Seasonal Performance Evaluation of Pavement Base Using Recycled Materials

Abstract

:1. Introduction

1.1. General Background

1.2. Scope and Objectives

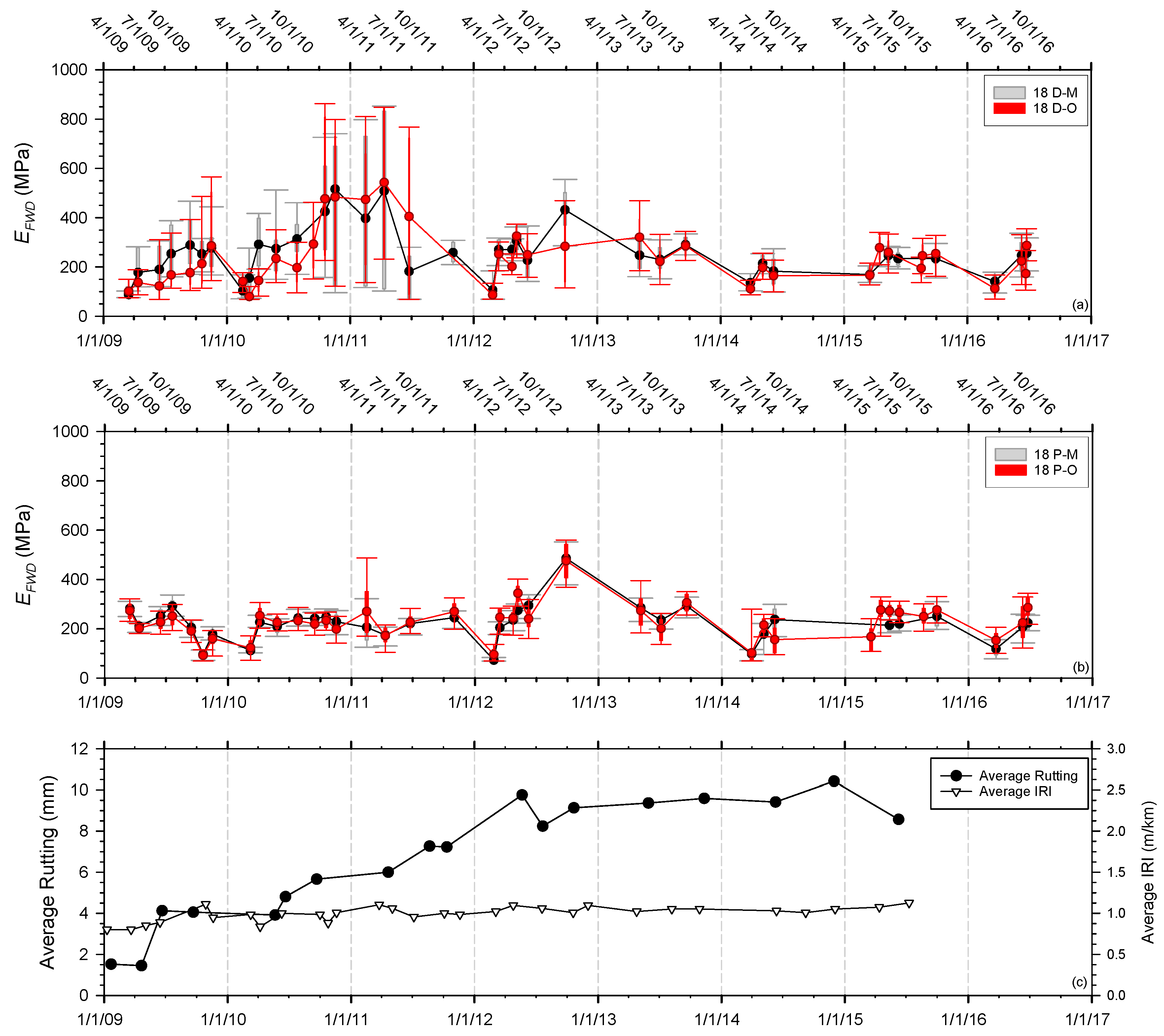

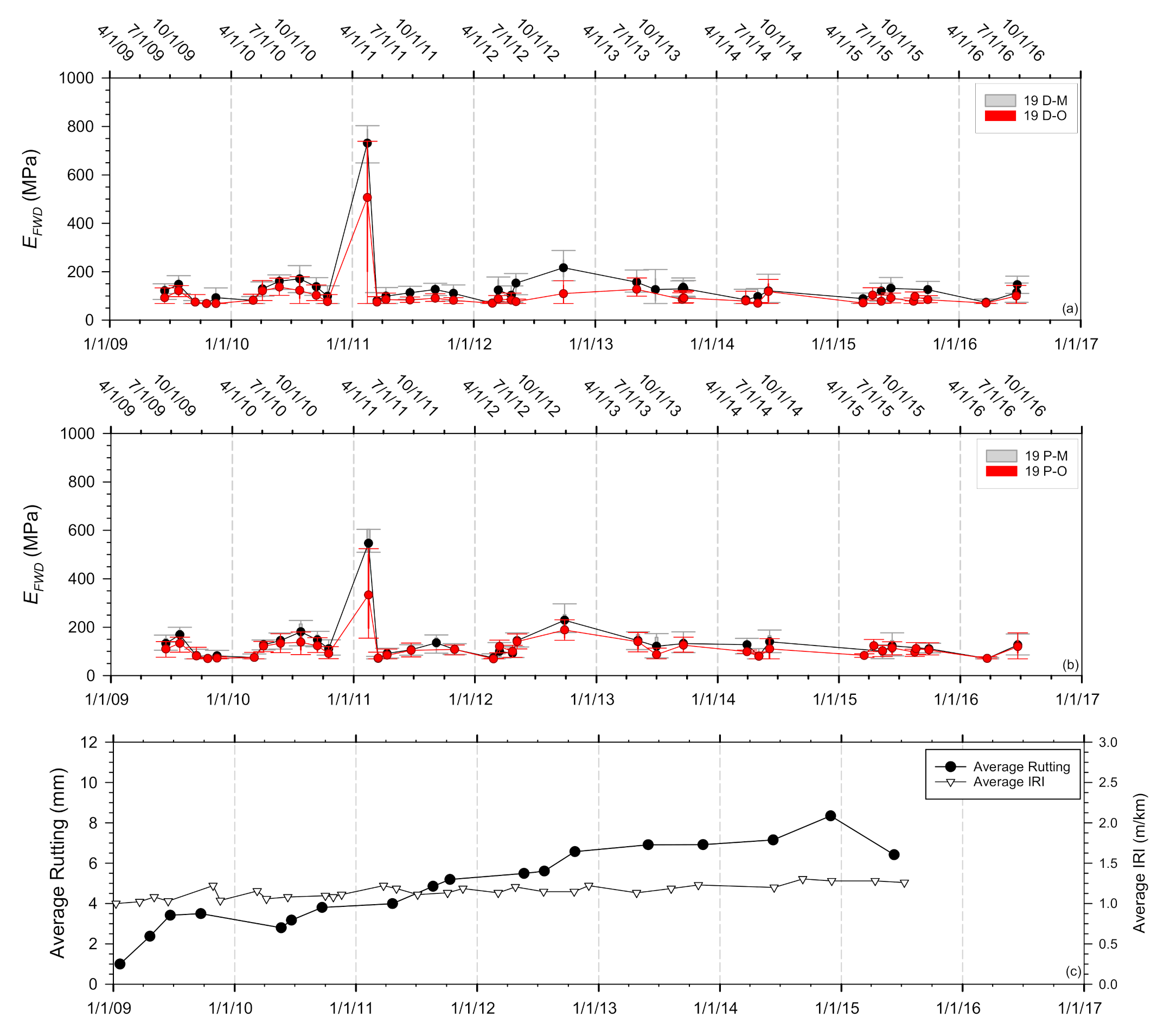

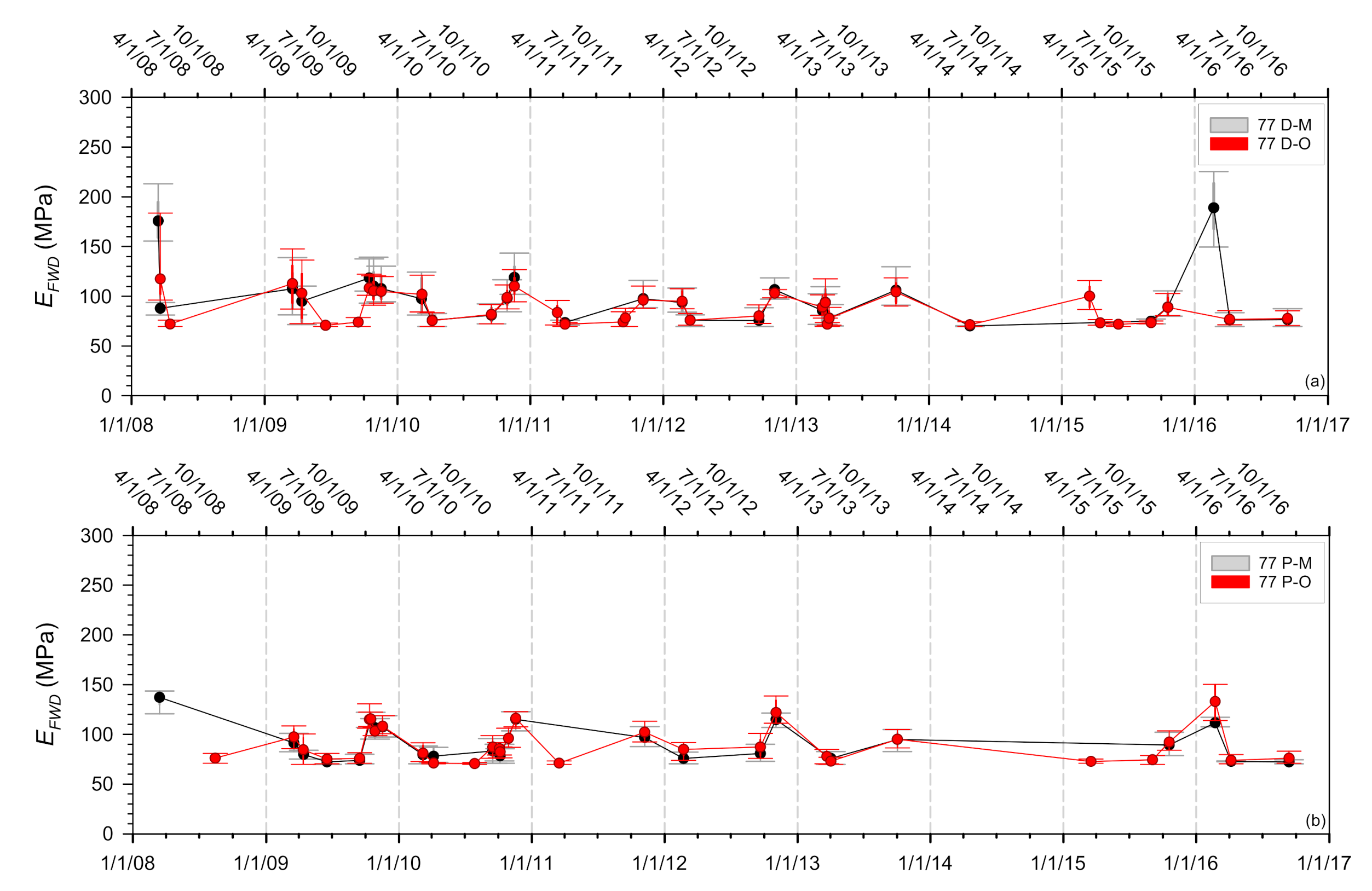

