Integrated Underground Mining Hazard Assessment, Management, Environmental Monitoring, and Policy Control in Pakistan

Abstract

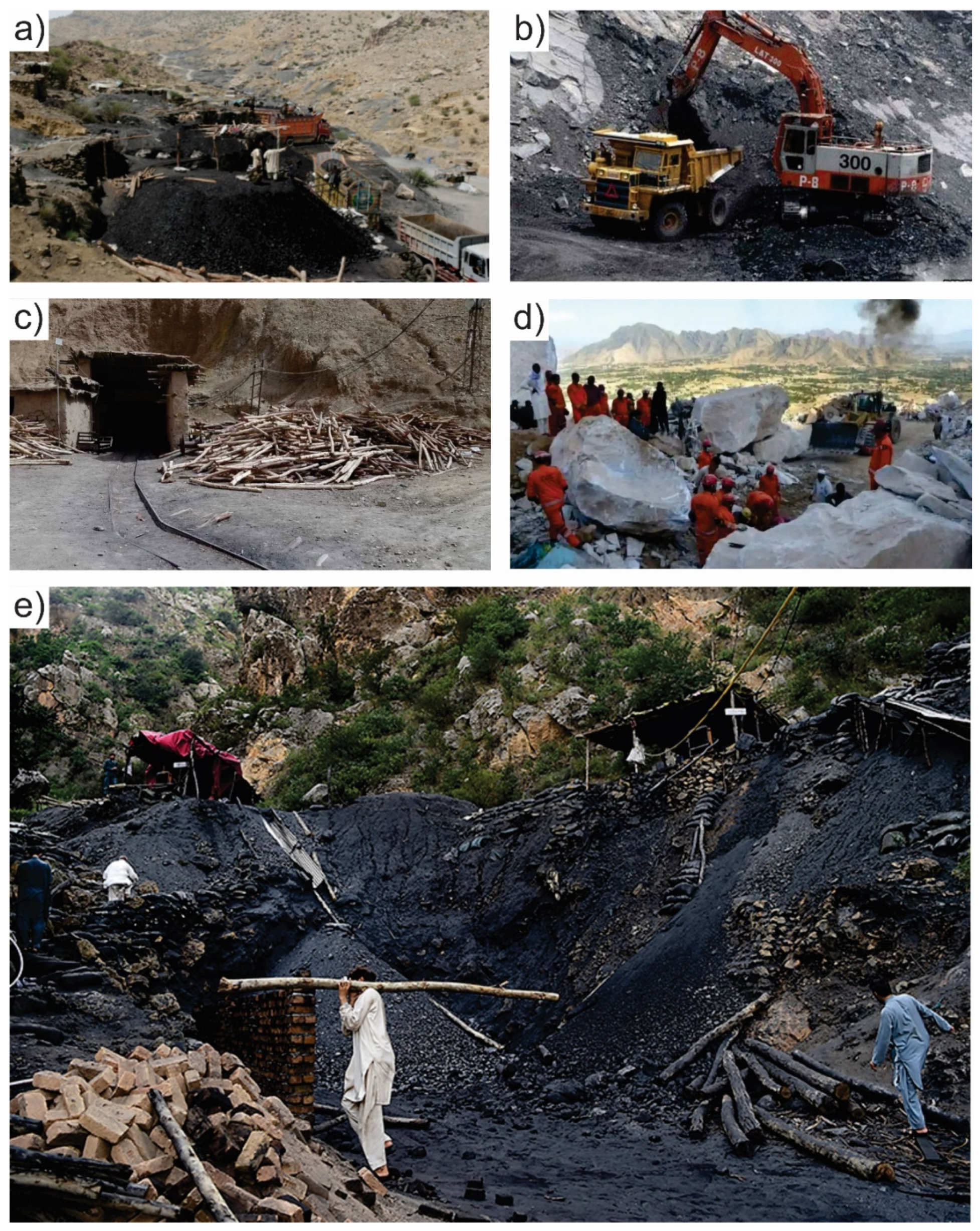

:1. Introduction

2. Methodology

3. Results and Discussion

4. Law Policies of Mineral and Mines in Pakistan

- It should be noted that “uneducated” and “unskilled” are not comparable, and the idea that education determines skill level is incredible.

- Off-nominal conduct may be a safety violation if the person doing it has not received proper training.

- Due to the severe nature of mining hazards, it is hard to believe miners would purposefully endanger their own and their colleagues’ lives if properly educated and trained.

- If miners lack the skills required to operate safely in a mine, inadequate training is the major cause. Mine owners, managers, and regulators are responsible for miner safety training.

5. Recommendations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Domínguez, C.R.; Martínez, I.V.; Peña, P.M.P.; Ochoa, A.R. Analysis and evaluation of risks in underground mining using the decision matrix risk-assessment (DMRA) technique, in Guanajuato, Mexico. J. Sustain. Min. 2019, 18, 52–59. [Google Scholar] [CrossRef]

- Hentschel, T.; Hruschka, F.; Priester, M. Global Report on Artisanal and Small-Scale Mining, Report Commissioned by the Mining, Minerals and Sustainable Development of the International Institute for Environment and Development. 2002, Volume 20, p. 2008. Available online: http://www.iied.org/mmsd/mmsd_pdfs/asm_global_report_draft_jan02 (accessed on 1 October 2021).

