Optimized Thin-Film Organic Solar Cell with Enhanced Efficiency

Abstract

:1. Introduction

- To achieve high conversion efficiency by optimizing the active layer of the cell;

- To observe the impact of DBR pairing on the performance of the cell;

- To observe the impact of high temperature on the cell performance parameters.

2. Materials and Methods

3. Result and Discussion

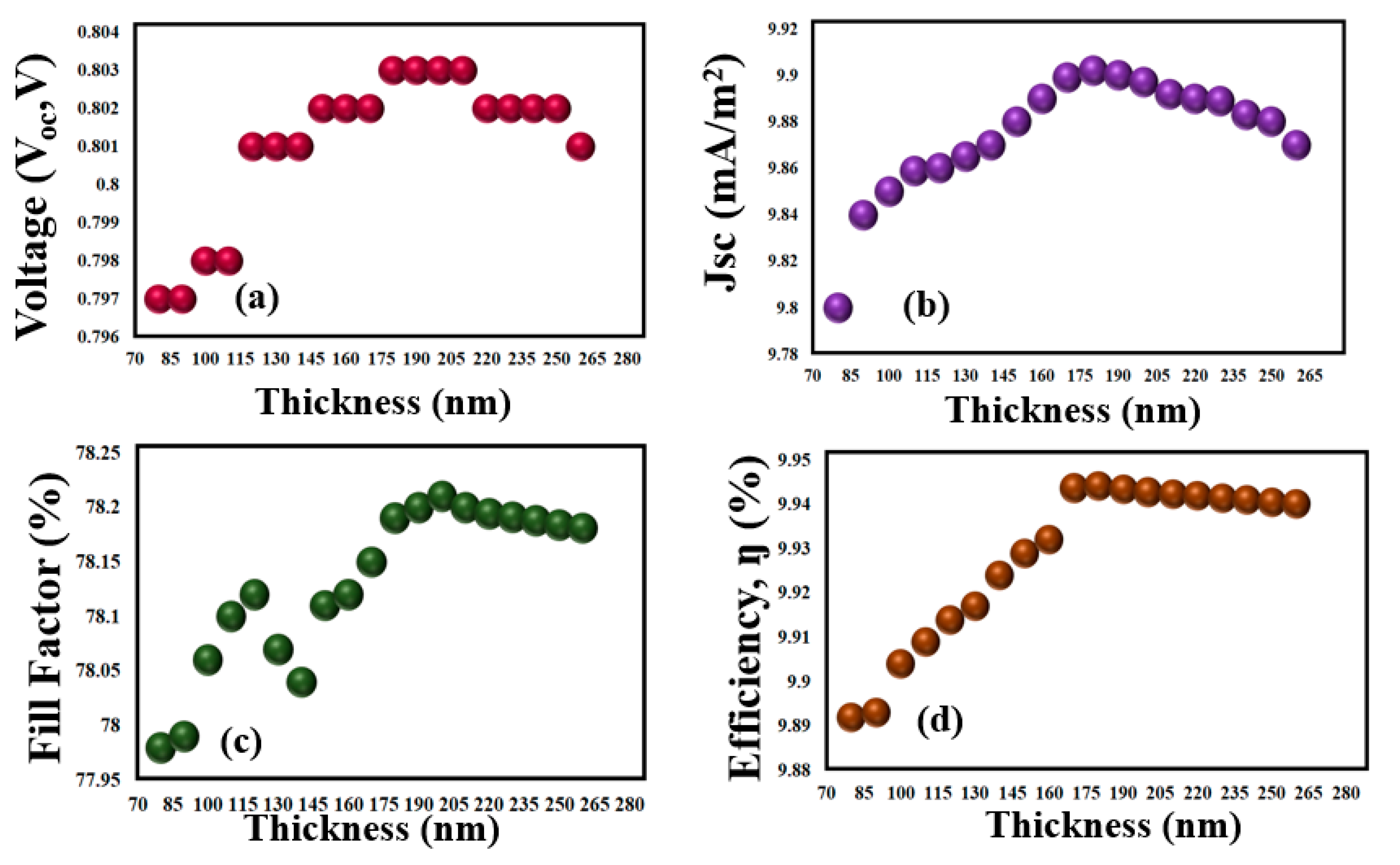

