Effects of Production of Woody Pellets in the Southeastern United States on the Sustainable Development Goals †

Abstract

:1. Introduction

2. Materials and Methods

3. Results

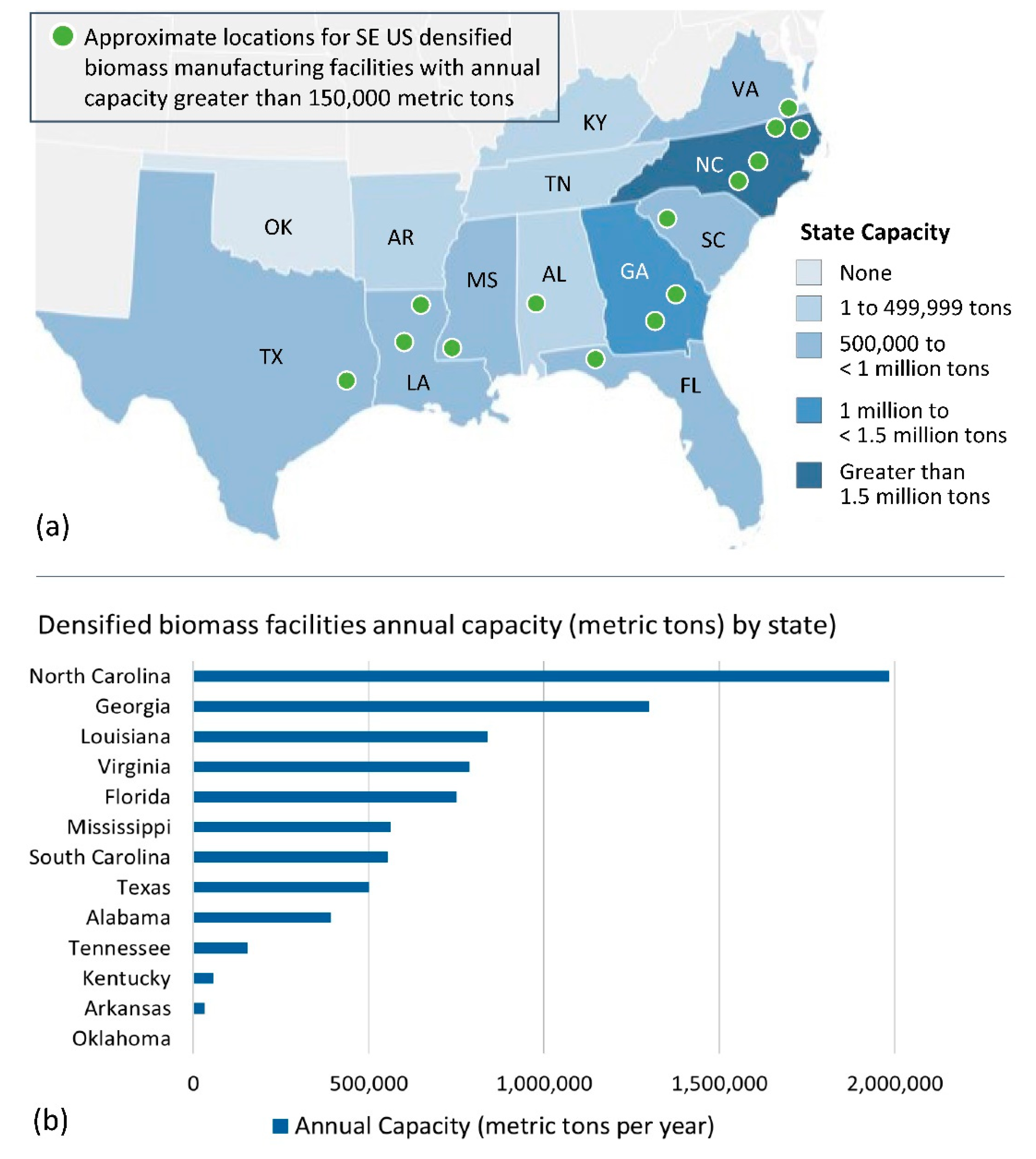

3.1. Processes, Feedstocks, and Stakeholders Involved in the Production of Woody Pellets in the SE US

3.2. SDGs Relevant to Production of Woody Pellets in the SE US

4. Discussion

4.1. Strengths and Weaknesses of the SE US Pellet Supply Chain

4.2. Threats to the SE US Pellet Supply Chain

4.3. Opportunities for the Pellet Industry to Make Progress toward Sustainability

4.4. Challenges in Assessing SDG Indicators for Wood Pellets

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- O’Connell, B.M.; LaPoint, E.B.; Turner, J.A.; Ridley, T.; Pugh, S.A.; Wilson, A.M.; Waddell, K.L.; Conkling, B.L. The Forest Inventory and Analysis Database: Database Description and User Guide Version 6.0.1 for Phase 2; U.S. Department of Agriculture, Forest Service: Washington, DC, USA, 2014; 748p, Available online: https://www.fia.fs.fed.us/library/database-documentation/historic/ver6/FIADB_user%20guide_6-0_p2_5-6-2014.pdf (accessed on 14 December 2020).

- Mann, C.C. 1491: New Revelations of the Americas Before Columbus; Knopf: New York, NY, USA, 2005. [Google Scholar]

- Delcourt, H.R.; Delcourt, P.A. Pre-Columbian Native American use of fire on Southern Appalachian landscapes. Conserv. Biol. 1997, 11, 1010–1014. [Google Scholar] [CrossRef] [Green Version]

- Cowell, M.C. Historical change in vegetation and disturbance on the Georgia Piedmont. Am. Midl. Nat. 1998, 140, 78–89. [Google Scholar] [CrossRef]

- Flatley, W.T.; Lafon, C.W.; Grossino-Mayer, H.D.; LaForest, L.B. Fire history, related to climate and land use in three southern Appalachian landscapes in the eastern United States. Ecol. Adapt. 2013, 23, 1250–1266. [Google Scholar] [CrossRef] [Green Version]

