Abstract

Maintaining shape accuracy in the production of concrete panels of free-form buildings is time-consuming and costly. In addition, disposable molds used for free-form panels are not sustainable. Such problems can be solved by developing a suitable computerized numeric control (CNC) machine that can produce an accurately shaped reusable form for free-form concrete materials in a short period of time. This project develops a production technology of quality free-form concrete panels using a CNC machine and verifies the shape quality through an experiment. We designed a multi-point press CNC machine and verified its quality. The CNC machine implements a smooth free-form shape by changing the shape of the silicon plate by movement of the rods. The silicone plate for the CNC machine generates a slight error due to the elastic cover and mechanical clearance. The mean error rate was within 3%, based on the thickness of the panels, at the 95% confidence level. Verification of these errors will provide meaningful information to a similar type of machine development. In addition, the project results will be helpful in technological development for the production of free-form concrete panels of uniform quality, whose shape accuracy is not influenced by the skills and competence of the workers producing the panels.

1. Introduction

A wide range of technologies have been applied to the construction of free-form buildings elements, but these newly built structures have required vast capital, and technologies are lacking to economically produce high-quality free-form members [1,2,3,4,5,6]. In addition, disposable molds used for free-form panels are not sustainable. For instance, the expected initial construction cost of the Sydney Opera House was USD 7 million, but it increased to USD 1.02 hundred million, about 15 times the initial cost [1], and the total construction cost of the Bilbao Guggenheim Museum was USD 1.27 hundred million, which is about 14 times the initially expected construction cost [2]. Similarly, the recently built Dongdaemun Design Plaza required twice the original budget, and the equivalent of more than USD 200 million was spent on the frequent design and service change orders [7]. Many other free-form buildings, including the MIT Stata Center and the Walt Disney Concert Hall, have exceeded their planned budgets [8]. Such increased costs result from the great amounts of manpower and time required to ensure the quality of curved surfaces. Time and manpower needs vary according to the materials and technology used to produce the free-form members. The most common materials used to produce free-form components are metal and concrete [9,10,11,12]. Metal may corrode or deform due to a slight impact, making it difficult to maintain, and it takes the maintenance costs for the insulation and corrosion protection. Concrete is superior to metal in terms of its formability and strength, it being easy to maintain, and it being able to solve the problems of metal [13]. However, the cost and construction time can be higher for concrete than metal when producing free-form members using the existing technology. In particular, the molds for free-form structures cannot be reused, which creates great burdens on the environment and cost [14]. In addition, shape accuracy is inconsistent, varying according to workers’ skills and competence in producing free-form concrete panels or segments. In particular, when different workers plaster and surface panels, the panel thickness may change depending on the worker. Moreover, panels of differing quality may be produced by the same worker, resulting in a quality control problem. For managers to interpret the designs of differently shaped panels, prepare shop drawings, and produce such panels is a fairly difficult job. Moreover, 3D printers can also make concrete panels. However, many technologies need to be developed in order to use 3D printers for manufacturing 3D panels. Such problems can be solved by developing a suitable computerized numeric control (CNC) machine that can produce accurately shaped molds for free-form concrete materials in a short period of time. This paper presents a production technology of high-quality free-form concrete panels using the CNC machine developed in this project, and the shape quality is experimentally verified.

The present project included the following four steps:

- (1)

- A CNC machine suitable for producing variable molds was developed, and a prototype was manufactured;

- (2)

- Concrete panels were designed based on the curvature and size of existing free-form buildings;

- (3)

- A variable mold was produced using the CNC machine, and concrete panels were produced;

- (4)

- The error in the shape produced by the CNC machine was analyzed to verify the performance.

2. Consideration of Previous Studies

Making a new formwork every time is very time-consuming and costly. Construction engineers can easily implement 3D designs through CNC machines. In preceding studies, Mandl et al. and Lindsey and Gehry used CNC processing technology to fabricate an expandable polystyrene (EPS) formwork [3,15], whereas Ito Toyo and associates processed wood with a CNC machine to produce molds and used them to fabricate free-form concrete members [16]. CNC-processed molds can ensure accuracy in the concrete shape, but they are not reusable, pointing to the need for improvement. Franken and ABB implemented free-form concrete based on a digital formwork using CNC and acrylic glass to render the surface tension of a water droplet [17]. However, these studies merely introduced the production and superiority of free-form concrete, failing to secure its economic viability. Thus, a variable formwork is needed that is reusable and capable of enabling mass production. Latorre studied technology utilized to build a free-form dorm using a pneumatic system [18]. This technology was limited in terms of the implementable shape, requiring separate fabrication for the construction. In addition, Verhaegh studied the use of fabric for a formwork to implement free-form concrete [19]. However, additional study was needed to achieve accurate shapes using fabric and develop a reinforcement approach. Accordingly, this approach required time for fabricating molds in large quantities used to restrain the shape of the fabric. EPS formwork is designed with 3D-CAD (Computer Aided Design), processed with a CNC system, and installed. Installed EPS blocks are utilized as formwork for concrete placement [2,20].

Texaco Petrol Stations embodied free form by covering EPS formwork with polyurea and Parking Amsterdam Oosterdokseiland used EPS formwork for placing concrete [20]. The Spencer Dock Bridge was built as EPS formwork, fabricated, and installed and concrete was placed for about 6 months [20]. Curing and formwork removal took about 2 months [19]. The concrete surface quality was good, but the joint between EPS blocks left unnecessary lines on the concrete surface. In addition, huge amounts of EPS waste caused environmental problems and a cost increase. Molds of the free-form concrete members used for the Dongdaemun Design Plaza in the Dongdaemun History and Culture Park were built using a BIM (Building Information Modeling) program—Digital Project. Wood was cut to be 300 mm long and formwork was built with internal and external ribs using wood frames. The polygonal formwork technique installs uniquely shaped systemized form panels and can embody free forms similar to the segment type. This technology uses wood panels and cuts each panel with a cutting robot or CNC machine [21].

The CRAFT (Center for Rapid Automated Fabrication Technologies) at the University of Southern California in the United States studied robot-enabled automation, construction processes, new materials, and computer-assisted design with the aim of automating free-form concrete placement and large machinery fabrication and utilization in building construction automation. The CRAFT proposed a concept for producing free-form members using a large 3D printing instrument. However, the CRAFT remains at an experimental level, producing small members about 1–2 m wide and incapable of producing large members wider than 2 m. In addition, the limitations of the plotting fabrication method result in a considerable production time, rendering mass production impossible [22]. Researchers from the Innovative Manufacturing and Construction Research Centre of Loughborough University in England are studying 3D printing of free-form concrete [23]. There are two types of molds used in this method: master and direct molds. The master mold produces free-form concrete panels using 3D printing, and the direct mold produces formed concrete shapes. These methods have the disadvantage that extra manpower is required to produce accurate shapes because a shape printed for the first time is severely rugged. In addition, because it is produced with a plotting method similar to the CRAFT, it is time-consuming to produce one panel, and mass production of panels is economically infeasibility [7]. As seen above, international studies on free-form building have attempted to put free-form building technology to practical use by employing CNC-processed expandable polystyrene (EPS), wood, fabric, and other materials. However, it is difficult to use this technology in practical applications due to time and cost constraints. Further, many free-form buildings completed to date [19,20,24,25,26] have used steel, wood, EPS, and plastic, among other materials, to produce free-form members, but such molds were not reusable, adding fabrication time, incurring significant costs, increasing total construction cost, and delaying the schedule. To address these issues, the CRAFT and IMCRC (Innovative Manufacturing and Construction Research Centre) are actively studying free-form building solutions through academic–industrial partnership initiatives, but they are still far from practical solutions due to the limitations of applicable technical concepts. Therefore, it is necessary to develop a cost-effective variable formwork and free-form concrete production technology with the aim to reuse formworks and minimize labor requirements [4]. Recognizing this need, Gramazio et al. used wax to develop reusable molds to produce concrete panels [27]. However, they did not provide analyses or solutions to problems such as those relating to the solidification time, crystallization, strength, solidification shrinkage, and cracking. They only proposed the concept of the equipment and technology to produce shapes with wax molds, without a specific explanation. Their study results are limited in not addressing critical problems such as shrinkage, the solidification time, and cracking caused by pure wax during their experiments with the composite phase change material (PCM) mold they developed. In addition, their study merely suggested the concept of utilizing the recently presented 3D display technology for the production of mold shapes, and it is greatly limited in that it provides no standards or dimensions of the equipment used for the production of free-form shapes. Pedersen and Lenau implemented a shape, using multiple pins [28]. However, the greater number of pins causes the cost of the CNC equipment to increase and the thin rubber membrane to become slack, resulting in greater errors. In addition, the absence of error analysis further compromises its trustworthiness. The CNC equipment herein is highly efficient in implementing smooth architectural designs. There have been several of attempts to study metal-working equipment using pin-type tools. Munro and Walczyk proposed a piece of metal-working equipment using a pin-type tool [29]. Among its disadvantages, the pin-type tool requires a very dense layout of pins, resulting in a significant rise in the unit cost and operating time. In addition, the absence of error analysis further compromises its trustworthiness. Vedel-Smith and Lenau proposed a pin-type tooling approach intended to print patterns on the surface [30]. Im et al. [31] compared pressing techniques widely used in forming metal shapes by applying pressure to metal with multiple pins. Tan et al. analyzed the multi-point forming (MPF) approach using multiple pins to apply pressure to form metal into curved shapes [32]. These studies dealt with metal with different research scopes and necessitated precision error testing. Savvides [33] developed the free-form formwork system technology (3FST), which makes free-form shapes using equally spaced rods on both sides. A total of 25 rods are installed to produce concrete members of 1 × 1 m. Moreover, 3FST uses a round head that can be rotated in all directions to produce curved shapes. However, Savvides did not go beyond the level of presenting the idea, and there was no verification of the performance of 3FST in producing shapes and errors.

