Multi-Criteria Decision-Making Approach for Nutraceuticals Greener Applications: The Cynara cardunculus Case Study

Abstract

1. Introduction

2. Materials and Methods

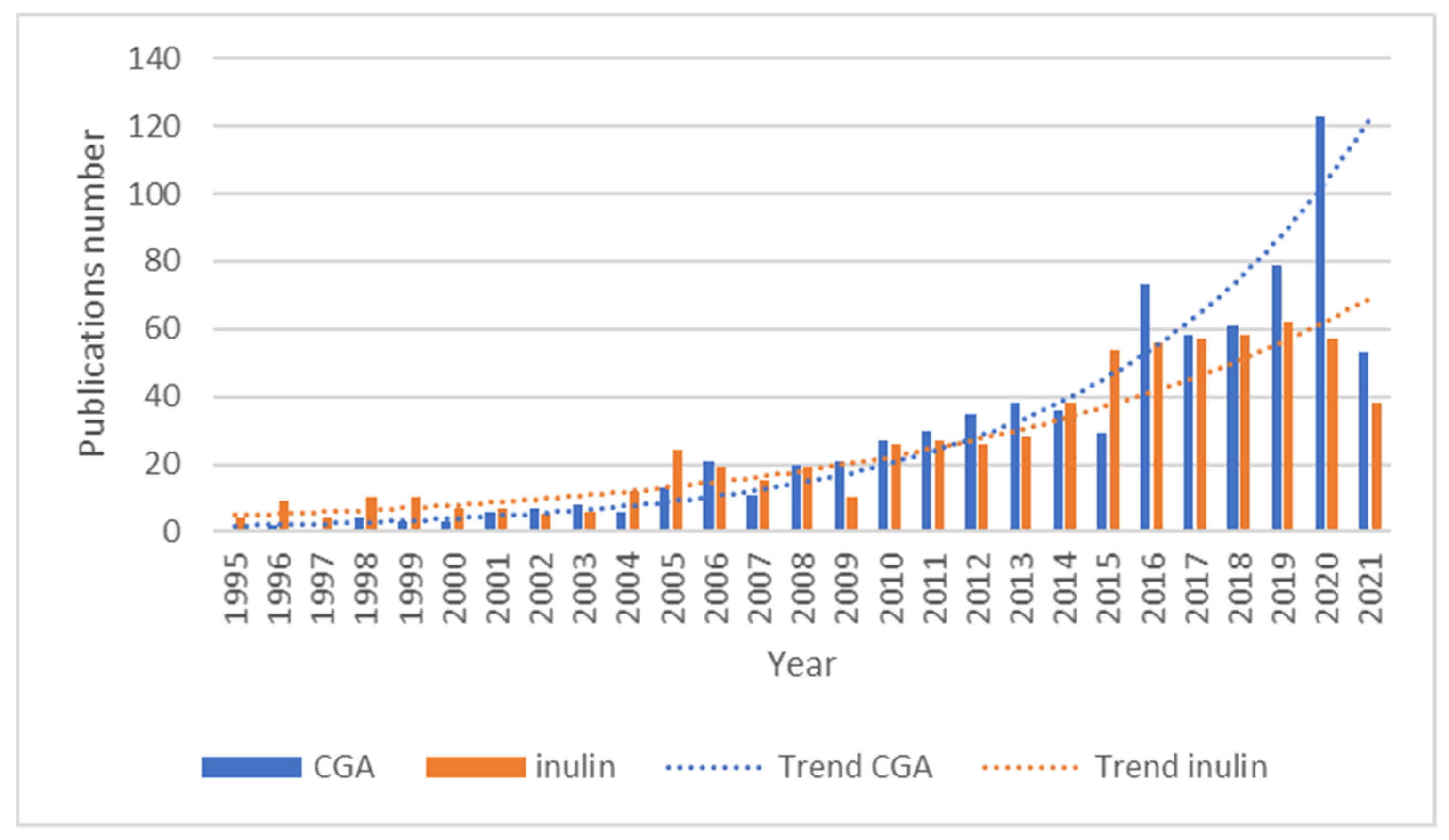

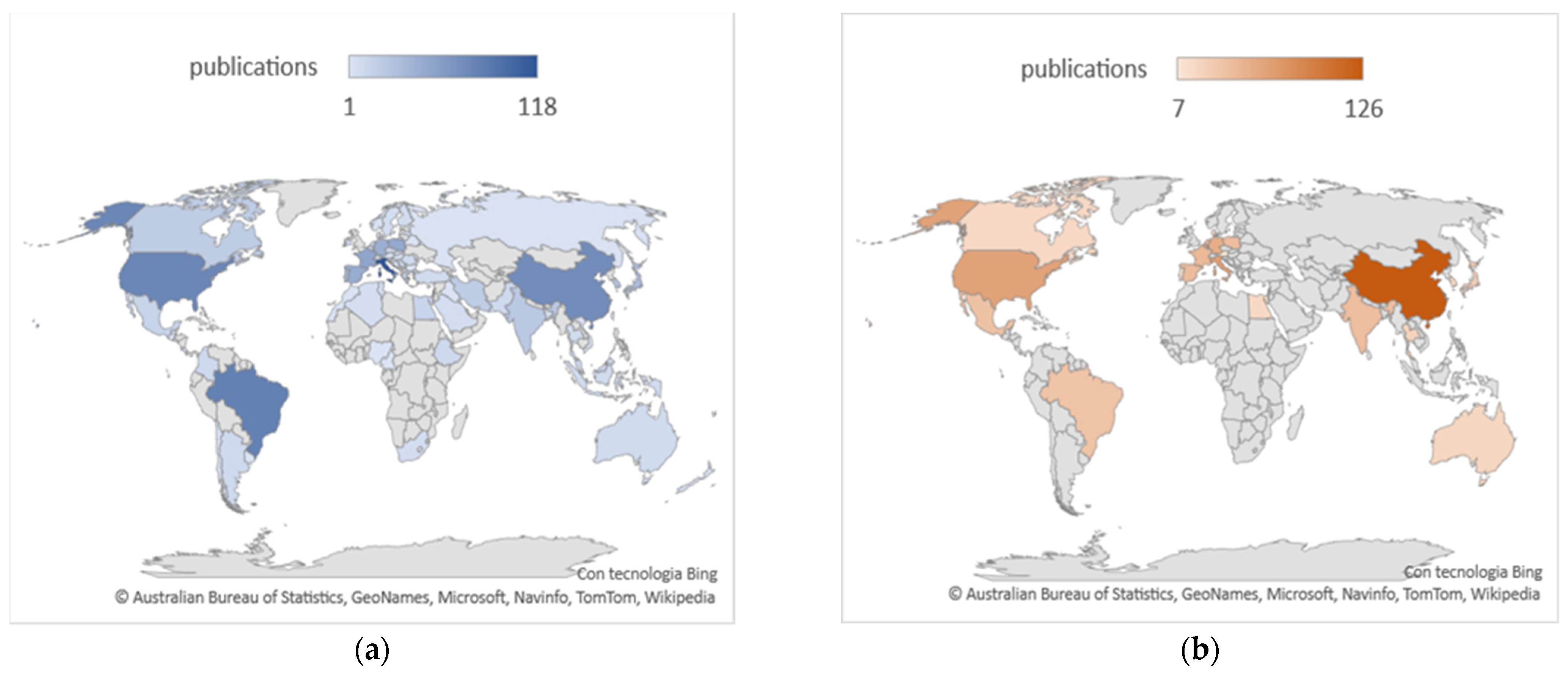

2.1. Bibliometric Analysis

- CGA search queries: (caffeoylquinic acid or chlorogenic acid or hydroxycinnamic acid) AND (market or anal * or applic * or employ * or review or extraction * or utilization * or exploit *) AND (biomass or artichoke or green coffee or Cynara cardunculus or synthesis) AND (nutraceuticals or cosmetic or pharmaceutical or pills or capsules or yield or efficiency or content or percentage).