- Azapagic, A. Developing a framework for sustainable development indicators for the mining and minerals industry. J. Clean. Prod. 2004, 12, 639–662. [Google Scholar] [CrossRef]

- Benites, A.J.; Simões, A.F. Assessing the urban sustainable development strategy: An application of a smart city services sustainability taxonomy. Ecol. Indic. 2021, 127, 107734. [Google Scholar] [CrossRef]

- Duro, A.; Piccione, V.; Ragusa, M.; Veneziano, V. New enviromentally sensitive patch index-ESPI-for MEDALUS protocol. In Proceedings of the 10th International Conference on Mathematical Problems in Engineering, Aerospace and Sciences: ICNPAA 2014, Narvik, Norway, 15–18 July 2014; pp. 305–312. [Google Scholar]

- Almeida, C.; Ruas, F.; Godinho, M.; Martins, A. Teaching Science Problem Based Learning (PBL) Implementation of Rocks and Minerals. In EGU General Assembly Conference Abstracts; 2016; p. EPSC2016-8644. Available online: https://ui.adsabs.harvard.edu/abs/2016EGUGA..18.8644A/abstract (accessed on 1 October 2021).

- Rebello, S.; Anoopkumar, A.; Aneesh, E.M.; Sindhu, R.; Binod, P.; Kim, S.H.; Pandey, A. Hazardous minerals mining: Challenges and solutions. J. Hazard. Mater. 2021, 402, 123474. [Google Scholar] [CrossRef] [PubMed]

- Yadoo, A.; Cruickshank, H. The role for low carbon electrification technologies in poverty reduction and climate change strategies: A focus on renewable energy mini-grids with case studies in Nepal, Peru and Kenya. Energy Policy 2012, 42, 591–602. [Google Scholar] [CrossRef]

- Foo, N.; Bloch, H.; Salim, R. The optimisation rule for investment in mining projects. Resour. Policy 2018, 55, 123–132. [Google Scholar] [CrossRef]

- Council, N.R. Mining Safety and Health Research at NIOSH: Reviews of Research Programs of the National Institute for Occupational Safety and Health; National Academies Press: Washington, DC, USA, 2007; Volume 2. [Google Scholar]

- Laurence, D. Establishing a sustainable mining operation: An overview. J. Clean. Prod. 2011, 19, 278–284. [Google Scholar] [CrossRef]

- Pietilä, J.; Räsänen, T.; Reiman, A.; Ratilainen, H.; Helander, E. Characteristics and determinants of recurrent occupational accidents. Saf. Sci. 2018, 108, 269–277. [Google Scholar] [CrossRef]

- Malkani, M.S.; Mahmood, Z. Mineral resources of Pakistan: A review. Geol. Surv. Pak. Rec. 2016, 128, 1–90. [Google Scholar]

- Ullah, M.F.; Mahmood, K.; Akram, M.S. Coal mining trends and future prospects: A case study of Eastern Salt Range, Punjab, Pakistan. J. Himal. Earth Sci. 2018, 51, 87–93. [Google Scholar]

- Khan, U.; Janjuhah, H.T.; Kontakiotis, G.; Rehman, A.; Zarkogiannis, S.D. Natural Processes and Anthropogenic Activity in the Indus River Sedimentary Environment in Pakistan: A Critical Review. J. Mar. Sci. Eng. 2021, 9, 1109. [Google Scholar] [CrossRef]

- Shah, S.A.H. Strategy for mineral sector development in Pakistan. Minist. Plan. 2018, 3, 1–24. [Google Scholar]

- Wang, K.-P.; Chin, E. Mineral Economics and Basic Industries in Asia; Routledge: London, UK, 2019. [Google Scholar]

- Vinti, G.; Vaccari, M. Natural resources. Consumption, pollution, and health risks: Developed versus developing economies. In The Routledge Handbook of Waste, Resources and the Circular Economy; Routledge: London, UK, 2020; pp. 11–19. [Google Scholar]

- Rodionova, I. Global industrial development trends: Dynamics and regional aspects. Весmник Казнy. Серия Географическая 2021, 60, 17–26. [Google Scholar] [CrossRef]

- Igaliyeva, L.; Niyazbekova, S.; Serikova, M.; Kenzhegaliyeva, Z.; Mussirov, G.; Zueva, A.; Tyurina, Y.; Maisigova, L. Towards Environmental Security via Energy Efficiency: A Case Study. Entrepreneurship 2020, 7, 3488–3499. [Google Scholar] [CrossRef]

- Shahani, N.M.; Sajid, M.J.; Zheng, X.; Brohi, M.A.; Jiskani, I.M.; Ul Hassan, F.; Qureshi, A.R. Statistical analysis of fatalities in underground coal mines in Pakistan. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 6, 1–16. [Google Scholar] [CrossRef]

- Shahani, N.M.; Sajid, M.J.; Jiskani, I.M.; Ullah, B.; Qureshi, A.R. Comparative analysis of coal Miner’s fatalities by fuzzy logic. J. Min. Environ. 2021, 12, 77–87. [Google Scholar]