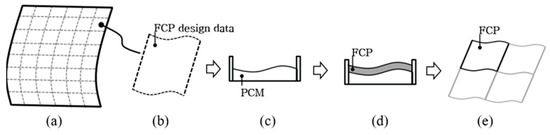

3. Design, Production, and Erection Process of FCPs

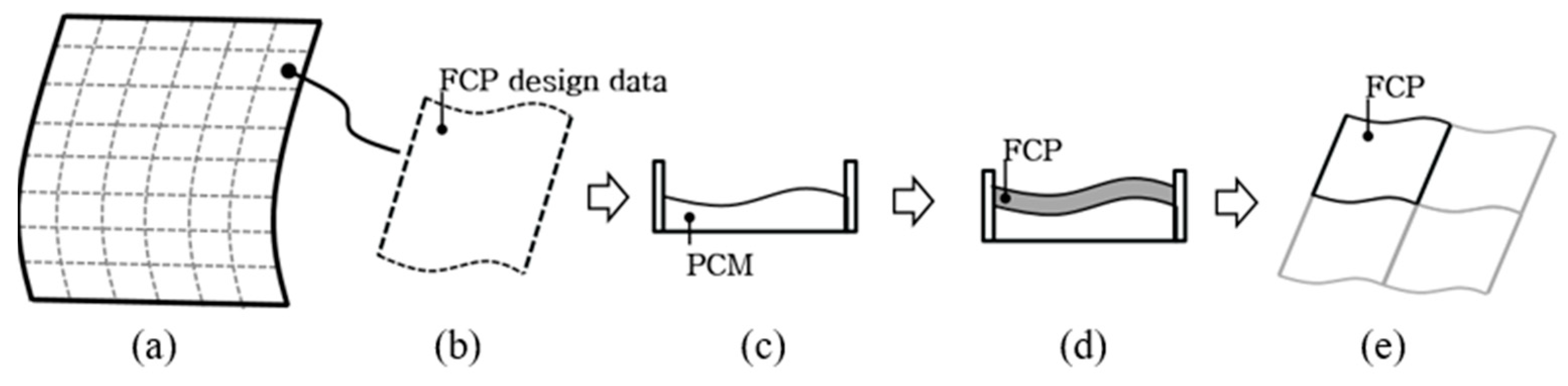

The CNC machine developed in the current study is appropriate for the production concept of the composite PCM mold proposed by Lee and Kim [14,34,35]. The technological concept of producing free-form concrete panels (FCPs) using composite PCM is shown in Figure 1 [14]. For FCP production, first, the design is divided, and data are extracted. Second, the extracted data are used to determine a shape using the CNC machine. On top of the numerical control rod (NCR) of the CNC machine, a shaping membrane made of rubber or silicone is installed. The shaping plate forms a continuous free form. As rubber and silicone, which are elastic, can be changed freely in length and shape, they form a shape, following the movement of the NCR. In addition, as the NCR moves up and down, the original shape is restored upon completion of the variable formwork fabrication. At this time, the shaping plate may become slack between the NCRs, which can be minimized by adjusting the thickness of the shaping plate. Third, the composite PCM is melted to produce a variable PCM mold. After the composite PCM is solidified, concrete is poured to produce a free-form panel. Finally, the produced FCP is installed in a given location, and the PCM mold is heated to a certain temperature to liquefy and reuse it as a mold for another FCP. For this method to be realized, a CNC machine that can quickly and accurately produce a PCM mold is essential. The CNC machine developed in this project was applied to phase (C) of Figure 1, and its operating accuracy was verified based on the quality of the mold.

Figure 1.

Design, production, and erection process of free-form concrete panels (FCPs) [14]: (a) 3D design; (b) member design; (c) producing phase change material (PCM) mold; (d) producing FCP; (e) erecting FCP.0.

4. An Adjustable Mold for Production of Free-Form Concrete Panels

4.1. Operation of the CNC Machine

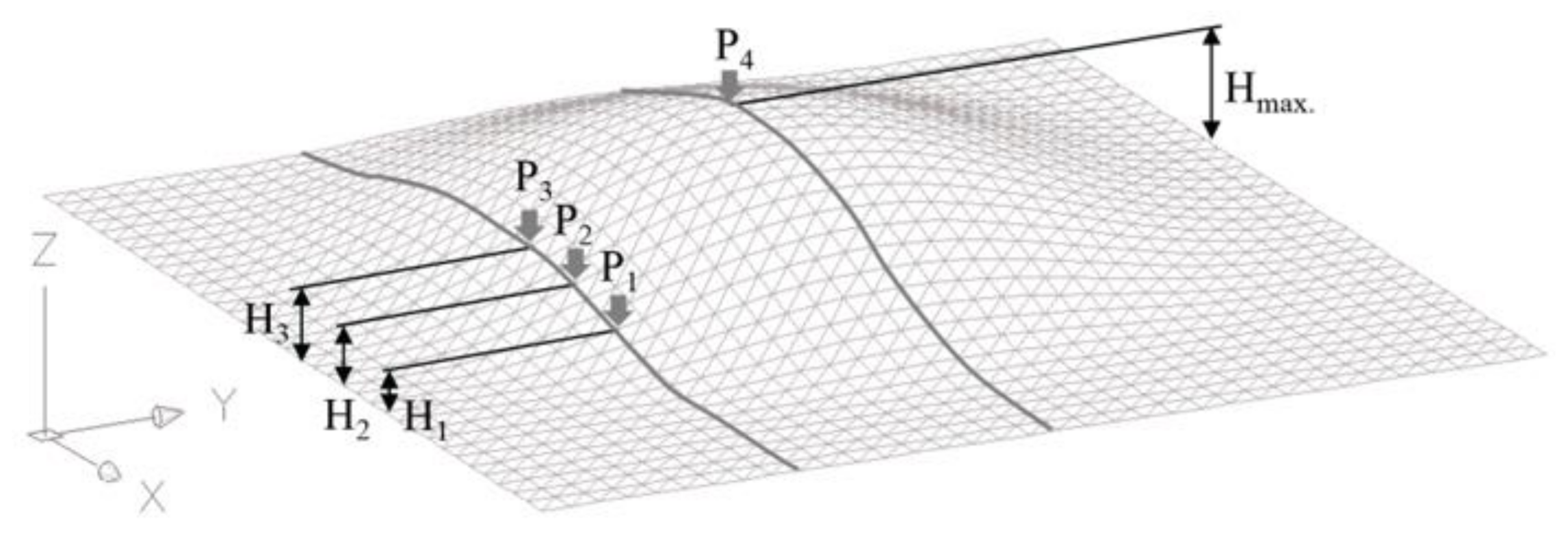

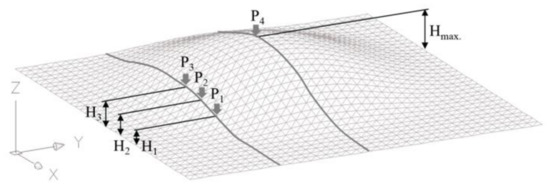

Since a 3D free-form shape can be rendered by assigning a Z value to coordinates on the X axis and Y axis, as shown in Figure 2, computerized numerical control (CNC) equipment renders the 3D free-form image by applying this concept. The X-Y coordinates are set when the BIM data of the free-form building are divided. The value controlled by the computer is the Z coordinate, and the curved surface data are the collection of Z coordinates required to implement the members. The CNC machine controls the elevation of the numerical control rod (NCR) in reference to the 3D curved surface data and the NCR implements the actual curved surface. In other words, the CNC machine implements the 3D curved surface, and more specifically, it is a 3D image implementation device in which the NCR deployed in the grid can implement the 3D curved surface in steps. The primary purpose of the CNC machine developed herein is to implement a free-form shape of a variable mold [4,36]. Figure 2 illustrates the method to implement the 3D free-form design by controlling the elevation as in the CNC machine. The four points shown in Figure 2 (P1~P4) are the ones included in the free-form design and are rendered as X, Y, and Z coordinates (elevation). When this design is implemented by the CNC machine, the desired 3D shape can be formed by deploying the NCR at the x, y coordinates and controlling the operating elevation of the NCR.

Figure 2.

3D free-form design implementation.