- Inulin search queries: (inulin or fructan * or fructooligosaccharde) AND (market or anal * or applic * or employ * or review or extraction * or utilization * or exploit *) AND (biomass or feedstock or chicory or Jerusalem artichoke or artichoke or Cynara cardunculus or synthesis) AND (production or nutraceuticals or cosmetic or pharmaceutical or powder or capsules or yield or efficiency or content or percentage or cost * or prebiotic).

- Bioactive compounds or biomasses other than the ones selected for the study;

- Structure, metabolic behavior, and pharmacokinetics of the compounds;

- Characterization of methodologies and processes relative to the bioactive compounds;

- Energy valorization and uses other than nutraceuticals or cosmetics;

- Clinical trials for medical applications of the bioactive compounds.

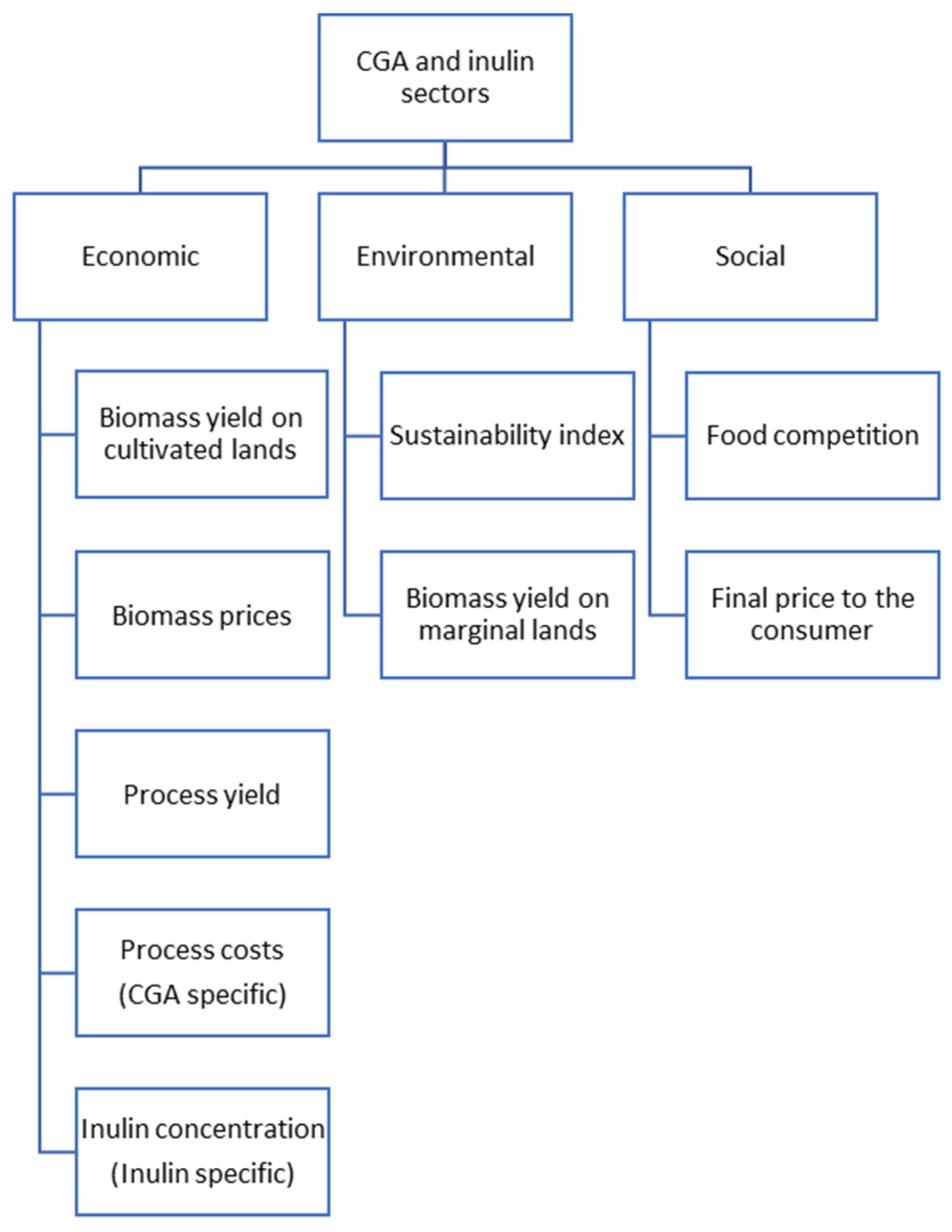

2.2. Multi-Criteria Decision Analysis

2.3. Study Limitations

3. Results

3.1. Bibliometric Analysis

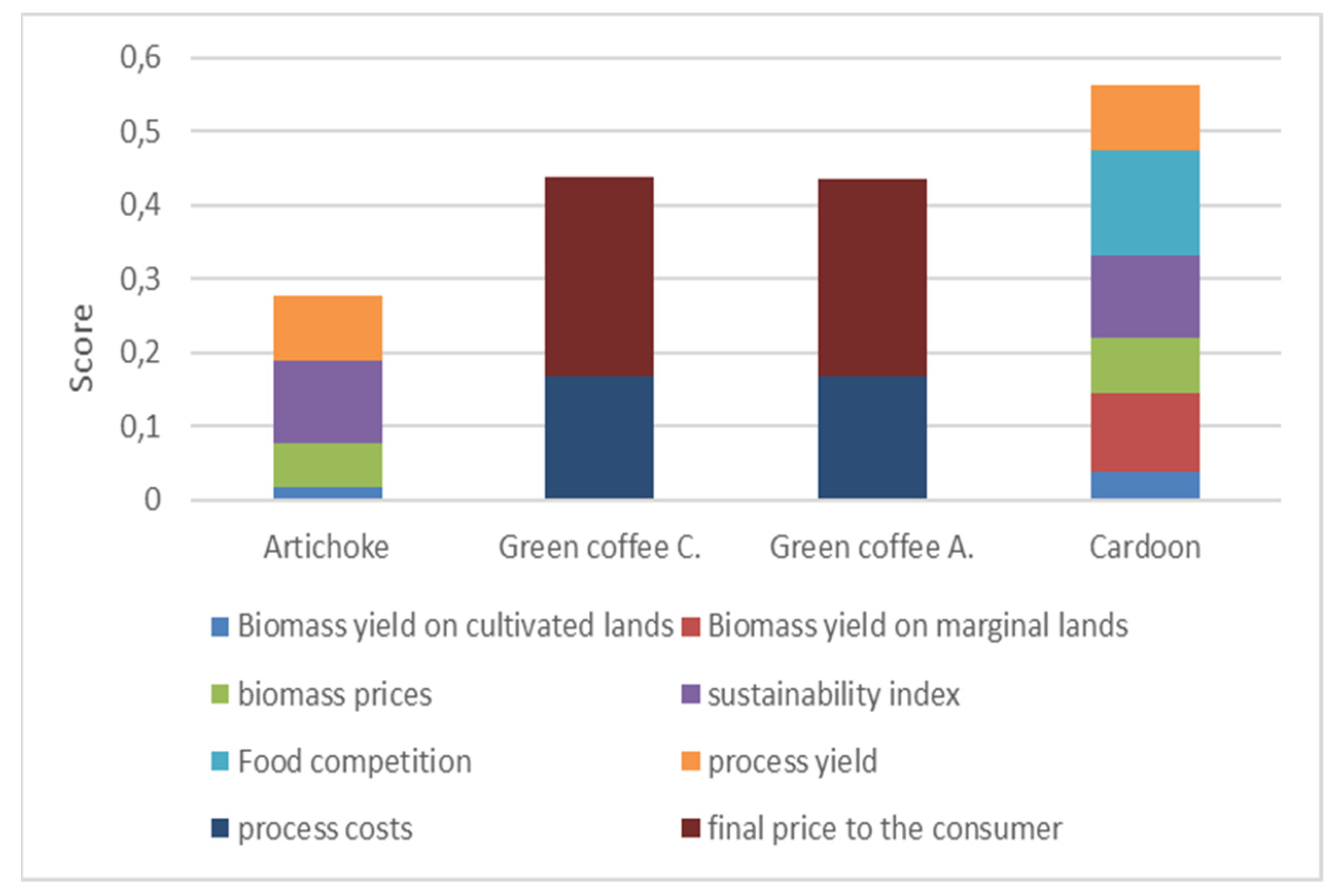

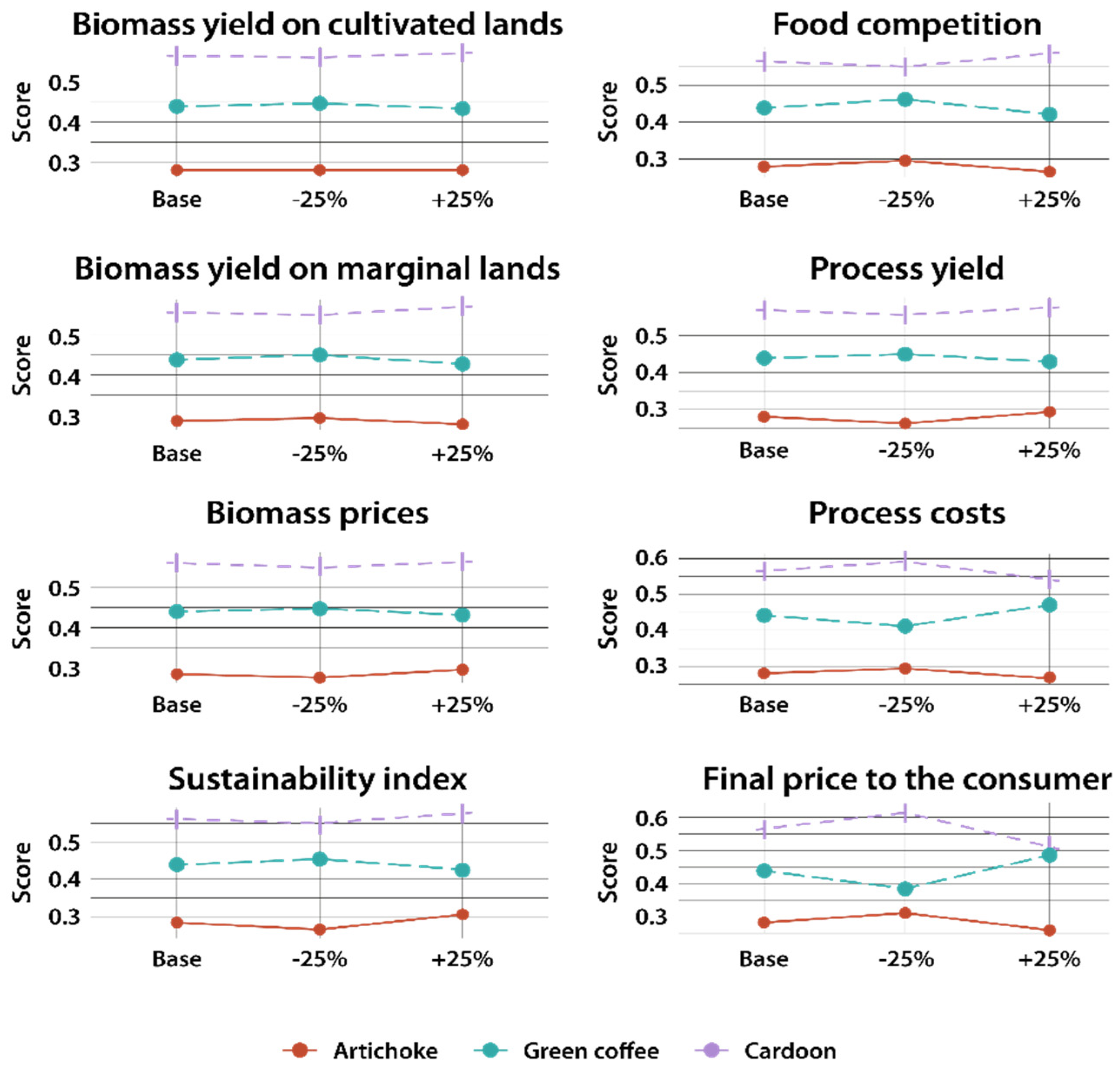

3.2. MCDA Results for CGA Extraction

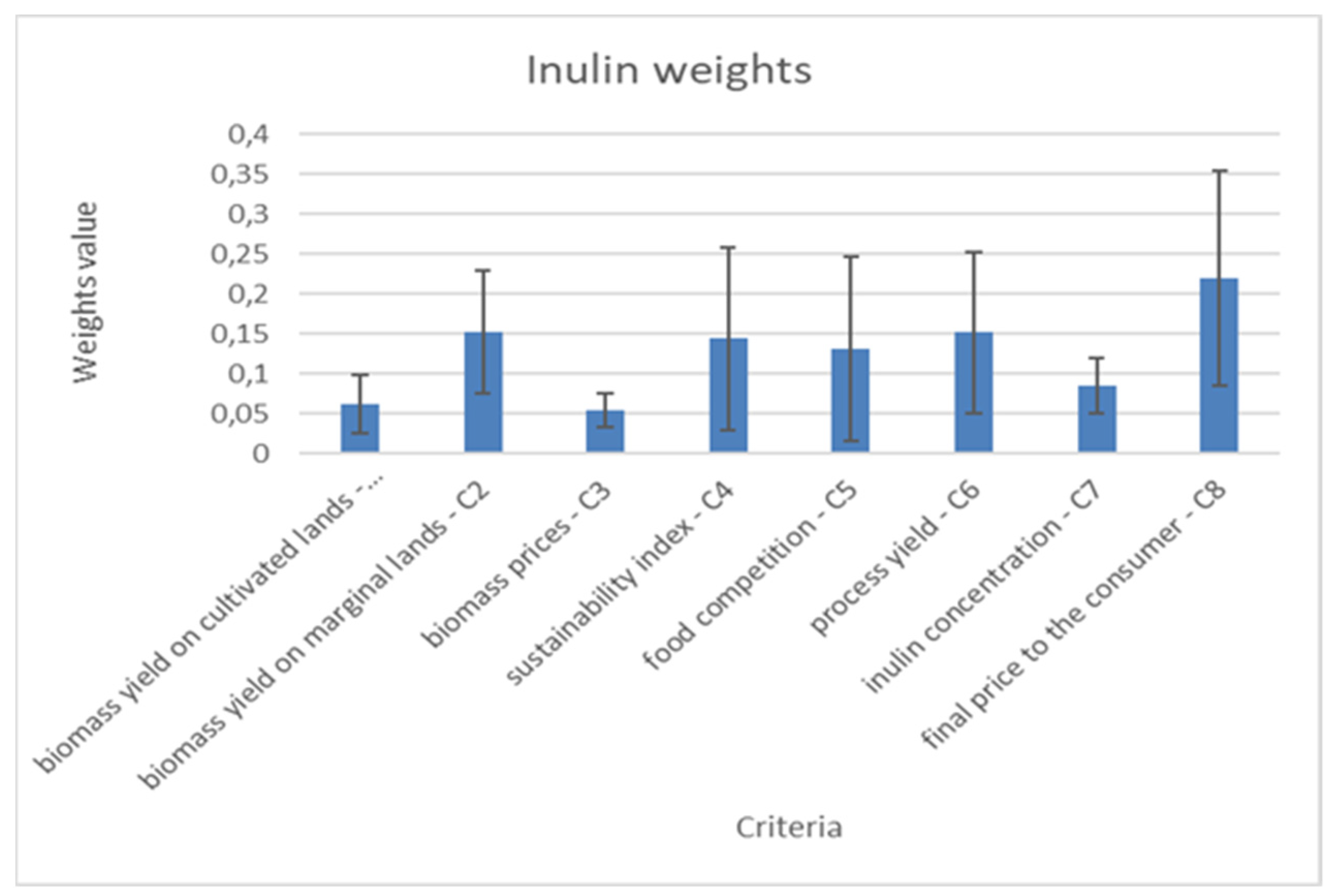

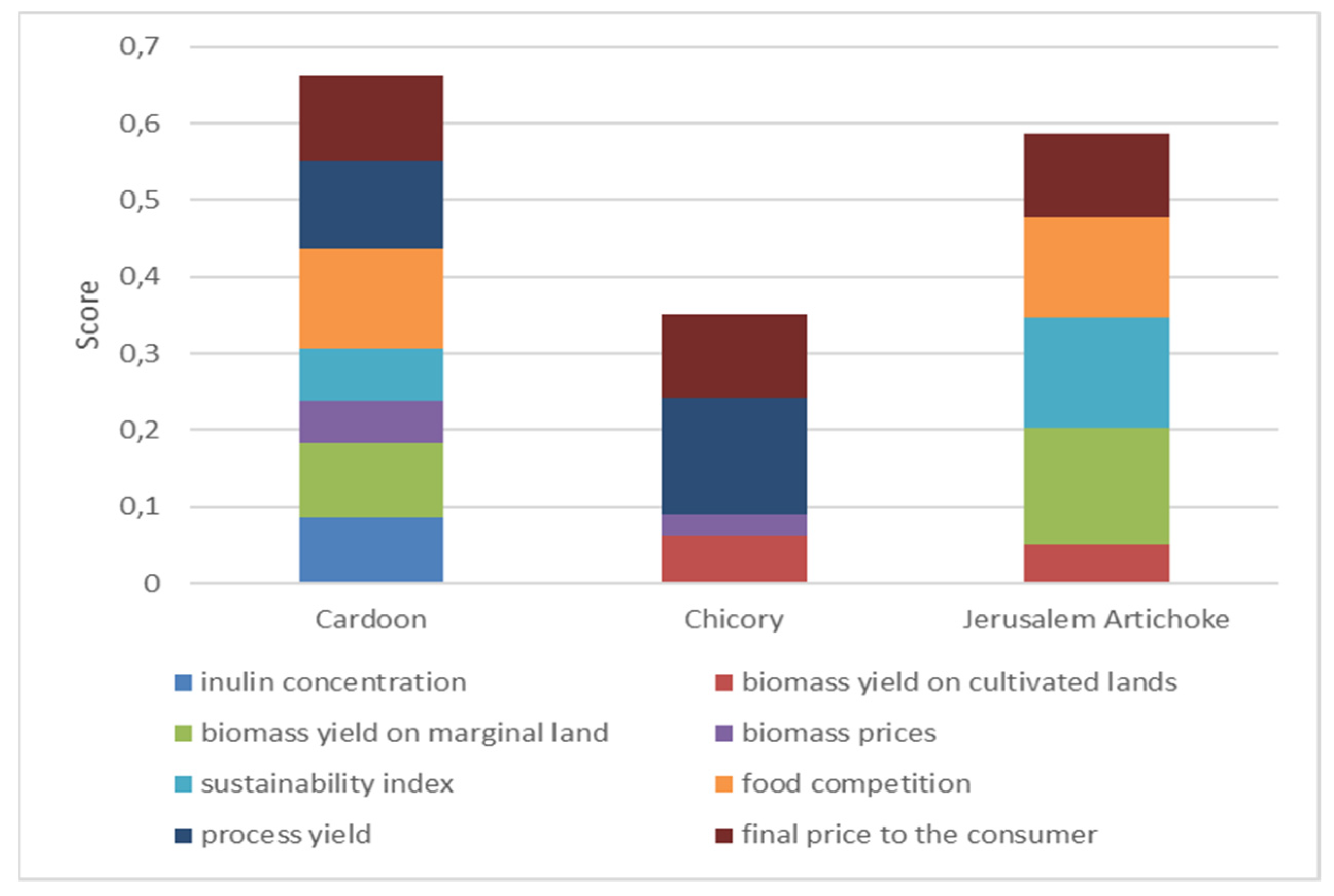

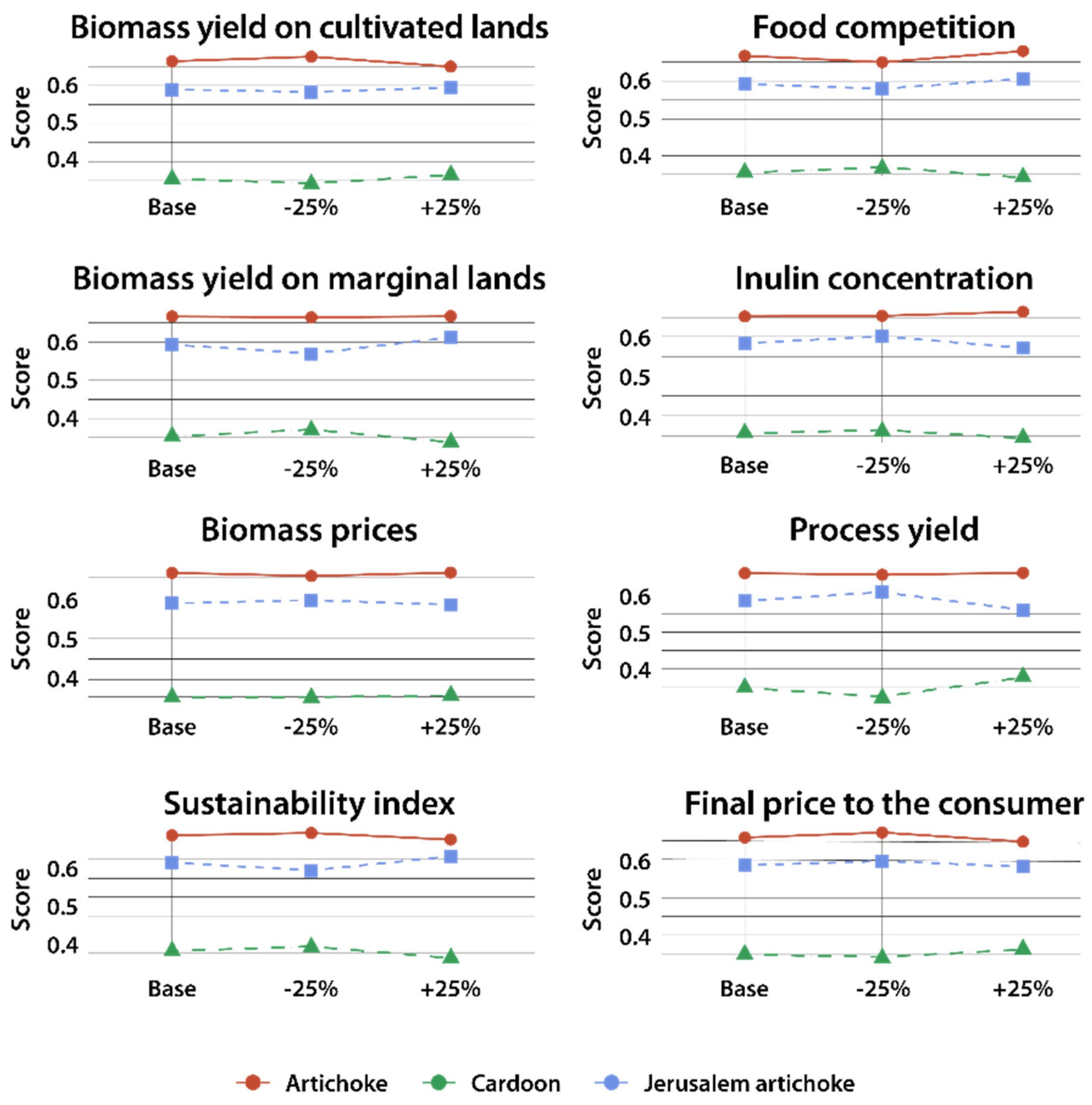

3.3. MCDA Results for Inulin Extraction

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Daliri, E.B.-M.; Lee, B.H. Current Trends and Future Perspectives on Functional Foods and Nutraceuticals. In Beneficial Microorganisms in Food and Nutraceuticals; Springer International Publishing: Cham, Switzerland, 2015; pp. 221–244. [Google Scholar] [CrossRef]

