Development of a Software System for Selecting Steam Power Plant to Convert Municipal Solid Waste to Energy

Abstract

:1. Introduction

Decision Support Systems (DSSs)

2. Materials and Methods

2.1. Determination of the Aggregate MSW Generated in Ilorin/Year, Using Collection Facts and Figures

2.2. Characterization of the MSW Fractions

2.3. Physicochemical and Heating Value Analysis of MSW

2.3.1. Moisture Content Analysis of MSW Components

2.3.2. Ultimate Analysis of MSW Components

2.4. Estimation of the Heating Value of the MSW Combustible Fractions

2.5. Determination of the Energy Potential and Electrical Power Potential of the MSW

2.5.1. Determination of Energy Potentials () of the Municipal Solid Waste

2.5.2. Determination of the Electrical Power Potential ( of the Municipal Solid Waste

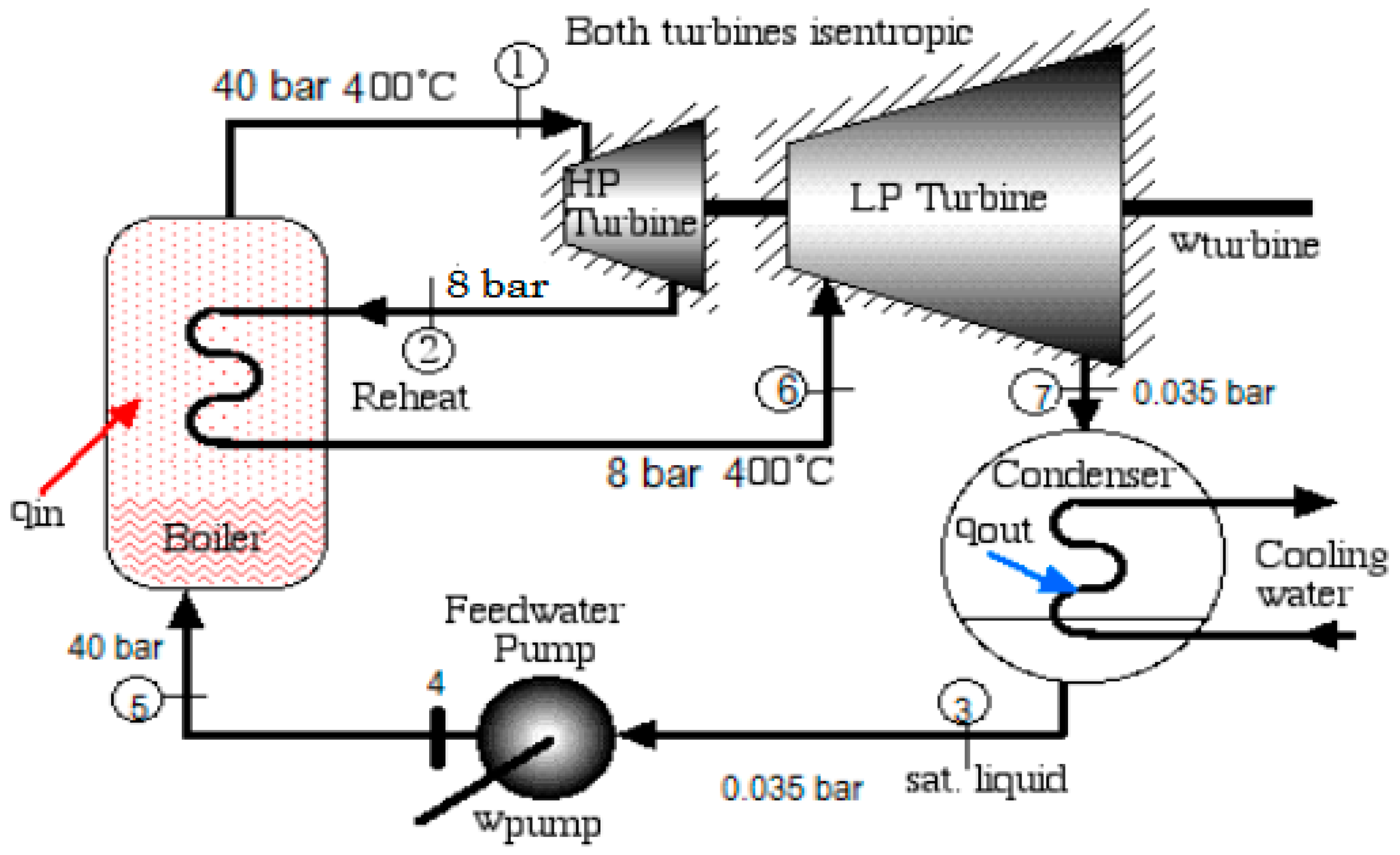

2.6. Determination of the Steam Power Plant Capacity Required for Energy Production

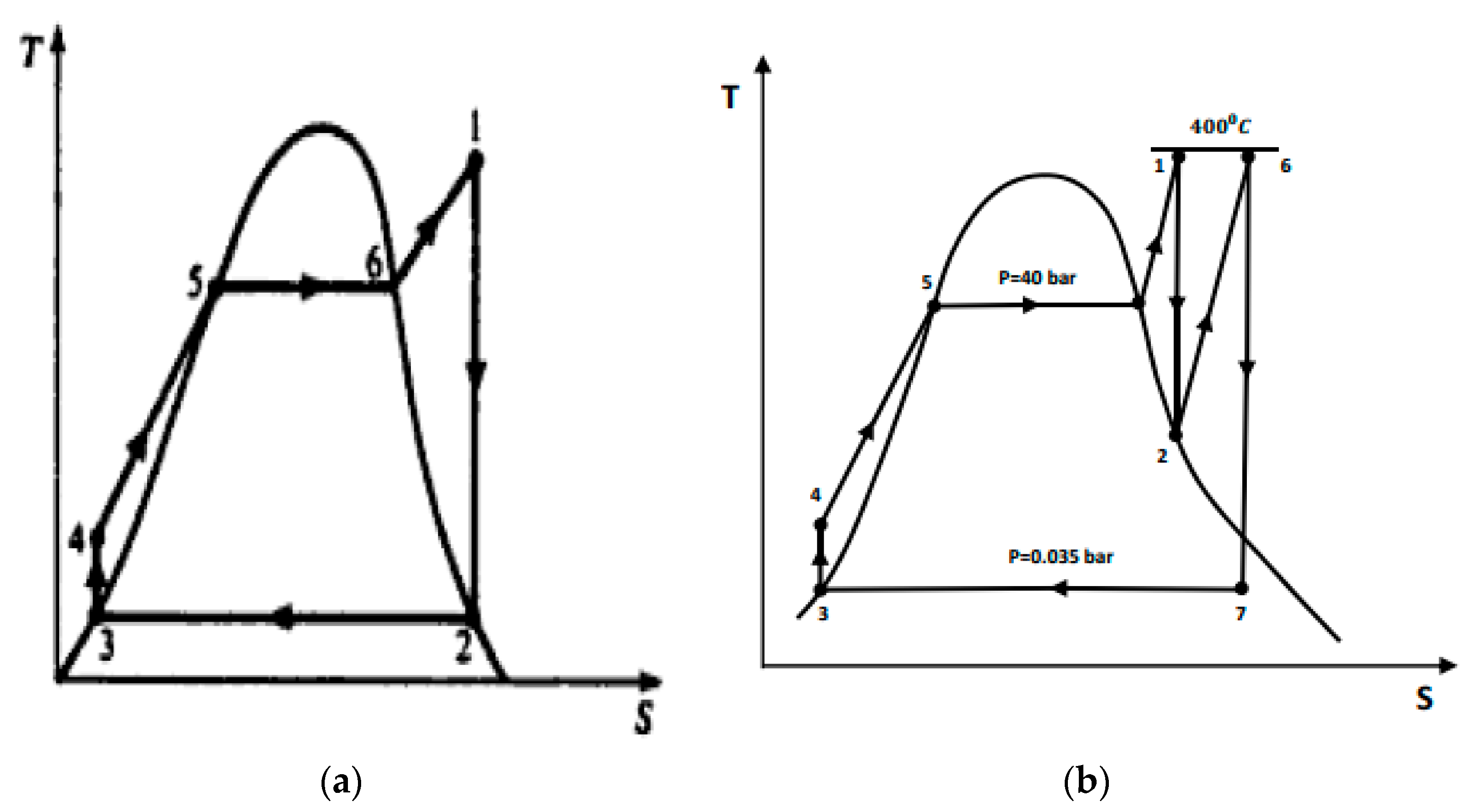

2.6.1. The Cycle Efficiency

2.6.2. The Net Heat Supplied (Qnet)

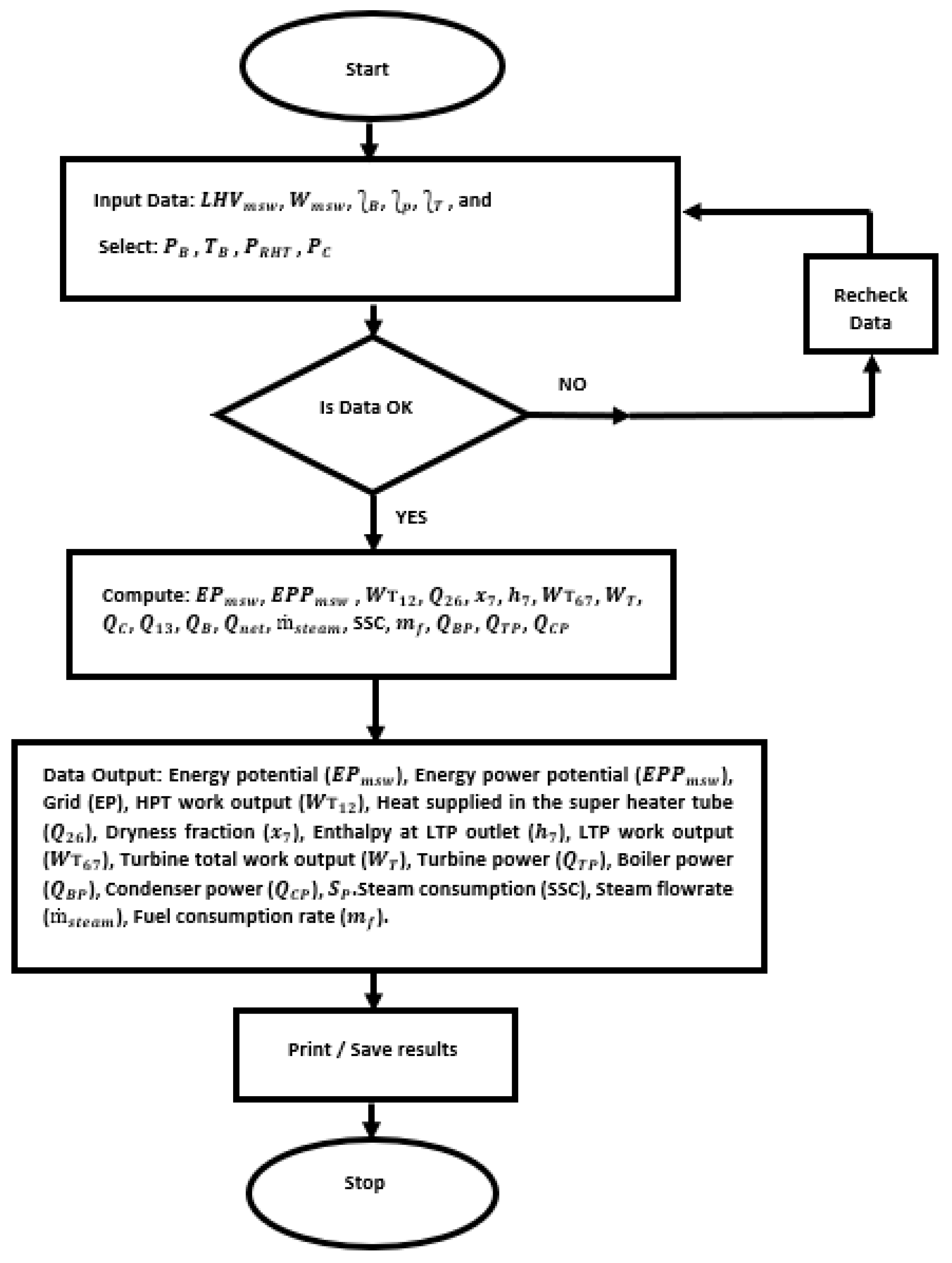

2.7. Development of Software for Selecting Power Plant Capacity

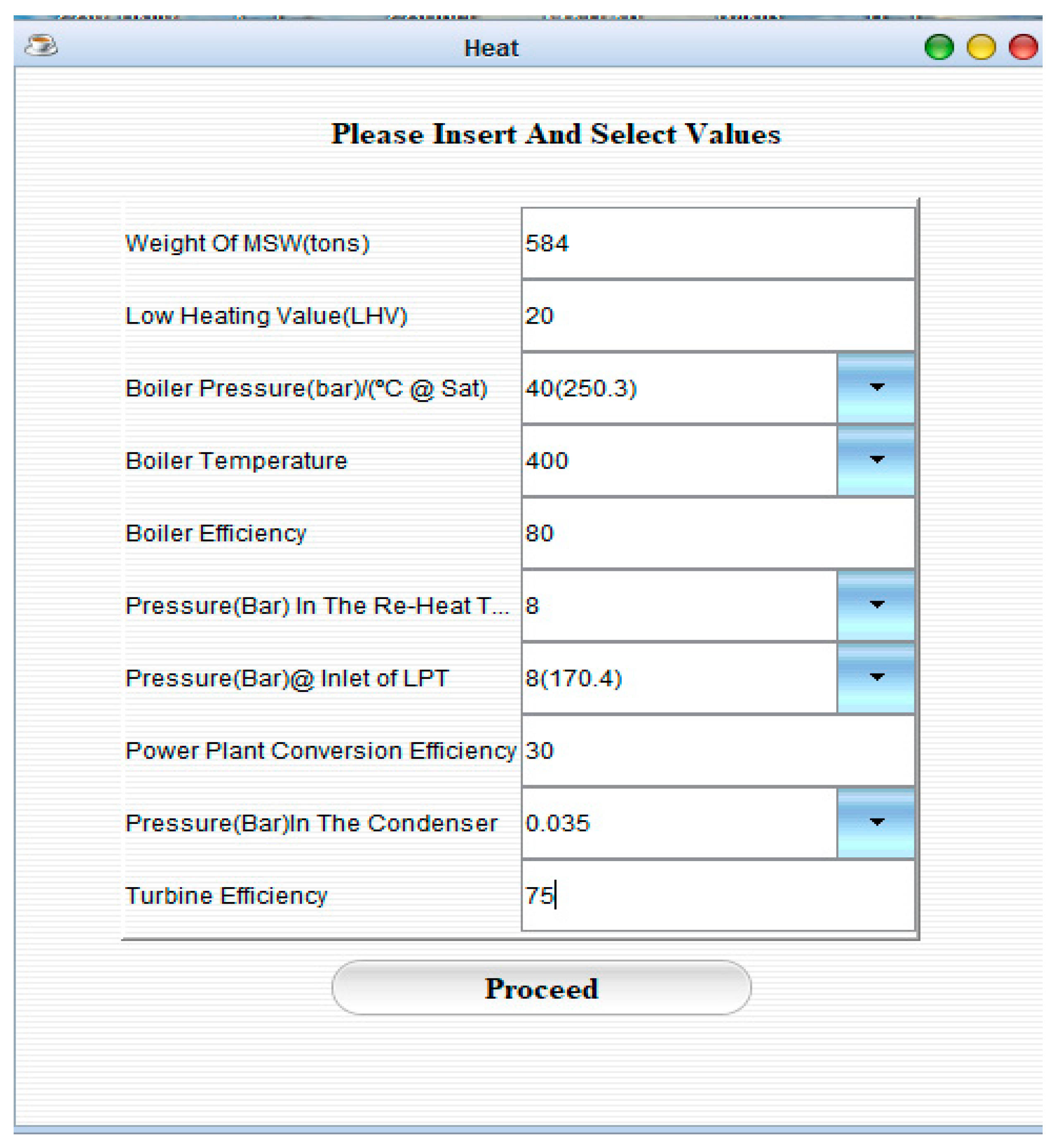

- The weight of MSW available for energy generation, heating value of the MSW, boiler efficiency, conversion efficiency, and turbine