- Ishtiaq, M.; Jehan, N.; Khan, S.A.; Muhammad, S.; Saddique, U.; Iftikhar, B. Potential harmful elements in coal dust and human health risk assessment near the mining areas in Cherat, Pakistan. Environ. Sci. Pollut. Res. 2018, 25, 14666–14673. [Google Scholar] [CrossRef] [PubMed]

- Gomes, C.S.; Silva, E.A. Health Benefits and Risks of Minerals: Bioavailability, Bio-Essentiality, Toxicity, and Pathologies. In Minerals Latu Sensu and Human Health; Springer: Berlin/Heidelberg, Germany, 2021; pp. 81–179. [Google Scholar]

- Rehman Ur, I.; Ishaq, M.; Ali, L.; Khan, S.; Ahmad, I.; Din, I.U.; Ullah, H. Enrichment, spatial distribution of potential ecological and human health risk assessment via toxic metals in soil and surface water ingestion in the vicinity of Sewakht mines, district Chitral, Northern Pakistan. Ecotoxicol. Environ. Saf. 2018, 154, 127–136. [Google Scholar] [CrossRef]

- Lassila, M. The Arctic mineral resource rush and the ontological struggle for the Viiankiaapa peatland in Sodankylä, Finland. Globalizations 2021, 18, 635–649. [Google Scholar] [CrossRef]

- Ali, D.; Rehman, A.U. Adoption of autonomous mining system in Pakistan–Policy, skillset, awareness and preparedness of stakeholders. Resour. Policy 2020, 68, 101796. [Google Scholar] [CrossRef]

- Shengo, L. Review of Practices in the Managements of Mineral Wastes: The Case of Waste Rocks and Mine Tailings. Water Air Soil Pollut. 2021, 232, 1–31. [Google Scholar] [CrossRef]

- Rudakov, M.L. Assessment of environmental and occupational safety in mining industry during underground coal mining. J. Environ. Manag. Tour. (JEMT) 2020, 11, 579–588. [Google Scholar] [CrossRef]

- Graczyk, H.; François, M.; Krief, P.; Guseva Canu, I. The role of the Swiss list of occupational diseases in the protection of workers’ health. Swiss Med. Wkly. 2021, 151, w20538. [Google Scholar] [CrossRef]

- Bahn, S. Workplace hazard identification and management: The case of an underground mining operation. Saf. Sci. 2013, 57, 129–137. [Google Scholar] [CrossRef]

- Schulte, P.A.; Chun, H. Climate change and occupational safety and health: Establishing a preliminary framework. J. Occup. Environ. Hyg. 2009, 6, 542–554. [Google Scholar] [CrossRef]

- Baloch, M.A.; Qureshi, A.A.; Waheed, A.; Ali, M.; Ali, N.; Tufail, M.; Batool, S.; Akram, M.; Iftikhar, P.; Qayyum, H. A study on natural radioactivity in Khewra Salt Mines, Pakistan. J. Radiat. Res. 2012, 53, 411–421. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khalid, B. Effect of temperature and humidity on salt mine environment. Pak. J. Meteorol. 2010, 7, 71–81. [Google Scholar]

- Sherin, S.; Rehman, Z.U.; Husain, S.; Muhammad, N.; Bilal, T. Assessment and Quantification of Risks Associated with Small Scale Mining, Khyber Pakhtunkhwa, Pakistan. Int. J. Econ. Environ. Geol. 2020, 11, 65–69. [Google Scholar]

- Sasmito, A.P.; Birgersson, E.; Ly, H.C.; Mujumdar, A.S. Some approaches to improve ventilation system in underground coal mines environment–A computational fluid dynamic study. Tunn. Undergr. Space Technol. 2013, 34, 82–95. [Google Scholar] [CrossRef]

- Raza, W.; Saeed, S.; Saulat, H.; Gul, H.; Sarfraz, M.; Sonne, C.; Sohn, Z.-H.; Brown, R.J.; Kim, K.-H. A review on the deteriorating situation of smog and its preventive measures in Pakistan. J. Clean. Prod. 2020, 279, 123676. [Google Scholar] [CrossRef]

- Saleem, A. A Rapid Assessment of Bonded Labour in Pakistan’s Mining Sector. Int. Labour Off. Geneva 2004, 20, 1–33. [Google Scholar]

- Shahani, N.; Sajid, M.; Zheng, X.; Jiskani, I.; Brohi, M.; Ali, M.; Ullah, B.; Qureshi, A. Mining of Mineral Deposits. J. Homepage 2019, 13, 121–128. Available online: http://mining.in.ua/articles/volume13_4/14.pdf (accessed on 1 October 2021).

