Paper Sensors Based on Fluorescence Changes of Carbon Nanodots for Optical Detection of Nanomaterials

Abstract

:1. Introduction

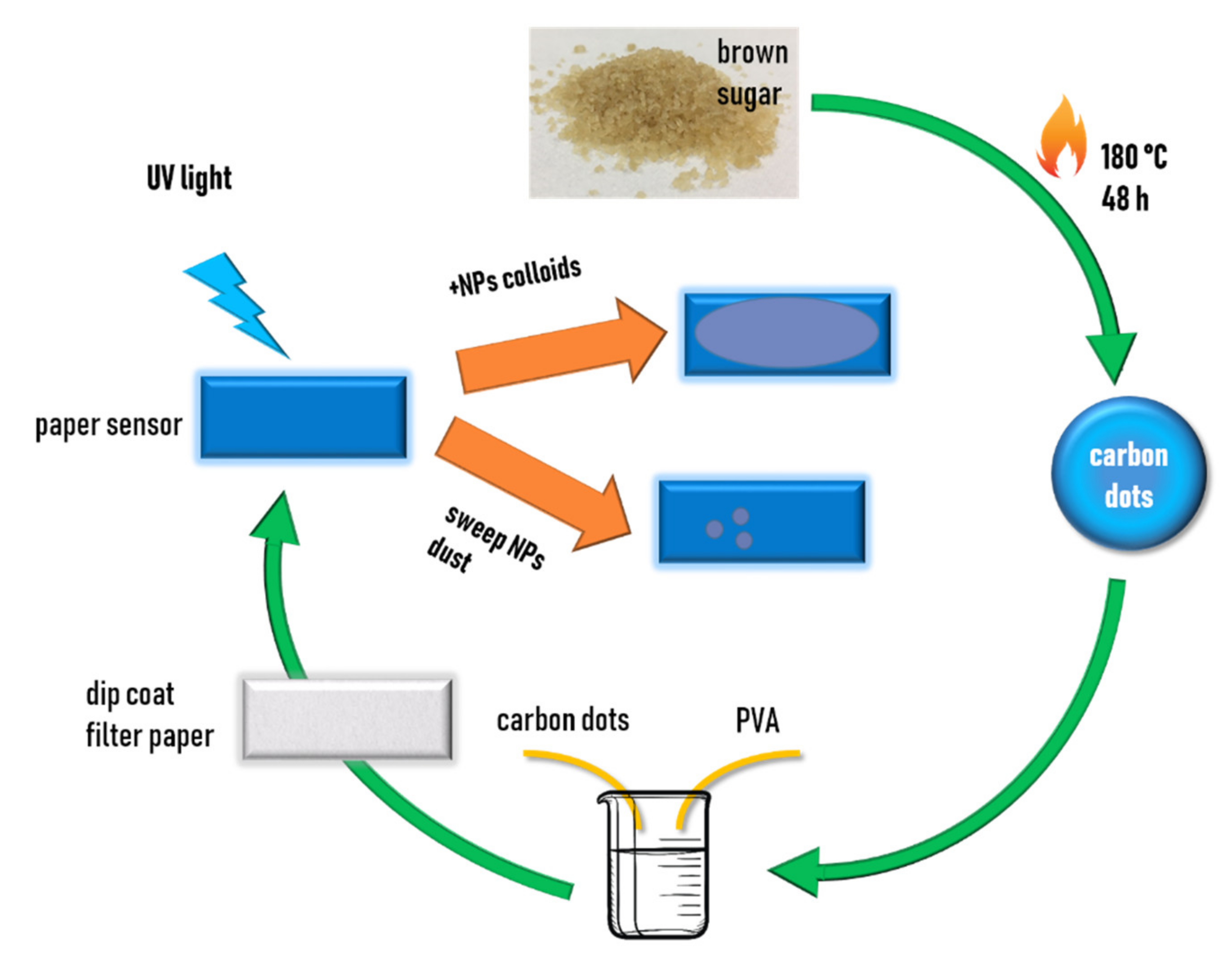

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Functionalization of Paper Strips

