Management and Logistics of Returnable Transport Items: A Review Analysis on the Pallet Supply Chain

Abstract

:1. Introduction

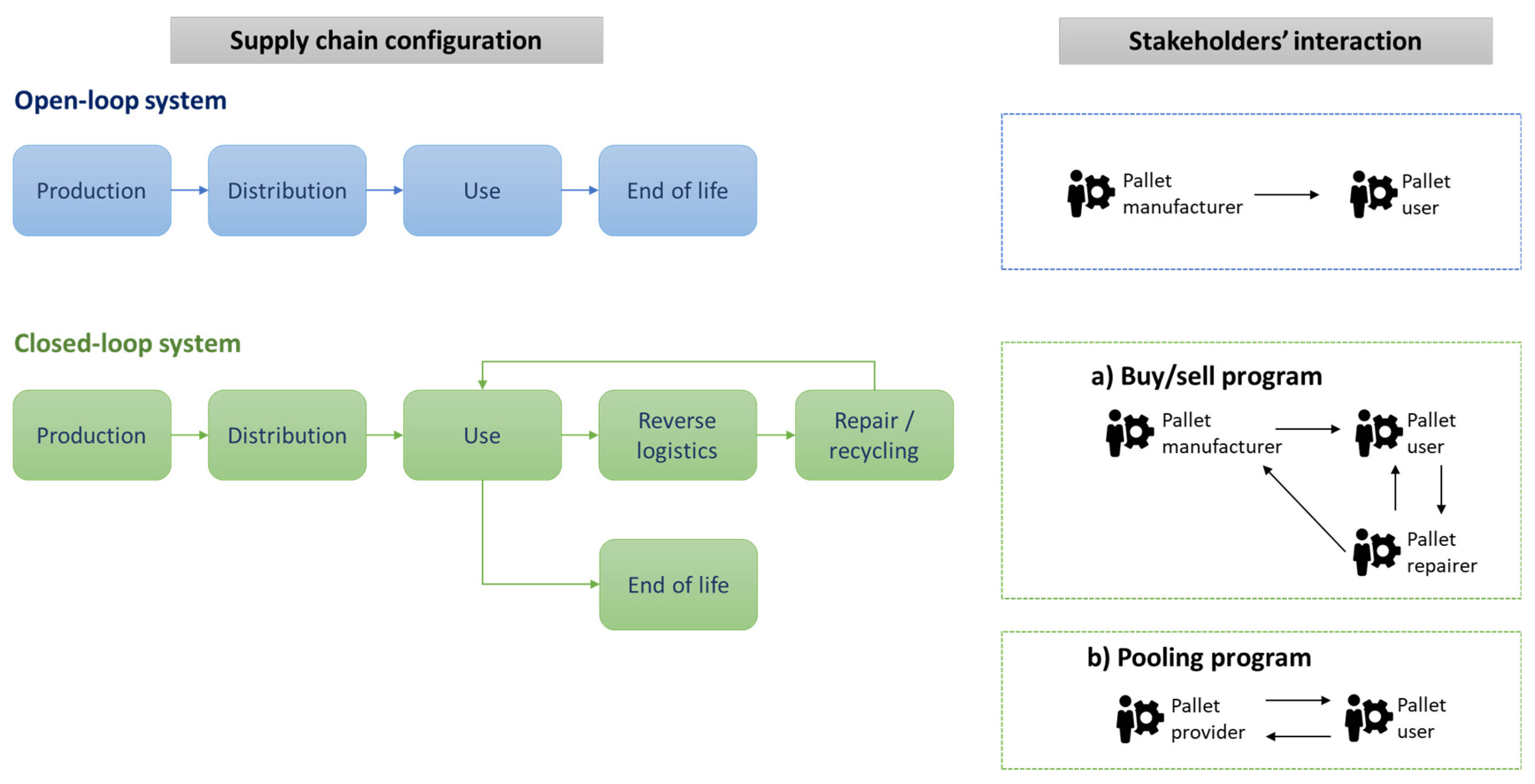

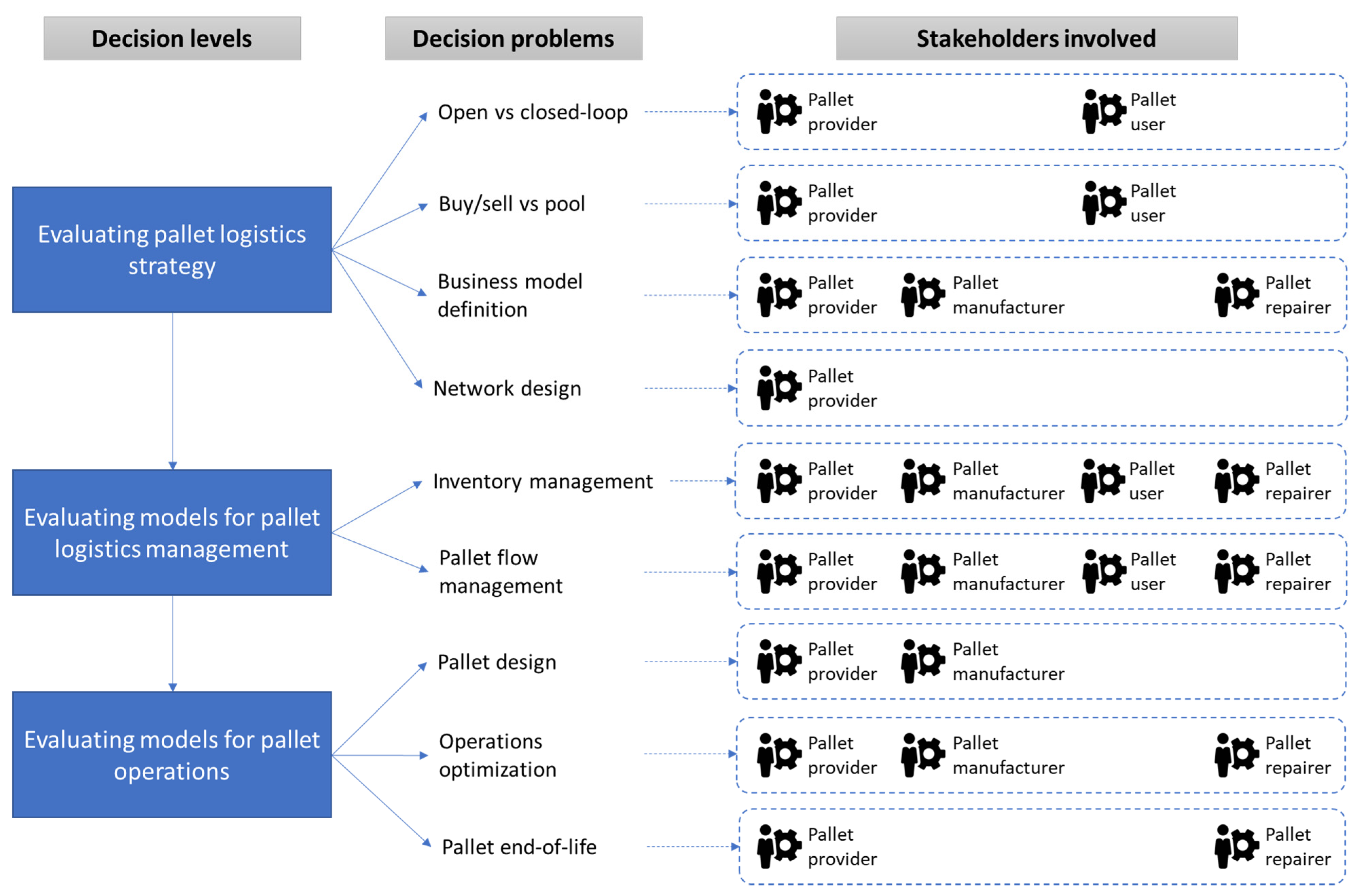

2. The Pallet Supply Chain: Decision Problems and Involved Stakeholders

3. The Research Methodology

- -

- Year and Journal of publication.

- -

- Objectives or benefits pursued in the analysis: the studies are classified in terms of whether they evaluate economic aspects, environmental impacts, social outcomes and technical performance (or efficiency) of the product/system.

- -

- Methodology adopted for the analysis: this factor identifies the type of method the authors used to address the problem presented in their study.

- -

- Perspective adopted in the study: the perspectives have been identified considering the stakeholders involved in the pallet supply chain (as explained in Section 2):

- Pallet manufacturer;

- Pallet provider;

- Pallet recycler/repairer;

- Pallet user;

- Supply chain: this category includes the works considering the performance of the whole pallet supply chain rather than of a single stakeholder.

4. Overview of Research on Pallet Supply Chain

4.1. Descriptive Analysis

4.2. Content Analysis

4.2.1. Pallet Manufacturer

4.2.2. Pallet Provider

4.2.3. Pallet User

4.2.4. Pallet Repairer/Recycler

4.2.5. Supply Chain

5. Discussion

5.1. The Stakeholders’ Perspectives

5.2. Research Gaps

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Authors, Year [Reference] | Perspective | Methodology | Objective |

|---|---|---|---|