- Jiskani, I.M.; Cai, Q.; Zhou, W.; Chang, Z.; Chalgri, S.R.; Manda, E.; Lu, X. Distinctive model of mine safety for sustainable mining in Pakistan. Min. Metall. Explor. 2020, 37, 1023–1037. [Google Scholar] [CrossRef]

- Jiskani, I.M.; Chalgri, S.R.; Memon, S.; Shahani, N.M.; Qureshi, A.R.; Jarwar, Z.A. Prospective study on safety climate of surface mining in Pakistan. J. Sustain. Min. 2020, 19, 2. [Google Scholar] [CrossRef]

- Batool, K.A. Occupational Health Hazards in Mining in Pakistan: An Overview. Eur. Acad. Res. 2015, 3, 5306–5319. [Google Scholar]

- Ishtiaq, M.; Nawaz, R.; Khan, K.U.; Khan, H.U.; Zakir, S.; Sarwar, G.; Jehan, N. Prevalance of pneumoconiosis among coal miners of Cherat, district Nowshera-Pakistan. J. Postgrad. Med Inst. 2014, 28, 139–144. [Google Scholar]

- Kunda, R.; Frantz, J.; Karachi, F. Prevalence and ergonomic risk factors of work-related musculoskeletal injuries amongst underground mine workers in Zambia. J. Occup. Health 2013, 55, 211–217. [Google Scholar] [CrossRef] [Green Version]

- Amponsah-Tawiah, K.; Leka, S.; Jain, A.; Hollis, D.; Cox, T. The impact of physical and psychosocial risks on employee well-being and quality of life: The case of the mining industry in Ghana. Saf. Sci. 2014, 65, 28–35. [Google Scholar] [CrossRef]

- Mościcka-Teske, A.; Sadłowska-Wrzesińska, J.; Najder, A.; Butlewski, M. The relationship between psychosocial risks and occupational functioning among miners. Int. J. Occup. Med. Environ. Health 2019, 32, 87–98. [Google Scholar] [CrossRef]

- Pollard, J.; Heberger, J.; Dempsey, P.G. Maintenance and repair injuries in US mining. J. Qual. Maint. Eng. 2014, 20, 20–31. [Google Scholar] [CrossRef]

- Karliński, J.; Ptak, M.; Działak, P.; Rusiński, E. The approach to mining safety improvement: Accident analysis of an underground machine operator. Arch. Civ. Mech. Eng. 2016, 16, 503–512. [Google Scholar] [CrossRef]

- Dhillon, B.S. Mining equipment safety: A review, analysis methods and improvement strategies. Int. J. Min. Reclam. Environ. 2009, 23, 168–179. [Google Scholar] [CrossRef]

- Soni, A.; Nema, P. Limestone Mining, Industry, and Society. In Limestone Mining in India; Springer: Berlin/Heidelberg, Germany, 2021; pp. 41–67. [Google Scholar]

- Remen, T.; Acouetey, D.; Paris, C.; Hannhart, B.; Poussel, M.; Chenuel, B.; Barbaud, A.; Zmirou-Navier, D. Early incidence of occupational asthma is not accelerated by atopy in the bakery/pastry and hairdressing sectors. Int. J. Tuberc. Lung Dis. 2013, 17, 973–981. [Google Scholar] [CrossRef]

- Hermanus, M. Occupational health and safety in mining-status, new developments, and concerns. J. S. Afr. Inst. Min. Metall. 2007, 107, 531–538. [Google Scholar]

- Lawson, S.M.; Masterson, E.A.; Azman, A.S. Prevalence of hearing loss among noise-exposed workers within the Mining and Oil and Gas Extraction sectors, 2006–2015. Am. J. Ind. Med. 2019, 62, 826–837. [Google Scholar] [CrossRef]

- Kirchsteiger, C. On the use of probabilistic and deterministic methods in risk analysis. J. Loss Prev. Process. Ind. 1999, 12, 399–419. [Google Scholar] [CrossRef]

- Ni, H.; Chen, A.; Chen, N. Some extensions on risk matrix approach. Saf. Sci. 2010, 48, 1269–1278. [Google Scholar] [CrossRef]

- Gul, M.; Guneri, A.F. A fuzzy multi criteria risk assessment based on decision matrix technique: A case study for aluminum industry. J. Loss Prev. Process. Ind. 2016, 40, 89–100. [Google Scholar] [CrossRef]

- Ma, Y.; Deilami, K.; Egodawatta, P.; Liu, A.; McGree, J.; Goonetilleke, A. Creating a hierarchy of hazard control for urban stormwater management. Environ. Pollut. 2019, 255, 113217. [Google Scholar] [CrossRef]

- Morris, G.A.; Cannady, R. Proper use of the hierarchy of controls. Prof. Saf. 2019, 64, 37–40. [Google Scholar]

- Zhou, S.; Yang, P. Risk management in distributed wind energy implementing Analytic Hierarchy Process. Renew. Energy 2020, 150, 616–623. [Google Scholar] [CrossRef]

- Marhavilas, P.K.; Filippidis, M.; Koulinas, G.K.; Koulouriotis, D.E. The integration of HAZOP study with risk-matrix and the analytical-hierarchy process for identifying critical control-points and prioritizing risks in industry–A case study. J. Loss Prev. Process. Ind. 2019, 62, 103981. [Google Scholar] [CrossRef]

- Manzi, M.; Malehmir, A.; Durrheim, R. The value of seismics in mineral exploration and mine safety. In Proceedings of the 81st EAGE Conference and Exhibition, London, UK, 3–6 June 2019; pp. 1–5. [Google Scholar]

