Development of Rice Bran Mixed Porous Clay Bricks for Permeable Pavements: A Sustainable LID Technique for Arid Regions

Abstract

1. Introduction

2. Material and Methods

2.1. Material

2.2. Manufacturing of Porous Clay Bricks

2.3. Testing of Porous Clay Bricks

2.3.1. Mechanical, Physical, and Hydrological Properties

2.3.2. Filtration Experiments

2.3.3. Water Quality Testing of Filtered Water

2.4. Statistical Analysis

3. Results and Discussion

3.1. Results

3.1.1. Porosity, Water Adsorption, and Bulk Density

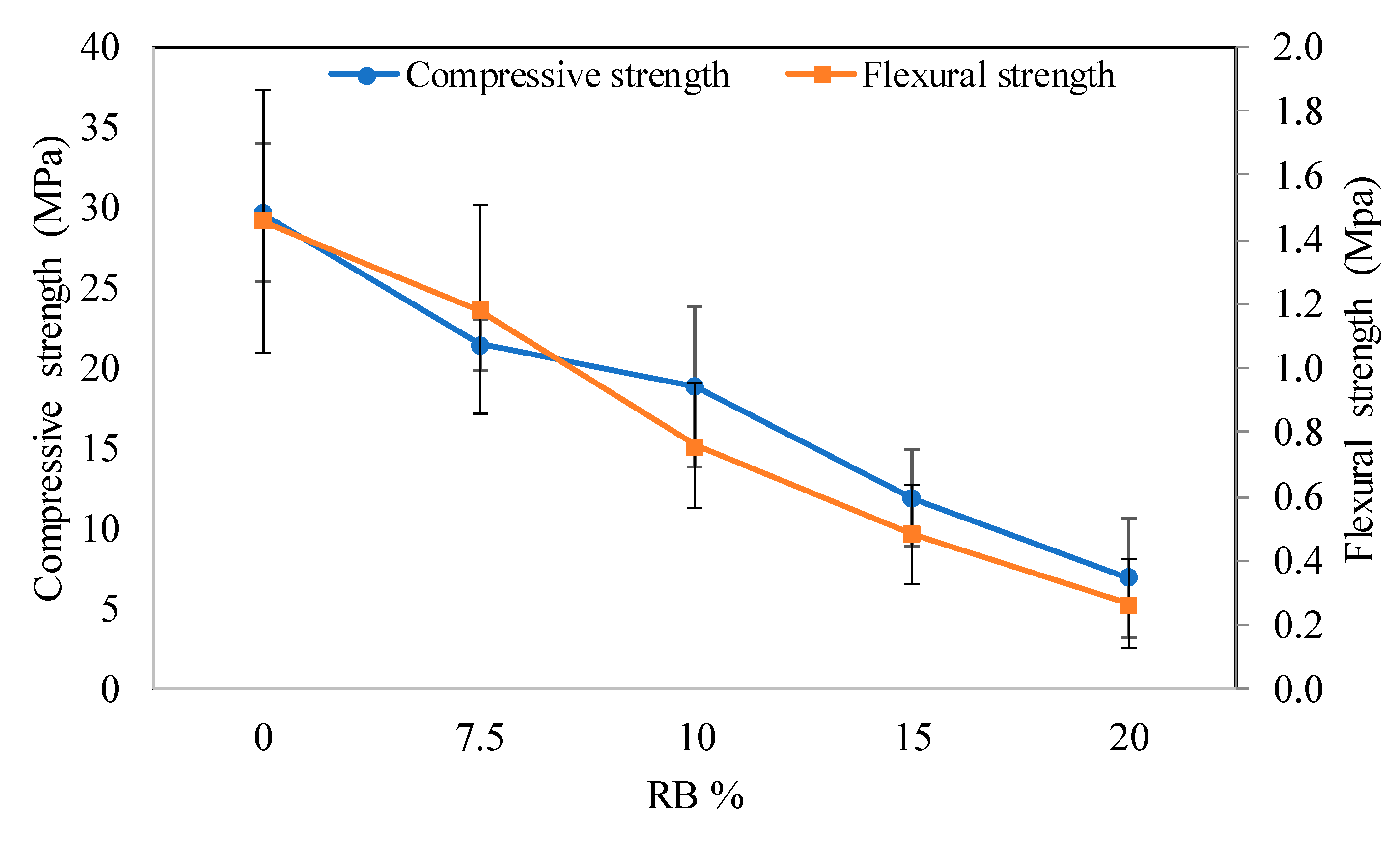

3.1.2. Compressive and Flexural Strength

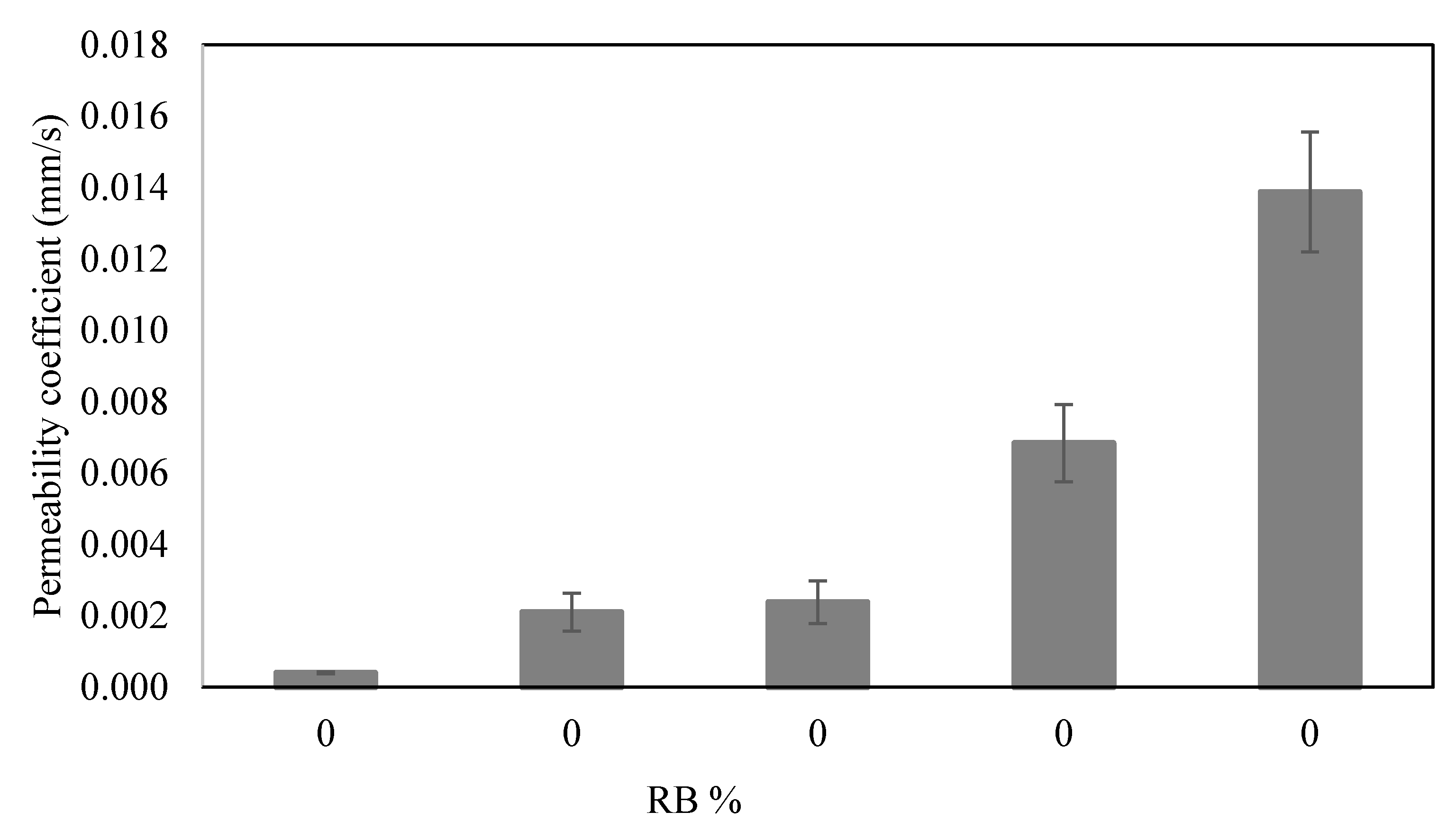

3.1.3. Permeability Coefficient

3.2. Stormwater Treatment Efficiency

3.3. Discussion

4. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alotaibi, K.; Ghumman, A.R.; Haider, H.; Ghazaw, Y.M. Shafiquzzaman Future Predictions of Rainfall and Temperature Using GCM and ANN for Arid Regions: A Case Study for the Qassim Region, Saudi Arabia. Water 2018, 10, 1260. [Google Scholar] [CrossRef]