| Accorsi et al., 2019 [53] | pallet provider | GIS-based simulation | environmental + efficiency |

| Alanya-Rosenbaum et al., 2018 [81] | supply chain | LCA | environmental |

| Alvarez and Ryubio, 2015 [26] | pallet manufacturer | Compound method + Carbon Footprint | environmental |

| Anil et al., 2020 [84] | supply chain | LCA | environmental |

| Bengtsson and Logie, 2015 [73] | supply chain | LCA | environmental |

| Bhattacharjya and Kleine-Moellhoff, 2013 [2] | supply chain | N/A | environmental |

| Bottani and Casella, 2018 [79] | supply chain | Simulation model + multicriteria optimization | environmental + efficiency |

| Bottani et al., 2015 [74] | supply chain | Simulation model + multicriteria optimization | economic |

| Buehlmann et al., 2009 [64] | pallet recycler/repairer | Field study | N/A |

| Bush et al., 1997 [10] | pallet recycler/repairer | Field study | N/A |

| Carrano et al., 2014 [3] | supply chain | LCA (Carbon Footprint) | environmental |

| Carrano et al., 2015 [72] | supply chain | Optimization model + Carbon Footprint | environmental |

| Chen et al., 2011 [42] | pallet provider | Optimization model | efficiency/technical performance |

| Chen et al., 2012 [17] | pallet manufacturer | Test case | efficiency/technical performance |

| Chen et al., 2019 [48] | pallet provider | Conceptual model | efficiency/technical performance |

| Chen et al., 2020 [35] | pallet provider | Optimization model | efficiency/technical performance |

| Chen et al., 2015 [34] | pallet provider | GIS spatial data mining | efficiency/technical performance |