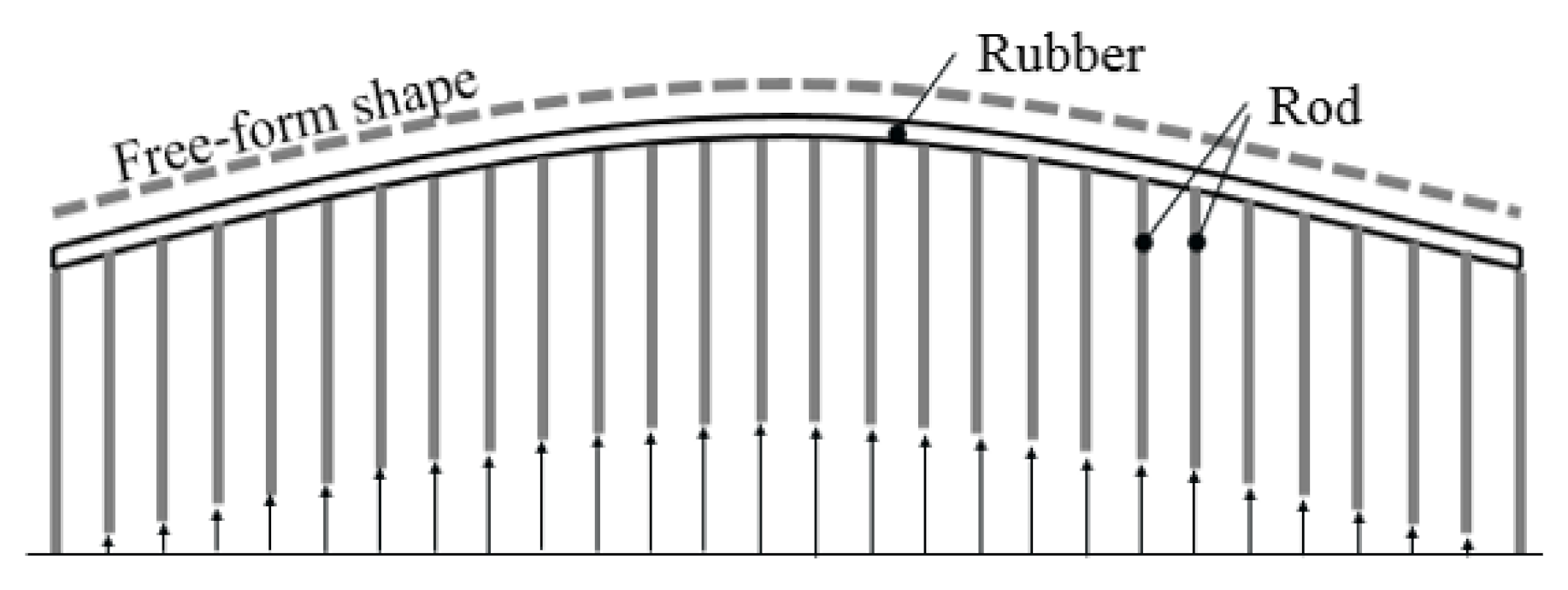

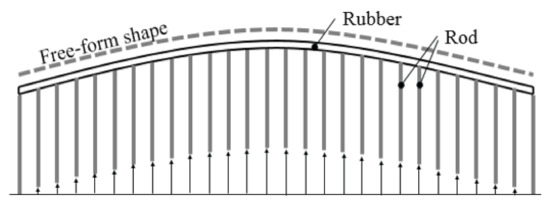

A shaping plate made of rubber or silicone is installed on top of the NCR of the CNC machine. As shown in Figure 3, the shaping plate implements a continuous free form. Since rubber or silicone is elastic and can freely change in length and shape, the formed shape is subject to the movement of the NCR. In addition, the shape is restored as the NCR moves up and down upon completion of the production of the variable formwork. At that time, the shaping plate can be deflected between the NCRs, which can be minimized by adjusting the thickness of the shaping plate. This project analyzes the deflection of the shaping plate through a shape implementation test.

Figure 3.

Concept of the computerized numerical control (CNC) machine.

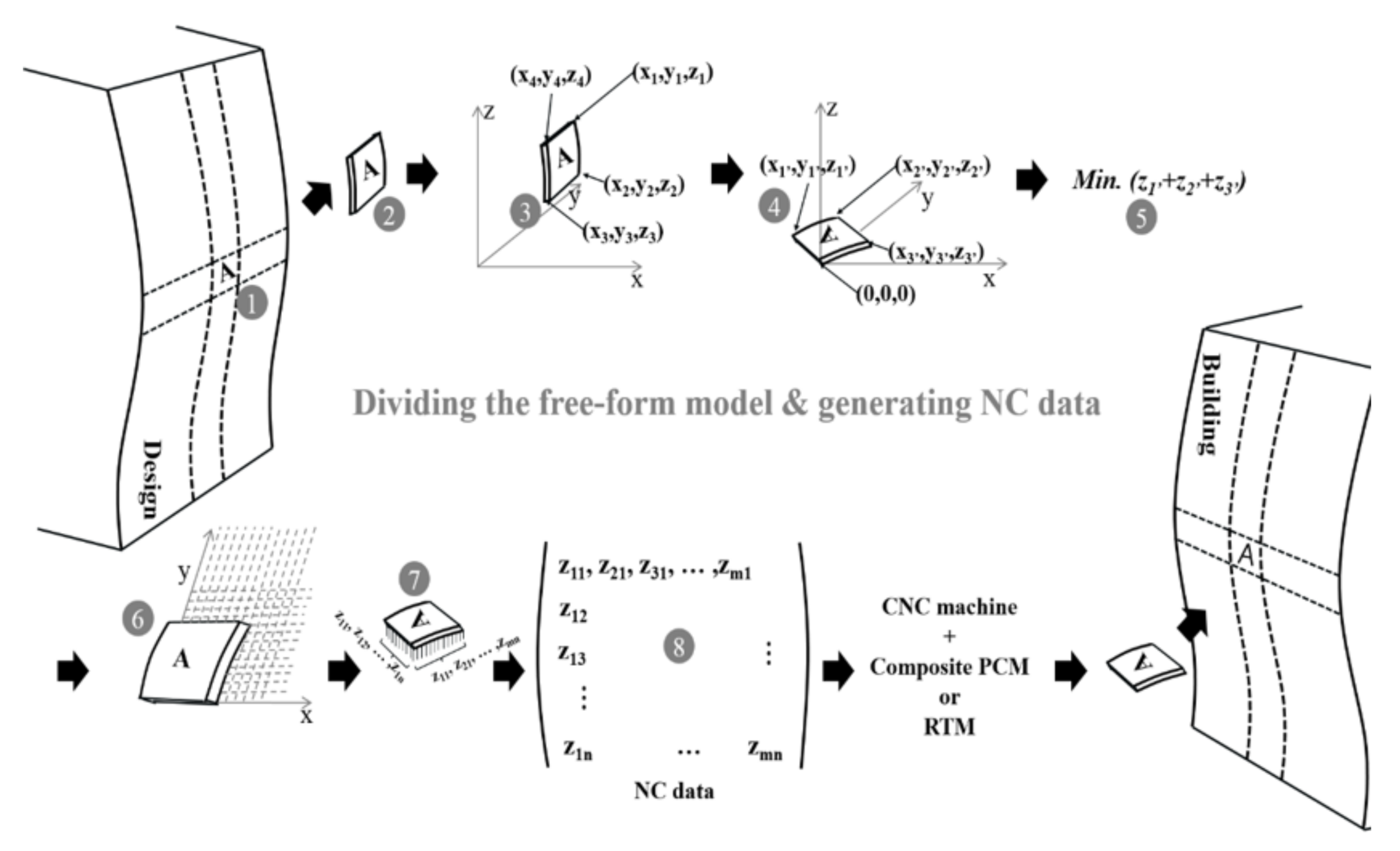

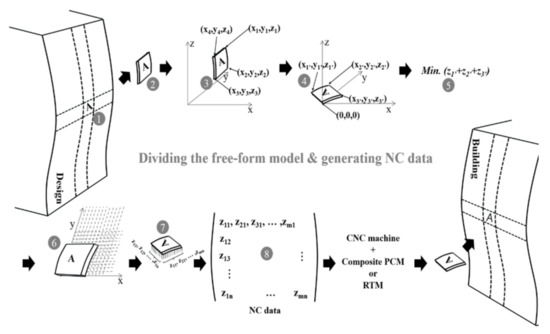

As shown in Figure 4, the process of splitting the BIM design and converting to NC (Numerical Control) data consists of 8 steps. First, identify free-form shapes in the BIM design (➀). Second, split the free-form model in consideration of the production, lifting, installation, and esthetics (➁). Third, call design segments with 3-axis coordinates and set the coordinates of the edge or outer line (➂).

Figure 4.

Process of splitting the free-form model and converting to NC data.

Fourth, place one dot among the edges at the origin (0,0,0) (➃). Fifth, rotate the design until the sum of Z values of all designated coordinates reaches its minimum (➄). Sixth, create a grid on the X-Y plane over the rotated member at the same spacing as the NCR (➅). This time, create the virtual grid in the same direction as the CNC machine. Seventh, calculate the distance of the member from the intersection of the grid (Z value) (➆). Lastly, deploy Z values in line with the grid location (➇). The deployed Z value represents the NCR elevation value as NC data for operating the CNC machine. Members are produced using NC data and installed to complete free-form buildings.

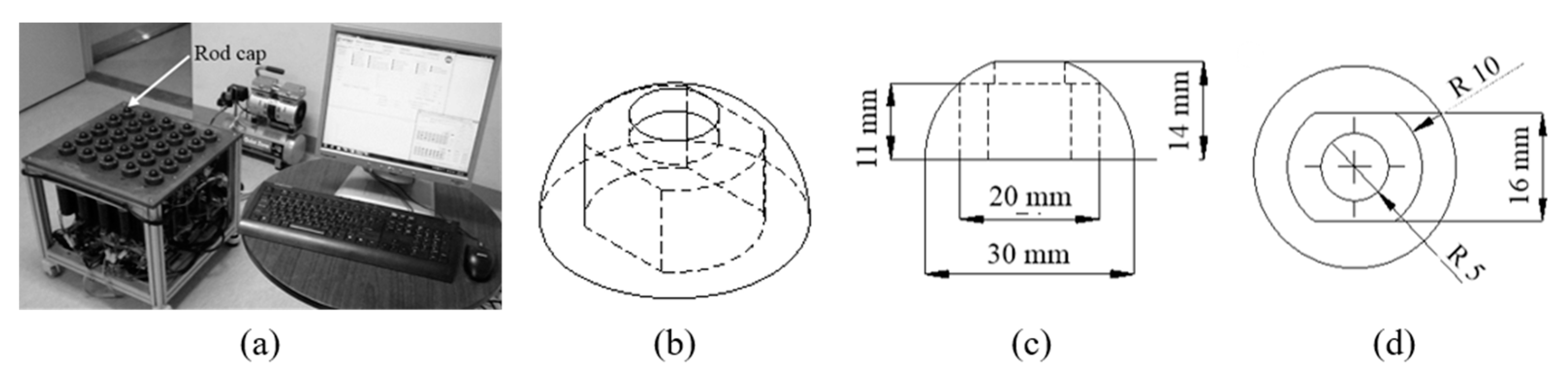

The CNC machine has multiple NCRs that can be moved up and down and deployed in series to render a curve at the rubber- or silicone-based shaping plate with varying elevation of the top of each NCR (shape implementation part). Data extracted from the FCP design data are entered into the CNC machine operating program, and each NCR is controlled to a specified elevation to implement the free-form shape. Then, the shape-smoothing plate is used to smoothly implement the free-form shape. Since it needs to withstand the rise and fall of the NCRs, the shape-smoothing plate should be made of an elastic material such as rubber. As shown in Figure 5a, the CNC machine is capable of implementing a shape of up to 360 × 360 mm with 5 × 5 ea. NCRs are fabricated for shape implementation and quality testing. The operating elevation of an NCR is limited to a maximum of 200 mm due to the size of the equipment. The maximum operating elevation is controlled mechanically by optical sensors. In addition, the rubber does not protrude because a cap is installed on top of the NCR. As shown in Figure 5b, this type of cap reduces the error so that the shape of the soft rubber should be maintained.

Figure 5.

CNC machine prototype fabrication and rod cap: (a) CNC machine prototype fabrication; (b) rod cap; (c) cross-section; (d) top view.

