Modular Green Roofs for the Sustainability of the Built Environment: The Installation Process

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

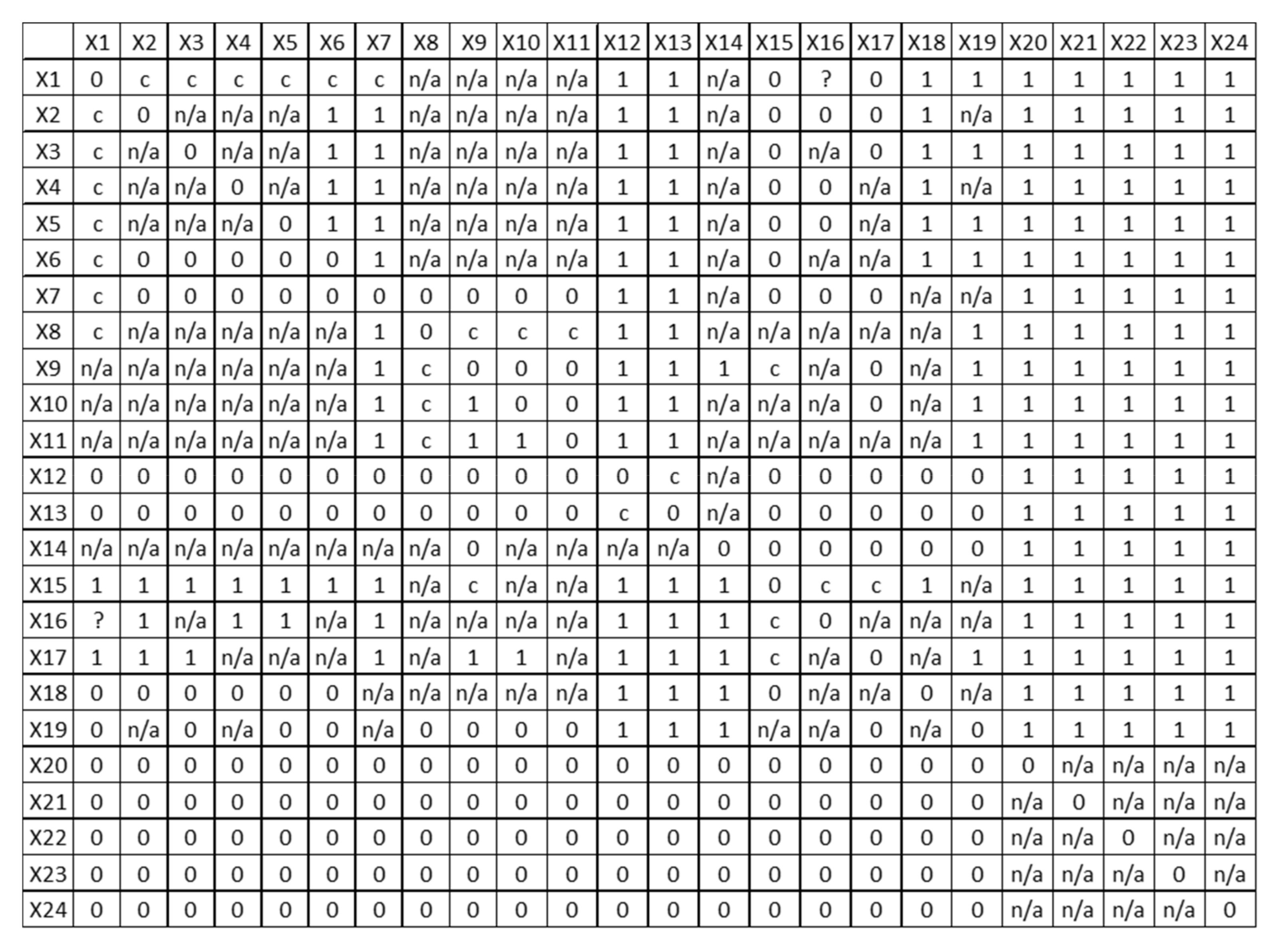

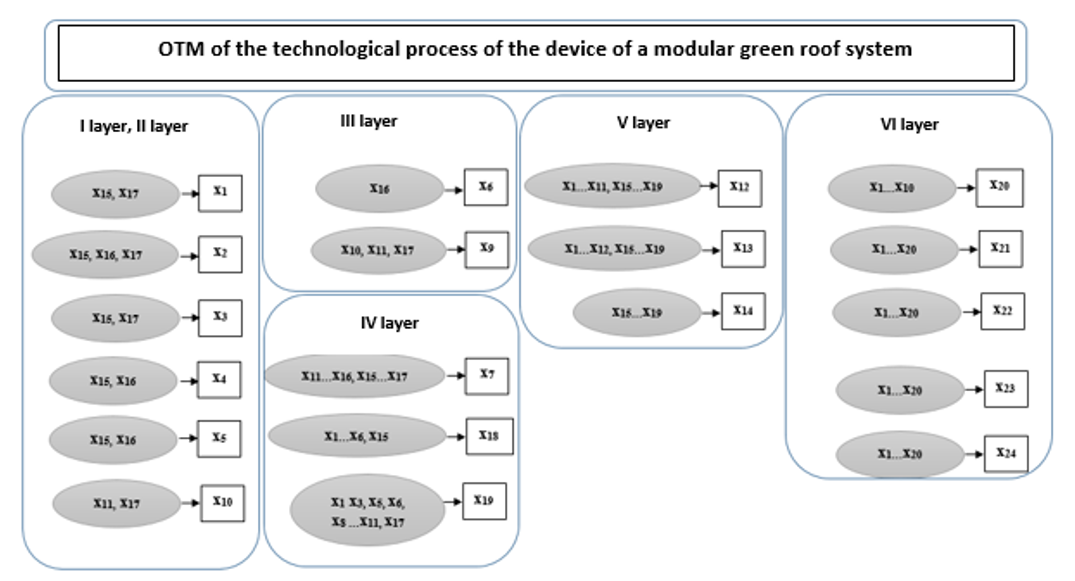

- Construction of a matrix of technological links of organisational and technological module processes based on the results of an expert assessment of the succession–precedence of technological processes (operations) in paired comparisons.

- Creation of a graph of the technological sequence based on the matrix data (excluding compound operations).

- Fragmentation of the graph into specific layers (finding and filtering out paths resulting from the transitivity property).

- Creation of the final graph of the spatial and technological structure of the organisational and technological module.

- (1)

- (2)

- (3)

- if condition 1 and condition 2 are not met.

- (4)

- if one of the elements is an integral part of the other.

- (5)

- if the relationship between a simple and a composite technological operation cannot be determined.

- All the rows of the matrix that satisfy the condition: are found.

- The elements are replaced in the first layer of the row in which they are found.

- Elements belonging to the next layer are found. It is necessary to find such rows that implies that the row is contained in the set of layers from the first layer to the layer under consideration.

- (1)

- Technological operation is composite.

- (2)

- It includes operations , which may be present in any of 1–3 layers.

- (3)

- Technological operation is not composite. It may be executed in parallel with operation .

- (4)

- Based on the results of constructing the graph, the cycles are eliminated.

