Assessment of Precise Land Levelling on Surface Irrigation Development. Impacts on Maize Water Productivity and Economics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Sites

2.2. Land Levelling Assessment and Computation

2.3. Irrigation Performance Assessment

- (a)

- Beneficial water use fraction (BWUF, %), expressing the efficiency of water application on field, is defined as:where Zavg is the average depth of water infiltrated in the whole irrigated field (mm), Zlq is the average low quarter depth of water infiltrated (mm), and D is the average water depth (mm) applied to the field. The two equations are used to distinguish the cases of over-irrigation (Zlq > Zreq) and under-irrigation (Zlq < Zreq).

- (b)

- Distribution uniformity (DU, %), expressing the quality of the irrigation system to uniformly infiltrate the water spatially, is defined as:

- (c)

- Irrigation Water Productivity (IWP, kg m−3), expressing the amount of physical production obtained per unit of irrigation water applied, is defined as:where Ya is the actual crop yield, and IWU the irrigation water use.

- (d)

- Economic Water Productivity Ratio (EWPR, ratio), expressing the economical production obtained per unit of cost relative to the irrigation water applied, is defined as:where Value (Yield) is the monetary value of yield, and TIC is the total irrigation cost.

- (e)

- Total Irrigation Cost (TIC, € ha−1) is defined as:where PLLC is the precise land levelling cost, IWC is the irrigation water cost, ILC is the irrigation labor cost, and DSC is the distribution system cost.

