Enhanced Nitrogen Removal of Steel Rolling Wastewater by Constructed Wetland Combined with Sulfur Autotrophic Denitrification

Abstract

1. Introduction

2. Materials and Methods

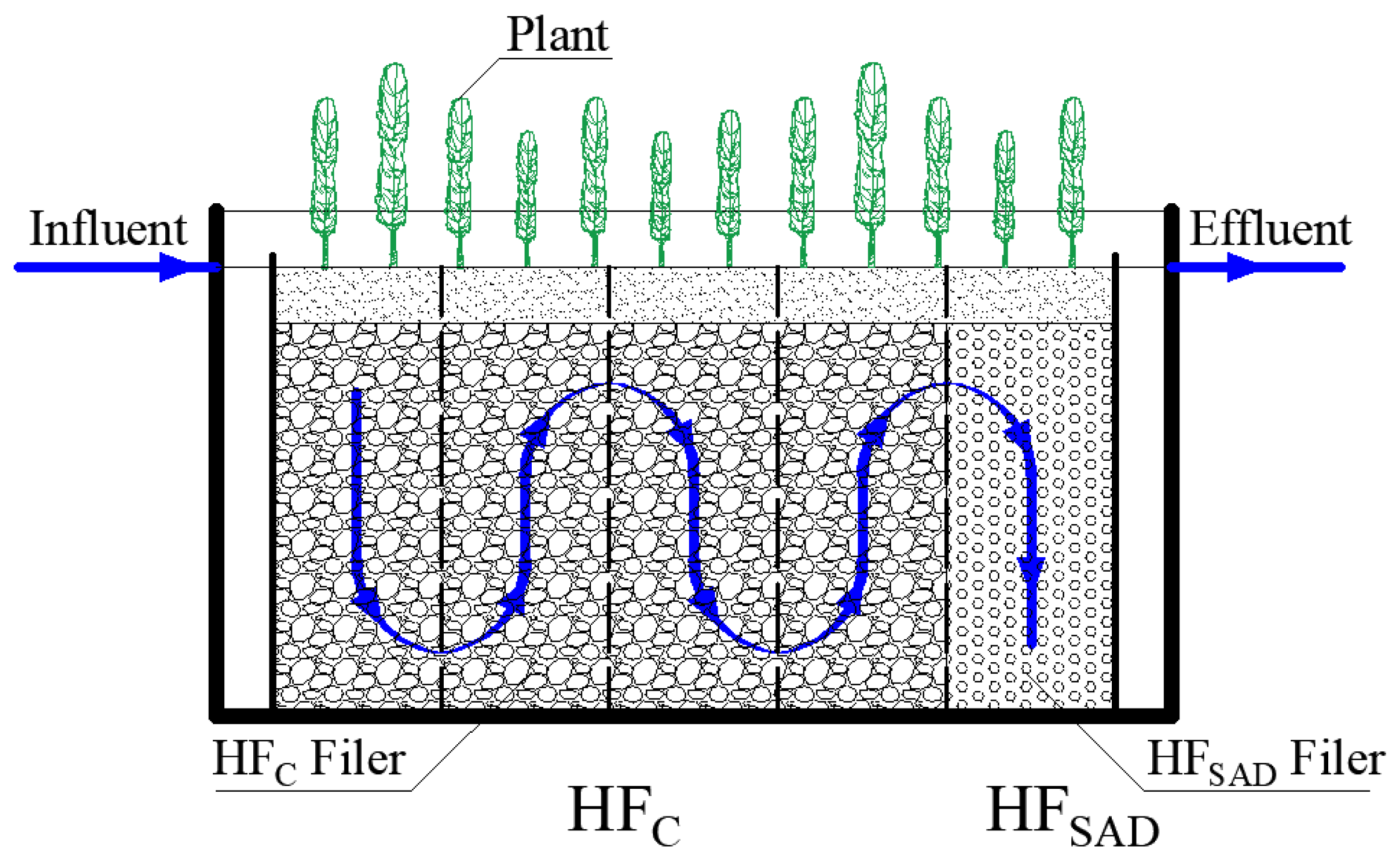

2.1. Materials and Reactor

2.2. Analytical Methods

3. Results and Discussions

3.1. Treatment Effect of Contaminants

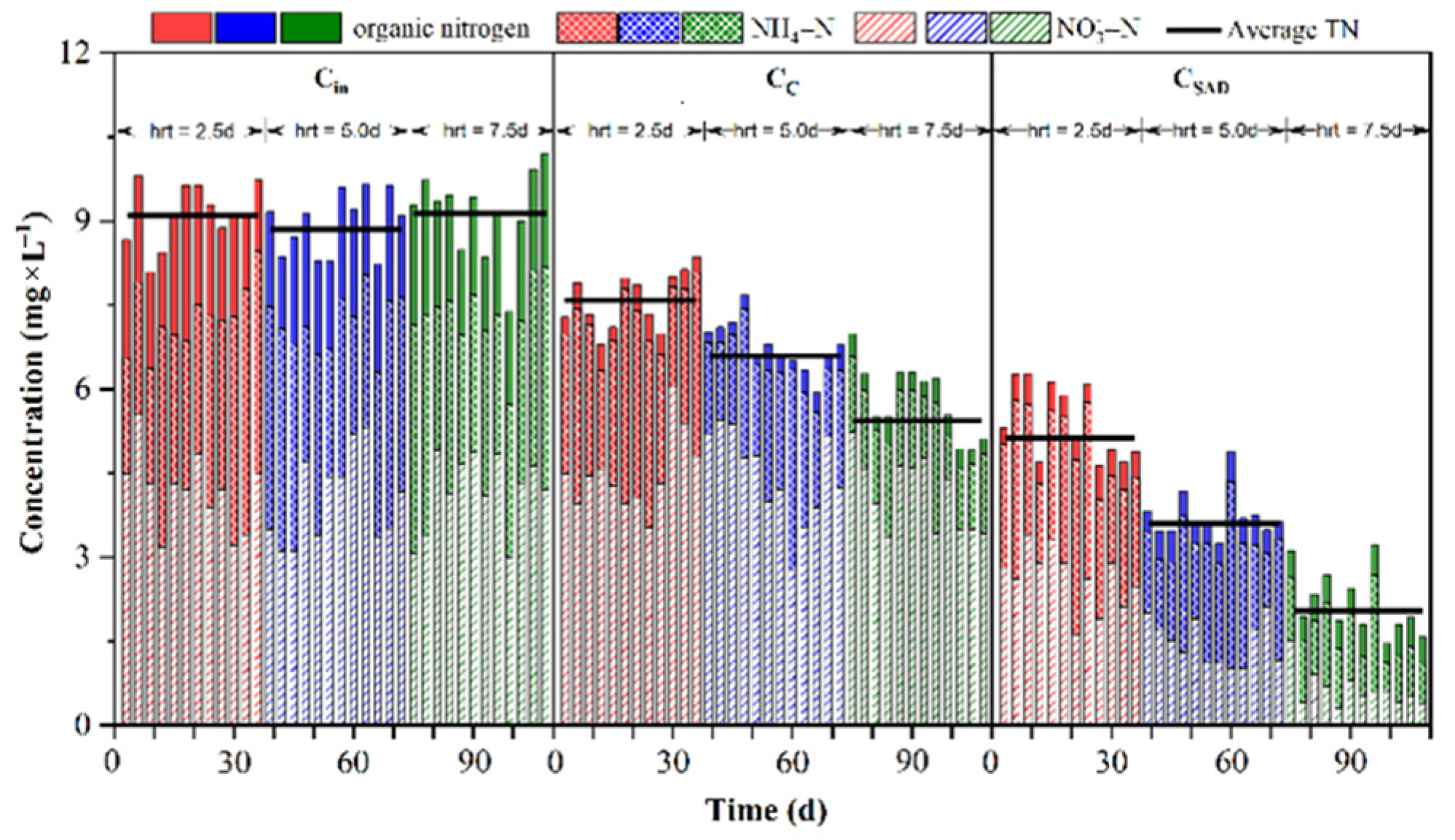

