republic cause the highest carbon footprint within this category [

9]. Due to the high share of climbing ropes in the company carbon footprint, this study further examines the environmental impact of this product.

There are no public studies available on the environmental impact of climbing ropes besides the carbon footprint analysis of Mammut. There are, however, studies on products which consist of the same basic material as climbing ropes: nylon [

10,

11,

12,

13]. Nylon belongs to the family of polyamides produced by the reaction of carbon-based chemicals found in coal and petroleum [

14]. The polyamide (PA) numbers 6 or 6.6 indicate the number of carbon atoms in the molecule [

13]. For the industrial production of polyamide 6 (PA6), the polyamide type used by Mammut, ring-opening polymerisation of caprolactam, is used.

In PA6 production, the global warming potential (GWP) has been significantly reduced in recent years [

15]. This is mainly due to an optimisation of energy efficiency and partly due to the progress made by the industry in mitigating nitrogen oxide (N

2O) emissions [

15]. According to PlasticsEurope [

15], the CO

2 emissions in 2013 were reduced by 26% (1.4 kg CO

2) and the N

2O emissions by 14% (1.2 g N

2O/kg) compared to 2005. However, PA6 production also has an impact on other environmental issues, such as freshwater ecotoxicity. This is in particular due to the raw material production process, which releases substantial amounts of phosphorus directly into aquatic media [

12].

Polyamide 6.6 (PA6.6) is very similar in its functional properties, but due to a different production process, different environmental impacts arise. PA 6.6 causes higher environmental impacts in the majority of the categories according to the Environmental Footprint (EF) method, except for ozone depletion, (−47%, −6.8 × 10

−8 kg CFC11 eq.), freshwater eutrophication (−14%, −4.3 × 10

−5 kg P eq.), terrestrial eutrophication (−11%, −5.20 × 10

−3 mol N eq.) [

16].

PA6 and 6.6 are characterized by mechanical and physical properties such as high tensile strength, elasticity and durability [

16]. This makes the synthetic fibre attractive not only for climbing ropes, but also for textiles. According to van der Velden et al. [

11] the polymer pellets of PA6 and 6.6 contribute, with 8.6 kg CO

2-eq., roughly 40% to the GHG emissions of the production of one kilogram of textiles. The process of weaving has, at approximately 50%, the highest impact in linear low-density textile production [

11]. According to Beton et al. [

12], the raw material production for a PA6 textile causes, with 11 kg CO

2-eq./kg, about 35% of the total production process, similar to the results of Van der Velden et al. [

11]. With 9 kg CO

2-eq., the finishing contributes about 30% to the GWP. Beton et al. [

12] also evaluated the usage and end-of-life phase based on the ReCiPe midpoint indicators. The usage phase contributes 45% to the GHG emissions of a textile’s life cycle, and up to 77% to toxicity categories (human, freshwater and marine).

An extension of the service life has the potential to lower the environmental impact of production-relevant products by avoiding the purchase of new products. In order to evaluate this potential, it is necessary to compare the recommended service life (absolute obsolescence) with the service life in practice (relative obsolescence) [

17]. According to Mammut, the absolute obsolescence of climbing ropes depends largely on the frequency and intensity of use [

18], which was also confirmed by Schubert [

19].

The rope producer is planning a project in which old climbing ropes are collected and recycled in an open-loop. According to the company, the recycled polyamide would be reused for non-personal protective equipment products, such as a T-shirt, as it cannot meet the high functional requirements as a base material for climbing ropes. By recycling old ropes, the environmental impact occurring through the disposal of plastic fibres and the production of the T-shirt’s base material can be avoided [

20]. The environmental benefits of recycling cotton and synthetic fibers were shown by Michaud et al. [

21] and Yasin et al. [

22], comparing waste management options. The studies confirmed that mechanical recycling causes the least environmental impact, mainly due to the avoidance of virgin material production.

The goal of this paper is to comprehensively analyse potential environmental impacts in the life cycle of a climbing rope and to identify environmental hotspots and mitigation potentials. Furthermore, the potential of a recycling project will be evaluated and factors to support its implementation determined.

2. Materials and Methods

2.1. Life Cycle Assessment

In order to analyse the environmental impact of climbing ropes, a life cycle assessment (LCA) was carried out. An LCA examines the environmental effects throughout a product’s life cycle from raw material acquisition through production, use, end-of-life treatment, recycling and final disposal [

23]. This methodology has become established for assessing the environmental impact of products [

24].

The impact assessment of GHG emissions was calculated according to the IPCC 2013 100a method. This method examines the GWP and the associated GHG emissions over a period of 100 years. The reference unit for the calculation is one kilogram of CO2-equivalent (kg CO2-eq.).

Additional impact categories have been assessed with the Environmental Footprint (EF) method. The EF is derived from the International Life Cycle Data System (ILCD), which was developed by the European Commission in 2007 and first published in 2010 [

25]. This study uses the second revision of the method (EF 3.0) and thus considers current midpoint indicators and their characterization [

25].

The foreground inventory data were linked to background data from the ecoinvent v3.6 database [

26] and modelled using SimaPro 9.0 software [

27]. For all ecoinvent background data, the system model ‘allocation, cut-off’ was used.

The weight of Mammut’s best-selling rope in 2019 was defined as the functional unit: the 9.5 Infinity Classic/Dry is 60 m long and weighs 3.54 kg [

28]. The system boundaries included the production, usage and disposal phases (

Figure 1). The production phase begins with the petroleum-based thermoplastic raw material, polyamide 6, which is processed into yarn by yarn manufacturers in Slovakia, Latvia, and Belarus. Next, in rope processing, the yarn is twisted into rope sheaths and cores, which are finally braided together. The sheath of an impregnated rope is dyed externally and shrunk in Switzerland. The finished rope is transported by lorry from the central warehouse to the various sales countries. During the average usage phase of five years, 32% of the users wash their rope by hand and 16% by machine. At the end of its service life, the rope is disposed either via incineration (91%) or sanitary landfill (9%). In a further scenario, the emissions avoided through the potential open-loop recycling project (saved polyester and avoided disposal) were also considered. The environmental impact of the recycling process itself was not included. The system boundaries apply for the rope production for Mammut in Europe in the reference year 2018.