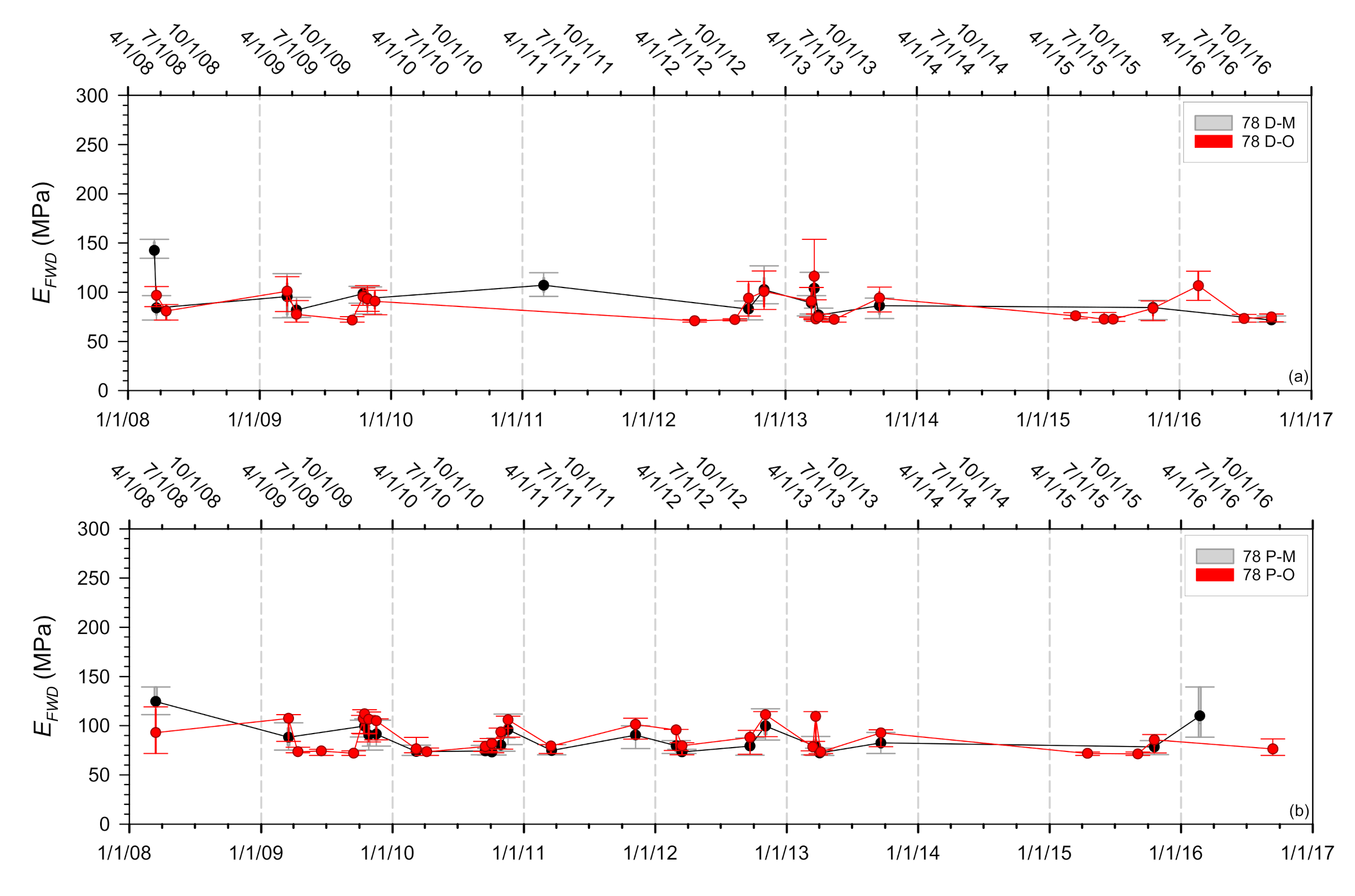

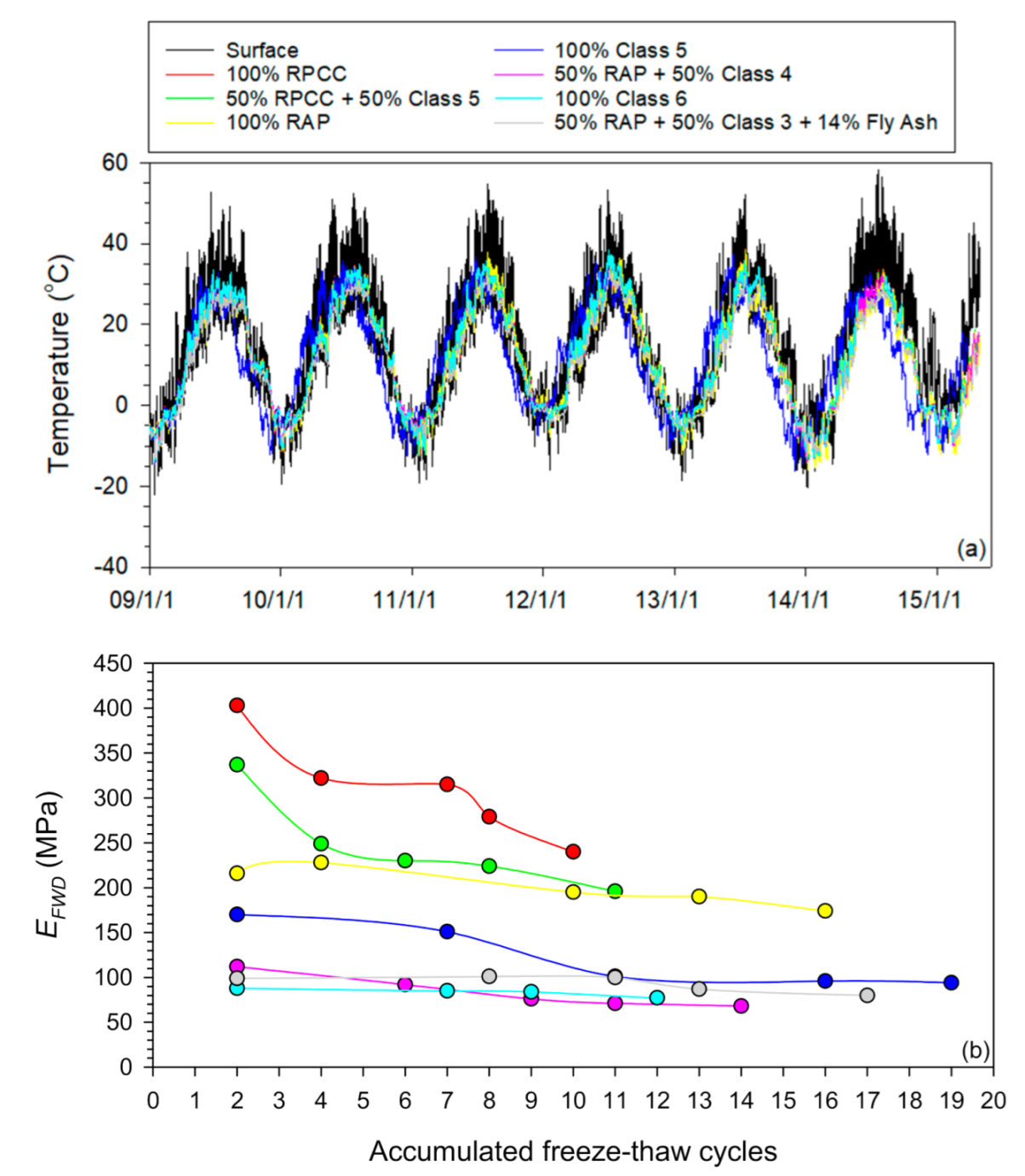

- To conduct in situ performance tests during seasons covering a long time span on test sections to evaluate the seasonal pavement performance changes;

- To back-calculate the layer modulus of test sections constructed with different recycled pavement materials, including RCA, RAP, and blends, with normally used aggregates in comparison with the conventional aggregate itself to monitor seasonal layer modulus changes;

- To evaluate the effect of fly ash stabilization on recycled pavement materials in terms of resisting weakening from seasonal freeze-thaw cycles;

- To compare the effects from seasonal variations and traffic loading on long-term pavement performance.