- Donoso, G.A.; Malehmir, A.; Brodic, B.; Pacheco, N.; Carvalho, J.; Araujo, V. Innovative seismic imaging of volcanogenic massive sulfide deposits, Neves-Corvo, Portugal—Part 2: Surface array. Geophysics 2021, 86, B181–B191. [Google Scholar] [CrossRef]

- Chattopadhyay, S.; Chattopadhyay, D. Coal and other mining operations: Role of sustainability. Foss. Energy 2020, 1, 333–356. [Google Scholar]

- Revuelta, M.B. Mineral Resource Extraction. Miner. Resour. 2018, 1, 311–421. [Google Scholar]

- Engström, K.G.; Angrén, J.; Björnstig, U.; Saveman, B.-I. Mass casualty incidents in the underground mining industry: Applying the Haddon matrix on an integrative literature review. Disaster Med. Public Health Prep. 2018, 12, 138–146. [Google Scholar] [CrossRef] [Green Version]

- Stemn, E.; Hassall, M.E.; Bofinger, C. Systemic constraints to effective learning from incidents in the Ghanaian mining industry: A correspondence analysis and AcciMap approach. Saf. Sci. 2020, 123, 104565. [Google Scholar] [CrossRef]

- Onifade, M. Countermeasures against coal spontaneous combustion: A review. Int. J. Coal Prep. Util. 2021, 2, 1–23. [Google Scholar] [CrossRef]

- Ammad, S.; Alaloul, W.S.; Saad, S.; Qureshi, A.H. Personal protective equipment (PPE) usage in construction projects: A scientometric approach. J. Build. Eng. 2020, 35, 102086. [Google Scholar] [CrossRef]

- Tamers, S.L.; Streit, J.; Pana-Cryan, R.; Ray, T.; Syron, L.; Flynn, M.A.; Castillo, D.; Roth, G.; Geraci, C.; Guerin, R. Envisioning the future of work to safeguard the safety, health, and well-being of the workforce: A perspective from the CDC’s National Institute for Occupational Safety and Health. Am. J. Ind. Med. 2020, 63, 1065–1084. [Google Scholar] [CrossRef]

- Zhang, H.; Han, W.; Xu, Y.; Wang, Z. Analysis on the Development Status of Coal Mine Dust Disaster Prevention Technology in China. J. Healthc. Eng. 2021, 2021, 5574579. [Google Scholar] [CrossRef]

- Fu, G.; Xie, X.; Jia, Q.; Tong, W.; Ge, Y. Accidents analysis and prevention of coal and gas outburst: Understanding human errors in accidents. Process. Saf. Environ. Prot. 2020, 134, 1–23. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Xiao, W.; Liu, T.; Yang, W.; Wang, Z.; Zhang, R. A safe mining approach for deep outburst coal seam groups with hard-thick sandstone roof: Stepwise risk control based on gas diversion and extraction. Energy Sci. Eng. 2020, 8, 2946–2965. [Google Scholar] [CrossRef]

- Agboola, O.; Babatunde, D.E.; Fayomi, O.S.I.; Sadiku, E.R.; Popoola, P.; Moropeng, L.; Yahaya, A.; Mamudu, O.A. A review on the impact of mining operation: Monitoring, assessment and management. Results Eng. 2020, 8, 100181. [Google Scholar] [CrossRef]

- Sanjana, P.; Prathilothamai, M. Drone design for first aid kit delivery in emergency situation. In Proceedings of the 2020 6th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, Tamil Nadu, India, 6–7 March 2020; pp. 215–220. [Google Scholar]

- Suryoputro, M.R.; Buana, F.A.; Sari, A.D.; Rahmillah, F.I. Active and Passive Fire Protection System in Academic Building KH. Mas Mansur, Islamic University of Indonesia. In MATEC Web of Conferences; p. 01094. Available online: https://www.matec-conferences.org/articles/matecconf/abs/2018/13/matecconf_icet4sd2018_01094/matecconf_icet4sd2018_01094.html (accessed on 1 October 2021).

- Ilo, P.I.; Izuagbe, R.; Mole, A.J.; Ekwueme, L. Measuring disaster preparedness and response practices in university libraries in Nigeria: The role of disaster equipment. Int. J. Disaster Risk Reduct. 2018, 31, 85–91. [Google Scholar] [CrossRef]

- Papadopoulou, M.; Da Col, F.; Mi, B.; Bäckström, E.; Marsden, P.; Brodic, B.; Malehmir, A.; Socco, L.V. Surface-wave analysis for static corrections in mineral exploration: A case study from central Sweden. Geophys. Prospect. 2020, 68, 214–231. [Google Scholar] [CrossRef] [Green Version]

- Park, S.; Choi, Y. Applications of unmanned aerial vehicles in mining from exploration to reclamation: A review. Minerals 2020, 10, 663. [Google Scholar] [CrossRef]

- Song, H.; Jeong, S.; Lee, E.; Alsabbagh, N.; Lee, J.; You, S.; Kwak, C.; Kim, S.; Han, W. Types of Hearing Protection Devices and Application. Korean J. Otorhinolaryngol.-Head Neck Surg. 2019, 62, 1–14. [Google Scholar] [CrossRef]