2.3. Characterization

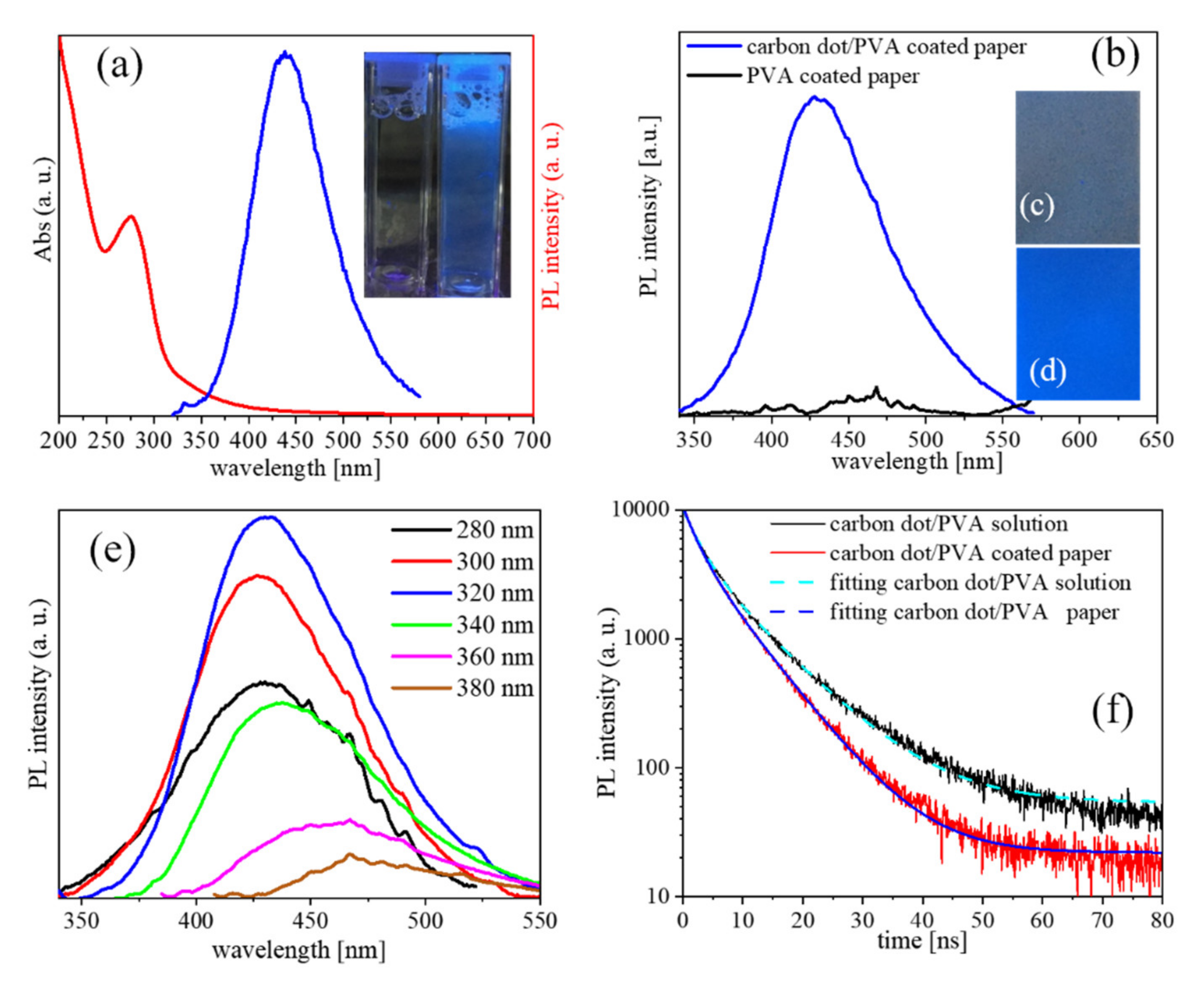

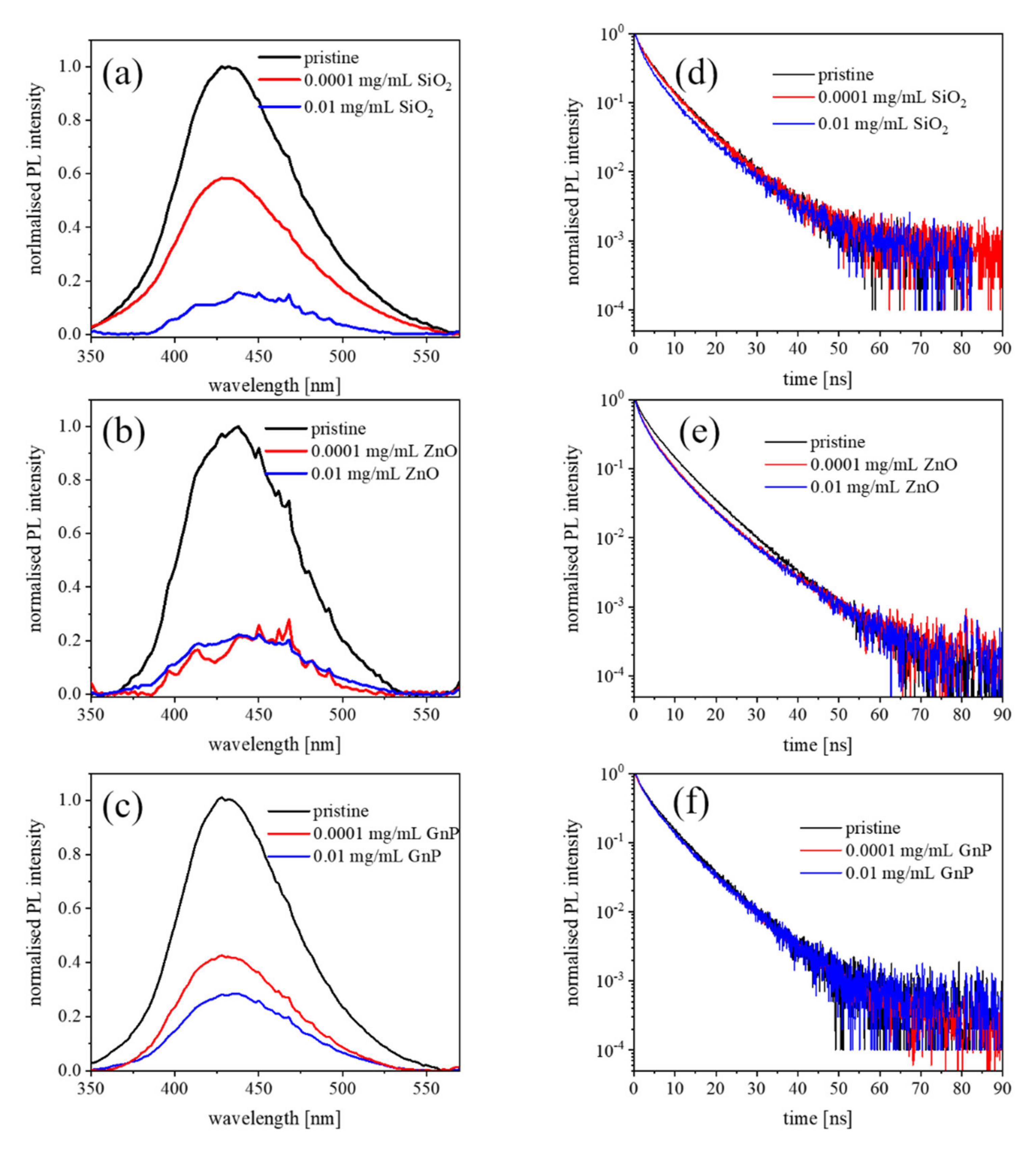

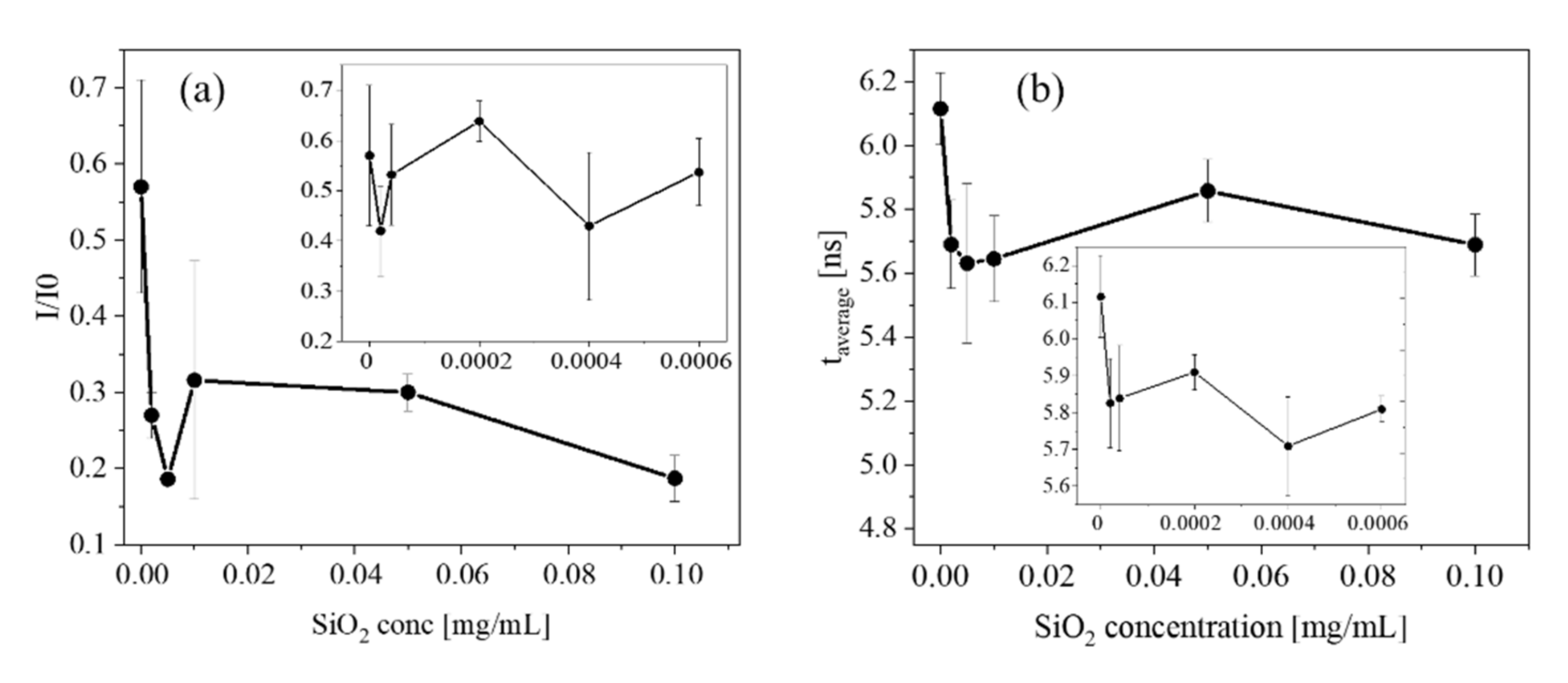

3. Results and Discussion

3.1. Detection of Nanomaterials

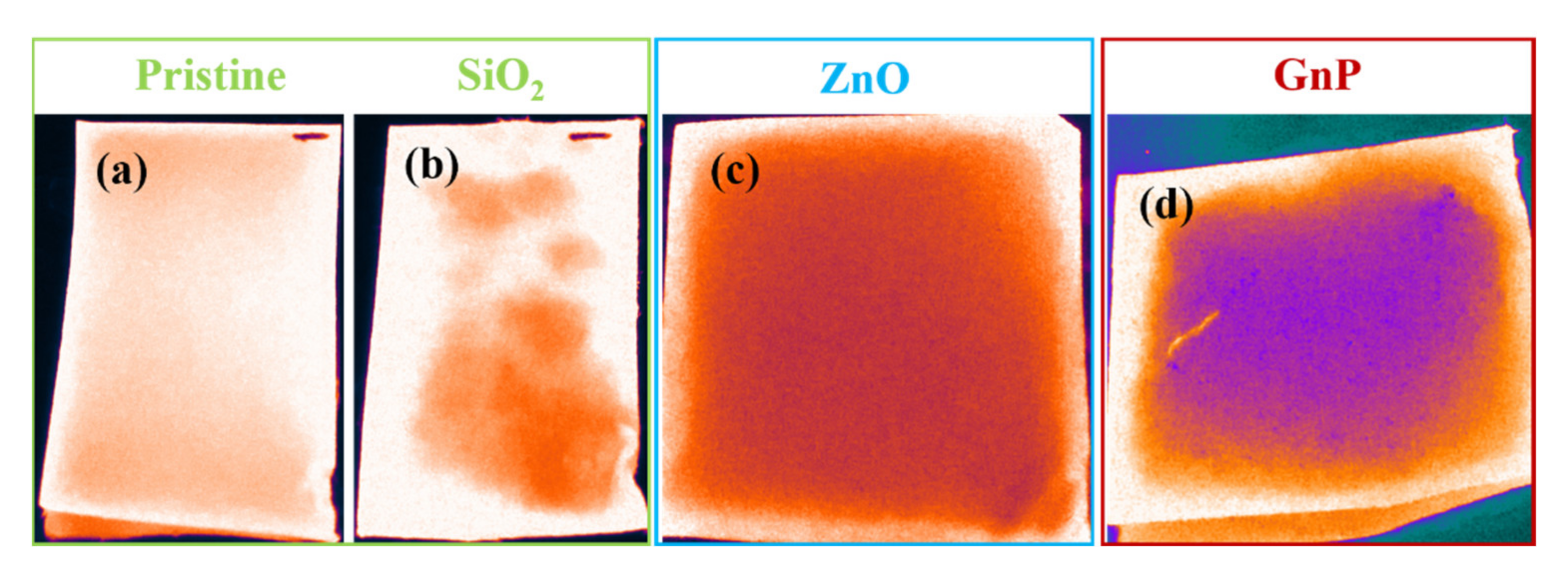

3.2. Optical Detection under a UV Lamp

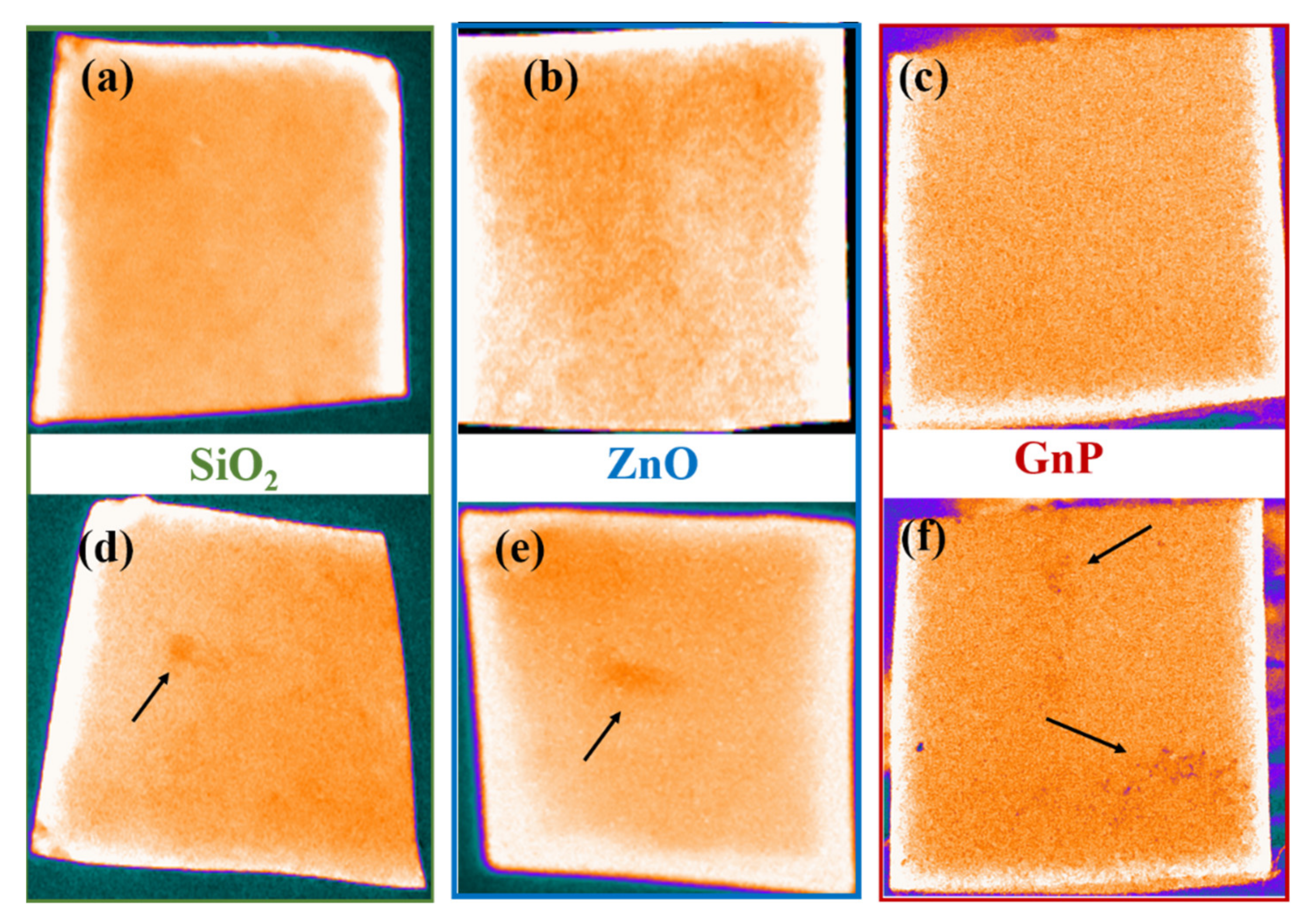

3.3. “Sweep Test” for the Detection of Powders

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fytianos, G.; Rahdar, A.; Kyzas, G.Z. Nanomaterials in