3.2. The TN Variation and Its Removal Efficiency

3.3. Transformation of Nitrogen Contaminants

3.4. Analysis of Nitrogen Removal Pathway

3.5. Microbial Community Structure

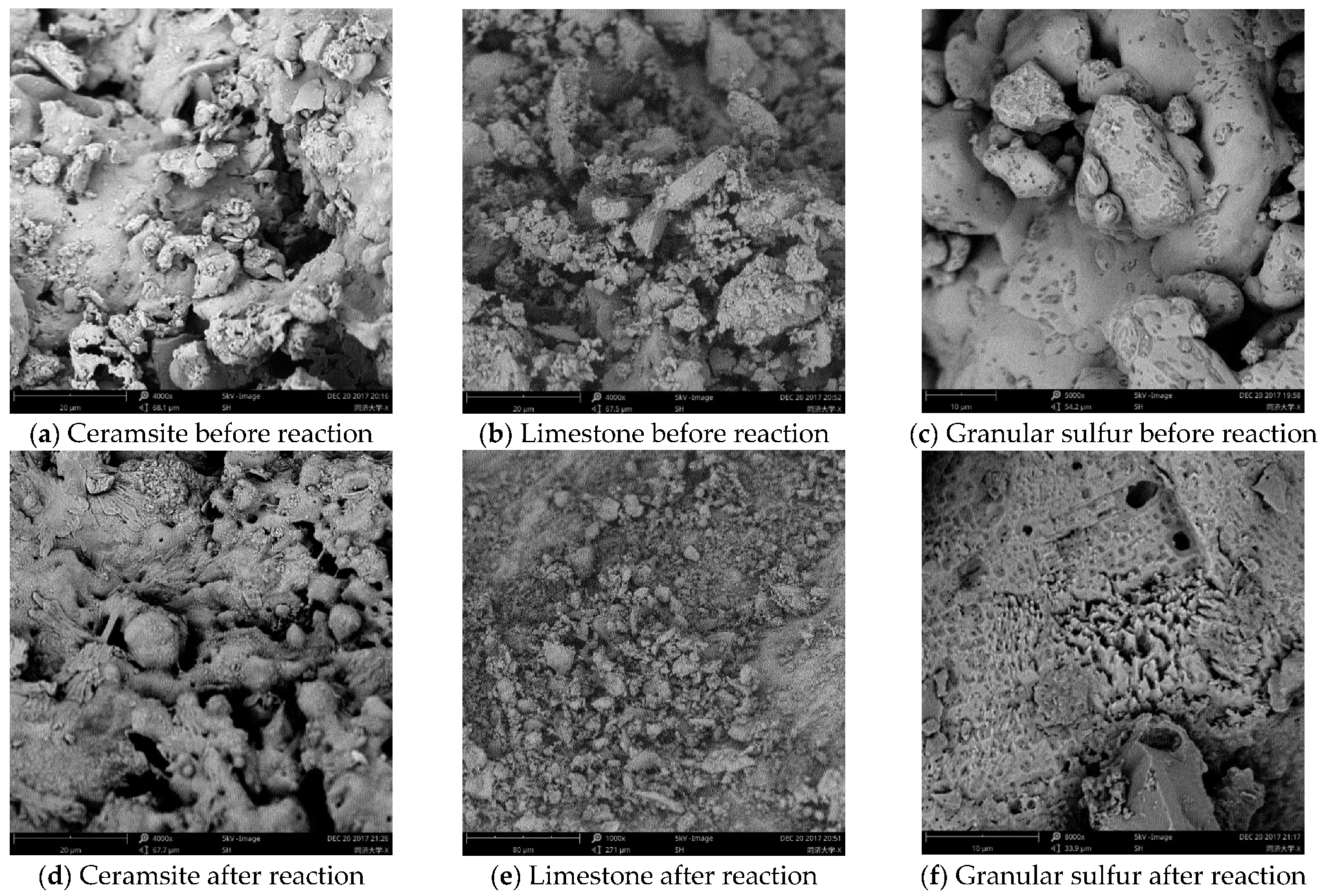

3.6. Characterization of Filler

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, Y.; Xu, J.; Keller, A.A.; Yuan, D.; Li, Y.; Zhang, B.; Weng, Q.; Zhang, X.; Deng, P.; Wang, H. Calculation of water footprint of the iron and steel industry: A case study in Eastern China. J. Clean. Prod. 2015, 92, 274–281. [Google Scholar] [CrossRef]

- Tong, Y.; Zhang, Q.; Cai, J.; Gao, C.; Wang, L.; Li, P. Water consumption and wastewater discharge in China’s steel industry. Ironmak. Steelmak. 2018, 45, 868–877. [Google Scholar] [CrossRef]