efficiency was supplied into the corresponding designated box in the input interface shown in Figure 5,

- The boiler pressure, boiler temperature, pressure in the reheat tube, and the pressure required in the condenser are selected from the corresponding draw-down of the icons provided in the input interface,

- After the required parameters have been supplied/selected; the system requests that you proceed, and the proceed button is clicked,

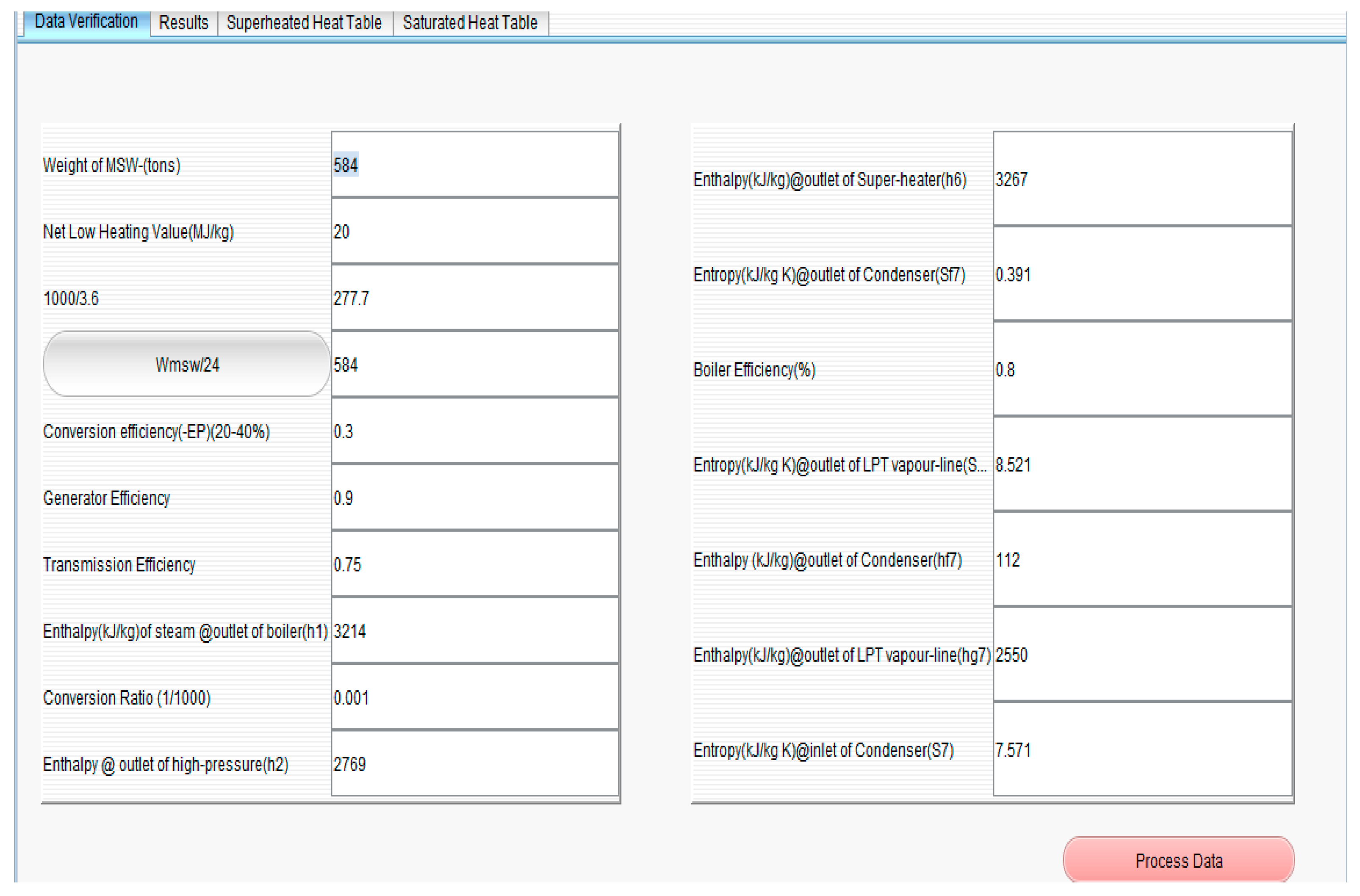

- Then, a verification interface, shown in Figure 6, will appear to ask if data is OKAY; if OK, click on proceed button otherwise click on the recheck data button and continue,

