Life Cycle Assessment of Thermoelectric Generators (TEGs) in an Automobile Application

Abstract

:1. Introduction

- Cradle-to-grave LCA analysis.

- Assessing the effect of scale (e.g., upscaling).

- Assessing the effect of TEGs on other environmental burdens and social impacts.

2. Methodology

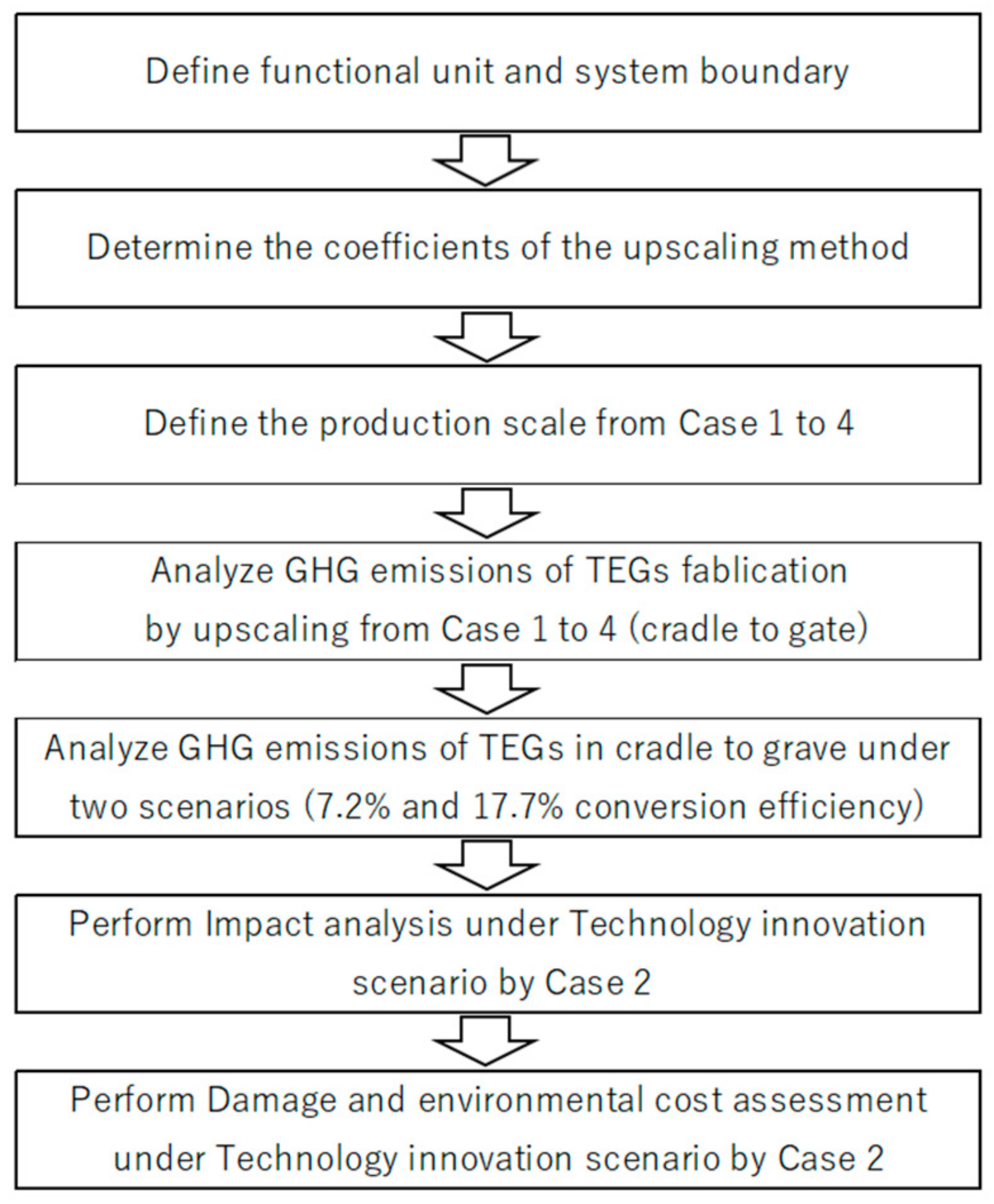

2.1. Analysis Method

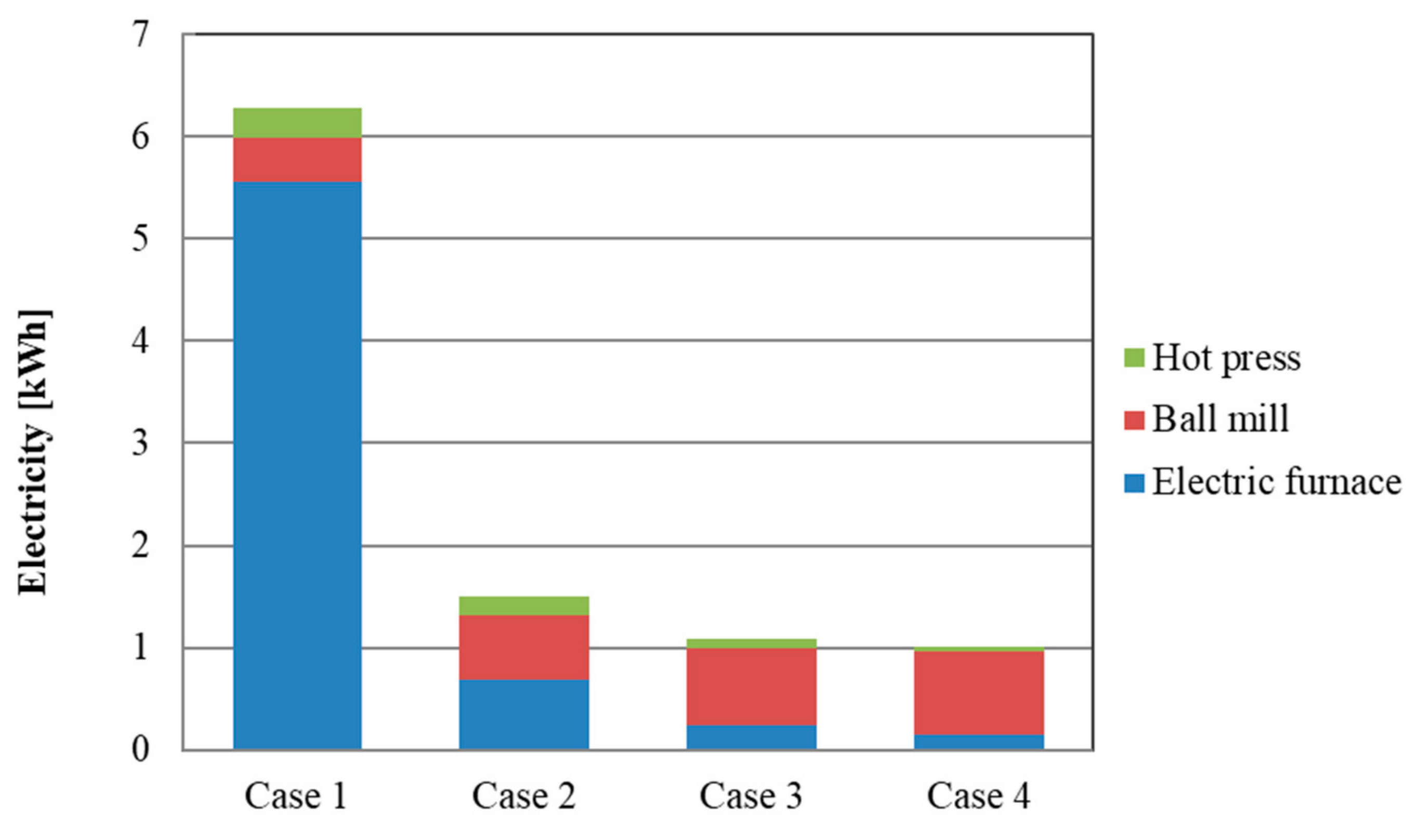

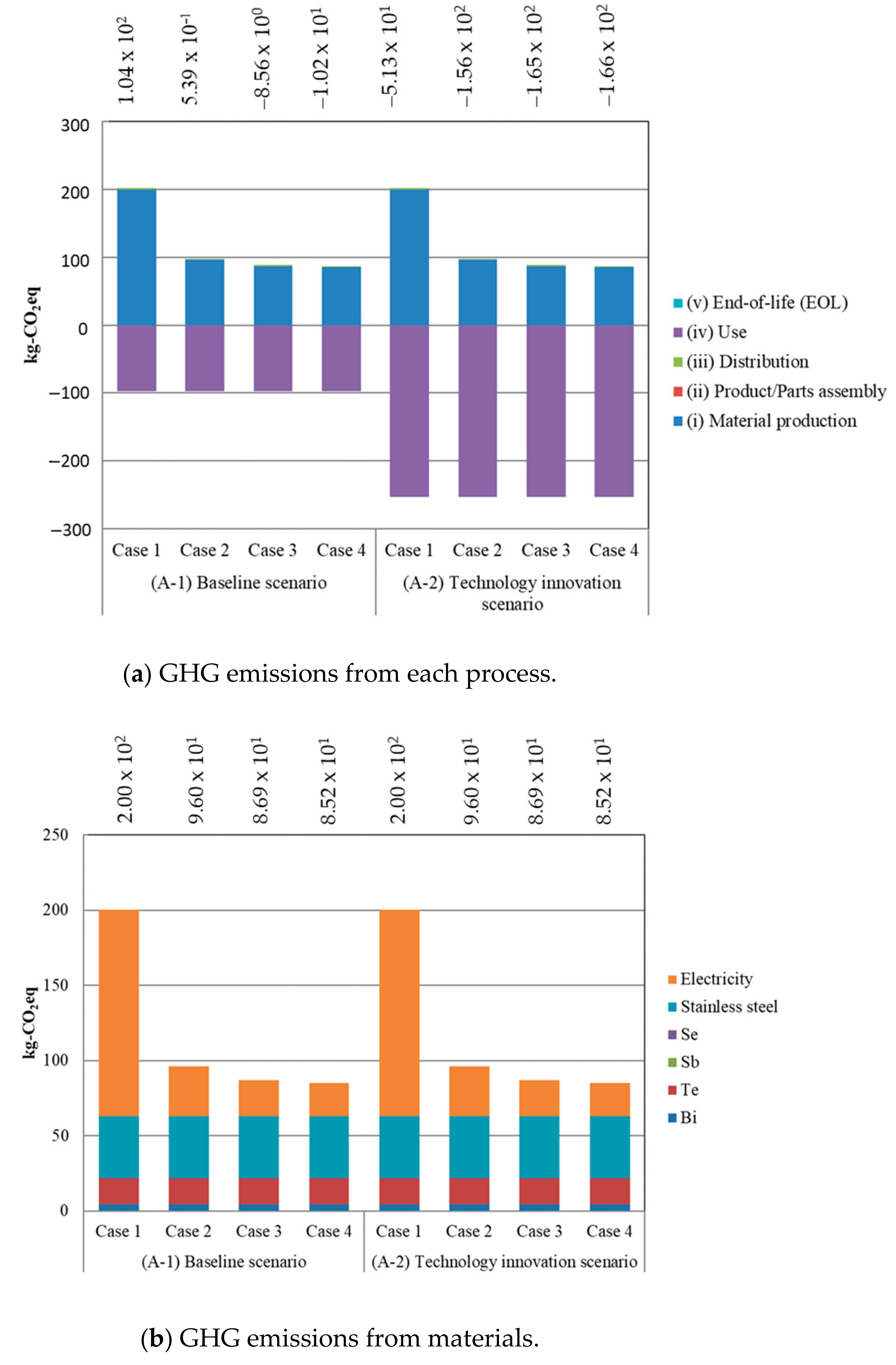

- GHG emissions of the TEG fabrication process were estimated with an upscaling technique from Case 1 to Case 4. The conditions for each case are shown in Table 2.

- GHG emissions were assessed based on two scenarios, a baseline scenario and a technology innovation scenario, from Case 1 to 4. Here, a cradle-to-grave analysis was conducted. The baseline scenario (A-1) was assumed to have a conversion efficiency of 7.2%, while the technology innovation scenario was assumed to have a conversion efficiency of 17.7%. Statistics in Suita City, in Japan, about its population, the automobile quantity, and its usage model, such as the distance run per day, were used in this analysis.

- A cradle-to-grave impact assessment for the environmental and social impacts were conducted using Life-cycle Impact Assessment Method based on Endpoint Modeling (LIME2). The analysis flow is shown in Figure 1.