- Sun, W.; Xu, X.; Lv, Z.; Mao, H.; Wu, J. Environmental impact assessment of wastewater discharge with multi-pollutants from iron and steel industry. J. Environ. Manag. 2019, 245, 210–215. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Zhao, G.; Huang, X.; Guo, H.; Liu, W. Use of horizontal subsurface flow constructed wetlands to treat reverse osmosis concentrate of rolling wastewater. Int. J. Phytoremediation 2017, 19, 262–269. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.C.; Chen, G.; Huang, X.F.; Li, G.M.; Liu, J.; Yang, N.; Gao, S.N. Iron and manganese removal by using manganese ore constructed wetlands in the reclamation of steel wastewater. J. Hazard. Mater. 2009, 169, 309–317. [Google Scholar] [CrossRef]

- Huang, X.F.; Ling, J.; Xu, J.C.; Feng, Y.; Li, G.M. Advanced treatment of wastewater from an iron and steel enterprise by a constructed wetland/ultrafiltration/reverse osmosis process. Desalination 2011, 269, 41–49. [Google Scholar] [CrossRef]

- Cheng, H.-H.; Whang, L.-M.; Yi, T.-F.; Liu, C.-P.; Lin, T.-F.; Yeh, M.-S. Pilot study of cold-rolling wastewater treatment using single-stage anaerobic fluidized membrane bioreactor. Bioresour. Technol. 2018, 263, 418–424. [Google Scholar] [CrossRef]

- Abou-Elela, S.I.; Golinielli, G.; Abou-Taleb, E.M.; Hellal, M.S. Municipal wastewater treatment in horizontal and vertical flows constructed wetlands. Ecol. Eng. 2013, 61, 460–468. [Google Scholar] [CrossRef]

- Vymazal, J. Constructed wetlands for treatment of industrial wastewaters: A review. Ecol. Eng. 2014, 73, 724–751. [Google Scholar] [CrossRef]

- Vymazal, J.; Kröpfelová, L. Multistage hybrid constructed wetland for enhanced removal of nitrogen. Ecol. Eng. 2015, 84, 202–208. [Google Scholar] [CrossRef]

- Zhu, H.; Yan, B.; Xu, Y.; Guan, J.; Liu, S. Removal of nitrogen and COD in horizontal subsurface flow constructed wetlands under different influent C/N ratios. Ecol. Eng. 2014, 63, 58–63. [Google Scholar] [CrossRef]

- Wu, S.; Kuschk, P.; Brix, H.; Vymazal, J.; Dong, R. Development of constructed wetlands in performance intensifications for wastewater treatment: A nitrogen and organic matter targeted review. Water Res. 2014, 57, 40–55. [Google Scholar] [CrossRef] [PubMed]

- Hang, Q.; Wang, H.; Chu, Z.; Ye, B.; Li, C.; Hou, Z. Application of plant carbon source for denitrification by constructed wetland and bioreactor: Review of recent development. Environ. Sci. Pollut. Res. 2016, 23, 8260–8274. [Google Scholar] [CrossRef] [PubMed]

- Cao, S.; Jing, Z.; Yuan, P.; Wang, Y.; Wang, Y. Performance of constructed wetlands with different substrates for the treated effluent from municipal sewage plants. J. Water Reuse Desalination 2019, 9, 452–462. [Google Scholar] [CrossRef]

- Li, E.; Jin, X.; Lu, S. Microbial communities in biological denitrification system using methanol as carbon source for treatment of reverse osmosis concentrate from coking wastewater. J. Water Reuse Desalination 2017, 8, 360–371. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, S.H.; Delaune, R.D.; Cho, J.S.; Heo, J.S.; Yong, S.O.; Seo, D.C. Enhancement of nitrate removal in constructed wetlands utilizing a combined autotrophic and heterotrophic denitrification technology for treating hydroponic wastewater containing high nitrate and low organic carbon concentrations. Agric. Water Manag. 2015, 162, 1–14. [Google Scholar] [CrossRef]

- Song, X.; Wang, S.; Wang, Y.; Zhao, Z.; Yan, D. Addition of Fe2+ increase nitrate removal in vertical subsurface flow constructed wetlands. Ecol. Eng. 2016, 91, 487–494. [Google Scholar] [CrossRef]