2. Materials and Pavement Layouts

2.1. Materials

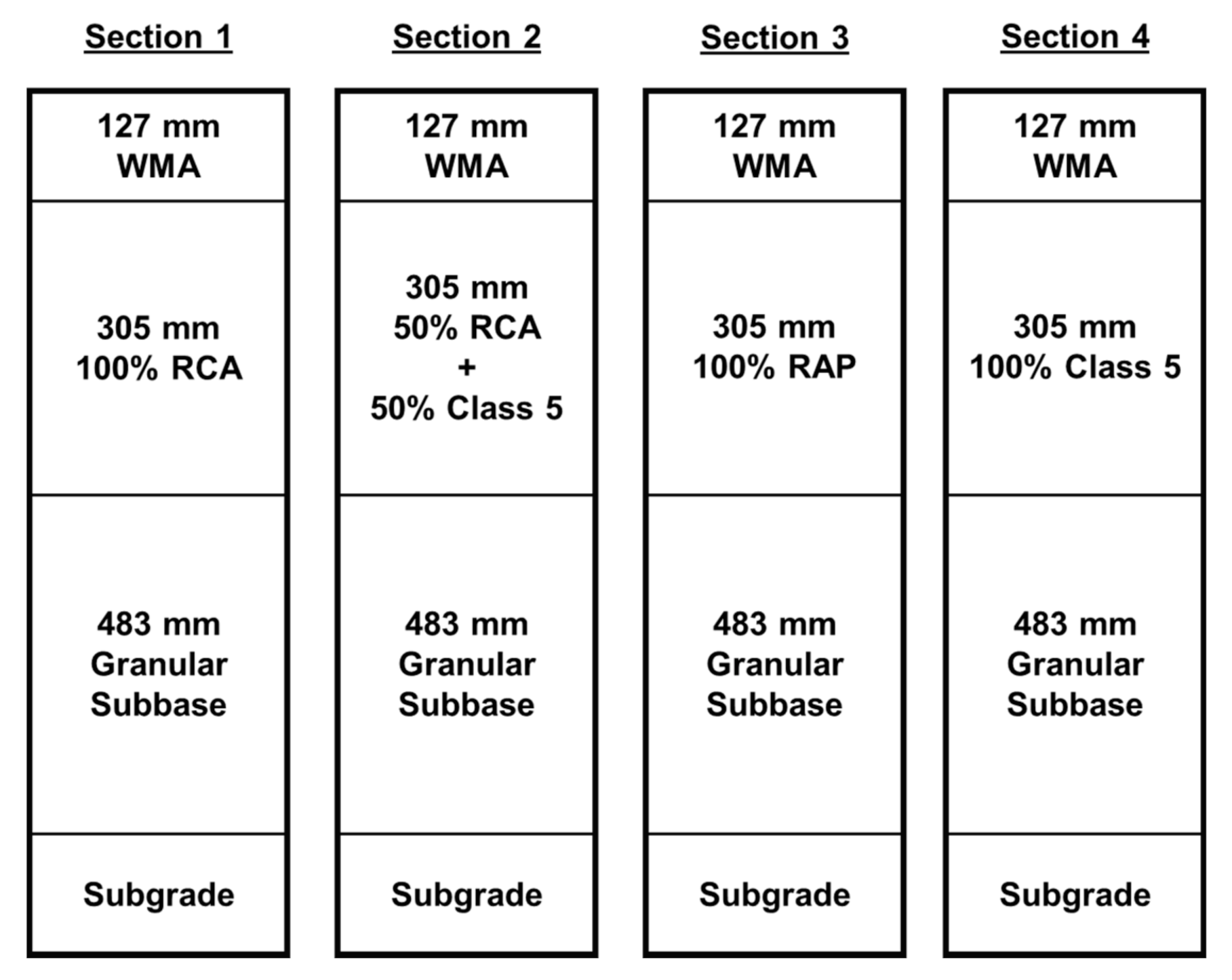

2.2. Pavement Layout

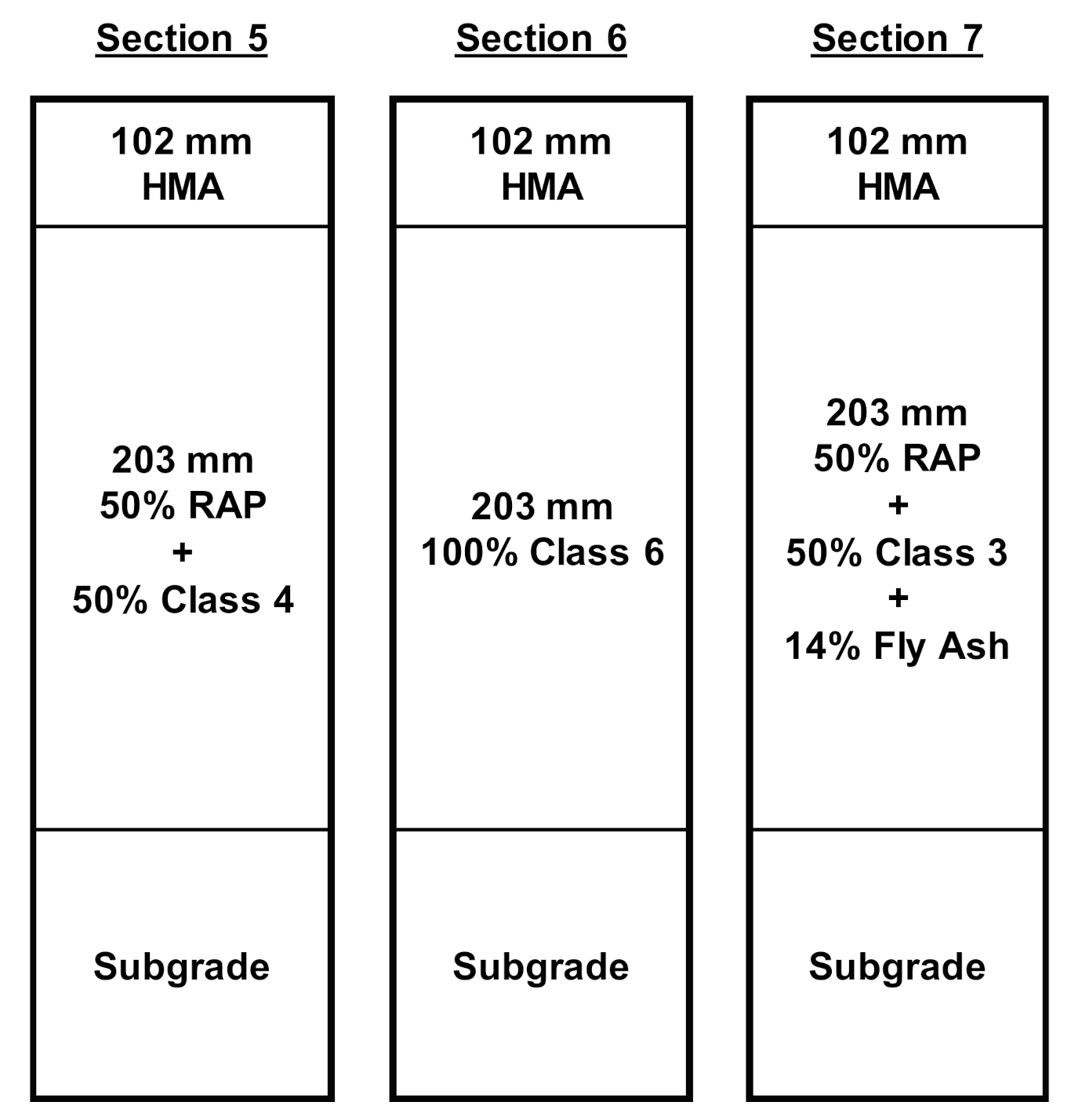

3. Methods

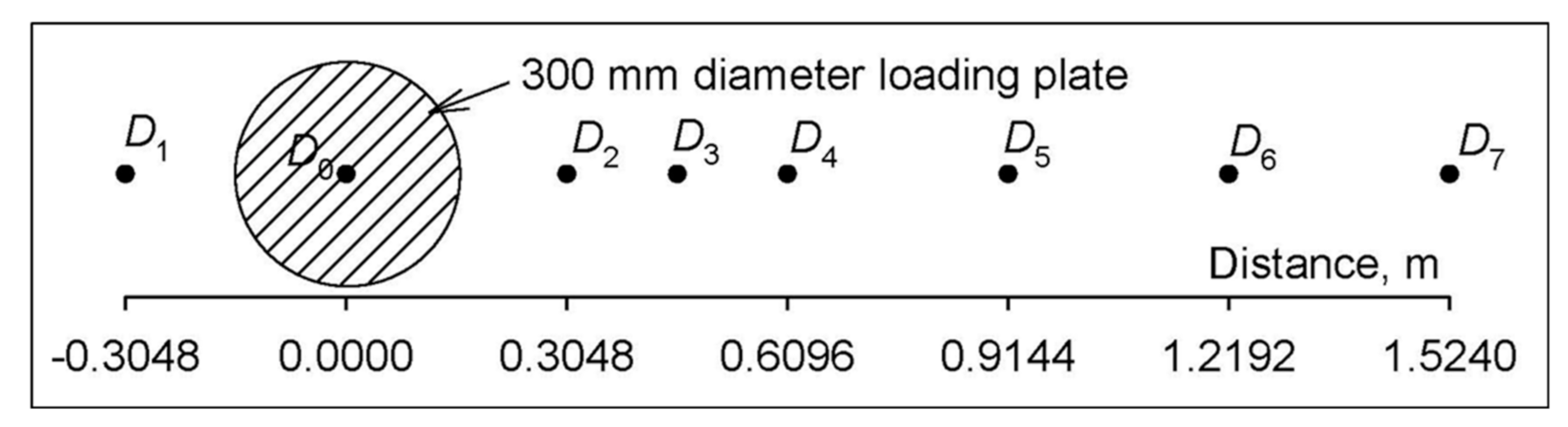

4. Results and Discussion

5. Summary and Conclusions

- In comparison with natural aggregate base, RCA and RAP improved the long-term performance of the base course. Replacing natural aggregates with 50% and 100% RCA and 100% RAP explicitly elevated the overall base layer modulus. This indicates that recycled pavement material has a higher stiffness than natural aggregates.

- The replacement of natural aggregates with recycled pavement materials led to wider seasonal variations in the base layer modulus. Different fine-content pavement base materials may result in different freeze-thaw resistance.

- Fly ash did not provide significant improvement in the long-term performance of 50% RAP plus 50% natural aggregate base.

- From a long-term point of view, the impact of traffic loading on pavement base performance was negligible compared to climatic loading. In other words, seasonal variations turned out to affect pavement performance more critically than traffic loading.

- Even though the base layer mechanical properties were altered with the varying materials, the pavement ride quality in terms of IRI and rutting depth was not observed to be significantly different.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Robinson, G.R.; Menzie, W.; Hyun, H. Recycling of construction debris as aggregate in the Mid-Atlantic Region, USA. Resour. Conserv. Recycl. 2004, 42, 275–294. [Google Scholar] [CrossRef]