| Chen and Liu, 2015 [28] | pallet provider | Conceptual model | efficiency/technical performance |

| Choi et al., 2020 [82] | supply chain | LCA | environmental |

| Deviatkin and Horttanainen, 2020 [83] | supply chain | LCA (Carbon Footprint) | environmental |

| Deviatkin et al., 2019 [86] | supply chain | Review | environmental |

| Ding and Xu, 2010 [43] | pallet provider | Field study | N/A |

| Doungpattra et al., 2012 [62] | user | Simulation model | economic |

| Duraccio et al., 2015 [58] | user | Activity Based Costing | economic |

| Elia and Gnoni, 2015 [8] | pallet provider | Simulation model | economic |

| Ewbank et al., 2020 [23] | pallet manufacturer | Fuzzy time series + clustering techniques | environmental |

| García-Duranona et al., 2016 [24] | pallet manufacturer | LCA | environmental |

| Gasol et al., 2008 [87] | supply chain | LCA | environmental |

| Gnimpieba et al., 2015 [75] | supply chain | conceptual model | N/A |

| Gnoni and Rollo, 2010 [46] | pallet provider | Scenario analysis | economic |

| Gnoni et al., 2011 [71] | supply chain | Simulation model | efficiency/technical performance |

| Grigolato et al., 2011 [19] | pallet manufacturer | Simulation model | efficiency/technical performance |

| Guzman-Siller et al., 2010 [55] | user | Field study | N/A |

| Hassanzadeh Amin et al., 2018 [76] | supply chain | Optimization model | economic |

| Jin et al., 2007 [69] | supply chain | conceptual model | N/A |

| Kim et al., 2009 [16] | pallet manufacturer | Test case | efficiency/technical performance |

| Kočí, 2019 [1] | supply chain | LCA | environmental |

| Li et al., 2009 [60] | user | Test case | efficiency/technical performance |

| Li et al., 2018 [50] | pallet provider | Test case | efficiency/technical performance |

| Liu and Peng, 2009 [44] | pallet provider | Test case | efficiency/technical performance |

| Lu et al., 2007 [56] | user | conceptual model | efficiency/technical performance |

| Masood and Haider Rizvi, 2006 [14] | pallet manufacturer | Finite element analysis | efficiency/technical performance |

| Mazeika Bilbao et al., 2010 [77] | supply chain | Optimization model | environmental |

| Mazeika Bilbao et al., 2011 [78] | supply chain | Optimization model | environmental |

| Mitchell et al., 2005 [20] | pallet manufacturer | Field study | efficiency/technical performance |

| Molter and Fottner, 2018 [61] | user | Test case | efficiency/technical performance |

| Ng et al., 2014 [25] | pallet manufacturer | LCA (Carbon Footprint) | environmental |

| Niero et al., 2014 [89] | supply chain | LCA | environmental |

| Ou and Ma, 2012 [27] | pallet provider | Optimization model | economic |

| Pang and Zhu, 2013 [21] | pallet manufacturer | AHP | economic + efficiency + environmental |

| Park et al., 2016 [65] | pallet recycler/repairer | Field study | N/A |

| Park et al., 2018 [67] | pallet recycler/repairer | LCA | environmental |

| Qinghua et al., 2009 [45] | pallet provider | conceptual model | N/A |

| Raballand and Aldaz-Carrol, 2005 [63] | user | Field study | economic |

| Ray et al., 2006 [54] | user | Scenario analysis | economic |

| Ren et al., 2010 [29] | pallet provider | conceptual model | efficiency/technical performance |

| Ren et al., 2017 [38] | pallet provider | Optimization model | economic |

| Ren et al., 2018 [47] | pallet provider | Optimization model | Economic |

| Ren et al., 2019 [36] | pallet provider | Optimization model | efficiency/technical performance |

| Ren et al., 2019 [7] | supply chain | Simulation model | economic |

| Ren et al., 2020 [40] | pallet provider | Optimization model | environmental + economic |

| Roy et al., 2016 [4] | user | Analytical model | economic |

| Ruebeck and Pfaffmann, 2011 [68] | supply chain | Simulation model | environmental + economic |

| Schweinle et al., 2020 [88] | supply chain | Material Flow Analysis | environmental + economic + social |

| Singh and Walker, 1995 [85] | supply chain | LCA | environmental |

| Soury et al., 2009 [15] | pallet manufacturer | Finite element analysis | efficiency/technical performance |

| Spieker and Rohrig, 2008 [59] | user | Test case | efficiency/technical performance |

| Tepic et al., 2012 [13] | pallet manufacturer | conceptual model | efficiency/technical performance |

| Tornese et al., 2016 [66] | pallet recycler/repairer | LCA (Carbon Footprint) | environmental |

| Tornese et al., 2018 [33] | pallet provider | Simulation model | environmental + economic |

| Tornese et al., 2019 [52] | pallet provider | Optimization model | environmental + economic |

| Vargas et al., 2019 [22] | pallet manufacturer | Field study | environmental + economic |

| von Lanzenauer and Wright, 1978 [11] | pallet provider | Optimization model | economic |

| Wattanasiriseth and Krairit, 2019 [18] | pallet manufacturer | Optimization model | environmental + economic |

| White and Hamner, 2005 [70] | supply chain | N/A | environmental + economic |

| White and Wallin, 1987 [12] | pallet manufacturer | Statistical analysis | efficiency/technical performance |