2.2. Data Acquisition: Production Phase

The energy consumption and energy sources for rope processing date from 2018 and were provided by the producer. The energy data for yarn production were taken from an earlier MyClimate calculation from 2011 [

29] and were adjusted according to the delivery quantities of 2018.

The production data were supplemented with the use of chemicals for the impregnation, the infrastructure of the factories and the average distribution to the European market.

In order to assess the environmental impact of the polyamide production, background data from PlasticsEurope were obtained [

30]. The main data source of the ‘polyamide (nylon) 6/EU-27′ data set was a data collection from four European producers of polyamide 6, which represent about 57% of the European PA6 production (EU27) in 2012 [

15].

2.3. Data Acquisition: Usage- and End-of-Life Phase

The data on the use and the end-of-life phases were collected in a quantitative research design with an online survey, which can be examined in the Online Survey chapter in the

supplementary materials. The questionnaire was activated between 7 April 2020 and 28 April 2020 and included a total of 17 questions and 6 subquestions.

A convenience sample was used for this study. The climbing magazine LaCrux, the outdoor equipment provider Transa and the Austrian Alps Association (ÖAV) published the link of the online survey in various online communication channels. Additionally, the survey link was issued on the climbing forums ‘8a.nu’ as well as ‘kletterportal.ch’ and ten climbing ropes from Mammut were raffled among the participants. A total of 1450 people took part in the survey with a completion rate of 82%. Only one survey submission was permitted per IP address. After data cleansing, 1185 data sets were evaluated. Incomplete answers (17%) and answers with extreme outliers, as well as suspicions of click-through participants due to an unrealistic response duration, were not considered in the evaluation. The majority of the survey participants are from Switzerland (n = 536, 45%), Austria (n = 302, 25%) and Germany (n = 255, 22%).

In the first section, the survey participants were asked if they had ever used a rope to the end of its service life or if they were still using their first rope for climbing. If they used a rope to the end of its service life, certain questions on rope usage and disposal were related to their last rope (simplified in the evaluation as ‘old rope’). If the survey participants were still climbing with their first rope, these questions were related to their current, most-used rope (simplified in the evaluation as ‘current rope’). In total, 67.1% of the survey participants (n = 795) were allocated to the group ‘old rope’ and 32.9% of the survey participants (n = 390) to the group ‘current rope’.

The participants were asked how long and how often they had been climbing. Based on this information, the survey participants were divided into three different levels of experience: beginner (n = 102), advanced (n = 224) and expert (n = 859). The assignment is shown in

Table S5 in the supplementary materials.

The middle section of the survey addressed the rope usage to evaluate the potential for a service life extension. The participants were asked about the frequency of their rope use and their rope treatment.

The third section focused on the end-of-life phase of climbing ropes. The answers provided information about the factors affecting relative obsolescence and what happens to the ropes at the end of their service life. In order to assess the potential of a recycling project for old ropes, the participants were asked about their likelihood of returning their rope and the factors influencing the return. The predetermined selection of factors was based on previous research findings on recycling incentives. Kennedy et al. [

31] pointed out the importance of convenience, Barnosky et al. [

32] showed the effect of intrinsic motivation and Viscusi et al. [

33] highlighted the influence of economic incentives.

The online survey was conducted using limesurvey.org [

34]. Pre-tests with people from the target group were conducted in advance to check the comprehensibility and duration of the questionnaire. The questions were designed in collaboration with socioeconomic research experts from the Zurich University of Applied Sciences. For the questions on the rope usage, the technical knowledge of Mammut was consulted.

The Likert Scale made it possible to quantify and statistically evaluate latent variables, such as the influence of factors on the decision that the rope has reached the end of its service life [

35]. In each case, five response options were provided and only the endpoint of the scale was verbalized. According to Porst [

35], a minimum width of 5 scale points is recommended, and it can be treated as interval scaled if only the endpoints are verbalized. Thus, the most positive (for example ‘very likely’) response option was rated 5, and the most negative response option (for example ‘very unlikely’) was rated 1.

Comparisons between groups, such as nationality or climbing experience, were performed using Pearson’s chi-squared and Kruskal-Wallis tests depending on whether the underlying data was nominal or ordinal with respect to the interval. Significant comparisons of multiple groups were followed with pairwise comparisons based on the Dunn-Bonferroni test. Differences with a p-value smaller than 0.05 were considered to be significant.

To determine the strength of the relationship between two variables, the Spearman-Rho rank correlation analysis was applied. According to Cohen [

36], the correlation coefficient (r), which identifies the strength of the linear correlation, can be interpreted in terms of its effect or correlation strength as follows: r: +/− 0.1 = small effect size, r: +/− = 0.3 moderate effect size, r: +/− 0.5 = large effect size.

The Spearman-Rho as well as the Kruskal-Wallis tests were preferred because the underlying data are not required to be metric [

37]. Although the literature allows exceptions, the Likert-scale is strictly speaking an ordinal scale. Several data on frequency (e.g., rope usage frequency) were also scaled in an ordinal manner because the interval between response options such as ‘almost daily’ or ‘several times a week’ cannot be precisely defined [

38].

2.4. Life Cycle Inventory

In the reference year 2018, Mammut sourced the processed polyamide 6 from different yarn suppliers in Europe. The wound-up yarn was transported by truck to the rope processing plant in the Czech Republic.

In 2016, Mammut outsourced its rope production from Seon in Switzerland to a factory in Veselí nad Lužnicí in the Czech Republic which also produces ropes for other companies. However, the original machines and processes have been retained. The thermal energy of the factory is based on natural gas and low voltage electricity is used for operation (

Table 1). The ecoinvent dataset of perfluoropentane was used to model the impregnation agent PFHxA (a perfluoroalkane sulfonic acid with 6 perfluoroalkyl carbons, C

6HF

11O

2) [

39]. Perfluorepentan is a perfluoroalkan with five perfluoroalkyl carbons but without hydrogens (C

5F

12) [

40]. It was assumed that 5% of the impregnating agents end up in the wastewater.

