Effect of Emitter Modifications on Spray Performance of a Solid Set Canopy Delivery System in a High-Density Apple Orchard

Abstract

:1. Introduction

- The design and fabrication of micro-emitter impactor plates intended to achieve uniform and efficient spray performance through modified emitters.

- Field evaluation of modified emitters integrated into SSCDS configurations suitable for a high-density apple orchard trained in a tall spindle architecture.

2. Materials and Methods

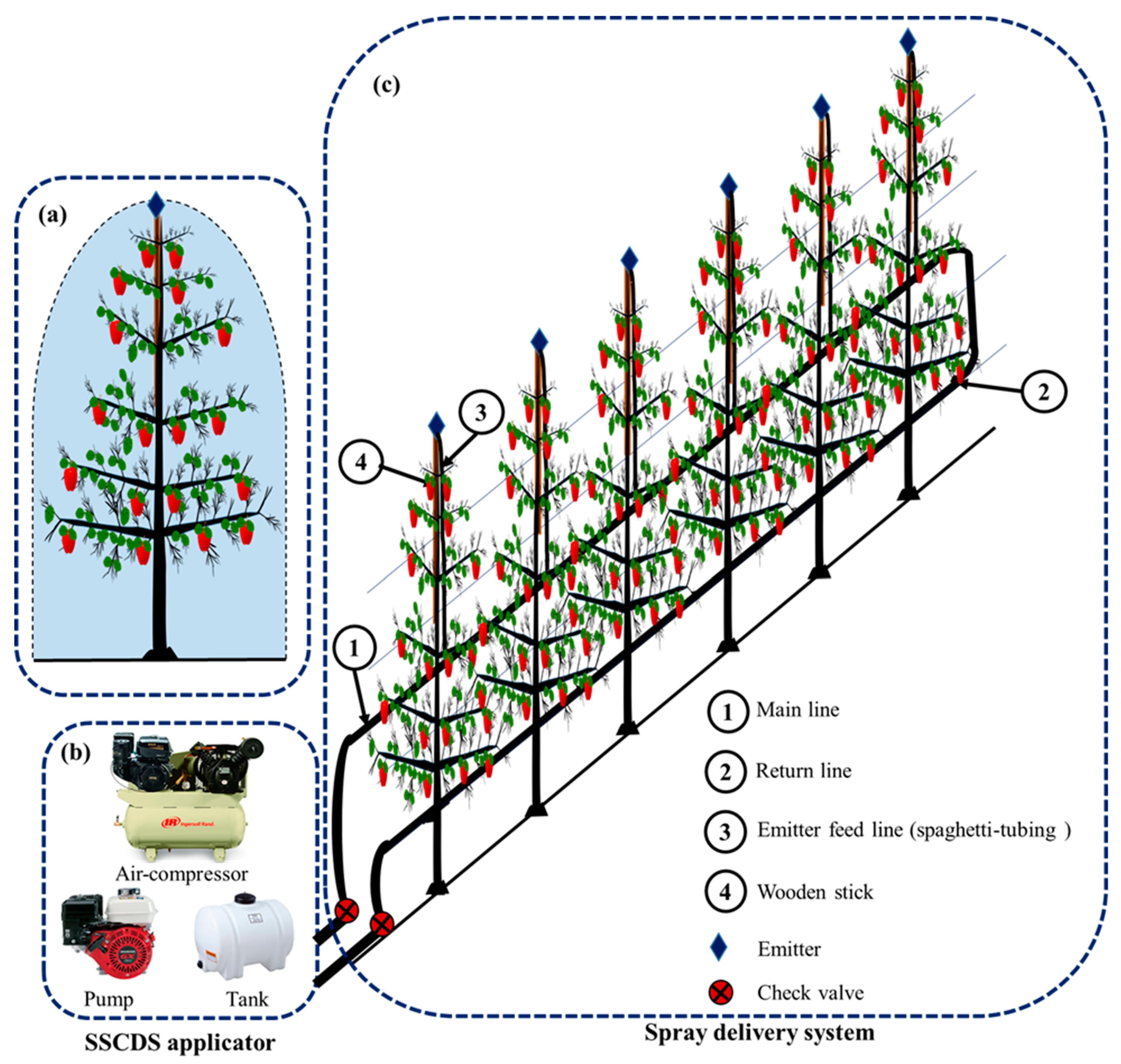

2.1. Solid Set Canopy Delivery System

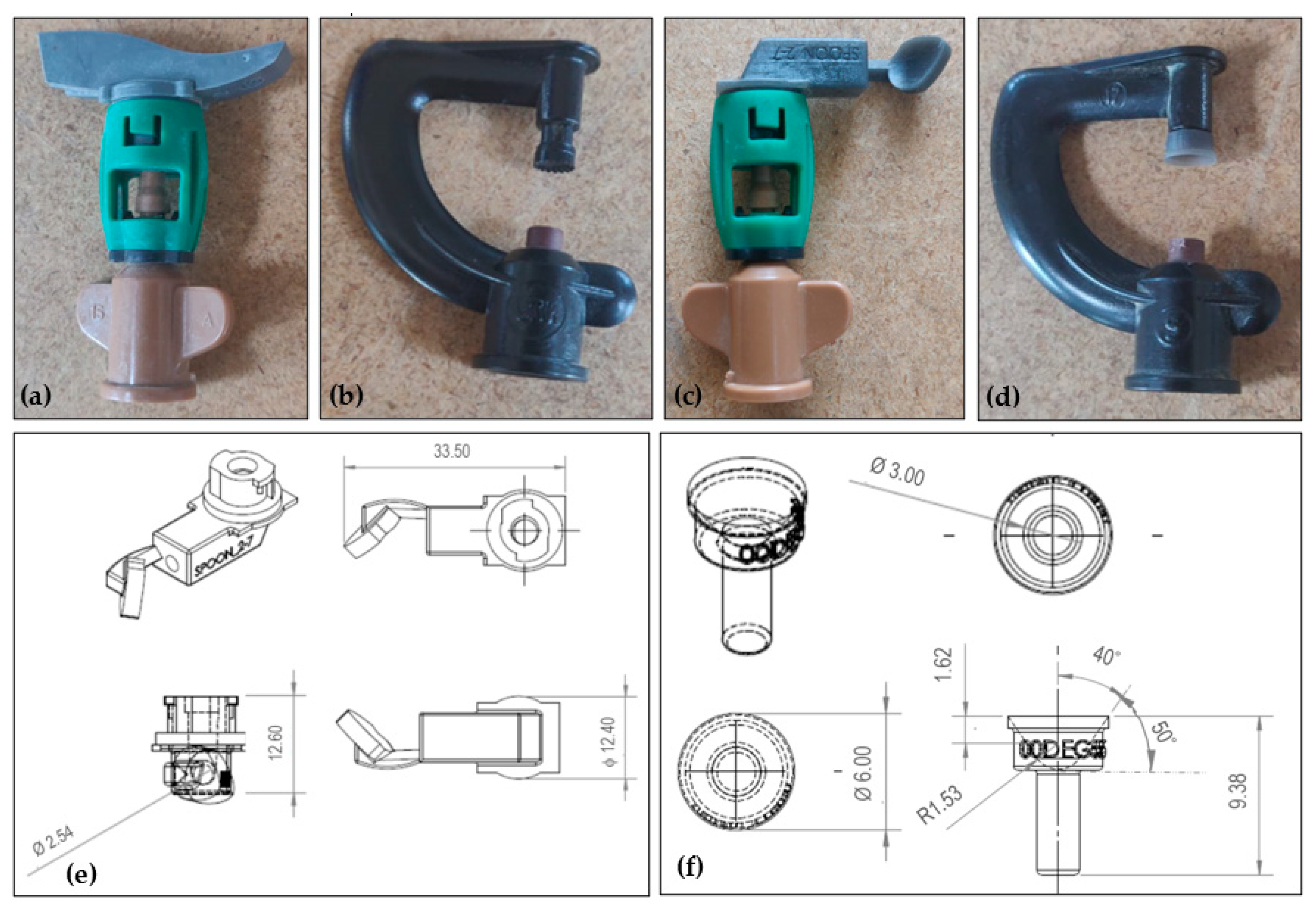

2.2. Micro-Emitter Modification

2.3. Experimental Site

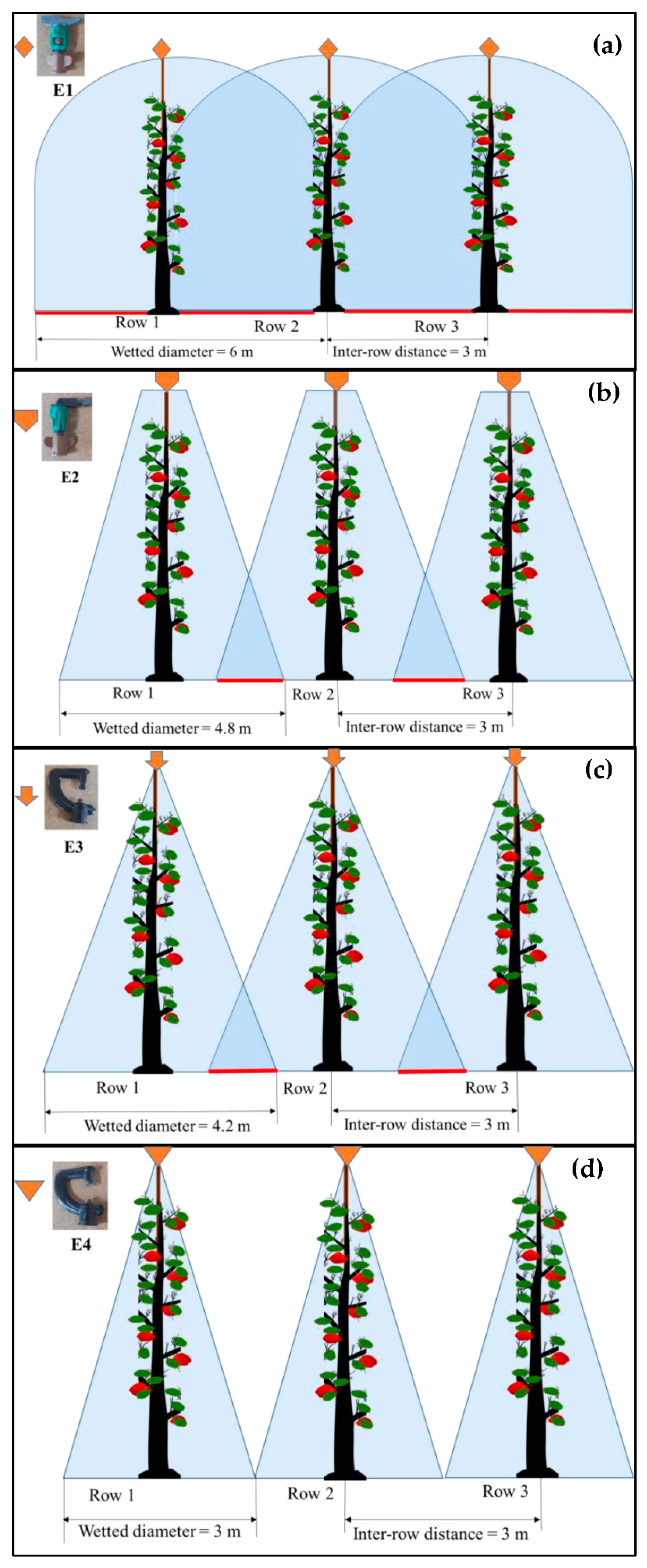

2.4. Experimental Design

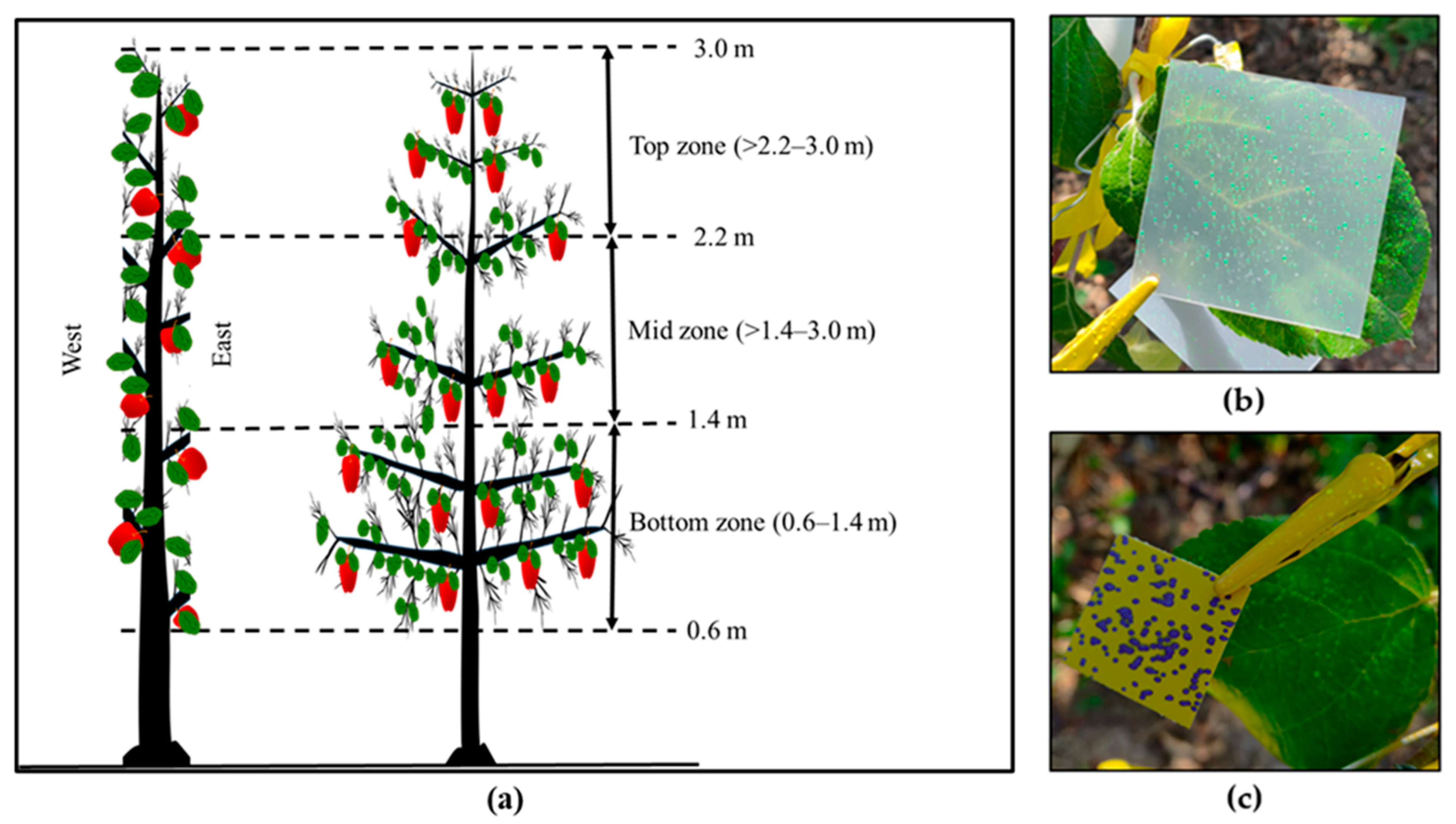

2.5. Data Collection Protocol

2.6. Meteorological Data

2.7. Data Analysis

3. Results and Discussion

