Understanding the Use of Timber in Semi-Arid Regions: Kurdistan Region of Iraq, a Case Study

Abstract

1. Introduction

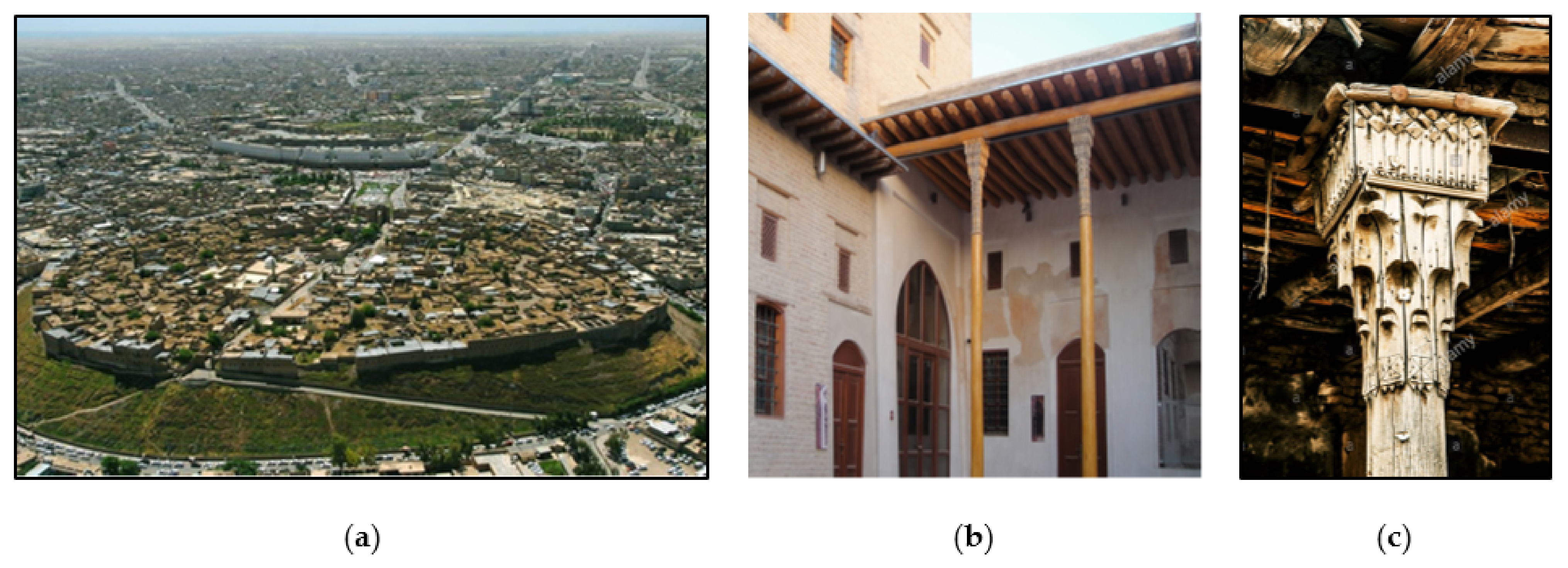

2. Utilization of Timber in KRI

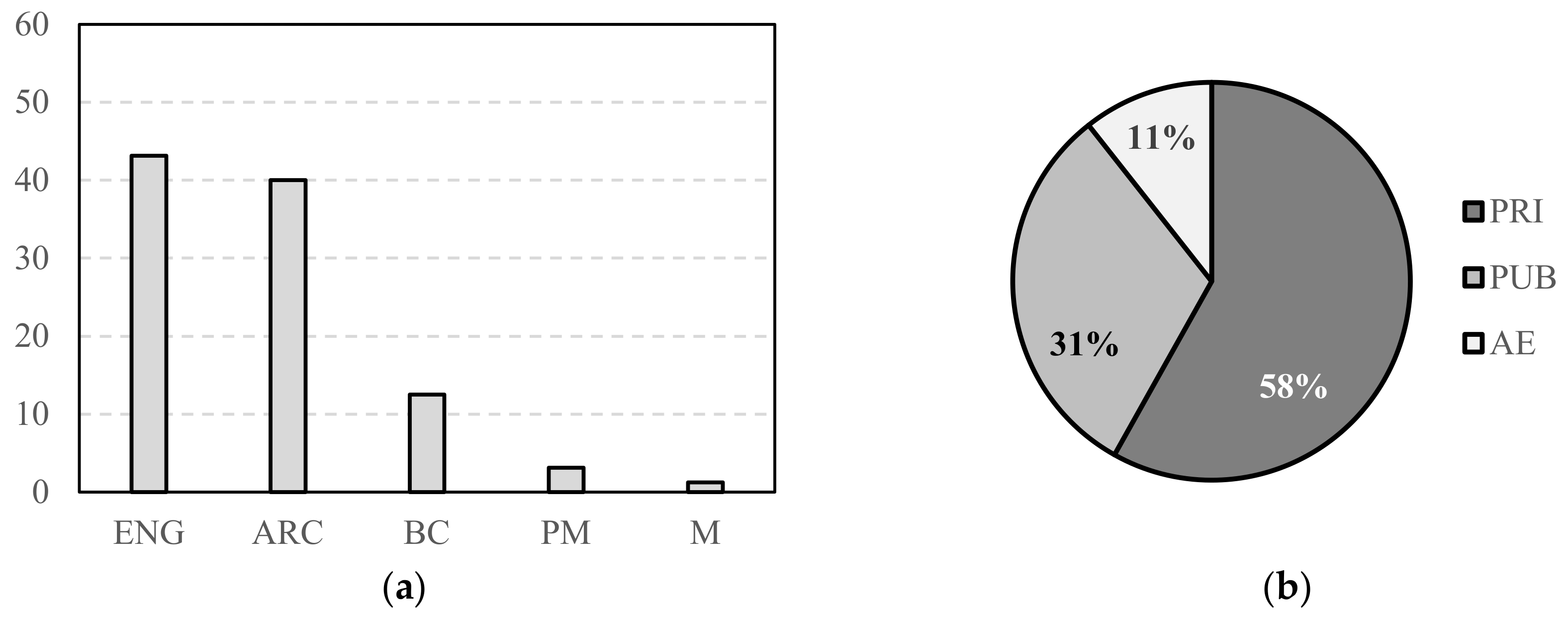

3. Research Methodology

- (1)

- Company/Organization: These questions focused on knowing the area of influence of the company/organization and field and type of business.

- (2)

- Construction Materials: Firstly, surveyees classified the importance of given characteristics of materials when selecting a construction material. Then, the same characteristics were used to rank different construction materials (timber, steel, concrete, masonry, and earth) based on their performance.

- (3)

- Timber Construction: These questions focused on the familiarity with timber construction in general and the actual current use of timber in surveyees’ projects.

- (4)