The operating time of the CNC machine deployed in 5 × 5 ea. is calculated using Equation (1), based on the screw lead, transmission distance, number of screws, motor RPM, and gear ratio. Assuming a transmission distance with 100 mm, the total operating time is 3.3 s, and it is designed to be 9.9 s based on applying a three-fold safety margin.

The variables in Equation (1) are defined as follows:

- : Screw lead (=3 mm);

- : Transmission distance (=100 mm);

- : Number of screws (=5 EA);

- : Motor RPM (=3000 rpm);

- : Gear ratio (=1:1).

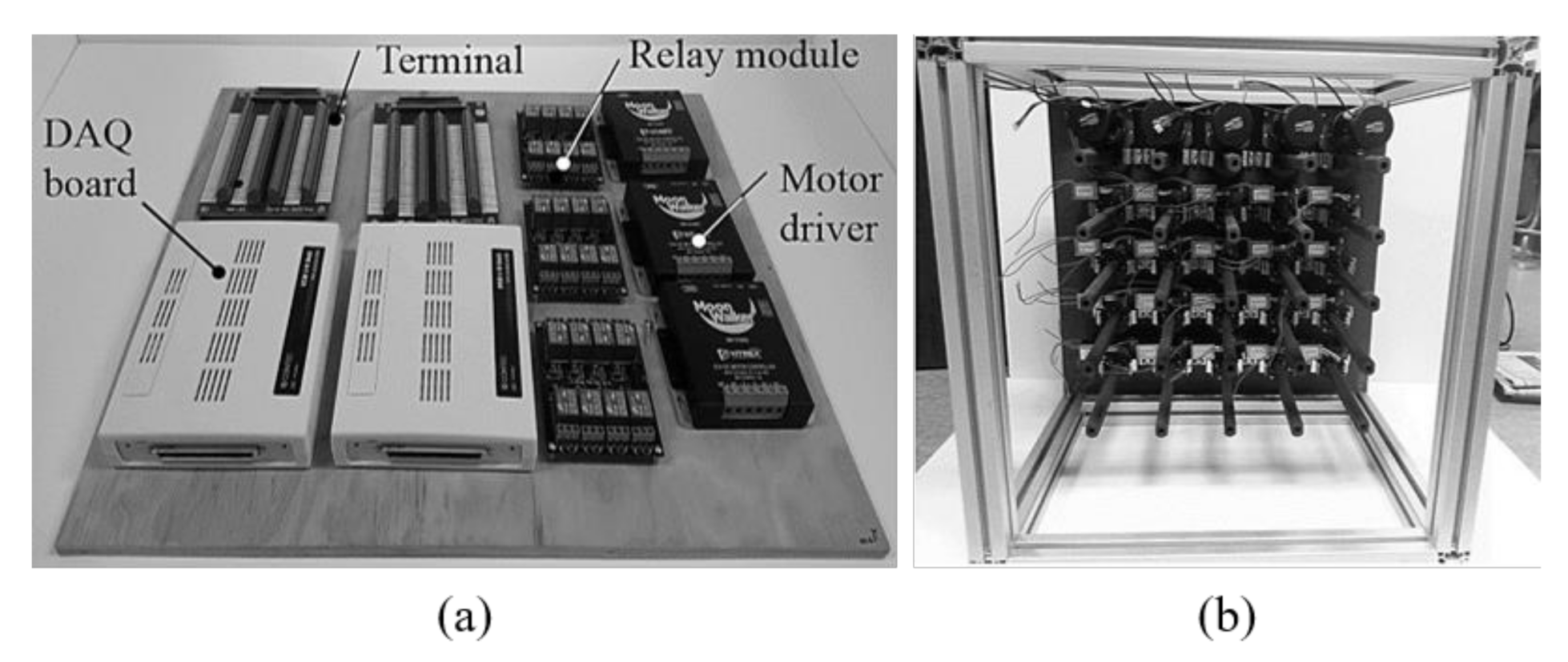

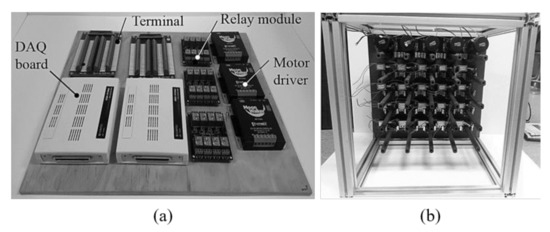

The control panel of the CNC machine is configured as shown in Figure 6a. The control panel is attached to the side and bottom of the CNC machine, and the terminal, relay module, data acquisition (DAQ) board, and motor driver are embedded on a single panel. The terminal receives data from the limit sensor attached to the NCR and forwards them to the relay module. The DAQ board is the hardware component controlling the analog signal I/O, digital data I/O, counter, and timer measurement. The relay module controls the motor RPM and revolution direction.

Figure 6.

Control panel and operating unit: (a) control panel; (b) bottom of operating unit.

4.2. Production of Free-Form Concrete Panels

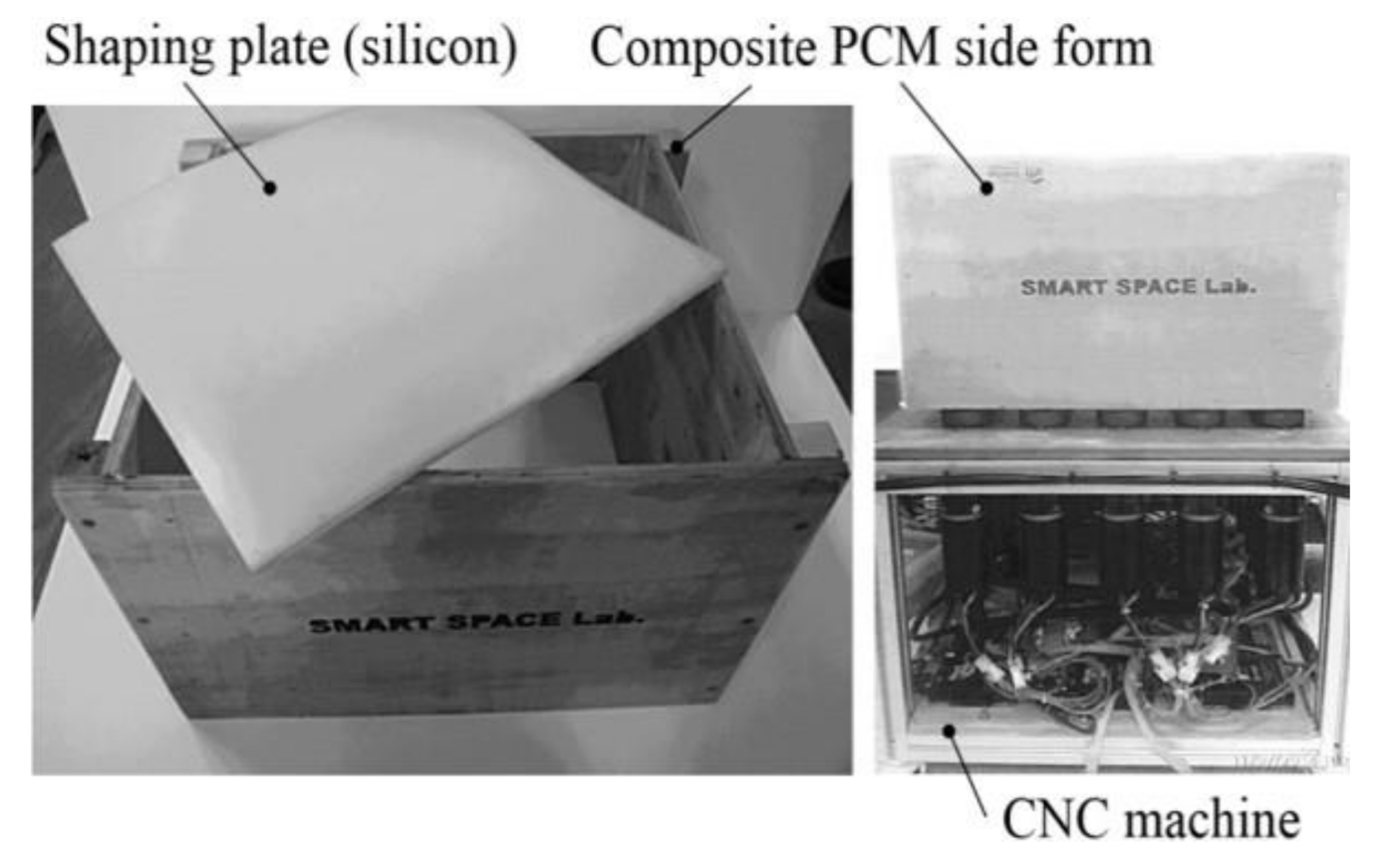

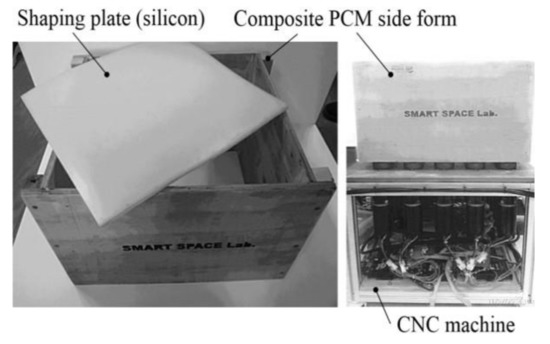

The CNC machine, a 10-mm-thick silicone shaping plate, and wooden molds are used to implement the curved shape with the composite PCM. The composite PCM is a mixture of aluminum powder and paraffin that shows the most ideal cooling time, shrinkage volume, and surface conditions. As shown in Figure 7, the 10-mm-thick silicone shaping plate and wooden molds are installed in the CNC machine, and a mixture of heated aluminum powder and paraffin is injected to fabricate the composite PCM.

Figure 7.

Box with the silicone shaping plate and the CNC machine.