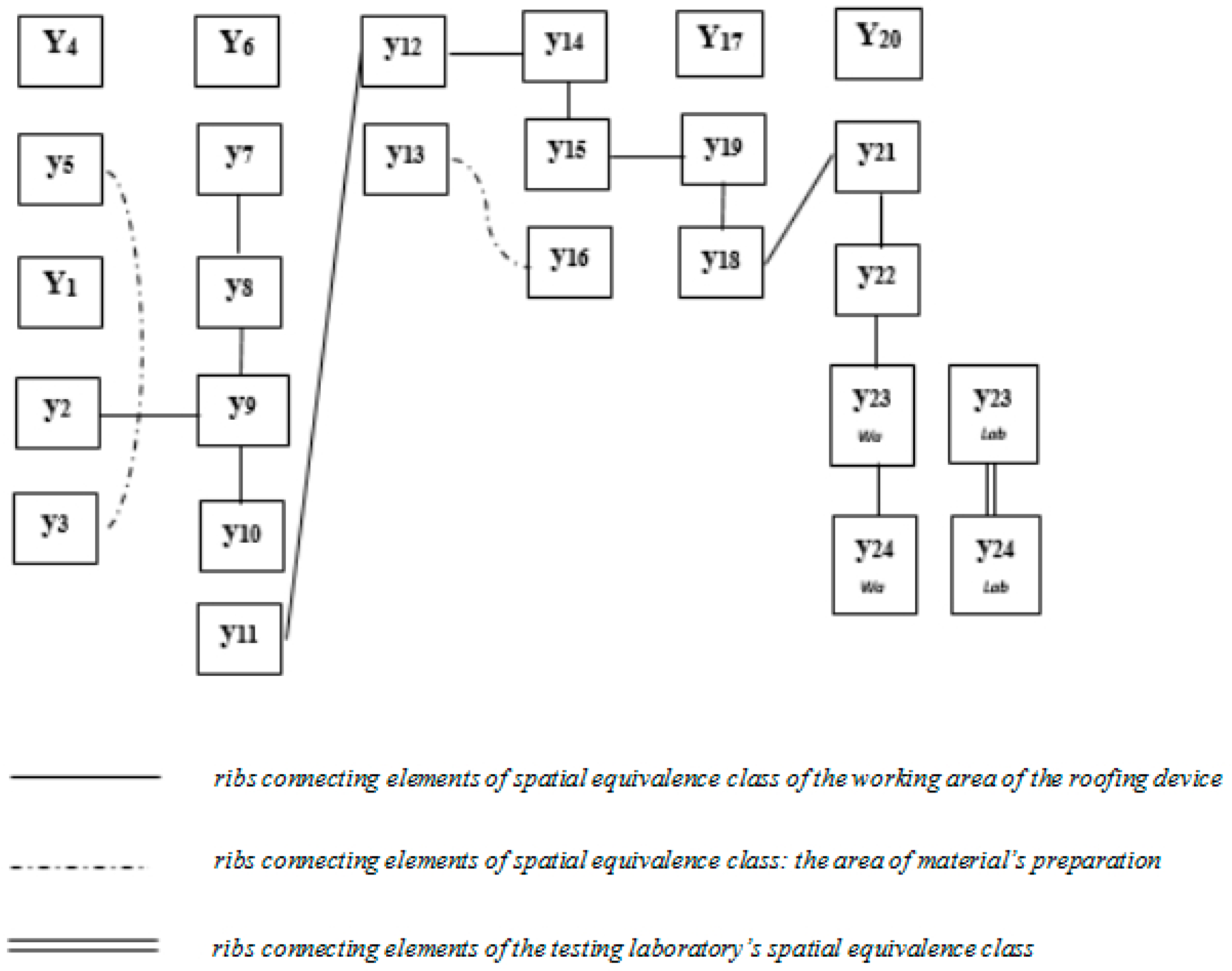

- is the main subspace, i.e., the class of spatial equivalence of the working area of the roofing device (connections between operations performed in the working area);

- is the class of spatial equivalence: site of acceptance and preparation of materials (serving subspace); and

- is the spatial equivalence class of the testing laboratory (serving subspace).

- is the labour resource equivalence of the class: master in the amount of one person;

- is the labour resource equivalence of the class: rigger of the second category in the amount of two persons, driver of the sixth category in the amount of one person;

- is the resource equivalence class: ancillary worker of the second category in the amount of one person;

- is the resource equivalence class: roofer of the second category in the amount of two persons, roofer of the third category in the amount of one person; and

- is the resource equivalence class: laboratory assistant in the amount of one person.