| Won et al., 2006 [57] | user | Test case | efficiency/technical performance |

| Wu et al., 2016 [39] | pallet provider | Optimization model | economic |

| Zhang et al., 2010 [31] | pallet provider | Field study | N/A |

| Zhang et al., 2012 [30] | pallet provider | conceptual model | n/A |

| Zhang et al., 2014 [32] | pallet provider | Optimization model | economic |

| Zhang and Feng, 2012 [51] | pallet provider | Optimization model | economic |

| Zhao, 2011 [49] | pallet provider | conceptual model | efficiency/technical performance |

| Zhou and Song, 2019 [37] | pallet provider | Optimization model | economic |

| Zhou et al., 2018 [41] | pallet provider | Optimization model | economic |

References

- Kočí, V. Comparisons of environmental impacts between wood and plastic transport pallets. Sci. Total Environ. 2019, 686, 514–528. [Google Scholar] [CrossRef]

- Bhattacharjya, J.; Kleine-Moellhoff, P. Environmental Concerns in the Design and Management of Pallets. In Collaborative Systems for Reindustrialization; Camarinha-Matos, L.M., Scherer, R.J., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 408, pp. 569–576. [Google Scholar] [CrossRef] [Green Version]

- Carrano, A.L.; Thorn, B.K.; Woltag, H. Characterizing the Carbon Footprint of Wood Pallet Logistics. For. Prod. J. 2014, 64, 232–241. [Google Scholar] [CrossRef]

- Roy, D.; Carrano, A.L.; Pazour, J.A.; Gupta, A. Cost-effective pallet management strategies. Transp. Res. Part E Logist. Transp. Rev. 2016, 93, 358–371. [Google Scholar] [CrossRef]

- Glock, C. Decision support models for managing returnable transport items in supply chains: A systematic literature review. Int. J. Prod. Econ. 2016, 183, 561–569. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Parviziomran, I. Reusable packaging in supply chains: A review of environmental and economic impacts, logistics system designs, and operations management. Int. J. Prod. Econ. 2020, 228, 107730. [Google Scholar] [CrossRef]

- Ren, J.; Zhao, Q.; Liu, B.; Chen, C. Selection of pallet management strategies from the perspective of supply chain cost with Anylogic software. PLoS ONE 2019, 14, e0217995. [Google Scholar] [CrossRef] [PubMed]

- Elia, V.; Gnoni, M.G. Designing an effective closed loop system for pallet management. Int. J. Prod. Econ. 2015, 170, 730–740. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Bush, R.J.; Reddy, V.S.; Araman, P.A. Pallets: A Growing Source of Recycled Wood. In Proceedings, the Use of Recycled Wood and Paper in Building Applications; USDA: Washington, DC, USA, 1997; pp. 24–28. [Google Scholar]

- Von Lanzenauer, C.H.; Wright, D.D. Developing an optimal repair-replacement strategy for pallets. Nav. Res. Logist. Q. 1978, 25, 169–178. [Google Scholar] [CrossRef] [Green Version]

- White, M.S.; Wallin, W.B. Effect of wood pallet design on structural durability: A statistical analysis of observed in-service damage. For. Prod. J. 1987, 37, 32–38. [Google Scholar]

- Tepić, J.; Todić, V.; Tanackov, I.; Lukić, D.; Stojić, G.; Sremac, S. Modular system design for plastic euro pallets. Metalurgija 2012, 51, 241. [Google Scholar]

- Masood, S.; Rizvi, S.H. An investigation of pallet design using alternative materials for cold room applications. Int. J. Adv. Manuf. Technol. 2005, 29, 1–8. [Google Scholar] [CrossRef]

- Soury, E.; Behravesh, A.; Esfahani, E.R.; Zolfaghari, A. Design, optimization and manufacturing of wood–plastic composite pallet. Mater. Des. 2009, 30, 4183–4191. [Google Scholar] [CrossRef]

- Kim, S.; Kim, H.-J.; Park, J.C. Application of recycled paper sludge and biomass materials in manufacture of green composite pallet. Resour. Conserv. Recycl. 2009, 53, 674–679. [Google Scholar] [CrossRef]

- Chen, Z.; White, M.; Wu, Y. Vacuum–Steam Phytosanitation of Hardwood Pallets and Pallet Stringers. For. Prod. J. 2012, 62, 378–382. [Google Scholar] [CrossRef]

- Wattanasiriseth, P.; Krairit, A. An Application of Cutting-Stock Problem in Green Manufacturing: A Case Study of Wooden Pallet Industry. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Penang, Malaysia, 2019; Volume 530. [Google Scholar] [CrossRef]

- Grigolato, S.; Bietresato, M.; Asson, D.; Cavalli, R. Evaluation of the manufacturing of desk and stringer boards for wood pallets production by discrete event simulation. Biosyst. Eng. 2011, 109, 288–296. [Google Scholar] [CrossRef]

- Mitchell, H.L.; White, M.; Araman, P.; Hamner, P. Hardwood pallet cant quality and pallet part yields. For. Prod. J. 2005, 55, 233–238. [Google Scholar]

- Pang, Y.; Zhu, Z.P. Optimization Scheme Selection on Bamboo-Wood Pallet Technological Process. Appl. Mech. Mater. 2013, 397–400, 739–745. [Google Scholar] [CrossRef]

- Vargas, B.; Miño, G.; Vega, P.; Mariño, J. Application of resource efficient and cleaner production through best management practice in a pallet manufacturer sawmill located in the city of Puyo-Ecuador. Cienc. Tecnol. 2019, 21, 367–380. [Google Scholar] [CrossRef]