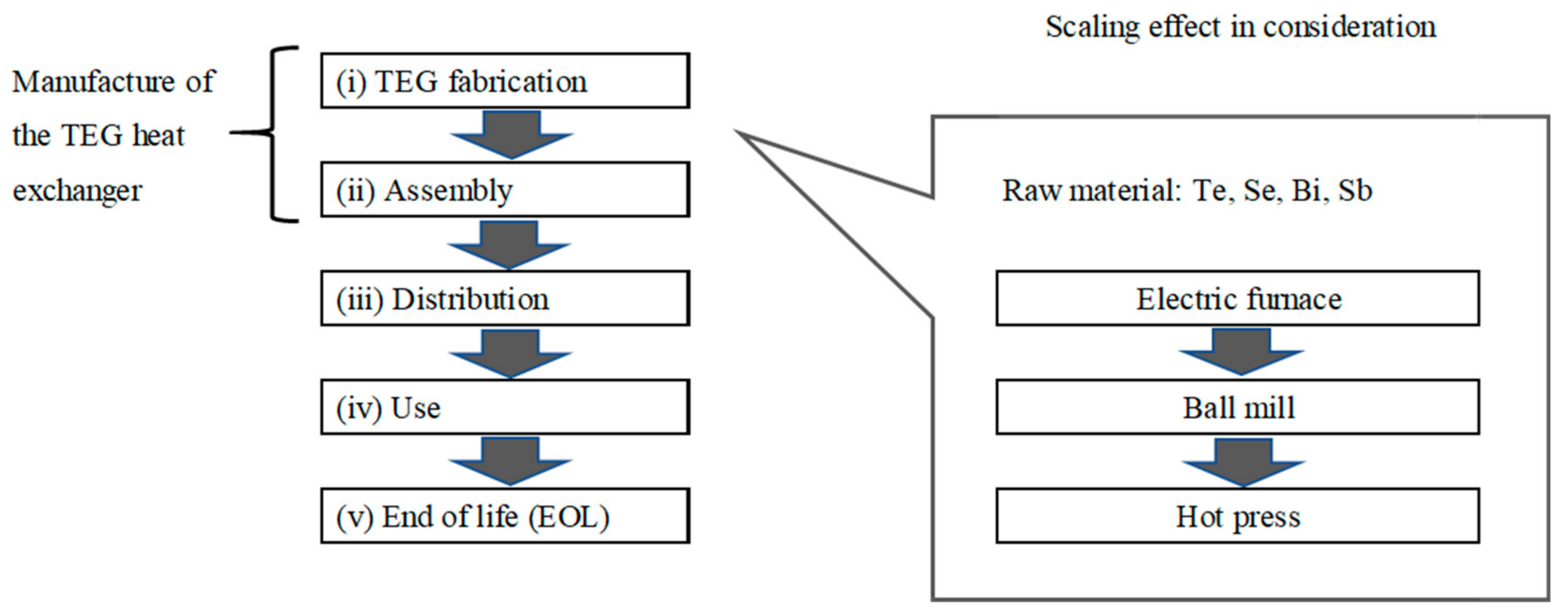

2.2. Functional Units and System Boundaries

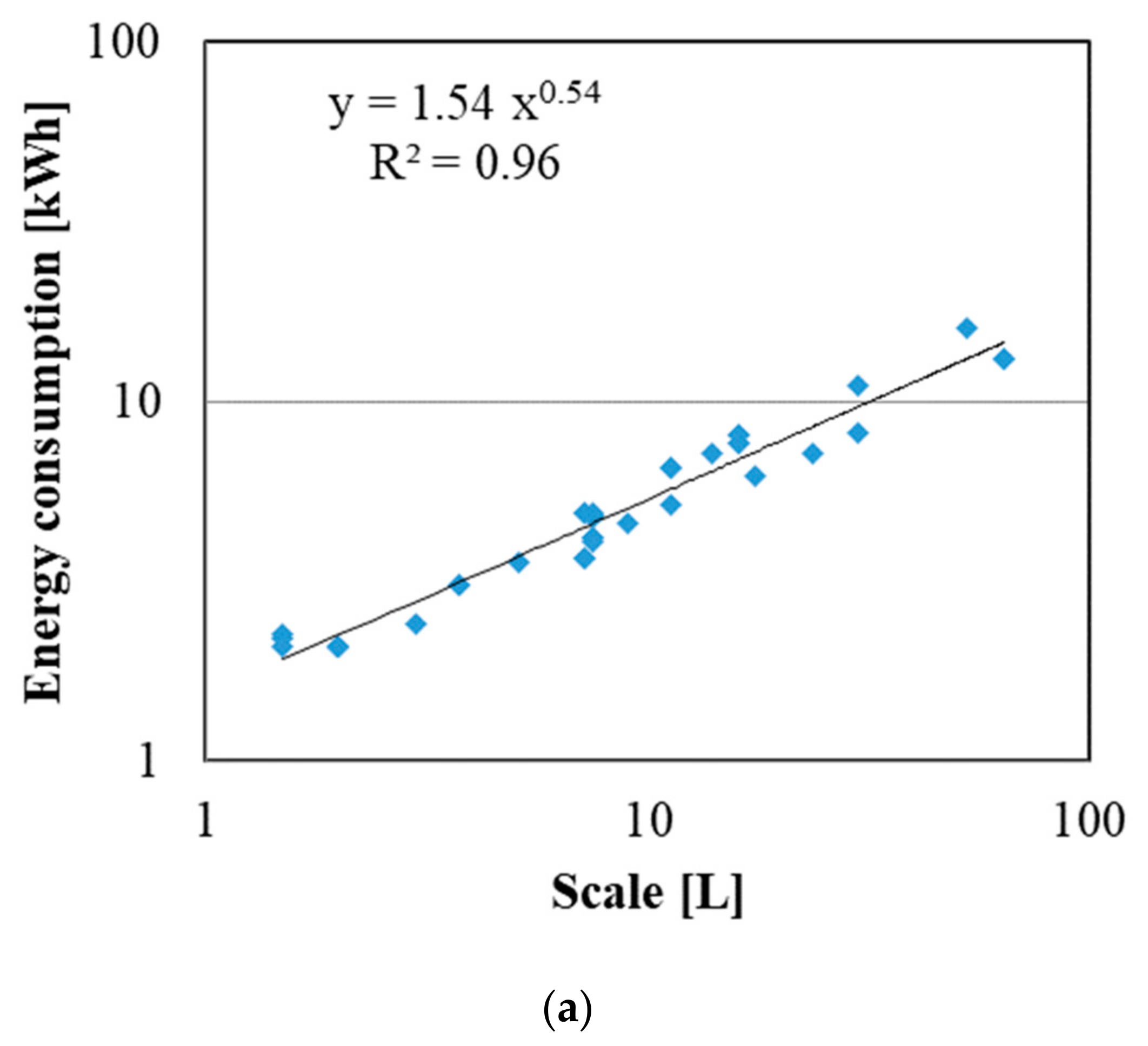

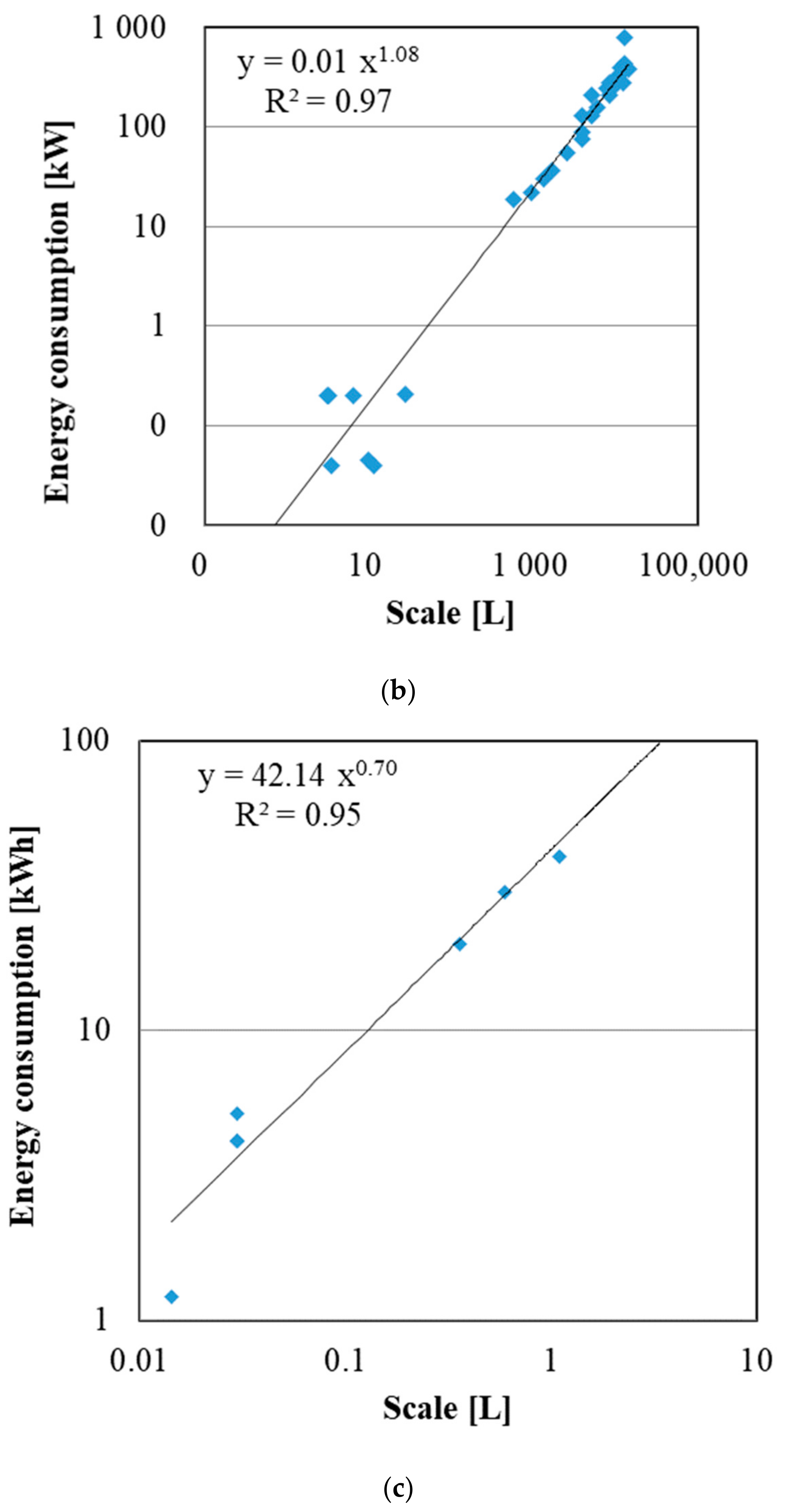

2.3. Upscaling Analysis

2.4. Scenario Analysis

2.5. Impact and Social Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jaziri, N.; Bough Moura, A.; Müller, J.; Mezghani, B.; Tounsi, F.; Ismail, M. A comprehensive review of Thermoelectric Generator: Technologies and common applications. Energy Rep. 2020, 6, 264–287. [Google Scholar] [CrossRef]

- David, A.P.J. Thermoelectric Generator: Power Generation Using Temperature Difference in Home Applications. 2019. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3455578 (accessed on 15 May 2020).

- Falcone, P.M.; Imbert, E. Social Life Cycle Approach as a Tool for Promoting the Market Uptake of Bio-based Products from a Consumer Perspective. Sustainability 2018, 10, 1013. [Google Scholar] [CrossRef] [Green Version]

- OICA, International Organization of Motor Vehicle Manufactures. Climate Change & CO2. 2015. Available online: http://www.oica.net/category/climate-change-and-co2/ (accessed on 15 May 2020).

- Yang, J. Potential applications of thermoelectric waste heat recovery in the automotive industry. In Proceedings of the 24th International Conference on Thermoelectrics, Clemson, SC, USA, 19–23 June 2005; pp. 170–174. Available online: https://www.semanticscholar.org/paper/Potential-applications-of-thermoelectric-waste-heat-Yang/8be845ba55c3d450600cf4a85871e2a563e170ff (accessed on 15 May 2020).