- Xu, D.; Xiao, E.; Xu, P.; Lin, L.; Zhou, Q.; Xu, D.; Wu, Z. Bacterial community and nitrate removal by simultaneous heterotrophic and autotrophic denitrification in a bioelectrochemically-assisted constructed wetland. Bioresour. Technol. 2017, 245, 993–999. [Google Scholar] [CrossRef]

- Sun, H.; Yang, Z.; Wei, C.; Wu, W. Nitrogen removal performance and functional genes distribution patterns in solid-phase denitrification sub-surface constructed wetland with micro aeration. Bioresour. Technol. 2018, 263, 223–231. [Google Scholar] [CrossRef]

- Uggetti, E.; Hughes-Riley, T.; Morris, R.H.; Newton, M.I.; Trabi, C.L.; Hawes, P.; Puigagut, J.; García, J. Intermittent aeration to improve wastewater treatment efficiency in pilot-scale constructed wetland. Sci. Total Environ. 2016, 559, 212–217. [Google Scholar] [CrossRef]

- Wang, W.; Ding, Y.; Wang, Y.; Song, X.; Ambrose, R.F.; Ullman, J.L. Intensified nitrogen removal in immobilized nitrifier enhanced constructed wetlands with external carbon addition. Bioresour. Technol. 2016, 218, 1261–1265. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.C.; Zeng, H. Development of a Response Surface for Prediction of Nitrate Removal in Sulfur–Limestone Autotrophic Denitrification Fixed-Bed Reactors. J. Environ. Eng. 2006, 132, 1068–1072. [Google Scholar] [CrossRef]

- Lv, X.; Shao, M.; Li, J.; Xie, C. Nitrate removal with lateral flow sulphur autotrophic denitrification reactor. Environ. Technol. 2014, 35, 2692–2697. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Ekama, G.A.; Chui, H.K.; Wang, B.; Cui, Y.X.; Hao, T.W.; van Loosdrecht, M.C.M.; Chen, G.H. Large-scale demonstration of the sulfate reduction autotrophic denitrification nitrification integrated (SANI®) process in saline sewage treatment. Water Res. 2016, 100, 496–507. [Google Scholar] [CrossRef] [PubMed]

- Montalvo, S.; Huilinir, C.; Galvez, D.; Roca, N.; Guerrero, L. Autotrophic denitrification with sulfide as electron donor: Effect of zeolite, organic matter and temperature in batch and continuous UASB reactors. Int. Biodeter. Biodegr. 2016, 108, 158–165. [Google Scholar] [CrossRef]

- Wang, Y.; Bott, C.; Nerenberg, R. Sulfur-based denitrification: Effect of biofilm development on denitrification fluxes. Water Res. 2016, 100, 184–193. [Google Scholar] [CrossRef]

- Yang, W.; Lu, H.; Khanal, S.K.; Zhao, Q.; Meng, L.; Chen, G.H. Granulation of sulfur-oxidizing bacteria for autotrophic denitrification. Water Res. 2016, 104, 507–519. [Google Scholar] [CrossRef]

- Park, J.Y.; Yoo, Y.J. Biological nitrate removal in industrial wastewater treatment: Which electron donor we can choose. Appl. Microbiol. Biotechnol. 2009, 82, 415–429. [Google Scholar] [CrossRef]

- Xu, M.; Liu, W.J.; Li, C.; Xiao, C.; Ding, L.L.; Xu, K.; Geng, J.J.; Ren, H.Q. Evaluation of the treatment performance and microbial communities of a combined constructed wetland used to treat industrial park wastewater. Environ. Sci. Pollut. Res. 2016, 23, 10990–11001. [Google Scholar] [CrossRef]

- Schulz, C.; Gelbrecht, J.; Rennert, B. Treatment of rainbow trout farm effluents in constructed wetland with emergent plants and subsurface horizonal water flow. Aquaculture 2003, 217, 207–221. [Google Scholar] [CrossRef]

- Torrijos, V.; Gonzalo, O.G.; Trueba-Santiso, A.; Ruiz, I.; Soto, M. Effect of by-pass and effluent recirculation on nitrogen removal in hybrid constructed wetlands for domestic and industrial wastewater treatment. Water Res. 2016, 103, 92–100. [Google Scholar] [CrossRef] [PubMed]