- Rosa, M.G.; Cetin, B.; Edil, T.B.; Benson, C.H. Development of a Test Procedure for Freeze-Thaw Durability of Geomaterials Stabilized With Fly Ash. Geotech. Test. J. 2016, 39, 20150126. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Butera, A.; Le, K.N. Recycled Aggregate in Concrete Production: A New Approach. In 21st International Symposium on Advancement of Construction Management and Real Estate; Springer Science and Business Media LLC: Berlin, Germany, 2017; pp. 1133–1139. [Google Scholar]

- Disfani, M.; Arulrajah, A.; Bo, M.; Hankour, R. Recycled crushed glass in road work applications. Waste Manag. 2011, 31, 2341–2351. [Google Scholar] [CrossRef] [PubMed]

- Singh, D.; Sawant, D.; Xiao, F. High and intermediate temperature performance evaluation of crumb rubber modified binders with RAP. Transp. Geotech. 2017, 10, 13–21. [Google Scholar] [CrossRef]

- Arabani, M.; Nejad, F.M.; Azarhoosh, A. Laboratory evaluation of recycled waste concrete into asphalt mixtures. Int. J. Pavement Eng. 2013, 14, 531–539. [Google Scholar] [CrossRef]

- Dang, L.C.; Fatahi, B.; Khabbaz, H. Behaviour of Expansive Soils Stabilized with Hydrated Lime and Bagasse Fibres. Procedia Eng. 2016, 143, 658–665. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.-Z.; Lin, J.-T.; Wu, S.-P.; Liu, C.-H. Utilization of recycled brick powder as alternative filler in asphalt mixture. Constr. Build. Mater. 2011, 25, 1532–1536. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef]

- Fauzi, A.; Fauzi, U.J.; Nazmi, W.A.R.W.M. Engineering Quality Improvement of Kuantan Clay Subgrade using Recycling and Reused Materials as Stabilizer. Procedia Eng. 2013, 54, 675–689. [Google Scholar] [CrossRef] [Green Version]

- Smagulova, N.; Kairbekov, Z.; Ermek, A.; Yermoldina, E. Production of Bitumens from Coal Sources Modified by Elementary Sulfur. Adv. Mater. Res. 2012, 535–537, 1815–1818. [Google Scholar] [CrossRef]

