Cyclic Shear Performance of Reinforced Concrete Columns Strengthened by External Steel Rods

Abstract

:1. Introduction

2. Strengthening Method Using External Prestressing Steel Rods and Corner Blocks

3. Experimental Program

3.1. Materials

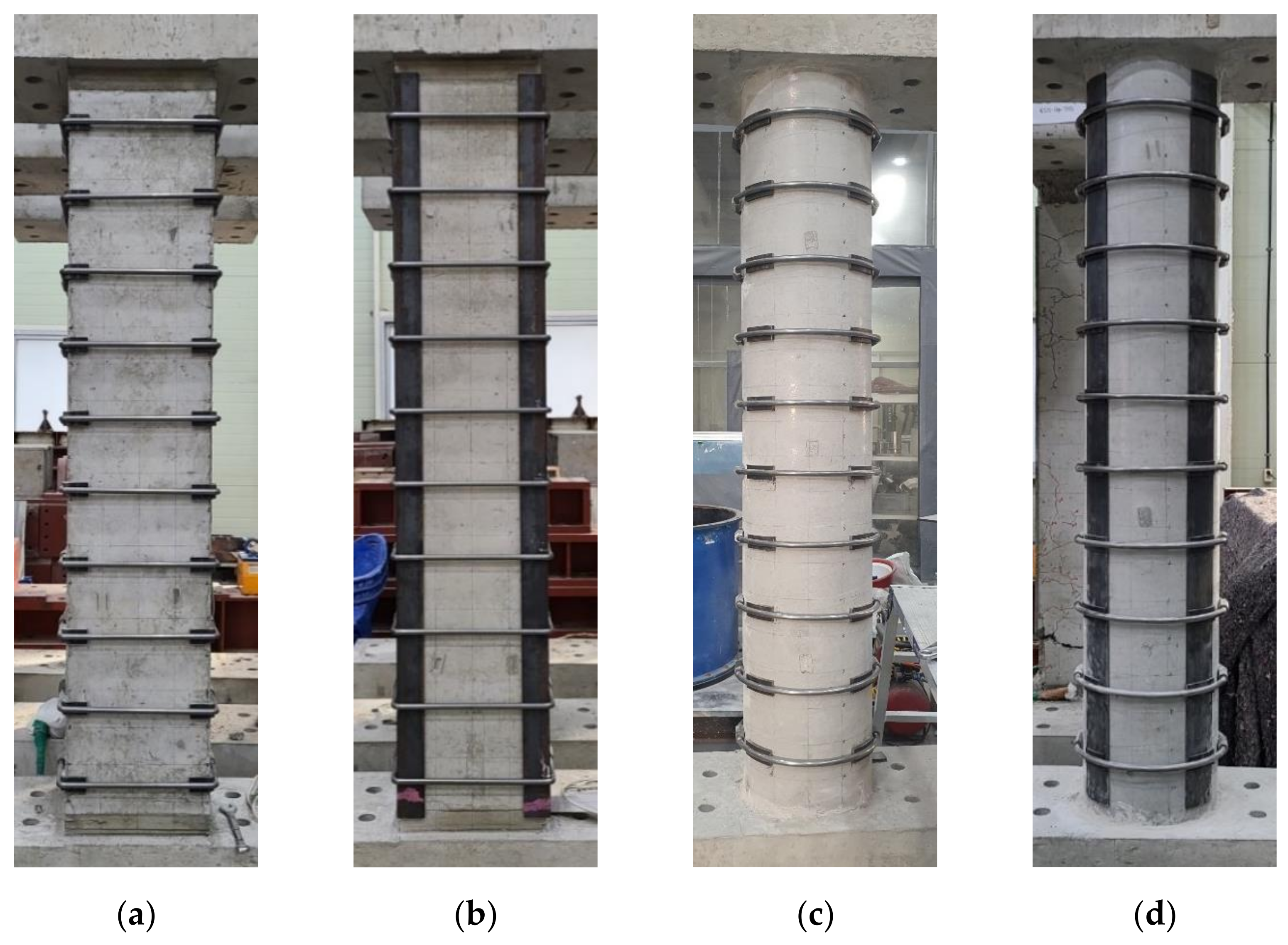

3.2. Description of Specimens

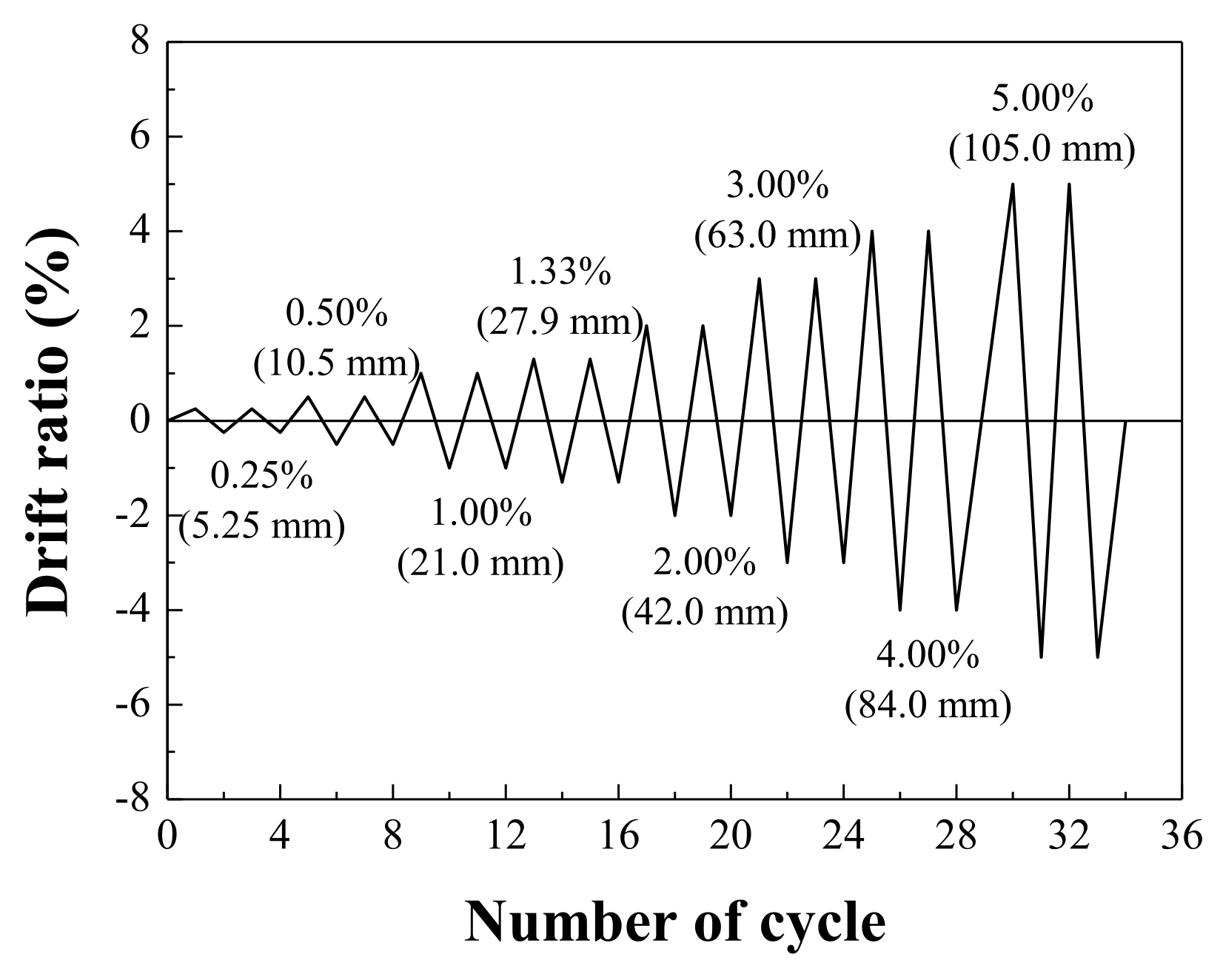

3.3. Loading and Measurement Plans

4. Experimental Results and Discussion

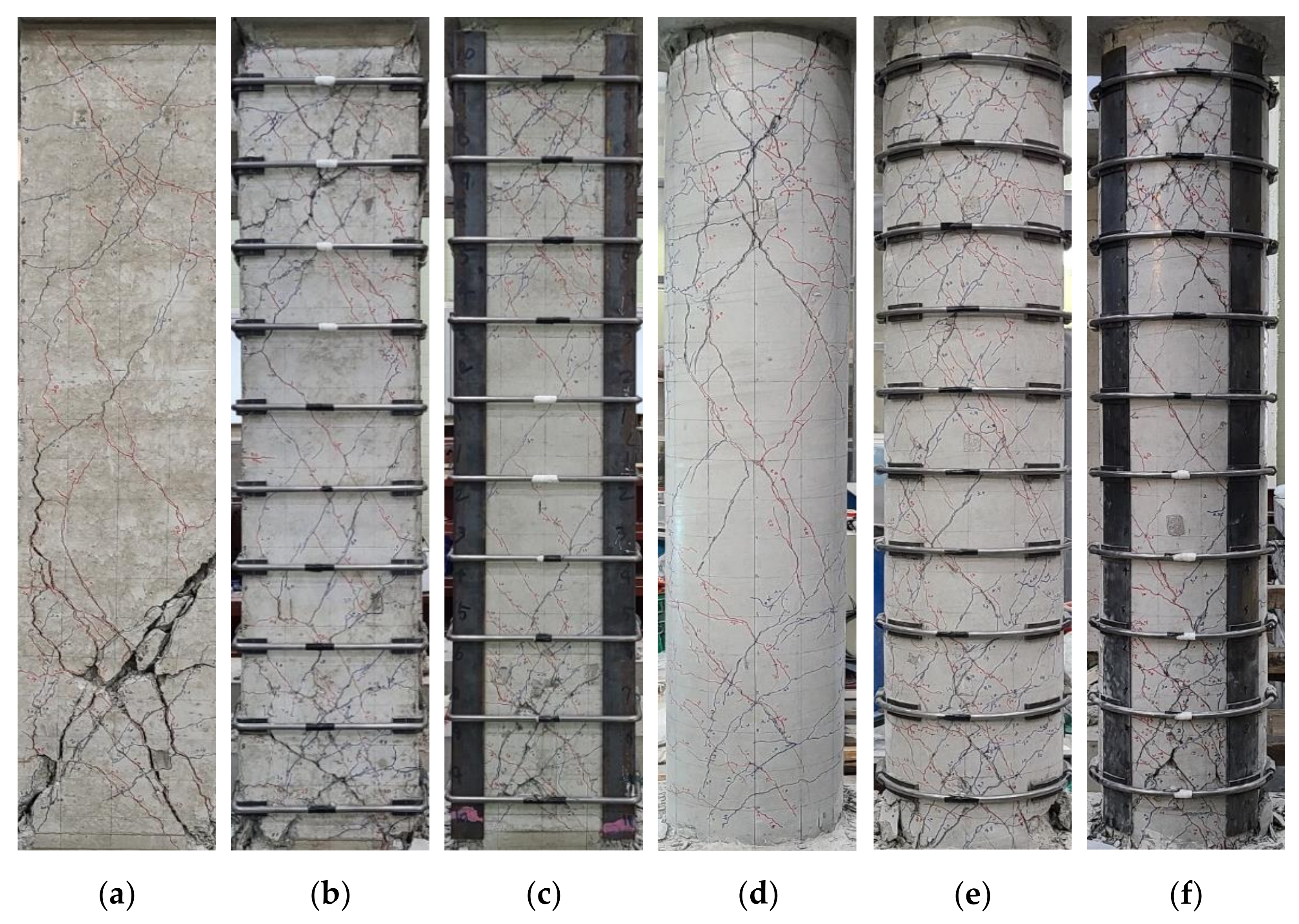

4.1. Load-Drift Ratio Hysteretic Curve and Failure Mode

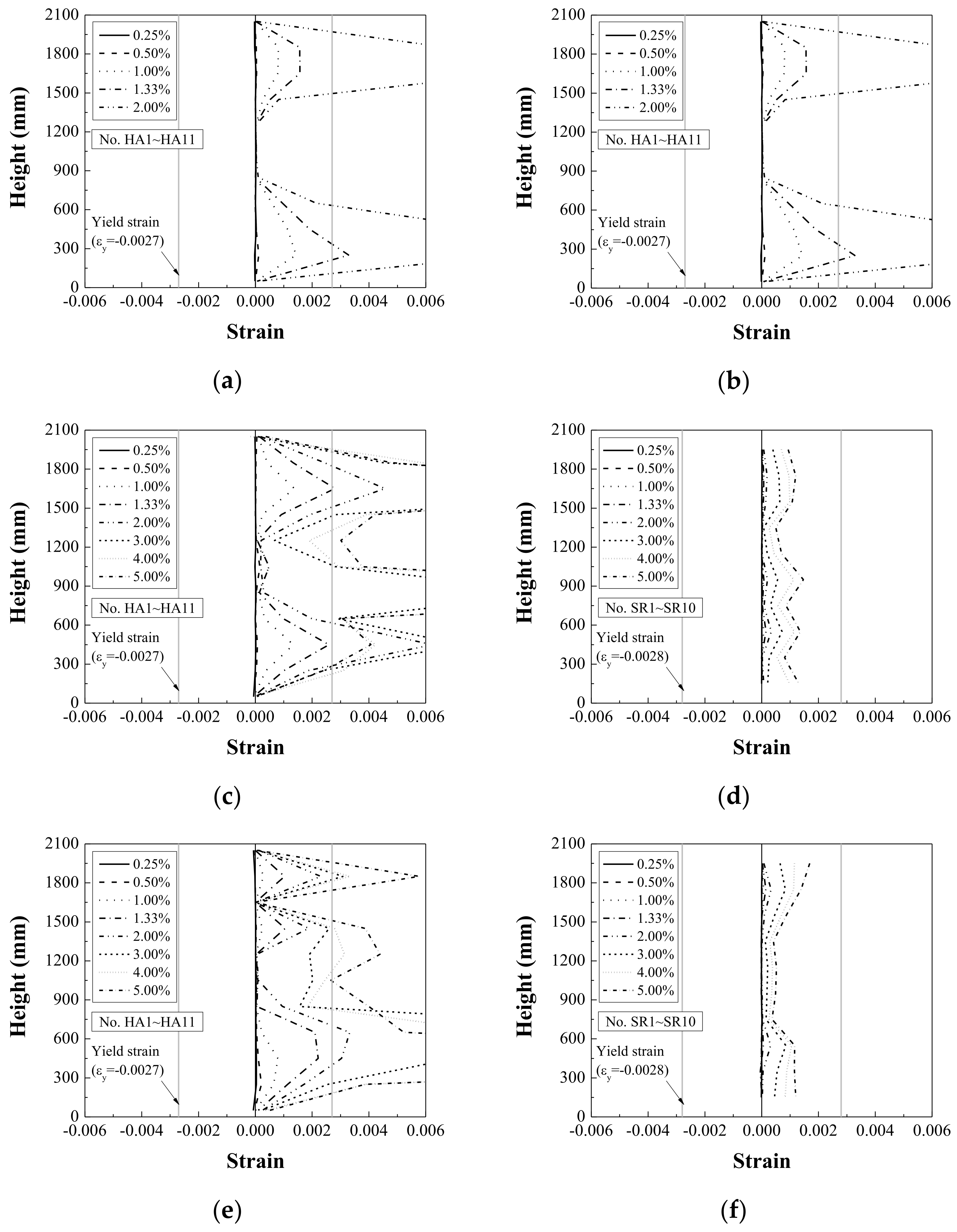

4.2. Characteristics of Strain Distribution

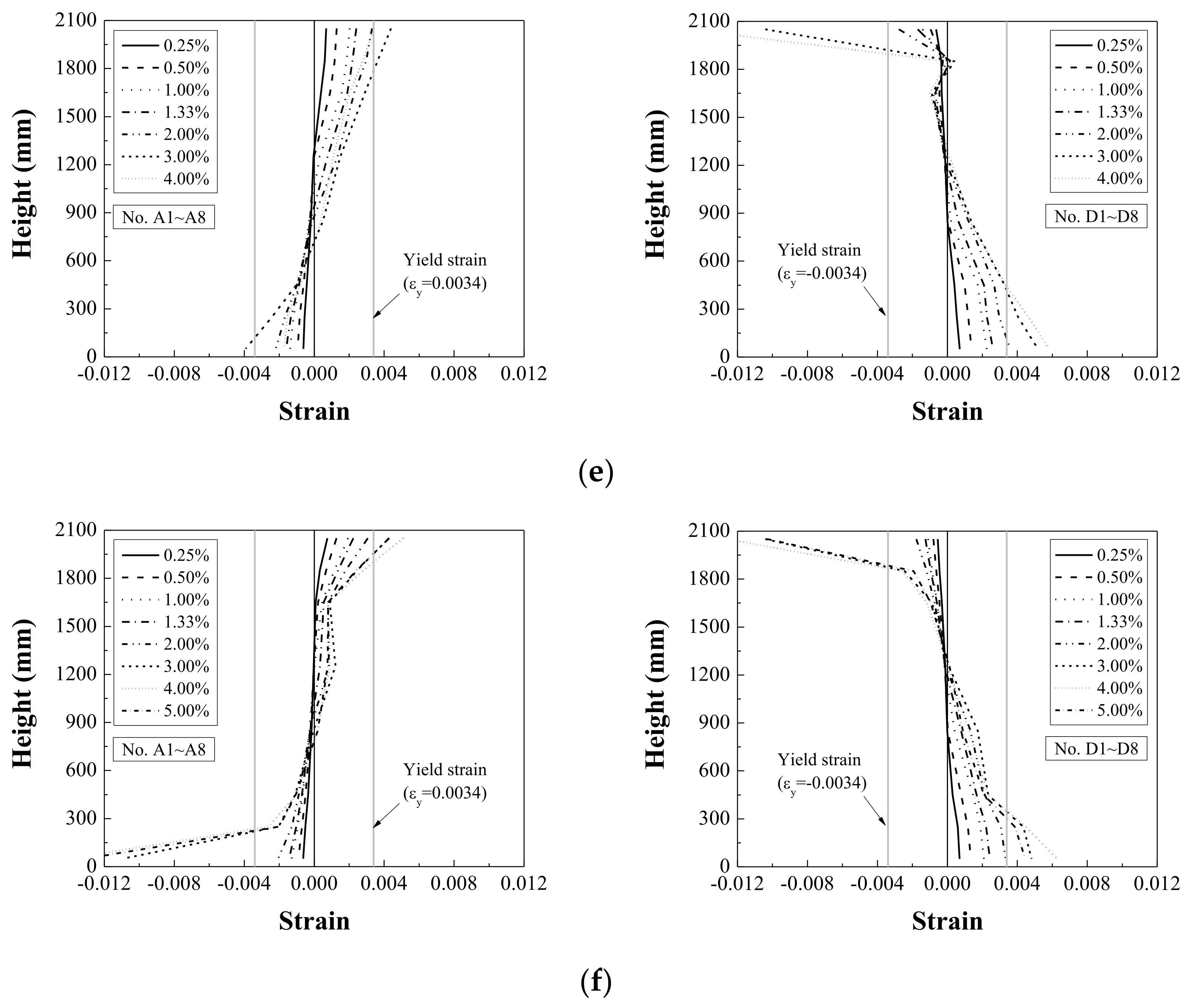

4.2.1. Strain Distribution in Longitudinal Rebars

4.2.2. Strain Distribution in Hoops and Steel Rods

4.3. Reinforcement Effect

4.3.1. Stiffness Degradation

4.3.2. Displacement Ductility

4.3.3. Energy Dissipation Capacity

4.3.4. Damage Assessment