Cosmetics: Recent Updates. Nanomaterials 2020, 10, 979. [Google Scholar] [CrossRef]

- Singh, T.; Shukla, S.; Kumar, P.; Wahla, V.; Bajpai, V.K.; Rather, I.A. Application of Nanotechnology in Food Science: Perception and Overview. Front. Microbiol. 2017, 8, 1501. [Google Scholar] [CrossRef] [Green Version]

- Mitchell, M.J.; Billingsley, M.M.; Haley, R.M.; Wechsler, M.E.; Peppas, N.A.; Langer, R. Engineering precision nanoparticles for drug delivery. Nat. Rev. Drug Discovery 2021, 20, 101–124. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Nayak, T.R.; Hong, H.; Cai, W. Biomedical applications of zinc oxide nanomaterials. Curr. Mol. Med. 2013, 13, 1633–1645. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Astruc, D. Introduction: Nanoparticles in Catalysis. Chem. Rev. 2020, 120, 461–463. [Google Scholar] [CrossRef] [Green Version]

- Kang, K.; Cho, Y.; Yu, K.J. Novel Nano-Materials and Nano-Fabrication Techniques for Flexible Electronic Systems. Micromachines 2018, 9, 263. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Keller, A.A.; McFerran, S.; Lazareva, A.; Suh, S. Global life cycle releases of engineered nanomaterials. J. Nanopart. Res. 2013, 15, 1692. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Vijver, M.G.; Peijnenburg, W.J.G.M. Setting the stage for debating the roles of risk assessment and life-cycle assessment of engineered nanomaterials. Nat. Nanotechnol. 2017, 12, 727–733. [Google Scholar] [CrossRef] [PubMed]

