Determining the Environmental Potentials of Urban Pavements by Applying the Cradle-to-Cradle LCA Approach for a Road Network of a Midscale German City

Abstract

:1. Introduction

2. Urban Pavements in Münster, Germany

2.1. Asphalt Production

- Cbit: Specific heat coefficient of bitumen (50/70)—kJ/kg·°C

- Ci: Specific heat coefficient of aggregates—kJ/kg·°C

- Cw: Specific heat coefficient of water (10 °C)—kJ/kg·°C

- Cvap: Specific heat coefficient of water vapor—kJ/kg·°C

- CRAP: Specific heat coefficient of RAP—kJ/kg·°C

- Wi: Water content of aggregates—%

- Lv: Latent heat of vaporization of water—kJ/kg

- CL: Casing loss factor—%

- t0: Ambient temperature—°C

- tmix: Maximum temperature of aggregates and RAP—°C

- mbit: Mass of bitumen—kg

- mi: Mass of aggregates and filler—kg

- mRAP: Mass of RAP—kg

- M: Materials

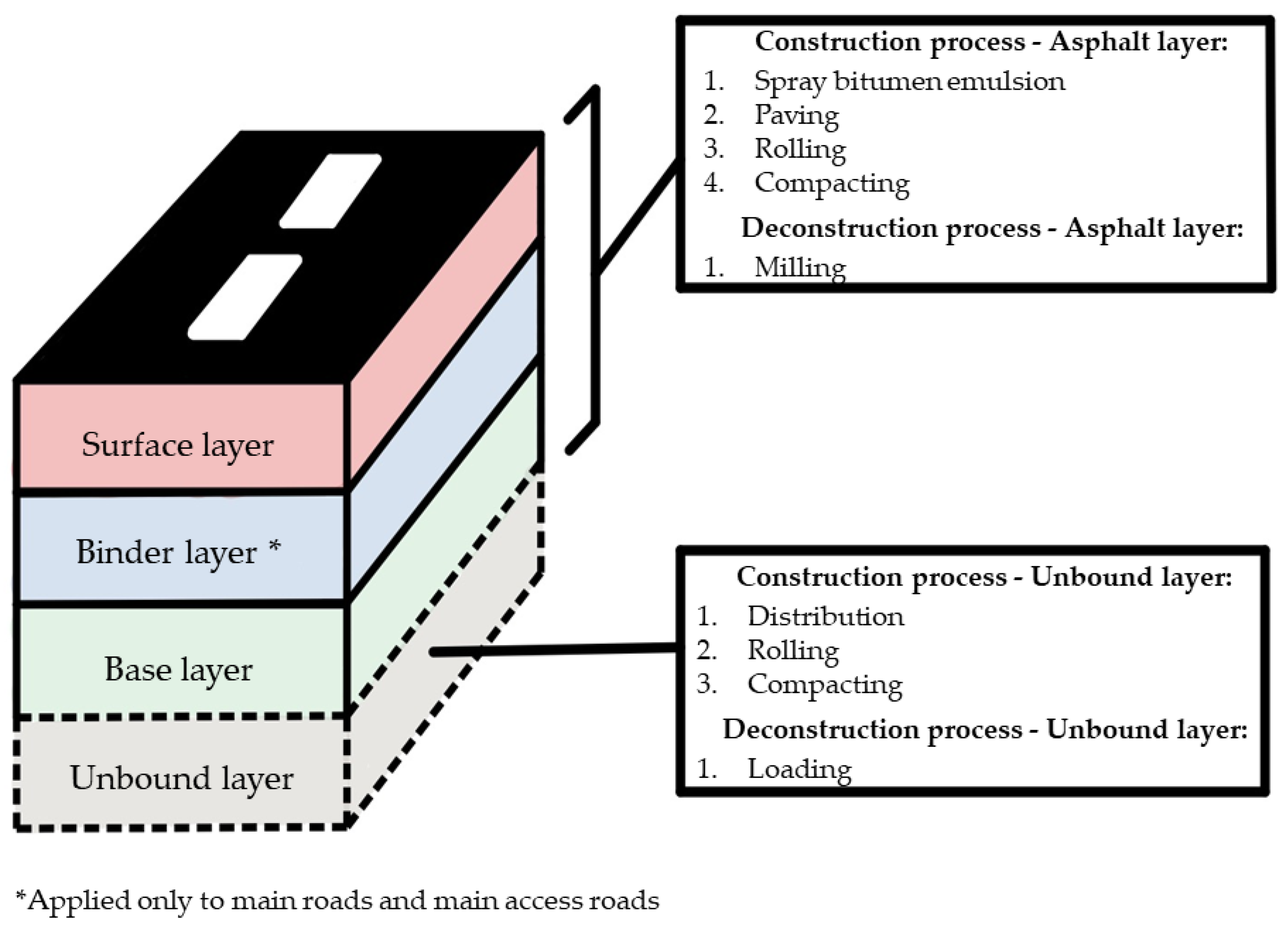

2.2. Construction and Deconstruction Processes

2.3. Maintenance Strategies

- Deconstruction and construction of the surface layer (M1);

- Deconstruction and construction of the surface layer and following layer, which can be either the binder layer for Bk 32 and Bk 3.2 structures or the base layer for Bk 1.0 and Bk 0.3 structures (M2);

- Total deconstruction and construction of the pavement (M3).