- Williamson, E.M.; Liu, X.; Izzo, A.A. Trends in use, pharmacology, and clinical applications of emerging herbal nutraceuticals. Br. J. Pharmacol. 2019, 177, 1227–1240. [Google Scholar] [CrossRef]

- Global Chlorogenic Acid Research Market Report 2021, Forecast to 2027. Available online: https://www.absolutereports.com/global-chlorogenic-acid-market-17977353 (accessed on 14 April 2021).

- Dini, I.; Laneri, S. The New Challenge of Green Cosmetics: Natural Food Ingredients for Cosmetic Formulations. Molecules 2021, 26, 3921. [Google Scholar] [CrossRef]

- Johnson, C.; Sierra, A.R.; Dettmer, J.; Sidiropoulou, K.; Zicmane, E.; Puzzolo, V.; Mengal, P.; Canalis, A.; Paiano, P. The Bio-Based Industries Joint Undertaking as a catalyst for a green transition in Europe under the European Green Deal. EFB Bioeconomy J. 2021, 1, 100014. [Google Scholar] [CrossRef]

- Dahiya, S.; Kumar, A.N.; Shanthi Sravan, J.; Chatterjee, S.; Sarkar, O.; Mohan, S.V. Food waste biorefinery: Sustainable strategy for circular bioeconomy. Bioresour. Technol. 2018, 248, 2–12. [Google Scholar] [CrossRef]

- Kumar, B.; Verma, P. Biomass-based biorefineries: An important architype towards a circular economy. Fuel 2020, 288, 119622. [Google Scholar] [CrossRef]

- Global Inulin and Fructooligosaccharide Market Research Report 2021; Market Research Reports, Inc.: Lewes, DE, USA, 2021.

- Naveed, M.; Hejazi, V.; Abbas, M.; Kamboh, A.A.; Khan, G.J.; Shumzaid, M.; Ahmad, F.; Babazadeh, D.; FangFang, X.; Modarresi-Ghazani, F.; et al. Chlorogenic acid (CGA): A pharmacological review and call for further research. Biomed. Pharmacother. 2018, 97, 67–74. [Google Scholar] [CrossRef]