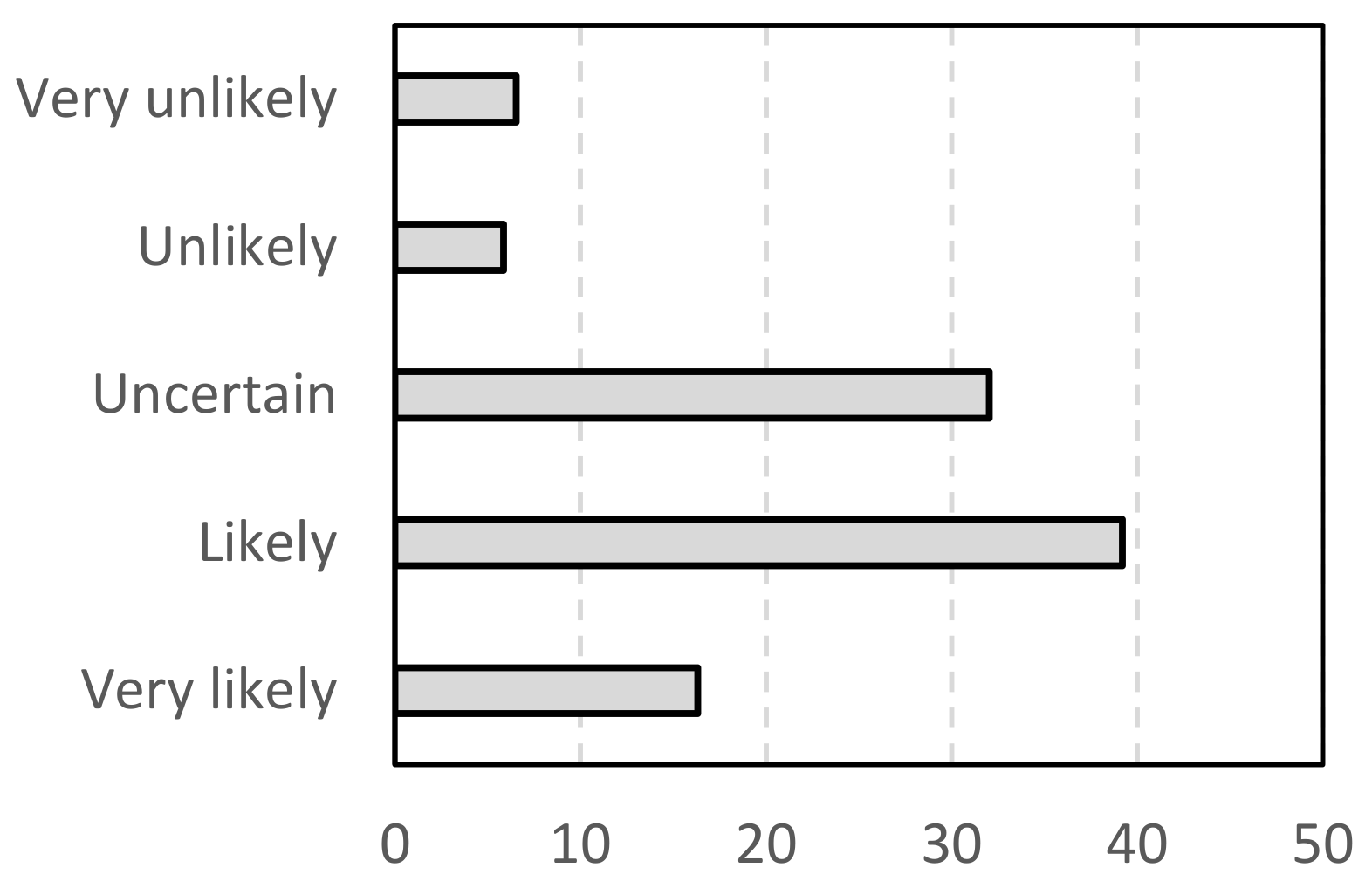

- Potential of Timber Construction in the KRI: These questions were about the likeliness of using timber in future projects considering the current international sustainability agreements.