3. Life Cycle Assessment

3.1. Goal

3.2. Scope of the Study

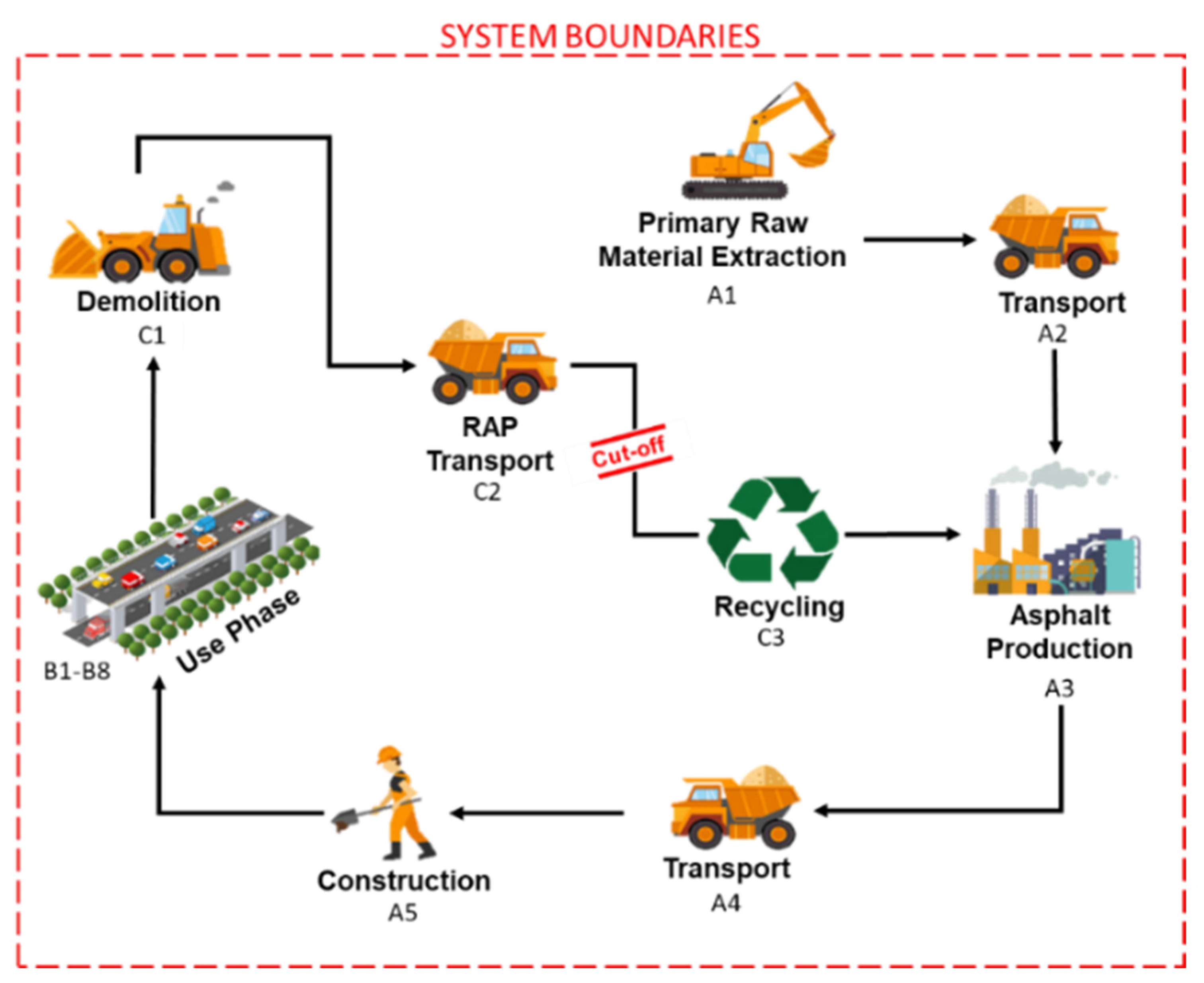

3.2.1. System Boundaries

- A1: raw material supply;

- A2: transport of raw material to the manufacturer;

- A3: manufacture of the asphalt mixtures at the asphalt plant;

- A4: transport of asphalt mixtures to the construction site;

- A5: construction of pavements;

- B1–B8: use, maintenance, repair, and replacement of asphalt layers;

- C1: demolition of pavement;

- C2: transport of milled asphalt pavement to the asphalt plant;

- C3: waste processing operations for reuse, recovery, or recycling (RAP production).