3.1. Spray Droplet Attributes

3.2. Spray Deposition

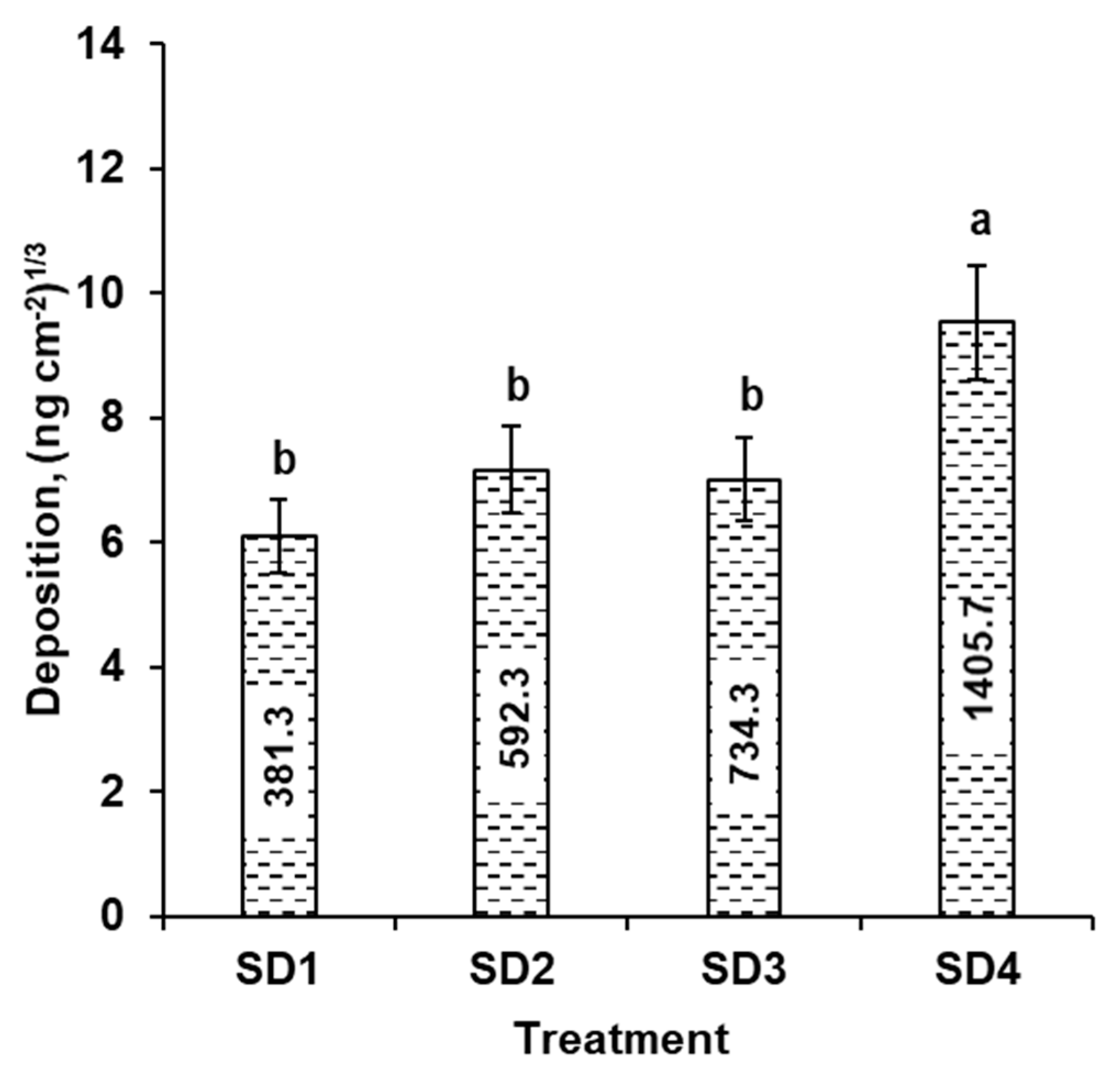

3.2.1. Effect of SSCDS Treatments and Canopy Zones on Deposition

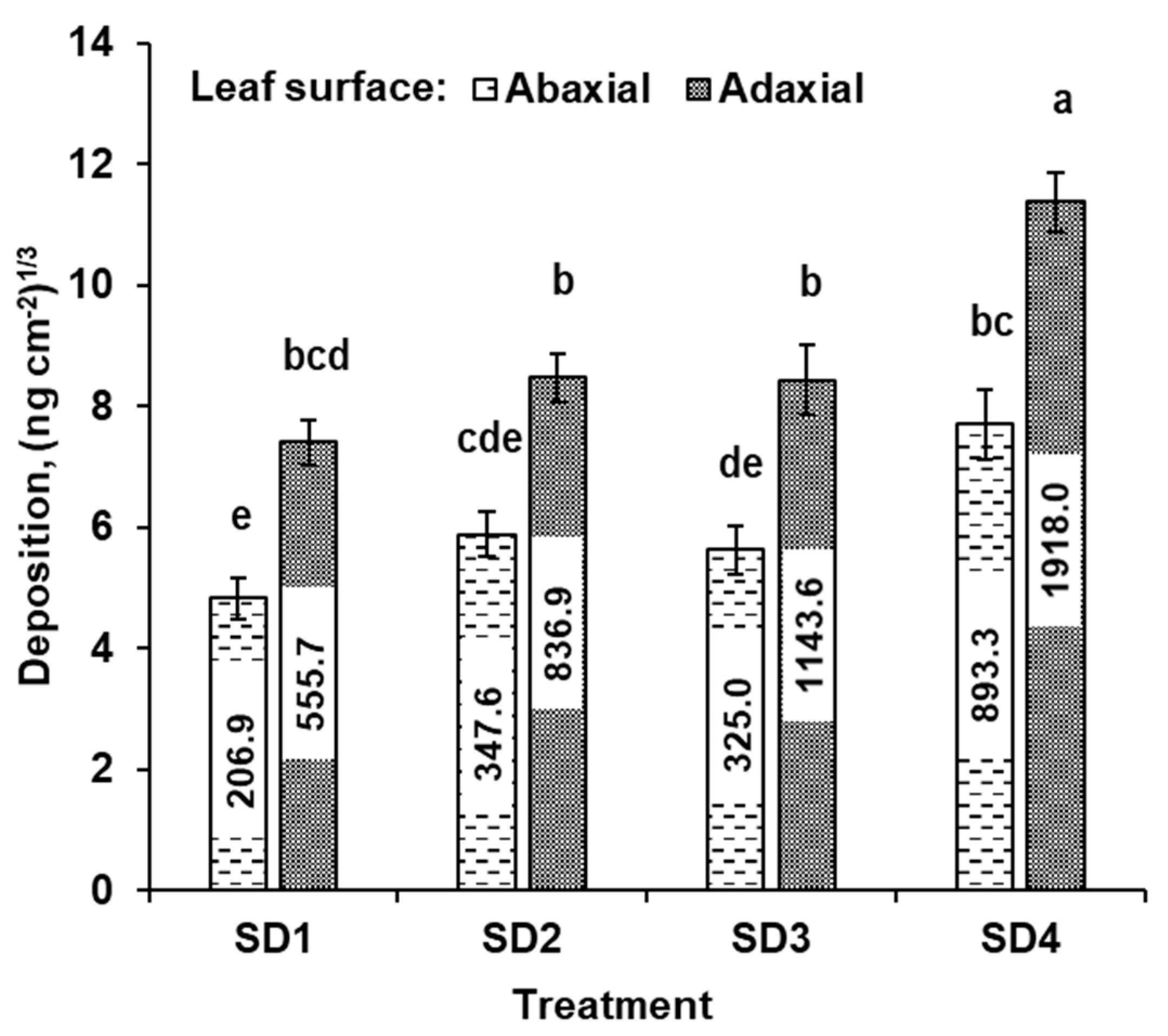

3.2.2. Effect of SSCDS Treatments and Leaf Surface on Deposition

3.3. Spray Coverage

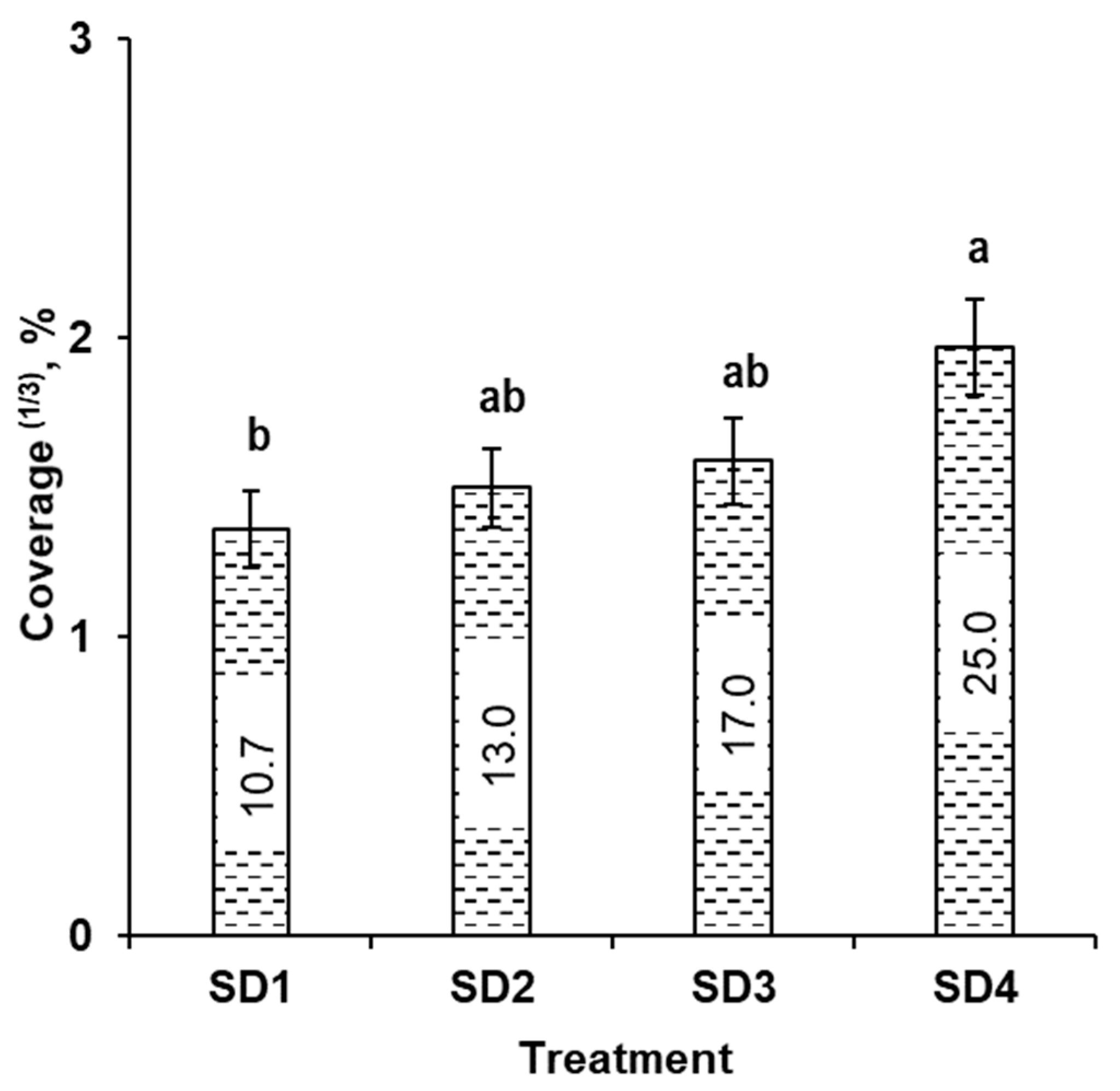

3.3.1. Effect of SSCDS Treatments and Canopy Zone on Coverage

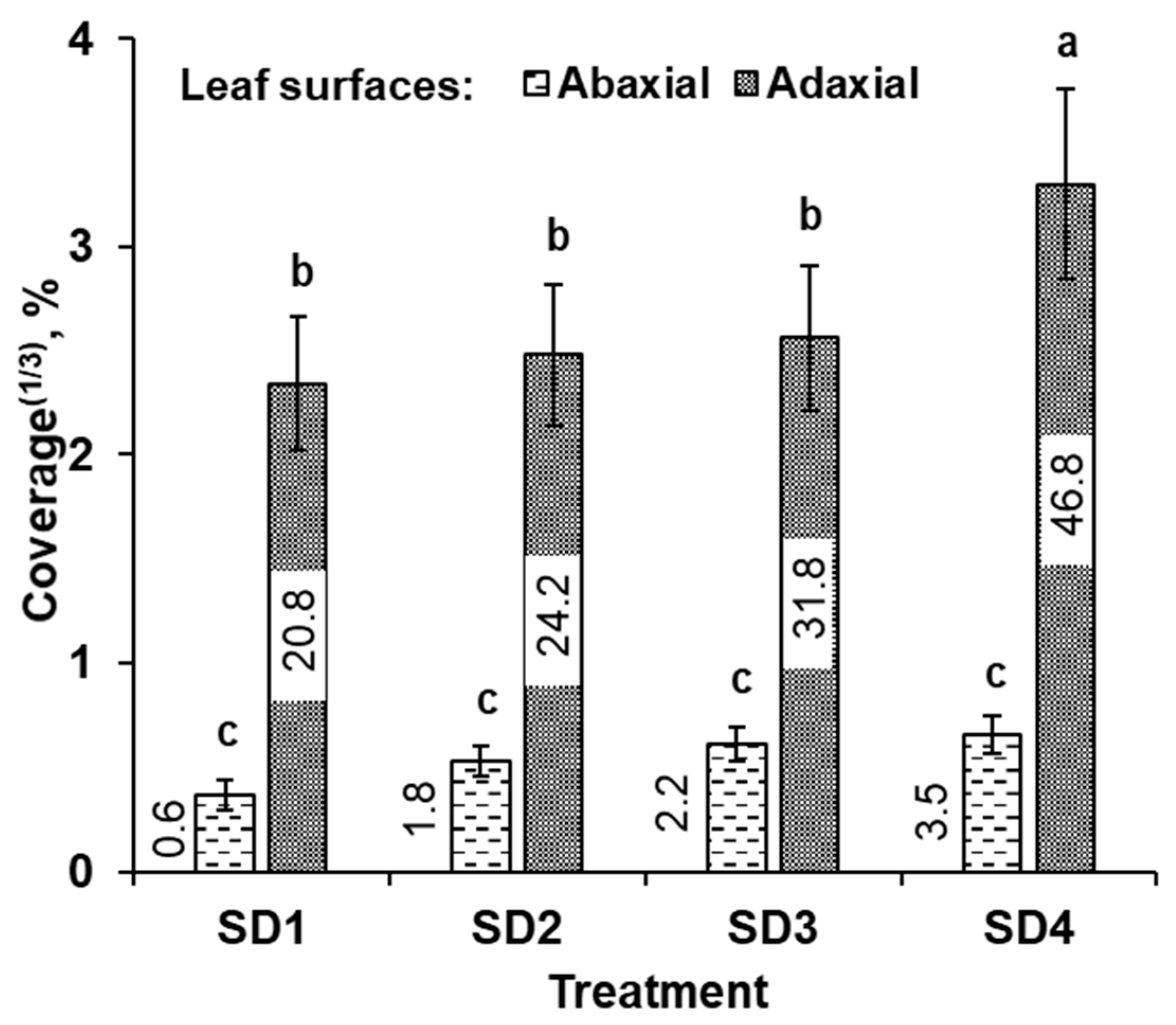

3.3.2. Effect of SSCDS Treatments and Leaf Surface on Coverage

4. Conclusions

- Pertinent modifications in the swivel deflector and static spreader of off-the-shelf micro-emitters considerably improved the spray performance of SSCDS configurations retrofitted with modified emitters.

- SSCDS treatment with the modified emitters had improved canopy deposition and coverage compared to treatments with off-the-shelf emitters.