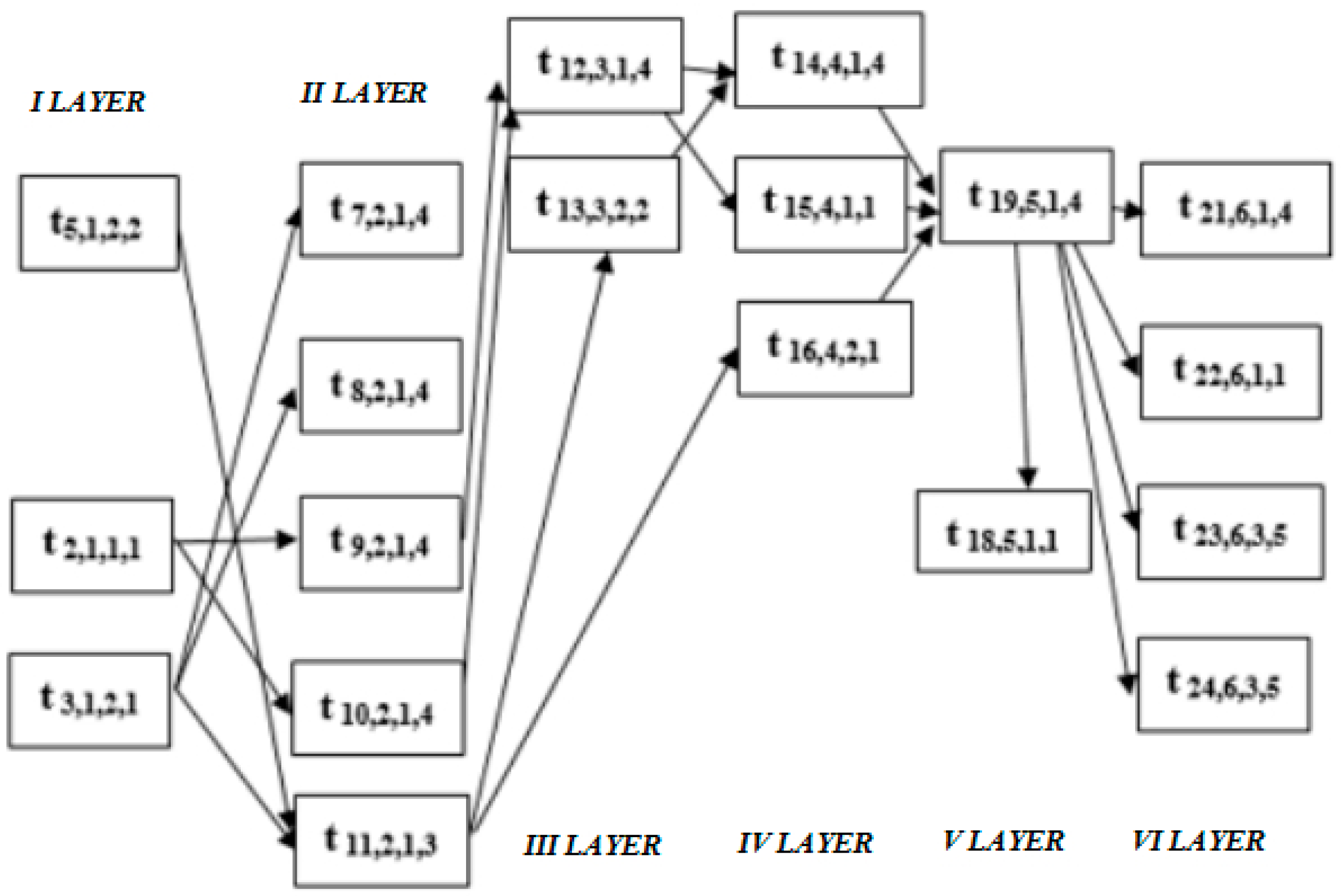

- is the index of the sequence element (operation number), ;

- is the number of the layer in which the operation is located, ;

- is the number of the main or serving subspace, ; and

- is the number (class) of the labour resource, .

4. Conclusions

- (1)

- The sequence and composition of technological processes and operations was established for installing the modular green roof.

- (2)

- The spatial and technological structure model has been built as a result of the formation of technological and spatial ordering of technological processes.