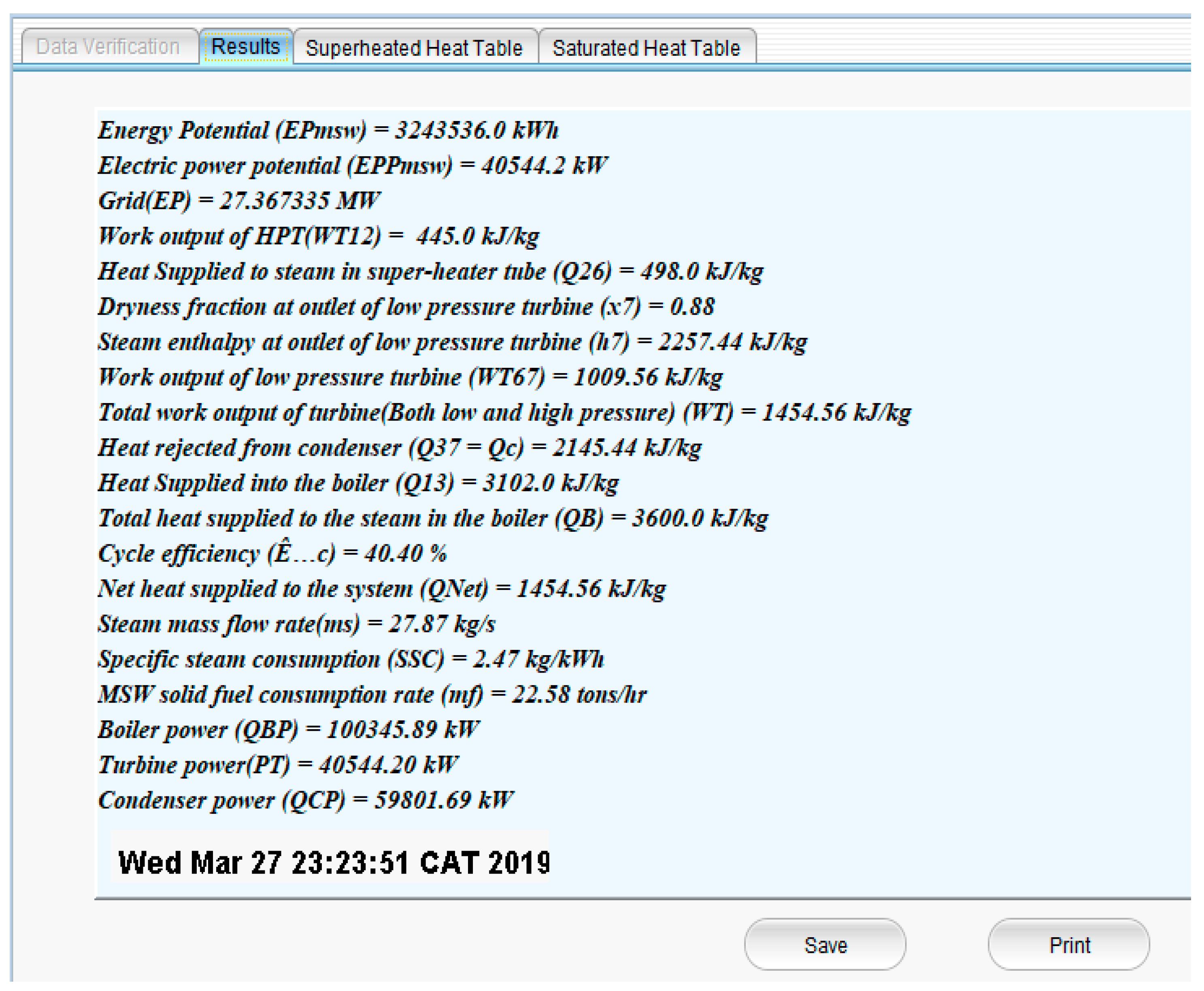

- Then click on the process button, and it will automatically process the data. After that, click on proceed button and the result will automatically be displayed on an output interface, as well as the date and exact time of processing as presented in Figure 7.

3. Results and Discussion

3.1. The Estimated Aggregate of MSW Produced

3.2. The Physical Characterization of the MSW Components

3.3. The Combustible MSW Fractions That Are Considered for Energy Production

3.4. The Thermochemical Analysis of Combustible MSW Components

3.5. The Energy Potential () and Electrical Power Potential of MSW ()

3.6. The Capacity of the Steam Power Plant Components Required to Convert the MSW

3.7. The Thermodynamic Properties at each State in the Power Plant Cycle and the Capacities of the Power Plant Components

3.8. Software-Generated Values on Power Potential and Power Plant Capacity

3.9. Comparison between Manually-Calculated and Software-Generated Values on: Energy Potentials and Power Plant Capacity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Omari, A.; Said, M.; Njau, K.; John, G.; Mtul, P. Energy Recovery routes from Municipal Solid Waste, A case study of Arusha-Tanzania. J. Energy Technol. Policy 2014, 4. Available online: https://www.iiste.org/Journals/index.php/JETP/article/view/13157 (accessed on 7 May 2021).

- Titiladunayo, I.F.; Akinnuli, B.O.; Ibikunle, R.A.; Agboola, O.O.; Ogunsemi, B.T. Analysis of combustible municipal solid waste fractions as fuel for energy production: Exploring its physicochemical and thermal characteristics. Int. J. Civil. Eng. Technol. 2018, 9, 1557–1575. Available online: http://www.iaeme.com/MasterAdmin/Journal_uploads/IJCIET/VOLUME_9_ISSUE_13/IJCIET_09_13_157.pdf (accessed on 20 December 2018).

- Islam, K.M.N. Municipal solid waste to energy generation in Bangladesh: Possible scenarios to generate renewable electricity in Dhaka and Chittagong city. J. Renew. Energy 2016, 1–16. Available online: http://www.hindawi.com/journals (accessed on 25 November 2017).

- Ibikunle, R.A.; Titiladunayo, I.F.; Lukman, A.F.; Dahunsi, S.O.; Akeju, E.A. Municipal solid waste sampling, quantification, and seasonal characterization for power evaluation: Energy potential and statistical modelling. Fuel 2020, 277, 118122. [Google Scholar] [CrossRef]

- Ibikunle, R.A. Investigating municipal solid waste generation and management in Ilorin for possible integrated waste-management system. J. Mater. Cycles Waste Manag. 2021, 23, 1239–1257. [Google Scholar] [CrossRef]

- Johari, A.; Hashim, H.; Mat, R.; Alias, H.; Hasshim, M.H.; Rozainee, M. Generalization, formulation, and heat contents of simulated MSW with moisture content. J. Eng. Sci. Technol. 2012, 7, 701–710. Available online: http://jestec.taylors.edu.my/Vol%207%20Issue%206%20December%2012/Vol7_.2012 (accessed on 5 May 2021).

- Ibikunle, R.A.; Titiladunayo, I.F.; Akinnuli, B.O.; Dahunsi, S.O.; Olayanju, T.M.A. Estimation of power generation from municipal solid wastes: A case study of Ilorin metropolis. Nigeria. Energy Rep. 2019, 9, 126–135. [Google Scholar] [CrossRef]

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management; Urban Development Series; Knowledge Papers no. 15; World Bank: Washington, DC, USA, 2012; Available online: https://openknowledge.worldbank.org/handle/10986/17388 (accessed on 5 May 2021).