- Tasdemir, Y. High temperature properties of wax modified binders and asphalt mixtures. Constr. Build. Mater. 2009, 23, 3220–3224. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H.; Rezagholilou, A. Investigating the engineering properties of asphalt binder modified with waste plastic polymer. Ain Shams Eng. J. 2021, 12, 1569–1574. [Google Scholar] [CrossRef]

- Costa, L.M.; Silva, H.M.; Peralta, J.; Oliveira, J.R. Using waste polymers as a reliable alternative for asphalt binder modification – Performance and morphological assessment. Constr. Build. Mater. 2019, 198, 237–244. [Google Scholar] [CrossRef]

- Cuadri, A.; Roman, C.; García-Morales, M.; Guisado, F.; Moreno, E.; Partal, P. Formulation and processing of recycled-low-density-polyethylene-modified bitumen emulsions for reduced-temperature asphalt technologies. Chem. Eng. Sci. 2016, 156, 197–205. [Google Scholar] [CrossRef]

- Vila-Cortavitarte, M.; González, P.L.; Calzada-Perez, M.A.; Indacoechea-Vega, I. Analysis of the influence of using recycled polystyrene as a substitute for bitumen in the behaviour of asphalt concrete mixtures. J. Clean. Prod. 2018, 170, 1279–1287. [Google Scholar] [CrossRef]

- Mastic asphalt modified with recycled polyurethane foam. J. Croat. Assoc. Civ. Eng. 2018, 70, 403–412. [CrossRef]

- Ahmedzade, P.; Demirelli, K.; Günay, T.; Biryan, F.; Alqudah, O. Effects of Waste Polypropylene Additive on the Properties of Bituminous Binder. Procedia Manuf. 2015, 2, 165–170. [Google Scholar] [CrossRef] [Green Version]

- Hasan, M.R.M.; Colbert, B.; You, Z.; Jamshidi, A.; Heiden, P.A.; Hamzah, M.O. A simple treatment of electronic-waste plastics to produce asphalt binder additives with improved properties. Constr. Build. Mater. 2016, 110, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Ziari, H.; Nasiri, E.; Amini, A.; Ferdosian, O. The effect of EAF dust and waste PVC on moisture sensitivity, rutting resistance, and fatigue performance of asphalt binders and mixtures. Constr. Build. Mater. 2019, 203, 188–200. [Google Scholar] [CrossRef]

- Milad, A.A.; Ali, A.S.B.; Yusoff, N.I.M. A Review of the Utilisation of Recycled Waste Material as an Alternative Modifier in Asphalt Mixtures. Civ. Eng. J. 2020, 6, 42–60. [Google Scholar] [CrossRef]

- Arulrajah, A.; Baghban, H.; Narsilio, G.A.; Horpibulsuk, S.; Leong, M. Discrete element analysis of recycled concrete aggregate responses during repeated load triaxial testing. Transp. Geotech. 2020, 23, 100356. [Google Scholar] [CrossRef]

- Fedrigo, W.; Núñez, W.P.; Visser, A.T. A review of full-depth reclamation of pavements with Portland cement: Brazil and abroad. Constr. Build. Mater. 2020, 262, 120540. [Google Scholar] [CrossRef]

- Gonzalo-Orden, H.; Linares-Unamunzaga, A.; Pérez-Acebo, H.; Díaz-Minguela, J. Advances in the Study of the Behavior of Full-Depth Reclamation (FDR) with Cement. Appl. Sci. 2019, 9, 3055. [Google Scholar] [CrossRef] [Green Version]

- Domitrović, J.; Rukavina, T.; Lenart, S. Effect of freeze-thaw cycles on the resilient moduli and permanent deformation of RAP/natural aggregate unbound base mixtures. Transp. Geotech. 2019, 18, 83–91. [Google Scholar] [CrossRef]

- Edil, T.B.; Cetin, B.; Soleimanbeigi, A. Laboratory and field performance of recycled aggregate base in a seasonally cold region. Sci. Cold Arid. Reg. 2018, 9, 183–191. [Google Scholar]

- Zhang, Y. Frost-Heave and Thaw-Weakening of Pavement Foundation Materials. Master’s Thesis, Iowa State University, Ames, IA, USA, 2013. Available online: https://lib.dr.iastate.edu/etd/13617 (accessed on 2 October 2021).

- Becker, P.J.; White, D.J.; Vennapusa, P.K.R.; White, C.I.; Zhang, Y. Performance Comparison of Recycled Pavement Foundation Layers. Transp. Res. Rec. J. Transp. Res. Board 2015, 2509, 29–39. [Google Scholar] [CrossRef]

- Lee, J.; Edil, T.B.; Benson, C.H.; Tinjum, J.M. Building Environmentally and Economically Sustainable Transportation Infrastructure: Green Highway Rating System. J. Constr. Eng. Manag. 2013, 139, A4013006. [Google Scholar] [CrossRef]

- Ullah, S.; Tanyu, B.F. Methodology to develop design guidelines to construct unbound base course with reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2019, 223, 463–476. [Google Scholar] [CrossRef]

- Arshad, M. Laboratory investigations on the mechanical properties of cement treated RAP-natural aggregate blends used in base/subbase layers of pavements. Constr. Build. Mater. 2020, 254, 119234. [Google Scholar] [CrossRef]

- Zhang, Y.; Johnson, A.E.; White, D.J. Freeze-thaw performance of cement and fly ash stabilized loess. Transp. Geotech. 2019, 21, 100279. [Google Scholar] [CrossRef]

- Lee, W.; Bohra, N.; Altschaeffl, A.; White, T. Resilient modulus of cohesive soils and the effect of freeze–thaw. Can. Geotech. J. 1995, 32, 559–568. [Google Scholar] [CrossRef]