3.1. Cell Architecture and Active Layer Optimization

3.2. Optimization of Light-Harvesting Layer (LHL)

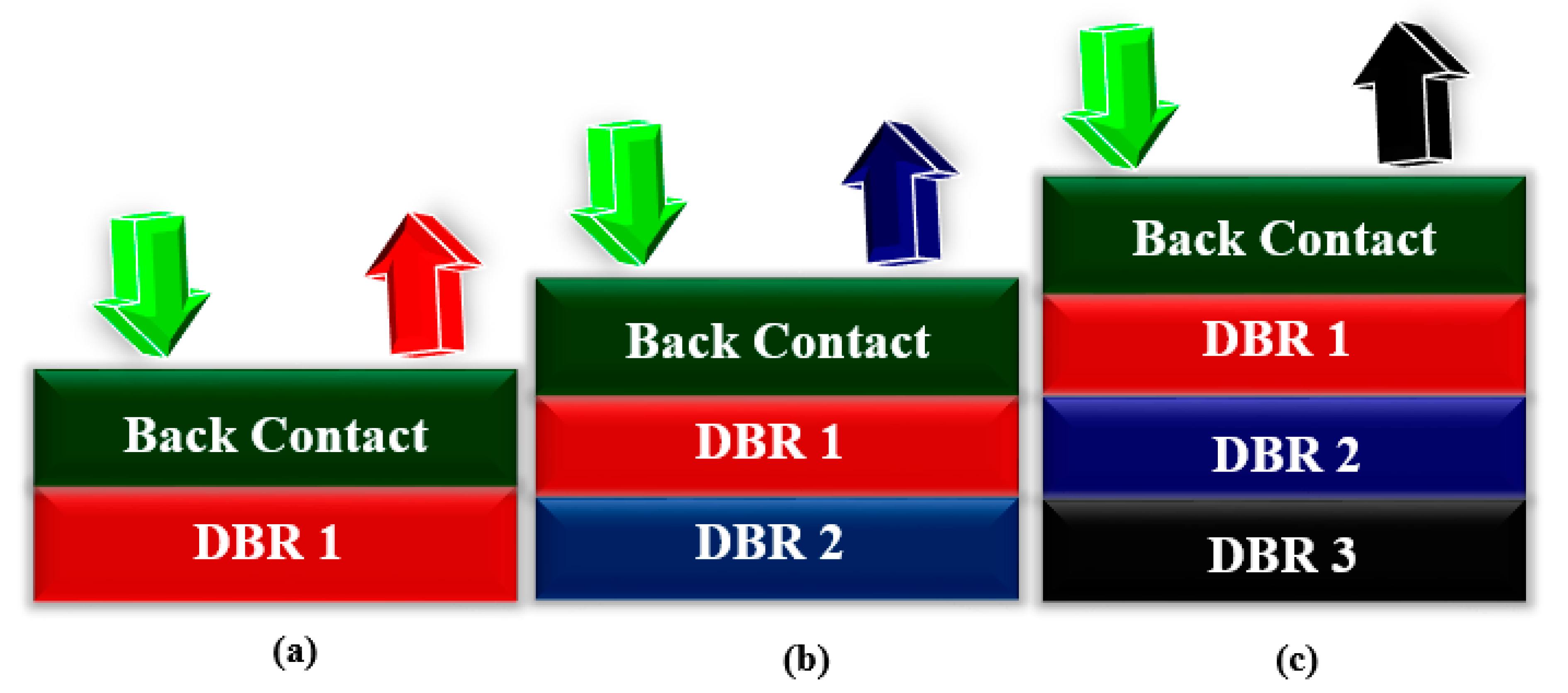

3.3. Implanting DBR Pairs

3.4. Thermal Stability Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benghanem, M.; Almohammedi, A. Organic Solar Cells: A Review. In A Practical Guide for Advanced Methods in Solar Photovoltaic Systems; Springer: Berlin/Heidelberg, Germany, 2020; pp. 81–106. [Google Scholar]

