Risk Management for Defense SoS in a Complex, Dynamic Environment

Abstract

:1. Introduction

2. Literature Review

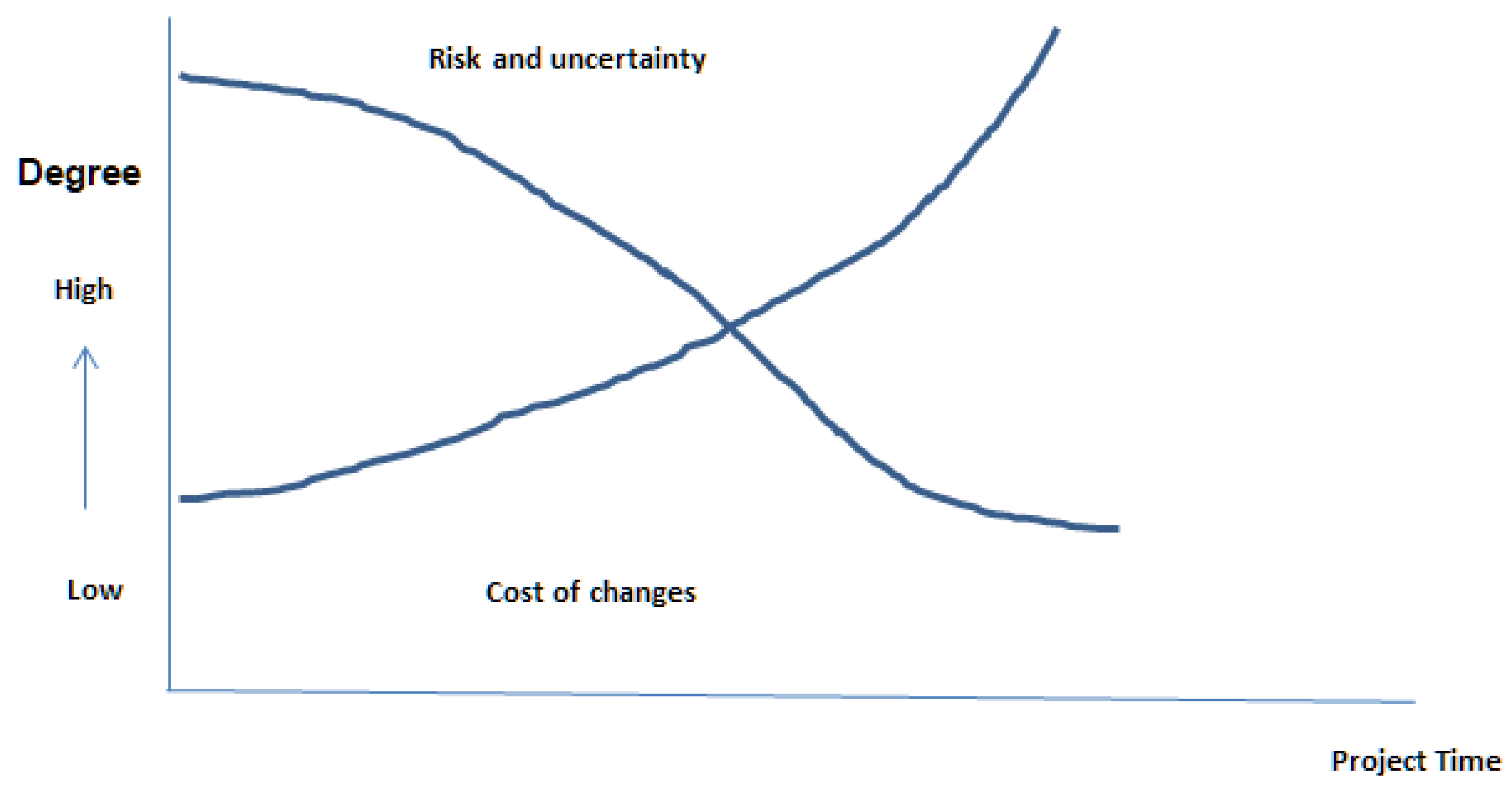

- Uncertainty that can be predicted in advance: It is possible to cope with this type of uncertainty by using an organized methodology, as presented in PMBOK [1]. For every stage of the project, there is an organized process that includes determining the project’s leading players, and defining inputs and outputs. Risks that stem from uncertainty may be managed making a plan to minimize them.

- Uncertainty that cannot be predicted in advance: In response to this possibility, buffers are defined in the schedule, budget, and statement of work (SOW), which provide leeway for dealing with unexpected changes.