To model the infrastructure, the ecoinvent dataset of a chemical factory was used and adapted. The factory area was calculated using Google maps (4820 m

2). The area corresponds to 9.8% of the area of the ecoinvent data set. A total of 23% of the heat demand from the factory derives from the rope processing for Mammut [

41]. Therefore, it was calculated that 23% of the infrastructure can also be assigned to the manufacture of the Mammut ropes.

The distance from the production site in Veselí nad Lužnicí to the central warehouse in Wolfertschwenden (Germany) is 469 km. From the central warehouse, the ropes are distributed to the sales markets in Europe with an average transport distance of 1380 km. All transportation is carried out by truck.

According to the results of the online survey, ropes are used for an average of five years. During the usage phase, washing has an environmental impact due to the consumption of energy and water, as well as the wastewater generated. In total, 32% of the survey participants wash their rope by hand and 16% use the washing machine. The median of the wash frequency for both washing methods is once a year. Consequently, 1.6 hand washing cycles (5 × 0.32) and 0.8 machine washing cycles (5 × 0.16) were calculated for the service life of a rope.

The wash cycles were modelled according to the Product Environmental Footprint Category Rules (PEFCR) for t-shirts [

42] and the LCA of textiles by Beton et al. [

12]. The washing weight was adjusted to the weight of the climbing rope of 3.54 kg [

42]. As recommended by Mammut [

18], the machine wash was modelled based on a gentle washing cycle with a temperature of 30°C. Electric water heating was used for the hand wash since this was the most common technology used in Europe in 2014 [

43]. The life cycle inventory (LCI) of the washing can be seen in

Table S1.

Most of the survey participants stated that they use their rope for other purposes at the end of its service life. Nevertheless, in this LCA the disposal is modelled as an integral part of the life cycle since it was assumed that these ropes would also be disposed of at some point.

The allocation of the disposal methods, municipal incineration (91%) and sanitary landfill (9%), is based on a function of Mammut’s ten largest sales markets in Europe and their waste treatment [

44]. The sales market’s share of the European turnover was multiplied by the respective percentage of the corresponding disposal method (

Table S2). In addition to the requirements of the Landfill Directive 1999/31/EC, most of the sales markets apply a landfill tax and/or a landfill ban to divert waste from landfills [

45].

3. Results and Discussion

3.1. Assessment of the Climbing Ropes’ Life Cycle

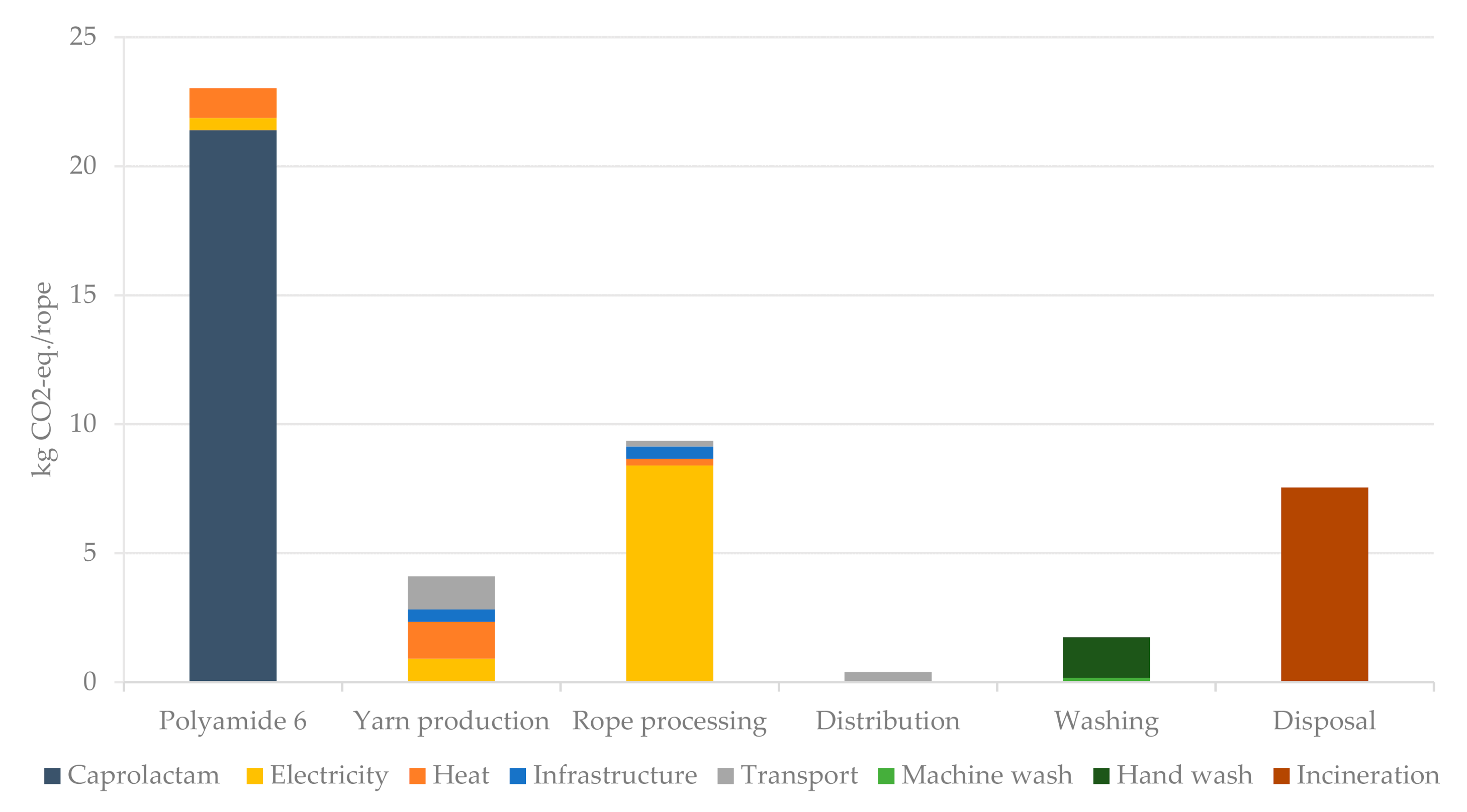

According to this study, the life cycle of the functional unit, the climbing rope Infinity Classic/Dry from Mammut (60 m), has a global warming potential (GWP) of 46.6 kg CO

2-eq. The basic material of the rope, polyamide 6 causes, with 23.3 kg CO

2-eq. per rope, the highest amount of GHG emissions, contributing 50% to the GWP (see

Figure 2). Caprolactam production is responsible for the majority of emissions in PA6 production (92%) [

15]. Carbon dioxide (CO

2) and dinitrogen monoxide (N

20) are the main drivers of the GWP with shares of 57.8% (CO

2) and 31.8% (N

2O).