- Masi, F. Enhanced Denitrification by a Hybrid HF-FWS Constructed Wetland in a Large-Scale Wastewater Treatment Plant. Wastewater Treat. Plant Dyn. Manag. Constr. Nat. Wetl. 2008. [Google Scholar] [CrossRef]

- Lee, C.g.; Fletcher, T.D.; Sun, G. Nitrogen removal in constructed wetland systems. Eng. Life Sci. 2009, 9, 11–22. [Google Scholar] [CrossRef]

- Ma, Y.; Zheng, X.; Fang, Y.; Xu, K.; He, S.; Zhao, M. Autotrophic denitrification in constructed wetlands: Achievements and challenges. Bioresour. Technol. 2020, 123778. [Google Scholar] [CrossRef]

- Sorokin, D.Y. Oxidation of Inorganic Sulfur Compounds by Obligately Organotrophic Bacteria. Microbiology 2003, 72, 725–739. [Google Scholar] [CrossRef]

- Nemati, M.; Jenneman, G.E.; Voordouw, G. Mechanistic study of microbial control of hydrogen sulfide production in oil reservoirs. Biotechnol. Bioeng. 2001, 74, 424–434. [Google Scholar] [CrossRef]

- Park, J.H.; Choi, O.; Lee, T.H.; Kim, H.; Sang, B.I. Pyrosequencing analysis of microbial communities in hollow fiber-membrane biofilm reactors system for treating high-strength nitrogen wastewater. Chemosphere 2016, 163, 192–201. [Google Scholar] [CrossRef]

- Zhao, Y.G.; Fang, Y.; Jin, Y.L.; Huang, J.; Ma, X.R.; He, K.Z.; He, Z.M.; Wang, F.; Zhao, H. Microbial community and removal of nitrogen via the addition of a carrier in a pilot-scale duckweed-based wastewater treatment system. Bioresour. Technol. 2015, 179, 549–558. [Google Scholar] [CrossRef]

- Kojima, H.; Fukui, M. Sulfurisoma sediminicola gen. nov., sp. nov., a facultative autotroph isolated from a freshwater lake. Int. J. Syst. Evol. Microbiol. 2011, 61, 1651–1655. [Google Scholar] [CrossRef]

- Kelly, D.P.; Wood, A.P. Confirmation of Thiobacillus denitrificans as a species of the genus Thiobacillus, in the beta-subclass of the Proteobacteria, with strain NCIMB 9548 as the type strain. Int. J. Syst. Evol. Microbiol. 2000, 50, 547–550. [Google Scholar] [CrossRef]

- Vlasceanu, L.; Popa, R.; Kinkle, B.K. Characterization of Thiobacillus thioparus LV43 and its distribution in a chemoautotrophically based groundwater ecosystem. Appl. Environ. Microbiol. 1997, 63, 3123–3127. [Google Scholar] [CrossRef] [PubMed]

- Silva, C.C.; Jesus, E.C.; Torres, A.P.; Sousa, M.P.; Santiago, V.M.; Oliveira, V.M. Investigation of bacterial diversity in membrane bioreactor and conventional activated sludge processes from petroleum refineries using phylogenetic and statistical approaches. J. Microbiol. Biotechnol. 2010, 20, 447–449. [Google Scholar] [PubMed]

- Ji, G.; Liao, B.; Tao, H.; Lei, Z. Analysis of bacteria communities in an up-flow fixed-bed (UFB) bioreactor for treating sulfide in hydrocarbon wastewater. Bioresour. Technol. 2009, 100, 5056–5062. [Google Scholar] [CrossRef] [PubMed]

- Fahrbach, M.; Kuever, J.; Meinke, R.; Kämpfer, P.; Hollender, J. Denitratisoma oestradiolicum gen. nov., sp. nov., a 17beta-oestradiol-degrading, denitrifying betaproteobacterium. Int. J. Syst. Evol. Microbiol. 2006, 56, 1547–1552. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.L.; Zhang, C.; Hu, C.Z.; Liu, H.J.; Qu, J.H. Denitrification of groundwater using a sulfur-oxidizing autotrophic denitrifying anaerobic fluidized-bed MBR: Performance and bacterial community structure. Appl. Microbiol. Biotechnol. 2015, 99, 2815–2827. [Google Scholar] [CrossRef]

- Shao, M.F.; Zhang, T.; Fang, H.H. Sulfur-driven autotrophic denitrification: Diversity, biochemistry, and engineering applications. Appl. Microbiol. Biotechnol. 2010, 88, 1027–1042. [Google Scholar] [CrossRef]