- Ewbank, H.; Roveda, J.A.F.; Roveda, S.R.M.M.; Ribeiro, A.; Bressane, A.; Hadi-Vencheh, A.; Wanke, P. Sustainable resource management in a supply chain: A methodological proposal combining zero-inflated fuzzy time series and clustering techniques. J. Enterp. Inf. Manag. 2020, 33, 1059–1076. [Google Scholar] [CrossRef]

- García-Durañona, L.; Farreny, R.; Navarro, P.; Boschmonart-Rives, J. Life Cycle Assessment of a coniferous wood supply chain for pallet production in Catalonia, Spain. J. Clean. Prod. 2016, 137, 178–188. [Google Scholar] [CrossRef]

- Ng, R.; Shi, C.W.P.; Tan, H.X.; Song, B. Avoided impact quantification from recycling of wood waste in Singapore: An assessment of pallet made from technical wood versus virgin softwood. J. Clean. Prod. 2014, 65, 447–457. [Google Scholar] [CrossRef]

- Alvarez, S.; Rubio, A. Compound method based on financial accounts versus process-based analysis in product carbon footprint: A comparison using wood pallets. Ecol. Indic. 2015, 49, 88–94. [Google Scholar] [CrossRef]

- Ou, W.; Ma, Q. Model of Reverse Logistics Network about Rental Pallet Recycling Considering Site Transport Capacity. In Proceedings of the ICLEM 2012: Logistics for Sustained Economic Development—Technology and Management for Efficiency, Chengdu, China, 8–10 October 2012. [Google Scholar] [CrossRef]

- Chen, N.; Liu, Y. Analysis of a Commercial Mode for the Pallet Pooling System. In Proceedings of the 5th International Conference on Transportation Engineering, Dalian, China, 26–27 September 2015; pp. 2095–2101. [Google Scholar]

- Ren, J.; Zhang, X.; Zhang, J.; Wang, P. Design of a Railway Pallet Pool Information System on Grid. In Proceedings of the ICLEM 2010: Logistics for Sustained Economic Development—Technolgy and Management for Efficiency, Chengdu, China, 8–10 September 2010; pp. 1252–1258. [Google Scholar] [CrossRef]

- Zhang, X.; Suo, Y.; Chen, N. Study on Closed Pallet Pooling System in Sichuan Province. In Proceedings of the ICLEM 2012: Logistics for Sustained Economic Development—Technolgy and Management for Efficiency, Chengdu, China, 8–10 October 2012; pp. 1314–1319. [Google Scholar] [CrossRef]

- Zhang, X.; Ren, J.; Sui, Y. Operation Model and Information System of China Pallet Pool System. In Proceedings of the ICLEM 2010: Logistics for Sustained Economic Development—Technolgy and Management for Efficiency, Chengdu, China, 8–10 September 2010; pp. 2162–2168. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, J.; Niu, Y. Pricing Strategy of Pallet Pooling System. In Proceedings of the ICLEM 2014: Logistics for Sustained Economic Development—Technolgy and Management for Efficiency, Shanghai, China, 9–11 October 2014; pp. 1217–1221. [Google Scholar] [CrossRef]

- Tornese, F.; Pazour, J.A.; Thorn, B.K.; Roy, D.; Carrano, A.L. Investigating the environmental and economic impact of loading conditions and repositioning strategies for pallet pooling providers. J. Clean. Prod. 2018, 172, 155–168. [Google Scholar] [CrossRef]

- Chen, N.; Wang, X.; Zhu, G.; Lv, Y. Analysis of a Freight Pallet Pooling System Based on Spatial Data Mining in GIS. In Proceedings of the ICTE 2015: Fifth International Conference on Transportation Engineering, Dailan, China, 26–27 September 2015; pp. 2089–2094. [Google Scholar] [CrossRef]

- Chen, C.; Liu, H.; Liu, B.; Zhang, J.; Gao, B.; Ren, J. Measuring the Performance of Pallet Rental Companies: Integer-Valued DEA Models with Generalized Reference Sets. IEEE Access 2019, 8, 3374–3386. [Google Scholar] [CrossRef]

- Ren, J.; Chen, C.; Gao, B.; Zhang, J. Performance Evaluation of Pallet Rental Companies: A Non-Oriented Super-Efficiency Integer-Valued DEA Model. IEEE Access 2019, 7, 151628–151637. [Google Scholar] [CrossRef]

- Zhou, K.; Song, R. Location Model of Pallet Service Centers Based on the Pallet Pool Mode. In Proceedings of the 2019 IEEE 3rd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chengdu, China, 15–17 March 2019; pp. 1185–1189. [Google Scholar]

- Ren, J.; Liu, B.; Wang, Z. An optimization model for multi-type pallet allocation over a pallet pool. Adv. Mech. Eng. 2017, 9, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Ren, J.; Liu, B.; Lu, T. Deterministic and multi-scenario models for pallet allocation over a pallet pool in a city joint distribution system. Adv. Mech. Eng. 2016, 8, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Ren, J.; Chen, C.; Gao, J.; Feng, C. An optimization model for fleet sizing and empty pallet allocation considering CO2 emissions. PLoS ONE 2020, 15, e0229544. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, K.; He, S.; Song, R.; Guo, X.; Li, K. Optimization Model and Algorithm of Empty Pallets Dispatching under the Time-Space Network of Express Shipment. J. Adv. Transp. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Chen, N.; Zhang, X.; Hao, W. Pallet Dispatch Optimization of Pallet Pool System Based on Fractal Data Mining. In Proceedings of the 3rd International Conference on Transportation Engineering—ICTE 2011, Chengdu, China, 23–25 July 2011; pp. 2181–2186. [Google Scholar] [CrossRef]