- (5)

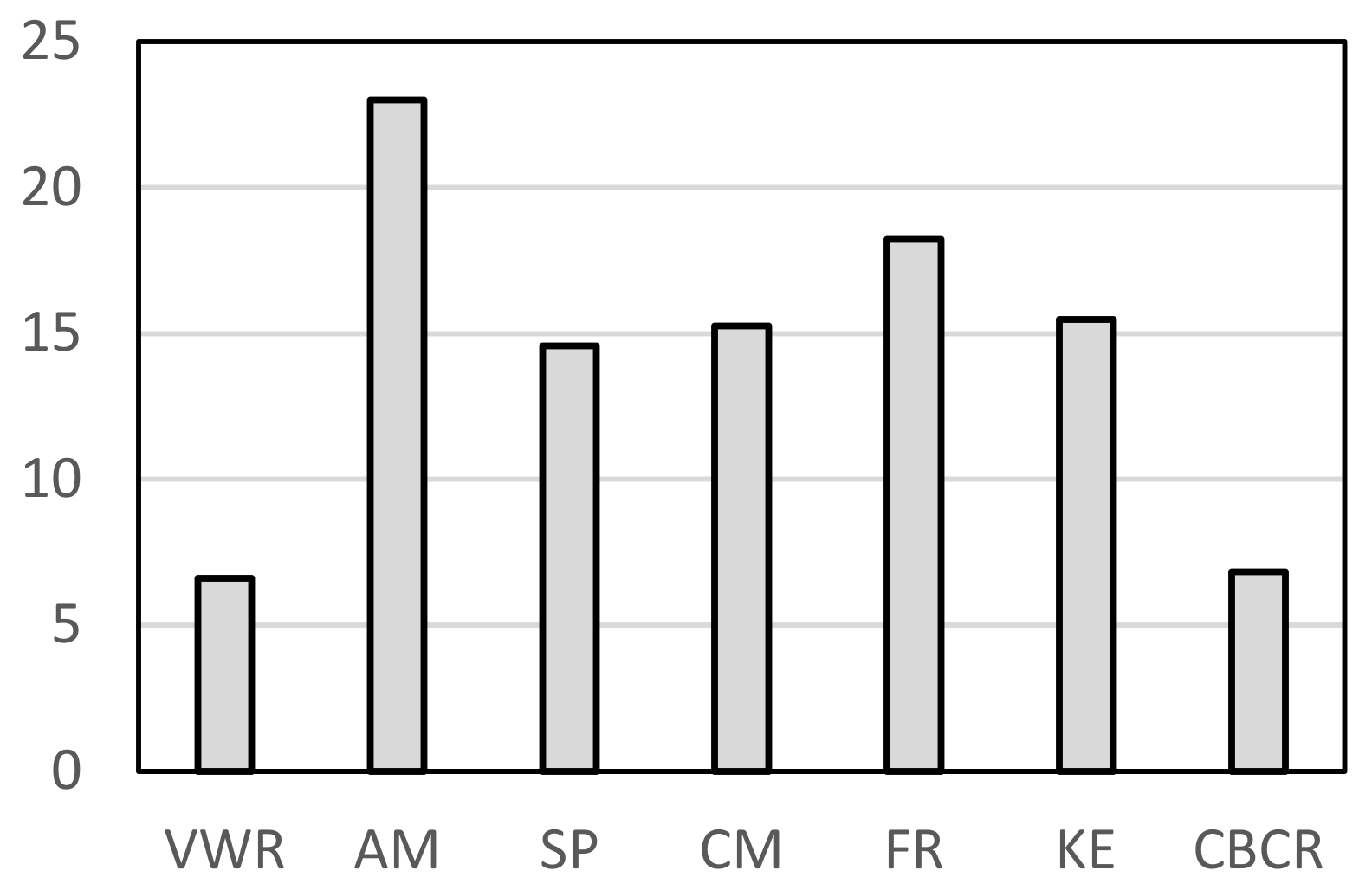

- Limitations of Timber Construction in the KRI: Three different barriers were selected from a list of seven given choices.