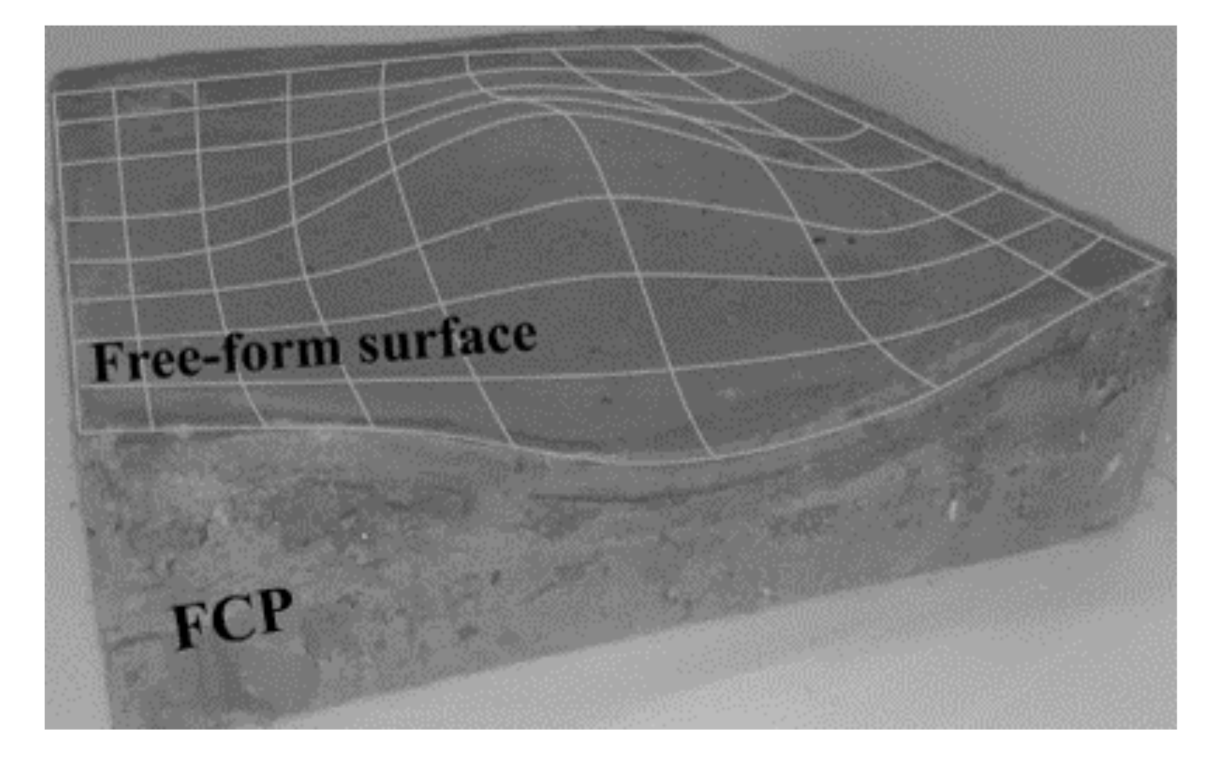

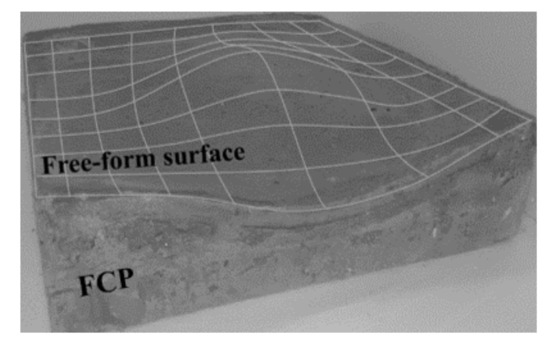

The completely cured FCP implements the shape of the composite PCM mold, as shown in Figure 8. The FCP was 80–150 mm thick and was easily removed from the composite PCM mold after complete curing. In addition, no deformation of the surface of the composite PCM mold developed during curing. The FCP confirmed that the surface fabricated by the composite PCM mold was cured to be smoother than the surface fabricated by the wooden mold on the side. The surface shape of the FCP is hard to capture in a photograph but can be checked easily using a wire frame, as shown in Figure 8.

Figure 8.

Free-form surface of the FCP.

The surface of the FCP was convex in the center and concave on one side. Comparison with the side of the FCP fabricated with the wooden mold confirmed that the quality of the top surface fabricated with the composite PCM mold was better. Material to be mixed in the composite PCM was selected after identifying the ideal mixing ratio of the two materials and examining their heat conductivity, shrinkage, and potential crack development. A combination of aluminum powder and paraffin showed the best performance as a material for the composite PCM, which posted the shortest cooling time of 50 min with shrinkage of less than 1%. In addition, a test specimen whose surface shape was uniform and dense was fabricated out of the combination. Therefore, this project confirmed that FCS could be fabricated out of an aluminum-mixed composite PCM which posed no issue in forming shapes of the composite PCM formwork.

5. Measurement of FCP Quality

The CNC machine can implement shapes freely. In addition, it delivers smooth shapes when a rubber- or silicone-based shape-smoothing plate is employed. However, the CNC machine may incur minute errors, and it is limited in terms of implementable shapes. Minor curves applied to buildings can be implemented sufficiently, but there is a limit in fabricating the dynamic shapes found in artwork. This project identifies the error of the CNC machine via a shape implementation test and analyzes its limitations. The shape implementation test was conducted by implementing a shape that reflects the curvature of existing buildings.

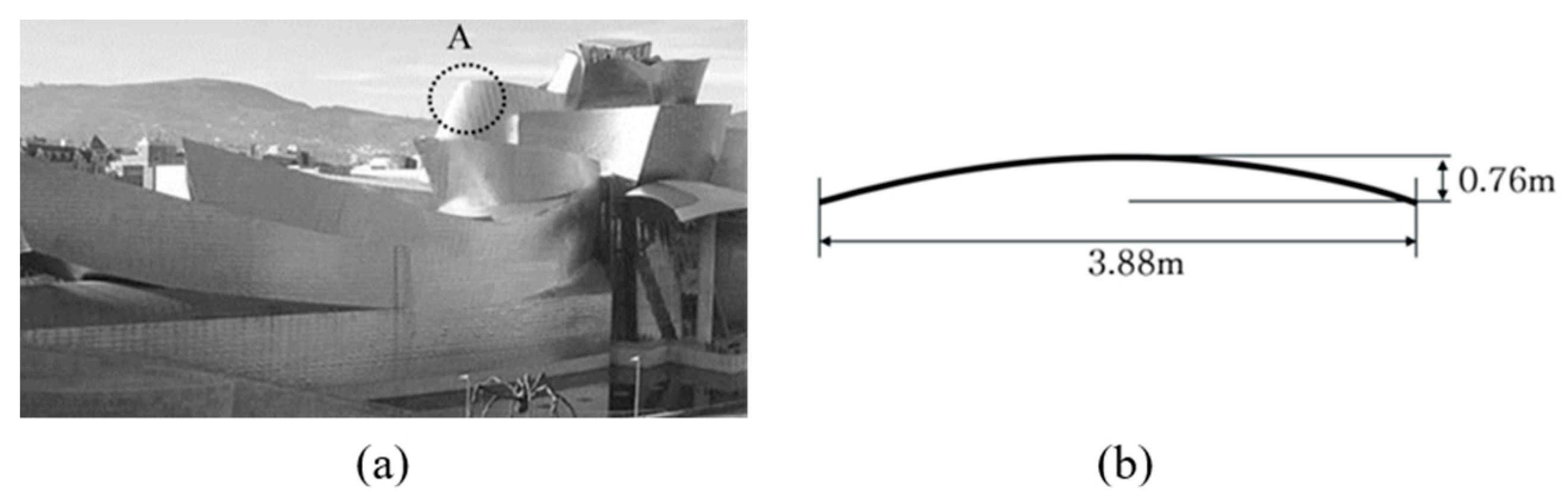

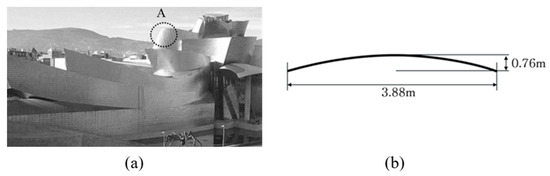

The subject of the test was selected as the area with the greatest curvature, and the test compared the size and curvature of the produced shape with those of the original building. The first case was the Guggenheim Museum. As shown in Figure 9a, the area of greatest curvature was selected, and the size and curvature were reviewed, as shown in Figure 9b. Area A in Figure 9 is a semi-circle about 15 m wide, and it was divided into six panels about 4 m wide to produce the members. The divided panel was 3.88 mm long with vertical variation of 0.76 m and a curvature radius of 7.5 m.

Figure 9.

Free-form panel of the Guggenheim Museum: (a) Guggenheim Museum Bilbao [2]; (b) free-form panel.