- Kishita, Y.; Ohishi, Y.; Uwasu, M.; Kuroda, M.; Takeda, H.; Hara, K. Evaluating the life cycle CO2 emission and costs of thermoelectric generators for passenger automobile: A scenario analysis. J. Clean. Prod. 2016, 126, 607–619. [Google Scholar] [CrossRef]

- Kaibe, H.; Kajihara, T.; Fujimoto, S.; Makini, K.; Hachiuma, H. Recovery of Plant Waste Heat by a Thermoelectric Generating System. Komatsu Tech. Rep. 2011, 57, 26–30. [Google Scholar]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 104–115. [Google Scholar] [CrossRef] [PubMed]

- Yazawa, K.; Shakouri, A. Cost-efficiency trade-off and the design of thermoelectric power generators. Environ. Sci. Technol. 2011, 45, 7548–7553. [Google Scholar] [CrossRef] [PubMed]

- Karvonen, M.; Kapoor, R.; Uusitalo, A.; Ojanen. Technology competition in the internal combustion engine waste heat recovery: A patent landscape analysis. J. Clean. Prod. 2016, 112, 3735–3743. [Google Scholar] [CrossRef]

- Evangelisti, S.; Tagliaferri, C.; Clift, R.; Lettieri, P.; Taylor, R. Life cycle Assessment of conventional and two-stage advanced energy-from-waste technologies for municipal solid waste treatment. J. Clean. Prod. 2015, 100, 212–223. [Google Scholar] [CrossRef]

- Murphy, F.; Devlin, G.; McDonnell, K. Greenhouse gas and energy based life cycle analysis of products from the Irish wood processing industry. J. Clean. Prod. 2015, 92, 134–141. [Google Scholar] [CrossRef] [Green Version]

- Wender, B.; Foley, R.; Prado-Lopez, V.; Ravikumar, D.; Eisenberg, D.; Hottle, T.; Sadowski, J.; Flanagan, W.; Fisher, A.; Laurin, L.; et al. Illustrating Anticipatory Life Cycle Assessment for Emerging Photovoltaic Technologies. Environ. Sci. Technol. 2014, 48, 10531–10538. [Google Scholar] [CrossRef] [PubMed]

- Kawajiri, K.; Goto, T.; Kon, Y.; Sakurai, S.; Hata. K.; Tahara, K. Development of life cycle assessment of an emerging technology at research and development stage: A case study on single-wall carbon nanotube produced by super growth method. J. Clean. Prod. 2020, 255, 120015. [Google Scholar] [CrossRef]

- Nemet, G. Beyond the Learning Curve: Factors Influencing Cost Reductions in Photovoltaics. Energy Policy 2006, 34, 3218–3232. [Google Scholar] [CrossRef]

- IDEA_v2.1.3 Database. Advanced Industry Science and Technology. 2017. Available online: https://en.aist-riss.jp/ (accessed on 5 August 2020).

- LIME2. JLCA (Life Cycle Assessment Society of Japan). 2013. Available online: https://lca-forum.org/database/impact/ (accessed on 10 August 2020).

- Crane, D.T. Thermoelectric waste heat recovery program for passenger vehicles. In 2012 DOE Hydrogen and Fuel Cells Program and Vehicle Technologies Program Annual Merit Review and Peer Evaluation Meeting; U.S. Department of Energy: Washington, DC, USA, 2012. [Google Scholar]

- Fairbanks, J.W. Automotive thermoelectric generators and HVAC. In 2012 Directions in Engine-Efficiency and Emissions Research (DEER) Conference; U.S. Department of Energy Office of Energy Efficiency & Renewable Energy: Dearborn, MI, USA, 2012. [Google Scholar]

- Japan Automobile Manufacturers Association, Inc. Trends of Mean Automobile Lifetimes. 2012. Available online: http://www.jama.or.jp/industry/four_wheeled/four_wheeled_3t3.html (accessed on 5 November 2015). (In Japanese).

- Suita City. Suita’s Environment White Paper. 2012. Available online: http://www.city.suita.osaka.jp/var/rev0/0062/9736/201342392442.pdf (accessed on 3 December 2015). (In Japanese).

- Suita City. Suita City Statistics in 2012FY. 2013. Available online: http://www.city.suita.osaka.jp/home/soshiki/div-somu/somu/001411/004513.html (accessed on 12 November 2015). (In Japanese).