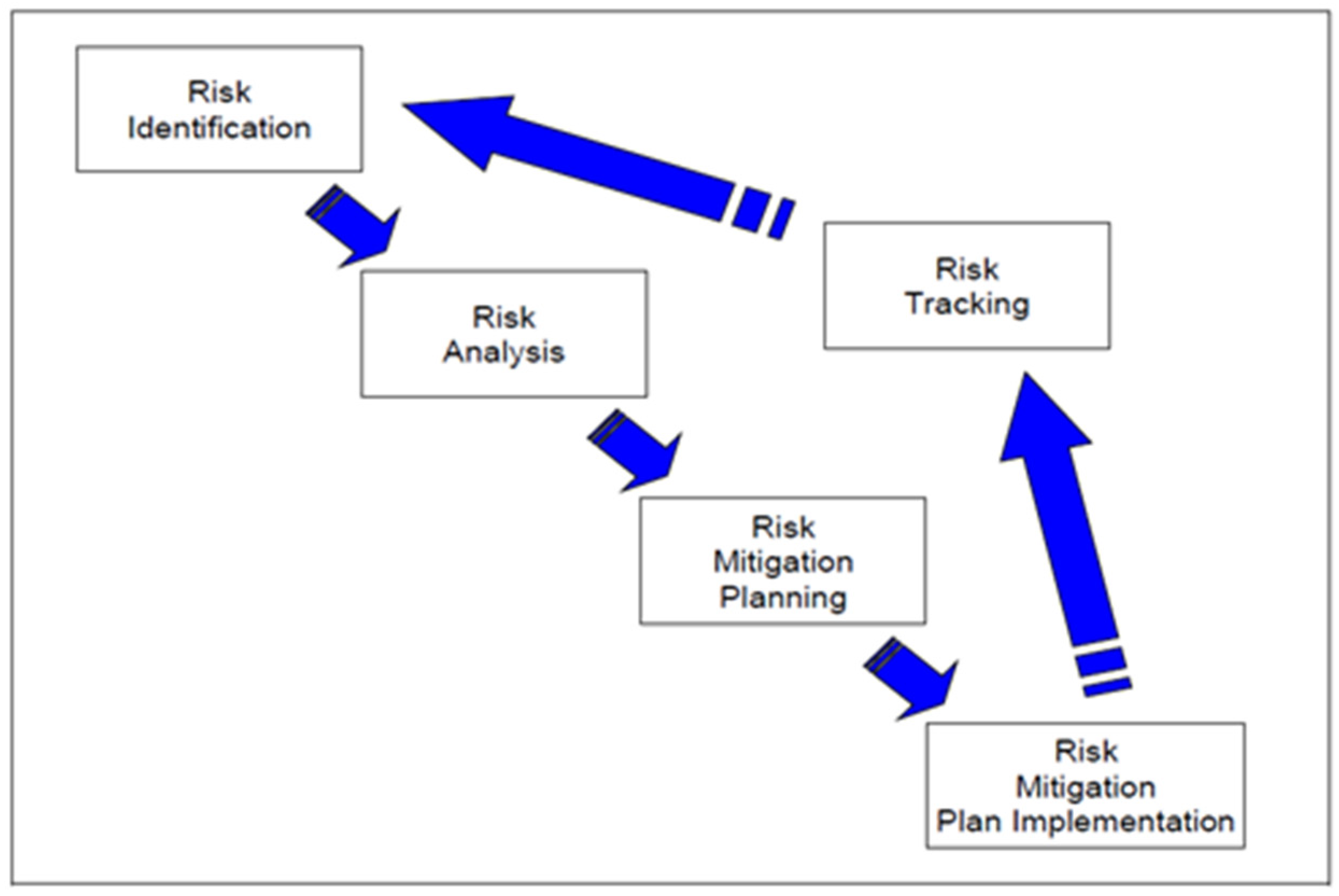

- Identifying risks using brainstorming;

- Analyzing the meaning and level of each risk, including assessments of severity, probability, and risk level;

- Risk factor analysis and defining responses, including a contingency plan;

- Risk presentation for authorization purposes;

- Monitoring and remeasuring the risk, including ongoing risk supervision.

- Risk survey—the goal of a risk survey is to reach an agreement about the risk level and ways to cope with each risk factor;

- Preemptive action—to be carried out in advance, usually at the earliest possible stage, with the goal of minimizing occurrence of the risk to the lowest possible level;

- Mitigation action—an action that should be carried out immediately upon the occurrence of a risk, with the goal of minimizing the extent of the damage caused;

- Corrective action—an action that must be carried out after the risk occurs, with the goal of returning the situation to its pre-risk state;

- Transferring the risk—transferring responsibility for the risk and its treatment to another party;

- Accepting the risk—taking a calculated risk, and deciding not to take any action.