3. Results

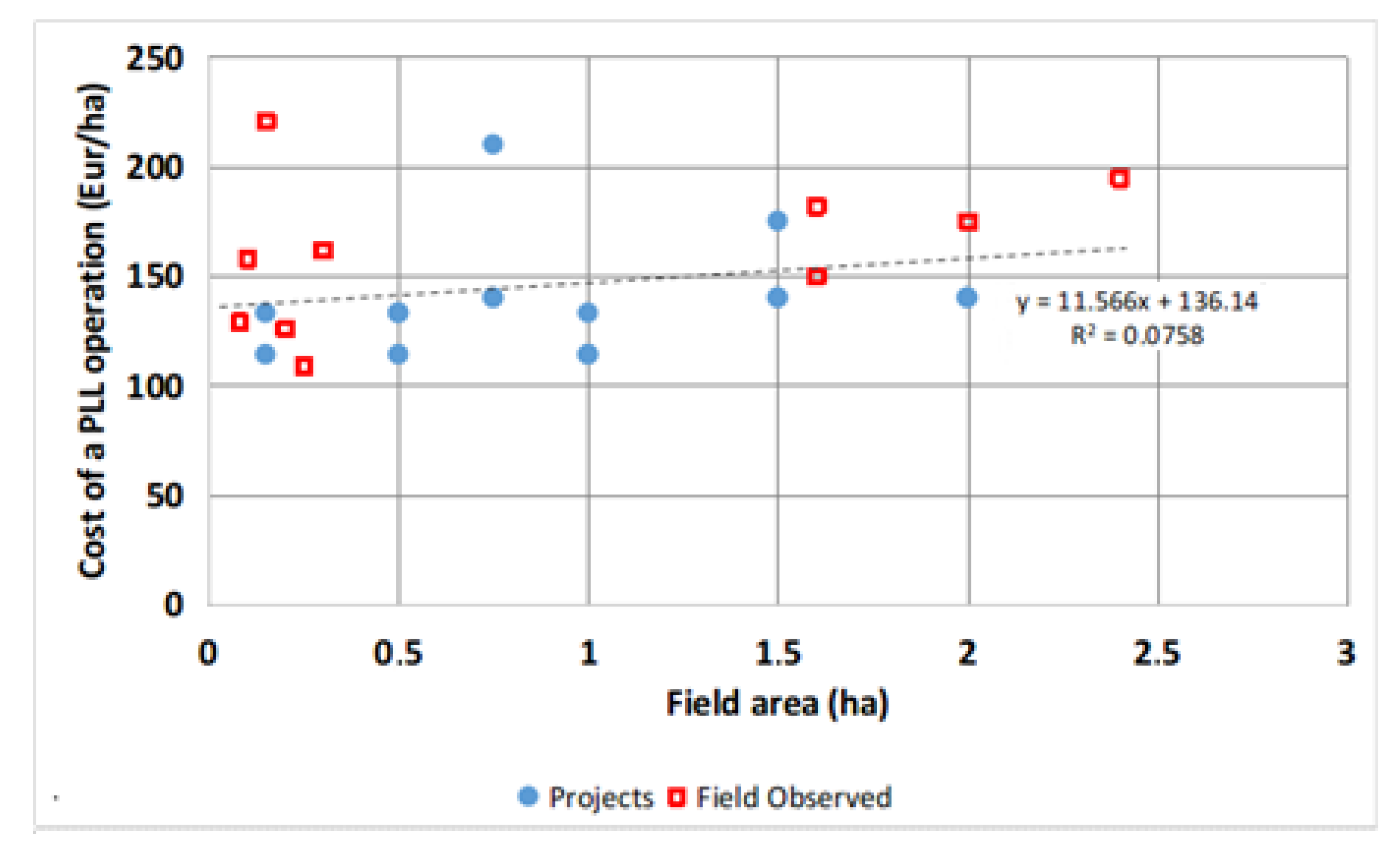

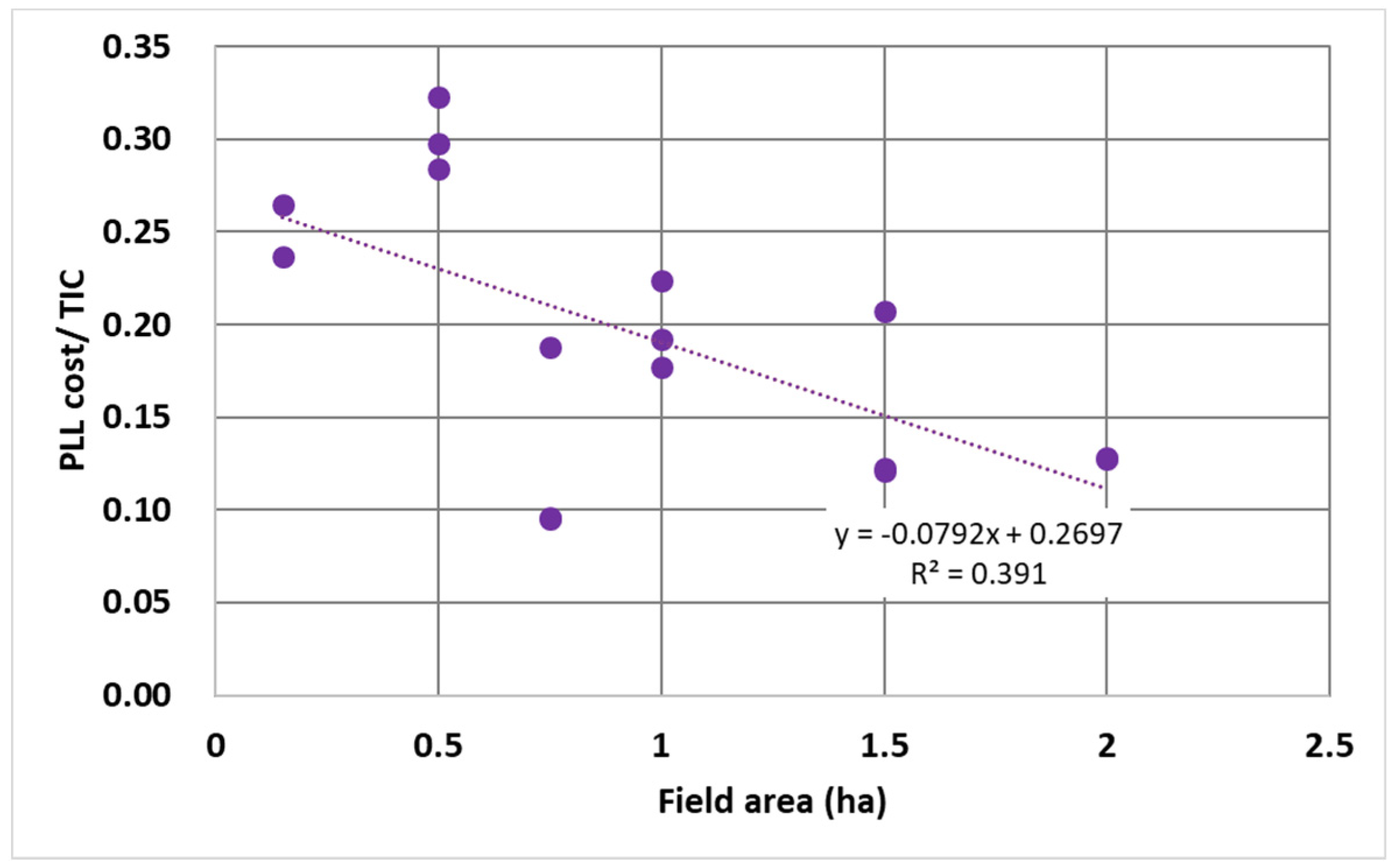

3.1. Land Levelling Assessment

3.2. Impacts on Irrigation Performance

3.3. Impacts on Economics

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Clemmens, A.J.; Dedrick, A.R.; Sousa, P.L.; Pereira, L.S. Effect of furrow elevation differences on level-basin performance. Trans. Am. Soc. Agric. Eng. 1995, 38, 153–158. [Google Scholar]

- Playan, E.; Faci, J.M.; Serreta, A. Characterizing microtopographical effects on level-basin irrigation performance. Agric. Water Manag. 1996, 29, 129–145. [Google Scholar] [CrossRef] [Green Version]