- Niggeweg, R.; Michael, A.J.; Martin, C. Engineering plants with increased levels of the antioxidant chlorogenic acid. Nat. Biotechnol. 2004, 22, 746–754. [Google Scholar] [CrossRef]

- Maher, E.A.; Bate, N.J.; Ni, W.; Elkind, Y.; Dixon, R.A.; Lamb, C.J. Increased disease susceptibility of transgenic tobacco plants with suppressed levels of preformed phenylpropanoid products. Proc. Natl. Acad. Sci. USA 1994, 91, 7802–7806. [Google Scholar] [CrossRef]

- Leiss, K.A.; Maltese, F.; Choi, Y.H.; Verpoorte, R.; Klinkhamer, P.G. Identification of Chlorogenic Acid as a Resistance Factor for Thrips in Chrysanthemum. Plant Physiol. 2009, 150, 1567–1575. [Google Scholar] [CrossRef]

- Cantos, E.; Espín, J.C.; Tomás-Barberán, F.A. Effect of Wounding on Phenolic Enzymes in Six Minimally Processed Lettuce Cultivars upon Storage. J. Agric. Food Chem. 2000, 49, 322–330. [Google Scholar] [CrossRef]

- Becerra-Moreno, A.; Benavides, J.; Cisneros-Zevallos, L.; Jacobo-Velázquez, D.A. Plants as Biofactories: Glyphosate-Induced Production of Shikimic Acid and Phenolic Antioxidants in Wounded Carrot Tissue. J. Agric. Food Chem. 2012, 60, 11378–11386. [Google Scholar] [CrossRef] [PubMed]

- Clé, C.; Hill, L.M.; Niggeweg, R.; Martin, C.R.; Guisez, Y.; Prinsen, E.; Jansen, M.A. Modulation of chlorogenic acid biosynthesis in Solanum lycopersicum; consequences for phenolic accumulation and UV-tolerance. Phytochemistry 2008, 69, 2149–2156. [Google Scholar] [CrossRef]

- Wang, M.; Simon, J.E.; Aviles, I.F.; He, K.; Zheng, Q.-Y.; Tadmor, Y. Analysis of Antioxidative Phenolic Compounds in Artichoke (Cynara scolymus L.). J. Agric. Food Chem. 2003, 51, 601–608. [Google Scholar] [CrossRef] [PubMed]