3.2.2. Functional Unit

3.2.3. RAP: Allocation and Closed-Loop Recycling

3.3. Life Cycle Inventory (LCI)

3.4. Life Cycle Impact Assessment

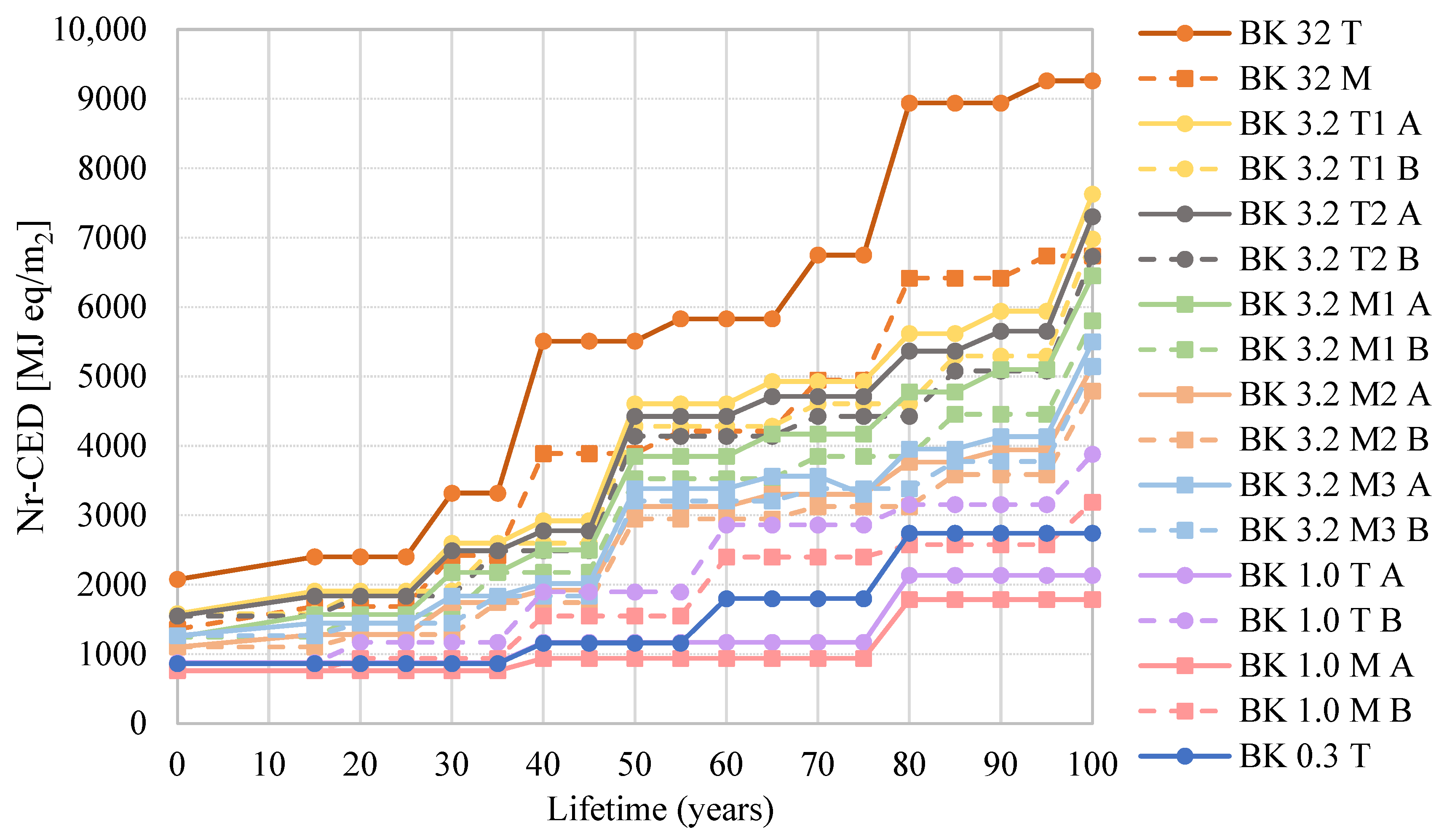

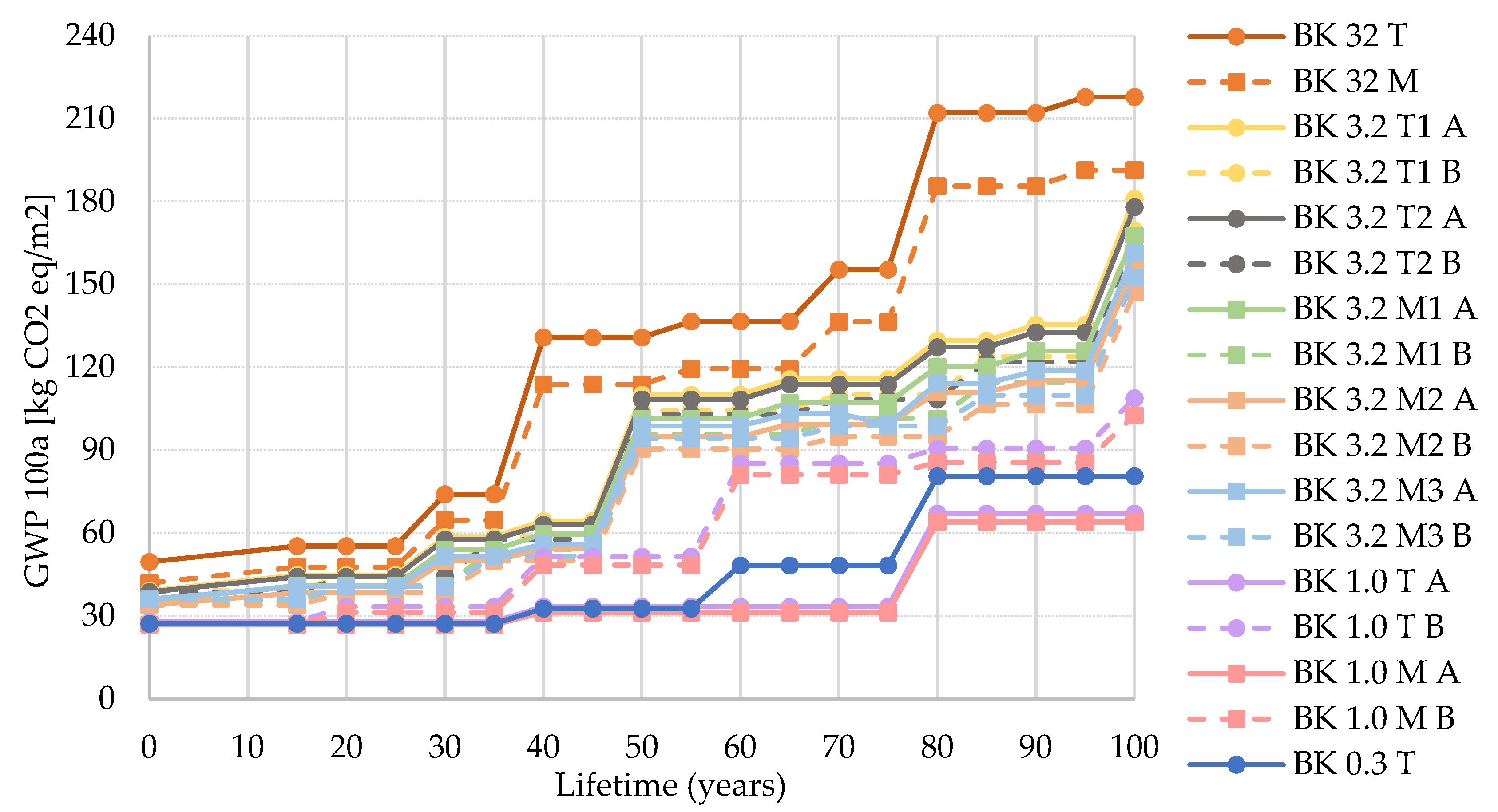

4. Results

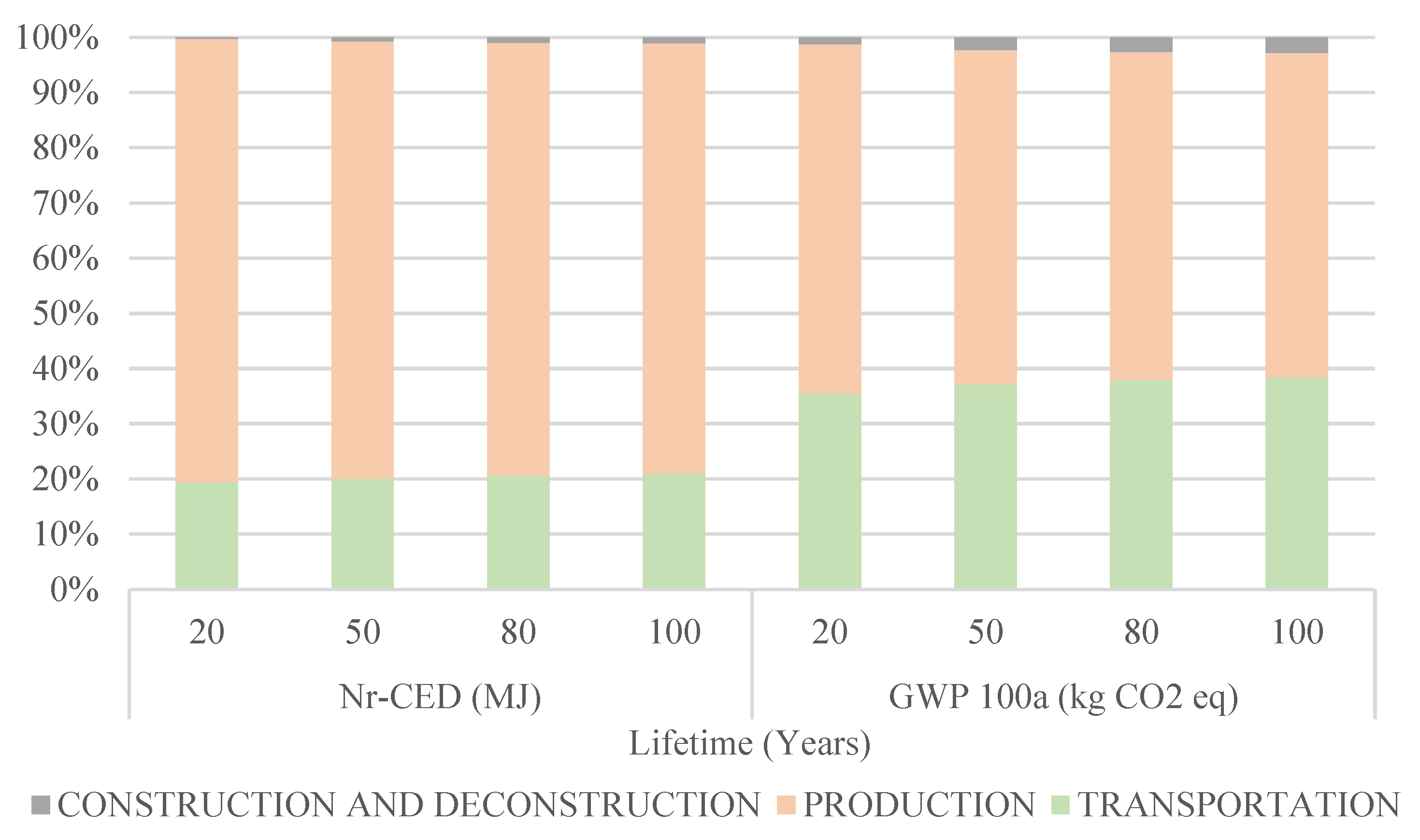

4.1. Impact Contribution per Category

4.2. Monte Carlo Analysis

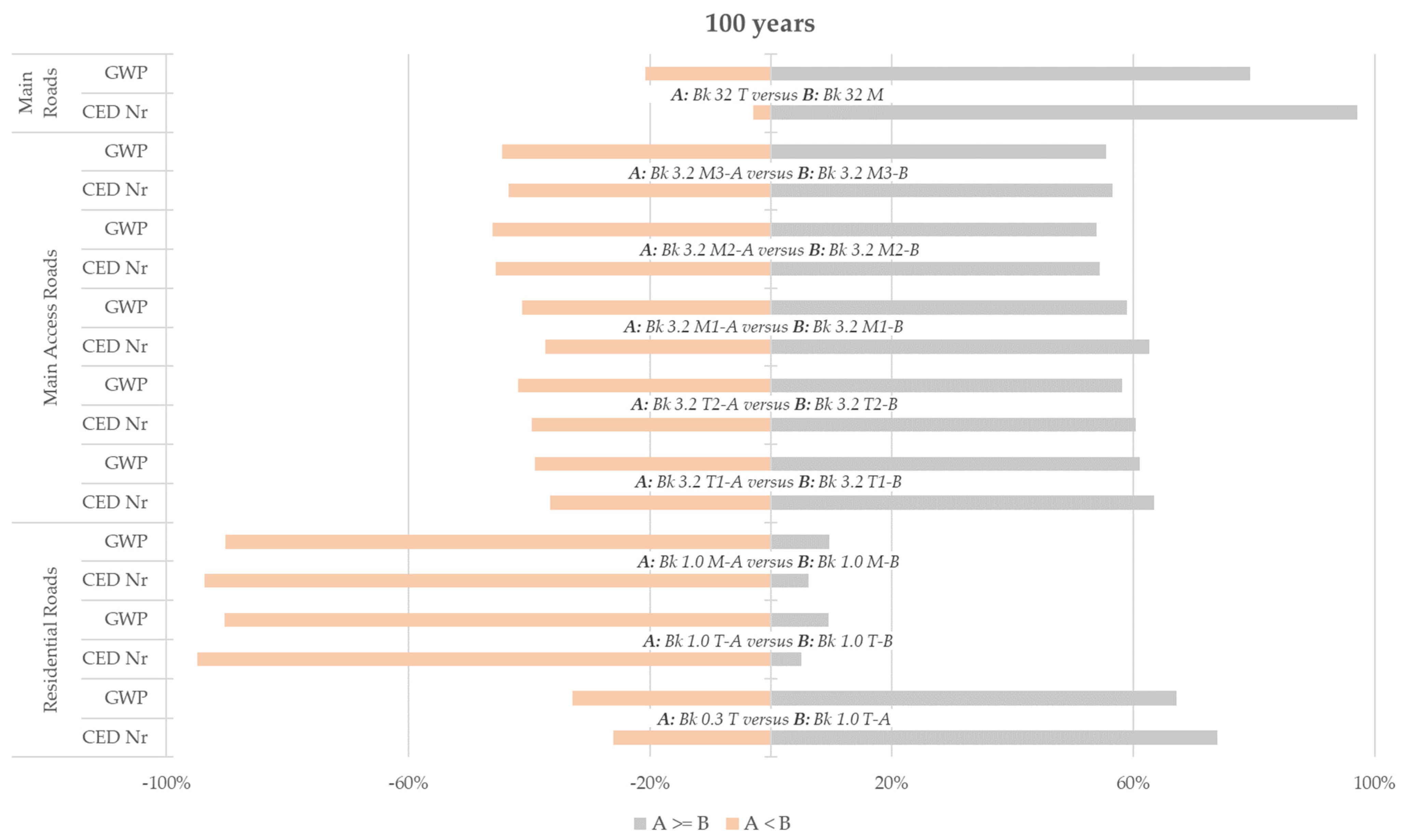

5. Conclusions

- Combining layers containing the largest possible amount of reclaimed asphalt pavement (RAP) might reduce potential environmental impacts in terms of non-renewable cumulative energy demand (nr-CED) and global warming potential (GWP);

- The longer the simulated service life, the greater the difference in environmental impact between the “traditional” and “modified” structures;

- In general, the higher the traffic load on roads, the greater the environmental impact;

- The higher the reconstruction interval and lifespan of pavements, the lower the environmental impact;

- In residential areas, it might be recommended to build stronger structures and reduce the maintenance interval than the opposite;

- Approximately 98% of the environmental impacts over the pavement life cycle is due to the production of asphalt mixtures and materials transportation (i.e., raw materials, asphalt mixtures, and reclaimed asphalt pavement);

- Construction and deconstruction have a negligible influence on the overall impact of pavements during the service life;

- Maintenance strategies can strongly influence the environmental impact of urban roads. Therefore, pavement design, service life, and maintenance periodicity should be carefully evaluated.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations, Sustainable Development Goals. Available online: https://sustainabledevelopment.un.org/?menu=1300 (accessed on 10 March 2020).