- Ghumman, A.R.; Ghazaw, Y.M.; Alodah, A.; Shafiquzzaman, M.; Haider, H. Identification of Parameters of Evaporation Equations Using an Optimization Technique Based on Pan Evaporation. Water 2020, 12, 228. [Google Scholar] [CrossRef]

- Brabec, E.; Schulte, S.; Richards, P.L. Impervious surfaces and water quality: A review of current literature and its implications for watershed planning. J. Plan. Lit. 2002, 16, 499–514. [Google Scholar] [CrossRef]

- Brattebo, B.O.; Booth, D.B. Long-term stormwater quantity and quality performance of permeable pavement systems. Water Res. 2003, 37, 4369–4376. [Google Scholar] [CrossRef]

- Newman, A.P.; Aitken, D.; Antizar-Ladislao, B. Stormwater quality performance of a macro-pervious pavement car park installation equipped with channel drain based oil and silt retention devices. Water Res. 2013, 47, 7327–7336. [Google Scholar] [CrossRef] [PubMed]

- Haider, H.; Ghumman, A.R.; Al-Salamah, I.S.; Ghazaw, Y.; Abdel-Maguid, R.H. Sustainability evaluation of rainwater harvesting based flood risk management strategies: A multilevel decision-making framework for arid environments. Arab. J. Sci. Eng. 2019, 10, 8465–8488. [Google Scholar] [CrossRef]

- Mugume, S.N.; Gomez, D.E.; Fu, G.; Farmani, R.; Butler, D. A global analysis approach for investigating structural resilience in urban drainage systems. Water Res. 2015, 81, 15–26. [Google Scholar] [CrossRef]

- Low Impact development Center. Available online: http://www.lid-stormwater.net/contact.htm (accessed on 24 November 2020).

- USEPA. Green Infrastructure in the Semi-Arid West, Low-Impact Development and Green Infrastructure in the Semi-Arid West. Available online: https://www.epa.gov/green-infrastructure/green-infrastructure-semi-arid-west#6 (accessed on 20 November 2020).

- Antunes, L.N.; Ghisi, E.; Thives, L.P. Permeable pavements life cycle assessment: A literature review. Water 2018, 10, 1575. [Google Scholar] [CrossRef]

- Scholz, M.; Grabowiecki, P. Review of permeable pavement systems. Build Environ. 2007, 42, 3830–3836. [Google Scholar] [CrossRef]

- Sansalone, J.; Kuang, X.; Ying, G.; Ranieri, V. Filtration and clogging of permeable pavement loaded by urban drainage. Water Res. 2012, 46, 6763–6774. [Google Scholar] [CrossRef]

- Mullaney, J.; Lucke, T. Practical Review of Pervious Pavement Designs. CLEAN Soil Air Water 2013, 42, 111–124. [Google Scholar] [CrossRef]

- Sounthararajah, D.P.; Loganathan, P.; Kandasamy, J.; Vigneswaran, S. Removing heavy metals using permeable pavement system with a titanate nano-fibrous adsorbent column as a post treatment. Chemosphere 2017, 168, 467–473. [Google Scholar] [CrossRef] [PubMed]

- Vadas, T.M.; Smith, M.; Luan, H.W. Leaching and retention of dissolved metals in particulate loaded pervious concrete columns. J. Environ. Manag. 2017, 190, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Yong, F.; McCarthy, D.T.; Deletic, A. Predicting long term removal of heavy metals from porous pavements for stormwater treatment. Water Res. 2018, 142, 236–245. [Google Scholar] [CrossRef] [PubMed]