- Abdullaev, I.; Hassan, M.; Jumaboev, K. Water saving and economic impacts of land leveling: The case study of cotton production in Tajikistan. Irrig. Drain. Syst. 2007, 21, 251–263. [Google Scholar] [CrossRef]

- Dedrick, A.R.; Gaddis, R.J.; Clark, A.W.; Moore, A.W. Land forming for irrigation. In Design and Operation of Farm Irrigation Systems, 2nd ed.; Hoffman, G.J., Evans, R.G., Jensen, M.E., Martin, D.L., Elliot, R.L., Eds.; ASABE: St. Joseph, MI, USA, 2007; pp. 320–346. [Google Scholar]

- Pereira, L.S.; Gonçalves, J.M. Surface irrigation. In Oxford Encyclopedia of Agriculture and the Environment, Subject: Sustainability and Solutions, Agriculture and the Environment; Oxford University Press: Oxford, UK, 2018. [Google Scholar] [CrossRef]

- SCS. Soil Conservation Service National Engineering Handbook; Land Leveling: Washington, DC, USA, 1970; Chapter 12, Section 15.

- Erie, L.J.; Dedrick, A.R. Level Basin Irrigation: A Method for Conserving Water and Labor; U.S. Department of Agriculture: Washington, DC, USA, 1979.

- Sousa, P.L.; Dedrick, A.R.; Clemmens, A.J.; Pereira, L.S. Benefits and costs of laser-controlled leveling—A case study. In Proceedings of the International Commission on Irrigation and Drainage, XVth Congress, The Hague, The Netherlands, 4–11 September 1993; pp. 1237–1247. [Google Scholar]

- Bai, M.; Xu, D.; Li, Y.; Zhang, S.; Liu, S. Coupled impact of spatial variability of infiltration and microtopography on basin irrigation performances. Irrig. Sci. 2017, 35, 437–449. [Google Scholar] [CrossRef]

- Das, A.; Lad, M.D.; Chalodia, A.L. Effect of laser land leveling on nutrient uptake and yield of wheat, water saving and water productivity. J. Pharmacogn. Phytochem. 2018, 7, 73–78. [Google Scholar]

- Naresh, R.K.; Rathore, R.S.; Yadav, R.B.; Singh, S.P.; Misra, A.K.; Kumar, V.; Kumar, N.; Gupta, R.K. Effect of precision land levelling and permanent raised bed planting on soil properties, input use efficiency, productivity and profitability under maize (Zea mays) wheat (Triticum aestivum) cropping system. Afr. J. Agric. Res. 2014, 9, 2781–2789. [Google Scholar] [CrossRef] [Green Version]

- Aryal, J.P.; Rahut, D.B.; Jat, M.L.; Maharjan, S.; Erenstein, O. Factors determining the adoption of laser land leveling in the irrigated rice–wheat system in Haryana, India. J. Crop Improv. 2018, 32, 477–492. [Google Scholar] [CrossRef]

- Jat, M.L.; Gathala, M.K.; Ladha, J.K.; Saharawat, Y.S.; Jat, A.S.; Kumar, V.; Sharma, S.K.; Kumar, V.; Gupta, R. Evaluation of precision land leveling and double zero-till systems in the rice–wheat rotation: Water use, productivity, profitability and soil physical properties. Soil Tillage Res. 2009, 105, 112–121. [Google Scholar] [CrossRef]

- Aquino, L.S.; Timm, L.C.; Reichardt, K.; Barbosa, E.P.; Parfitt, J.M.; Nebel, A.L.; Penning, L.H. State-space approach to evaluate effects of land levelling on the spatial relationships of soil properties of a lowland area. Soil Tillage Res. 2015, 145, 135–147. [Google Scholar] [CrossRef]

- Jat, M.L.; Singh, Y.; Gill, G.; Sidhu, H.S.; Aryal, J.P.; Stirling, C.; Gerard, B. Laser-Assisted Precision Land Leveling Impacts in Irrigated Intensive Production Systems of South Asia. Adv. Soil Sci. 2014, 22, 323–352. [Google Scholar]

- Booher, L.J. Surface Irrigation; Development Paper, 95; FAO United Nations: Rome, Italy, 1974. [Google Scholar]

- Pereira, L.S.; Gonçalves, J.M.; Dong, B.; Mao, Z.; Fang, S.X. Assessing basin irrigation and scheduling strategies for saving irrigation water and controlling salinity in the upper Yellow River Basin, China. Agric. Water Manag. 2007, 93, 109–122. [Google Scholar] [CrossRef]

- Gonçalves, J.M.; Horst, M.G.; Pereira, L.S.; Muga, A.P. Furrow Irrigation Design with Multicriteria Analysis. Biosyst. Eng. 2011, 109, 266–275. [Google Scholar] [CrossRef]

- Bai, M.; Xu, D.; Li, Y.; Pereira, L.S. Stochastic modeling of basins microtopography: Analysis of spatial variability and model testing. Irrig. Sci. 2010, 28, 157–172. [Google Scholar] [CrossRef]