- Ding, Z.; Xu, Q. Research on the RFID-Based Pallet Pool Information System. In Proceedings of the ICLEM 2010: Logistics for Sustained Economic Development—Technolgy and Management for Efficiency, Chengdu, China, 8–10 September 2010; pp. 2551–2558. [Google Scholar] [CrossRef]

- Liu, H.; Peng, Y. Research of mobile business integrated with RFID technology in the logistics pallet leasing. In Proceedings of the 2009 International Conference on Machine Learning and Cybernetics, Baoding, China, 12–15 July 2009; pp. 3101–3105. [Google Scholar] [CrossRef]

- Zhang, Q.; Wei, J.; Cheng, G.; Wang, Z.; Yan, D.; Zhao, S. Pallet rental information system based on RFID. In Proceedings of the 2009 4th IEEE Conference on Industrial Electronics and Applications, Xi’an, China, 25–27 May 2009; pp. 886–891. [Google Scholar] [CrossRef]

- Gnoni, M.G.; Rollo, A. A scenario analysis for evaluating RFID investments in pallet management. Int. J. RF Technol. Res. Appl. 2010, 2, 1–21. [Google Scholar] [CrossRef]

- Ren, J.; Chen, C.; Xu, H.; Zhao, Q. An optimization model for the operations of a pallet pool with both radio-frequency identification–tagged pallets and non-tagged pallets. Adv. Mech. Eng. 2018, 10, 1–13. [Google Scholar] [CrossRef]

- Chen, N.; Dong, Y.; Gui, X. Decentralized Application of Pallet Pool System Based on Blockchain. In Proceedings of the ICTE 2019: The 4th International Conference on Technology in Education, Guangzhou, China, 15–17 March 2020; pp. 681–688. [Google Scholar] [CrossRef]

- Zhao, N. Quick Response System for Logistics Pallets Pooling Service Supply Chain Based on XML Data Sharing. In Electrical Engineering and Control; Zhu, M., Ed.; Springer: Berlin/Heidelberg, Germany, 2011; Volume 98, pp. 367–374. [Google Scholar] [CrossRef]

- Li, J.-B.; He, S.-W.; Yin, W.-C. The Study of Pallet Pooling Information Platform Based on Cloud Computing. Sci. Program. 2018, 2018, 1–5. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, X. Research on Pallet Recycling Based on the Closed-Loop Supply Chain. In Proceedings of the ICLEM 2012: Logistics for Sustained Economic Development—Technology and Management for Efficiency, Chengdu, China, 8–10 October 2012; pp. 974–979. [Google Scholar] [CrossRef]

- Tornese, F.; Pazour, J.A.; Thorn, B.K.; Carrano, A. Environmental and economic impacts of preemptive remanufacturing policies for block and stringer pallets. J. Clean. Prod. 2019, 235, 1327–1337. [Google Scholar] [CrossRef]

- Accorsi, R.; Baruffaldi, G.; Manzini, R.; Pini, C. Environmental Impacts of Reusable Transport Items: A Case Study of Pallet Pooling in a Retailer Supply Chain. Sustainability 2019, 11, 3147. [Google Scholar] [CrossRef] [Green Version]

- Ray, C.D.; Michael, J.H.; Scholnick, B.N. Supply-chain system costs of alternative grocery industry pallet systems. For. Prod. J. 2006, 56, 52–57. [Google Scholar]

- Guzman-Siller, C.F.; Twede, D.; Mollenkopf, D.A. Differences in the Perception of Pallet Systems between U.S. and Canadian Grocery Retailers. J. Food Distrib. Res. 2010, 41, 1–14. [Google Scholar] [CrossRef]

- Lu, S.; Wu, Y.; Fu, Y. Research and design on pallet-throughout system based on RFID. In Proceedings of the 2007 IEEE International Conference on Automation and Logistics, Jinan, China, 18–21 August 2007; pp. 2592–2595. [Google Scholar] [CrossRef]

- Won, J.U.; Choi, Y.; Park, J.H. Pallet management system based on RFID in the postal logistics. Int. J. Serv. Oper. Inform. 2006, 1, 321. [Google Scholar] [CrossRef]

- Duraccio, V.; Elia, V.; Forcina, A. An activity based costing model for evaluating effectiveness of RFID technology in pallet reverse logistics system. AIP Conf. Proc. 2015, 1648, 570005. [Google Scholar] [CrossRef]

- Spieker, S.; Rohrig, C. Localization of pallets in warehouses using Wireless Sensor Networks. In Proceedings of the 2008 16th Mediterranean Conference on Control and Automation, Ajaccio, France, 25–27 June 2008; pp. 1833–1838. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Y.; Chen, L. Design of Wireless Logistics Pallet Location System Based on Zigbee Protocol. In Proceedings of the Logistics: The Emerging Frontiers of Transportation and Development in China: Proceedings of the Eighth International Conference, Chengdu, China, 8–10 October 2009; pp. 2115–2120. [Google Scholar] [CrossRef]