- Klein Goldewijk, K.; Beusen, A.; Doelman, J.; Stehfest, E. Anthropogenic land use estimates for the Holocene—HYDE 3.2. Earth Syst. Sci. Data 2017, 9, 927–953. [Google Scholar] [CrossRef] [Green Version]

- Oswalt, S.N.; Smith, W.B.; Miles, P.D.; Pugh, S.A. Forest Resources of the United States, 2017. A Technical Document Supporting the Forest Service 2020 RPA Assessment (WO-97); 2019. Available online: https://www.fs.usda.gov/treesearch/pubs/57903 (accessed on 19 December 2020).

- Hurtt, G.C.; Frolking, S.; Fearon, M.G.; Moore, B.; Shevliakova, E.; Malyshev, S.; Pacala, S.W.; Houghton, R.A. The underpinnings of land-use history: Three centuries of global gridded land-use transitions, wood harvest activity, and resulting secondary lands. Glob. Change Biol. 2006, 12, 1208–1229. [Google Scholar] [CrossRef]

- Schweizer, P.E.; Matlack, G.R. Factors driving land use change and forest distribution on the coastal plain of Mississippi, USA. Landsc. Urban Plan. 2014, 121, 55–64. [Google Scholar] [CrossRef]

- Gragson, T.L.; Bolstad, P.V. Land use legacies and the future of Southern Appalachia. Soc. Nat. Res. 2006, 19, 175–190. [Google Scholar] [CrossRef] [Green Version]

- Wear, D.N.; Greis, J.G. The Southern Forest Futures Project: Summary Report; Technical Report SRS-178; USDA-Forest Service, Southern Research Station: Asheville, NC, USA, 2012; p. 552. Available online: https://www.srs.fs.usda.gov/pubs/42526 (accessed on 19 December 2020).

- Wear, D.N.; Gries, J.G. Southern Forest Resource Assessment; Gen. Technical Report SRS–53; U.S. Department of Agriculture, Forest Service, Southern Research Station: Asheville, NC, USA, 2002; 635p. [Google Scholar]

- Wear, D.N.; Carter, D.R.; Prestemon, J. The U.S. South’s Timber Sector in 2005: A Prospective Analysis of Recent Change; General Technical Report SRS-99; USDA Forest Service Southern Research Station: Ashville, NC, USA, 2012; 44p. Available online: https://www.srs.fs.usda.gov/sustain/report/pdf/gtr-srs-99.pdf (accessed on 19 December 2020).