The rope processing causes 9.57 kg CO2-eq. (18%) and the yarn production 4.08 kg CO2-eq. (9%).

Comparing the GHG emissions of the production phase of one kilogram of a climbing rope with that of a nylon garment [

11,

12], a climbing rope with 10.4 kg CO

2-eq/kg causes about half or a third of the GHG emissions (21.5 kg CO

2-eq. [

11] and 30.9 kg CO

2-eq./kg [

12]). According to van der Velden et al. [

11] and Beton et al. [

12], the further processing of the polyamide into textiles causes around 12 [

11] and 20 kg CO

2-eq./kg [

12], respectively. Thus, the processing of a nylon textile has a higher GWP than the processing of a climbing rope (3.86 kg CO

2-eq./kg). According to van der Velden et al. [

11], weaving causes most GHG emissions in the processing of nylon textiles (10.5 kg CO

2-eq.)

With 1.75 kg CO2-eq. (4%), the usage phase, or the washing, of the rope has a substantially lower impact on the climate than the production phase. The disposal, with 7.58 kg CO2-eq., contributes 16% to the GWP of the climbing rope.

Polyamide 6 also accounts for the largest share of most environmental issues based on the EF method, except ozone depletion and freshwater eutrophication (

Figure 3). For photochemical ozone formation, particulate matter, acidification, marine and terrestrial eutrophication, the main drivers are nitrogen oxides emissions.

Table S4 in the supplementary materials provides an overview of the emissions created by the PA6 production, assessed with the EF method.

Rope processing has the greatest impact on ozone depletion and freshwater eutrophication. These emissions will be further examined in the next subchapter. Yarn production has a slightly higher impact according to the EF categories than the usage phase (washing), contributing between 5% and 34% to the environmental categories. The complete results of the relative environmental impacts, based on the EF and IPCC 2013 100a method, can be found in the

supplementary materials in Table S3.

3.2. Yarn Production and Rope Processing

The processing of polyamide into yarn causes a total of 4.08 kg CO2-eq. per rope. With 1.42 kg CO2-eq. (35%), the heat supply has the highest influence on the GWP, followed by the transport of polyamide to the yarn manufacturers as well as to the rope processing plant with 1.28 kg CO2-eq. (32%). Looking at the remaining environmental categories based on the EF method, the yarn production primarily has an impact on particulate matter (34%), caused by the transport (42%) and the heat supply (28%).

As

Figure 2 illustrates, the rope processing causes a total of 9.57 kg CO

2-eq. per climbing rope based on the IPCC 2013 100a method. The GWP is mainly derived from the electricity consumption (87.8%). Coal as an energy source is responsible for 92% of the respective GHG emissions. The electricity is also the main driver for the other environmental burdens based on the EF method, except ozone depletion (

Figure 4). In total, 96.5% of the high impact on ozone depletion is caused by ethane emissions occurring during the production of the impregnating agent. The construction of the infrastructure of the factory contributes between 29% and 45% to particulate matter, non-cancerous and cancerous human toxicity and freshwater ecotoxicity.

Figure S1 additionally shows the environmental impacts broken down by the individual processes of the rope processing. Due to its high electricity consumption, twining is the main contributor to most of the environmental categories. As for ozone depletion, twine and rope finishing have the highest impact as a result of the impregnation.

3.3. Usage Phase

The only impact in the usage phase occurs with washing the rope. Annual rope washing by 48% of the climbers causes a total of 1.75 kg CO

2-eq. during an average service life of five years. This equates to 4% of the climbing rope’s GWP. The highest impact based on the EF method is on non-cancerous human toxicity (23%) and freshwater ecotoxicity (22%). Of the impact on the non-cancerous human toxicity, 83.1% derives from the sodium in the washing agent. With regard to the freshwater ecotoxicity, wastewater is the main contributor (39.9%). These environmental burdens are mainly caused by hand washing (in both cases >70%), not only due to the higher application of this washing method, but also due to its higher energy and water consumption.

Figure S2 in the supplementary materials provides a comparison of the environmental impact of the two washing methods based on the EF and IPCC 2013 100a method.

3.4. End-of-Life Phase

With 7.58 kg CO

2-eq., rope disposal contributes 16% to the GWP of the climbing rope based on the IPCC 2013 100a method. A total of 99.6% is derived from the incineration of the rope. The incineration also contributes 8% to the cancerous human toxicity of the climbing rope’s life cycle. The environmental issues vary significantly according to the disposal method, as can be seen in

Figure S3 in the supplementary materials.