- Pagotto, C.; Legret, M.; Le Cloirec, P. Comparison of the hydraulic behaviour and the quality of highway runoff water according to the type of pavement. Water Res. 2000, 34, 4446–4454. [Google Scholar] [CrossRef]

- Fwa, T.F.; Lim, E.; Tan, K.H. Comparison of permeability and clogging characteristics of porous asphalt and pervious concrete pavement materials. Transport. Res. Rec. 2015, 2511, 72–80. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Pervious concrete as a sustainable pavement material–research findings and future prospects: A state-of-the-art review. Constr. Build. Mater. 2016, 111, 262–274. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 16416/2015: Pavimentos Permeáveis de Concreto—Requisitos e Procedimentos (NBR 16416/2015: Pervious Concrete Pavement—Requirements and Procedures); Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2015. [Google Scholar]

- Marcaida, A.K.; Nguyen, T.H.; Ahn, J. Investigation of particle-related clogging of sustainable concrete pavements. Sustainability 2018, 10, 4845. [Google Scholar] [CrossRef]

- Elizondo-Martinez, E.J.; Tataranni, P.; Rodriguez-Hernandez, J.; Castro-Fresno, D. Physical and Mechanical Characterization of Sustainable and Innovative Porous Concrete for Urban Pavements Containing Metakaolin. Sustainability 2020, 12, 4243. [Google Scholar] [CrossRef]

- Sprouse, C.E., III; Hoover, C.; Obritsch, O.; Thomazin, H. Advancing Pervious Pavements through Nomenclature, Standards, and Holistic Green Design. Sustainability 2020, 12, 7422. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.; Heidrich, O. Development of a life cycle assessment tool for construction and maintenance of asphalt pavements. J. Clean. Prod. 2009, 17, 283–296. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.; Ghadimi, B.; Abdelhady, A.; Harvey, J. Initial evaluation methodology and case studies for life cycle impact of permeability of permeable pavements. Int. J. Transp. Sci. Technol. 2018, 7, 169–178. [Google Scholar] [CrossRef]

- Spatari, S.; Yu, Z.; Montalto, F.A. Life cycle implications of urban green infrastructure. Environ. Pollut. 2011, 159, 2174–2179. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Huang, Y.; Quanliang, Y.; Zhang, W.; Meng, F.; Zhang, S. Multi-objective optimization integrated with life cycle assessment for rainwater harvesting systems. J. Hydrol. 2018, 558, 659–666. [Google Scholar] [CrossRef]

- Biofilico, Organic Building Materials and Their Benefits. Available online: https://biofilico.com/news/2019/12/19/organic-building-materials-and-their-benefits (accessed on 15 November 2020).

- Dondi, M.; Guarini, G.; Raimondo, M.; Zanelli, C.; Fabbriche, D.D.; Agostini, A. Recycling the insoluble residue from titania slag dissolution (tionite) in clay bricks. Ceram. Int. 2010, 36, 2461–2467. [Google Scholar] [CrossRef][Green Version]

- Eliche-Quesada, D.; Corpas-Iglesias, F.A.; Pérez-Villarejo, L.; Iglesias-Godino, F.J. Recycling of sawdust, spent earth from oil filtration, compost and marble residues for brick manufacturing. Constr. Build. Mater. 2012, 34, 275–284. [Google Scholar] [CrossRef]

- Faria, K.C.P.; Gurgel, R.F.; Holanda, J.N.F. Recycling of sugarcane bagasse ash waste in the production of clay bricks. J. Environ. Manage. 2012, 101, 7–12. [Google Scholar] [CrossRef]

- Bories, C.; Borredon, M.E.; Vedrenne, E.; Vilarem, G. Development of eco-friendly porous fired clay bricks using pore-forming agents: A review. J. Environ. Manag. 2014, 143, 186–196. [Google Scholar] [CrossRef]

- Bories, C.; Aouba, L.; Vedrenne, E.; Vilarem, G. Fired clay bricks using agricultural biomass wastes: Study and characterization. Constr. Build. Mater. 2015, 91, 158–163. [Google Scholar] [CrossRef]

- Brick Industry Association (BIA). Permeable Clay Brick Pavements; TECHNICAL NOTES on Brick Construction; Brick Industry Association: Reston, VA, USA, 2012. [Google Scholar]