- European Union. The EU in the World: 2020 Edition; Publications Office of the European Union: Luxembourg, 2020; Available online: https://ec.europa.eu/eurostat/documents/3217494/10934584/KS-EX-20-001-EN-N.pdf/8ac3b640-0c7e-65e2-9f79-d03f00169e17?t=1590936683000 (accessed on 9 March 2021).

- European Commission. Transport Emissions: A European Strategy for Low-Emission Mobility. Available online: https://ec.europa.eu/clima/policies/transport_en (accessed on 9 March 2021).

- Llopis-Castelló, D.; García-Segura, T.; Montalbán-Domingo, L.; Sanz-Benlloch, A.; Pellicer, E. Influence of Pavement Structure, Traffic, and Weather on Urban Flexible Pavement Deterioration. Sustainability 2020, 12, 9717. [Google Scholar] [CrossRef]

- Trupia, L.; Parry, T.; Neves, L.C.; Lo Presti, D. Rolling Resistance Contribution to a Road Pavement Life Cycle Carbon Footprint Analysis. Int. J. Life Cycle Assess. 2017, 22, 972–985. [Google Scholar] [CrossRef] [Green Version]

- Plati, C. Sustainability Factors in Pavement Materials, Design, and Preservation Strategies: A Literature Review. Constr. Build. Mater. 2019, 211, 539–555. [Google Scholar] [CrossRef]

- Praticò, F.G.; Anfosso-Lédée, F. Trends and Issues in Mitigating Traffic Noise Through Quiet Pavements. Procedia Soc. Behav. Sci. 2012, 53, 203–212. [Google Scholar] [CrossRef]

- Praticò, F.G.; Vaiana, R.; Giunta, M.; Iuele, T.; Moro, A. Recycling Pems Back to Tlpas: Is That Possible Notwithstanding RAP Variability? Appl. Mech. Mater. 2012, 253–255, 376–384. [Google Scholar] [CrossRef]

- Licitra, G.; Moro, A.; Teti, L.; Del Pizzo, A.; Bianco, F. Modelling of Acoustic Ageing of Rubberized Pavements. Appl. Acoustics 2019, 146, 237–245. [Google Scholar] [CrossRef]

- Dumitrescu, L.; Maxineasa, S.G.; Simion, I.M.; Taranu, N.; Andrei, R.; Gavrilescu, M. Evaluation of the Environmental Impact of Road Pavements from a Life Cycle Perspective. Environ. Eng. Manag. J. 2014, 13, 449–455. [Google Scholar] [CrossRef]

- EPA, Global Greenhouse Gas Emissions by Economic Sector. Available online: https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data (accessed on 15 March 2021).

- Siverio Lima, M.S.; Hajibabaei, M.; Hesarkazzazi, S.; Sitzenfrei, R.; Buttgereit, A.; Queiroz, C.; Tautschnig, A.; Gschösser, F. Environmental Potentials of Asphalt Materials Applied to Urban Roads: Case Study of the City of Münster. Sustainability 2020, 12, 6113. [Google Scholar] [CrossRef]

- Gschösser, F.; Wallbaum, H.; Boesch, M.E. Life-Cycle Assessment of the Production of Swiss Road Materials. J. Mater. Civ. Eng. 2012, 24, 168–176. [Google Scholar] [CrossRef]

- Liu, X.; Cui, Q.; Schwartz, C. Greenhouse Gas Emissions of Alternative Pavement Designs: Framework Development and Illustrative Application. J. Environ. Manag. 2014, 132, 313–322. [Google Scholar] [CrossRef] [PubMed]

- Vidal, R.; Moliner, E.; Martínez, G.; Rubio, M.C. Life Cycle Assessment of Hot Mix Asphalt and Zeolite-Based Warm Mix Asphalt with Reclaimed Asphalt Pavement. Resour. Conserv. Recycl. 2013, 74, 101–114. [Google Scholar] [CrossRef]

- Aurangzeb, Q.; Al-Qadi, I.L.; Ozer, H.; Yang, R. Hybrid Life Cycle Assessment for Asphalt Mixtures with High RAP Content. Resour. Conserv. Recycl. 2014, 83, 77–86. [Google Scholar] [CrossRef]

- Stanković, J.C.; Mladenović, G.; Queiroz, C. Impact of CO2 Emissions on Low Volume Road Maintenance Policy: Case Study of Serbia. 2019. Available online: https://www.researchgate.net/publication/335832262_Impact_of_CO_2_Emissions_on_Low_Volume_Road_Maintenance_Policy_Case_Study_of_Serbia (accessed on 9 March 2021).