- Schulte, P.A.; Geraci, C.L.; Murashov, V.; Kuempel, E.D.; Zumwalde, R.D.; Castranova, V.; Hoover, M.D.; Hodson, L.; Martinez, K.F. Occupational safety and health criteria for responsible development of nanotechnology. J. Nanopart. Res. Interdiscip. Forum Nanoscale Sci. Technol. 2014, 16, 2153. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, X.; Liu, X.; Zhang, A.; Lu, D.; Li, G.; Zhang, Q.; Liu, Q.; Jiang, G. Distinguishing the sources of silica nanoparticles by dual isotopic fingerprinting and machine learning. Nat. Commun. 2019, 10, 1620. [Google Scholar] [CrossRef]

- Tombolini, F.; Boccuni, F.; Ferrante, R.; Natale, C.; Marasco, L.; Mantero, E.; Del Rio Castillo, A.E.; Leoncino, L.; Pellegrini, V.; Sabella, S.; et al. An integrated and multi-technique approach to characterize airborne graphene flakes in the workplace during production phases. Nanoscale 2021, 13, 3841–3852. [Google Scholar] [CrossRef]

- Aureli, F.; D’Amato, M.; Raggi, A.; Cubadda, F. Quantitative characterization of silica nanoparticles by asymmetric flow field flow fractionation coupled with online multiangle light scattering and ICP-MS/MS detection. J. Anal. At. Spectrom. 2015, 30, 1266–1273. [Google Scholar] [CrossRef]

- Montaño, M.D.; Majestic, B.J.; Jämting, Å.K.; Westerhoff, P.; Ranville, J.F. Methods for the Detection and Characterization of Silica Colloids by Microsecond spICP-MS. Anal. Chem. 2016, 88, 4733–4741. [Google Scholar] [CrossRef]

- Schmid, S.; Kurek, M.; Adolphsen, J.Q.; Boisen, A. Real-time single airborne nanoparticle detection with nanomechanical resonant filter-fiber. Sci. Rep. 2013, 3, 1288. [Google Scholar] [CrossRef]

- Song, Y.; Zhu, S.; Xiang, S.; Zhao, X.; Zhang, J.; Zhang, H.; Fu, Y.; Yang, B. Investigation into the fluorescence quenching behaviors and applications of carbon dots. Nanoscale 2014, 6, 4676–4682. [Google Scholar] [CrossRef] [PubMed]

- Zu, F.; Yan, F.; Bai, Z.; Xu, J.; Wang, Y.; Huang, Y.; Zhou, X. The quenching of the fluorescence of carbon dots: A review on mechanisms and applications. Microchim. Acta 2017, 184, 1899–1914. [Google Scholar] [CrossRef]

- Das, R.; Rajender, G.; Giri, P.K. Anomalous fluorescence enhancement and fluorescence quenching of graphene quantum dots by single walled carbon nanotubes. Phys. Chem. Chem. Phys. 2018, 20, 4527–4537. [Google Scholar] [CrossRef] [PubMed]

- Mintz, K.J.; Guerrero, B.; Leblanc, R.M. Photoinduced Electron Transfer in Carbon Dots with Long-Wavelength Photoluminescence. J. Phys. Chem. C 2018, 122, 29507–29515. [Google Scholar] [CrossRef]

- Kim, Y.; Jang, G.; Lee, T.S. New Fluorescent Metal-Ion Detection Using a Paper-Based Sensor Strip Containing Tethered Rhodamine Carbon Nanodots. ACS Appl. Mater. Interfaces 2015, 7, 15649–15657. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Y.; Wang, W.; Feng, J.; Liang, M.; Ma, S.; Chen, X. “Switch-On” Fluorescent Sensing of Ascorbic Acid in Food Samples Based on Carbon Quantum Dots–MnO2 Probe. J. Agric. Food Chem. 2016, 64, 371–380. [Google Scholar] [CrossRef] [PubMed]

- Abbas, M.W.; Soomro, R.A.; Kalwar, N.H.; Zahoor, M.; Avci, A.; Pehlivan, E.; Hallam, K.R.; Willander, M. Carbon quantum dot coated Fe3O4 hybrid composites for sensitive electrochemical detection of uric acid. Microchem. J. 2019, 146, 517–524. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, E.; Li, J.; Wang, J. L-tyrosine methyl ester-stabilized carbon dots as fluorescent probes for the assays of biothiols. Anal. Chim. Acta 2018, 1006, 83–89. [Google Scholar] [CrossRef]

- Pooja, D.; Saini, S.; Thakur, A.; Kumar, B.; Tyagi, S.; Nayak, M.K. A “Turn-On” thiol functionalized fluorescent carbon quantum dot based chemosensory system for arsenite detection. J. Hazard. Mater. 2017, 328, 117–126. [Google Scholar] [CrossRef]

- Yu, P.; Wen, X.; Toh, Y.-R.; Lee, Y.-C.; Huang, K.-Y.; Huang, S.; Shrestha, S.; Conibeer, G.; Tang, J. Efficient electron transfer in carbon nanodot–graphene oxide nanocomposites. J. Mater. Chem. C 2014, 2, 2894–2901. [Google Scholar] [CrossRef]