4.4. Shear and Ultimate Strengths in the Flexure of Externally Strengthened RC Columns

5. Conclusions

- The initial elastic stiffness was not increased in the specimens strengthened by the external steel rods with a low prestress level at a drift ratio of 0.25 to 0.50% before the occurrence of the flexure-shear cracks. However, the external steel rods suppressed the expansion of the diagonal tensile cracks generated in the specimens at a larger drift ratio, so the load-carrying capacity of the columns was improved by more than 1.2 times.

- Installing the external steel rods and the L-type corner blocks improved the transverse concrete confinement and the bond strength of the longitudinal rebars; moreover, this induced flexural failure with a ductility higher than three in the strengthened columns.

- The evaluation of the damage degree level of the specimens showed that, while the control specimens reached collapse level at a drift ratio of 2.0%, the strengthened ones reached collapse level at a drift ratio of 4.0 to 5.0%. It was found that the proposed strengthening method can effectively improve the seismic capacity of RC columns.

- The flexural analysis considering the hoops and external steel rods’ average yield strength, the cross-section’s average dimensions, and the confined concrete strength can reasonably predict the failure mode, the shear strength, and the ultimate flexural strength of RC columns strengthened by the external steel rods. Further studies are needed on the effect of prestressing and axial load levels on the transverse confinement of concrete and the strength and ductility capacity of column members.

- The experimental and analytical results showed the possibility that the proposed strengthening method can improve the lifespan expectancy and the service life of existing RC structures against seismic events by suppressing the expansion of cracks