3. Methodology and Research Design

3.1. The Exploratory Stage

3.2. The Survey

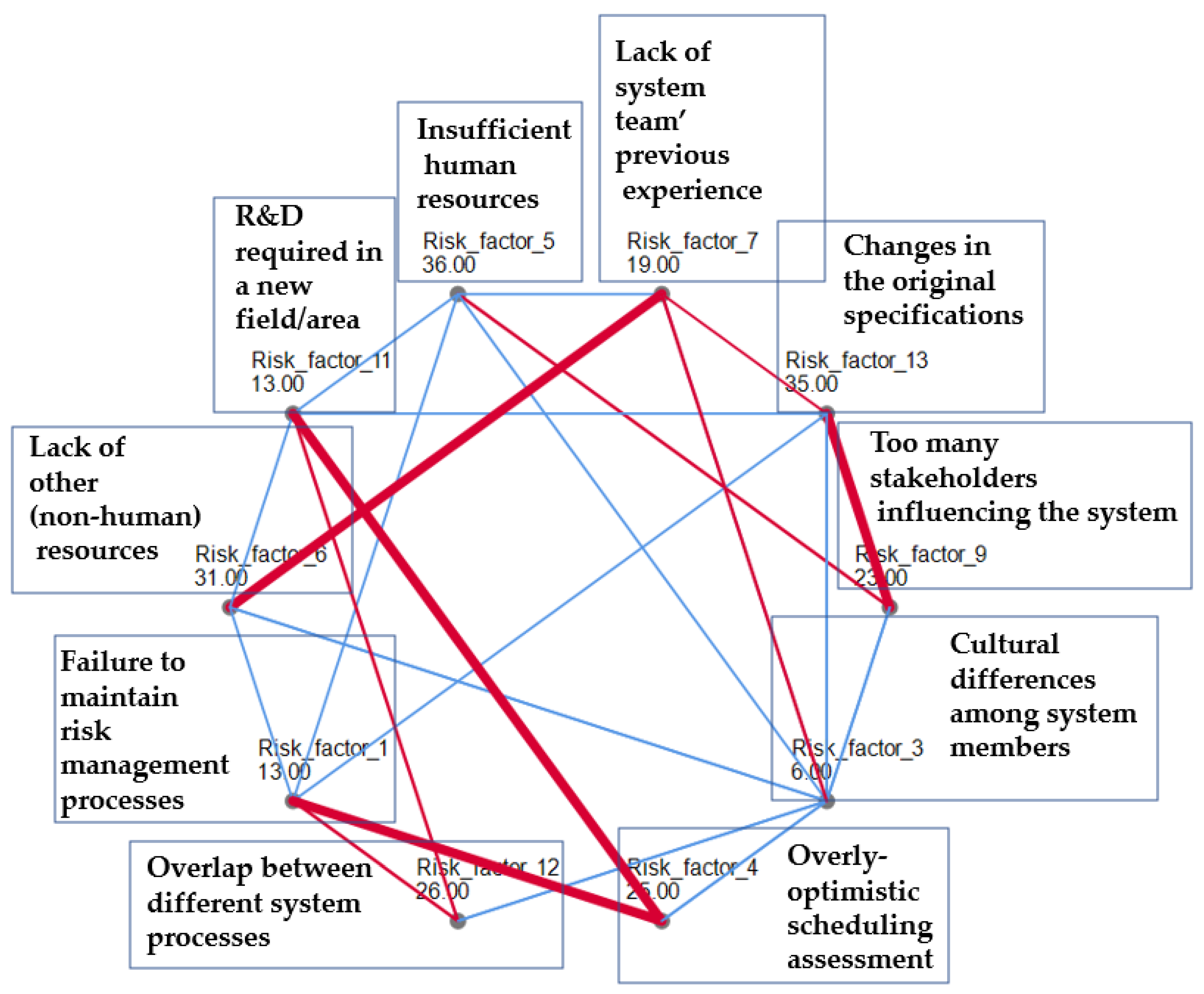

- Risk factor 1: Failure to maintain risk management processes;

- Risk factor 2: Delays in supporting infrastructure;

- Risk factor 3: Cultural differences among system members;

- Risk factor 4: Overly optimistic scheduling assessment;

- Risk factor 5: Insufficient human resources;

- Risk factor 6: Lack of other (nonhuman) resources;

- Risk factor 7: Lack of system team’ previous experience;

- Risk factor 8: Lack of system stakeholders’ previous experience;

- Risk factor 9: Too many stakeholders influencing the system;

- Risk factor 10: Complexity of the military operation;

- Risk factor 11: Research and development (R&D) required in a new field/area;

- Risk factor 12: Overlap between different system processes;

- Risk factor 13: Changes in the original specifications;

- Risk factor 14: Gap in knowledge management;

- Risk factor 15: Dependence on other factors.

4. Results

4.1. Findings of the Exploratory Study (Interviews)

- The quality and quantity of human resources are critical factors in the development process; an insufficient workforce is a significant risk in the defense industry.

- The dynamics of defense industries often makes it necessary to shorten the time-to-market, even though development processes are usually very time-consuming.

- Too many stakeholders are involved, influencing one another, in addition to many parties from external companies working on the system and interdependent on one another.

- Additions to the statement of work (SoW) and/or changes to the system’s initial design.

- The tendency to change roles/jobs once every 2–3 years in the military may create a sense of partial commitment and an “until the end of my term” attitude toward the system. This may also cause project managers to commit to challenging SoWs and schedules.

- A bigger system budget leads to more potential risks.

- The risks that cause schedule delays can be divided into two types: insufficient planning/management and resource constraints (mainly workforce and budget-related).