- Sun, X.; Zhang, D.; Butler, B.J. Timberland ownerships and reforestation in the Southern United States. For. Sci. 2015, 61, 336–343. [Google Scholar] [CrossRef]

- Dale, V.H.; Joyce, L.A.; McNulty, S.; Neilson, R.P.; Ayres, M.P.; Flannigan, M.D.; Hanson, P.J.; Irland, L.C.; Lugo, A.E.; Peterson, C.J.; et al. Forest disturbances and climate change. BioScience 2001, 51, 723–734. [Google Scholar] [CrossRef] [Green Version]

- United Nations General Assembly. Transforming Our World: The 2030 Agenda for Sustainable Development (adopted on 25 September 2015) A/RES/70/1 2015. Available online: https://www.refworld.org/docid/57b6e3e44.html (accessed on 16 November 2020).

- United Nations. The Sustainable Development Goals Report 2019 Database 2019. Available online: https://unstats.un.org/sdgs/indicators/database/ (accessed on 31 May 2020).

- United Nations. SDG Indicators. Global Indicator Framework for the Sustainable Development Goals and Targets of the 2030 Agenda for Sustainable Development. 2020. Available online: https://unstats.un.org/sdgs/indicators/indicators-list/ (accessed on 18 November 2020).

- United Nations. SDG #15, Why It Matters—Life on Land, Facts and Figures. Available online: https://www.un.org/sustainabledevelopment/wp-content/uploads/2019/07/15_Why-It-Matters-2020.pdf (accessed on 16 November 2020).

- International Energy Agency. Uneven Progress on Achieving Access to Sustainable Energy for All. 2017. Available online: https://www.iea.org/newsroom/news/2017/april/uneven-progress-on-achieving-access-to-sustainable-energy-for-all.html (accessed on 31 May 2020).

- Eggers, J.; Melin, Y.; Lundström, J.; Bergström, D.; Öhman, K. Management strategies for wood fuel harvesting—Trade-offs with biodiversity and forest ecosystem services. Sustainability 2020, 12, 4089. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Summary for Policymakers, Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group 3 to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Efroymson, R.A.; Dale, V.H.; Bielicki, J.; McBride, A.; Smith, R.; Parish, E.; Schweizer, P.; Kline, K.L.; Shaw, D. Environmental indicators of biofuel sustainability: What about context? Environ. Manag. 2013, 51, 291–306. [Google Scholar] [CrossRef]

- Creutzig, F.; Ravindranath, N.H.; Berndes, G.; Bolwig, S.; Bright, R.; Cherubini, F.; Chum, H.; Corbera, E.; Delucchi, M.; Faaij, A.; et al. Bioenergy and climate change mitigation: An assessment. Glob. Change Biol. Bioenergy 2015, 7, 916–944. [Google Scholar] [CrossRef] [Green Version]

- IEA Bioenergy Technology Collaboration Programme. Inter-Task Projects for 2019–2022 Triennium. 2020. Available online: https://www.ieabioenergy.com/blog/task/inter-task-projects/ (accessed on 16 November 2020).

- Kittler, B.; Stupak, I.; Smith, C.T. Assessing the wood sourcing practices of the U.S. industrial wood pellet industry supplying European energy demand. Sustain. Soc. 2020, 10. [Google Scholar] [CrossRef]

- Favero, A.; Daigneault, A.; Sohngen, B. Forests: Carbon sequestration, biomass energy, or both? Sci. Adv. 2020, 6. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Parish, E.S.; Dale, V.H.; Kline, K.L.; Abt, R.C. Reference scenarios for evaluating wood pellet production in the Southeastern United States. WIREs Energy Environ. 2017, 6, e259. [Google Scholar] [CrossRef]

- Hoefnagels, R.; Junginger, M.; Faaij, A. The economic potential of wood pellet production from alternative, low-value wood sources in the southeast of the US. Biomass Bioenergy 2014, 71, 443–454. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. In Monthly Densified Biomass Fuel Report, Data Archive Form EIA-63C. Available online: https://www.eia.gov/biofuels/biomass/ (accessed on 16 November 2020).