- Tajik, N.; Tajik, M.; Mack, I.; Enck, P. The potential effects of chlorogenic acid, the main phenolic components in coffee, on health: A comprehensive review of the literature. Eur. J. Nutr. 2017, 56, 2215–2244. [Google Scholar] [CrossRef] [PubMed]

- Vogt, M. The international coffee industry. In Variance in Approach toward a ‘Sustainable’ Coffee Industry in Costa Rica; Ubiquity Press: London, UK, 2019; pp. 39–53. [Google Scholar] [CrossRef]

- Nab, C.; Maslin, M. Life cycle assessment synthesis of the carbon footprint of Arabica coffee: Case study of Brazil and Vietnam conventional and sustainable coffee production and export to the United Kingdom. Geo: Geogr. Environ. 2020, 7, e00096. [Google Scholar] [CrossRef]

- DaMatta, F.M.; Ronchi, C.P.; Maestri, M.; Barros, R.S. Ecophysiology of coffee growth and production. Braz. J. Plant Physiol. 2007, 19, 485–510. [Google Scholar] [CrossRef]

- Applied Food Sciences, Inc. Innovative Functional Ingredients. Available online: https://appliedfoods.com/ (accessed on 10 August 2021).

- BENEO Together We Contribute to Better Nutrition and Health. Available online: https://www.beneo.com/ (accessed on 10 August 2021).

- Naturex, Global Leader in Specialty Plant-Based Natural Ingredients. Available online: https://www.naturex.com/ (accessed on 10 August 2021).

- Adam, D.J.; Mainwaring, J.; Quigley, M.N. Soxhlet Extraction of Caffeine from Beverage Plants. 1996. Available online: https://pubs.acs.org/sharingguidelines (accessed on 21 April 2021).