- Bai, M.J.; Xu, D.; Li, Y.N.; Pereira, L.S. Impacts of spatial variability of basins microtopography on irrigation performance. Irrig. Sci. 2011, 29, 359–368. [Google Scholar] [CrossRef]

- Miao, Q.; Shi, H.; Gonçalves, J.M.; Pereira, L.S. Field assessment of basin irrigation performance and water saving in Hetao, Yellow River basin: Issues to support irrigation systems modernisation. Biosyst. Eng. 2015, 136, 102–116. [Google Scholar] [CrossRef] [Green Version]

- Gonçalves, J.M.; Pereira, L.S. A decision support system for surface irrigation design. J. Irrig. Drain. Eng. 2009, 135, 343–356. [Google Scholar] [CrossRef] [Green Version]

- Gonçalves, J.M.; Ferreira, S.; Nunes, M.; Eugénio, R.; Amador, A.; Filipe, O.; Duarte, I.M.; Teixeira, M.; Vasconcelos, T.; Oliveira, F.; et al. Developing Irrigation Management at District Scale Based on Water Monitoring: Study on Lis Valley, Portugal. AgriEngineering 2020, 2, 78–95. [Google Scholar] [CrossRef] [Green Version]

- Aggarwal, R.; Kaur, S.; Singh, A. Assessment of saving in water resources through precision land leveling in Punjab. J. Soil Water Conserv. 2010, 9, 182–185. [Google Scholar]

- Reba, M.L.; Massey, J.H. Surface irrigation in the Lower Mississippi River Basin: Trends and Innovations. In Transactions of the ASABE; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2020; Volume 63, pp. 1305–1314. [Google Scholar] [CrossRef]

- Enciso, J.; Jung, J.; Chang, A.; Chavez, J.C.; Yeom, J.; Landivar, J.; Cavazos, G. Assessing land leveling needs and performance with unmanned aerial system. J. Appl. Remote Sens. 2018, 12, 016001. [Google Scholar] [CrossRef] [Green Version]

- Walker, W.R.; Skogerboe, G.V. Surface Irrigation. Theory and Practice; Prentice-Hall: Englewood Cliffs, NJ, USA, 1987. [Google Scholar]

- Scaloppi, E.J.; Willardson, L.S. Practical land grading based on least squares. J. Irrig. Drain. Eng. 1986, 112, 98–109. [Google Scholar] [CrossRef] [Green Version]

- Gebre-Selassie, N.A.; Willardson, L.S. Application of Least Squares Land Leveling. J. Irrig. Drain. Eng. 1991, 117, 962–966. [Google Scholar] [CrossRef]

- Rego, Z.C.; Serafim, A.P. Land Levelling: Calculation methods. Ingenium. Dec. 1992, 39–53. [Google Scholar]

- Hamad, S.N.; Ali, A.M. Land-grading design by using nonlinear programming. J. Irrig. Drain. Eng. 1990, 116, 219–226. [Google Scholar] [CrossRef]

- Kumar, Y.; Chauhan, H.S. Gradient search technique for land levelling design. Trans. ASAE 1987, 30, 319–393. [Google Scholar]

- Zhang, D.J.; Yuan, S.P.; Peng, W.; Yu, F.F. Methods for delineating the land leveling range in land consolidation and rehabilitation projects. Lowl. Technol. Int. 2017, 19, 111–116. [Google Scholar]

- Alzoubi, I.; Delavar, M.R.; Mirzaei, F.; Arrabi, B.N. Comparing ANFIS and integrating algorithm models (ICA-ANN, PSO-ANN, and GA-ANN) for prediction of energy consumption for irrigation land leveling. Geosyst. Eng. 2018, 21, 81–94. [Google Scholar] [CrossRef]

- Liu, L.; Ma, J.; Luo, Y.; He, C.; Liu, T. Hydrologic simulation of a winter wheat–summer maize cropping system in an irrigation district of the Lower Yellow River Basin, China. Water 2017, 9, 7. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Liu, T.; Ding, Y.; Wang, G.; Liu, X. Characteristics and tendency of climate change in the Hetao irrigation District in the past 50 years. J. Beijing Norm. Univ. 2016, 52, 402–407. [Google Scholar]

- Zhang, D.; Liu, X.; Hong, H. Assessing the effect of climate change on reference evapotranspiration in China. Stoch. Environ. Res. Risk Assess. 2013, 27, 1871–1881. [Google Scholar] [CrossRef]

- Qu, Z.; Yang, X.; Huang, Y. Analysis and assessment of water-saving project of Hetao Irrigation District in Inner Mongolia. Trans. Chin. Soc. Agric. Mach. 2015, 46, 70–76. [Google Scholar]

- Wang, X.; Liu, H.; Zhang, L.; Zhang, R. Climate change trend and its effects on reference evapotranspiration at Linhe Station, Hetao Irrigation District. Water Sci. Eng. 2014, 7, 250–266. [Google Scholar]