- Otoo, J.K. The Determinants of Hearing Protection Device Use among Noise-Exposed Workers of Chirano Gold Mines; University of Ghana: Accra, Ghana, 2019. [Google Scholar]

- Ilbahar, E.; Karaşan, A.; Cebi, S.; Kahraman, C. A novel approach to risk assessment for occupational health and safety using Pythagorean fuzzy AHP & fuzzy inference system. Saf. Sci. 2018, 103, 124–136. [Google Scholar]

- Bartkowiak, G.; Baszczyński, K.; Bogdan, A.; Brochocka, A.; Dąbrowska, A.; Hrynyk, R.; Irzmańska, E.; Koradecka, D.; Kozłowski, E.; Majchrzycka, K. Use of Personal Protective Equipment. Handb. Hum. Factors Ergon. 2021, 1, 668–684. [Google Scholar]

- Bazaluk, O.; Petlovanyi, M.; Zubko, S.; Lozynskyi, V.; Sai, K. Instability Assessment of Hanging Wall Rocks during Underground Mining of Iron Ores. Minerals 2021, 11, 858. [Google Scholar] [CrossRef]

- Moura, R.; Beer, M.; Patelli, E.; Lewis, J.; Knoll, F. Learning from accidents: Interactions between human factors, technology and organisations as a central element to validate risk studies. Saf. Sci. 2017, 99, 196–214. [Google Scholar] [CrossRef] [Green Version]

- Matveykin, V.; Nemtinov, V.; Dmitrievsky, B.; Praveen, K. Development and implementation of network based underground mines safety, rescue and aided rescue system. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2019; p. 012017. [Google Scholar] [CrossRef]

- Tong, R.; Yang, Y.; Ma, X.; Zhang, Y.; Li, S.; Yang, H. Risk assessment of Miners’ unsafe behaviors: A case study of gas explosion accidents in coal mine, China. Int. J. Environ. Res. Public Health 2019, 16, 1765. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mukai, N.; Fujita, K.; AL-Kasasbeh, A.; Karrani, S.M.; Al-Marzouqi, A. A New Approach to the Feasibility Design in Development Fields. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Abu Dhabi, United Arab Emirats, 26–28 January 2016; pp. 512–520. [Google Scholar]

- Sherrigton, C. Slips Trips and Falls in Northern Ontario Underground Hard-Rock Mines; Laurentian University of Sudbury: Sudbury, ON, Canada, 2020. [Google Scholar]

- Jain, P.; Pasman, H.J.; Waldram, S.; Pistikopoulos, E.; Mannan, M.S. Process Resilience Analysis Framework (PRAF): A systems approach for improved risk and safety management. J. Loss Prev. Process. Ind. 2018, 53, 61–73. [Google Scholar] [CrossRef]

| Province | Mineral | Production (Tons) | Province | Mineral | Production (Tons) |

|---|---|---|---|---|---|

| Baluchistan | Aragonite/marble | 1,442,346 | Punjab | Gypsum | 1,402,367 |

| Baluchistan | Barytes | 154,637 | Punjab | Limestone | 24,390,674 |

| Baluchistan | Chromite | 55,219 | Punjab | Orchre | 68,352 |

| Baluchistan | Coal | 1,671,727 | Punjab | Rock salt | 3,465,987 |

| Baluchistan | Fluorite | 5932 | Punjab | Silica sand | 283,413 |

| Baluchistan | Limestone/clay | 1,113,674 | Punjab | Sulphur | 14,869 |

| Baluchistan | Magnesite | 32,540 | Khyber Pakhtunkhwa | Antimony | 21 |

| Sindh | Aragonite | 3125 | Khyber Pakhtunkhwa | Aragonite or marble | 2,473,562 |

| Sindh | China clay | 5434 | Khyber Pakhtunkhwa | Barytes | 2770 |

| Sindh | Coal | 752,124 | Khyber Pakhtunkhwa | Bauxite | 3985 |

| Sindh | Fuller’s earth | 3049 | Khyber Pakhtunkhwa | Chromite | 4072 |

| Sindh | Gravel | 420,695 | Khyber Pakhtunkhwa | Coal | 87,892 |

| Sindh | Limestone | 7,361,866 | Khyber Pakhtunkhwa | Fire clay | 10,869 |

| Sindh | Silica sand | 26,972 | Khyber Pakhtunkhwa | Gypsum | 469,349 |

| Punjab | Bauxite | 53,039 | Khyber Pakhtunkhwa | Limestone | 13,127,957 |

| Punjab | China clay | 16,249 | Khyber Pakhtunkhwa | Magnesite | 2688 |

| Punjab | Coal | 935,019 | Khyber Pakhtunkhwa | Manganese | 70,000 |

| Punjab | Fire clay | 540,108 | Khyber Pakhtunkhwa | Rock salt | 86,997 |

| Punjab | Fuller’s earth | 10,691 | Khyber Pakhtunkhwa | Silica sand | 85,485 |

| Punjab | Gravel | 4295 | Khyber Pakhtunkhwa | Soapstone | 116,830 |

| Scheme | Hazard | ||||||

|---|---|---|---|---|---|---|---|

| Physical | Chemical | Ergonomic | Psychological | Mechanical | Electrical | Natural | |