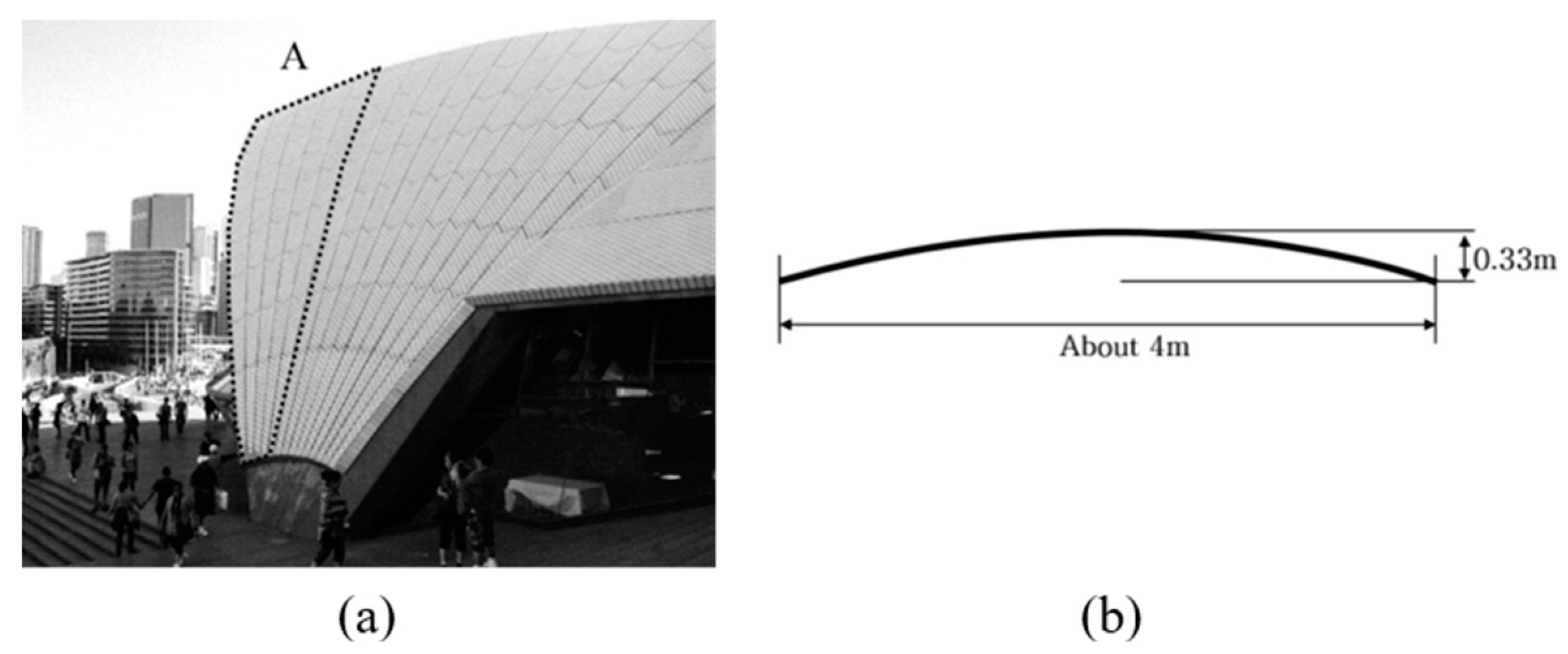

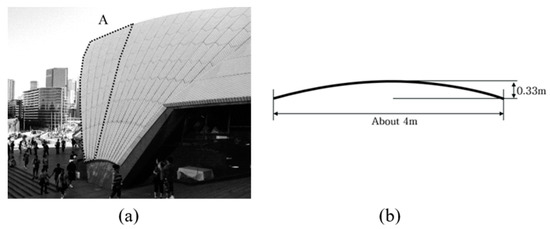

The second case was the Sydney Opera House. The area with the greatest curvature is marked “A” and indicated with dotted lines in Figure 10a. This area was selected as the subject of review, and the size and curvature were examined, as shown in Figure 10b. Area “A” in Figure 10 is a free form about 15 m high, and it was divided into four equal panels about 4 m wide. Each divided panel was 4 mm long horizontally and varied 0.33 m vertically.

Figure 10.

Free-from panel of the Sydney Opera House: (a) Sydney Opera House [1]; (b) free-form panel.

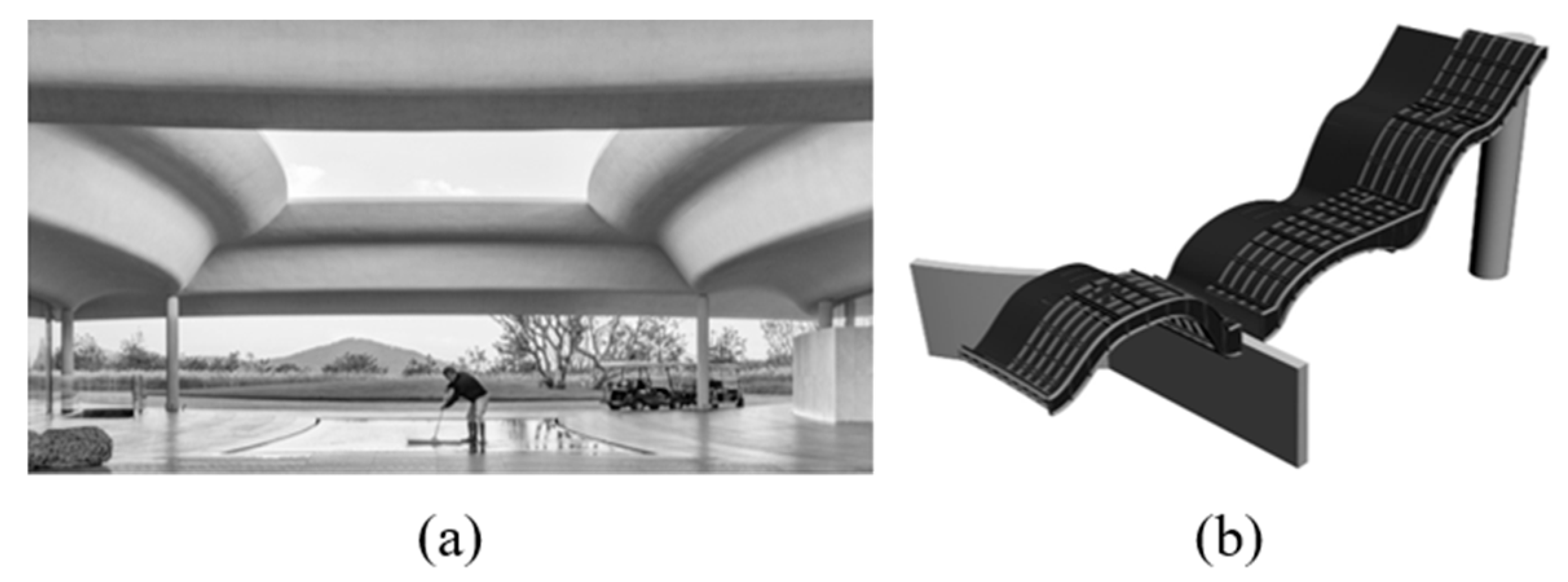

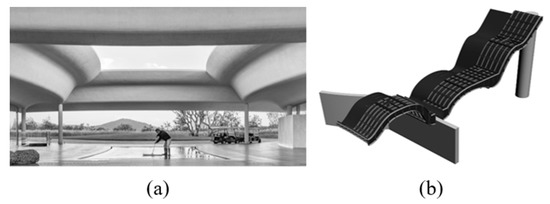

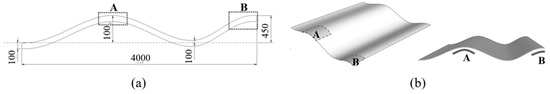

The third case reviewed was Club House “S” in Korea. The roof of this building varies significantly in terms of shape, as shown in Figure 11b. The conventional technique of placing concrete after fabricating and installing a metal formwork was applied to the construction of the free-form roof. An interview with the construction contractor revealed that the actual cost exceeded the contract amount 10-fold, and most of the overrun was in labor costs. The roof of the building, which was responsible for most of the cost increase, has many inflection points, and the area with the greatest curvature shows vertical variation of about 70 mm per 1 m. This project conducted the shape implementation test on the roof shape of Club House “S,” which was thought to be more challenging.

Figure 11.

Free-from panel of Club House “S”: (a) Club House “S” [37]; (b) formwork plan.

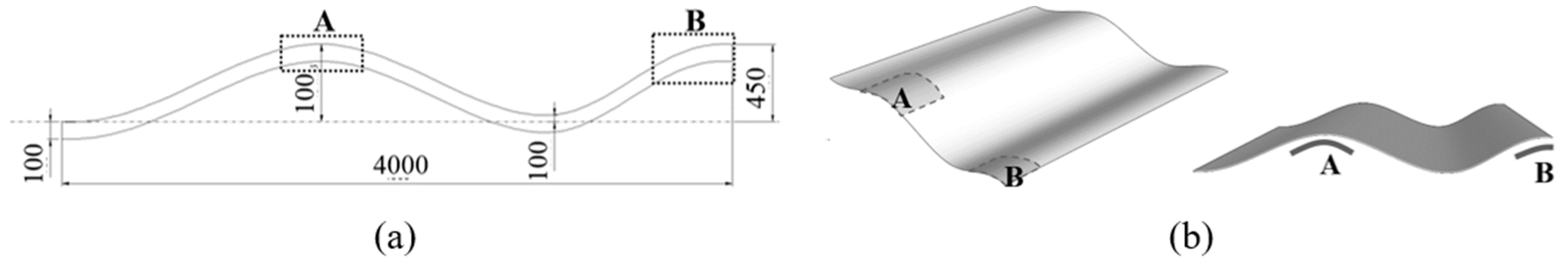

The shape of Club House “S” was reproduced in parts, with sharp curves and relatively gentle curves repeated, as in Panels A and B shown in Figure 12a. The reproduced design is 4 m long and varies about 0.45 m in elevation with two inflection points and three centers of curvature. The shape implementation test was conducted on Panels A and B, which had the greatest curvature. The CNC machine prototype was fabricated in reflection of the actual curvature of the as-built architecture. Since the other panels had little curvature, no difficulties were expected when implementing their shapes with the CNC.

Figure 12.

Design fabrication for the shape implementation test: (a) shape implementation test segment; (b) shape implementation test design.