- Miao, Q.; Shi, H.; Gonçalves, J.M.; Pereira, L.S. Basin Irrigation Design with Multi-Criteria Analysis Focusing on Water Saving and Economic Returns: Application to Wheat in Hetao, Yellow River Basin. Water 2018, 10, 67. [Google Scholar] [CrossRef] [Green Version]

- Shi, H.; Yang, S.; Li, R.; Li, X.; Li, W.; Yan, J.; Miao, Q.; Li, Z. Soil Water and Salt Movement and Soil Salinization Control in Hetao Irrigation District: Current State and Future Prospect. J. Irrig. Drain. 2020, 39, 1–17. [Google Scholar] [CrossRef]

- Hernández-Saucedo, F.R.; Sanchez-Bravo, J.R.; Garcia-Herrera, F. A computer program for agricultural land levelling. In Proceedings of the 6th International Conference on Computers in Agriculture, ASAE, Cancun, Mexico, 1–14 June 1996. [Google Scholar]

- Katopodes, N.D.; Tang, J.H.; Clemmens, A.J. Estimation of surface irrigation parameters. J. Irrig. Drain. Eng. 1990, 116, 676–696. [Google Scholar] [CrossRef]

- Walker, W.R. SIRMOD III: Surface Irrigation Simulation, Evaluation and Design; Guide and Technical Documentation; Department of Biological and Irrigation Engineering, Utah State University: Logan, Utah, 2003. [Google Scholar]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration. Guidelines for Computing Crop Water Requirements; FAO Irrigation and Drainage Paper 56; FAO: Rome, Italy, 1998; p. 300. [Google Scholar]

- Miao, Q.; Rosa, R.D.; Shi, H.; Paredes, P.; Zhu, L.; Dai, J.; Gonçalves, J.M.; Pereira, L.S. Modeling water use, transpiration and soil evaporation of spring wheat-maize and spring wheat-sunflower relay intercropping using the dual crop coefficient approach. Agric. Water Manag. 2016, 165, 211–229. [Google Scholar] [CrossRef]

- Darouich, H.; Gonçalves, J.M.; Muga, A.; Pereira, L.S. Water saving vs. farm economics in cotton surface irrigation: An application of multicriteria analysis. Agric. Water Manag. 2012, 115, 223–231. [Google Scholar] [CrossRef]

- Darouich, H.; Pedras, C.M.; Gonçalves, J.M.; Pereira, L.S. Drip vs. surface irrigation: A comparison focusing water saving and economic returns using multicriteria analysis applied to cotton. Biosyst. Eng. 2014, 122, 74–90. [Google Scholar] [CrossRef]

- Pereira, L.S.; Cordery, I.; Iacovides, I. Improved indicators of water use performance and productivity for sustainable water conservation and saving. Agric. Water Manag. 2012, 108, 39–51. [Google Scholar] [CrossRef]

- Spencer, G.D.; Krutz, L.J.; Falconer, L.L.; Henry, W.B.; Henry, C.G.; Larson, E.J.; Pringle, H.C.; Bryant, C.J.; Atwill, R.L. Irrigation Water Management Technologies for Furrow Irrigated Corn that Decrease Water Use and Improve Yield and On-Farm Profitability. Crop Forage Turfgrass Manag. 2019, 5, 180100. [Google Scholar] [CrossRef] [Green Version]

- Hosseini, S.F.; Bordbar, M.; Rajabi, S. The Perception of Farmers about Laser Land Levelling as an Appropriate Technology in Agricultural Sector of Iran. Annu. Res. Rev. Biol. 2014, 4, 2207–2214. [Google Scholar] [CrossRef]

- Ferreira, S.; Oliveira, F.; Silva, F.G.; Teixeira, M.; Gonçalves, M.; Eugénio, R.; Damásio, H.; Gonçalves, J.M. Assessment of Factors Constraining Organic Farming Expansion in Lis Valley, Portugal. AgriEngineering 2020, 3, 111–127. [Google Scholar] [CrossRef] [Green Version]

- Sidhu, H.S.; Mahal, J.S.; Dhaliwal, I.S.; Bector, V.; Manpreet, S.; Sharda, A.; Singh, T. Laser Land Leveling–A Boon for Sustaining Punjab Agriculture. Dept. of FPM, Punjab Agricultural University, Ludhiana, India. Farm. Mach. Bull. 2007, 1, 13. [Google Scholar]

- Groenfeldt, D. Multifunctionality of agricultural water: Looking beyond food production and ecosystem services. Irrig. Drain. 2006, 55, 73–83. [Google Scholar] [CrossRef]

- Clemmens, A.J.; Dedrick, A.R. Estimating distribution uniformity in level basins. Trans. ASAE 1981, 24, 1177–1180. [Google Scholar] [CrossRef]

- Aryal, J.P.; Mehrotra, M.B.; Jat, M.L.; Sidhu, H.S. Impacts of laser land leveling in rice–wheat systems of the north–western indo-gangetic plains of India. Food Sec. 2015, 7, 725–738. [Google Scholar] [CrossRef]

Hetao;

Hetao;  Lower-Mondego) (Map Data © 2020 Google, INEGI).