- Saleem, M.A.; Kazmi, S.M.S.; Abbas, S. Clay bricks prepared with sugarcane bagasse and rice husk ash—A sustainable solution. MATEC Web Conf. 2017, 120, 03001. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM). Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- American Society for Testing and Materials (ASTM). Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- American Society for Testing and Materials (ASTM). Standard Test Methods of Conducting Strength Tests of Panels for Building Construction; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- American Society for Testing and Materials (ASTM). Standard Test Method for Permeability of Granular Soils (Constant Head); ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Khoo, Y.C.; Johari, I.; Ahmad, Z.A. Influence of Rice Husk Ash on the Engineering Properties of Fired-Clay Brick. Advanced Mater. Res. 2013, 795, 14–18. [Google Scholar] [CrossRef]

- ASTM. Standard Specification for Pedestrian and Light Traffic Paving Brick; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Ziccarelli, M.; Valore, C. Hydraulic conductivity and strength of pervious concrete for deep trench drains. Geomech. Energy Environ. 2019, 18, 41–55. [Google Scholar] [CrossRef]

- Mayne, P.W.; Christopher, B.R.; DeJong, J. Manual on Subsurface Investigations National Highway Institute; Publication No. FHWA NHI-01-031; Federal Highway Administration: Washington, DC, USA, 2001; p. 305. [Google Scholar]

- World Health Organization (WHO). Guidelines for the Safe Use of Wastewater, Excreta and Greywater; Excreta and Greywater Use in Agriculture; WHO: Geneva, Switzerland, 2006; Volume 4. [Google Scholar]

- Ogunmodede, O.T.; Adebayo, O.L.; Ojo, A.A. Enhancing adsorption capacity of clay and application in dye removal from wastewater. Int. Lett. Chem. Physi. Astron. 2014, 39, 35–51. [Google Scholar] [CrossRef]

- Ahiablame, L.M.; Engel, B.A.; Chaubey, I. Effectiveness of low impact development practices: Literature review and suggestions for future research. Water Air Soil Pollut. 2012, 223, 4253–4273. [Google Scholar] [CrossRef]

- Zarezadeh, V.; Lung, T.; Dorman, T.; Shipley, H.T.; Giacomoni, M. Assessing the performance of sand filter basins in treating urban stormwater runoff. Environ. Monit. Assess. 2018, 190, 697. [Google Scholar] [CrossRef] [PubMed]

| Coarse Sand % | Fine Sand % | Silt % | Clay % | D10 (mm) | D30 (mm) | D60 (mm) |

|---|---|---|---|---|---|---|

| 10.8 | 75.5 | 11.6 | 2.1 | 0.007 | 0.0258 | 0.058 |

| Parameters | B-0 | B-7.5 | B-10 | B-15 | B-20 |

|---|---|---|---|---|---|

| Porosity (%) | 10.1 ± 1.7 | 21.7 ± 2.2 | 29.2 ± 1.8 | 39.0 ± 2.5 | 59.1 ± 2.5 |

| Water adsorption (%) | 10.5 ± 1.4 | 15.2 ± 0.7 | 22.3 ± 4.0 | 27.8 ± 2.9 | 39.3 ± 3.5 |

| bulk density (kg/m3) | 1.9 ± 0.07 | 1.7 ± 0.05 | 1.61 ± 0.04 | 1.51 ± 0.03 | 1.3 ± 0.04 |

| Parameters | Contaminants Removal by Permeable Bricks (This Study) | Contaminants Removal % by Other LID Technologies | Wastewater Reuse Standard c | |||||

|---|---|---|---|---|---|---|---|---|

| Raw Stormwater | After Filtration * | Removal (%) | Bio-Retention Systems a | Permeable Pavements a | Grass Swales a | Sand Filter b | ||

| pH | 7.7 | 7.6 | - | 6.0–9.0 | ||||

| Suspended Solids (mg/L) | 345 | 5.0 | 98.5 | 47–99 | 58–94 | 46–97 | 32–93.5 | - |