- The treatment with modified emitters yielded improved deposition and coverage in the middle and bottom canopy zones as well as on the abaxial side of leaves.

- SSCDS treatment SD4 utilizing E4 emitters with a static spreader with 50° concavity had the highest canopy deposition and coverage. The same configuration also resulted in relatively uniform spray distribution and coverage along the canopy zone and on both sides of the leaf. Therefore, we recommend further biological efficacy studies with SD4 prior to potential large-scale emplacements.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Robinson, T.L. Effect of tree density and tree shape on light interception, tree growth, yield and economic performance of apples. Acta Hortic. 2007, 732, 405–414. [Google Scholar] [CrossRef]

- Grieshop, M.; Gut, L.; Wise, J.; Smith, P.O.; Sundin, G.; Flore, S.M.J.; Lang, G.; Perry, R. Development of solid set delivery systems for high density apples. NY Fruit Quart. 2015, 16–20. [Google Scholar]

- Cross, J.V.; Walklate, P.J.; Murray, R.A.; Richardson, G.M. Spray deposits and losses in different sized apple trees from axial fan orchard sprayers: 1. Effects of liquid flow rate. Crop Prot. 2001, 20, 13–30. [Google Scholar] [CrossRef]

- Cross, J.V.; Walklate, P.J.; Murray, R.A.; Richardson, G.M. Spray deposits and losses in different sized apple trees from axial fan orchard sprayers: 2. Effects of spray quality. Crop Prot. 2001, 20, 333–343. [Google Scholar] [CrossRef]

- Cross, J.V.; Walklate, P.J.; Murray, R.A.; Richardson, G.M. Spray deposits and losses in different sized apple trees from an axial fan orchard sprayer: 3. Effects of air volumetric flow rate. Crop Prot. 2003, 22, 381–394. [Google Scholar] [CrossRef]