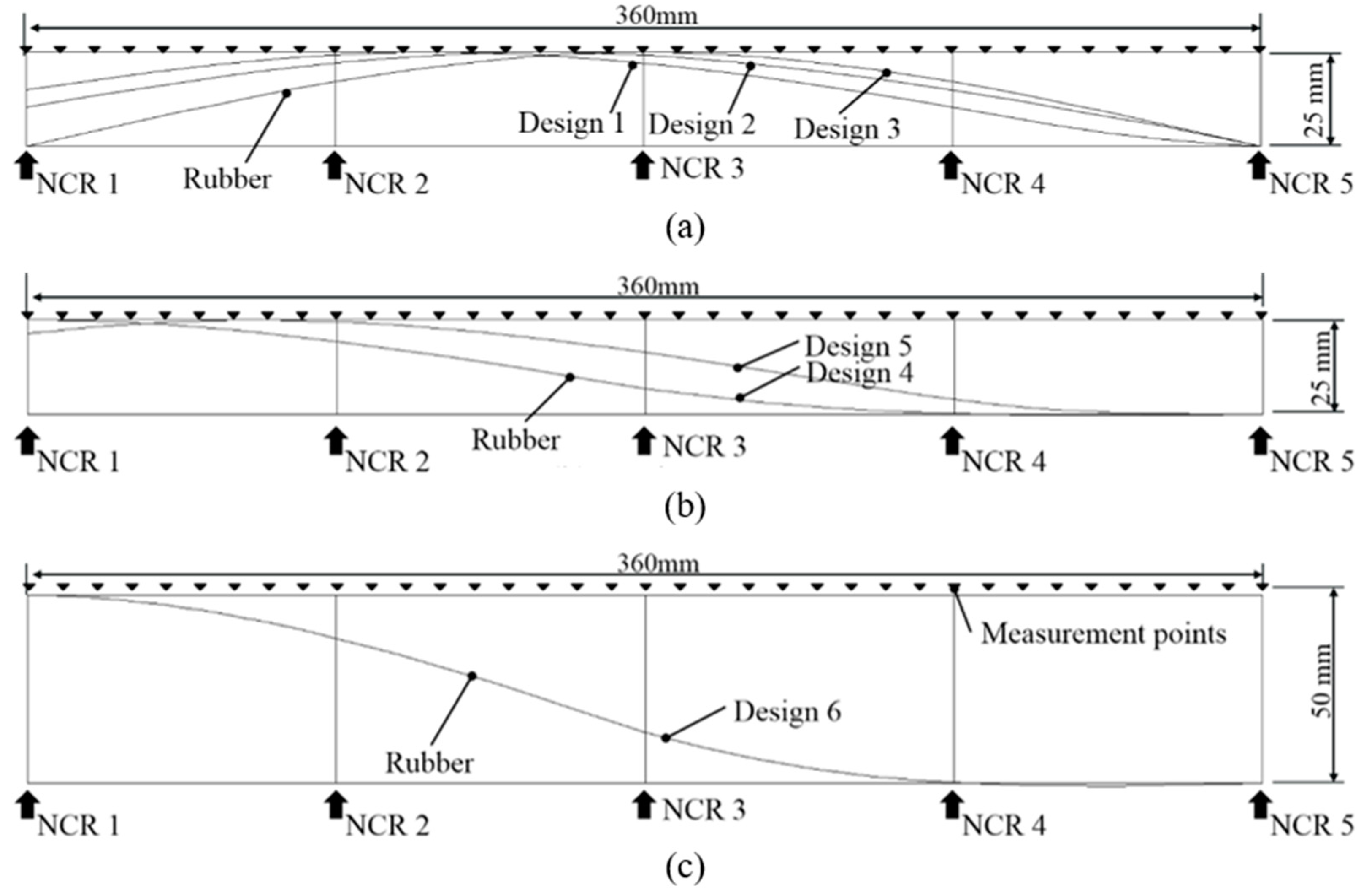

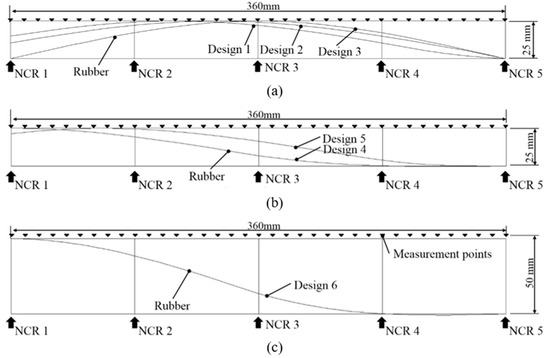

Panel A’s center was convex with the center of curvature existing in one direction. Panel B had an inflection point with the center of curvature in both directions. Three different designs adopting the mold of Panel A were prepared, as shown in Figure 13a. Two other designs adopting the mold of Panel B were fabricated as shown in Figure 13b, and a sixth design, shown in Figure 13c, was fabricated by doubling the variation in elevation in Panel B. Designs 1 through 5 were 360 mm long with a maximum height of 25 mm and contoured in reference to the curvature of Panels A and B of Club House “S”, which is the reference case. In the case of Panel B, an arbitrary inflection point that did not exist in the case was inserted to measure the shape implementation capability. Design 6 reflected the shape of Design 4, but its variation in elevation was set to 50 mm to increase the experimental strength.

Figure 13.

Design of the shape implementation test (Designs 1–6): (a) Design 1~3; (b) Design 4~5; (c) Design 6.

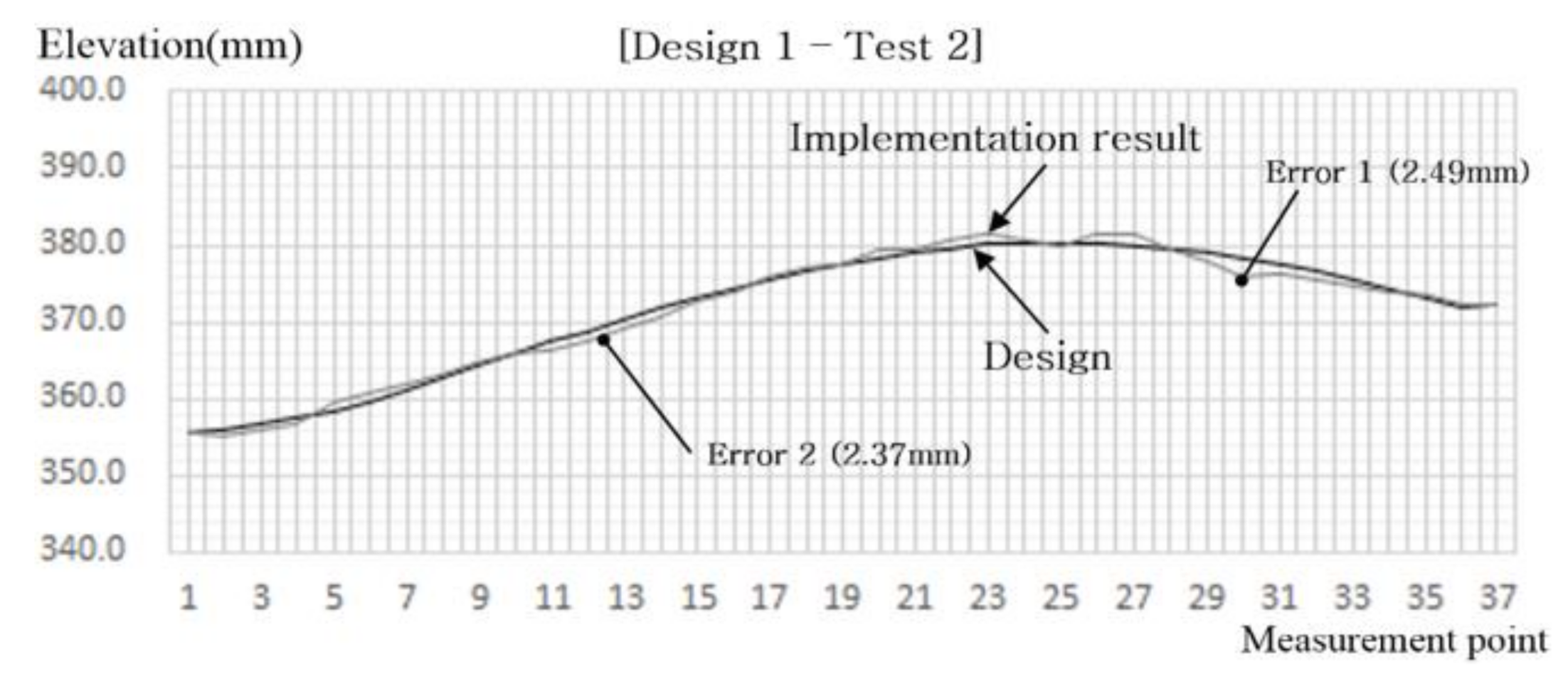

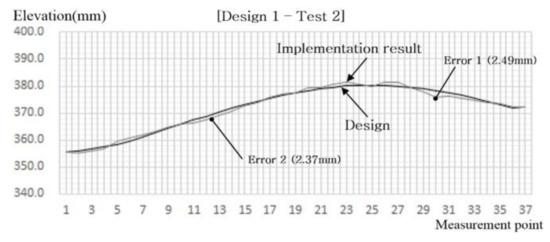

It is difficult to see any difference between the shape implemented by the CNC machine and the design. However, precise measurements reveal errors in each panel as shown in Figure 14. Given the precise operation of the NCR, most of the errors are deemed to have occurred in the shaping plate during the CNC machine operation.

Figure 14.

Error measurement results (Design 1—2nd test).

Table 1 shows the descriptive statistics from the test results on Designs 1 through 5. Four tests were performed on each design, and the tests were numbered Tests 1~20 to facilitate the overall analysis and differentiation. The value “N” is the number of points measured in one experiment. The distance was measured using a laser distance meter. The total number of tests on all designs was 740, and on average, the elevation of the NCRs was 359.91 mm, the standard deviation was 8.43, and the maximum and minimum values were 373.95 and 348.63 mm, respectively.

Table 1.

Descriptive statistics (Tests 1~20).

A standard tolerance of 3% for wall thickness was applied in accordance with the tolerance standard set forth in Article 20 of the Enforcement Decree to the Building Act of Korea. When the FCP thickness was set to 150 mm, the error range was 4.5 mm. The t test value (tx) of the test results for Designs 1~5 calculated using the T distribution was −61.46, which is smaller than the −1.65 threshold of t(0.05,739) at a significance level of 0.05 (one-tailed), enabling the rejection of the null hypothesis of Equation (2) (H0).

Since it is elastic, the shaping plate can be deflected by gravity. In addition, unlike an NCR implemented with precision, it is likely to deviate from the designed shape. Thus, in the shape implementation test results, errors may increase as the distance from an NCR increases. This is investigated via data analysis.

To confirm whether the relationship between the distance from an NCR and error also relates to changes in the design, the shape implementation test results for Designs 1~5 were integrated and verified. Table 2 shows the descriptive statistics and error occurrence in Designs 1~5. The “Error” means the vertical error arising in the implemented shape with the design in this test.

Table 2.

Descriptive statistics per distance from the numerical control rod (NCR) (Designs 1~5).

As listed in Table 2, 740 datasets were analyzed, and an average error of 0.44 mm occurred when the distance from the NCR was 10 mm. When the distance was 20 mm, the average error was 0.8 mm, and it was 1.15 mm when the distance was 30 mm. Further, when the distance was 40 mm, an average error of 1.19 mm appeared. However, the maximum value incurred an error of 5.62 mm at a distance of 30 mm from the NCR, rather than 40 mm.