- Gu, Y.; Liu, Y.; Russell, T.P. Fullerene-Based Interlayers for Breaking Energy Barriers in Organic Solar Cells. ChemPlusChem 2020, 85, 751–759. [Google Scholar] [CrossRef]

- Firdaus, Y.; He, Q.; Lin, Y.; Nugroho, F.A.A.; Le Corre, V.M.; Yengel, E.; Balawi, A.H.; Seitkhan, A.; Laquai, F.; Langhammer, C.; et al. Novel wide-bandgap non-fullerene acceptors for efficient tandem organic solar cells. J. Mater. Chem. A 2020, 8, 1164–1175. [Google Scholar] [CrossRef]

- Xue, R.; Zhang, J.; Li, Y.; Li, Y. Organic solar cell materials toward commercialization. Small 2018, 14, 1801793. [Google Scholar] [CrossRef]

- Cha, H.; Wu, J. Understanding what determines the organic solar cell stability. Joule 2021, 5, 1322–1325. [Google Scholar] [CrossRef]

- Zhu, C.; Huang, H.; Jia, Z.; Cai, F.; Li, J.; Yuan, J.; Meng, L.; Peng, H.; Zhang, Z.; Zou, Y.; et al. Spin-coated 10.46% and blade-coated 9.52% of ternary semitransparent organic solar cells with 26.56% average visible transmittance. Sol. Energy 2020, 204, 660–666. [Google Scholar] [CrossRef]

- Farooq, W.; Alshahrani, T.; Kazmi, S.A.A.; Iqbal, J.; Khan, H.A.; Khan, M.; Raja, A.A.; Rehman, A.U. Materials optimization for thin-film copper indium gallium selenide (CIGS) solar cell based on distributed braggs reflector. Optik 2021, 227, 165987. [Google Scholar] [CrossRef]

- Kazmi, S.A.A.; Khan, A.D.; Khan, A.D.; Rauf, A.; Farooq, W.; Noman, M.; Ali, H. Efficient materials for thin-film CdTe solar cell based on back surface field and distributed Bragg reflector. Appl. Phys. A 2020, 126, 46. [Google Scholar] [CrossRef]

- He, Z.; Zhong, C.; Su, S.; Xu, M.; Wu, H.; Cao, Y. Enhanced power-conversion efficiency in polymer solar cells using an inverted device structure. Nat. Photonics 2012, 6, 591–595. [Google Scholar] [CrossRef]

- Farooq, W.; Khan, A.D.; Khan, A.D.; Rauf, A.; Khan, S.D.; Ali, H.; Iqbal, J.; Khan, R.U.; Noman, M. Thin-film tandem organic solar cells with improved efficiency. IEEE Access 2020, 8, 74093–74100. [Google Scholar] [CrossRef]

- Ompong, D.; Narayan, M.; Singh, J. Optimization of photocurrent in bulk heterojunction organic solar cells using optical admittance analysis method. J. Mater. Sci. Mater. Electron. 2017, 28, 7100–7106. [Google Scholar] [CrossRef]

- Murugesan, V.S.; Ono, S.; Tsuda, N.; Yamada, J.; Shin, P.-K.; Ochiai, S. Characterization of organic thin film solar cells of PCDTBT: PC71BM prepared by different mixing ratio and effect of hole transport layer. Int. J. Photoenergy 2015, 2015, 687678. [Google Scholar] [CrossRef]

- Ourahmoun, O. Effect of the interfacial materials on the performance of organic photovoltaic cells. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Hamed, M.; Oseni, S.O.; Kumar, A.; Sharma, G.; Mola, G.T. Nickel sulphide nano-composite assisted hole transport in thin film polymer solar cells. Solar Energy 2020, 195, 310–317. [Google Scholar] [CrossRef]