- (6)

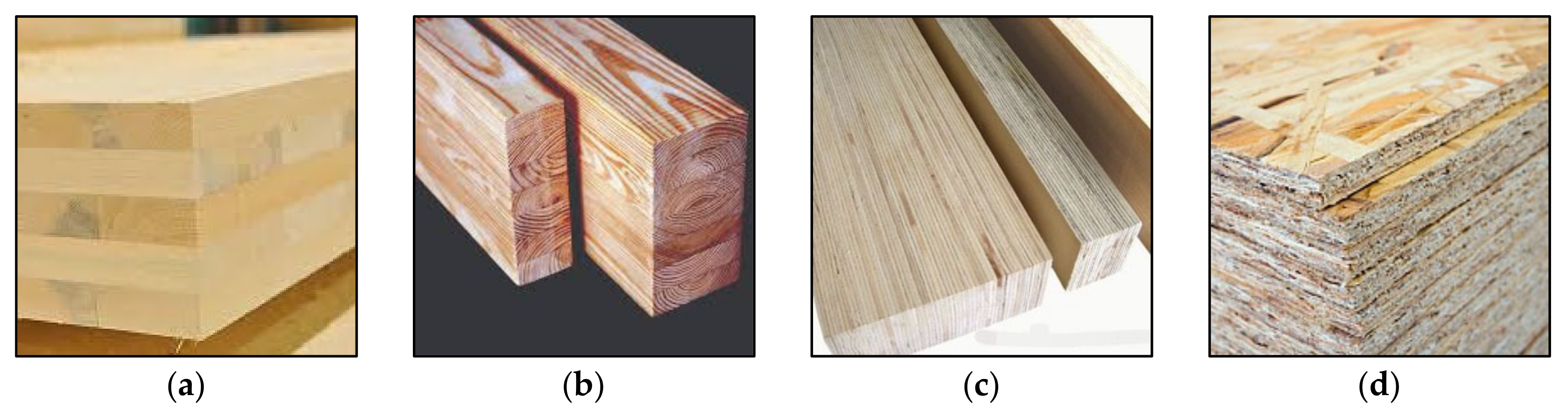

- Novel Wood-Based Products: Surveyees were asked about their familiarization with different engineered wood products.