- Visser, L.; Hoefnagels, R.; Junginger, M. Wood pellet supply chain costs—A review and cost optimization analysis. Renew. Sustain. Energy Rev. 2020, 118. [Google Scholar] [CrossRef]

- Barrette, J.; Durocher, C.; Mansuy, N.; Béland, M.; Thiffault, E. From Unloved Woods to Desirable Renewable Biofuels: Policy Brief. Can. J. For. Res. 2017, 48, 1470–1481. Available online: https://biofuelnet.ca/wp-content/uploads/2017/09/2017.0 7.03_BFN_Policy-Brief_Unloved-Wood.pdf (accessed on 16 November 2020). [CrossRef]

- USDA Forest Inventory Analysis Timber Products Output Studies, TPO Interactive Reporting Tool. Available online: https://www.fia.fs.fed.us/program-features/tpo/ (accessed on 16 November 2020).

- Brandeis, C.; Guo, Z. Decline in the pulp and paper industry: Effects on backward-linked forest industries and local economies. For. Prod. J. 2016, 66, 113–118. [Google Scholar] [CrossRef]

- Hodges, D.G.; Hartsell, A.J.; Brandeis, C.; Brandeis, T.J.; Bentley, J.W. Recession effects on the forests and forest products industries of the south. For. Prod. J. 2012, 61, 614–624. [Google Scholar] [CrossRef]

- Brandeis, C.; Abt, K.L. Roundwood use by southern wood pellet mills: Findings from Timber Product Output mill surveys. J. For. 2019, 117, 427–434. [Google Scholar] [CrossRef]

- National Association of State Foresters. Protecting Water Quality through State For. Best Management Practices; National Association of State Foresters: Washington, DC, USA, 2015; Available online: http://www.stateforesters.org/sites/default/files/issues-and-policies-document-attachments/Protecting_Water_ Quality_through_State_For._BMPs_FINAL.pdf (accessed on 18 November 2020).

- Dale, V.H.; Kline, K.L.; Parish, E.S.; Cowie, A.L.; Emory, R.; Malmsheimer, R.W.; Slade, R.; Smith, C.T.; Wigley, T.B.; Bentsen, N.S.; et al. Status and prospects for renewable energy using wood pellets from the southeastern United States. Glob. Change Biol. Bioenergy 2017, 1296–1305. [Google Scholar] [CrossRef]

- Hodges, D.G.; Chapagain, B.; Watcharaanantapong, P.; Poudyal, N.C.; Kline, K.L.; Dale, V.H. Opportunities and attitudes of private forest landowners in supplying woody biomass for renewable energy. Renew. Sustain. Energy Rev. 2019, 113, 109205. [Google Scholar] [CrossRef]

- Cornwall, W. Is wood a green source of energy? Scientists are divided. Science 2017, 355, 18–21. [Google Scholar] [CrossRef] [PubMed]

- German Wood Fuel and Pellet Association. Recommendations for Storage of Wood Pellets; UK Pellet Council: Chippenham, UK, 2012; Available online: https://www.intricoproducts.com/user_uploads/wood-pellet-storage-guide.pdf (accessed on 16 December 2020).

- European Commission Renewable Energy Directive (RED). Available online: https://ec.europa.eu/energy/topics/renewable-energy/renewable-energy-directive/overview_en (accessed on 16 November 2020).

- Abt, K.L.; Abt, R.C.; Galik, C.S.; Skog, K.E. Effect of Policies on Pellet Production and Forests in the US South; USDA Forest Service Southern Research Station: Asheville, NC, USA, 2014. [Google Scholar]

- U.S. Department of Agriculture. USDA Foreign Agricultural Service Searchable Database. 2019. Available online: https://apps.fas.usda.gov/Gats/default.aspx (accessed on 31 May 2020).

- Lowenthal-Savy, D. UK’s Renewable Energy Targets Drive Increases in U.S. Wood Pellet Exports; 2015. Available online: https://www.eia.gov/todayinenergy/detail.php?id=20912 (accessed on 31 May 2020).