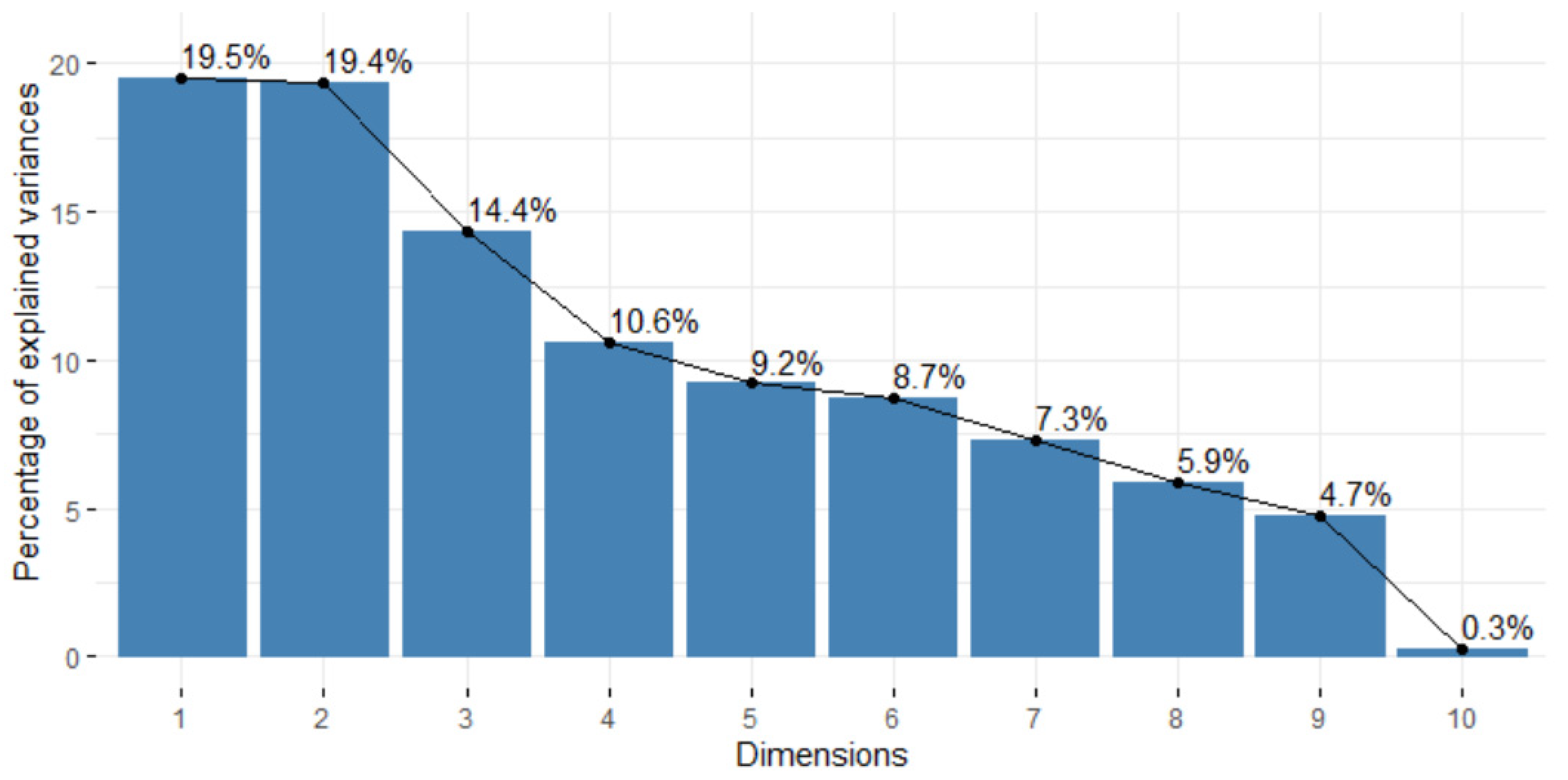

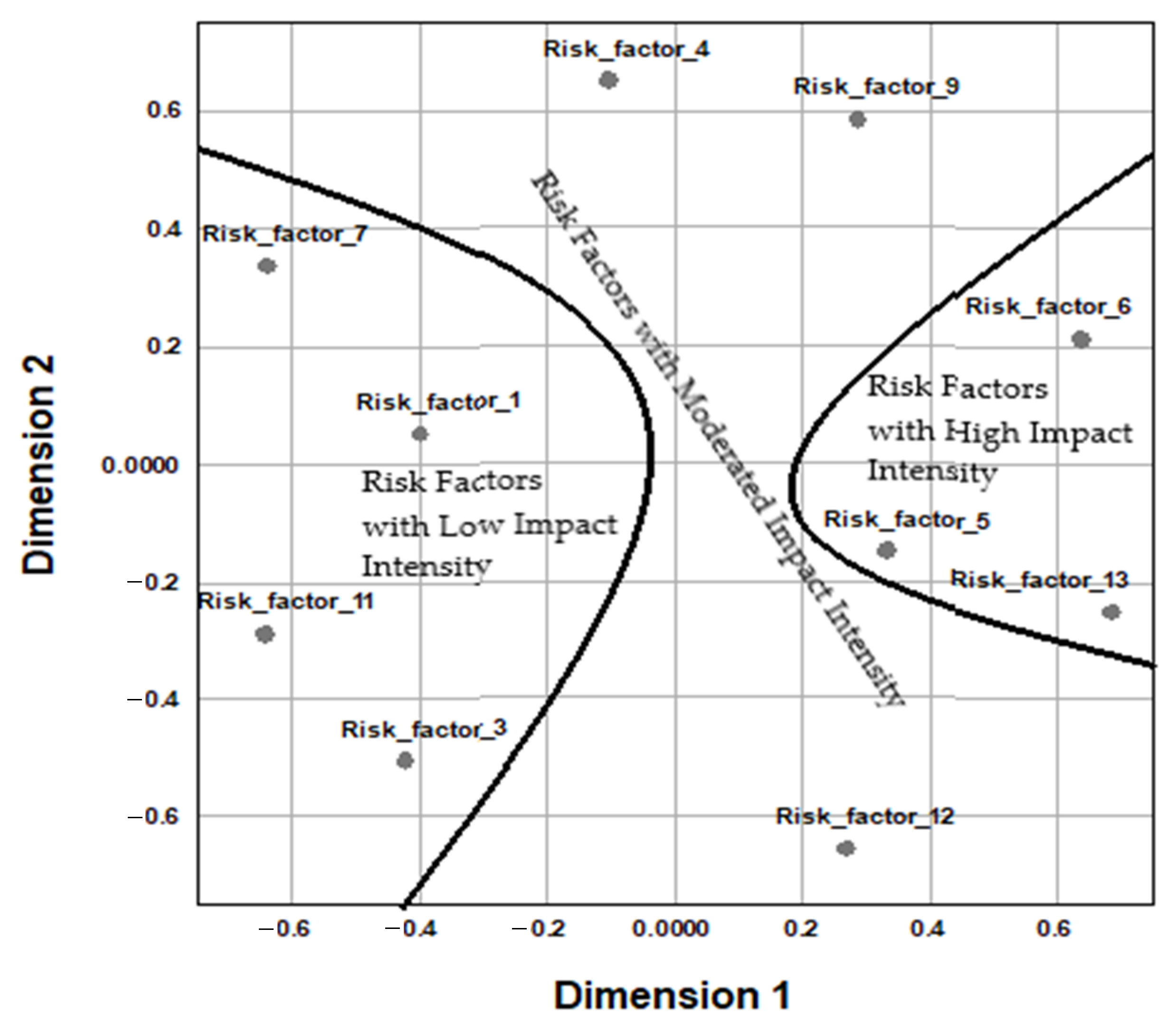

4.2. Findings from the Survey

5. Discussion

- The exploratory study found that the quality and quantity of human resources is a critical factor in development processes, but it was sometimes found to be insufficient. This risk was mentioned as a significant factor in almost every interview. The survey results showed that insufficient human resources (risk factor 5) represented the primary risk factor, ahead of all others.

- Another risk presented in the exploratory study, reported mainly by those respondents who had a broader picture (managerial level), is the continuously changing battlefield that forces all involved parties to reduce the time of IOC, although development processes take a substantial amount of time. This need was also mentioned in Naaman [31]. Ongoing systems need to remain relevant despite rapidly changing battlefield conditions; thus, changes in the original specifications (risk factor 13) represent a significant risk factor, as the survey indeed found.

- In many defense systems, it is necessary to change the system’s predefined goals because of changing security requirements. This results in changes in the end product, which in turn delays other processes. This is why the intelligence–mission–technology analysis conducted at the beginning of the process is so critical. This analysis facilitates the prediction of possible future changes in system goals, accordingly making it possible to introduce system changes, with a minimal influence on schedule. Thus, the robustness principle becomes stronger as a defense SoS advances. The ability of a product to adapt itself to changing conditions, requirements, and infrastructures is especially significant in the defense industry.

- Defense SoSs suffer from too many stakeholders who mutually influence each other. This finding is in line with previous findings [5,28,29] regarding the need for many partners when managing projects under constraints. Sometimes, entities from different organizations and companies are involved in a project and are mutually dependent on one another. An example of this dependence is the hiring of subcontractors, who are required to provide services or products to the primary contractor, which are a critical part of the defense SoS. The interview findings show that subcontractors have a meaningful influence on SoSs on several levels, from product quality to scheduling issues. This subject came up in interviews with project managers who are required to cope with complex challenges in their work with subcontractors.

- 5.

- The survey findings showed a linkage between risk factor 13: changes in the original specifications and some others factors (risk factors 4, 5, 6, 9, and 12) that may in some instances be caused by managerial considerations. All these potential risks might lead to future changes that impact scheduling delays.

- 6.