4. Results and Analysis

5. Discussion

5.1. Availability in the Market

5.2. Fire Resistance

5.3. Technicality

5.3.1. Knowledge and Expertise

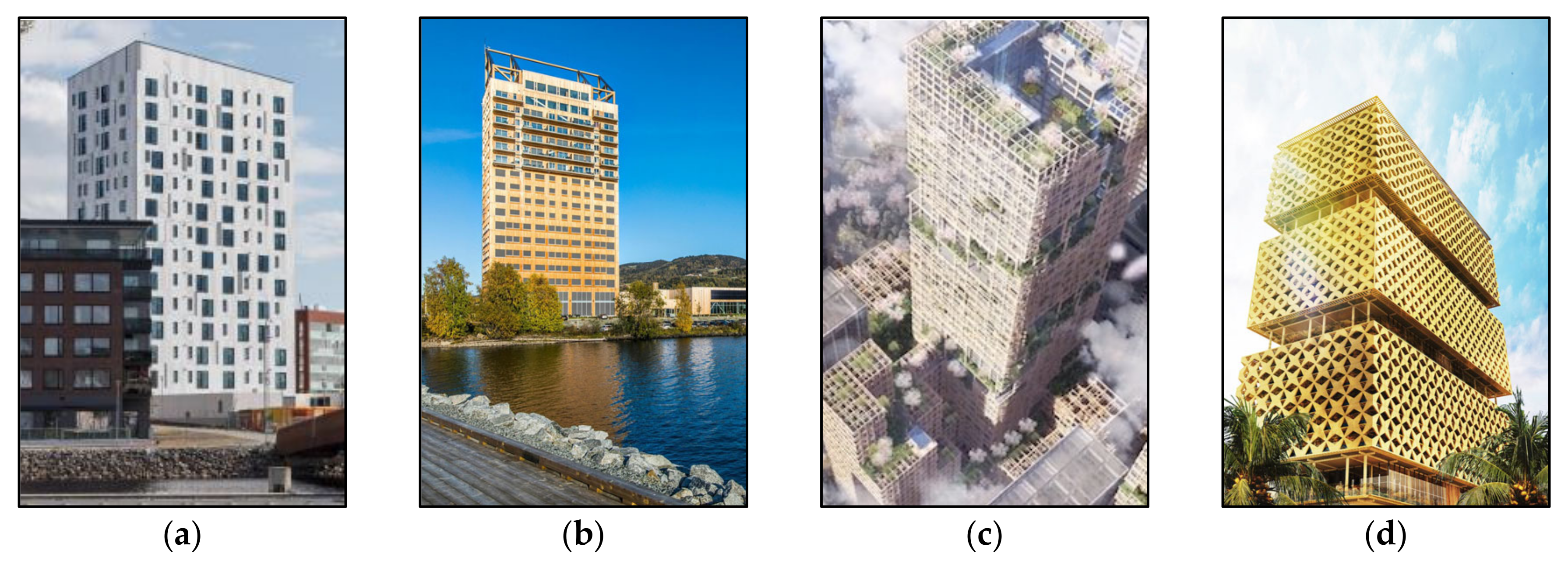

5.3.2. Structural Performance

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Environment Programme. 2020 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; UN Environment and the International Energy Agency: Nairobi, Kenya, 2020. [Google Scholar]

- Zhang, Z.; Provis, J.; Reid, A.; Wang, H. Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Build. Mater. 2014, 56, 113–127. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Mineral Commodity Summaries—Tracking Report. Available online: https://www.iea.org/reports/cement (accessed on 20 July 2020).

- Lynch, H. Environment or Development: Can Kurdish Cement Boom Balance Both. Available online: https://www.rudaw.net/english/business/15022020 (accessed on 20 July 2020).

- Koehn, E.; Ahmmed, M. Quality of building construction materials (cement) in developing countries. J. Arch. Eng. 2001, 7, 44–50. [Google Scholar] [CrossRef]

- Ürge-Vorsatz, D.; Cabeza, L.F.; Serrano, S.; Barreneche, C.; Petrichenko, K. Heating and cooling energy trends in buildings. Renew. Sustain. Energy Rev. 2015, 41, 85. [Google Scholar] [CrossRef]

- Das, B.B.; Neithalath, N. Sustainable construction and building materials. In Select Proceedings of ICSCBM 2018; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Genin, D.; Simenel, R. Endogenous berber forest management and the functional shaping of rural forests in southern Morocco: Implications for shared forest management options. Hum. Ecol. 2011, 39, 257–269. [Google Scholar] [CrossRef]

- Lippke, B.; Wilson, J.; Perez-Garcia, J.; Boyer, J.; Meil, J. CORRIM: Life-cycle environmental performance of renewable building materials. For. Prod. J. 2004, 54, 8–19. [Google Scholar]

- Dennehy, K. Using more wood for construction can slash global alliance on fossil fuels. In Yale News; Office of Public Affairs & Communications, Yale University: New Haven, CT, USA, 2014. [Google Scholar]

- Yue, M.; Li, W.; Cheng, X.; Chen, Y.; Xu, L.; Shi, Y. Study on energy conservation and carbon emission reduction design of timber structure building. J. Eng. 2019, 2019, 5455–5466. [Google Scholar] [CrossRef]

- Roberts, D. The Hottest New Thing in Sustainable Building Is, uh, Wood. Available online: https://www.vox.com/energy-and-environment/2020/1/15/21058051/climate-change-building-materials-mass-timber-cross-laminated-clt (accessed on 20 July 2020).

- Gold, S.; Rubik, F. Consumer attitudes towards timber as a construction material and towards timber frame houses—Selected findings of a representative survey among the German population. J. Clean. Prod. 2009, 17, 303–309. [Google Scholar] [CrossRef]

- Xia, B.; O’Neill, T.; Zuo, J.; Skitmore, M.; Chen, Q.; Skitmore, R. Perceived obstacles to multi-storey timber-frame construction: An Australian study. Arch. Sci. Rev. 2014, 57, 169–176. [Google Scholar] [CrossRef]

- Caniato, M.; Bettarello, F.; Ferluga, A.; Marsich, L.; Schmid, C.; Fausti, P. Thermal and acoustic performance expectations on timber buildings. Build. Acoust. 2017, 24, 219–237. [Google Scholar] [CrossRef]

- Petruch, M.; Walcher, D. Timber for future? Attitudes towards timber construction by young millennials in Austria—Marketing implications from a representative study. J. Clean. Prod. 2021, 294, 126324. [Google Scholar] [CrossRef]

- Mohammed, A.O. Evaluation of Multi-Storey Housing Projects in the Context of Sustainability/The City of Duhok. Master’s Thesis, University of Duhok, Duhok, Iraq, 2013. [Google Scholar]

- Wirya, S.; Salah, M.; Kuzović, D. LEED rating system barriers in the construction sector in Northern Iraq. Industrija 2017, 45, 167–186. [Google Scholar] [CrossRef]

- Li, J.; Rismanchi, B.; Ngo, T. Feasibility study to estimate the environmental benefits of utilising timber to construct high-rise buildings in Australia. Build. Environ. 2018, 147, 108–120. [Google Scholar] [CrossRef]

- Tahir, B.; Wang, X.; Zhong, Y.; Mezori, H.; Liu, Y.; Liao, W. Bioethanol production from leaves of Quercus infectoria in Kurdistan region. Res. Sq. 2020. [Google Scholar] [CrossRef]

- Eklund, L.; Abdi, A.; Shahpurwala, A.; Dinc, P. On the geopolitics of fire, conflict and land in the Kurdistan region of Iraq. Remote Sens. 2021, 13, 1575. [Google Scholar] [CrossRef]

- Abdullah, R. 2.2 Million Acres of Forest Lost to Fire, Deforestation, Budget Cuts: KRG. Available online: https://www.rudaw.net/english/kurdistan/171020182 (accessed on 20 July 2020).