- Parish, E.S.; Herzberger, A.; Phifer, C.; Dale, V.H. Transatlantic wood pellet trade demonstrates telecoupled benefits. Ecology Society 2018, 23, 28. [Google Scholar] [CrossRef]

- Galik, C.S.; Abt, R.C. Sustainability guidelines and forest market response: An assessment of European Union pellet demand in the southeastern United States. Glob. Change Biol. Bioenergy 2015, 8, 658–669. [Google Scholar] [CrossRef]

- Butler, B.J.; Hewes, J.H.; Dickinson, B.J.; Andrejczyk, K.; Butler, S.M.; Markowski-Lindsay, M. Family forest ownerships of the United States: Findings from the U.S. Department of Agriculture forest service’s National woodland owner survey. J. For. 2016, 114, 638–647. [Google Scholar] [CrossRef]

- Butler, B.J.; Ma, Z.; Kittredge, D.B.; Catanzaro, P. Social versus biophysical availability of wood in the northern United States. North. J. Appl. For. 2010, 27, 151–159. [Google Scholar] [CrossRef] [Green Version]

- Galik, C.S.; Abt, R.; Wu, Y. Forest biomass supply in the Southeastern United States—Implications for industrial roundwood and bioenergy production. J. For. 2009, 107, 69–77. [Google Scholar] [CrossRef]

- Gruchy, S.R.; Grebner, D.L.; Munn, I.A.; Joshi, O.; Hussain, A. An assessment of nonindustrial private forest landowner willingness to harvest woody biomass in support of bioenergy production in Mississippi: A contingent rating approach. For. Policy Econ. 2012, 15, 140–145. [Google Scholar] [CrossRef]

- Joshi, O.; Mehmood, S.R. Factors affecting nonindustrial private forest landowners’ willingness to supply woody biomass for bioenergy. Biomass Bioenergy 2011, 35, 186–192. [Google Scholar] [CrossRef]

- Joshi, O.; Grebner, D.L.; Hussain, A.; Grado, S.C. Landowner knowledge and willingness to supply woody biomass for wood-based bioenergy: Sample selection approach. J. For. Econ. 2013, 19, 97–109. [Google Scholar] [CrossRef]

- Butler, S.M.; Butler, B.J.; Markowski-Lindsay, M. Family forest owner characteristics shaped by life cycle, cohort, and period effects. Small Scale For. 2017, 16, 1–18. [Google Scholar] [CrossRef]

- Koester, S.; Davis, S. Siting of wood pellet production facilities in environmental justice communities in the Southeastern United States. Environ. Justice 2018, 11. [Google Scholar] [CrossRef]

- Ramseth, L. World’s Largest Pellet Mill Could Boost Mississippi’s Economy. But will it Hurt Environment, Residents? Mississippi Clarion Ledger: Jackson, MS, USA, 2019; Available online: https://www.clarionledger.com/story/news/politics/2019/07/08/mississippi-pellet-mill-economic-boon-environmental-threat/1351677001/ (accessed on 19 December 2020).

- Hamilton, D.S.; Quinlan, J.P. The Transatlantic Economy 2017: Annual Survey of Jobs, Trade and Investment between the United States and Europe; American Chamber of Commerce to the European Union: Brussels, Belgium, 2017; Available online: http://www.amchameu.eu/sites/default/files/170227_full-book.pdf (accessed on 17 November 2020).

- International Renewable Energy Agency (IRENA). Renewable Energy Highlights (July 2020). Available online: https://www.irena.org/publications/2020/Jul/Renewable-energy-statistics-2020 (accessed on 17 November 2020).

- Dahal, R.P.; Aguilar, F.X.; McGarvey, R.G.; Becker, D.; Abt, K.L. Localized economic contributions to renewable wood-based biopower generation. Energy Econ. 2020, 91. [Google Scholar] [CrossRef]

- Henderson, J.E.; Joshi, O.; Parajuli, R.; Hubbard, W.G. A regional assessment of wood resource sustainability and potential economic impact of the wood pellet market in the U.S. south. Biomass Bioenergy 2017, 105, 421–427. [Google Scholar] [CrossRef]

- Cowie, A.; Brandão, M.; Soimakallio, S. Quantifying the climate effects of forest-based bioenergy. In Managing Global Warming: An Interface of Technology and Human Issues, 1st ed.; Letcher, T.M., Ed.; Elsevier Academic Press: Cambridge, MA, USA, 2019; Chapter 13; pp. 399–418. [Google Scholar] [CrossRef]

- Visser, L.; Hoefnagels, R.; Junginger, M. The potential contribution of imported biomass to renewable energy targets in the EU—The trade-off between ambitious greenhouse gas emission reduction targets and cost thresholds. Energies 2020, 13, 1761. [Google Scholar] [CrossRef] [Green Version]

- Dwivedi, P.; Khanna, M.; Bailis, R.; Ghilardi, A. Potential greenhouse gas benefits of transatlantic wood pellet trade. Environ. Res. Lett. 2014, 9, 024007. [Google Scholar] [CrossRef] [Green Version]

- Malmsheimer, R.W.; Fernholz, K. How laws, practices, and markets ensure sustainable forest biomass feedstocks from the southeast US. In World Biomass 2015–2016; DCM Productions: York, UK, 2015; pp. 8–12. Available online: http://dcm-productions.co.uk/world-biomass-2015-2016/ (accessed on 17 November 2020).