- Mandal, V.; Mohan, Y.; Hemalatha, S. Microwave Assisted Extraction-An Innovative and Promising Extraction Tool for Medicinal Plant Research. Available online: https://www.phcogrev.com (accessed on 21 April 2021).

- Li, Y.; Radoiu, M.; Fabiano-Tixier, A.S.; Chemat, F. From laboratory to industry: Scale-up, quality, and safety consideration for microwave-assisted extraction. In Food Engineering Series; Springer: Cham, Switzerland, 2013; pp. 207–229. [Google Scholar] [CrossRef]

- Upadhyay, R.; Ramalakshmi, K.; Rao, L.J.M. Microwave-assisted extraction of chlorogenic acids from green coffee beans. Food Chem. 2012, 130, 184–188. [Google Scholar] [CrossRef]

- Garcia-Garcia, G.; Rahimifard, S.; Mathau, A.S.; Dugmore, T.I.J. Life-Cycle Analysis of Microwave Assisted Pectin Extraction at Pilot-scale. ACS Sustain. Chem. Eng. 2019, 5, 5167–5175. [Google Scholar]

- Gonçalves, B.; Moeenfard, M.; Rocha, F.; Alves, A.; Estevinho, B.N.; Santos, L. Microencapsulation of a Natural Antioxidant from Coffee—Chlorogenic Acid (3-Caffeoylquinic Acid). Food Bioprocess Technol. 2017, 10, 1521–1530. [Google Scholar] [CrossRef]

- De Falco, B.; Incerti, G.; Amato, M.; Lanzotti, V. Artichoke: Botanical, agronomical, phytochemical, and pharmacological overview. Phytochem. Rev. 2015, 14, 993–1018. [Google Scholar] [CrossRef]

- Roberfroid, M.B. Introducing inulin-type fructans. Br. J. Nutr. 2005, 93, S13–S25. [Google Scholar] [CrossRef]

- Pandino, G.; Lombardo, S.; Mauromicale, G.; Williamson, G. Phenolic acids and flavonoids in leaf and floral stem of cultivated and wild Cynara cardunculus L. genotypes. Food Chem. 2011, 126, 417–422. [Google Scholar] [CrossRef]

- Shoaib, M.; Shehzad, A.; Omar, M.; Rakha, A.; Raza, H.; Sharif, H.R.; Shakeel, A.; Ansari, A.; Niazi, S. Inulin: Properties, health benefits and food applications. Carbohydr. Polym. 2016, 147, 444–454. [Google Scholar] [CrossRef]

- Lattanzio, V.; Kroon, P.A.; Linsalata, V.; Cardinali, A. Globe artichoke: A functional food and source of nutraceutical ingredients. J. Funct. Foods 2009, 1, 131–144. [Google Scholar] [CrossRef]

- Baldini, M.; Danuso, F.; Monti, A.; Amaducci, M.T.; Stevanato, P.; de Mastro, G. Chicory and Jerusalem Artichoke Productivity in Different Areas of Italy; Agronomy, Italy. In Relation to Water Availability and Time of Harvest; PAGEPress®: Pavia, Italy, 2006. [Google Scholar] [CrossRef]

- Elias, T.S.; Dykeman, P.A. Edible Wild Plants: A North American Field Guide to over 200 Natural Foods; Sterling Publishing: New York, NY, USA, 2009. [Google Scholar]

- Li, G.; Kemp, P.D. Forage Chicory (Cichorium intybus L.): A Review of Its Agronomy and Animal Production. Adv. Agron. 2005, 88, 187–222. [Google Scholar] [CrossRef]

- Tamburini, E.; Pedrini, P.; Marchetti, M.G.; Fano, E.A.; Castaldelli, G. Life Cycle Based Evaluation of Environmental and Economic Impacts of Agricultural Productions in the Mediterranean Area. Sustainability 2015, 7, 2915–2935. [Google Scholar] [CrossRef]

- D’Egidio, M.; Cecchini, C.; Cervigni, T.; Donini, B.; Pignatelli, V. Production of fructose from cereal stems and polyannual cultures of Jerusalem artichoke. Ind. Crop. Prod. 1998, 7, 113–119. [Google Scholar] [CrossRef]

- Pappalardo, H.D.; Toscano, V.; Puglia, G.D.; Genovese, C.; Raccuia, S.A. Cynara cardunculus L. as a Multipurpose Crop for Plant Secondary Metabolites Production in Marginal Stressed Lands. Front. Plant Sci. 2020, 11, 240. [Google Scholar] [CrossRef]

- Neri, U.; Pennelli, B.; Simonetti, G.; Francaviglia, R. Biomass partition and productive aptitude of wild and cultivated cardoon genotypes (Cynara cardunculus L.) in a marginal land of central Italy. Ind. Crop. Prod. 2017, 95, 191–201. [Google Scholar] [CrossRef]

- Rossini, F.; Provenzano, M.E.; Kuzmanović, L.; Ruggeri, R. Jerusalem Artichoke (Helianthus tuberosus L.): A Versatile and Sustainable Crop for Renewable Energy Production in Europe. Agronomy 2019, 9, 528. [Google Scholar] [CrossRef]

- Ramalakshmi, S.T.K. Microwave-Assisted Extraction of Inulin from Chicory Roots Using Response Surface Methodology. J. Nutr. Food Sci. 2014, 5. [Google Scholar] [CrossRef]

- Gominho, J.; Curt, M.D.; Lourenço, A.; Fernández, J.; Pereira, H. Cynara cardunculus L. as a biomass and multi-purpose crop: A review of 30 years of research. Biomass-Bioenergy 2018, 109, 257–275. [Google Scholar] [CrossRef]

- Barracosa, P.; Barracosa, M.; Pires, E. Cardoon as a Sustainable Crop for Biomass and Bioactive Compounds Production. Chem. Biodivers. 2019, 16, e1900498. [Google Scholar] [CrossRef] [PubMed]

- Fernández, J.; Curt, M.D.; Aguado, P.L. Industrial applications of Cynara cardunculus L. for energy and other uses. Ind. Crop. Prod. 2006, 24, 222–229. [Google Scholar] [CrossRef]

- Schmidt, T.; Fernando, A.L.; Monti, A.; Rettenmaier, N. Life Cycle Assessment of Bioenergy and Bio-Based Products from Perennial Grasses Cultivated on Marginal Land in the Mediterranean Region. BioEnergy Res. 2015, 8, 1548–1561. [Google Scholar] [CrossRef]

- Kahr, H.; Wimberger, J.; Schürz, D.; Jäger, A. Evaluation of the Biomass Potential for the Production of Lignocellulosic Bioethanol from Various Agricultural Residues in Austria and Worldwide. Energy Procedia 2013, 40, 146–155. [Google Scholar] [CrossRef][Green Version]

- Santchurn, D.; Ramdoyal, K.; Badaloo, M.; Labuschagne, M. From sugar industry to cane industry: Evaluation and simultaneous selection of different types of high biomass canes. Biomass-Bioenergy 2014, 61, 82–92. [Google Scholar] [CrossRef]

- Vaezi, M.; Passandideh-Fard, M.; Moghiman, M.; Charmchi, M. On a methodology for selecting biomass materials for gasification purposes. Fuel Process. Technol. 2012, 98, 74–81. [Google Scholar] [CrossRef]

- Cobuloglu, H.I.; Büyüktahtakın, I.E. A stochastic multi-criteria decision analysis for sustainable biomass crop selection. Expert Syst. Appl. 2015, 42, 6065–6074. [Google Scholar] [CrossRef]

- Ho, W. Integrated analytic hierarchy process and its applications—A literature review. Eur. J. Oper. Res. 2008, 186, 211–228. [Google Scholar] [CrossRef]

- Multi-Criteria Analysis: A Manual. Available online: www.communities.gov.ukcommunity,opportunity,prosperity (accessed on 15 May 2021).