- Another aspect that leads to scheduling delays, and which was expressed in the interviews, is the high frequency of role switching within the defense industry, especially when working on classified SoSs. Role switching can have numerous advantages, but it has two significant disadvantages:

- There is an initial learning process, during which the individual must learn to solve problems on the basis of existing and new knowledge. At this stage, the individual may pay less attention to the project.

- We can assume that a project manager or officer who knows, from the beginning, that they will be managing a project from beginning to end will be more committed than one who will likely be transferred before its completion. Another related, common occurrence is the introduction of new professionals to an existing project at advanced stages. Naturally, each professional wants to make their mark on the project, even when they enter a pre-existing, stable project at a later stage. This need may generate a desire to make changes or additions that will be remembered as being initiated by specific people, but could potentially influence the project schedule.

6. Conclusions and Recommendations

- Risk factor 5: Insufficient human resources;

- Risk factor 6: Lack of other (nonhuman) resources;

- Risk factor 13: Changes in the original specifications.

6.1. Main Conclusions and Recommendations

- Organizational adaptations will make it possible to minimize the common risk factors found in the study; the study found that changing the project’s initial design specifications, insufficient human resources, and lack of other (nonhuman) resources were the three main risk factors. Defense systems have unique characteristics. Therefore, there must be a close connection between the end-user (e.g., air force operator), the department responsible for making the request (e.g., development) and the accountable unit that carries out the request (e.g., procurement department). Generally, the party making the request is also the one that defines the technical specifications. There is a real need for organizational change that permits transferring responsibility for SoW specifications to the party carrying out the work. This could reduce the number of specification changes during a project. We further found that the experience accrued by officials in the departments implementing and/or making requests can also help reduce some of the above risks. One critical remark is that these organizational changes are necessary to cope with rapid developmental changes and mitigate project risks. We also found that insufficient human resources represent a significant risk factor. Assuming that there are sufficient resources, outsourcing of the SoW has the potential to reduce these risks. However, these processes sometimes present other risks that are preferable to avoid. To minimize potential risks, an organization should develop tools that allow for a proper, intelligent analysis of outsourcing processes on the basis of past studies/data and valid professional knowledge.