- CEN. EN 15643-5, Sustainability of Construction Works—Sustainability Assessment of Buildings and Civil Engineering Works: Part 5—Framework for the Assessment of Sustainability Performance of Civil Engineering Works; CEN: Brussels, Belgium, 2016. [Google Scholar]

- ISO. ISO 14040, Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Trunzo, G.; Moretti, L.; D’Andrea, A. Life Cycle Analysis of Road Construction and Use. Sustainability 2019, 11, 377. [Google Scholar] [CrossRef] [Green Version]

- Jiang, R.; Wu, C.; Song, Y.; Wu, P. Estimating Carbon Emissions from Road Use, Maintenance and Rehabilitation through a Hybrid Life Cycle Assessment Approach—A Case Study. J. Clean. Prod. 2020, 277, 123276. [Google Scholar] [CrossRef]

- Mladenovic, G.; Cirilovic, J.; Queiroz, C. Optimization of Road Maintenance and Rehabilitation on Serbian Toll Roads; Transportation Research Board of the National Academies: Washington, DC, USA, 2011. [Google Scholar]

- Richtlinien Für Die Standardisierung Des Oberbaus von Verkehrsflächen: Rsto 12; FGSV Verlag: Cologne, Germany, 2012; Volume 499.

- Santos, J.; Bressi, S.; Cerezo, V.; Lo Presti, D.; Dauvergne, M. Life Cycle Assessment of Low Temperature Asphalt Mixtures for Road Pavement Surfaces: A Comparative Analysis. Resour. Conserv. Recycl. 2018, 138, 283–297. [Google Scholar] [CrossRef] [Green Version]

- Santos, J.; Flintsch, G.; Ferreira, A. Environmental and Economic Assessment of Pavement Construction and Management Practices for Enhancing Pavement Sustainability. Resour. Conserv. Recycl. 2017, 116, 15–31. [Google Scholar] [CrossRef] [Green Version]

- Gschösser, F. Environmental Assessment of Road Constructions: Life Cycle Assessment of Swiss Road Pavements and Accompanying Analysis of Construction and Maintenance Costs. Ph.D. Thesis, ETH Zurich, Zürich, Switzerland, 2011. [Google Scholar]

- CEN. EN 15804, Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products; CEN: Brussels, Belgium, 2018. [Google Scholar]

- Commission Regulation (EU) 2016/646 of 20 April 2016 Amending Regulation (EC) No 692/2008 as Regards Emissions from Light Passenger and Commercial Vehicles (Euro 6). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32016R0646 (accessed on 8 November 2021).

- Gschösser, F.; Wallbaum, H. Life Cycle Assessment of Representative Swiss Road Pavements for National Roads with an Accompanying Life Cycle Cost Analysis. Environ. Sci. Technol. 2013, 47, 8453–8461. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Caterpillar Inc. Caterpillar Performance Handbook; Caterpillar Inc.: Deerfield, IL, USA, 2010. [Google Scholar]

- Lissmac. FS 31 D—Robust Lloor Cutter for the Roughest Building Site Use; Lissmac Machinenbau GmbH: Wurzach, Germany, 2010. [Google Scholar]

- Weber. Bodenverdichter CR 10; Weber Maschinentechnik GmbH: Bad Laasphe, Germany, 2010. [Google Scholar]

- Wirtgen Group. Technical Specification—Slipform Paver SP 1200; Wirtgen Group: Windhagen, Germany, 2010. [Google Scholar]

- Wirtgen Group. Technical Specification—Cold Milling Machine W 200; Wirtgen Group: Windhagen, Germany, 2010. [Google Scholar]

- PRé Consultants. SimaPro Tutoria; PRé Sustainability: LE Amersfoort, The Netherlands, 2019. [Google Scholar]

- Ecoinvent Center. Ecoinvent Database: Version 3.7.1; Ecoinvent: Zurich, Switzerland, 2020. [Google Scholar]

- Intergovernmental Panel on Climate Change. IPCC. Available online: http://www.ipcc.ch/ (accessed on 1 July 2020).

- Hajibabaei, M.; Hesarkazzazi, S.; Lima, M.; Gschösser, F.; Sitzenfrei, R. Environmental Assessment of Construction and Renovation of Water Distribution Networks Considering Uncertainty Analysis. Urban Water J. 2020, 17, 723–734. [Google Scholar] [CrossRef]

- Althaus, H.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S. Ecoinvent 2 Overview and Methodology; Frischknecht, R., Niels, J., Eds.; Ecoinvent: Zurich, Switzerland, 2007. [Google Scholar]

| TRADITIONAL STRUCTURES | MODIFIED STRUCTURES | |||||

|---|---|---|---|---|---|---|

| Type | Load Class | Material | Thickness (cm) | Load Class | Material | Thickness (cm) |