Lower-Mondego) (Map Data © 2020 Google, INEGI).

| Irrigation District | Field Code | L (m) | W (m) | A (ha) | S (%) | IM | Soil Texture | Irrigation District Sector |

|---|---|---|---|---|---|---|---|---|

| Hetao | H1 | 50 | 15 | 0.08 | 0.06 | GB | silty loam | Dengkou |

| H2 | 50 | 20 | 0.10 | 0.02 | GB | silty loam | Dengkou | |

| H3 | 50 | 30 | 0.15 | 0.02 | GB | silty loam | Dengkou | |

| H4 | 50 | 40 | 0.20 | 0.05 | GB | silty loam | Dengkou | |

| H5 | 50 | 50 | 0.25 | 0.05 | GB | silty loam | Dengkou | |

| H6 | 50 | 60 | 0.30 | 0.08 | GB | silty loam | Dengkou | |

| Lower— Mondego | M1 | 200 | 120 | 2.4 | 0.23 | GF | sandy loam | Margem Esquerda |

| M2 | 160 | 100 | 1.6 | 0.14 | GF | sandy loam | Margem Esquerda | |

| M3 | 100 | 160 | 1.6 | 0 | LB | loamy | Tentúgal | |

| M4 | 180 | 80 | 1.4 | 0.10 | GF | silty loam | Montemor-o-Velho |

| Study Site | NIE | NTI (mm) | SNI (mm) | SNIS (mm) | Yield (Mg ha−1) | AI (mm) | ER (mm) | ETc Act (mm) | CC (days) |

|---|---|---|---|---|---|---|---|---|---|

| Hetao | 5 | 90 | 450 | 303 | 12.00 | 230 | 103 | 753 | 154 |

| Lower— Mondego | 7 | 56 | 392 | 140 | 12.00 | 0 | 130 | 535 | 140 |

| Irrigation Event | K (m3 m−1 min−a) | a (−) | f0 (m3 m−1 min−1) | n (m−1/3 s) | |

|---|---|---|---|---|---|

| Hetao | First | 0.0049 | 0.526 | 0 | 0.04 |

| Later | 0.0045 | 0.510 | 0 | 0.04 | |

| Lower—Mondego | First | 0.0042 | 0.625 | 0.00020 | 0.04 |

| Later | 0.0032 | 0.563 | 0.00017 | 0.04 |

| Parameter | Hetao | Lower-Mondego | |

|---|---|---|---|

| Water distribution equipment | type of equipment | Non-lined canal | Layflat tubing |

| aquisition cost | 0.125 € m−1 | 1.0 € m−1 | |

| effective life-time | 1 year | 1 year | |

| Water cost | price per volume | 0.010 € m−3 | 0.025 € m−3 |

| fixed per area | 100 € ha−1 | 100 € ha−1 | |

| Crop price | yield price | 0.30 € kg−1 | 0.30 € kg−1 |

| Labour cost | unit cost | 4.0 € h−1 | 5.0 € h−1 |

| Study Site | L (m) | S (%) | IM | W (m) | A (ha) | Project Identifier |

|---|---|---|---|---|---|---|

| Hetao | 50 | 0 | LB | 30 | 0.15 | H-LB-50-null |

| 50 | 0.05 | GB | 30 | 0.15 | H-GB-50-0.05 | |

| 100 | 0 | LB | 50 | 0.50 | H-LB-100-null | |

| 100 | 0.05 | GB | 50 | 0.50 | H-GB-100-0.05 | |

| 100 | 0.10 | GB | 50 | 0.50 | H-GB-100-0.10 | |

| 200 | 0 | LB | 50 | 1.0 | H-LB-200-null | |

| 200 | 0.05 | GB | 50 | 1.0 | H-GB-200-0.05 | |

| 200 | 0.10 | GB | 50 | 1.0 | H-GB-200-0.10 | |

| Lower- -Mondego | 100 | 0 | LB | 75 | 0.75 | M-LB-100-null |

| 100 | 0.05 | GF | 75 | 0.75 | M-GF-100-0.05 | |

| 100 | 0.10 | GF | 75 | 0.75 | M-GF-100-0.10 | |

| 200 | 0 | LB | 75 | 1.5 | M-LB-200-null | |

| 200 | 0.05 | GF | 75 | 1.5 | M-GF-200-0.05 | |

| 200 | 0.10 | GF | 75 | 1.5 | M-GF-200-0.10 | |

| 265 | 0.05 | GF | 75 | 2.0 | M-GF-265-0.05 | |

| 265 | 0.10 | GF | 75 | 2.0 | M-GF-265-0.10 |

| Study Site | TP (HP) | LBW (m) | HC (€ h−1) | LR (h ha−1) | OF (Year) | RFA (ha) |