- Sartorio, C.; Campisciano, V.; Chiappara, C.; Cataldo, S.; Scopelliti, M.; Gruttadauria, M.; Giacalone, F.; Pignataro, B. Enhanced power-conversion efficiency in organic solar cells incorporating copolymeric phase-separation modulators. J. Mater. Chem. A 2018, 6, 3884–3894. [Google Scholar] [CrossRef]

- Jiang, P.; Lu, H.; Jia, Q.Q.; Feng, S.; Li, C.; Li, H.B.; Bo, Z. Dihydropyreno [1, 2-b: 6, 7-b′] dithiophene based electron acceptors for high efficiency as-cast organic solar cells. J. Mater. Chem. A 2019, 7, 5943–5948. [Google Scholar] [CrossRef]

- Park, S.; Kang, R.; Cho, S. Effect of an Al-doped ZnO electron transport layer on the efficiency of inverted bulk heterojunction solar cells. Curr. Appl. Phys. 2020, 20, 172–177. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, M.; Liu, C.; Li, Z.; Fu, D.; Guo, W. Realizing efficiency improvement of polymer solar cells by using multi-functional cascade electron transport layers. Org. Electron. 2020, 76, 105482. [Google Scholar] [CrossRef]

- Mohammad, T.; Kumar, V.; Dutta, V. Spray deposited indium doped tin oxide thin films for organic solar cell application. Phys. E Low-Dimens. Syst. Nanostruct. 2020, 117, 113793. [Google Scholar] [CrossRef]

- Wu, M.; Shi, L.; Hu, Y.; Chen, L.; Hu, T.; Zhang, Y.; Yuan, Z.; Chen, Y. Additive-free non-fullerene organic solar cells with random copolymers as donors over 9% power conversion efficiency. Chin. Chem. Lett. 2019, 30, 1161–1167. [Google Scholar] [CrossRef]

- Özen, Y. The enhancement in cell performance of CdTe-based solar cell with Si/SiO2 distributed Bragg reflectors. Appl. Phys. A 2020, 126, 632. [Google Scholar] [CrossRef]

- Rouhbakhshmeghrazi, A.; Madadi, M. Novel Design of polycrystalline CdTe/Si Tandem Solar Cells Using SiO2/TiO2 Distributed Bragg Reflector. Tecciencia 2020, 15, 67–75. [Google Scholar] [CrossRef]

- Yu, W.; Fu, X.; Dong, K. Study of semitransparent polymer solar cells with ZnSe/LiF distributed Bragg Reflector. J. Mater. Sci. Mater. Electron. 2021, 32, 13409–13417. [Google Scholar] [CrossRef]

- Wang, H.-Q.; Li, N.; Guldal, N.S.; Brabec, C.J. Nanocrystal V2O5 thin film as hole-extraction layer in normal architecture organic solar cells. Org. Electron. 2012, 13, 3014–3021. [Google Scholar] [CrossRef]

- Brédas, J.-L.; Norton, J.E.; Cornil, J.; Coropceanu, V. Molecular understanding of organic solar cells: The challenges. Acc. Chem. Res. 2009, 42, 1691–1699. [Google Scholar] [CrossRef]

- Stelling, C.; Singh, C.R.; Karg, M.; König, T.A.F.; Thelakkat, M.; Retsch, M. Plasmonic nanomeshes: Their ambivalent role as transparent electrodes in organic solar cells. Sci. Rep. 2017, 7, 42530. [Google Scholar] [CrossRef] [PubMed]

- Roy, A.; Bhandari, S.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Incorporating Solution-Processed Mesoporous WO3 as an Interfacial Cathode Buffer Layer for Photovoltaic Applications. J. Phys. Chem. A 2020, 124, 5709–5719. [Google Scholar] [CrossRef] [PubMed]

- MacKenzie, R.C.I.; Kirchartz, T.; Dibb, G.F.A.; Nelson, J. Modeling nongeminate recombination in P3HT: PCBM solar cells. J. Phys. Chem. C 2011, 115, 9806–9813. [Google Scholar] [CrossRef]