- Mardani, A.; Jusoh, A.; Nor, K.M.; Khalifah, Z.; Zakwan, N.; Valipour, A. Multiple criteria decision-making techniques and their applications—a review of the literature from 2000 to 2014. Econ. Res. Ekon. Istraz. 2015, 28, 516–571. [Google Scholar] [CrossRef]

- Lee, H.C.; Chang, C. Comparative analysis of MCDM methods for ranking renewable energy sources in Taiwan. In Renewable and Sustainable Energy Reviews; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; Volume 92, pp. 883–896. [Google Scholar] [CrossRef]

- Saaty, T.L. Analytical Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Chatzimouratidis, A.I.; Pilavachi, P.A. Sensitivity analysis of the evaluation of power plants impact on the living standard using the analytic hierarchy process. Energy Convers. Manag. 2008, 49, 3599–3611. [Google Scholar] [CrossRef]

- Amer, M.; Daim, T.U. Selection of renewable energy technologies for a developing county: A case of Pakistan. Energy Sustain. Dev. 2011, 15, 420–435. [Google Scholar] [CrossRef]

- Neely, T.; Russell, P.; O’hagan, S.; Walsh-Mason, B.; Der Horst, A.; Lahorkar, P. A multi-criteria decision analysis model to assess the safety of botanicals utilizing data on history of use. Toxicol. Int. Former. Indian J. Toxicol. 2011, 18, S20–S29. [Google Scholar] [CrossRef] [PubMed]

- Oketch-Rabah, H.A.; Hardy, M.L.; Patton, A.P.; Chung, M.; Sarma, N.D.; Yoe, C.; Ayyadurai, V.A.S.; Fox, M.A.; Jordan, S.A.; Mwamburi, M.; et al. Multi-Criteria Decision Analysis Model for Assessing the Risk from Multi-Ingredient Dietary Supplements (MIDS). J. Diet. Suppl. 2020, 18, 293–315. [Google Scholar] [CrossRef]

- Gatto, F.; Daniotti, S.; Re, I. Driving Green Investments by Measuring Innovation Impacts. Multi-Criteria Decision Analysis for Regional Bioeconomy Growth. Sustainability 2021, 13, 11709. [Google Scholar] [CrossRef]

- Saaty, R. The analytic hierarchy process—what it is and how it is used. Math. Model. 1987, 9, 161–176. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, L.; Nieto, J.J. A delayed epidemic model with stage-structure and pulses for pest management strategy. Nonlinear Anal. Real World Appl. 2008, 9, 1714–1726. [Google Scholar] [CrossRef]

- Zadeh, L.A.; Kacprzyk, J. Computing with Words in Information/Intelligent Systems 1. Physica 1999, 33, 103–111. [Google Scholar] [CrossRef]

- Ortega, R.G.; Rodríguez, M.D.O.; Vázquez, M.L.; Ricardo, E.E.; Figueiredo, J.A.S.; Smarandache, F. Pestel analysis based on neutrosophic cognitive maps and neutrosophic numbers for the sinos river basin management. Neutrosophic Sets Syst. 2019, 26, 105–113. [Google Scholar]

- Remigio. Baldoni and Luigi. Giardini, “Coltivazioni Erbacee”; Pàtron: San Francisco, CA, USA, 2000. [Google Scholar]

- Mercati, I. Analisi e Studio Filiere Agroalimentari. Available online: http://www.ismeamercati.it/analisi-e-studio-filiere-agroalimentari (accessed on 19 August 2021).

- LO, G.A. Life Cycle Assessment Interpretation and Improvement of the Sicilian Artichokes Production. Int. J. Environ. Res. 2014, 8, 305–316. [Google Scholar]

- Mena-García, A.; Rodríguez-Sánchez, S.; Ruiz-Matute, A.; Sanz, M. Exploitation of artichoke byproducts to obtain bioactive extracts enriched in inositols and caffeoylquinic acids by Microwave Assisted Extraction. J. Chromatogr. A 2019, 1613, 460703. [Google Scholar] [CrossRef]

- International Coffee Organization—What’s New. Available online: https://ico.org/ (accessed on 19 August 2021).

- Trinh, L.T.K.; Hu, A.H.; Lan, Y.C.; Chen, Z.-H. Comparative life cycle assessment for conventional and organic coffee cultivation in Vietnam. Int. J. Environ. Sci. Technol. 2019, 17, 1307–1324. [Google Scholar] [CrossRef]

- Razza, F.; Sollima, L.; Falce, M.; Costa, R.M.; Toscano, V.; Novelli, A.; Ciancolini, A.; Raccuia, S.A. Life cycle assessment of cardoon production system in different areas of Italy. Acta Hortic. 2016, 329–334. [Google Scholar] [CrossRef]

- Francavilla, M.; Marone, M.; Marasco, P.; Contillo, F.; Monteleone, M. Artichoke Biorefinery: From Food to Advanced Technological Applications. Foods 2021, 10, 112. [Google Scholar] [CrossRef] [PubMed]

- Zeaiter, Z.; Regonesi, M.E.; Cavini, S.; Labra, M.; Sello, G.; Di Gennaro, P. Extraction and Characterization of Inulin-Type Fructans from Artichoke Wastes and Their Effect on the Growth of Intestinal Bacteria Associated with Health. BioMed Res. Int. 2019, 2019, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Perović, J.; Šaponjac, V.T.; Kojić, J.; Krulj, J.; Moreno, D.A.; García-Viguera, C.; Bodroža-Solarov, M.; Ilić, N. Chicory (Cichorium intybus L.) as a food ingredient—Nutritional composition, bioactivity, safety, and health claims: A review. Food Chem. 2020, 336, 127676. [Google Scholar] [CrossRef] [PubMed]

- CAAT Centro Agro Alimentare di Torino. Available online: https://www.caat.it/it (accessed on 19 August 2021).

- Lv, S.; Wang, R.; Xiao, Y.; Li, F.; Mu, Y.; Lu, Y.; Gao, W.; Yang, B.; Kou, Y.; Zeng, J.; et al. Growth, yield formation, and inulin performance of a non-food energy crop, Jerusalem artichoke (Helianthus tuberosus L.), in a semi-arid area of China. Ind. Crop. Prod. 2019, 134, 71–79. [Google Scholar] [CrossRef]

- Petkova, N.; Genchev, G.; Vassilev, D.; Koleva, M.; Denev, A.K.A.P. Microwave-Assisted Isolation and Acetylation of Inulin from Helianthus Tuberosus L Tubers. J. Renew. Mater. 2018, 6, 671–679. [Google Scholar] [CrossRef]

- 2030 Climate & Energy Framework Climate Action. Available online: https://ec.europa.eu/clima/policies/strategies/2030_en (accessed on 20 September 2021).

- 2050 Long-Term Strategy Climate Action. Available online: https://ec.europa.eu/clima/policies/strategies/2050_en (accessed on 20 September 2021).

- DDD Conference. Available online: https://dddconf.org/ (accessed on 3 September 2021).

- Solinas, S.; Tiloca, M.T.; Deligios, P.A.; Cossu, M.; Ledda, L. Carbon footprints and social carbon cost assessments in a perennial energy crop system: A comparison of fertilizer management practices in a Mediterranean area. Agric. Syst. 2020, 186, 102989. [Google Scholar] [CrossRef]

- Matrilox Bioproducts. Available online: https://www.matrica.it/public/docs/matrica-prodotti-2016-en-web.pdf (accessed on 3 September 2021).