|---|---|---|---|---|---|---|

| Hetao | 100 | 3.0 | 30 | 5–7 | 1–3 | 0.1–0.4 |

| 120 | 3.0 | 30 | 5–6 | 2–3 | 0.2–0.4 | |

| 120 | 3.2 | 30 | 4–6 | 2–3 | 0.2–0.4 | |

| 150 | 3.2 | 33 | 3–5 | 2–4 | 0.2–0.4 | |

| 200 | 3.2 | 38 | 3–4 | 2–4 | 0.2–0.4 | |

| 150 | 3.5 | 35 | 3–4 | 2–4 | 0.4–1.0 | |

| 200 | 3.5 | 38 | 2–4 | 2–4 | 0.4–1.0 | |

| Lower— Mondego | 140 | 4.5 | 65 | 2.5 | 3 | 0.3–5 |

| 145 | 4.5 | 60 | 2.5 | 5 | 0.6–6 | |

| 240 | 6.0 | 80 | 2.0 | 5 | 0.3–7 | |

| 360 | 6.0 | 100 | 1.5 | 5 | 1.2–20 | |

| 155 | 4.5 | 60 | 2.0 | 8 | 0.3–5 | |

| 210 | 6.0 | 85 | 2.0 | 6 | 1.2–15 | |

| 200 | 5.0 | 80 | 2.0 | 10 | 0.5–13 | |

| 165 | 4.5 | 60 | 2.5 | 8 | 0.3–16 | |

| 140 | 4.0 | 60 | 2.5 | 8 | 0.35–10 |

| Field Parcel Code | TP (HP) | LBW (m) | HC (€/h) | RMSDEL (cm) | LR (h/ha) | EV 2 (m3 ha−1) | EVH (m3 h−1) | PLLC 3 (€/ha) | |

|---|---|---|---|---|---|---|---|---|---|

| Before PLL 1 | After PLL | ||||||||

| H1 | 100 | 3.0 | 30 | 8.3 | 3.5 | 4.3 | 374 | 87 | 129 |

| H2 | 100 | 3.0 | 33 | 7.2 | 2.5 | 4.8 | 327 | 68 | 158 |

| H3 | 100 | 3.0 | 35 | 9.1 | 2.6 | 6.3 | 414 | 66 | 221 |

| H4 | 100 | 3.0 | 30 | 14.9 | 3.4 | 4.2 | 601 | 143 | 126 |

| H5 | 120 | 3.2 | 33 | 10.9 | 3.0 | 3.3 | 442 | 134 | 109 |

| H6 | 120 | 3.2 | 30 | 5.3 | 2.8 | 5.4 | 247 | 46 | 162 |

| ave 4 | --- | --- | 32 | 9.3 | 3.0 | 4.7 | 401 | 91 | 151 |

| std 4 | --- | --- | 3.3 | 0.41 | 1.0 | 120 | 39 | 40 | |

| M1 | 140 | 4.0 | 65 | 4.4 | 2.3 | 3.0 | 180 | 60 | 195 |

| M2 | 140 | 4.0 | 60 | 4.2 | 2.6 | 2.5 | 175 | 79 | 150 |

| M3 | 140 | 4.0 | 65 | 3.1 | 2.0 | 2.8 | 96 | 34 | 182 |

| M4 | 145 | 4.5 | 70 | 4.3 | 2.4 | 2.5 | 215 | 86 | 175 |

| ave 5 | --- | --- | 65 | 4.0 | 2.3 | 2.7 | 167 | 65 | 176 |

| std 5 | --- | --- | 0.6 | 0.2 | 0.2 | 50 | 23 | 2 | |

| Field Code | BWUF (%) | DU (%) | Zreq (mm) | DP (%) | q0 (l s−1 m−1) | tav (min) | tco (min) |

|---|---|---|---|---|---|---|---|

| H3 1 | 88 | 95 | 109 | 12 | 1.9 | 35 | 48 |

| M1 | 86 | 91 | 56 | 14 | 2.5 | 47 | 56 |

| M2 | 78 | 81 | 71 | 22 | 1.4 | 70 | 102 |

| M3 | 76 | 80 | 57 | 24 | 1.9 | 37 | 60 |

| M4 | 75 | 77 | 85 | 25 | 1.6 | 80 | 120 |

| Projects | Y (kg/ha) | RY (-) | ELP (€/ha) | BWUF (%) | IWU (m3/ha) | IWP (kg m−3) | EWPR (-) |