- (3)

- The functional model of installing a modular green roof has been developed. The model makes it possible to optimise on the principles of saving labour contribution (working hours) and time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bevilacqua, P. The effectiveness of green roofs in reducing building energy consumptions across different climates. A summary of literature results. Renew. Sustain. Energy Rev. 2021, 151, 111523. [Google Scholar] [CrossRef]

- Hanumesh, M.; Claverie, R.; Séré, G. A roof of greenery, but a sky of unexplored relations—Meta-analysis of factors and properties that affect green roof hydrological and thermal performances. Sustainability 2021, 13, 10017. [Google Scholar] [CrossRef]

- Liu, H.; Kong, F.; Yin, H.; Middel, A.; Zheng, X.; Huang, J.; Xu, H.; Wang, D.; Wen, Z. Impacts of green roofs on water, temperature, and air quality: A bibliometric review. Build. Environ. 2021, 196, 107794. [Google Scholar] [CrossRef]

- Knight, T.; Price, S.; Bowler, D.; Hookway, A.; King, S.; Konno, K.; Richter, R.L. How effective is ‘greening’ of urban areas in reducing human exposure to ground-level ozone concentrations, UV exposure and the ‘urban heat island effect’? An updated systematic review. Environ. Evid. 2021, 10, 1–38. [Google Scholar] [CrossRef]

- Priya, U.K.; Senthil, R. A review of the impact of the green landscape interventions on the urban microclimate of tropical areas. Build. Environ. 2021, 205, 108190. [Google Scholar] [CrossRef]

- Gorshkov, A.S.; Vatin, N.I.; Rymkevich, P.P. Climate change and the thermal island effect in the million-plus city. Constr. Unique Build. Struct. 2020, 89, 8902. [Google Scholar] [CrossRef]

- Parsaee, M.; Joybari, M.M.; Mirzaei, P.A.; Haghighat, F. Urban heat island, urban climate maps and urban development policies and action plans. Environ. Technol. Innov. 2019, 14, 100341. [Google Scholar] [CrossRef]

- Jamei, E.; Chau, H.W.; Seyedmahmoudian, M.; Stojcevski, A. Review on the cooling potential of green roofs in different climates. Sci. Total Environ. 2021, 791, 148407. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, W.; Jim, C.Y.; Morakinyo, T.E.; Shi, Y.; Ng, E. Heat mitigation benefits of urban green and blue infrastructures: A systematic review of modeling techniques, validation and scenario simulation in ENVI-met V4. Build. Environ. 2021, 200, 107939. [Google Scholar] [CrossRef]

- Wong, N.H.; Tan, C.L.; Kolokotsa, D.D.; Takebayashi, H. Greenery as a mitigation and adaptation strategy to urban heat. Nat. Rev. Earth Environ. 2021, 2, 166–181. [Google Scholar] [CrossRef]

- Krayenhoff, E.S.; Broadbent, A.M.; Zhao, L.; Georgescu, M.; Middel, A.; Voogt, J.A.; Martilli, A.; Sailor, D.J.; Erell, E. Cooling hot cities: A systematic and critical review of the numerical modelling literature. Environ. Res. Lett. 2021, 16, 053007. [Google Scholar] [CrossRef]

- Liu, T.; Lawluvy, Y.; Shi, Y.; Yap, P.-S. Low Impact Development (LID) Practices: A Review on Recent Developments, Challenges and Prospects. Water. Air Soil Pollut. 2021, 232, 1–36. [Google Scholar] [CrossRef]

- Adem Esmail, B.; Suleiman, L. Analyzing Evidence of Sustainable Urban Water Management Systems: A Review through the Lenses of Sociotechnical Transitions. Sustainability 2020, 12, 4481. [Google Scholar] [CrossRef]

- Hachoumi, I.; Pucher, B.; De Vito-Francesco, E.; Prenner, F.; Ertl, T.; Langergraber, G.; Fürhacker, M.; Allabashi, R. Impact of Green Roofs and Vertical Greenery Systems on Surface Runoff Quality. Water 2021, 13, 2609. [Google Scholar] [CrossRef]

- Statistical Review of World Energy 2021 by British Petroleum. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2021-full-report.pdf (accessed on 29 October 2021).