- Barman, M.K.; Mitra, P.; Bera, R.; Das, S.; Pramanik, A.; Parta, A. An efficient charge separation and photocurrent generation in the carbon dot–zinc oxide nanoparticle composite. Nanoscale 2017, 9, 6791–6799. [Google Scholar] [CrossRef] [PubMed]

- Essner, J.B.; Baker, G.A. The emerging roles of carbon dots in solar photovoltaics: A critical review. Environ. Sci. Nano 2017, 4, 1216–1263. [Google Scholar] [CrossRef]

- Algadi, H.; Mahata, C.; Woo, J.; Lee, M.; Kim, M.; Lee, T. Enhanced Photoresponsivity of All-Inorganic (CsPbBr3) Perovskite Nanosheets Photodetector with Carbon Nanodots (CDs). Electronics 2019, 8, 678. [Google Scholar] [CrossRef] [Green Version]

- Algadi, H.; Umar, A.; Albargi, H.; Alsuwian, T.; Baskoutas, S. Carbon Nanodots as a Potential Transport Layer for Boosting Performance of All-Inorganic Perovskite Nanocrystals-Based Photodetector. Crystals 2021, 11, 717. [Google Scholar] [CrossRef]

- Li, M.; Li, X.; Xiao, H.-N.; James, T.D. Fluorescence Sensing with Cellulose-Based Materials. Chem. Open 2017, 6, 685–696. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, D.; Chen, P.; Zong, L.; Sun, Y.; Liu, G.; Yu, X.; Qin, J. Colorimetric and fluorescent probes for real-time naked eye sensing of copper ion in solution and on paper substrate. R. Soc. Open Sci. 2017, 4, 171161. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sarwar, M.; Leichner, J.; Naja, G.M.; Li, C.-Z. Smart-phone, paper-based fluorescent sensor for ultra-low inorganic phosphate detection in environmental samples. Microsyst. Nanoeng. 2019, 5, 56. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, H.; Vagin, S.I.; Rieger, B.; Meldrum, A. An Ultrasensitive Fluorescent Paper-Based CO2 Sensor. ACS Appl. Mater. Interfaces 2020, 12, 20507–20513. [Google Scholar] [CrossRef]

- Maity, A.; Mitra, S.; Das, C.; Siraj, S.; Raychaudhuri, A.K.; Ghosh, B. Universal sensing of ammonia gas by family of lead halide perovskites based on paper sensors: Experiment and molecular dynamics. Mater. Res. Bull. 2021, 136, 111142. [Google Scholar] [CrossRef]

- Senthamizhan, A.; Fragouli, D.; Balusamy, B.; Patil, B.; Palei, M.; Sabella, S.; Uyar, T.; Athanassiou, A. Hydrochromic carbon dots as smart sensors for water sensing in organic solvents. Nanoscale Adv. 2019, 1, 4258–4267. [Google Scholar] [CrossRef] [Green Version]

- Rasband, W.S. ImageJ U.S. National Institutes of Health: Bethesda, MD, USA. Available online: http://imagej.nih.gov/ij (accessed on 10 September 2021).

- Wang, W.; Lai, H.; Cheng, Z.; Kang, H.; Wang, Y.; Zhang, H.; Wang, J.; Liu, Y. Water-induced poly(vinyl alcohol)/carbon quantum dot nanocomposites with tunable shape recovery performance and fluorescence. J. Mater. Chem. B 2018, 6, 7444–7450. [Google Scholar] [CrossRef]

- Yang, X.; Zhuo, Y.; Zhu, S.; Luo, Y.; Feng, Y.; Dou, Y. Novel and green synthesis of high-fluorescent carbon dots originated from honey for sensing and imaging. Biosens. Bioelectron. 2014, 60, 292–298. [Google Scholar] [CrossRef] [PubMed]

- Pan, D.; Zhang, J.; Li, Z.; Wu, M. Hydrothermal Route for Cutting Graphene Sheets into Blue-Luminescent Graphene Quantum Dots. Adv. Mater. 2010, 22, 734–738. [Google Scholar] [CrossRef] [PubMed]

- Eda, G.; Lin, Y.-Y.; Mattevi, C.; Yamaguchi, H.; Chen, H.-A.; Chen, I.-S.; Chen, C.-W.; Chhowalla, M. Blue Photoluminescence from Chemically Derived Graphene Oxide. Adv. Mater. 2010, 22, 505–509. [Google Scholar] [CrossRef] [PubMed]

- Ehrat, F.; Bhattacharyya, S.; Schneider, J.; Löf, A.; Wyrwich, R.; Rogach, A.L.; Stolarczyk, J.K.; Urban, A.S.; Feldmann, J. Tracking the Source of Carbon Dot Photoluminescence: Aromatic Domains versus Molecular Fluorophores. Nano Lett. 2017, 17, 7710–7716. [Google Scholar] [CrossRef]