- Suita City and Center for Environmental Innovation Design for Sustainability. A Randomized Household Survey on Energy-Savings Measures; Osaka University: Osaka, Japan, 2012. [Google Scholar]

- Søndergaard, R.S.; Hösel, M.; Espinosa, N.; Jørgensen, M.; Krebs, C.F. Practical evaluation of organic polymer thermoelectrics by large-area R2R processing on flexible substrates. Energy Sci. Eng. 2013, 1, 81–88. [Google Scholar] [CrossRef] [Green Version]

- Ghojel, I.J. Thermal and environmental assessment of a conceputual waste HAT recovery system for automotive application. Int. Conf. Eng. Des. 2005, 5, 15–18. [Google Scholar]

- Patyk, A. Thermoelectrics: Impacts on the Environment and Sustainability. J. Electron. Mater. 2010, 39, 9. [Google Scholar] [CrossRef]

- Patyk, A. Thermoelectric generators for efficiency improvement of power generation by motor generators—Environmental and economic perspectives. Appl. Energy 2012, 102, 1448–1457. [Google Scholar] [CrossRef]

- Irshad, K.; Habib, K.; Algarni, S.; Saha, B. Bidyut.; Jamil, B. Sizing and life-cycle assessment of building integrated thermoelectric air cooling and photovoltaic wall system. Appl. Therm. Eng. 2019, 154, 302–314. [Google Scholar] [CrossRef]

- Krishnamoorthy, R.; Pilla, S. Environmental profile of thermoelectrics for applications with continuous waste heat generation vis life cycle assessment. Sci. Total Environ. 2021, 752, 121274. [Google Scholar]

- Kawajiri, K.; Kobayashi, M.; Sakamoto, K. Lightweight Materials Equal Lightweight Greenhouse Gas Emissions? A Historical Analysis of Greenhouse Gases of Vehicle Material. J. Clean. Prod. 2020, 253, 119805. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| Size | 50 × 50 × 4.2 mm |

| Conversion efficiency | 7.2% |

| Maximum allowable temperature | 280 °C |

| Maximum power output | 24 W module−1 |

| Total weight of TEG | 47 g·module−1 |

| Weight of Bi-Te thermoelectric material in TEG | 27 g·module−1 |

| Unit | Case 1 | Case 2 | Case 3 | Case 4 | |

|---|---|---|---|---|---|

| Electric furnace | ℓ | 0.011 | 1.000 | 10.000 | 30.000 |

| Ball mill | ℓ | 0.011 | 1.000 | 10.000 | 30.000 |

| Hot press | m2 | 0.003 | 0.010 | 0.100 | 1.000 |

| Reference | TEG Type | LCA (Production) | LCA (Use) | LCA (EOL) | Impact Analysis | Scaling Effect | TEG Merit | TEG Efficiency | Application |

|---|---|---|---|---|---|---|---|---|---|

| Søndergaard at al. [24] | Organic polymer | Yes | No | No | No | No | No | No mention | Test devise |

| Ghojel. [25] | Bi-Te | Yes | Yes | Yes | Yes | No | Yes | 5% | Automobile |

| Patyk. [26] | Bi-Te | No | Yes | No | Yes | No | Yes | 10% | Automobile |

| Patyk. [27] | Bi-Te | Yes | Yes | No | Yes | No | Yes | 7.5% | Steam Expander |

| Kishita et al. [6] | Bi-Te | Yes | Yes | Yes | No | No | No | 7.2% | Automobiles |

| Irshad et al. [28] | Photovoltaic wall | No | Yes | No | No | No | Yes | 14% | Air conditioner |

| Krishnamoorthy et al. [29] | Various types | Yes | Yes | Yes | Yes | No | Yes | 10% | Coal power plant |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kawajiri, K.; Kishita, Y.; Shinohara, Y. Life Cycle Assessment of Thermoelectric Generators (TEGs) in an Automobile Application. Sustainability 2021, 13, 13630. https://doi.org/10.3390/su132413630

Kawajiri K, Kishita Y, Shinohara Y. Life Cycle Assessment of Thermoelectric Generators (TEGs) in an Automobile Application. Sustainability. 2021; 13(24):13630. https://doi.org/10.3390/su132413630

Chicago/Turabian StyleKawajiri, Kotaro, Yusuke Kishita, and Yoshikazu Shinohara. 2021. "Life Cycle Assessment of Thermoelectric Generators (TEGs) in an Automobile Application" Sustainability 13, no. 24: 13630. https://doi.org/10.3390/su132413630

APA StyleKawajiri, K., Kishita, Y., & Shinohara, Y. (2021). Life Cycle Assessment of Thermoelectric Generators (TEGs) in an Automobile Application. Sustainability, 13(24), 13630. https://doi.org/10.3390/su132413630