in columns damaged due to deterioration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yarandi, M.S.; Saatcioglu, M.; Foo, S. Rectangular concrete columns retrofitted by external prestressing for seismic shear re-sistance. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004; p. 2720. [Google Scholar]

- Andrawes, B.; Shin, M.; Wierschem, N. Active Confinement of Reinforced Concrete Bridge Columns Using Shape Memory Alloys. J. Bridg. Eng. 2010, 15, 81–89. [Google Scholar] [CrossRef]

- California Department of Transportation. Seismic Design Criteria, Version 2.1; Caltrans: Sacramento, CA, USA, 2019.

- Miyagi, T.; Yamagawa, T.; Li, W.; Rahman, M.N. A study on emergency retrofit using prestressing bars and steel plates for damaged columns. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004; p. 1169. [Google Scholar]

- Zhang, D.; Ueda, T.; Furuuchi, H. Concrete cover separation failure of overlay-strengthened reinforced concrete beams. Constr. Build. Mater. 2012, 26, 735–745. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Thermou, G.E.; Pantazopoulou, S.J. Behavior of rehabilitated RC beams with self-compacting concrete jacketing – Analytical model and test results. Constr. Build. Mater. 2014, 55, 257–273. [Google Scholar] [CrossRef]

- Zhang, D.; Li, N.; Li, Z.-X.; Xie, L. Rapid repair of RC bridge columns with prestressed stainless-steel hoops and stainless-steel jackets. J. Constr. Steel Res. 2021, 177, 106441. [Google Scholar] [CrossRef]

- Ren, Z.; Zeng, X.; Sun, J. Using Two-Way Prestressed Semicircular Steel Plate for Construction of Reinforced Concrete Cylinder Column. Complexity 2018, 2018, 1481837. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Hwang, J.; Chen, S.; Hsieh, Y. A study of reinforced concrete bridge columns retrofitted by steel jackets. J. Chin. Inst. Eng. 2005, 28, 319–328. [Google Scholar] [CrossRef]