- Cetin, B.; Aydilek, A.H.; Guney, Y. Stabilization of recycled base materials with high carbon fly ash. Resour. Conserv. Recycl. 2010, 54, 878–892. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Ashlock, J.C.; Lin, S.; Vennapusa, P.K. In situ modulus reduction characteristics of stabilized pavement foundations by multichannel analysis of surface waves and falling weight deflectometer tests. Constr. Build. Mater. 2018, 188, 809–819. [Google Scholar] [CrossRef]

- Zhang, Y.; Johnson, A.E.; White, D.J. Laboratory freeze–thaw assessment of cement, fly ash, and fiber stabilized pavement foundation materials. Cold Reg. Sci. Technol. 2016, 122, 50–57. [Google Scholar] [CrossRef]

- NASA Earth Observatory, Published 11 December 2000. Available online: https://earthobservatory.nasa.gov/ (accessed on 2 October 2021).

- Soleimanbeigi, A.; Shedivy, R.F.; Tinjum, J.M.; Edil, T.B. Climatic effect on resilient modulus of recycled unbound aggregates. Road Mater. Pavement Des. 2015, 16, 836–853. [Google Scholar] [CrossRef]

- Vuong, B.T. The use of finite element methods for verifying the choice of elastic layer models adopted in a back-analysis model for pavement overlay design. In Proceedings of the 6th International Conference on Finite Element Methods, Sydney, Australia, 8–10 July 1991; Available online: https://trid.trb.org/view/1199570 (accessed on 2 October 2021).

- AASHTO. Guide for Design of Pavement Structures; American Association of State Highway and Transportation Officials: Washington, DC, USA, 1993. [Google Scholar]

- Liu, W.; Scullion, T. MODULUS 6.0 FOR WINDOWS: USER’S MANUAL; Texas Transportation Institute: College Station, TX, USA, 2001. Available online: https://apps.itd.idaho.gov/apps/manuals/Materials/Materials%20References/Rep-1869-3b.pdf (accessed on 2 October 2021).

- Fernando, E.G.; Liu, W.; Ryu, D. Development of A Procedure for Temperature Correction of Backcalculated AC Modulus; Report FHWA/TX-02/1863-1. Texas Transportation Institute, The Texas A&M University System: College Station, TX, USA, 2001. Available online: https://static.tti.tamu.edu/tti.tamu.edu/documents/1863-1.pdf (accessed on 2 October 2021).

- Sigdel, P. Improving Design Strategies for Composite Pavement Overlay: Multi-layered Elastic Approach and Reliability Based Models. Ph.D. Thesis, The University of Toledo, Ohio, OH, USA, 2016. Available online: http://rave.ohiolink.edu/etdc/view?acc_num=toledo1480435567302893 (accessed on 2 October 2021).

- Huang, Y. Pavement Analysis and Design; Pearson: Upper Saddle River, NJ, USA, 2004. [Google Scholar]

- Sidess, A.; Ravina, A.; Oged, E. A model for predicting the deterioration of the international roughness index. Int. J. Pavement Eng. 2020, 1–11. [Google Scholar] [CrossRef]

- Pérez-Acebo, H.; Gonzalo-Orden, H.; Findley, D.J.; Rojí, E. Modeling the international roughness index performance on semi-rigid pavements in single carriageway roads. Constr. Build. Mater. 2021, 272, 121665. [Google Scholar] [CrossRef]

- Song, Y.; Wu, P.; Li, Q.; Liu, Y.; Karunaratne, L. Hybrid Nonlinear and Machine Learning Methods for Analyzing Factors Influencing the Performance of Large-Scale Transport Infrastructure. IEEE Trans. Intell. Transp. Syst. 2021, 1–14. [Google Scholar] [CrossRef]

| Section No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Material | 100% RCA | 50% RCA + 50% MnDOT Class 5 | 100% RAP | 100% MnDOT Class 5 | 50% RAP + 50% MnDOT Class 4 | 100% MnDOT Class 6 | 50% RAP + 50% MnDOT Class 3 + 14% Fly Ash |

| USCS Symbol | SW | SP | SP | GW-GM | SP | SP | SP |

| AASHTO Symbol | A-1-a | A-1-b | A-1-a | A-1-b | A-1-a | A-1-a | A-1-a |

| Gravel Content (%) | 31.8 | 32.7 | 26.3 | 22.9 | 28.4 | 31.5 | 35.1 |

| Sand Content (%) | 64.9 | 63.8 | 71.2 | 67.6 | 69.1 | 62.4 | 60.4 |

| Fine Content (%) | 3.3 | 3.4 | 2.5 | 9.5 | 2.5 | 6.1 | 4.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Cetin, B.; Edil, T.B. Seasonal Performance Evaluation of Pavement Base Using Recycled Materials. Sustainability 2021, 13, 12714. https://doi.org/10.3390/su132212714

Zhang Y, Cetin B, Edil TB. Seasonal Performance Evaluation of Pavement Base Using Recycled Materials. Sustainability. 2021; 13(22):12714. https://doi.org/10.3390/su132212714

Chicago/Turabian StyleZhang, Yang, Bora Cetin, and Tuncer B. Edil. 2021. "Seasonal Performance Evaluation of Pavement Base Using Recycled Materials" Sustainability 13, no. 22: 12714. https://doi.org/10.3390/su132212714

APA StyleZhang, Y., Cetin, B., & Edil, T. B. (2021). Seasonal Performance Evaluation of Pavement Base Using Recycled Materials. Sustainability, 13(22), 12714. https://doi.org/10.3390/su132212714