- Coppoletta, M.; Merriam, K.E.; Collins, B.M. Post-fire vegetation and fuel development influences fire severity patterns in reburns. Ecol. Appl. 2016, 26, 686–699. [Google Scholar] [CrossRef]

- Fox, T.R.; Jokela, E.J.; Allen, H.L. The development of pine plantation silviculture in the southern United States. J. For. 2007, 105, 337–347. [Google Scholar]

- Evans, A.M.; Perschel, R.T.; Kittler, B.A. Overview of forest biomass harvesting guidelines. J. Sustain. For. 2013, 32, 89–107. [Google Scholar] [CrossRef]

- Poudyal, N.C.; Joshi, O.; Hodges, D.G.; Hoyt, K. Factors related with nonindustrial private forest landowners’ forest conversion decisions in Cumberland Plateau, Tennessee. For. Sci. 2014, 60, 988–993. [Google Scholar] [CrossRef]

- Kline, K.L.; Dale, V.H. Protecting biodiversity through forest management: Lessons learned and strategies for success. Int. J. Environ. Sci. Nat. Res. 2020, 26, 556194. [Google Scholar] [CrossRef]

- Joly, C.A.; Huntley, B.J.; Verdade, L.M.; Dale, V.H.; Mace, G.; Muok, B.; Ravindranath, N.H. Biofuel Impacts on Biodiversity and Ecosystem Services. In Scientific Committee on Problems of the Environment (SCOPE) Rapid Assessment Process on Bioenergy and Sustainability; Souza, G.M., Joly, C.A., Eds.; SCOPE: Paris, France, 2015; Chapter 16; pp. 555–580. [Google Scholar]

- Aguilar, F.X.; Mirzaee, A.; McGarvey, R.G.; Shifley, S.R.; Burtraw, D. Expansion of US wood pellet industry points to positive trends but the need for continued monitoring. Sci. Rep. 2020, 10, 18607. [Google Scholar] [CrossRef] [PubMed]

- Varner, J.M.; Gordon, D.R.; Putz, E.; Hiers, J.K. Restoring fire to long-unburned Pinus palustris ecosystems: Novel fire effects and consequences for long-unburned ecosystems. Restor. Ecol. 2005, 13, 536–544. [Google Scholar] [CrossRef]

- Greene, R.E.; Iglay, R.B.; Evans, K.O.; Miller, D.A.; Wigley, T.B.; Riffell, S.K. A meta-analysis of biodiversity responses to management of southeastern pine forests—Opportunities for open pine conservation. For. Ecol. Manag. 2016, 360, 30–39. [Google Scholar] [CrossRef]

- Costanza, J.K.; Abt, R.C.; McKerro, A.J.; Collazo, J.A. Bioenergy production and forest landscape change in the southeastern United States. Glob. Change Biol. Bioenergy 2017, 9, 924–939. [Google Scholar] [CrossRef]

- Olesen, A.S.; Kittler, B.; Price, W.; Aguilar, F.X. Environmental Implications of Increased Reliance of the EU on Biomass from the South East US. European Commission Report ENV.B.1/ETU/2014/0043; Publications Office of the European Union: Brussels, Belgium, 2016. [Google Scholar] [CrossRef]

- Parish, E.S.; Baskaran, L.; Dale, V.H. Framework for assessing land management effects on species of concern: An example using wood pellet production and the gopher tortoise. WIRES Wiley Interdiscip. Rev. 2020. [Google Scholar] [CrossRef]

- Dale, V.H.; Parish, E.; Kline, K.L.; Tobin, E. How is wood-based pellet production affecting forest conditions in the southeastern United States? For. Ecol. Manag. 2017, 396, 143–149. [Google Scholar] [CrossRef] [Green Version]