- Rafael, S.; Correia, L.P.; Ascenso, A.; Augusto, B.; Lopes, D.; Miranda, A.I. Are green roofs the path to clean air and low carbon cities? Sci. Total Environ. 2021, 798, 149313. [Google Scholar] [CrossRef]

- Seyedabadi, M.R.; Eicker, U.; Karimi, S. Plant selection for green roofs and their impact on carbon sequestration and the building carbon footprint. Environ. Chall. 2021, 4, 100119. [Google Scholar] [CrossRef]

- Nadeeshani, M.; Ramachandra, T.; Gunatilake, S.; Zainudeen, N. Carbon Footprint of Green Roofing: A Case Study from Sri Lankan Construction Industry. Sustainability 2021, 13, 6745. [Google Scholar] [CrossRef]

- Trovato, M.R.; Nocera, F.; Giuffrida, S. Life-Cycle Assessment and Monetary Measurements for the Carbon Footprint Reduction of Public Buildings. Sustainability 2020, 12, 3460. [Google Scholar] [CrossRef] [Green Version]

- Joshi, M.Y.; Teller, J. Urban Integration of Green Roofs: Current Challenges and Perspectives. Sustainability 2021, 13, 12378. [Google Scholar] [CrossRef]

- Hirano, Y.; Ihara, T.; Gomi, K.; Fujita, T. Simulation-Based Evaluation of the Effect of Green Roofs in Office Building Districts on Mitigating the Urban Heat Island Effect and Reducing CO2 Emissions. Sustainability 2019, 11, 2055. [Google Scholar] [CrossRef] [Green Version]

- Balaban, O.; Puppim de Oliveira, J.A. Sustainable buildings for healthier cities: Assessing the co-benefits of green buildings in Japan. J. Clean. Prod. 2017, 163, S68–S78. [Google Scholar] [CrossRef]

- Shafique, M.; Luo, X.; Zuo, J. Photovoltaic-green roofs: A review of benefits, limitations, and trends. Sol. Energy 2020, 202, 485–497. [Google Scholar] [CrossRef]

- Cascone, S. Green roof design: State of the art on technology and materials. Sustainability 2019, 11, 3020. [Google Scholar] [CrossRef] [Green Version]

- Halwatura, R.U.; Jayasinghe, M.T.R. Thermal performance of insulated roof slabs in tropical climates. Energy Build. 2008, 40, 1153–1160. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Mazzeo, D.; Arcuri, N. Thermal inertia assessment of an experimental extensive green roof in summer conditions. Build. Environ. 2018, 131, 264–276. [Google Scholar] [CrossRef]

- Abdo, P.; Huynh, B.P.; Irga, P.J.; Torpy, F.R. Evaluation of air flow through an active green wall biofilter. Urban For. Urban Green. 2019, 41, 75–84. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Mazzeo, D.; Bruno, R.; Arcuri, N. Surface temperature analysis of an extensive green roof for the mitigation of urban heat island in southern mediterranean climate. Energy Build. 2017, 150, 318–327. [Google Scholar] [CrossRef]

- Korol, E.; Shushunova, N. Benefits of a Modular Green Roof Technology. Procedia Eng. 2016, 161, 1820–1826. [Google Scholar] [CrossRef] [Green Version]

- Korol, O.; Shushunova, N.; Lopatkin, D.; Zanin, A.; Shushunova, T. Application of High-tech Solutions in Ecodevelopment. MATEC Web Conf. 2018, 251, 06002. [Google Scholar] [CrossRef]

- Korol, E.; Shushunova, N. Green Roofs: Standardization and Quality Control of Processes in Green Construction. In Proceedings of the MATEC Web of Conferences, Taichung, Taiwan, 28 October–1 November 2017; Volume 106. [Google Scholar]

- Korol, E.; Shushunova, N. Research and Development for the International Standardization of Green Roof Systems. Procedia Eng. 2016, 153, 287–291. [Google Scholar] [CrossRef] [Green Version]

- Teotónio, I.; Silva, C.M.; Cruz, C.O. Economics of green roofs and green walls: A literature review. Sustain. Cities Soc. 2021, 69, 102781. [Google Scholar] [CrossRef]