- Parashar, C.K.; Das, P.; Samanta, S.; Ganguly, A.; Chatterjee, P.K. Municipal Solid Wastes—A Promising Sustainable Source of Energy: A Review on Different Waste-to-Energy Conversion Technologies. Energy Recovery Processes from Wastes. 2019, pp. 151–163. Available online: https://link.springer.com/chapter/10.1007/978-981-32-9228-4_13 (accessed on 5 May 2021).

- Ibikunle, R.A.; Titiladunayo, I.F.; Dahunsi, S.O.; Akeju, E.A.; Osueke, C.O. Characterization and projection of dry season municipal solid waste for energy production in Ilorin metropolis, Nigeria. J. Waste Manag. Res. 2021, 1–10. [Google Scholar] [CrossRef]

- World Bank. Sustainable Energy for All Database from SE4ALL Global Tracking Framework Led Jointly by the World Bank International Energy Agency, and Energy Management Assistance Programme. Available online: https://data.worldbank.org (accessed on 24 April 2018).

- Akhator, E.P.; Obonor, A.I.; Ezemonye, L.I. Electricity generation in Nigeria from municipal solid waste using the Swedish Waste-to-Energy Model. J. Appl. Sci. Environ. Manag. 2016, 20, 635–643. [Google Scholar] [CrossRef] [Green Version]

- Ogunjuyigbe, A.S.O.; Ayodele, T.R.; Alao, M.A. Electricity generation from municipal solid waste in some selected cities of Nigeria: An assessment of feasibility, potential technologies. J. Renew. Sustain. Energy Rev. 2017, 80, 149–162. [Google Scholar] [CrossRef]

- Rasmus, L.; Brian, V.M. Large combined heat and power plants in sustainable energy systems. Appl. Energy 2015, 142, 389–395. Available online: https://ideas.repec.org/a/eee/appene/v142y2015icp389-395.html (accessed on 4 April 2021).

- Tsolas, S.D.; Karim, M.N.; Hasan, M.M.F. Optimization of water-energy nexus: A network representation-based graphical approach. Appl. Energy 2018, 224, 230–250. [Google Scholar] [CrossRef]

- Xuerui, G.; Yong, Z.; Shibao, L.; Qianyun, C.; Tingli, A.; Xinxueqi, H.; La, Z. Impact of coal power production on sustainable water resources management in the coal-fired power energy bases of Northern China. Appl. Energy 2019, 250, 821–833. [Google Scholar]

- Do, W.K.; Tong, S.K.; Kwang, B.H.; Jung, K.P. The effect of firing biogas on the performance and operating characteristics of simple and recuperative cycle gas turbine combined heat and power systems. Appl. Energy 2012, 93, 215–228. [Google Scholar]

- Njoku, N.; Lamond, J.; Everett, G.; Manu, P. An overview of municipal solid waste management in developing and developed economies: Analysis of practices andcontributions to urban flooding in Sub-Saharan Africa. In Proceedings of the 12th International Post Graduate Research Conference, Media City, UK, 10–12 June 2015. [Google Scholar] [CrossRef]

- Ibikunle, R.A.; Lukman, A.F.; Titiladunayo, I.F.; Akeju, E.A.; Dahunsi, S.O. Modeling and robust prediction of high heating values of municipal solid waste based on ultimate analysis. Energy Sources Part A Recovery Util. Environ. Effects 2020. [Google Scholar] [CrossRef]

- Worldometer-Real Time Statistics (Population by Country). Available online: https://www.worldometers.info2019 (accessed on 3 May 2019).

- Hongtao, W.; Yongfeng, N. Municipal Solid Waste Characteristics and Management in China. J. Air Waste Manag. Assoc. 2001, 51, 250–263. [Google Scholar] [CrossRef] [Green Version]

- Kosuke, K.; Tomohiro, T. Revisiting estimates of municipal solid waste generation per capita and their reliability. J. Mater. Cycles Waste Manag. 2016, 18, 1–3. [Google Scholar]

- U.S. Energy Information Administration (U.S. EIA). Electricity in the United States is Produced (Generated) with Diverse Energy Sources and Technologies. 2020. Available online: https://www.eia.gov/energyexplained/electricity/electricity-in-the-us.php (accessed on 4 July 2020).

- United Nations Environmental Programme (UNEP). Euthopia Marching towards Africa’s First Waste-to-Energy Plant: Africa News. 2017. Available online: http://www.africanews.com/2017/11/25/ethiopia-marching-towards-africas-first-waste-to-energy-plant-unep (accessed on 20 December 2018).

- Oladende, O. 12 Nigerian Power Plants Produced Zero Megawatt Electricity on Christmas Day. Premiums Times (News). 4 January 2017. Available online: https://www.premiumtimesng.com/news/headlines/219590-12-nigerian-power-plants-produced-zero-megawatt-electricity-christmas-day.html (accessed on 25 June 2021).

- Larmuth, J.; Cuellar, A. An updated review of South African CSP projects under the renewable energy independent power producer procurement programme (REIPPPP). In AIP Conference Proceedings; AIP Publishing LLC.: Melville, NY, USA, 2019; Volume 2126, p. 040001. [Google Scholar] [CrossRef]

- Ibikunle, R.A. Decision Support System for Power Plant Design Using Available Municipal Solid Waste in Ilorin Metropolis as Fuel. Ph.D. Thesis, Federal University of Technology, Akure, Nigeria, 2019. [Google Scholar]

- Mareck, J.D.; Roger, R.F. Decision Support Systems. In Encyclopedia of Library and Information Sciences, 2nd ed.; Kent, A., Ed.; Marcel Dekker, Inc.: New York, NY, USA, 2002. [Google Scholar]

- Claudio, B. Decision Support Systems Development: A Methodological Approach. J. Appl. Bus. Inf. Syst. 2011, 2, 151–158. Available online: http://www.jabis.ro/2011/4/0204012011.pdf (accessed on 1 May 2021).

- Konstantinos, I.; Georgios, T.; Garyfallos, A.; Zacharoula, A.; Eleni, Z. A Spatial Decision Support System Framework for the Evaluation of Biomass Energy Production Locations: Case Study in the Regional Unit of Drama Greece. Sustainability 2018, 10, 531–553. [Google Scholar] [CrossRef] [Green Version]

- Fatima, C.C.D.; Erhard, W.P. A decision support system for power plant design. Eur. J. Oper. Res. 1998, 109, 310–320. Available online: http://www.sciencedirect.com/science/article/pii/S0377-2217(98)00059-91998 (accessed on 5 July 2019).

- Konstantinos, I.; Paragnotis, L.; Arabatzis, Z. Development of a decision support system for the study of an area after the occurrence of forest fire. Int. J. Sustain. Soc. 2011, 3, 5–53. [Google Scholar] [CrossRef]

- NT ENVR-01 (Nordtest Method). Solid Waste Municipal Sampling and Characterization. Published by Nordtest Tekniikantie 12, FIN–02150 ESPOO FINLAND. 1998. Available online: http://www.nordtest.info/wp/1995/05/14/solid-waste-municipal-sampling-and-characterisation-nt-envir-001/ (accessed on 7 July 2019).