- Kline, K.L.; Mayer, A.L.; Martinelli, F.S.; Medeiros, R.; Oliveira, C.O.F.; Sparovek, G.; Walter, A.; Venier, L. Bioenergy and biodiversity: Key lessons from the Pan America Region. Environ. Manag. 2015, 56, 1377–1396. [Google Scholar] [CrossRef]

- Berndes, G.; Cowie, A.; Pelkmans, L. IEA Bioenergy Bulletin: The Use of Forest Biomass for Climate Change Mitigation: Dispelling Some Misconceptions. 2020. Available online: https://www.ieabioenergy.com/wp-content/uploads/2020/08/The-use-of-biomass-for-climate-change-mitigation-dispelling-some-misconceptions-August-2020-Rev1.pdf (accessed on 17 November 2020).

- Matthews, R.; Hogan, G.; Mackie, E. Carbon Impacts of Biomass Consumed in the EU: Supplementary Analysis and Interpretation for the European Climate Foundation. 2018. Available online: https://www.drax.com/wp-content/uploads/2019/10/CIB-Summary-report-for-ECF-v10.5-May-20181.pdf (accessed on 17 November 2020).

- Jonker, J.G.G.; Junginger, M.; Faaij, A. Carbon payback period and carbon offset parity point of wood pellet production in the South-eastern United States. Glob. Change Biol. Bioenergy 2014, 6, 371–389. [Google Scholar] [CrossRef] [Green Version]

- Rolls, W.; Forster, P.M. Quantifying forest growth uncertainty on carbon payback times in a simple biomass carbon model. Environ. Res. Commun. 2020, 2, 045001. [Google Scholar] [CrossRef]

- Anderson, P.; Powell, K. Dirty deception: How the wood biomass industry skirts the Clean Air Act. Reports sponsored by the Environmental Integrity Project (April 26). 2018. Available online: https://www.environmentalintegrity.org/wp-content/uploads/2017/02/Biomass-Report.pdf (accessed on 17 November 2020).

- Schelhas, J.; Hitchner, S.; Brosius, J.P. Envisioning and implementing wood-based bioenergy systems in the southern United States: Imaginaries in everyday talk. Energy Res. Soc. Sci. 2018, 35, 182–192. [Google Scholar] [CrossRef]

- International Labour Organization. Guidelines for a Just Transition towards Environmentally Sustainable Economies and Societies for All. 2015. Available online: https://www.ilo.org/global/topics/green-jobs/publications/WCMS_432859/lang--en/index.htm (accessed on 18 November 2020).

- Duden, A.S.; Verweij, P.A.; Junginger, H.M.; Abt, R.C.; Henderson, J.D.; Dale, V.H.; Kline, K.L.; Karssenberg, D.; Verstegen, J.A.; Faaij, A.P.C.; et al. Modeling the impacts of wood pellet demand on forest dynamics in southeastern United States. Biofuels Bioprod. Biorefin. 2017. [Google Scholar] [CrossRef] [Green Version]

- Nepal, P.; Abt, K.L.; Skog, K.E.; Prestemon, J.P.; Abt, R.C. Projected market competition for wood biomass between traditional products and energy: A simulated interaction of US regional, national, and global forest product markets. For. Sci. 2018, 65, 14–26. [Google Scholar] [CrossRef]

- Dezember, R. Man Who Steered Timber Subsidy Program Calls It His Biggest Regret. The Wall Street Journal. 2018. Available online: https://www.wsj.com/articles/man-who-steered-timber-subsidy-program-calls-it-his-biggest-regret-1539946801 (accessed on 19 December 2020).

- King, J.S.; Ceulemans, R.; Albaugh, J.M.; Dillen, S.Y.; Domec, J.C.; Fichot, R.; Fischer, M.; Leggett, Z.; Sucre, E.; Trnka, M.; et al. The challenge of lignocellulosic bioenergy in a water-limited world. BioScience 2013, 63, 102–117. [Google Scholar] [CrossRef] [Green Version]

- Gagnon, B.; Kline, K.L. Personal Communications in Regular Meetings of the WB2-SDG Inter-Task Case Study Team, May–November. 2020. Updates will be Available online: https://www.ieabioenergy.com/blog/task/inter-task-projects/ (accessed on 14 January 2021).