- Molter, B.; Fottner, J. Real-time Pallet Localization with 3D Camera Technology for Forklifts in Logistic Environments. In Proceedings of the 2018 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Singapore, 31 July–2 August 2018; pp. 297–302. [Google Scholar] [CrossRef] [Green Version]

- Doungpattra, N.; Jarupan, L.; Ongkunaruk, P. Simulation for Transport Pallet Cost Reduction in Pet Food Manufacturing: An Empirical Case Study: Pallet Cost Reduction in Pet Food Manufacturing. Packag. Technol. Sci. 2011, 25, 311–319. [Google Scholar] [CrossRef]

- Raballand, G.; Aldaz-Carroll, E. How Do Differing Standards Increase Trade Costs? The Case of Pallets. World Econ. 2007, 30, 685–702. [Google Scholar] [CrossRef]

- Buehlmann, U.; Bumgardner, M.; Fluharty, T. Ban on landfilling of wooden pallets in North Carolina: An assessment of recycling and industry capacity. J. Clean. Prod. 2009, 17, 271–275. [Google Scholar] [CrossRef]

- Park, J.; Bush, R.J.; Horvath, L. Process Methods and Levels of Automation of Wood Pallet Repair in the United States. BioResources 2016, 11, 6822–6835. [Google Scholar] [CrossRef] [Green Version]

- Tornese, F.; Carrano, A.L.; Thorn, B.K.; Pazour, J.A.; Roy, D. Carbon footprint analysis of pallet remanufacturing. J. Clean. Prod. 2016, 126, 630–642. [Google Scholar] [CrossRef]

- Park, J.; Horvath, L.; Bush, R.J. Life Cycle Inventory Analysis of the Wood Pallet Repair Process in the United States. J. Ind. Ecol. 2017, 22, 1117–1126. [Google Scholar] [CrossRef]

- Ruebeck, C.S.; Pfaffmann, O.J. Open- and Closed-Loop Supply Chain Dynamics: Specification and Exploration of an Agent-based Model. East. Econ. J. 2010, 37, 85–108. [Google Scholar] [CrossRef] [Green Version]

- Jin, S.; Jiang, M.; Yao, Z.; Ge, H.; Feng, D. Study on the Pallet-bank and its Construction. In Proceedings of the 2007 IEEE International Conference on Automation and Logistics, Jinan, China, 18–21 August 2007; pp. 885–889. [Google Scholar] [CrossRef]

- White, M.S.; Hamner, P. Pallets Move the World: The Case for Developing System-Based Designs for Unit Loads. For. Prod. J. 2005, 55, 8–16. [Google Scholar]

- Gnoni, M.G.; Lettera, G.; Rollo, A. A simulation comparison analysis of effective pallet management scenarios. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2011; pp. 1228–1232. [Google Scholar] [CrossRef]

- Carrano, A.; Pazour, J.A.; Roy, D.; Thorn, B.K. Selection of pallet management strategies based on carbon emissions impact. Int. J. Prod. Econ. 2015, 164, 258–270. [Google Scholar] [CrossRef]

- Bengtsson, J.; Logie, J. Life Cycle Assessment of One-way and Pooled Pallet Alternatives. Procedia CIRP 2015, 29, 414–419. [Google Scholar] [CrossRef]

- Bottani, E.; Montanari, R.; Rinaldi, M.; Vignali, G. Modeling and multi-objective optimization of closed loop supply chains: A case study. Comput. Ind. Eng. 2015, 87, 328–342. [Google Scholar] [CrossRef]

- Gnimpieba, Z.D.R.; Nait-Sidi-Moh, A.; Durand, D.; Fortin, J. Using Internet of Things Technologies for a Collaborative Supply Chain: Application to Tracking of Pallets and Containers. Procedia Comput. Sci. 2015, 56, 550–557. [Google Scholar] [CrossRef]

- Amin, S.H.; Wu, H.; Karaphillis, G. A perspective on the reverse logistics of plastic pallets in Canada. J. Remanuf. 2018, 8, 153–174. [Google Scholar] [CrossRef] [Green Version]

- Bilbao, M.A.; Carrano, A.L.; Thorn, B.K.; Hewitt, M.R. Environmental impact analysis of pallets management. In Proceedings of the Industrial Engineering Research Conference, IERC 2010, Cancun, Mexico, 5–9 June 2010. [Google Scholar]

- Bilbao, A.M.; Carrano, A.; Hewitt, M.; Thorn, B. On the environmental impacts of pallet management operations. Manag. Res. Rev. 2011, 34, 1222–1236. [Google Scholar] [CrossRef]

- Bottani, E.; Casella, G. Minimization of the Environmental Emissions of Closed-Loop Supply Chains: A Case Study of Returnable Transport Assets Management. Sustainability 2018, 10, 329. [Google Scholar] [CrossRef] [Green Version]

- Bierer, A.; Götze, U.; Meynerts, L.; Sygulla, R. Integrating life cycle costing and life cycle assessment using extended material flow cost accounting. J. Clean. Prod. 2015, 108, 1289–1301. [Google Scholar] [CrossRef]

- Alanya-Rosenbaum, S.; Bergman, R.; Gething, B. Developing Procedures and Guidance for Performing an Environmental Assessment of US Wooden Pallets. WIT Trans. Ecol. Environ. 2018, 215, 37–45. [Google Scholar] [CrossRef] [Green Version]