- Chaurasia, S.; Pati, R.K.; Padhi, S.S.; Jensen, J.M.K.; Gavirneni, N. Achieving the United Nations Sustainable Development Goals-2030 through the nutraceutical industry: A review of managerial research and the role of operations management. Decis. Sci. 2021, 16. [Google Scholar] [CrossRef]

- Li, S.; Kallas, Z. Meta-analysis of consumers’ willingness to pay for sustainable food products. Appetite 2021, 163, 105239. [Google Scholar] [CrossRef] [PubMed]

- Vanclay, J.K.; Shortiss, J.; Aulsebrook, S.; Gillespie, A.M.; Howell, B.C.; Johanni, R.; Maher, M.J.; Mitchell, K.M.; Stewart, M.D.; Yates, J. Customer Response to Carbon Labelling of Groceries. J. Consum. Policy 2011, 34, 153–160. [Google Scholar] [CrossRef]

| Criterium | Criterium Title | Measurement Unit | Description | Evaluation Type |

|---|---|---|---|---|

| C1 | Biomass yield on cultivated lands | Mg/ha | The amount of biomass obtained from each crop in optimal cultivation conditions. | Maximization |

| C2 | Biomass yield on marginal lands | Mg/ha | The amount of biomass obtained in harsh soil unsuitable for conventional cultivation, capturing the added value of promoting rural and social development. | Maximization |

| C3 | Biomass prices | EUR/kg | Calculated on 1 kg of biomass. This value is subject to environmental, social, and economic fluctuations (e.g., pandemic crisis, climate change, regulatory provisions). | Minimization |

| C4 | Sustainability index | kg CO2 eq/kg | The carbon footprint of each biomass. | Minimization |

| C5 | Food competition | Present/absent | The capacity of the species to spare arable lands otherwise intended for edible crops or exploitation of edible crops (as in the case of coffee or artichoke). | Maximization |

| C6 | Extraction yield | % | The efficiency of the extraction processes for each biomass. | Maximization |

| C8 | Final sale price | EUR/kg | The final price to the consumer of the bioactive compounds. | Minimization |

| CGA-Specific Criterium | ||||

| C7 | Extraction costs | EUR/cycle | The extraction costs from a 75 L pilot plant for one work cycle, referring to extraction conditions, electricity, heating, and raw material requirements. | Minimization |

| Inulin-Specific Criterium | ||||

| C7 | Inulin concentration | mg/g | The availability of the bioactive compound in fresh biomass, before extraction. | Maximization |

| Chlorogenic Acid Source | Inulin Source |

|---|---|

| Cardoon (Cynara cardunculus) | Cardoon (Cynara cardunculus) |

| Green coffee beans (Coffea canephora) | Chicory (Chicorium intybus) |

| Green coffee beans (Coffea arabica) | Jerusalem artichoke (Heliantus tuberosus) |

| Artichoke (Cynara scolymus) |

| Biomass | Biomass Yield on Cultivated Lands (Mg/ha) | Biomass Yield on Marginal Lands (Mg/ha) | Biomass Prices (EUR/kg) | Sustainability Index (kgCO2eq/kg) | Food Competition | Process Yield (%) | Process Costs (EUR/kg) | Final Price to the Consumer (EUR/kg) |

|---|---|---|---|---|---|---|---|---|

| Artichoke (Cynara scolymus) | 9 [44,66] | Not suitable | 1 [67] | 0.3 [68] | Yes | 22.5 [69] | 18.88 [69] | 55 [3] |

| Green coffee (Coffea canephora) | 3.1 [70] | Not suitable | 5 [70] | 6.85 [71] | Yes | 7.4 [27] | 8.51 [27] | 23.9 [3] |

| Green coffee (Coffea arabica) | 2.3 [70] | Not suitable | 5 [70] | 6.84 [18] | Yes | 7.4 [27] | 8.51 [27] | 23.9 [3] |

| Cardoon (Cynara cardunculus) | 17 [44,73] | 7.95 [44] | 0.098 [67] | 0.2 [72] | No [44] | 22.5 [69] | 18.88 [69] | 55 [3] |

| Biomass | Biomass Yield on Cultivated Lands | Biomass Yield on Marginal Lands | Biomass Prices | Sustainability Index | Food Competition | Process Yield | Process Costs | Final Price to the Consumer |

|---|---|---|---|---|---|---|---|---|

| Artichoke (Cynara scolymus) | 0.456 | 0 | 0.816 | 0.980 | 0 | 1 | 0 | 0 |

| Green coffee (Coffea canephora) | 0.055 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| Green coffee (Coffea arabica) | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| Cardoon (Cynara cardunculus) | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 |

| Biomass | Inulin Concentration (mg/g) | Biomass Yield on Cultivated Lands (Mg/ha) | Biomass Yield on Marginal Lands (Mg/ha) | Biomass Prices (EUR) | Sustainability Index (kgCO2eq/kg) | Food Competition | Process Yield (%) | Final Price to the Consumer (EUR) |

|---|---|---|---|---|---|---|---|---|

| Cardoon (Cynara cardunculus) | 278 [45] | 9.8 [45] | 8 [44] | 0.098 [67] | 0.2 [72] | No [44] | 57.5 [73,74] | 3 [8] |

| Chicory (Chicorium intybus) | 155 [75] | 51.5 [38] | Not suitable | 0.9 [76] | 0.327 [77] | Yes | 63 [43] | 3 [8] |

| Jerusalem artichoke (Heliantus tuberosus) | 155 [75] | 43.5 [38] | 12.4 [42] | 1.7 [76] | 0.06 [42] | No [42] | 40 [78] | 3 [8] |

| Biomass | Inulin Concentration | Biomass Yield on Cultivated Lands | Biomass Yield on Marginal Lands | Biomass Prices | Sustainability Index | Food Competition | Process Yield | Final Price to the Consumer |

|---|---|---|---|---|---|---|---|---|

| Cardoon (Cynara cardunculus) | 1 | 0 | 0.64 | 1 | 0.46 | 1 | 0.76 | 0.5 |

| Chicory (Chicorium intybus) | 0 | 1 | 0 | 0.50 | 0 | 0 | 1 | 0.5 |

| Jerusalem artichoke (Heliantus tuberosus) | 0 | 0.81 | 1 | 0 | 1 | 1 | 0 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borroni, M.; Pozzi, C.M.; Daniotti, S.; Gatto, F.; Re, I. Multi-Criteria Decision-Making Approach for Nutraceuticals Greener Applications: The Cynara cardunculus Case Study. Sustainability 2021, 13, 13483. https://doi.org/10.3390/su132313483

Borroni M, Pozzi CM, Daniotti S, Gatto F, Re I. Multi-Criteria Decision-Making Approach for Nutraceuticals Greener Applications: The Cynara cardunculus Case Study. Sustainability. 2021; 13(23):13483. https://doi.org/10.3390/su132313483

Chicago/Turabian StyleBorroni, Michele, Carlo Massimo Pozzi, Sara Daniotti, Fabiana Gatto, and Ilaria Re. 2021. "Multi-Criteria Decision-Making Approach for Nutraceuticals Greener Applications: The Cynara cardunculus Case Study" Sustainability 13, no. 23: 13483. https://doi.org/10.3390/su132313483

APA StyleBorroni, M., Pozzi, C. M., Daniotti, S., Gatto, F., & Re, I. (2021). Multi-Criteria Decision-Making Approach for Nutraceuticals Greener Applications: The Cynara cardunculus Case Study. Sustainability, 13(23), 13483. https://doi.org/10.3390/su132313483