3.4.1. Relative Obsolescence of a Climbing Rope

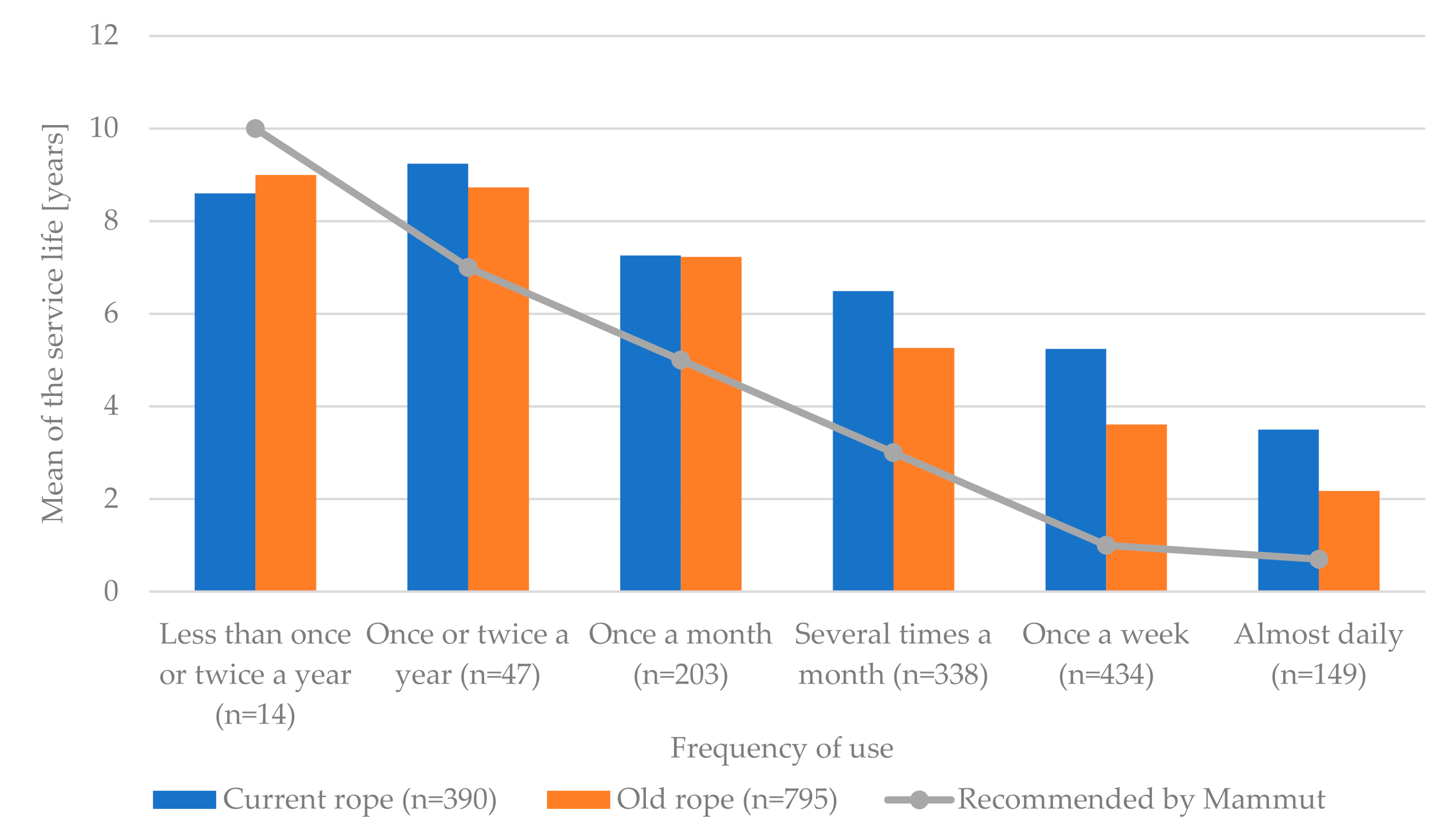

The survey has revealed that the relative obsolescence of a rope is higher than the absolute obsolescence according to rope manufacturers’ lifetime recommendations, except when the frequency of use was less than once or twice a year. The planned service life of the current rope generally exceeds the actual service life of the old, worn-out rope. Here too, the only exception is at the lowest usage frequency, where the service life of the old rope is less than the planned service life (

Figure 5).