- Grieshop, M.J.; Emling, J.; Ledebuhr, M. Re-envisioning agrichemical input delivery: Solid Set Delivery Systems for high density fruit production, Impacts on off-target deposition. In Proceedings of the 2018 ASABE Annual International Meeting, Detroit, MI, USA, 29 July–1 August 2018; p. 1. [Google Scholar]

- Klein, R.; Schulze, L.; Ogg, C. Factors Affecting Spray Drift of Pesticides. 2008. Available online: https://www.certifiedcropadviser.org/files/certifications/certified/education/self–study/exam–pdfs/119.pdf (accessed on 15 January 2020).

- Garcerá, C.; Moltó, E.; Chueca, P. Spray pesticide applications in Mediterranean citrus orchards: Canopy deposition and off-target losses. Sci. Total Environ. 2017, 599, 1344–1362. [Google Scholar] [CrossRef]

- Sinha, R.; Khot, L.R.; Hoheisel, G.A.; Grieshop, M.J.; Bahlol, H. Feasibility of a Solid set canopy delivery system for efficient agrochemical delivery in vertical shoot position trained vineyards. Biosyst. Eng. 2019, 179, 59–70. [Google Scholar] [CrossRef]

- Owen-Smith, P.; Wise, J.; Grieshop, M.J. Season Long Pest Management Efficacy and Spray Characteristics of a Solid Set Canopy Delivery System in High Density Apples. Insects 2019, 10, 193. [Google Scholar] [CrossRef] [Green Version]

- Owen-Smith, P.; Perry, R.; Wise, J.; Jamil, R.Z.R.; Gut, L.; Sundin, G.; Grieshop, M.J. Spray coverage and pest management efficacy of a solid set canopy delivery system in high density apples. Pest Manag. Sci. 2019, 75, 3050–3059. [Google Scholar] [CrossRef]

- Sinha, R.; Ranjan, R.; Khot, L.R.; Hoheisel, G.A.; Grieshop, M.J. Drift potential from a solid set canopy delivery system and an axial–fan air–assisted sprayer during applications in grapevines. Biosyst. Eng. 2019, 188, 207–216. [Google Scholar] [CrossRef]