- Zhang, L.L.; Zhang, C.; Hu, C.Z.; Liu, H.J.; Bai, Y.H.; Qu, J.H. Sulfur-based mixotrophic denitrification corresponding to different electron donors and microbial profiling in anoxic fluidized-bed membrane bioreactors. Water Res. 2015, 85, 422–431. [Google Scholar] [CrossRef]

- Koenig, A.; Liu, L.H. Kinetic model of autotrophic denitrification in sulphur packed-bed reactors. Water Res. 2001, 35, 1969–1978. [Google Scholar] [CrossRef]

- Moon, H.S.; Sun, W.C.; Nam, K.; Choe, J.; Kim, J.Y. Effect of reactive media composition and co-contaminants on sulfur-based autotrophic denitrification. Environ. Pollut. 2006, 144, 802–807. [Google Scholar] [CrossRef]

| Index | pH | Turbidity | CODCr (O2, mg·L−1) | TP (mg·L−1) | TN (mg·L−1) | C/N |

|---|---|---|---|---|---|---|

| Range | 6.0–9.3 | 6.97–9.82 | 32.9–42.6 | 0.19–0.49 | 7.38–9.90 | 3.5–5.3 |

| Average | 7.6 | 8.38 | 37.9 | 0.34 | 9.01 | 4.2 |

| Recycling Standard | 7–8 | ≤5 | ≤30 | ≤0.8 | ≤5 | -- |

| Index | Cin (mg·L−1) | CC (mg·L−1) | CSAD (mg·L−1) | REC | RESAD | TRE |

|---|---|---|---|---|---|---|

| Turbidity | 8.43 (6.97–9.95) | 0.71 | 0.55 | 91.5% | 15.2% | 93.5% |

| pH | 7.15 (7.04–7.30) | 7.11 | 6.85 | - | - | - |

| DO | 3.6 (3.2–4.1) | 3.1 | 0.4 | 13.9% | 86.1% | 88.0% |

| TP | 0.33 (0.22–0.53) | 0.10 | 0.05 | 65.5% | 45.1% | 81.3% |

| COD | 39.1 (32.6–56.2) | 17.7 | 14.9 | 53.9% | 15.5% | 61.4% |

| NH4+-N | 4.12 (2.99–5.54) | 2.06 | 1.75 | 50.2% | 16.3% | 58.6% |

| NO3−-N | 3.14 (2.07–4.39) | 4.34 | 1.57 | −42.9% | 64.1% | 47.4% |

| Organic nitrogen | 1.83 (1.27–2.78) | 0.31 | 0.60 | 81.9% | −63.4% | 74.0% |

| TN | 9.07 (7.38–10.19) | 6.72 | 3.75 | 25.6% | 45.6% | 58.6% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, T.; Lin, X.; Xu, J.; Ren, J.; Sun, D.; Gu, Y.; Huang, J. Enhanced Nitrogen Removal of Steel Rolling Wastewater by Constructed Wetland Combined with Sulfur Autotrophic Denitrification. Sustainability 2021, 13, 1559. https://doi.org/10.3390/su13031559

Zheng T, Lin X, Xu J, Ren J, Sun D, Gu Y, Huang J. Enhanced Nitrogen Removal of Steel Rolling Wastewater by Constructed Wetland Combined with Sulfur Autotrophic Denitrification. Sustainability. 2021; 13(3):1559. https://doi.org/10.3390/su13031559

Chicago/Turabian StyleZheng, Tao, Xiaohu Lin, Jingcheng Xu, Jie Ren, Danyan Sun, Yunhui Gu, and Juwen Huang. 2021. "Enhanced Nitrogen Removal of Steel Rolling Wastewater by Constructed Wetland Combined with Sulfur Autotrophic Denitrification" Sustainability 13, no. 3: 1559. https://doi.org/10.3390/su13031559

APA StyleZheng, T., Lin, X., Xu, J., Ren, J., Sun, D., Gu, Y., & Huang, J. (2021). Enhanced Nitrogen Removal of Steel Rolling Wastewater by Constructed Wetland Combined with Sulfur Autotrophic Denitrification. Sustainability, 13(3), 1559. https://doi.org/10.3390/su13031559