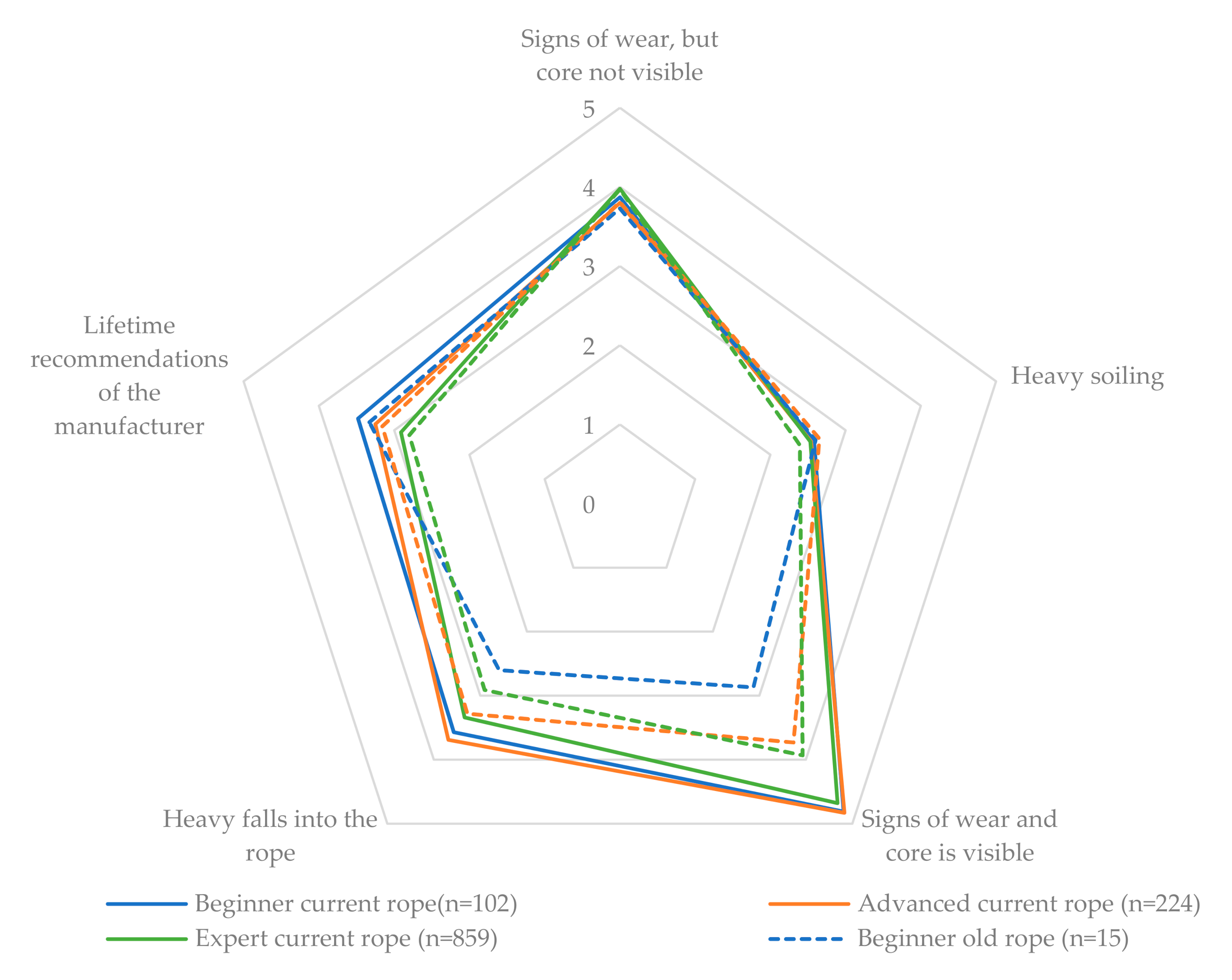

The main factor for the relative obsolescence of the old rope was signs of wear, without any visibility of the core (mean: 3.94; 5 = very big influence). On the current rope, the visibility of the core was indicated as the main reason for the rope’s end of service life (mean: 4.72;

Figure 6). Considering the level of experience, heavy falls have less influence on experts than on advanced climbers. This was observed for both climbers reporting on their old rope (Kruskal-Wallis p: 0.000; Dunn-Bonferroni p: 0.050) and climbers reporting on their current rope (Kruskal-Wallis p: 0.006; Dunn-Bonferroni p: 0.000). Heavy falls are characterized by a long fall distance, often caused by large distances between the protections [

46].

There is a correlation with a small, negative effect size between the experience of climbers and the importance of the service life recommendations (Spearman Rho r: −0.165; p: 0.000). This finding is consistent with the results of a separate question on awareness and consideration of the service life recommendations by Mammut (

Table S6).

In the open response field, 71 respondents (6%) also stated that poor handling and/or rope stiffness was a factor of major influence. A further 26 respondents (2%) said that a sheath shift was of great importance to stop using the rope for climbing.

At the end of the rope’s service life, 59% of the participants with an old rope stated that they used it for non-climbing purposes and 18% stored it at home. Only 6% disposed of their ropes after their service life. The most probable scenarios for the participants with the current rope were also predicted to be the further usages for non-climbing purposes (mean: 4.3; 5 = very likely) and storage at home (mean 3.36;

Figure S4). Disposal is unlikely (mean: 2.05). The only significant nationality difference is between the Austrians and Swiss for the option ‘use it for non-climbing purposes’ (Kruskal-Wallis p: 0.006; Dunn-Bonferroni p: 0.010), where the Austrians show the higher value.

3.4.2. Recycling

The willingness to return the rope at the end of its service life, as part of Mammut’s recycling project, can be rated as high with a mean of 4.01 and a median of 4 (1 = very unlikely; 5 = very likely). The difference of the likelihood of returning the rope between Swiss and Austrians is significant, as can be seen in

Table S7 (Kruskal-Wallis p: 0.000; Dunn-Bonferroni p: 0.002;). There is no correlation between the age of the survey participants and the likelihood of returning their rope (Spearman’s Rho r: −0.002; p: 0.952).

A price reduction on a new rope when returning the old rope has the greatest impact on the likelihood of participating in the recycling project (mean: 4.32; 5 = very likely), as can be seen in

Table S8. In the comparison of the German speaking countries, a convenient return option has a significantly higher impact on Swiss than on Austrian climbers (Kruskal-Wallis p: 0.002; Dunn-Bonferroni p: 0.002). Additionally, 17 survey participants (1.4%) indicated in the open text box that knowing what happens to the rope would encourage them to return it.

There is a negative correlation with a small effect between the age of the subjects and the influence of the price reduction. This means that the older the test persons are, the less influence a price reduction has on returning the rope (Spearman-Rho r: −0.146, p: 0.000).

The climbing gym is the preferred return option for Germans (mean: 4.46), while the Austrian climbers prefer to return the rope to a sports shop (mean: 4.25;

Table S9). For the Swiss, the likelihood of usage is close to identical for both return options (mean sports shop: 4.31, mean climbing gym: 4.32). The results of the pairwise country comparisons based on the Dunn-Bonferroni test can be seen in

Table S10 in the supplementary materials.

3.5. Sensitivity Analysis

The usage phase did not have a major impact on the life cycle impact assessment, which was also due to the fact that only 48% of the participants stated that they wash their rope. However, considering a ‘worst-case’ washing scenario where all climbers would wash the rope by hand and with a higher frequency of three times per year as practiced by 6.6% of the participants (instead of once a year), the usage phase would contribute 25% to the GWP (14.8kg CO

2-eq.;

Figure 7). Moreover, the washing would be the largest contributor to ionising radiation, particulate matter, human toxicity (cancerous and non-cancerous), acidification, as well as the eutrophication (freshwater, marine and terrestrial;

Figure S5).

The GWP based on the IPCC 2013 100a method, as well as the environmental impacts based on the EF method, strongly depend on the production of the basic material. Polyamide 6 can therefore be defined as a significant parameter.

In total, 92% of the GHG emissions of polyamide 6 derive from the caprolactam production, whereas the dinitrogen monoxide emissions are responsible for 29.9% of the GWP. According to PlasticsEurope, the adoption of dinitrogen monoxide emission abatement technologies is at fairly different stages across the caprolactam production industry, which led to some disparities in the reported N

20 levels for the dataset [

15]. Additionally, different monitoring methods added some further uncertainty to the reported levels [

15].

With the best available technology, an N

20 emission reduction of up to 94% is possible in the caprolactam production process [

47]. However, PlasticsEurope’s ecoprofile does not show the reduction percentage used for the life cycle inventory. This study therefore assumes a nitrous oxide abatement of 47% and compares it with a best-case (94%) and worst-case scenario (0%). The GHG emissions of the two N

2O filter scenarios differ from the main scenario by 13% each (6.17 kg CO

2-eq.;

Figure 7).