- Lin, M.-L.; Chen, P.-C.; Tsai, K.-C.; Yu, Y.-J.; Liu, J.-G. Seismic steel jacketing of rectangular RC bridge columns for the mitigation of lap-splice failures. Earthq. Eng. Struct. Dyn. 2010, 39, 1687–1710. [Google Scholar] [CrossRef]

- Choi, E.; Chung, Y.-S.; Park, C.; Kim, D.J. Seismic performance of circular RC columns retrofitted with prefabricated steel wrapping jackets. Mag. Concr. Res. 2013, 65, 1429–1440. [Google Scholar] [CrossRef]

- Hawileh, R.; Naser, M.Z.; Zaidan, W.; Rasheed, H. Modeling of insulated CFRP-strengthened reinforced concrete T-beam exposed to fire. Eng. Struct. 2009, 31, 3072–3079. [Google Scholar] [CrossRef]

- Mofidi, A.; Chaallal, O. Tests and Design Provisions for Reinforced-Concrete Beams Strengthened in Shear Using FRP Sheets and Strips. Int. J. Concr. Struct. Mater. 2014, 8, 117–128. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.-F.; Liu, K. Characterization of Mechanically Enhanced FRP Bonding System. J. Compos. Constr. 2013, 17, 34–49. [Google Scholar] [CrossRef]

- Capani, F.; D’Ambrisi, A.; De Stefano, M.; Focacci, F.; Luciano, R.; Nudo, R.; Penna, R. Experimental investigation on cyclic response of RC elements repaired by CFRP external reinforcing systems. Compos. Part B Eng. 2017, 112, 290–299. [Google Scholar] [CrossRef] [Green Version]

- Obaidat, Y.T.; Ashteyat, A.M.; Obaidat, A.T.; Alfaris, S.F. A new technique for repairing reinforced concrete columns. J. Build. Eng. 2020, 30, 101256. [Google Scholar] [CrossRef]

- Wang, J.; Yang, J.; Cheng, L. Experimental Study of Seismic Behavior of High-Strength RC Columns Strengthened with CFRP Subjected to Cyclic Loading. J. Struct. Eng. 2019, 145, 04018240. [Google Scholar] [CrossRef]

- Kothandaraman, S.; Vasudevan, G. Flexural retrofitting of RC beams using external bars at soffit level – An experimental study. Constr. Build. Mater. 2010, 24, 2208–2216. [Google Scholar] [CrossRef]

- Demir, A.; Ercan, E.; Demir, D.D. Strengthening of reinforced concrete beams using external steel members. Steel Compos. Struct. 2018, 27, 453–464. [Google Scholar]

- Saatcioglu, M.; Yalcin, C. External Prestressing Concrete Columns for Improved Seismic Shear Resistance. J. Struct. Eng. 2003, 129, 1057–1070. [Google Scholar] [CrossRef]

- Deng, Z.C.; Jumbe, R.; Li, H. Seismic Behavior of Short Concrete Columns with Prestressing Steel Wires. Adv. Mater. Sci. Eng. 2014, 2014, 180193. [Google Scholar] [CrossRef]

- Li, Y.; Wu, M.; Wang, W.; Xue, X. Shear Behavior of RC Beams Strengthened by External Vertical Prestressing Rebar. Adv. Civ. Eng. 2021, 2021, 5483436. [Google Scholar] [CrossRef]

- Osman, B.H.; Wu, E.; Bohai, J.; Abdallah, M. Repair technique of pre-cracked reinforced concrete (RC) beams with transverse openings strengthened with steel plate under sustained load. J. Adhes. Sci. Technol. 2017, 31, 2360–2379. [Google Scholar] [CrossRef]

- Yang, S.-H.; Cao, S.-Y.; Gu, R.-N. New technique for strengthening reinforced concrete beams with composite bonding steel plates. Steel Compos. Struct. 2015, 19, 735–757. [Google Scholar] [CrossRef]

- Hamad, B.; Masri, A.; Basha, H.; Baalbaki, O. Behavior of T-shaped reinforced concrete beams partially confined by structural steel. Constr. Build. Mater. 2011, 25, 1037–1043. [Google Scholar] [CrossRef]

- Su, R.; Siu, W.; Smith, S. Effects of bolt–plate arrangements on steel plate strengthened reinforced concrete beams. Eng. Struct. 2010, 32, 1769–1778. [Google Scholar] [CrossRef]

- Swamy, R.N.; Jones, R.; Charif, A. The effect of external plate reinforcement on the strengthening of structurally damaged RC beams. Struct. Eng. 2008, 67, 45–56. [Google Scholar]

- Arslan, G.; Sevuk, F.; Ekiz, I. Steel plate contribution to load-carrying capacity of retrofitted RC beams. Constr. Build. Mater. 2008, 22, 143–153. [Google Scholar] [CrossRef]