| Alkalinity (mg/L) | 28.0 | 41.3 | −47.3 | - | - | - | - | |

| EC (µs/cm) | 614 | 612 | 0.33 | - | - | - | -0.92 | - |

| DO (mg/L) | 7.9 | 7.8 | - | - | - | - | - | |

| Turbidity (NTU) | 13.8 | 0.4 | 97.2 | - | - | - | - | 5 |

| TDS (mg/L) | 423 | 413 | 2.0 | - | - | - | - | 2500 |

| BOD5 (mg/L) | 21.4 | 5.0 | 76.7 | - | - | - | - | - |

| TOC (mg/L) | 3.7 | 3.85 | −5.3 | - | - | 23–64 | - | - |

| TN (mg/L) | 12.0 | 11.6 | 3.4 | 32–99 | >75 | 14–61 | −34–74 | - |

| NH3-N (mg/L) | 0.68 | 0.4 | 42.8 | - | - | - | - | - |

| NO2-N (mg/L) | 0.05 | 0.04 | 12.5 | - | - | - | - | - |

| NO3-N (mg/L) | 4.90 | 3.7 | 23.9 | 1–83 | 0–45 | 0–70 | - | |

| PO4-P (mg/L) | 0.08 | 0.06 | 23.4 | - | - | - | 0–66 | - |

| Fe (mg/L) | 0.00 | 0.00 | 0.0 | - | - | - | - | 5.00 |

| Mn (mg/L) | 0.04 | 0.02 | 55.7 | - | - | - | - | 0.20 |

| B(µg/L) | 35.5 | 65.9 | −84.3 | - | - | - | - | - |

| Ba (µg/L) | 19.41 | 22.4 | −15.2 | - | - | - | - | - |

| Cd (µg/L) | ND | ND | - | - | - | 12–98 | - | - |

| Cr (µg/L) | 17.9 | 25.7 | −43.4 | 100 | ||||

| Cu (µg/L) | 30.3 | 14.7 | 51.6 | 43–97 | 20–99 | 14–67 | −15–68 | 200 |

| Ni (µg/L) | ND | ND | - | 200 | ||||

| Pb (µg/L) | ND | ND | - | 31–98 | 75–99 | 18–94 | −24–98 | 5000 |

| Se (µg/L) | ND | ND | - | 20 | ||||

| Zn (µg/L) | 48.9 | 13.6 | 72.1 | 62–97 | 73–99 | 47–81 | 0–93 | 2000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alharbi, F.; Almoshaogeh, M.; Shafiquzzaman, M.; Haider, H.; Rafiquzzaman, M.; Alragi, A.; ElKholy, S.; Bayoumi, E.A.; EL-Ghoul, Y. Development of Rice Bran Mixed Porous Clay Bricks for Permeable Pavements: A Sustainable LID Technique for Arid Regions. Sustainability 2021, 13, 1443. https://doi.org/10.3390/su13031443

Alharbi F, Almoshaogeh M, Shafiquzzaman M, Haider H, Rafiquzzaman M, Alragi A, ElKholy S, Bayoumi EA, EL-Ghoul Y. Development of Rice Bran Mixed Porous Clay Bricks for Permeable Pavements: A Sustainable LID Technique for Arid Regions. Sustainability. 2021; 13(3):1443. https://doi.org/10.3390/su13031443

Chicago/Turabian StyleAlharbi, Fawaz, Meshal Almoshaogeh, Md. Shafiquzzaman, Husnain Haider, Md. Rafiquzzaman, Ahmed Alragi, Sherif ElKholy, ELSaid Abdallah Bayoumi, and Yassine EL-Ghoul. 2021. "Development of Rice Bran Mixed Porous Clay Bricks for Permeable Pavements: A Sustainable LID Technique for Arid Regions" Sustainability 13, no. 3: 1443. https://doi.org/10.3390/su13031443

APA StyleAlharbi, F., Almoshaogeh, M., Shafiquzzaman, M., Haider, H., Rafiquzzaman, M., Alragi, A., ElKholy, S., Bayoumi, E. A., & EL-Ghoul, Y. (2021). Development of Rice Bran Mixed Porous Clay Bricks for Permeable Pavements: A Sustainable LID Technique for Arid Regions. Sustainability, 13(3), 1443. https://doi.org/10.3390/su13031443