- Developing generic infrastructure, which allows for the integration of new systems, would contribute significantly in two ways:

- Reduced R&D required for future integration, thereby reducing potential R&D-related risks.

- Decreased development times for new abilities.

- Process automation, with an emphasis on automated control processes, is necessary in order to reduce the risk of insufficient resources. For example, transitioning to automated checking of new systems instead of manual checking has many advantages, including increased effectiveness, the ability to run more tests in less time, the ability to work 24/7, and a reduced need for and dependence on human resources, which reduces risk related to workforce availability, as well as costs.

- Changes in performance specifications at advanced stages represent one of the main reasons for system delays. In-depth preparation of technical and performance specifications at the beginning of the project may mitigate this risk. A project’s progress generates a great deal of stress for most of the involved parties, which may consequently create inadequate thoroughness in certain areas, including specification processes. We recommend defining principles to regulate orderly work procedures, which includes anchoring the time windows of all of the system partners.

6.2. Study Limitations and Recommendations for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- A Guide to the Project Management Body of Knowledge (PMBOK GUIDE); Project Management Institute: Newtown Square, PA, USA, 2018.

- Fairley, R. Risk Management for software projects. IEEE Softw. 1994, 11, 57–67. [Google Scholar] [CrossRef]

- Boehm, B.W. Software risk management: Principles and practices. IEEE Softw. 1991, 8, 32–41. [Google Scholar] [CrossRef]

- Kliem, R.L.; Ludin, I.S. Reducing Project Risk; Gower: Farnham, UK, 1997. [Google Scholar]

- Risk Management—Principles and Guidelines; ISO 31000:2018; Available online: https://www.iso.org/standard/65694.html (accessed on 6 February 2021).

- Ye, S.; Tiong, R.L.K. NPV-at-risk method in infrastructure project investment evaluation. J. Constr. Eng. Manag. 2000, 126, 227–233. [Google Scholar] [CrossRef]

- Hastak, M.; Shaked, A. ICRAM-1: Model for international construction risk assessment. J. Manag. Eng. 2000, 16, 59–69. [Google Scholar] [CrossRef]

- Wu, Y.; Song, Z.; Li, L.; Xu, R. Risk management of public-private partnership charging infrastructure projects in China based on a three-dimension framework. Energy 2018, 165, 1089–1101. [Google Scholar] [CrossRef]

- Thomas, A.V.; Kalidindi, S.N.; Ganesh, L.S. Modelling and assessment of critical risks in BOT road projects. Constr. Manag. Econ. 2006, 24, 407–424. [Google Scholar] [CrossRef]

- Mu, J.; Peng, G.; MacLachlan, D.L. Effect of risk management strategy on NPD performance. Technovation 2009. [Google Scholar] [CrossRef]

- Pimchangthong, D.; Boonjing, V. Effects of risk management practices on IT project success. Manag. Prod. Eng. Rev. 2017, 8, 30–37. [Google Scholar] [CrossRef] [Green Version]

- Raz, T.; Shenhar, A.J.; Dvir, D. Risk management, project success, and technological uncertainty. R&D Manag. 2002, 32, 101–109. [Google Scholar] [CrossRef]

- Bannerman, P.L. Risk and risk management in software projects: A reassessment. J. Syst. Softw. 2008, 81, 2118–2133. [Google Scholar] [CrossRef]

- Oehmen, J.; Olechowski, A.; Robert Kenley, C.; Ben-Daya, M. Analysis of the effect of risk management practices on the performance of new product development programs. Technovation 2014, 34, 441–453. [Google Scholar] [CrossRef] [Green Version]

- De Carvalho, M.M.; Rabechini, R., Jr. Impact of risk management on project performance: The importance of soft skills. Int. J. Prod. Res. 2015, 53, 321–340. [Google Scholar] [CrossRef]

- Jin, X.-H.; Zhang, G. Modelling optimal risk allocation in PPP projects using artificial neural networks. Int. J. Proj. Manag. 2011, 29, 591–603. [Google Scholar] [CrossRef]

- Ojiako, U.; Papadopoulos, T.; Thumborisuthi, C.; Yang, Y.F. Perception variability for categorized risk factors. Ind. Manag. Data Syst. 2012, 112, 600–618. [Google Scholar] [CrossRef]

- Besner, C.; Hobbs, B. Contextualized project management practice: A cluster analysis of practices and best practices. Proj. Manag. J. 2013, 44, 17–34. [Google Scholar] [CrossRef]

- Gil, N.; Tether, B.S. Project risk management and design flexibility: Analyzing a case and conditions of complementarity. Res. Policy 2011, 40, 415–428. [Google Scholar] [CrossRef]

- Baharmand, H.; Zad, M.; Hashemi, S.H. Prioritization of effective risk factors on oil industry construction projects (by PMBOK Standard Approach). Res. J. Appl. Sci. Eng. Technol. 2013, 6, 521–528. [Google Scholar] [CrossRef]