- Afshin, H.; Shirazi, M.R.N.; Abedi, K. Experimental and numerical study about seismic retrofitting of corrosion – damaged reinforced concrete columns of bridge using combination of FRP wrapping and steel profiles. Steel Compos. Struct. 2019, 30, 231–251. [Google Scholar]

- Chou, C.C.; Lee, C.S.; Wu, K.Y.; Chin, V.L. Development and validation of a FRP-wrapped spiral corrugated tube for seismic performance of circular concrete columns. Constr. Build. Mater. 2018, 170, 489–511. [Google Scholar] [CrossRef]

- Chrysanidis, T.; Tegos, I. Axial and transverse strengthening of R/C circular columns: Conventional and new type of steel and hybrid jackets using high-strength mortar. J. Build. Eng. 2020, 30, 101236. [Google Scholar] [CrossRef]

- Zhang, D.; Li, N.; Li, Z.-X.; Xie, L. Experimental investigation and confinement model of composite confined concrete using steel jacket and prestressed steel hoop. Constr. Build. Mater. 2020, 256, 119399. [Google Scholar] [CrossRef]

- Fakharifar, M.; Chen, G.; Arezoumandi, M.; ElGawady, M.; Information, R. Hybrid Jacketing for Rapid Repair of Seismically Damaged Reinforced Concrete Columns. Transp. Res. Rec. J. Transp. Res. Board 2015, 2522, 70–78. [Google Scholar] [CrossRef]

- Li, J.; Gong, J.; Wang, L. Seismic behavior of corrosion-damaged reinforced concrete columns strengthened using combined carbon fiber-reinforced polymer and steel jacket. Constr. Build. Mater. 2009, 23, 2653–2663. [Google Scholar] [CrossRef]

- Realfonzo, R.; Napoli, A. Cyclic Behavior of RC Columns Strengthened by FRP and Steel Devices. J. Struct. Eng. 2009, 135, 1164–1176. [Google Scholar] [CrossRef]

- Moghaddam, H.; Samadi, M.; Pilakoutas, K.; Mohebbi, S. Axial compressive behavior of concrete actively confined by metal strips; part A: Experimental study. Mater. Struct. 2010, 43, 1369–1381. [Google Scholar] [CrossRef]

- The World Green Building Council. Bringing Embodied Carbon Upfront-Coordinated Action for the Building and Construction Sector to Tackle Embodied Carbon; World Green Building Council: London, UK, 2019. [Google Scholar]

- Priestley, M.J.N.; Seible, F.; Calvi, G.M. Seismic Design and Retrofit of Bridges; John Wiley & Sons, Inc.: New York, NY, USA, 1996. [Google Scholar]

- Park, Y.; Ang, A.H. Mechanistic Seismic Damage Model for Reinforced Concrete. J. Struct. Eng. 1985, 111, 722–739. [Google Scholar] [CrossRef]

- Park, Y.; Ang, A.H.; Wen, Y.K. Seismic Damage Analysis of Reinforced Concrete Buildings. J. Struct. Eng. 1985, 111, 740–757. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical Stress-Strain Model for Confined Concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef] [Green Version]

- ACI Committee 318. In Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary (ACI 318R-19); American Concrete Institute: Farmington Hills, MI, USA, 2019; pp. 401–410.

| f’c | Gmax | W/C | S/a | Unit Weight (kg/m3) | ||||

|---|---|---|---|---|---|---|---|---|

| (MPa) | (mm) | (%) | (%) | W | C | S | G | AD |

| 30 | 25 | 36.4 | 45.2 | 162 | 460 | 785 | 970 | 4.46 |

| Specimen | b (mm) | h (mm) | a/d (-) | Longitudinal Rebar | Inner Hoop | External Steel Rod | Strengthening Method |

|---|---|---|---|---|---|---|---|

| S-N | 400 | 400 | 3.1 | 12-D22 fy = 650.7 MPa | D10@200 fy = 455.0 MPa | Φ13@200 fy = 544.1 MPa | None-strengthened |

| S-P | S-type corner block | ||||||

| S-F | L-type corner block | ||||||

| C-N | 400(D) | None-strengthened | |||||

| C-P | S-type corner block | ||||||

| C-F | L-type corner block | ||||||

| Specimen | Load (Pi) and Drift Angle (α) | Failure Mode | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pcr | α | Pyh | α | Pyl | α | Pm | α | Pu | α | ||

| (kN) | (%) | (kN) | (%) | (kN) | (%) | (kN) | (%) | (kN) | (%) | ||

| S–N | 163.4 | 0.25 | 227.2 | 0.97 | − | − | −350.2 | ∑∑1.34 | −297.7 | −1.51 | Shear |