- Khwarahm, N.R. Mapping current and potential future distributions of the oak tree (Quercus aegilops) in the Kurdistan region, Iraq. Ecol. Process. 2020, 9, 56. [Google Scholar] [CrossRef]

- Aree, A.A.; Suliman, H.H.; Saeed, H.S.; Dawod, N.A. Some of phenotypic, physical and anatomical wood properties of valonia oak trees in Kurdistan Iraq. Iraqi J. Agric. Sci. 2021, 52, 589–600. [Google Scholar] [CrossRef]

- United Nations Development Programme. Drought—Impact Assessment, Recovery and Mitigation Framework and Regional Project Design in Kurdistan Region (KR); United Nations Development Programme: New York, NY, USA, 2010. [Google Scholar]

- Mosa, W.L. Forest Cover Change and Migration in Iraqi Kurdistan: A Case Study from Zawita Sub-District; Michigan State University: East Lansing, MI, USA, 2016. [Google Scholar]

- International Organization for Migration. Demography Survey: Kurdistan Region of Iraq; UN Migration: Geneva, Switzerland, 2018. [Google Scholar]

- Khoshnaw, R. Sustainable construction in Kurdish vernacular architecture. Period. Polytech. Arch. 2019, 50, 178–185. [Google Scholar] [CrossRef]

- Karol, S.; Jianli, H.; Isaac, G.; Weiqi, X.; Subo, W.; Zitong, C. Feasibility study on further utilization of timber in China. IOP Conf. Series Mater. Sci. Eng. 2018, 383, 012029. [Google Scholar] [CrossRef]

- Gibbons, M.J.; Nikafshar, S.; Saravi, T.; Ohno, K.; Chandra, S.; Nejad, M. Analysis of a wide range of commercial exterior wood coatings. Coatings 2020, 10, 1013. [Google Scholar] [CrossRef]

- Preston, V. Questionnaire survey. Int. Encycl. Hum. Geogr. 2009, 46–52. [Google Scholar] [CrossRef]

- Evison, D.C. Mass timber construction in Australia and New Zealand—Status, and economic and environmental influences on adoption. Wood Fiber Sci. 2018, 50, 128–138. [Google Scholar] [CrossRef]

- Adeli, K.; Yachkaschi, A.; Limaei, S.M.; Fallah, A. A Study of the condition of timber production in Iran and the expected production rate in the next decade. J. Sustain. Dev. 2011, 5, 144. [Google Scholar] [CrossRef]

- Crafford, P.; Wessels, C.B. South African log resource availability and potential environment impact of timber construction. S. Afr. J. Sci. 2020, 116, 7–8. [Google Scholar] [CrossRef]

- Kalwry, H.S.K. An Investigation of Building Construction and Materials Issues in Northern Iraq for Residential Projects. Master’s Thesis, Eastern Mediterranean University (EMU)-Doğu Akdeniz Üniversitesi (DAÜ), Famagusta, Turkey, 2017. [Google Scholar]

- Rida, N.M.; Hussein, A.A.; Ahmed, D.A.; Mousa, R.M.; Abid, M.F.; Hassan, R.A.; Salman, A.N. Sixth National Report of Iraq to the Convention on Biological Diversity; Ministry of Health and Environment, and Convention on Biological Diversity: Baghdad, Iraq, 2018. [Google Scholar]

- Shatz Howard, J.; Constant, L.; Luoto, J.E.; Smith, A.; Abramzon, S. An Assessment of the Present and Future Labor Market in the Kurdistan Region-Iraq, Implications for Policies to Increase Private-Sector Employment; RAND Corporation: Santa Monica, CA, USA, 2014. [Google Scholar]

- Coe, R. Farmer-designed agroforestry trials: Farmers’ experiences in western Kenya. In Trees and Farmers: Assessing the Adoption Potential of Agroforestry Practices in Africa; Franzel, S., Scherr, S., Eds.; World Agroforestry Centre (ICRAF): Nairobi, Kenya, 1998. [Google Scholar]

- Larocque, G.R. Ecological Forest Management Handbook; CRC Press, Taylor & Francis: Boca Raton, FL, USA, 2016. [Google Scholar]

- Oliver, C.D. Sustainable forestry: What is it? How do we achieve it? J. For. 2003, 101, 8–14. [Google Scholar]