According to the calculations in this study, the impregnation agent has the biggest impact on ozone depletion. As ecoinvent does not provide a data set of the impregnation agent PFHxA and no life cycle inventory was available in literature, the perfluoropentane data set from ecoinvent was used as a substitute. However, It can be assumed that the impregnation agent based on PFHxA has lower Chlorofluorocarbons-11-eq. (CFC-11-eq.) emissions than perfluoropentane. Perfluorinated carboxylic acids (PFCAs), such as PFHxA, do not directly deplete the stratospheric ozone layer [

48] and only possibly generate CFC-11-eq. emissions during their production [

49].

3.6. Data Quality and Uncertainties

There were no primary data available on the supply source of the polyamide used for yarn production. However, according to Mersiowsky, who reviewed the eco-profile of PlasticsEurope, the PA6 dataset used for this study can be considered representative, reliable and high-quality [

15]. The uncertainty of N

2O emissions were discussed previously in Chapter 5.1.

The data basis for the yarn production was a CO2 compensation calculation from the year 2011. Even though the processes have mainly been retained according to Mammut, it cannot be ruled out that there have been changes in the corresponding production data.

For rope processing in the Czech Republic, the electricity demand was known, but not the specific source. Therefore, the Czech electricity mix was used for the calculations. If, in fact, the factory sources an alternative electricity mix, the environmental impact of this process could vary significantly. Furthermore, no distinction was made between rope type (single, half or twin rope) and impregnation of the rope. A thinner rope without impregnation will cause less environmental impact. The chemicals used for dyeing and the packaging material had not been considered due to lack of data.

Since there was not enough data available on the industrial infrastructure of the rope processing, the ‘chemical factory’ data set from ecoinvent v3.6 was used to model the infrastructure. The industrial area was calculated using Google maps. The same infrastructure calculation was also used for yarn production since no information on their production sites was available. Thus, the actual environmental burden caused by the infrastructure could vary considerably due to the high degree of uncertainty, especially for yarn production.

To assess the representativeness of the climbing rope study sample, the distribution of demographics was compared with the ‘Sport Schweiz’ (Sport Switzerland) study. The ‘Sport Schweiz’ survey is a central monitoring instrument of Swiss sports, among others climbing (total n = 10,652, climbing n = 232) [

50]. The age and gender distribution of ‘Sport Schweiz’ and the Swiss participants of the climbing rope study sample (n = 536) can be considered similar. The biggest difference is to be found in the female age group of 45–59 with −15% compared to the ‘Sport Schweiz’ survey (

Figure S6). Based on the similarity of the two samples, as well as the large sample size (n = 1185), the data collected on the use phase and end-of-life phase can be considered fairly representative.

The proportion of experts in the survey was high at 76%, and the proportion of beginners low at 6%. On the one hand, beginners may not yet own a rope. On the other hand, they may not yet be firmly anchored in the climbing community and are not familiar with the climbing media landscape and the communication channels in which the survey was distributed.

In summary, the data quality of this study can be considered high since numerous initial data were provided by Mammut on the production processes and by the online survey on user behaviour.

3.7. Recommendations

Based on the results of the life cycle assessment, the climbing rope can be assigned to the category of production-relevant products. The usage phase in the standard scenario has a comparatively low impact on the LCA of a climbing rope. Consequently, the recommendations as outlined by Dettli et al. [

51] mainly address the production and the end-of-life phases.

3.7.1. Alternatives to Polyamide 6

Even though GHG emissions in polyamide 6 production have been significantly reduced in recent years [

15], this stage of the life cycle still represents the environmental hotspot of the climbing rope. Therefore, the question arises as to whether there are substitutes available for this basic material.

Besides polyamide, the most synthetic materials used by Mammut are polyester and ethylene vinyl acetate (EVA) [

52]. These cause fewer environmental issues than polyamide in most environmental categories based on the EF method (

Figure S7). Only polyester production has a higher environmental impact on particulate matter (36%) and acidification. However, neither polyester nor EVA meet the high requirements of a climbing rope regarding the breaking force and the elongation at break [

53]. The most common alternative to polyamide 6 is polyamide 6.6, but, as indicated in the introduction, PA6.6 only causes a lower impact on a few environmental categories.

Biobased polyamides are traded as an ecological alternative to conventional polyamides [

54]. Conventional polyamides like PA6 and PA6.6 are based up to 99% on fossil raw materials. Biobased polyamides, such as PA 6.10, PA10.10 and PA11, on the other hand, are produced entirely or partially from renewable raw materials [

14]. Polyamide 6.10 is based on 60% and polyamide 10.10 and 11 on 100% plant-based raw material sources [

55]. The raw material for their production is castor oil, which is obtained from the seeds of the tropical tree Ricinus communis [

14].

According to Brehmer [

56], PA 6.10 causes 4.8 kg CO

2-eq. and PA 10.10 4.6 kg CO

2-eq. per produced kilogram of the corresponding polyamide. PA11 has the lowest GWP of approx. 4.2 kg CO

2-eq/kg [

57]. Thus, the bio-polyamides emit 27% to 36% fewer GHG emissions compared to the fossil-based polyamides, as can be seen in

Figure S7 in the supplementary materials.

Even though the bio-polyamides have significant advantages with regard to GHG emissions, other environmental issues can arise due to the energy requirement for the cultivation of the plant, such as the tillage and the production of the fertilizers [

58].

Bio-polyamides have similar functional properties to petroleum-based polyamides (

Table S11). However, the tensile strength and the elongation at break do not reach the values of PA6 [

14,

59]. In other industries, bio-polyamides are therefore strengthened with wood or carbon fibres, which considerably improves their tensile strength [

60]. These hybrids also have a higher stiffness value which can be advantageous for certain applications, but are disadvantageous for climbing ropes [

60]. Another disadvantage of adding wood or carbon fibres is the loss of the purity of the polyamide. Since the plastic then no longer consists of only one basic material, it is more difficult to recycle [

61].