- Issam, A.K.A.; Maria, M.B.; Salam, A.T.; Saheed, H.Q.; Kassinos, D.B. Solid waste characterization, qualification, and management practices in developing countries, a case study: Nubulus district-palestine. J. Environ. Manag. 2010, 91, 1131–1138. [Google Scholar]

- Vairam, S.; Ramesh, S. Engineering Chemistry; John Wiley and Sons Ltd.: Southern Gate, Chichester, UK, 2013. [Google Scholar]

- Shi, H.; Maphinpey, N.; Aqsha, A.; Silbermann, R. Characterization, thermochemical conversion studies and heating value modeling of municipal solid waste. J. Waste Manag. 2016, 48, 34–47. [Google Scholar] [CrossRef]

- Ibikunle, R.A.; Titiladunayo, I.F.; Akinnuli, B.O.; Lukman, A.F.; Ikubanni, P.P.; Agboola, O.O. Modeling the energy content of municipal solid waste and determination of its physicochemical correlation using multiple regression analysis. Int. J. Mech. Eng Technol. 2018, 9, 220–232. [Google Scholar]

- Kumar, J.S.; Subbaiah, K.V.; Rao, P.P. Waste to energy-a case study of eluru city, andhara pradesh. Int. J. Environ. Sci. 2010, 2, 151–162. [Google Scholar]

- Daura, L.A. Electricity generation potential of municipal solid waste in kanometropolis. J. Sci. Eng. Res. 2016, 3, 157–161. [Google Scholar]

- Muhammad, A.; Farid, N.A.; Ab Saman, K. The energy potential of municipal solid waste for power generation in indonesia. J. Mech. 2014, 2, 42–54. [Google Scholar]

- Bright Hub Engineering (BHE). Conversion Efficiencies in the Steam Power Plants. 2016. Available online: www.brighthubengineering.com/power-plants/72369-compare-thefficiency (accessed on 22 February 2017).

- Kapooria, R.K.; Kumar, S.; Kasana, K.S. An analysis of a thermal power plant working on a Rankine cycle: A theoretical investigation. J. Energy S. Afr. 2008, 19, 77–83. [Google Scholar] [CrossRef]

- Somplak, R.; Ferdan, T.; Palvas, M.; Palvas, M.; Popela, P. Waste-to-energy facility planning under uncertain circumstances. J. Appl. Therm. Eng. 2013, 61, 106–114. [Google Scholar] [CrossRef]

- Karlsson, L.; Jonsson, T.L. Pre-Feasibility Study of a Waste-to-Energy Plant in Chisinau, Moldova. Uppsala Universitet. 2012. Available online: https://www.diva-portal.org/smash/get/diva2:510286/FULLTEXT01.pdf (accessed on 25 October 2016).

- Arabkoohsar, A. Combined steam based high-temperature heat and power storage with an Organic Rankine Cycle, an efficient mechanical electricity storage technology. J. Clean. Prod. 2020, 247, 119098. [Google Scholar] [CrossRef]

- Loni, R.; Najafi, G.; Bellos, E.; Rajaee, F.; Said, F.; Mazlan, M. A review of industrial waste heat recovery system for power generation with Organic Rankine Cycle: Recent challenges and future outlook. J. Clean. Prod. 2020, 125070. [Google Scholar] [CrossRef]

- Jordi, B. Development and Implementation of a Nuclear Power Plant Steam Turbine Model in the System Code ATHLET. Master Thesis, Technische Universitat Muchen, Muchen, Germany, 2011. [Google Scholar]

- Hesham, G.I. Steam Power Plant Design Upgrading (Case Study: Khoms Steam Power Plant). J. Energy Environ. Res. 2011, 1, 202. [Google Scholar] [CrossRef]

- Eastop, T.D.; Mc Conkey, A. Applied Thermodynamics, 5th ed.; Dorling Kindersley Pvt. Ltd.: Delhi, India, 2014. [Google Scholar]

- Sadhu, S. Handbook of Mechanical Engineering; S. Chand & Company Ltd.: New Delhi, India, 2011. [Google Scholar]

- Ting, Y.; Noam, L. Thermodynamic analysis of hybrid Rankine cycles using multiple heat sources of different temperatures. Appl. Energy 2018, 222, 564–583. [Google Scholar] [CrossRef]

- Winterbone, O.E.; Turan, A. Advanced Thermodynamics for Engineers; John Wiley and Sons Inc.: New York, NY, USA; Toronto, ON, Canada, 2015. [Google Scholar]

- Ibrahim, D.; Yusuf, B. Fundamentals of Energy System. Integrated Energy Systems for Multigeneration (Elsevier Inc.). 2019. Available online: https://www.elsevier.com/books/integrated-energy-systems-formultigeneration/dincer/978-0-12-809943-8 (accessed on 7 May 2021). [CrossRef]

- Oyedepo, S.O.; Fakeye, B.A.; Mabinuori, B.; Babalola, P.O.; Leramo, R.O.; Kilanko, O.; Dirisu, J.O.; Udo, M.; Efemwenkiekie, U.K.; Oyebanji, J.A. Thermodynamics analysis and performance optimization of a reheat–Regenerative steam turbine power plant with feed water heaters. Fuel 2020, 280, 118577. [Google Scholar] [CrossRef]

- Maxwell, U.N. Solid waste generation and disposal in a nigerian city: An empirical analysis in onitsha metropolis. J. Environ. Manag. Saf. 2010, 1, 180–191. [Google Scholar]

- Rominiyi, O.L.; Fapetu, O.P.; Owolabi, J.O.; Adaramola, B.A. Determination of energycontent of the municipal solid waste of Ado-Ekiti Metropolis, Southwest, Nigeria. Curr. J. Appl. Sci. Technol. 2017, 23, 1–11. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration (USEIA). Biomass Explained. Waste-to-Energy (Municipal Solid Waste) Energy Recovery from Municipal Solid Waste. 2018. Available online: https://www.eia.gov/state/seds/sep_fuel/notes/use_glossary.pdf (accessed on 7 July 2019).

- Swedish Waste Management (SWM). 2015. Available online: www.arfallaverage.se/fileadmin/uploads/Rapporter/SWM2015.pdf (accessed on 20 June 2016).

- Scarlet, W.; Dellemand, J.F.; Monforti-Ferrano, F.; Nita, V. The role of biomass and bioenergy in a future bioeconomy: Policies and facts. Environ. Dev. 2015, 15, 3–34. [Google Scholar] [CrossRef]

- Wale, B. Energy. Energy Consult Powering Clean Energy Future, Solid Waste Management in Nigeria. 2018. Available online: https://www.bioenergyconsult.com/solid-waste-nigeria (accessed on 20 December 2018).

- U.S. IEA Statistics. Ghana-Combustible Renewables and Waste (% of Total Energy). OECD/IEA. 2014. Available online: http://www.iea.org/stats/index.asp (accessed on 29 June 2021).

- Deep Resource World Press (DRW). Energy Conversion Factors. 2012. Available online: https://deepresource.worldpress.com/2012/04/23/energyrelatedconversionfactors (accessed on 14 September 2018).