- Zhang, G.; He, B.-J. Towards green roof implementation: Drivers, motivations, barriers and recommendations. Urban For. Urban Green. 2021, 58, 126992. [Google Scholar] [CrossRef]

- Korol, O.A. Development of the methodology of calendar planning in the system of organizational and technological preparation of capital repair of multi-apartment residential houses. J. Phys. Conf. Ser. 2019, 1425, 012086. [Google Scholar] [CrossRef] [Green Version]

| The Name of the Technological Process (Technological Operation) | Workers (Profession and Persons’ Number) | Designation of the Process (Operation) in the Original List | Redesignation of the Process (Operation) in the Technological Sequence |

|---|---|---|---|

| Preparation of the base | Roofers of the 2nd category in the amount of two persons, roofer of the 3rd category in one person | ||

| Marking the covering for laying out the supports (levelling) | Roofers of the 2nd category in the amount of two persons, roofer of the 3rd category in one person | ||

| Layout and gluing of supports | Roofers of the 2nd category in two persons, roofer of the 3rd category in one person | ||

| Support tilt angle adjustment | Roofers of the 2nd category in two persons, roofer of the 3rd category in one person | ||

| Fastening the clips | Roofers of the 2nd category in two persons, roofer of the 3rd category in one person | ||

| Laying and fixing the grating on the supports | Roofers of the 2nd category in two persons, roofer of the 3rd category in one person | ||

| Installation and connection of a group of modules in the amount of 4 pcs. fixed to the gratings | Roofers of the 2nd category in two persons, roofer of the 3rd category in one person | ||

| Preparation and transportation of the materials | Riggers of the 2nd category in two persons, driver of the 4th category in one person, driver of the 6th category in one person, ancillary worker of the 2nd category in one person | ||

| Supply of concrete mix solution in boxes by truck crane | Riggers of the 2nd category in two persons, driver of the 4th category in one person | ||

| Transportation of materials (goods) by hand carts | Ancillary worker of the 2nd category in one person | ||

| Feeding materials to the roof by crane | Riggers of the 2nd category in two persons, driver of the 6th category in one person | ||

| Installation of planters | Roofers of the 2nd category in two persons, ancillary worker of the 1st category in one person | ||

| Filling a group of modules with soil and planting material | Roofers of the 2nd category in two persons, ancillary worker of the 1st category in one person | ||

| Operational control of the technological process | Master | ||

| Incoming inspection of materials | Master | ||

| Verification of compliance with the project arrangement of roof elements | Master | ||

| Checking the conformity of the project of the incoming materials | Master | ||

| Quality of preparation of the coating base | Master | ||

| Control of the technical condition of technological equipment | Master | ||

| Quality control of finished joints of structural elements | Laboratory assistant, roofer of the 3rd category, master | ||

| Visual control | Roofer of the 3rd category | ||

| Control of geometric parameters of roof elements | Master | ||

| Non-destructive testing methods | Laboratory assistant | ||

| Testing of roof structures and materials | Laboratory assistant |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shushunova, N.S.; Korol, E.A.; Vatin, N.I. Modular Green Roofs for the Sustainability of the Built Environment: The Installation Process. Sustainability 2021, 13, 13749. https://doi.org/10.3390/su132413749

Shushunova NS, Korol EA, Vatin NI. Modular Green Roofs for the Sustainability of the Built Environment: The Installation Process. Sustainability. 2021; 13(24):13749. https://doi.org/10.3390/su132413749

Chicago/Turabian StyleShushunova, Natalia Sergeevna, Elena Anatolyevna Korol, and Nikolai Ivanovich Vatin. 2021. "Modular Green Roofs for the Sustainability of the Built Environment: The Installation Process" Sustainability 13, no. 24: 13749. https://doi.org/10.3390/su132413749

APA StyleShushunova, N. S., Korol, E. A., & Vatin, N. I. (2021). Modular Green Roofs for the Sustainability of the Built Environment: The Installation Process. Sustainability, 13(24), 13749. https://doi.org/10.3390/su132413749