- Flueck, W.T. Evolution of forest systems: The role of biogeochemical cycles in determining sustainable forestry practices. Ecol. Soc. 2009, 14, r4. [Google Scholar] [CrossRef]

- Eulewi, H.K.; Hasan, A. Monitoring of the temporal changes in the forests of northern Iraq through the directed classification and the index of natural vegetative difference. Plant Arch. 2020, 20, 5745–5750. [Google Scholar]

- Adedeji, A.A.; Jimoh, A.A.; Aina, S.T. Timber as a Sustainable Construction Material; Its Impact on Climate Change and Innovative Development of the African Continent; Africa Unity for Renaissance Conference: Pretoria, South Africa, 2017. [Google Scholar]

- Wilson, P.L. Designing with timber, Adleaderin Association with ARCA. In Proceedings of the Conference on Scottish Hardwoods, New Lanark, UK, 14 March 2000. Organised by the Scottish Hardwood Timber Market Development Group. [Google Scholar]

- du Toit, B.; Malherbe, G.F.; Kunneke, A.; Seifert, T.; Wessels, B. Survival and long-term growth of eucalypts on semi-arid sites in a Mediterranean climate, South Africa. South. For. 2017, 79, 1–15. [Google Scholar] [CrossRef]

- Taha, M.A.Y.; Abd Ali, B.A. Estimating waste wood through conversion of whole stem into lumber of Eucalyptus camaldulensis growing in Askikalak Kurdistan region of Iraq. In Proceedings of the 2nd Scientific Agricultural Conference, Kurdistan Region of Iraq, Iraq, 26–27 April 2016; p. 273. [Google Scholar]

- Taha, M.A.Y. Some technological properties of sawn board Eucalyptus Camaldulensis Denh. grown in Askikalak. Sci. J. Univ. Zakho 2015, 3, 107–112. [Google Scholar] [CrossRef]

- Foroughbakhch, R.; Carrillo-Parra, A.; Hernandez-Pinero, J.L.; Guzman, M.A. Growth and yield of an eucalyptus subtropical plantation in a Northeastern Mexico degraded land soil. Madera y Bosques 2017, 23, 71–85. [Google Scholar] [CrossRef]

- Lowden, L.A.; Hull, T.R. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci. Rev. 2013, 2, 4. [Google Scholar] [CrossRef]

- Popescu, C.; Pfriem, A. Treatments and modification to improve the reaction to fire of wood and wood based products—An overview. Fire Mater. 2019, 44, 100–111. [Google Scholar] [CrossRef]

- Kumar, S.P.; Takamori, S.; Araki, H.; Kuroda, S. Flame retardancy of clay-sodium silicate composite coatings on wood for construction purposes. RSC Adv. 2015, 5, 34109–34116. [Google Scholar] [CrossRef]

- Carosio, F.; Cuttica, F.; Medina, L.; Berglund, L.A. Clay nanopaper as ultifunctional brick and mortar fire protection coating—Wood case study. Maternite 2016, 93, 357–363. [Google Scholar] [CrossRef]

- Kim, H.; Park, J.W.; Lee, J.H.; Jang, S.W.; Kim, H.J.; Choi, Y.; Choy, J.H.; Yang, J.H. Clay-organic intumescent hybrid system for the synergetic flammability of polymer nanocomposites. J. Therm. Anal. Calorim. 2018, 132, 2009–2014. [Google Scholar] [CrossRef]

- European Committee for Standardization. Eurocode 5: Design of Timber Structure; BSI: Brussels, Belgium, 1994. [Google Scholar]

- Al-Taie, E.; Al-Ansari, N.; Knutsson, S. The need to develop a building code for Iraq. Engineering 2014, 6, 610–632. [Google Scholar] [CrossRef][Green Version]

- Grebner, A.L.; Bettinger, P.; Siry, J.P. Introduction to Forestry and Natural Resources, 2nd ed.; Academic Press: Cambridge, MA, USA, 2021; ISBN 978-0-12-819002-9. [Google Scholar]

- Foster, R.M.; Ramage, H. Tall timber. In Nonconventional and Vernacular Construction Materials, 2nd ed.; Woodhead Publishing, Elsevier: Amsterdam, The Netherlands, 2020; pp. 467–490. [Google Scholar]

- Yue, K.; Liang, B.; Shao, Y.; Xie, C.; Hu, W.; Zhao, M.; Chen, Z.; Lu, W. Lateral behavior of wood frame shear walls sheathed with densified plywood under monotonic loading. Thin Walled Struct. 2021, 166, 108082. [Google Scholar] [CrossRef]

- Sankar, A.; Sajan, S. Manufacturing of high strength plywood composites reinforced with copper fibers. Mater. Today Proc. 2021, 47, 5255–5259. [Google Scholar] [CrossRef]

- Mallo, M.F.L.; Espinoza, O. Awareness, perceptions and willingness to adopt Cross-Laminated Timber by the architecture community in the United States. J. Clean. Prod. 2015, 94, 198–210. [Google Scholar] [CrossRef]