| Explosion—breaks mineral-bearing materials | Fracture, vibration, noise, dust, sliding, rock fall, temperature | Eye infection, irritation, less visibility due to dust and explosive chemical | Vibration-potential for internal organ damage | Anxiety | Drill rods, drill strings, and rod handlers-rotating and moving components | Electric-wire dislocation, ground faults or poor contacts | Land sliding, land or mine sinking, floods, fire, earthquake |

| Rock-excavation products and equipment | Anthropogenic activity, noise, artificial seismicity | Oil leakage, slippery surface, leaching | Equipment adjustment and their precision | Work environment | Moving parts, friction, abrasion, cutting, shearing, puncturing, crushing, unnatural positions | Electrical-driven equipment failures, wireline current dispersion | Fire, rock sliding, slop failure, fractures |

| Mineral exploration—to determine the area containing minerals underground | Sampling, site cleanup, deforestation, noise, vibration | Harmful chemicals, skin disease, corrosive dermal exposures | Metabolic demands of repetitive tasks, thermal responses to working in hot mining | Mental stress, emotional destruction, conflict | Transportation, heavy equipment, entanglement, cutting | Power supply, electrical-driven equipment | Flood, mine collapse, fire |

| Mining-supporting wall—internal supporting structure of the mine | Infrastructure, fortification, ventilation, access track | Gases, harmful chemicals | Vibration-potential for internal organ damage | Consternation, loneliness | Join failure, track damage, cutting, shearing, ceiling bracers, stamped | Electrical-driven equipment failures, wireline current dispersion | Fire, flood, rock fall, fracture |

| Mine compactivity—testing the wall for labor movement in the mine | Wall structure, depth, area, lighting | Toxicity, smoke | Inadequate and repetitive postures | Depression, monotonous activity | Rock-cutting equipment, moving parts | Electric-wire dislocation, power supply | Fire, flood, rock fall, fracture |

| Road accessibility—transporting the excavated minerals | Steep slope, sliding, remote area, security, weather | Lubricants, toxic minerals, anions | Road accidents, wild animals’ interference | Vehicles, heavy machinery | Power cables | Road damage, raining, string flood. | |

| Outcome of Seriousness “s” | |||||

|---|---|---|---|---|---|

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | ||

| Probability | Prevalence Pr-1 | H1 | H2 | H4 | H5 |

| Prevalence Pr-2 | H2 | H5 | H6 | H10 | |

| Prevalence Pr-3 | H3 | H7 | H8 | H12 | |

| Prevalence Pr-4 | H4 | H9 | H11 | H15 | |

| Task | Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries |

|---|---|---|---|---|

| Explosion—breaks mineral-bearing materials | 2 | 0 | 0 | 0 |

| Rock excavation; products and equipment | 5 | 3 | 2 | 0 |

| Mineral exploration—to determine the area containing minerals underground | 9 | 4 | 1 | 0 |

| Mining-supporting wall—internal supporting structure of the mine | 15 | 3 | 4 | 2 |

| Mine compactivity—testing the wall for labor movement in the mine | 45 | 16 | 0 | 0 |

| Road accessibility—transporting the excavated minerals | 4 | 1 | 0 | 0 |

| Explosion—Breaks Mineral-Bearing Materials | Outcome of Seriousness “s” | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | ||||||

| Probability | Prevalence Pr-1 | H1 | H2 | H4 | H5 | ||||

| Prevalence Pr-2 | H2 | H5 | H6 | H10 | |||||

| Prevalence Pr-3 | H3 | H7 | H8 | H12 | |||||

| Prevalence Pr-4 | H4 | H9 | H11 | H15 | |||||

| Rock Excavation; Products and Equipment | Outcome of Seriousness “s” | ||||||||

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | ||||||

| Probability | Prevalence Pr-1 | H1 | H2 | H4 | H5 | ||||

| Prevalence Pr-2 | H2 | H5 | H6 | H10 | |||||

| Prevalence Pr-3 | H3 | H7 | H8 | H12 | |||||

| Prevalence Pr-4 | H4 | H9 | H11 | H15 | |||||

| Mineral Exploration—to Determine the Area Containing Minerals Underground | Outcome of Seriousness “s” | ||||||||

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | ||||||

| Probability | Prevalence Pr-1 | H1 | H2 | H4 | H5 | ||||

| Prevalence Pr-2 | H2 | H5 | H6 | H10 | |||||

| Prevalence Pr-3 | H3 | H7 | H8 | H12 | |||||

| Prevalence Pr-4 | H4 | H9 | H11 | H15 | |||||

| Mining-Supporting Wall—Internal Supporting Structure of the Mine | Outcome of Seriousness “s” | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | ||||||

| Probability | Prevalence Pr-1 | H1 | H2 | H4 | H5 | ||||

| Prevalence Pr-2 | H2 | H5 | H6 | H10 | |||||

| Prevalence Pr-3 | H3 | H7 | H8 | H12 | |||||

| Prevalence Pr-4 | H4 | H9 | H11 | H15 | |||||

| Mine Compactivity—Testing the Wall for Labor Movement in the Mine | Outcome of Seriousness “s” | ||||||||