- World Nuclear Association (WNA): Heat Values of Various Fuels. 2018. Available online: www.world-nuclear.org (accessed on 14 October 2018).

- Ibadan Electricity Distribution Company (IBEDC). Kwara Needs 270 MW for 24-Hour Electricity. 2016. Available online: https://www.ilorin.info/fullnews.php?id=18082 (accessed on 3 October 2018).

- Akinnuli, B.; Ogedengbe, T.I.; Oladosu, K.O. Computer Aided Design and Drafting of Helical gears. J. Eng. Trends Appl. Sci. 2012, 3, 959–968. [Google Scholar]

| Collection Trucks | Trucks Used Per Day | Capacity (Tons) | Capacity (m3) | Trips of Truck/Day | MSW Collected (Tons) | MSW Generated (Tons) |

|---|---|---|---|---|---|---|

| Dinno Tipper Truck | 5 | 20 | 16 | 3 | 26,006.25 | 35,143.5 |

| Hippo Tipper Truck | 3 | 25 | 22 | 3 | 19,498.5 | 26,349 |

| Scannia Compactor | 2 | 30 | 22 | 2 | 10,405.5 | 14,061 |

| Arm Roller | 3 | 15 | 8 | 5 | 19,504.5 | 26,358 |

| Total | 13 | 90 | 68 | 13 | 75,414.75 | 101,911.5 |

| MSW Components | Jan. | Feb. | March | April | May | June | Total | Wt. | Kg/Capita |

|---|---|---|---|---|---|---|---|---|---|

| Wt. (kg) | Wt. (kg) | Wt. (kg) | Wt. (kg) | Wt. (kg) | Wt. (kg) | Wt. (kg) | % | /Day | |

| Food residue | 12.25 | 10.00 | 8.35 | 8.00 | 14.21 | 26.35 | 79.16 | 8.04 | 0.012 |

| Wood | 4.65 | 4.85 | 4.25 | 3.85 | 3.25 | 2.45 | 23.30 | 2.37 | 0.003 |

| Paper | 8.80 | 6.50 | 6.20 | 4.60 | 8.35 | 6.55 | 41.00 | 4.16 | 0.006 |

| Packaging box | 14.24 | 18.55 | 12.50 | 7.80 | 10.55 | 12.20 | 75.84 | 7.70 | 0.011 |

| Grass/trimmings | 3.64 | 8.20 | 10.60 | 12.40 | 21.12 | 24.22 | 80.18 | 8.14 | 0.012 |

| Textiles (rags) | 4.20 | 6.22 | 8.46 | 10.20 | 10.25 | 14.24 | 53.57 | 5.44 | 0.008 |

| Toiletries | 3.40 | 4.56 | 2.28 | 1.12 | 0.84 | 3.18 | 15.38 | 1.56 | 0.002 |

| Feces | 1.64 | 4.62 | 2.08 | 5.10 | 8.24 | 10.32 | 32.00 | 3.25 | 0.005 |

| Cow dung | 8.45 | 6.45 | 5.45 | 3.35 | 4.42 | 4.45 | 32.57 | 3.31 | 0.005 |

| Nylon (water sachet) | 18.00 | 16.24 | 10.24 | 8.46 | 6.45 | 8.22 | 67.61 | 6.87 | 0.010 |

| Polypropylene sack | 12.20 | 8.42 | 6.20 | 8.20 | 10.55 | 20.14 | 65.71 | 6.67 | 0.010 |

| Plastic bottle | 30.25 | 22.00 | 20.68 | 14.24 | 18.24 | 20.12 | 125.53 | 12.75 | 0.018 |

| Rubber | 0.82 | 1.20 | 1.22 | 0.14 | 5.20 | 5.24 | 13.82 | 1.40 | 0.002 |

| Leather | 0.64 | 0.26 | 1.20 | 0.22 | 4.10 | 4.16 | 10.58 | 1.07 | 0.002 |

| Glass/Ceramics | 10.40 | 9.80 | 10.40 | 6.00 | 10.12 | 9.85 | 56.57 | 5.74 | 0.008 |

| Animal bones | 2.64 | 1.12 | 0.80 | 2.45 | 10.22 | 12.25 | 29.48 | 2.99 | 0.004 |

| Tins/Metals | 12.00 | 10.00 | 14.00 | 8.20 | 6.35 | 14.66 | 65.21 | 6.62 | 0.010 |

| Sand/Ash | 10.90 | 8.80 | 6.30 | 4.30 | 5.12 | 4.62 | 40.04 | 4.07 | 0.006 |

| Other biogenic | 6.24 | 8.64 | 5.40 | 6.80 | 24.54 | 25.52 | 77.14 | 7.83 | 0.011 |

| Grand total | 165.36 | 156.43 | 136.61 | 115.43 | 182.12 | 228.74 | 984.69 | 100.00 | 0.145 |

| MSW Components | Jan. | Feb. | March | April | May | June | Total | Wt. |

|---|---|---|---|---|---|---|---|---|

| Wt. (kg) | Wt. (kg) | Wt. (kg) | Wt. (kg) | Wt. (kg) | Wt. (kg) | Wt. (kg) | % | |

| Food residue | 12.25 | 10.00 | 8.35 | 8.00 | 14.21 | 26.35 | 79.16 | 8.04 |

| Wood | 4.65 | 4.85 | 4.25 | 3.85 | 3.25 | 2.45 | 23.30 | 2.37 |

| Paper | 8.80 | 6.50 | 6.20 | 4.60 | 8.35 | 6.55 | 41.00 | 4.16 |

| Packaging box | 14.24 | 18.55 | 12.50 | 7.80 | 10.55 | 12.20 | 75.84 | 7.70 |

| Grass/garden trimmings | 3.64 | 8.20 | 10.60 | 12.40 | 21.12 | 24.22 | 80.18 | 8.14 |

| Textiles (rags) | 4.20 | 6.22 | 8.46 | 10.20 | 10.25 | 14.24 | 53.57 | 5.44 |

| Nylon (water sachet) | 18.00 | 16.24 | 10.24 | 8.46 | 6.45 | 8.22 | 67.61 | 6.87 |

| Polypropylene sack | 12.20 | 8.42 | 6.20 | 8.20 | 10.55 | 20.14 | 65.71 | 6.67 |

| Plastic bottle | 30.25 | 22.00 | 20.68 | 14.24 | 18.24 | 20.12 | 125.53 | 12.75 |

| Total | 108.23 | 100.98 | 87.48 | 77.75 | 102.97 | 134.49 | 611.90 | 62.14 |

| MSW Fractions | C% | H% | N% | S% | O% | HHV (MJ/kg) |

|---|---|---|---|---|---|---|

| Food residue | 18.56 | |||||

| Wood | 18.38 | |||||

| Paper | 17.28 | |||||

| Packaging box | 16.68 | |||||

| Grass/garden trimmings | 17.78 | |||||

| Textiles (rags) | 16.45 | |||||

| Nylon | 45.26 | |||||

| Polypropylene sack | 0 | 38.88 | ||||

| Plastic bottle | 0.00 | 36.86 |

| (a) | |||||

| MSW Fractions | HHV (MJ/kg) | HV% | LHVb (MJ/kg) | LHVc (MJ/kg) | Typical LHV (MJ/kg) |