| Main Roads | Bk 32-T | SMA 8 S | 3 | Bk 32-M | SMA 8 S | 3 |

| AC 22 BS | 8 | AC 22 BS + 30% RAP | 8 | |||

| AC 32 TS | 14 | AC 32 TS + 60% RAP | 14 | |||

| Unbound | 45 | Unbound | 45 | |||

| Main Access Roads | Bk 3.2-T1 | SMA 8 S | 3 | Bk 3.2-M1 | SMA 8 S | 3 |

| AC 16 BS | 5 | AC 16 BS + 30% RAP | 5 | |||

| AC 22 TS | 10 | AC 22 TS + 30% RAP | 10 | |||

| Unbound | 45 | Unbound | 45 | |||

| OR | OR | |||||

| Bk 3.2-T2 | AC 8 DS | 3 | Bk 3.2-M2 | AC 8 DS + 50% RAP | 3 | |

| AC 16 BS | 5 | AC 16 BS + 30% RAP | 5 | |||

| AC 22 TS | 10 | AC 22 TS + 30% RAP | 10 | |||

| Unbound | 45 | Unbound | 45 | |||

| OR | ||||||

| Bk 3.2-M3 | AC 8 DS + 50% RAP | 3 | ||||

| AC 16 BS + 50% RAP | 5 | |||||

| AC 22 TS | 10 | |||||

| Unbound | 45 | |||||

| Residential Roads | Bk 1.0-T | AC 8 DN | 3 | Bk 1.0-M | AC 8 DS + 50% RAP | 3 |

| AC 22 TN + 40% RAP | 10 | AC 22 TN + 40% RAP | 10 | |||

| Unbound | 45 | Unbound | 45 | |||

| OR | Surface Layer | |||||

| Bk 0.3-T | AC 8 DN | 3 | Binder Layer | |||

| AC 22 TN + 40% RAP | 8 | Base Layer | ||||

| Unbound | 39 | Unbound Layer | ||||

| Inputs of Asphalt Production | ||

|---|---|---|

| Energy | 667,500 | kWh/year |

| Heat (Light fuel oil) | 118,500 | kWh/year |

| Heat (Coal) | 11,551,500 | kWh/year |

| Diesel | 355,500 | kWh/year |

| Process | Machine Type | Model |

|---|---|---|

| Spraying bitumen emulsion | Bitumen sprayer on a lorry | Atlas AE 6000 |

| Paving | Asphalt paver | CAT AP 555 E |

| Rolling | Single Drum Smooth—Vibration compactor | CAT CS 74 C |

| Compacting | Vibration plate | Weber CR 10 |

| Distribution | Bulldozer | CAT D5K LGP |

| Milling | Mill cutter | Wirtgen W 200 |

| Loading | Hydraulic digger | CAT 345 D |

| Classification | Load Class | Pavement Structure | Maintenance Strategies (Years) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | |||||||||

| M1 | M2 | M3 | M4 | M1 | M2 | M3 | ||||

| Main roads | Bk 32 | Surface layer | 15 | 30 | 40 | or | ||||

| Binder layer | 30 | 40 | ||||||||

| Base layer | 40 | |||||||||

| Unbound | 40 | |||||||||

| Main access roads | Bk 3.2 | Surface layer | 15 | 30 | 40 | 50 | 20 | 35 | 50 | |

| Binder layer | 30 | 50 | 35 | 50 | ||||||

| Base layer | 50 | 50 | ||||||||

| Unbound | 50 | 50 | ||||||||

| Residential roads | Bk 1.0 | Surface layer | 40 | 80 | 20 | 40 | 60 | |||

| Base layer | 80 | 40 | 60 | |||||||

| Unbound | 80 | 60 | ||||||||

| Bk 0.3 | Surface layer | 40 | 60 | 80 | ||||||

| Base layer | 60 | 80 | ||||||||

| Unbound | 80 | |||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siverio Lima, M.S.; Hajibabaei, M.; Hesarkazzazi, S.; Sitzenfrei, R.; Buttgereit, A.; Queiroz, C.; Haritonovs, V.; Gschösser, F. Determining the Environmental Potentials of Urban Pavements by Applying the Cradle-to-Cradle LCA Approach for a Road Network of a Midscale German City. Sustainability 2021, 13, 12487. https://doi.org/10.3390/su132212487

Siverio Lima MS, Hajibabaei M, Hesarkazzazi S, Sitzenfrei R, Buttgereit A, Queiroz C, Haritonovs V, Gschösser F. Determining the Environmental Potentials of Urban Pavements by Applying the Cradle-to-Cradle LCA Approach for a Road Network of a Midscale German City. Sustainability. 2021; 13(22):12487. https://doi.org/10.3390/su132212487

Chicago/Turabian StyleSiverio Lima, Mayara S., Mohsen Hajibabaei, Sina Hesarkazzazi, Robert Sitzenfrei, Alexander Buttgereit, Cesar Queiroz, Viktors Haritonovs, and Florian Gschösser. 2021. "Determining the Environmental Potentials of Urban Pavements by Applying the Cradle-to-Cradle LCA Approach for a Road Network of a Midscale German City" Sustainability 13, no. 22: 12487. https://doi.org/10.3390/su132212487

APA StyleSiverio Lima, M. S., Hajibabaei, M., Hesarkazzazi, S., Sitzenfrei, R., Buttgereit, A., Queiroz, C., Haritonovs, V., & Gschösser, F. (2021). Determining the Environmental Potentials of Urban Pavements by Applying the Cradle-to-Cradle LCA Approach for a Road Network of a Midscale German City. Sustainability, 13(22), 12487. https://doi.org/10.3390/su132212487