- Robinson, L.A.; Levy, J.I. The [r]evolving relationship between risk assessment and risk management. Risk Anal. 2011, 31, 1334–1344. [Google Scholar] [CrossRef] [PubMed]

- Fortune, J.; White, D.; Jugdev, K.; Walker, D. Looking again at current practice in project management. Int. J. Manag. Proj. Bus. 2011, 4, 553–572. [Google Scholar] [CrossRef] [Green Version]

- Teller, J.; Kock, A. An empirical investigation on how portfolio risk management influences project portfolio success. Int. J. Proj. Manag. 2013, 31, 817–829. [Google Scholar] [CrossRef]

- Pajares, J.; López-Paredes, A. An extension of the EVM analysis for project monitoring: The cost control index and the schedule control index. Int. J. Proj. Manag. 2011, 29, 615–621. [Google Scholar] [CrossRef]

- Schroeder, K.; Hatton, M. Rethinking risk in development projects: From management to resilience. Dev. Pract. 2012, 22, 409–416. [Google Scholar] [CrossRef]

- Petit, Y. Project portfolios in dynamic environments: Organizing for uncertainty. Int. J. Proj. Manag. 2012, 30, 539–553. [Google Scholar] [CrossRef] [Green Version]

- Kuo, Y.-C.; Lu, S.-T. Using fuzzy multiple criteria decision making approach to enhance risk assessment for metropolitan construction projects. Int. J. Proj. Manag. 2013, 301, 602–614. [Google Scholar] [CrossRef]

- Wang, Y.; Wan, Y.; Wu, X.; Li, J. Exploring the risk factors of infrastructure PPP projects for sustainable delivery: A social network perspective. Sustainability 2020, 12, 4152. [Google Scholar] [CrossRef]

- Ameyaw, E.E.; Chan, A.P.C. Evaluation and ranking of risk factors in public–private partnership water supply projects in developing countries using fuzzy synthetic evaluation approach. Expert Syst. Appl. 2015, 42, 5102–5116. [Google Scholar] [CrossRef]

- Lessard, D.R. Uncertainty and Risk in Global Supply Chains; Research Paper No. 4991-13; MIT Sloan School: Cambridge, MA, USA, 2013. [Google Scholar]

- Naaman, A. Establishment of the Armed Force—Research Development in Air Force, Between the Poles, Part 3; IDF: Jerusalem, Israel, 2016; pp. 85–99. [Google Scholar]

- Wang, J.; Lin, W.; Huang, Y.H. A performance-oriented risk management framework for innovative R&D projects. Technovation 2010, 32, 601–611. [Google Scholar]

- Lee, E.; Park, Y.; Shin, J.G. Expert systems with applications. large engineering project risk management using a Bayesian Belief Network. Expert Syst. Appl. 2009, 36, 5880–5887. [Google Scholar] [CrossRef]

- Department of Defense. Risk, Issue, and Opportunity Management Guide for Defense Acquisition Programs; Office of the Deputy Assistant Secretary of Defense for Systems Engineering/Department of Defense: Washington, DC, USA, 2015.

- Chris, C.; Stephen, W. Managing Project Risk and Uncertainty: A Constructively Simple Approach to Decision Making; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- Haskins, C. System Engineering Handbook; INCOSE: San Diego, CA, USA, 2010. [Google Scholar]