- Kline, K.L.; Parish, E.S.; Dale, V.H. The importance of reference conditions in assessing effects of bioenergy wood pellets produced in the southeastern United States. In World Biomass 2018–2019; DCM Productions: York, UK, 2018; pp. 82–87. Available online: http://dcm-productions.co.uk/world-biomass-2018-2019/ (accessed on 17 November 2020).

- Koponen, K.; Soimakallio, S.; Kline, K.L.; Cowie, A.; Brandão, M. Quantifying the climate effects of bioenergy—Choice of reference system. Renew. Sustain. Energy Rev. 2018, 81, 2271–2280. [Google Scholar] [CrossRef]

- Norman, S.P.; Hargrove, W.W.; Spruce, J.P.; Christie, W.M.; Schroeder, S.W. Highlights of Satellite-Based Forest Change Recognition and Tracking Using the for Warn System. Gen. Tech. Rep. SRS-GTR-180; USDA-Forest Service, Southern Research Station: Asheville, NC, USA, 2012; 30p. Available online: http://www.srs.fs.usda.gov/pubs/44239 (accessed on 31 May 2020).

- Parish, E.S.; Dale, V.H.; Tobin, E.; Kline, K.L. Dataset of timberland variables used to assess forest conditions in two Southeastern United States’ fuelsheds. Data Brief 2017, 13, 278–290. [Google Scholar] [CrossRef]

- Dale, V.H.; Kline, K.L.; Parish, E.S.; Eichler, S.E. Engaging stakeholders to assess landscape sustainability. Landsc. Ecol. 2019, 34, 1199–1218. [Google Scholar] [CrossRef] [Green Version]

- Enviva Forest Conservation Fund. Available online: https://envivaforestfund.org/ (accessed on 18 November 2020).

| SDG | SDG Target Number and Relationship | Evidence |

|---|---|---|

| 7.2: Increase share of renewable energy. Bioenergy makes important contributions to national and regional renewable targets. | Biomass contributed to raising the share of energy from renewable sources consumed in the EU to 19% in 2018 (double that from 2004). |

| 8.4: Increase efficiency and sustainability; decouple growth from environmental degradation. Improved forest management using woody residues to displace fossil coal for energy. | New industries in depressed rural areas provide needed investments in infrastructure, value-added processing, and more sustainable ‘green economy’ jobs relative to nonrenewable alternatives. |

| 9.2, 9.3: Develop inclusive, sustainable, small-scale industries. Small land holders play important roles in forest management and feedstock supply. 9.4 (also SDG 13): Upgrade industries with clean, climate-smart technologies. Pellet industry adds value to otherwise unmerchantable but renewable feedstocks; Net CO2 emissions are reduced relative to fossil fuels. | 60% of SE US private timberland is family owned with activities underway to provide technical assistance and facilitate group certification to improve market access for sustainably sourced biomass. Overall GHG emissions are substantially reduced when wood pellets replace fossil coal. |

| 12.2: Sustainable natural resource management. Bioenergy affects environmental, economic, and social indicators of sustainability through more efficient natural resource use. | Knowledge, skills, and financial resources are generated by pellet industry to support continual improvement in forest management aiming toward optimal use of residues. |

| 15.2: Halt deforestation, restore degraded forests. Pellet markets provide incentives to protect and conserve SE forest lands. | Demand for forest products and emphasis on sustainability promotes good forest stewardship in the SE US and helps retain private lands in forest. |

| Strengths | Opportunities |

|

|

| Weaknesses | Threats |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kline, K.L.; Dale, V.H.; Rose, E.; Tonn, B. Effects of Production of Woody Pellets in the Southeastern United States on the Sustainable Development Goals. Sustainability 2021, 13, 821. https://doi.org/10.3390/su13020821

Kline KL, Dale VH, Rose E, Tonn B. Effects of Production of Woody Pellets in the Southeastern United States on the Sustainable Development Goals. Sustainability. 2021; 13(2):821. https://doi.org/10.3390/su13020821

Chicago/Turabian StyleKline, Keith L., Virginia H. Dale, Erin Rose, and Bruce Tonn. 2021. "Effects of Production of Woody Pellets in the Southeastern United States on the Sustainable Development Goals" Sustainability 13, no. 2: 821. https://doi.org/10.3390/su13020821