- Yang, P.; Zhou, L.; Zhang, S.; Wan, N.; Pan, W.; Shen, W. Facile synthesis and photoluminescence mechanism of graphene quantum dots. J. Appl. Phys. 2014, 116, 244306. [Google Scholar] [CrossRef]

- Guha, S.; Rice, J.D.; Yau, Y.T.; Martin, C.M.; Chandrasekhar, M.; Chandrasekhar, H.R.; Guentner, R.; Scanduicci de Freitas, P.; Scherf, U. Temperature-dependent photoluminescence of organic semiconductors with varying backbone conformation. Phys. Rev. B 2003, 67, 125204. [Google Scholar] [CrossRef] [Green Version]

- Rose, A.; Tovar, J.D.; Yamaguchi, S.; Nesterov, E.E.; Zhu, Z.; Swager, T.M. Energy migration in conjugated polymers: The role of molecular structure. Philos. Trans. R. Soc. A 2007, 365, 1589–1606. [Google Scholar] [CrossRef] [PubMed]

- Velayudham, S.; Lee, C.H.; Xie, M.; Blair, D.; Bauman, N.; Yap, Y.K.; Green, S.A.; Liu, H. Noncovalent Functionalization of Boron Nitride Nanotubes with Poly(p-phenylene-ethynylene)s and Polythiophene. ACS Appl. Mater. Interfaces 2010, 2, 104–110. [Google Scholar] [CrossRef] [PubMed]

- Papadopoulou, E.L.; Zorba, V.; Pagkozidis, A.; Barberoglou, M.; Stratakis, E.; Fotakis, C. Reversible wettability of ZnO nanostructured thin films prepared by pulsed laser deposition. Thin Solid Films 2009, 518, 1267–1270. [Google Scholar] [CrossRef]

- Li, H.; Kang, Z.; Liu, Y.; Lee, S.-T. Carbon nanodots: Synthesis, properties and applications. J. Mater. Chem. 2012, 22, 24230–24253. [Google Scholar] [CrossRef]

- Long, R. Understanding the Electronic Structures of Graphene Quantum Dot Physisorption and Chemisorption onto the TiO2 (110) Surface: A First-Principles Calculation. ChemPhysChem 2013, 14, 579–582. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, S.; Prasad, E.; Chadha, A. H-Bonding controls the emission properties of functionalized carbon nano-dots. Phys. Chem. Chem. Phys. 2017, 19, 7288–7296. [Google Scholar] [CrossRef]

- Giusti, L.A.; Marini, V.G.; Machado, V.G. Solvatochromic behavior of 1-(p-dimethylaminophenyl)-2-nitroethylene in 24 binary solvent mixtures composed of amides and hydroxylic solvents. J. Mol. Liq. 2009, 150, 9–15. [Google Scholar] [CrossRef]

- Liao, H.-Y.; Chu, S.-Y. Hydrogen bond acceptor capability of carbonyl π-electrons—case study of the hydrogen-bonded urea dimer. New J. Chem. 2003, 27, 421–424. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.-H.; Gole, J.L.; White, M.G.; Watkins, C.; Street, S.C.; Fang, Z.; Dixon, D.A. The surprising oxidation state of fumed silica and the nature of water binding to silicon oxides and hydroxides. Chem. Phys. Lett. 2011, 501, 159–165. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papadopoulou, E.L.; Biffi, G.; Senthamizhan, A.; Martín-García, B.; Carzino, R.; Krahne, R.; Athanassiou, A. Paper Sensors Based on Fluorescence Changes of Carbon Nanodots for Optical Detection of Nanomaterials. Sustainability 2021, 13, 11896. https://doi.org/10.3390/su132111896

Papadopoulou EL, Biffi G, Senthamizhan A, Martín-García B, Carzino R, Krahne R, Athanassiou A. Paper Sensors Based on Fluorescence Changes of Carbon Nanodots for Optical Detection of Nanomaterials. Sustainability. 2021; 13(21):11896. https://doi.org/10.3390/su132111896

Chicago/Turabian StylePapadopoulou, Evie L., Giulia Biffi, Anitha Senthamizhan, Beatriz Martín-García, Riccardo Carzino, Roman Krahne, and Athanassia Athanassiou. 2021. "Paper Sensors Based on Fluorescence Changes of Carbon Nanodots for Optical Detection of Nanomaterials" Sustainability 13, no. 21: 11896. https://doi.org/10.3390/su132111896

APA StylePapadopoulou, E. L., Biffi, G., Senthamizhan, A., Martín-García, B., Carzino, R., Krahne, R., & Athanassiou, A. (2021). Paper Sensors Based on Fluorescence Changes of Carbon Nanodots for Optical Detection of Nanomaterials. Sustainability, 13(21), 11896. https://doi.org/10.3390/su132111896