- Khan, A.D.; Iqbal, J.; Rehman, S.U. Polarization-sensitive perfect plasmonic absorber for thin-film solar cell application. Appl. Phys. A 2018, 124, 610. [Google Scholar] [CrossRef]

- Kosyachenko, L.; Savchuk, A.; Grushko, E. Dependence of efficiency of thin-film CdS/CdTe solar cell on parameters of absorber layer and barrier structure. Thin Solid Film. 2009, 517, 2386–2391. [Google Scholar] [CrossRef]

- Kim, M.-S.; Kim, B.-G.; Kim, J. Effective variables to control the fill factor of organic photovoltaic cells. ACS Appl. Mater. Interfaces 2009, 1, 1264–1269. [Google Scholar] [CrossRef]

- Chen, S.; Small, C.E.; Amb, C.M.; Subbiah, J.; Lai, T.-H.; Tsang, S.-W.; Manders, J.R.; Reynolds, J.R.; So, F. Inverted polymer solar cells with reduced interface recombination. Adv. Energy Mater. 2012, 2, 1333–1337. [Google Scholar] [CrossRef]

- Khan, A.D.; Khan, A.D. Optimization of highly efficient GaAs–silicon hybrid solar cell. Appl. Phys. A 2018, 124, 851. [Google Scholar] [CrossRef]

- Sen, S.; Islam, R. Effect of Different Layers on the Performance of P3HT: PCBM-Based Organic Solar Cell. Braz. J. Phys. 2021, 51, 1661–1669. [Google Scholar] [CrossRef]

- Zidan, M.N.; Ismail, T.; Fahim, I.S. Effect of thickness and temperature on flexible organic P3HT: PCBM solar cell performance. Mater. Res. Express 2021, 8, 095508. [Google Scholar] [CrossRef]

- Khairulaman, F.L.; Yap, C.C.; Jumali, M.H.H. Improved performance of inverted type organic solar cell using copper iodide-doped P3HT: PCBM as active layer for low light application. Mater. Lett. 2021, 283, 128827. [Google Scholar] [CrossRef]

- Bendenia, C.; Merad-Dib, H.; Bendenia, S.; Bessaha, G.; Hadri, B. Theoretical study of the impact of the D/A system polymer and anodic interfacial layer on inverted organic solar cells (BHJ) performance. Opt. Mater. 2021, 121, 111588. [Google Scholar] [CrossRef]

- Moujoud, S.; Hartiti, B.; Touhtouh, S.; Rachidy, C.; Belhora, F.; Thevenin, P.; Hajjaji, A. Numerical modeling of copper indium disulfide thin film based solar cells. Opt. Mater. 2021, 122, 111749. [Google Scholar] [CrossRef]

- Al-Hattab, M.; Moudou, L.; Khenfouch, M.; Bajjou, O.; Chrafih, Y.; Rahmani, K. Numerical simulation of a new heterostructure CIGS/GaSe solar cell system using SCAPS-1D software. Sol. Energy 2021, 227, 13–22. [Google Scholar] [CrossRef]

- Jamal, S.; Khan, A.D.; Khan, A.D. High performance perovskite solar cell based on efficient materials for electron and hole transport layers. Optik 2020, 218, 164787. [Google Scholar] [CrossRef]

- Kumar, A. Impact of selenium composition variation in CZTS solar cell. Optik 2021, 234, 166421. [Google Scholar] [CrossRef]

- Islam, A.; Islam, S.; Sobayel, K.; Emon, E.; Jhuma, F.; Shahiduzzaman, M.; Akhtaruzzaman, M.; Amin, N.; Rashid, M. Performance analysis of tungsten disulfide (WS2) as an alternative buffer layer for CdTe solar cell through numerical modeling. Opt. Mater. 2021, 120, 111296. [Google Scholar] [CrossRef]