- Carpenter, T.G.; Reichard, D.L.; Wilson, S.M. Design and feasibility of a permanent pesticide application system for orchards. Trans. ASABE 1985, 28, 350–355. [Google Scholar] [CrossRef]

- Agnello, A.M.; Landers, A.J. Current progress in development of a fixed spray pesticide application system for high-density apple plantings. NY Fruit Quart. 2006, 14, 22–26. [Google Scholar]

- Panneton, B.; Piche, M.; Philion, V.; Chouinard, G. Leaf deposition with fixed sprinklers, low drift emitters and conventional emitters in apple orchard. ASABE 2011, 11, 1110798. [Google Scholar] [CrossRef]

- Sinha, R.; Khot, L.R.; Hoheisel, G.A.; Grieshop, M.J. Field Performance of a Solid Set Canopy Delivery System Configured for High-Density Tall Spindle Architecture Trained Apple Canopies. Trans. ASABE 2021, 64, 1735–1745. [Google Scholar] [CrossRef]

- Niemann, S.M.; Whiting, M.D. Spray coverage in apple and cherry orchards using a solid set canopy delivery system. In Proceedings of the XXIX International Horticultural Congress on Horticulture: Sustaining Lives, Livelihoods and Landscapes (IHC2014), Brisbane, Australia, 25 November 2014; Volume 1130, pp. 647–654. [Google Scholar]

- Sharda, A.; Karkee, M.; Hoheisel, G.; Zhang, Q.; Mangus, D. Design and Evaluation of Solid Set Canopy Delivery System for Spray Application in High-density Apple Orchards. Appl. Eng. Agric. 2019, 35, 751–757. [Google Scholar] [CrossRef]

- Sinha, R.; Ranjan, R.; Khot, L.R.; Hoheisel, G.A.; Grieshop, M.J. Comparison of within canopy deposition for a solid set canopy delivery system (SSCDS) and an axial–fan airblast sprayer in a vineyard. Crop Prot. 2020, 132, 105124. [Google Scholar] [CrossRef]

- Sinha, R.; Ranjan, R.; Shi, G.; Hoheisel, G.A.; Grieshop, M.; Khot, L.R. Solid set canopy delivery system for efficient agrochemical delivery in modern architecture apple and grapevine canopies. Acta Hortic. 2020, 1269, 277–286. [Google Scholar] [CrossRef]

- Sinha, R.; Ranjan, R.; Khot, L.R.; Hoheisel, G.A.; Grieshop, M.J. Development and performance evaluation of a pneumatic spray delivery based solid set canopy delivery system for spray application in a high–density apple orchard. Trans. ASABE 2020, 63, 37–48. [Google Scholar] [CrossRef]

- Ranjan, R.; Shi, G.; Sinha, R.; Khot, L.R.; Hoheisel, G.A.; Grieshop, M.J. Automated Solid Set Canopy Delivery System for Large-Scale Spray Applications in Perennial Specialty Crops. Trans. ASABE 2019, 62, 585–592. [Google Scholar] [CrossRef]

- Sharda, A.; Karkee, M.; Zhang, Q.; Ewlanow, I.; Adameit, U.; Brunner, J. Effect of emitter type and mounting configuration on spray coverage for solid set canopy delivery system. Comput. Electron. Agric. 2015, 112, 184–192. [Google Scholar] [CrossRef]

- Ranjan, R.; Sinha, R.; Khot, L.R.; Hoheisel, G.A.; Grieshop, M.; Ledebuhr, M. Spatial Distribution of Spray from a Solid Set Canopy Delivery System in a High-Density Apple Orchard Retrofitted with Modified Emitters. Appl. Sci. 2021, 11, 709. [Google Scholar] [CrossRef]

- Lefebvre, A.H.; McDonell, V.G. Atomization and Sprays; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- ASABE S572.3. Spray Nozzle Classification by Droplet Spectra; ASABE: St. Joseph, MI, USA, 2020. [Google Scholar]

- ISO 22522:2007. Crop Protection Equipment—Field Measurement of Spray Distribution in Tree and Bush Crops; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- Chaim, A.; Pessoa, M.C.P.Y.; Camargo Neto, J.; Hermes, L.C. Comparison of microscopic method and computational program for pesticide deposition evaluation of spraying. Pesqui. Agropecu. Bras. 2002, 37, 493–496. [Google Scholar] [CrossRef]

- Nansen, C.; Ferguson, J.C.; Moore, J.; Groves, L.; Emery, R.; Garel, N.; Hewitt, A. Optimizing pesticide spray coverage using a novel web and smartphone tool, SnapCard. Agron. Sustain. Dev. 2015, 35, 1075–1085. [Google Scholar] [CrossRef]

- R Studio, R Core Team. R: A language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2020; Available online: https://www.R-project.org/ (accessed on 10 January 2020).

- Koch, H.; Weisser, P. Sensor equipped orchard spraying–efficacy, savings and drift reduction. Aspect Appl. Biol. 2000, 57, 357–362. [Google Scholar]

- Hilz, E.; Vermeer, A.W. Spray drift review: The extent to which a formulation can contribute to spray drift reduction. Crop Prot. 2013, 44, 75–83. [Google Scholar] [CrossRef]

- Martin, D.E. A fluorescent imaging technique for quantifying spray deposits on plant leaves. At. Sprays 2014, 24, 367–373. [Google Scholar] [CrossRef] [Green Version]