- Agyekum, K.; Kissi, E.; Danku, J.C. Professionals’ views of vernacular building materials and techniques for green building delivery in Ghana. Sci. Afr. 2020, 8, e00424. [Google Scholar] [CrossRef]

- Xian-Qing, X.; Ying-Ying, Y.; Yi-Ting, N.; Liang-Ting, Z. Development of a cornstarch adhesive for laminated veneer lumber bonding for use in engineered wood flooring. Int. J. Adhes. 2019, 98, 102534. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Mohammed, O.K. Composite concrete—Unregularized timber section for flat roof construction. Structures 2020, 27, 1324–1334. [Google Scholar] [CrossRef]

- Ceccotti, A.; Fragiacomo, M.; Giordano, S. Long-term and collapse tests on a timber-concrete composite beam with glued-in connection. Mater. Struct. 2006, 40, 15–25. [Google Scholar] [CrossRef]

- Mirdad, A.H.; Daneshvar, H.; Joyce, T.; Chui, Y.H. Sustainability design considerations for timber-concrete composite floor systems. Adv. Civ. Eng. 2021, 2021, 6688076. [Google Scholar] [CrossRef]

- Navaratnam, S.; Small, D.W.; Gatheeshgar, P.; Poologanathan, K.; Thamboo, J.; Higgins, C.; Mendis, P. Development of cross laminated timber-cold-formed steel composite beam for floor system to sustainable modular building construction. Structures 2021, 32, 681–690. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Y.; Crocetti, R.; Franco, L.; Schweigler, M.; Wålinder, M. An innovative timber-steel hybrid beam consisting of glulam mechanically reinforced by means of steel rod: Analytical and preliminary numerical investigations. J. Build. Eng. 2021, 43, 102549. [Google Scholar] [CrossRef]

- Chiniforush, A.A.; Akbarnezhad, A.; Valipour, H.; Xiao, J. Energy implications of using steel-timber composite (STC) elements in buildings. Energy Build. 2018, 176, 203–215. [Google Scholar] [CrossRef]

- Perković, N.; Rajčić, V.; Barbalić, J. Analytical and numerical verification of vibration design in timber concrete composite floors. Forests 2021, 12, 707. [Google Scholar] [CrossRef]

- Chiniforush, A.A.; Valipour, H.; Akbarnezhad, A.; Bradford, M. 08.27: Steel-timber composite (STC) beams: Numerical simulation of long-term behaviour. ce/papers 2017, 1, 2051–2059. [Google Scholar] [CrossRef]

- Dias, A.; Skinner, J.; Crews, K.; Tannert, T. Timber-concrete-composites increasing the use of timber in construction. Eur. J. Wood Wood Prod. 2015, 74, 443–451. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A. Thermally modified timber: Recent developments in Europe and North America. Wood Fiber Sci. 2016, 48, 28–39. [Google Scholar]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N.; et al. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef]

- Vantyghem, G.; De Corte, W.; Steeman, M.; Boel, V. Density-based topology optimization for 3D-printable building structures. Struct. Multidiscip. Optim. 2019, 60, 2391–2403. [Google Scholar] [CrossRef]

- Chan, R.; Liu, X.; Galobardes, I. Parametric study of functionally graded concretes incorporating steel fibres and recycled aggregates. Constr. Build. Mater. 2020, 242, 118186. [Google Scholar] [CrossRef]

| Characteristic | Punctuation |

|---|---|

| Fire performance | 6.08 |

| Environmental friendliness | 6.39 |

| Durability | 6.47 |

| Cost of production | 6.38 |

| Cost of material | 6.37 |

| Cost of maintenance | 6.29 |

| Availability in the market | 6.59 |

| Aesthetics | 6.25 |

| Acoustic performance | 6.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdulwahid, M.Y.; Galobardes, I.; Radoine, H. Understanding the Use of Timber in Semi-Arid Regions: Kurdistan Region of Iraq, a Case Study. Sustainability 2021, 13, 11845. https://doi.org/10.3390/su132111845

Abdulwahid MY, Galobardes I, Radoine H. Understanding the Use of Timber in Semi-Arid Regions: Kurdistan Region of Iraq, a Case Study. Sustainability. 2021; 13(21):11845. https://doi.org/10.3390/su132111845

Chicago/Turabian StyleAbdulwahid, Mohanad Yaseen, Isaac Galobardes, and Hassan Radoine. 2021. "Understanding the Use of Timber in Semi-Arid Regions: Kurdistan Region of Iraq, a Case Study" Sustainability 13, no. 21: 11845. https://doi.org/10.3390/su132111845

APA StyleAbdulwahid, M. Y., Galobardes, I., & Radoine, H. (2021). Understanding the Use of Timber in Semi-Arid Regions: Kurdistan Region of Iraq, a Case Study. Sustainability, 13(21), 11845. https://doi.org/10.3390/su132111845