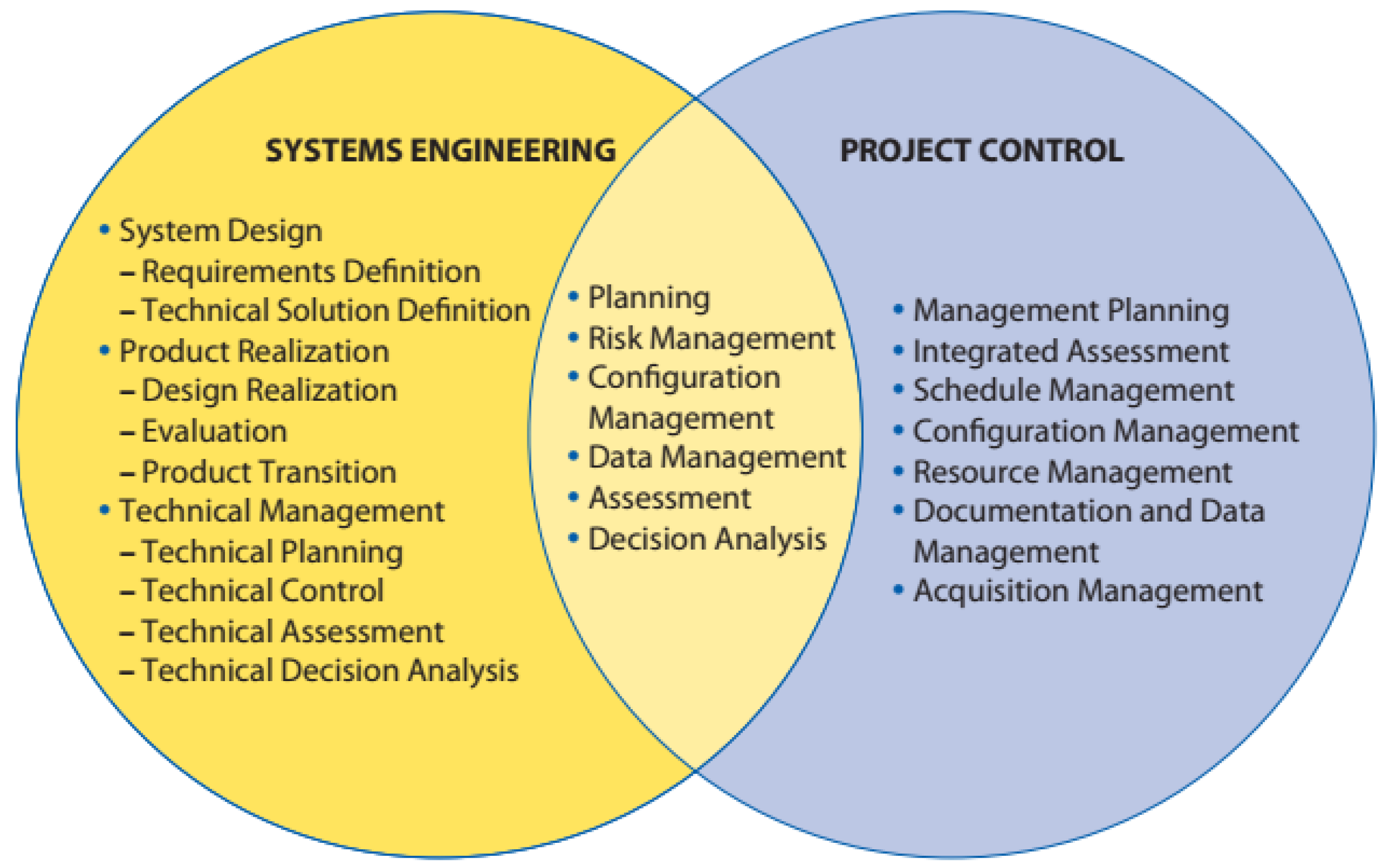

- Sharon, A.; Weck, O.L.; Dori, D. Project management vs. systems engineering management: A practitioners’ view on integrating the project and product domains. Syst. Eng. 2010, 14, 427–440. [Google Scholar] [CrossRef]

- Alexander, W.N. Systems Engineering Principles; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Koral Kordova, S.; Katz, E.; Frank, M. Managing development projects—The partnership between project managers and systems engineers. Syst. Eng. 2018, 1–16. [Google Scholar] [CrossRef]

- BKCASE Editorial Board. The Guide to the Systems Engineering Body of Knowledge (SEBoK); Version 1.9.1 R.D. Adcock (EIC); The Trustees of the Stevens Institute of Technology: Hoboken, NJ, USA, 2018. [Google Scholar]

- Maier, M.W. Architecting principles for system of systems. Syst. Eng. 1998, 1, 267–284. [Google Scholar] [CrossRef]

- da-Silvaa, L.R.; Crispima, J.A. The project risk management process: A preliminary study. Proc. Technol. 2014, 16, 943–949. [Google Scholar] [CrossRef] [Green Version]

| Risk Factor | Proportion |

|---|---|

| Risk factor 5: Insufficient human resources | 0.78 |

| Risk factor 13: Changes in the original specifications | 0.76 |

| Risk factor 6: Lack of other (nonhuman) resources | 0.67 |

| Risk factor 12: Overlap between different project processes | 0.57 |

| Risk factor 4: Overly optimistic scheduling assessment | 0.54 |

| Risk factor 9: Too many stakeholders influencing the system | 0.50 |

| Risk factor 7: Lack of system team’ previous experience | 0.41 |

| Risk factor 1: Failure to maintain risk management processes | 0.28 |

| Risk factor 11: Research and development (R&D) required in a new field/area | 0.28 |

| Risk factor 3: Cultural differences among project members | 0.13 |

| Sample a | Subset | |

|---|---|---|

| 1 | 2 | |

| Risk factor 3: Cultural differences among system members | 0.130 | |

| Risk factor 1: Failure to maintain risk management processes | 0.283 | |

| Risk factor 11: R&D required in a new field/area | 0.283 | |

| Risk factor 7: Lack of system team’ previous experience | 0.413 | |

| Risk factor 9: Too many stakeholders influencing the system | 0.500 | 0.500 |

| Risk factor 4: Overly-optimistic scheduling assessment | 0.543 | 0.543 |

| Risk factor 12: Overlap between different project processes | 0.565 | 0.565 |

| Risk factor 6: Lack of other (non-human) resources | 0.674 | |

| Risk factor 13: Changes in the original specifications | 0.761 | |

| Risk factor 5: Insufficient human resources | 0.783 | |

| Test statistic | 10.096 | −64.96 |

| Significance (two-sided test) | 0.121 | 1.000 |

| Adjusted significance (two-sided test) | 0.168 | 1.000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kordova, S.; Fridkin, S. Risk Management for Defense SoS in a Complex, Dynamic Environment. Sustainability 2021, 13, 1789. https://doi.org/10.3390/su13041789

Kordova S, Fridkin S. Risk Management for Defense SoS in a Complex, Dynamic Environment. Sustainability. 2021; 13(4):1789. https://doi.org/10.3390/su13041789

Chicago/Turabian StyleKordova, Sigal, and Shimon Fridkin. 2021. "Risk Management for Defense SoS in a Complex, Dynamic Environment" Sustainability 13, no. 4: 1789. https://doi.org/10.3390/su13041789