- Verpont, F.; Favareille, J.; Zavagli, F. Fixed spraying system: A future potential way to apply pesticides in an apple orchard? Julius-Kühn-Archiv 2015, 448, 53. [Google Scholar]

| Emitter | Model $ | Flow Rate (L min−1) * | Wetted Diameter (m) # | SSCDS Treatment |

|---|---|---|---|---|

| E1 | Green Spin | 0.9 | 6.0 | SD1 |

| E2 | Modified | 0.9 | 4.8 | SD2 |

| E3 | Modular | 0.9 | 4.2 | SD3 |

| E4 | Modified | 0.9 | 3.0 | SD4 |

| Date | Weather Parameter | SSCDS Treatment | |||

|---|---|---|---|---|---|

| SD1 | SD2 | SD3 | SD4 | ||

| 28 June 2019 | Wind speed (m s−1) | 0.63 ± 0.1 | 0.24 ± 0.0 | 0.4 ± 0.1 | 0.3 ± 0.1 |

| Wind direction (°) * | 64.5 ± 3.6 | 322.5 ± 25.4 | 218.3 ± 20.4 | 190.1 ± 19.2 | |

| Air temperature (°C) | 11.9 ± 0.2 | 14.6 ± 0.0 | 13.1 ± 0.2 | 12.8 ± 0.16 | |

| Relative humidity | 0.7 ± 0.0 | 0.6 ± 0.0 | 0.7 ± 0.0 | 0.7 ± 0.01 | |

| 1 July 2019 | Wind speed (m s−1) | 0.8 ± 0.2 | 0.9 ± 0.3 | 0.7 ± 0.3 | 1.1 ± 0.2 |

| Wind direction (°) * | 243.6 ± 19.0 | 249.9 ± 10.9 | 245.1 ± 13.4 | 227.8 ± 13.4 | |

| Air temperature (°C) | 19.8 ± 0.2 | 15.5 ± 0.2 | 19.3 ± 0.2 | 18.4 ± 0.1 | |

| Relative humidity | 0.6 ± 0.0 | 0.6 ± 0.0 | 0.6 ± 0.0 | 0.6 ± 0.0 | |

| 3 July 2019 | Wind speed (m s−1) | 0.7 ± 0.1 | 1.8 ± 0.4 | 0.8 ± 0.2 | 1.0 ± 0.2 |

| Wind direction (°) * | 233.7 ± 15.3 | 248.3 ± 14.1 | 190.1 ± 6.6 | 222.7 ± 14.4 | |

| Air temperature (°C) | 15.2 ± 0.1 | 16.1 ± 0.1 | 14.5 ± 0.1 | 15.9 ± 0.2 | |

| Relative humidity | 0.7 ± 0.0 | 0.6 ± 0.0 | 0.7 ± 0.0 | 0.6 ± 0.0 | |

| Emitter | Treatment | Volume Percentile-Based Diameter (μm) | Category * | ||

|---|---|---|---|---|---|

| DV0.1 | DV0.5 | DV0.9 | |||

| E1 | SD1 | 186.8 | 283.0 | 532.2 | Medium |

| E2 | SD2 | 119.3 | 214.8 | 699.3 | Fine |

| E3 | SD3 | 72.5 | 130.9 | 360.1 | Very fine |

| E4 | SD4 | 134.6 | 256.2 | 416.8 | Medium |

| Variables | Df | MS | F | p |

|---|---|---|---|---|

| Main plot | ||||

| Block | 1 | 42.49 | ||

| Treatment | 3 | 55.25 | 7 | <0.001 |

| Error(a) | 3 | 193.80 | ||

| Canopy zone | 2 | 116.10 | 14.7 | <0.001 |

| Leaf surface | 1 | 117.60 | 14.9 | <0.001 |

| Treatment × Canopy zone | 6 | 9.72 | 1.2 | 0.29 |

| Treatment × Leaf surface | 3 | 15.40 | 1.9 | 0.12 |

| Canopy zone × Leaf surface | 2 | 17.40 | 2.2 | 0.11 |

| Treatment × Canopy zone × Leaf surface | 6 | 15.50 | 1.97 | 0.07 |

| Error(b) | 384 | 7.89 |

| Variables | Df | MS | F | p |

|---|---|---|---|---|

| Main plot | ||||

| Block | 1 | 0.13 | ||

| Treatment | 3 | 3.3 | 3.9 | 0.009 |

| Error(a) | 3 | 8.5 | ||

| Canopy zone | 2 | 12.2 | 14.5 | <0.001 |

| Leaf surface | 1 | 62.5 | 74.2 | <0.001 |

| Treatment × Canopy zone | 6 | 1.5 | 1.7 | 0.11 |

| Treatment × Leaf surface | 3 | 2.9 | 3.4 | 0.02 |

| Canopy zone × Leaf surface | 2 | 0.39 | 0.5 | 0.63 |

| Treatment × Canopy zone × Leaf surface | 6 | 1.6 | 1.9 | 0.08 |

| Error(b) | 379 | 0.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ranjan, R.; Sinha, R.; Khot, L.R.; Hoheisel, G.-A.; Grieshop, M.J.; Ledebuhr, M. Effect of Emitter Modifications on Spray Performance of a Solid Set Canopy Delivery System in a High-Density Apple Orchard. Sustainability 2021, 13, 13248. https://doi.org/10.3390/su132313248

Ranjan R, Sinha R, Khot LR, Hoheisel G-A, Grieshop MJ, Ledebuhr M. Effect of Emitter Modifications on Spray Performance of a Solid Set Canopy Delivery System in a High-Density Apple Orchard. Sustainability. 2021; 13(23):13248. https://doi.org/10.3390/su132313248

Chicago/Turabian StyleRanjan, Rakesh, Rajeev Sinha, Lav R. Khot, Gwen-Alyn Hoheisel, Matthew J. Grieshop, and Mark Ledebuhr. 2021. "Effect of Emitter Modifications on Spray Performance of a Solid Set Canopy Delivery System in a High-Density Apple Orchard" Sustainability 13, no. 23: 13248. https://doi.org/10.3390/su132313248

APA StyleRanjan, R., Sinha, R., Khot, L. R., Hoheisel, G.-A., Grieshop, M. J., & Ledebuhr, M. (2021). Effect of Emitter Modifications on Spray Performance of a Solid Set Canopy Delivery System in a High-Density Apple Orchard. Sustainability, 13(23), 13248. https://doi.org/10.3390/su132313248