| Food residue | 18.56 | 8.21 | 27.20 | 26.50 | 26.85 |

| Wood | 18.38 | 8.13 | 24.12 | 24.31 | 24.22 |

| Paper | 17.28 | 7.64 | 26.03 | 26.00 | 26.02 |

| Packaging box | 16.68 | 7.38 | 16.01 | 16.01 | 16.01 |

| Grass/garden trimmings | 17.78 | 7.86 | 21.03 | 21.51 | 21.27 |

| Textiles (rags) | 16.45 | 7.27 | 24.21 | 23.34 | 23.78 |

| Nylon | 45.26 | 20.02 | 17.02 | 18.10 | 17.56 |

| Polypropylene sack | 38.88 | 17.19 | 15.25 | 17.02 | 16.14 |

| Plastic bottle | 36.86 | 16.30 | 15.16 | 17.00 | 16.08 |

| Total | 226.13 | 100 | 186.03 | 189.79 | 187.91 |

| Average | 25 | 20.67 | 21.09 | 20.88 | |

| (b) | |||||

| Types | MSW (tons)/day | LHV (MJ/kg) | (kWh) | ||

| Food residue | 85.75 | 1.93 | 263,067 | 3288.34 | |

| Wood | 6.62 | 0.15 | 265,084 | 3313.55 | |

| Paper | 49.95 | 1.03 | 244,915 | 3061.44 | |

| Packaging box | 80.14 | 1.54 | 229,067 | 2863.34 | |

| Grass/garden trimmings | 36.97 | 0.80 | 256,440 | 3205.50 | |

| Textiles (rags) | 73.69 | 1.40 | 226,186 | 2827.33 | |

| Nylon | 125.95 | 7.03 | 665,592 | 8319.90 | |

| Polypropylene sack | 43.99 | 2.09 | 561,863 | 7023.29 | |

| Plastic bottle | 80.96 | 3.65 | 535,931 | 6699.14 | |

| Total | 584 | 20 | 3,248,145 | 40,601.83 | |

| (a) | |||||

| Description | Node | Pressure (bar) | Temperature (°C) | Enthalpy(KJ/kg) | Entropy(kJ/kg K) |

| Boiler outlet/H-P turbine inlet | 1 | 40 | 400 | 3214 | 6.769 |

| H-P turbine outlet/intermediate superheater inlet | 2 | 8 | 170.42 | 2769 | 6.663 |

| Intermediate superheater outlet/L-P turbine inlet | 6 | 8 | 400 | 3267 | 7.571 |

| L-P turbine outlet/condenser inlet | 7 | 0.035 | 26.7 | 2257.44 | 7.571 |

| Condenser outlet/pump inlet | 3 | 0.035 | 26.7 | 112 | 0.391 |

| Pump outlet/boiler inlet | 4 | 40 | 205 | 875 | 2.382 |

| (b) | |||||

| Work done | kJ/kg | Heat | kJ/kg | ||

| H-P turbine ) | 445 | Heat supplied into boiler ) | 498 | ||

| L-P turbine ) | 1010 | Heat supplied during reheat ) | 498 | ||

| Total work output of turbine (WT) | 1455 | Heat rejected from condenser | 2145 | ||

| Net work done | 1455 | Net heat supplied ) | 1455 | ||

| (c) | |||||

| Equipment | Heat (kJ/kg) | Work (kJ/kg) | Power (MW) | ||

| Boiler | 3600 | – | 101 | ||

| Turbine | – | 1455 | 41 | ||

| Condenser | 2145 | – | 60 | ||

| Steam and Fuel Consumption Rate of The Plant | |||||

| Water/fuel consumption | kg/s | (tons/h) | (kg/kWh) | ||

| Steam mass flow rate ) | 27.87 | 100 | |||

| Fuel consumption rate ) | 6.25 | 22.58 | |||

| Specific steam consumption (SSC) | 2.48 | ||||

| Parameters | Manually-Calculated Values | Software-Generated Values |

|---|---|---|

| Energy potential ) | 3,243,536.0 kW | 3,243,536.0 kW |

| Electrical power potential ) | 40,544.3 kW | 40,544.3 kW |

| Power to grid | 27.36732 MW | 27.36733 MW |

| Work output of the high-pressure turbine ) | 445.0 kJ/kg | 445.0 KJ/kg |

| Heat supplied during reheat process | 498.0 kJ/kg | 498.0 kJ/kg |

| Dryness fraction at outlet of low-pressure turbine ) | 0.88 | 0.88 |

| Steam enthalpy at outlet of low-pressure turbine ) | 2257.44 kJ/kg | 2257.44 kJ/kg |

| Work output of low-pressure turbine | 1009.56 kJ/kg | 1009.56 kJ/kg |

| Total work output of turbine | 1454.56 kJ/kg | 1454.56 kJ/kg |

| Heat rejected from condenser | 2145.44 kJ/kg | 2145.44 kJ/kg |

| Heat supplied into the boiler | 3102.0 kJ/kg | 3102.0 kJ/kg |

| Total heat supplied to the steam in the boiler | 3600.0 kJ/kg | 3600.0 kJ/kg |

| Cycle efficiency ) | 40.40% | 40.40% |

| Net heat supplied to the system | 1454.56 kJ/kg | 1454.56 kJ/kg |

| Steam mass flow rate ) | 27.87 kg/s | 27.87 kg/s |

| Specific steam consumption (SSC) | 2.48 kg/kWh | 2.47 kg/kWh |

| MSW (fuel) consumption rate ) | 22.58 tons/h | 22.58 tons/h |

| Boiler power ) | 100,345.88 kW | 100,345.89 kW |

| Turbine power ) | 40,540.20 kW | 40,544.20 kW |

| Condenser power ) | 59,801.68 kW | 59,801.68 kW |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibikunle, R.A.; Titiladunayo, I.F.; Akinnuli, B.O. Development of a Software System for Selecting Steam Power Plant to Convert Municipal Solid Waste to Energy. Sustainability 2021, 13, 11665. https://doi.org/10.3390/su132111665

Ibikunle RA, Titiladunayo IF, Akinnuli BO. Development of a Software System for Selecting Steam Power Plant to Convert Municipal Solid Waste to Energy. Sustainability. 2021; 13(21):11665. https://doi.org/10.3390/su132111665

Chicago/Turabian StyleIbikunle, Rotimi A., Isaac F. Titiladunayo, and Basil O. Akinnuli. 2021. "Development of a Software System for Selecting Steam Power Plant to Convert Municipal Solid Waste to Energy" Sustainability 13, no. 21: 11665. https://doi.org/10.3390/su132111665

APA StyleIbikunle, R. A., Titiladunayo, I. F., & Akinnuli, B. O. (2021). Development of a Software System for Selecting Steam Power Plant to Convert Municipal Solid Waste to Energy. Sustainability, 13(21), 11665. https://doi.org/10.3390/su132111665