- Choi, B.; Yoo, S.; Lee, K.-D.; Park, S.-I. An environmental impact comparison of disposable wood pallets and reusable steel cradles: A case study on rolled steel coils in container shipping in South Korea. Int. J. Sustain. Transp. 2019, 14, 335–342. [Google Scholar] [CrossRef]

- Deviatkin, I.; Horttanainen, M. Carbon footprint of an EUR-sized wooden and a plastic pallet. E3S Web Conf. 2020, 158, 03001. [Google Scholar] [CrossRef]

- Anil, S.K.; Ma, J.; Kremer, G.E.; Ray, C.D.; Shahidi, S.M. Life cycle assessment comparison of wooden and plastic pallets in the grocery industry. J. Ind. Ecol. 2020, 24, 871–886. [Google Scholar] [CrossRef]

- Singh, S.P.; Walker, R. Life cycle analysis of nestable plastic and wood pallets. J. Plast. Film Sheeting 1995, 11, 312–325. [Google Scholar]

- Deviatkin, I.; Khan, M.; Ernst, E.; Horttanainen, M. Wooden and Plastic Pallets: A Review of Life Cycle Assessment (LCA) Studies. Sustainability 2019, 11, 5750. [Google Scholar] [CrossRef] [Green Version]

- Gasol, C.M.; Farreny, R.; Gabarrell, X.; Rieradevall, J. Life cycle assessment comparison among different reuse intensities for industrial wooden containers. Int. J. Life Cycle Assess. 2008, 13, 421–431. [Google Scholar] [CrossRef]

- Schweinle, J.; Geng, N.; Iost, S.; Weimar, H.; Jochem, D. Monitoring Sustainability Effects of the Bioeconomy: A Material Flow Based Approach Using the Example of Softwood Lumber and Its Core Product Epal 1 Pallet. Sustainability 2020, 12, 2444. [Google Scholar] [CrossRef] [Green Version]

- Niero, M.; Di Felice, F.; Ren, J.; Manzardo, A.; Scipioni, A. How can a life cycle inventory parametric model streamline life cycle assessment in the wooden pallet sector? Int. J. Life Cycle Assess. 2014, 19, 901–918. [Google Scholar] [CrossRef]

- Mišić, V.V.; Perakis, G. Data Analytics in Operations Management: A Review. Manuf. Serv. Oper. Manag. 2020, 22, 158–169. [Google Scholar] [CrossRef] [Green Version]

| Journal/Proceeding | #Papers |

|---|---|

| Forest Products Journal | 6 |

| Journal of Cleaner Production | 6 |

| Sustainability | 4 |

| ICLEM 2010: Proceedings of the 2010 International Conference of Logistics Engineering and Management | 3 |

| ICLEM 2012: Proceedings of the 2012 International Conference of Logistics Engineering and Management | 3 |

| Other (63 papers) | ≤2 |

| Methodology | Frequency |

|---|---|

| Optimization model | 18 |

| Conceptual model | 10 |

| LCA | 10 |

| Field study | 9 |

| Test case | 8 |

| Simulation model | 7 |

| LCA (Carbon footprint) | 4 |

| Other (19 papers) | ≤2 |

| Total | 85 |

| Perspective | Commonly Investigated Problems | Prevailing Objectives | Prevailing Decision Levels | Research Gaps |

|---|---|---|---|---|

| Pallet manufacturer | Alternative materials for pallet production Efficiency of production operations | Economic Environmental Efficiency | Operational | Demand forecast Production capacity planning Evaluation of strategic partnerships |

| Pallet provider | Design and analysis of pallet systems IT for pallet traceability Pallet allocation problem | Economic Efficiency | Operational Tactical Strategic | Pool sizing Inventory management Real-time data management (dynamic decision making) Business model definition Network design |

| Pallet recycler/repairer | Assessment of recycling industry Environmental analysis of repair and recycling operations | Environmental | Operational Strategic | Economic performance of recycling operations Evaluation of strategic partnerships |

| Pallet user | Selection of alternative pallet systems Pallet traceability | Economic Efficiency | Operational Tactical | Inventory models for owned pallets Environmental assessment of user’s decisions |

| The whole supply chain | Selection of alternative pallet systems Design and analysis of pallet systems Environmental impact of pallet management alternatives Environmental impact of different pallet materials | Environmental | Strategic | Design of pallet management system Network design |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tornese, F.; Gnoni, M.G.; Thorn, B.K.; Carrano, A.L.; Pazour, J.A. Management and Logistics of Returnable Transport Items: A Review Analysis on the Pallet Supply Chain. Sustainability 2021, 13, 12747. https://doi.org/10.3390/su132212747

Tornese F, Gnoni MG, Thorn BK, Carrano AL, Pazour JA. Management and Logistics of Returnable Transport Items: A Review Analysis on the Pallet Supply Chain. Sustainability. 2021; 13(22):12747. https://doi.org/10.3390/su132212747

Chicago/Turabian StyleTornese, Fabiana, Maria Grazia Gnoni, Brian K. Thorn, Andres L. Carrano, and Jennifer A. Pazour. 2021. "Management and Logistics of Returnable Transport Items: A Review Analysis on the Pallet Supply Chain" Sustainability 13, no. 22: 12747. https://doi.org/10.3390/su132212747

APA StyleTornese, F., Gnoni, M. G., Thorn, B. K., Carrano, A. L., & Pazour, J. A. (2021). Management and Logistics of Returnable Transport Items: A Review Analysis on the Pallet Supply Chain. Sustainability, 13(22), 12747. https://doi.org/10.3390/su132212747