There is also a biobased caprolactam on the market, made from regenerative raw material sources, such as corn stover [

58,

59]. This alternative base material for polyamide 6 is converted from biomass via glucose and 5-hydroxymenthyl furfural (HMF) [

62]. The production of biobased caprolactam generates roughly 40% lower GHG emissions than the conventional fossil-based caprolactam production. If biobased caprolactam is produced from agricultural residues such as corn stover, environmental impact from plant cultivation can be avoided. However, at this stage the production costs, and therefore the market price of bio-caprolactam, is not yet competitive. The valorisation of co-products and cost reduction would be essential for achieving greater viability [

62].

In conclusion, it can be said that bio-polyamides and PA6 produced with bio-caprolactam currently still represent a market niche, but they are increasingly attracting attention [

60]. Large economic sectors, such as the automotive and electrical industries, with high functional demands on plastics already use bio-polyamides and investigate large sums in the R&D [

60]. It may, therefore, be advisable to invest in research into bio-polyamide and additional fibres, both of which make the bio-polyamide stronger without restricting its elasticity. In addition, the development of bio-caprolactam should be monitored. Even though it is not yet economically competitive, many such synthesis routes are expected to be realised in the coming years [

62].

3.7.2. Recycling

According to Mammut, the ropes returned in the context of the recycling project are to be reused to produce t-shirts that were previously made of polyester. Assuming a recycling rate of 90% (3.2 kg recycled polyamide), a total of 25 t-shirts could be produced from one returned rope (weight per shirt = 126 g).

The environmental benefits of avoiding the production of virgin materials by recycling textiles has been shown in literature [

21,

22]. In the case of climbing ropes, the substitution of virgin polyester with the recycled polyamide and the avoidance of disposal could save 18.3 kg CO

2-eq./rope, which equals 39% of the GHG emissions of the climbing rope’s life cycle. To calculate the emissions of polyester the Industry 2.0 dataset ‘PET (amorphous) E’ was used. Based on the EF method, the recycling could lead to emission savings of 81% in particulate matter, 43% in fossils resource use and 43% in acidification, among others (

Figure S8).

The results of the online survey showed a high willingness to participate in a recycling project. In total, 78.1% the Swiss survey participants indicated a high or very high likelihood of participating in a recycling project. According to the ‘Sport Schweiz’ study, 2.2% of the Swiss population (8.54 million [

63]) practice the sport of climbing [

50]. This results in a potential 147,000 participants. Based on this extrapolation, 2690 t CO

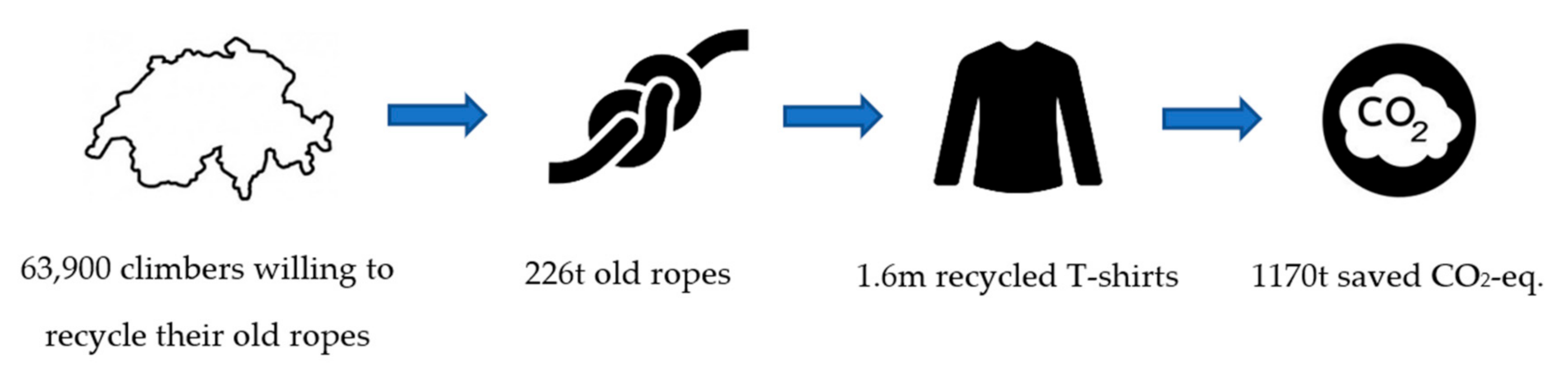

2-eq. could be saved in Switzerland, which corresponds to a GWP of more than 57,600 new ropes. However, some of those climbers are still using their first rope, so the date of return would be uncertain. If only those participants are considered who obtain an old rope, stored it at home or used it for another purpose, and indicated at least a high likelihood of participating (34% of the Swiss participants), the extrapolations would result in 226 t of climbing ropes which could be returned. In this scenario, there is still a potential of 1170 t CO

2-eq. savings, which equals the GWP of more than 25,100 new ropes (

Figure 8).

In order to implement the recycling project successfully, the findings from the survey can be consulted. Consequently, a price reduction on the new rope when returning the old rope has the highest influence. This can be optimally combined with the return location of the sports shop, which is preferred by the Swiss and German survey participants.

4. Conclusions

Polyamide 6 represents the major environmental hotspot along the life cycle of the climbing rope, causing, at 50%, the highest impact on the total GWP of 46.6 kg CO2-eq. and on most of the other environmental issues. Based on the current state of research, this study did not find an alternative as a base material. However, the online survey has shown that there is a high likelihood among climbers of participating in a recycling project for old ropes. In order to further increase the participation rate, price reductions on the new rope when returning the old rope are recommended, as well as the possibility to return the rope to a sports shop (Switzerland, Austria) or climbing gym (Switzerland, Germany).

Based on extrapolations, there are 226 tons of old ropes stored at home or used for non-climbing purposes by Swiss climbers who would be willing to return their ropes. The recycling of these ropes would lead to GHG emission savings of 1170 tons CO2-eq. by avoiding the production of the base material of the recycled product and the disposal of the ropes.

From the findings of this study, it can be concluded that there is great potential for both the rope manufacturer and the rope user to reduce the environmental impact of climbing ropes during their life cycle.