|---|---|---|---|---|---|---|---|

| H-LB-50-null | 11,992 | 0.999 | 3598 | 90.0 | 5000 | 2.40 | 7.16 |

| H-GB-50-0.05 | 11,991 | 0.999 | 3597 | 90.0 | 5000 | 2.40 | 7.47 |

| H-LB-100-null | 11,994 | 1.000 | 3598 | 88.0 | 5114 | 2.35 | 8.73 |

| H-GB-100-0.05 | 11,977 | 0.998 | 3593 | 84.3 | 5340 | 2.24 | 8.95 |

| H-GB-100-0.10 | 11,090 | 0.924 | 3327 | 78.0 | 5767 | 1.92 | 7.44 |

| H-LB-200-null | 11,719 | 0.977 | 3516 | 67.0 | 6720 | 1.74 | 11.82 |

| H-GB-200-0.05 | 11,628 | 0.969 | 3488 | 71.4 | 6300 | 1.85 | 11.73 |

| H-GB-200-0.10 | 10,767 | 0.897 | 3230 | 76.8 | 5859 | 1.84 | 10.04 |

| M-LB-100-null | 11,483 | 0.957 | 3445 | 86.0 | 4557 | 2.52 | 6.16 |

| M-GF-100-0.05 | 11,390 | 0.949 | 3417 | 87.2 | 4498 | 2.53 | 6.99 |

| M-GF-100-0.10 | 11,202 | 0.934 | 3361 | 87.6 | 4476 | 2.50 | 6.88 |

| M-LB-200-null | 10,084 | 0.840 | 3025 | 78.5 | 4995 | 2.02 | 7.16 |

| M-GF-200-0.05 | 11,315 | 0.943 | 3395 | 85.1 | 4605 | 2.46 | 8.89 |

| M-GF-200-0.10 | 11,842 | 0.987 | 3553 | 89.4 | 4387 | 2.70 | 9.20 |

| M-GF-265-0.05 | 11,250 | 0.938 | 3375 | 81.6 | 4806 | 2.34 | 9.26 |

| M-GF-265-0.10 | 11,777 | 0.981 | 3533 | 80.6 | 4864 | 2.42 | 9.65 |

| Projects | PLL Parameters 1 | Costs 2 (€/ha) | Cost Ratio | ||||||

|---|---|---|---|---|---|---|---|---|---|

| OT (h/ha) | HC (€/h) | OF (years) | PLLC | IWC | ILC | DSC | TIC | PLLC/TIC | |

| H-LB-50-null | 3.5 | 38 | 1 | 133 | 150 | 194 | 25 | 502 | 0.26 |

| H-GB-50-0.05 | 3.0 | 38 | 1 | 114 | 150 | 193 | 25 | 482 | 0.24 |

| H-LB-100-null | 3.5 | 38 | 1 | 133 | 151 | 116 | 13 | 412 | 0.32 |

| H-GB-100-0.05 | 3.0 | 38 | 1 | 114 | 153 | 121 | 13 | 401 | 0.28 |

| H-GB-100-0.10 | 3.0 | 38 | 1 | 114 | 158 | 144 | 13 | 428 | 0.27 |

| H-LB-200-null | 3.5 | 38 | 2 | 67 | 167 | 58 | 6 | 297 | 0.22 |

| H-GB-200-0.05 | 3.0 | 38 | 2 | 57 | 163 | 71 | 6 | 297 | 0.19 |

| H-GB-200-0.10 | 3.0 | 38 | 2 | 57 | 159 | 100 | 6 | 322 | 0.18 |

| M-LB-100-null | 3.0 | 70 | 2 | 105 | 214 | 140 | 100 | 559 | 0.19 |

| M-GF-100-0.05 | 2.0 | 70 | 3 | 47 | 212 | 130 | 100 | 489 | 0.10 |

| M-GF-100-0.10 | 2.0 | 70 | 3 | 47 | 212 | 130 | 100 | 489 | 0.10 |

| M-LB-200-null | 2.5 | 70 | 2 | 88 | 225 | 60 | 50 | 422 | 0.21 |

| M-GF-200-0.05 | 2.0 | 70 | 3 | 47 | 215 | 70 | 50 | 382 | 0.12 |

| M-GF-200-0.10 | 2.0 | 70 | 3 | 47 | 210 | 80 | 50 | 386 | 0.12 |

| M-GF-265-0.05 | 2.0 | 70 | 3 | 47 | 220 | 60 | 38 | 365 | 0.13 |

| M-GF-265-0.10 | 2.0 | 70 | 3 | 47 | 222 | 60 | 38 | 366 | 0.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, Q.; Gonçalves, J.M.; Li, R.; Gonçalves, D.; Levita, T.; Shi, H. Assessment of Precise Land Levelling on Surface Irrigation Development. Impacts on Maize Water Productivity and Economics. Sustainability 2021, 13, 1191. https://doi.org/10.3390/su13031191

Miao Q, Gonçalves JM, Li R, Gonçalves D, Levita T, Shi H. Assessment of Precise Land Levelling on Surface Irrigation Development. Impacts on Maize Water Productivity and Economics. Sustainability. 2021; 13(3):1191. https://doi.org/10.3390/su13031191

Chicago/Turabian StyleMiao, Qingfeng, José M. Gonçalves, Ruiping Li, Diana Gonçalves, Tiago Levita, and Haibin Shi. 2021. "Assessment of Precise Land Levelling on Surface Irrigation Development. Impacts on Maize Water Productivity and Economics" Sustainability 13, no. 3: 1191. https://doi.org/10.3390/su13031191