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | ||||||

| Probability | Prevalence Pr-1 | H1 | H2 | H4 | H5 | ||||

| Prevalence Pr-2 | H2 | H5 | H6 | H10 | |||||

| Prevalence Pr-3 | H3 | H7 | H8 | H12 | |||||

| Prevalence Pr-4 | H4 | H9 | H11 | H15 | |||||

| Road Accessibility—Transporting the Excavated Minerals | Outcome of Seriousness “s” | ||||||||

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | ||||||

| Probability | Prevalence Pr-1 | H1 | H2 | H4 | H5 | ||||

| Prevalence Pr-2 | H2 | H5 | H6 | H10 | |||||

| Prevalence Pr-3 | H3 | H7 | H8 | H12 | |||||

| Prevalence Pr-4 | H4 | H9 | H11 | H15 | |||||

| Explosion–Breaks Mineral-Bearing Materials | Outcome of Seriousness “s” | |||

|---|---|---|---|---|

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | |

| Accidents | 2 | 0 | 0 | 0 |

| Probability of its consequences | Prevalence Pr-1 | Prevalence Pr-2 | Prevalence Pr-3 | Prevalence Pr-4 |

| Hazard factor | H1 | H2 | H4 | H5 |

| No human harm | Slightly injuries and major injuries | |||

| Rock Excavation; Products and Equipment | Outcome of Seriousness “s” | |||

|---|---|---|---|---|

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | |

| Accidents | 5 | 3 | 2 | 0 |

| Probability of its consequences | Prevalence Pr-1 | Prevalence Pr-2 | Prevalence Pr-3 | Prevalence Pr-4 |

| Hazard factor | H2 | H5 | H4 | H5 |

| No human harm | Slight injuries and major injuries | |||

| Mineral Exploration—to Determine the Area Containing Minerals Underground | Outcome of Seriousness “s” | |||

|---|---|---|---|---|

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | |

| Accidents | 9 | 4 | 1 | 0 |

| Probability of its consequences | Prevalence Pr-1 | Prevalence Pr-2 | Prevalence Pr-3 | Prevalence Pr-4 |

| Hazard factor | H3 | H5 | H6 | H5 |

| No human harm | Serious injuries and major injuries | |||

| Mining-Supporting Wall—Internal Supporting Structure of the Mine | Outcome of Seriousness “s” | |||

|---|---|---|---|---|

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | |

| Accidents | 15 | 3 | 4 | 2 |

| Probability of its consequences | Prevalence Pr-1 | Prevalence Pr-2 | Prevalence Pr-3 | Prevalence Pr-4 |

| Hazard factor | H4 | H7 | H8 | H10 |

| Slight injuries and major injuries | ||||

| Mine Compactivity—Testing the Wall for Labor Movement in the Mine | Outcome of Seriousness “s” | |||

|---|---|---|---|---|

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | |

| Accidents | 45 | 16 | 0 | 0 |

| Probability of its consequences | Prevalence Pr-1 | Prevalence Pr-2 | Prevalence Pr-3 | Prevalence Pr-4 |

| Hazard factor | H4 | H7 | H4 | H5 |

| Slight injuries and major injuries | ||||

| Road Accessibility—Transport the Excavated Minerals | Outcome of Seriousness “s” | |||

|---|---|---|---|---|

| Seriousness Unimportant | Seriousness Important | Serious Injuries | Major Injuries | |

| Accidents | 45 | 16 | 0 | 0 |

| Probability of its consequences | Prevalence Pr-1 | Prevalence Pr-2 | Prevalence Pr-3 | Prevalence Pr-4 |

| Hazard factor | H4 | H7 | H4 | H5 |

| Slight injuries and major injuries | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janjuhah, H.T.; Ishfaque, M.; Mehmood, M.I.; Kontakiotis, G.; Shahzad, S.M.; Zarkogiannis, S.D. Integrated Underground Mining Hazard Assessment, Management, Environmental Monitoring, and Policy Control in Pakistan. Sustainability 2021, 13, 13505. https://doi.org/10.3390/su132413505

Janjuhah HT, Ishfaque M, Mehmood MI, Kontakiotis G, Shahzad SM, Zarkogiannis SD. Integrated Underground Mining Hazard Assessment, Management, Environmental Monitoring, and Policy Control in Pakistan. Sustainability. 2021; 13(24):13505. https://doi.org/10.3390/su132413505

Chicago/Turabian StyleJanjuhah, Hammad Tariq, Muhammad Ishfaque, Muhammad Ifzal Mehmood, George Kontakiotis, Syed Muzyan Shahzad, and Stergios D. Zarkogiannis. 2021. "Integrated Underground Mining Hazard Assessment, Management, Environmental Monitoring, and Policy Control in Pakistan" Sustainability 13, no. 24: 13505. https://doi.org/10.3390/su132413505

APA StyleJanjuhah, H. T., Ishfaque, M., Mehmood, M. I., Kontakiotis, G., Shahzad, S. M., & Zarkogiannis, S. D. (2021). Integrated Underground Mining Hazard Assessment, Management, Environmental Monitoring, and Policy Control in Pakistan. Sustainability, 13(24), 13505. https://doi.org/10.3390/su132413505