- Barman, B.; Kalita, P. Influence of back surface field layer on enhancing the efficiency of CIGS solar cell. Sol. Energy 2021, 216, 329–337. [Google Scholar] [CrossRef]

| Layers | Thickness (nm) | Composition | Role |

|---|---|---|---|

| FTO | 125 | Transparent Conductive Oxide | Electrode |

| V2O5 | 70 | Inorganic | HTL |

| PTB7:PCBM | 180 | Organic | Active Layer |

| PCBM | 10 | Organic | ETL |

| ZnO | 5 | Inorganic | ETL |

| W03 | 70 | Inorganic | ETL |

| Ag | 100 | Metal | Electrode |

| DBR | 450 | Inorganic | Back Reflector |

| Ref | Struture | Method | Junction Mode | η |

|---|---|---|---|---|

| [34] | Substrate/ITO/PEDOT:PSS/P3HT:PCBM/TiOx/Al | Computational | Single | 5.14 |

| [34] | Substrate/ITO/PEDOT:PSS/P3HT:PCBM/PCBM/Al | Computational | Single | 4.95 |

| [35] | PET/ITO/PEDOT:PSS/P3HT:PCBM/Al | Computational | Single | 4.34 |

| [36] | Glass/FTO/ZnO/doped P3HT:PCBM/Ag | Experimental | Single | 4.84 |

| [37] | ITO/ZnO/PTB7:PCBM/PEDOT:PSS/Ag | Computational | Single | 5.73 |

| [37] | ITO/ZnO/PTB7:PCBM/MoO3/Ag | Computational | Single | 5.92 |

| [38] | ZnO:Al/i-ZnO/CdS/CuInS2/Cu2O/Mo | Computational | Single | 22.73 |

| [38] | ZnO:Al/i-ZnO/SnS2/CuInS2/Cu2O/Mo | Computational | Single | 21.62 |

| [39] | ITO/GaSe/CIGS-P+ /Back Contact/Glass | Computational | Single | 33.36 |

| [40] | Glass/ZnO:Al/In2S3/CH3NH3PbI3/Spiro-OMeTAD/Au | Computational | Single | 23.05 |

| [41] | AZO/ZnO/CdS/Cu2ZnSnS1.8Se2.2/Back contact/Glass substrate | Computational | Single | 15.3 |

| [42] | SLG/ITO/WS2/CdTe/Au | Computational | Single | 20.55 |

| [43] | Al/ITO/Al-ZnO/i-ZnO/CIGS/PbS/Mo | Computational | Single | 24.22 |

| Present Work | Glass/FTO/V2O5/PTB7:PCBM/PCBM/ZnO/WO3/Ag/DBR | Computational | Single | 11.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farooq, W.; Musarat, M.A.; Iqbal, J.; Kazmi, S.A.A.; Khan, A.D.; Alaloul, W.S.; Baarimah, A.O.; Elnaggar, A.Y.; Ghoneim, S.S.M.; Ghaly, R.N.R. Optimized Thin-Film Organic Solar Cell with Enhanced Efficiency. Sustainability 2021, 13, 13087. https://doi.org/10.3390/su132313087

Farooq W, Musarat MA, Iqbal J, Kazmi SAA, Khan AD, Alaloul WS, Baarimah AO, Elnaggar AY, Ghoneim SSM, Ghaly RNR. Optimized Thin-Film Organic Solar Cell with Enhanced Efficiency. Sustainability. 2021; 13(23):13087. https://doi.org/10.3390/su132313087

Chicago/Turabian StyleFarooq, Waqas, Muhammad Ali Musarat, Javed Iqbal, Syed Asfandyar Ali Kazmi, Adnan Daud Khan, Wesam Salah Alaloul, Abdullah O. Baarimah, Ashraf Y. Elnaggar, Sherif S. M. Ghoneim, and Ramy N. R. Ghaly. 2021. "Optimized Thin-Film Organic Solar Cell with Enhanced Efficiency" Sustainability 13, no. 23: 13087. https://doi.org/10.3390/su132313087