| S–P | 170.0 | 0.25 | 351.3 | 1.29 | 402.4 | 1.74 | 448.0 | 2.76 | 380.8 | 4.85 | Shear-flexural |

| S–F | 168.0 | 0.25 | −355.0 | −1.29 | 432.5 | 1.93 | 451.1 | 2.96 | 383.4 | 5.00 | Shear-flexural |

| C–N | 117.0 | 0.25 | 239.5 | 1.19 | 236.0 | 1.33 | 296.1 | 1.96 | 251.7 | 2.00 | Shear |

| C–P | 110.6 | 0.25 | 290.4 | 1.68 | −290.2 | -1.28 | −343.5 | −2.02 | -291.9 | −3.26 | Flexure |

| C–F | 119.6 | 0.25 | 320.5 | 1.76 | −257.3 | -1.09 | 345.7 | 2.70 | 293.8 | 4.43 | Flexure |

| Specimen | At Pcr | At Pyl | At Pm | At Pu | μ | ||||

|---|---|---|---|---|---|---|---|---|---|

| Δcr | kcr | Δy | ky | Δm | km | Δu | ku | ||

| (mm) | (kN/mm) | (mm) | (kN/mm) | (mm) | (kN/mm) | (mm) | (kN/mm) | (mm/mm) | |

| S-N | 5.3 | 31.1 | 18.1 | 19.0 | 27.8 | 12.3 | 33.4 | 8.7 | 1.85 |

| S-P | 5.3 | 32.4 | 31.4 | 14.2 | 50.0 | 8.9 | 96.8 | 3.9 | 3.09 |

| S-F | 5.3 | 32.0 | 31.7 | 14.0 | 62.6 | 7.1 | 105.0 | 3.6 | 3.31 |

| C-N | 5.3 | 22.3 | 22.5 | 12.7 | 34.5 | 8.3 | 42.0 | 5.8 | 1.87 |

| C-P | 5.3 | 21.1 | 31.8 | 10.5 | 50.1 | 6.7 | 76.2 | 3.7 | 2.39 |

| C-F | 5.3 | 22.8 | 36.8 | 9.4 | 49.4 | 7.0 | 90.2 | 3.2 | 2.45 |

| Damage Level | Damage Index (DI) | Visual Damage State |

|---|---|---|

| Slight damage | DI < 0.1 | No damage or minor cracking |

| Minor damage | 0.1 < DI < 0.25 | Light cracking throughout |

| Moderate damage | 0.25 < DI < 0.4 | Extensive large cracks, spalling of concrete cover |

| Severe damage | 0.4 < DI < 1.0 | Extensive concrete crushing, visible buckling of reinforcement |

| Collapse | DI > 1.0 | Partial or total collapse of RC members |

| Specimen | Experimental Results (Vtest) | Analytical Results (Vanal) | Vanal/Vtest | |||||

|---|---|---|---|---|---|---|---|---|

| Vyh.e | Vyl.e | Vmax.e | Vn | Vy | Vu | Vmax.a | ||

| (kN) | (kN) | (kN) | (kN) | (kN) | (kN) | (kN) | ||

| S-N | 277.3 | - | 342.4 | 292.0 | - | - | 292.0 | 1.05 |

| S-P | 351.3 | 402.4 | 443.8 | 623.6 | 356.3 | 454.0 | 454.4 | 1.02 |

| S-F | 355.0 | 432.4 | 442.6 | 623.6 | 364.7 | 462.4 | 462.4 | 1.04 |

| C-N | 239.5 | - | 286.3 | 271.2 | - | - | 271.2 | 1.13 |

| C-P | 290.4 | 290.2 | 344.8 | 602.9 | 215.1 | 325.1 | 325.1 | 0.94 |

| C-F | 320.5 | 257.3 | 343.7 | 602.9 | 215.8 | 325.9 | 325.9 | 0.95 |

| Ave. | 1.02 | |||||||

| C.V(%) | 6.95 | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-G.; Lee, Y.-J.; Kim, K.-H. Cyclic Shear Performance of Reinforced Concrete Columns Strengthened by External Steel Rods. Sustainability 2021, 13, 13224. https://doi.org/10.3390/su132313224

Kim H-G, Lee Y-J, Kim K-H. Cyclic Shear Performance of Reinforced Concrete Columns Strengthened by External Steel Rods. Sustainability. 2021; 13(23):13224. https://doi.org/10.3390/su132313224

Chicago/Turabian StyleKim, Hyeong-Gook, Yong-Jun Lee, and Kil-Hee Kim. 2021. "Cyclic Shear Performance of Reinforced Concrete Columns Strengthened by External Steel Rods" Sustainability 13, no. 23: 13224. https://doi.org/10.3390/su132313224