ANOVA analysis was conducted on the errors in Designs 1–5. The means of errors measured at distances of 10, 20, 30, and 40 mm from the NCR were denoted M1, M2, M3, and M4, respectively. As given in Equation (3), the null hypothesis (H0) is that “the means of the four groups are the same,” and the project hypothesis (H1) is that “the means of the four groups are different.” Verification was performed at a confidence level of 95%. The results of the ANOVA analysis on the 739 datasets are provided in Table 3; the F-value was 12.48, and the p-value was 0.0. Thus, the null hypothesis (H0) can be rejected, and it is deemed that errors increase significantly as the distance from the NCR increases, with respect to the means of the four groups in Designs 1~5.

Table 3.

ANOVA (errors per distance from the NCR, Designs 1~5).

A regression model of the two variables was developed based on the NCR and the datasets of the shape implementation error tests. The regression model provides a basis for estimating errors that may arise in reference to the distance from the NCR. Due to the purpose and structural characteristics of the CNC machine, the spacing is not wide between the NCRs. Therefore, a linear regression model was applied without considering the case in which the error rate increased, which can arise if the spacing between the NCRs is wide. Table 4 summarizes the details of the regression model for Designs 1~5. R squared was 0.06, and the standard deviation of the measured values was 1.6.

Table 4.

Regression model summary (Designs 1~5).

Equation (4) shows the estimated line of regression indicating the relationship between the NCR and the shape implementation error. In addition, as shown in Table 5, the variance analysis results show that the F-value is 46.85 and the p-value is 0.0, indicating statistical significance of the regression model at a confidence level of 0.05.

Table 5.

ANOVA (regression model of Tests 1~5).

Design 6 was fabricated with the vertical variation rate of the curved surface doubled. The first shape implementation test on Design 6 revealed a maximum measurement error of 4.23 mm; the second biggest error was 2.37 mm, and the third biggest error was 2.32 mm. The overall shape did not deviate significantly from the design, but it was confirmed that errors occurred across a wide range.

The descriptive statistics of the test results for Design 6 are provided in Table 6. The test was conducted four times in total, and they were numbered Tests 21~24 to facilitate the overall analysis and differentiation. The total measurement frequency during the tests of Design 6 was 148 times, and on average, the elevation of the NCR was 321.9 mm, the standard deviation was 18.96, and the maximum and minimum values were 290.28 and 342.03 mm, respectively.

Table 6.

Descriptive statistics (Tests 21~24).

The t test value of the test results for Design 6 was calculated to be −27.91, which is smaller than the −1.65 threshold of t(0.05,739) at a significance level of 0.05 (one-tailed), enabling the rejection of the null hypothesis of Equation (5) (H0).

6. Conclusions

This project developed production technology for high-quality free-form concrete panels using a CNC machine developed in this project and verified the shape quality through an experiment. The CNC machine implements a smooth free-form shape by changing the shape of the silicon plate by the movement of rods. The silicone plate for the CNC machine generates a slight error due to the elastic cover and mechanical clearance. Verification of these errors will provide meaningful information to a similar type of machine development. Moreover, 3D free-form shapes can be expressed by allotting a Z-value to the X-Y coordinates. The CNC machine produces 3D free-form shapes using this concept. The X and Y coordinates are set when the BIM information of a free-form building is divided. The value controlled by a computer is the Z-value, and the collection of Z-values needed to come up with panels is the data of the curved surfaces. The CNC machine controls the height of the NCR (numerical control rod) according to the data of the 3D curved surfaces, so that the NCR can accurately shape the curved surfaces. The up/down rod of the CNC machine is arranged in a grid, and it can produce 3D shapes by displaying 3D curved surfaces according to the level differences. The main purpose of the CNC machine developed in this project was to produce free-form shapes with a variable mold. Experiments to investigate the shapes produced using the CNC machine were conducted by measuring the difference (error) between the planned designs and the produced shapes. The mean error rate was within 3%, based on the thickness of the panels, at the 95% confidence level. In addition, when the designed variation in the existing free-form panels was doubled, the mean error rate was within 3%, demonstrating that it is suitable for producing free-form concrete panels. These results suggest that manual work can be greatly reduced or avoided using the proposed approach, and it represents a significant development compared to the existing technology for producing free-form concrete panels finished with plastering. The project findings will be helpful in technological development related to producing members of uniform quality, wherein the shape accuracy is not influenced by the skills and competence of the workers producing the free-form concrete panels. As future study, it is necessary to develop the side form of free-form concrete panels.

Author Contributions

Conceptualization, D.L. and S.K.; writing—original draft preparation, D.L.; writing—review and editing, S.K. and S.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (No. 2020R1C1C1012600).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Payne, J. The Sydney Opera House, Inside and Out; The University of Sydney: Sydney, Australia, 2003; pp. 247–277. Available online: https://ses.library.usyd.edu.au/bitstream/handle/2123/1415/08chapter7.pdf;jsessionid=A02ECB8BE3B55C6E3CD3746D1B9B9738?sequence=8 (accessed on 10 October 2020).

- Plaza, B. The return on investment of the Guggenheim Museum Bilbao. Int. J. Urban Reg. Res. 2006, 30, 452–467. [Google Scholar] [CrossRef]

- Mandl, P.; Winter, P.; Schmid, V. Free Forms in Composite Constructions—The New House of Music and Music Theatre in Graz; European convention for constructional steelwork, European Conference on Steel and Composite Structures: Brussels, Belgium, 2008; pp. 1209–1214. [Google Scholar]

- Kim, K.; Son, K.; Kim, E.D.; Kim, S. Current trends and future directions of free-form building technology. Archit. Sci. Rev. 2015, 58, 230–243. [Google Scholar] [CrossRef]

- Lee, D.; Hong, W.K.; Kim, J.T.; Kim, S. Conceptual Study of Production Technology of Free-Form Concrete Segments. IJET 2015, 7, 321. [Google Scholar] [CrossRef]

- Lim, J.; Lee, D.; Kim, S. Analysis on the factors influencing layout for production-installation work of freeform concrete panels in PCM mold. In Proceedings of the Korean Institute of Building Construction Conference, 2015; Volume 15, pp. 121–122. Available online: https://www.koreascience.or.kr/article/CFKO201526857080063.page (accessed on 1 March 2020).

- Kim, G.; Lim, C.; Kim, S. A basic study of manufacturing technology of free-form concrete segments. In Proceedings of the Korean Institute of Building Construction Conference, Buyeo, Korea, 9 September 2013; Volume 13, pp. 12–13. [Google Scholar]

- Lee, G. Construction Issues of Irregular-Shaped Buildings. JAIK 2008, 52, 63–65. [Google Scholar]

- Ghugal, Y.M.; Deshmukh, S.B. Performance of alkali-resistant glass fiber reinforced concrete. JRPC 2006, 25, 617–630. [Google Scholar] [CrossRef]

- Choi, Y.; Yuan, R.L. Experimental relationship between splitting tensile strength and compressive strength of GFRC and PFRC. Cem. Concr. Res. 2005, 35, 1587–1591. [Google Scholar] [CrossRef]

- Krishna, R.; Kumar, R.P.; Srinivas, B. Effect of size and shape of specimen on compressive strength of glass fiber reinforced concrete (GFRC). Facta Univ. Ser. Archit. Civil Eng. 2011, 9, 1–9. [Google Scholar] [CrossRef]

- Marikunte, S.; Aldea, C.; Shah, S.P. Durability of glass fiber reinforced cement composites: Effect of silica fume and metakaolin. Adv. Cem. Based Mater. 1997, 5, 100–108. [Google Scholar] [CrossRef]

- Son, S.; Kim, D.; Son, K.; Kim, S. Predicting production time of free-form concrete panels using 3D plastering technology. Autom. Constr. 2020, 119, 103327. [Google Scholar] [CrossRef]

- Son, S.; Lim, J.; Kim, S. Planning algorithms for in-situ production of free-form concrete panels. Autom. Constr. 2018, 91, 83–91. [Google Scholar] [CrossRef]

- Lindsey, B.; Gehry, F.O. Digital Gehry. Englische Ausgabe: Material Resistance Digital Construction; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2001; pp. 16–90. [Google Scholar]

- Ito, T. Meiso No Mori Crematorium Gifu Japan; Toyo Ito & Associates: Gifu, Japan, 2006; pp. 7–25. [Google Scholar]

- Franken, B. The Bubble. Available online: http://www.franken-architekten.de/index.php?pagetype=projectdetail&lang=en&cat=6¶m=cat¶m2=21¶m3=0&. (accessed on 23 October 2020).

- Pérez Latorre, J.I. Construction Method to Build Ice Shells with Pneumatic Formwork. Master’s Thesis, Vienna University of Technology Faculty of Civil Engineering, Vienna, Austria, 2010. Available online: http://hdl.handle.net/10016/10080 (accessed on 1 March 2020).

- Verhaegh, R.W.A. Free Forms in Concrete Fabric. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2010. [Google Scholar]

- Spencer Dock Bridge. Available online: https://www.archdaily.com/96400/spencer-dock-bridge-amanda-levete-architects (accessed on 24 April 2020).

- Tailorcrete. Available online: http://www.tailorcrete.com (accessed on 1 February 2020).

- CRAFT (Center for Rapid Automated Fabrication Technologies). Available online: http://www.craft-usc.com/ (accessed on 1 March 2020).

- Loughborough University. Available online: http://www.lboro.ac.uk/eng/research/imcrc/ (accessed on 1 December 2020).

- Schipper, H.R.; Janssen, B. Manufacturing double-curved elements in precast concrete using a flexible mould: First experimental results. In Proceedings of the FIB Symposium, Concrete engineering for excellence and efficiency, Prague, Czech Republic, 8–10 June 2011; Czech Concrete Society and fib International Federation for Structural Concrete. Available online: http://resolver.tudelft.nl/uuid:fc718916-cecf-42a8-a3d9-0bb8c2c8fe02 (accessed on 1 March 2020).

- G. Fuehrer [AL_A Team]. Available online: https://www.yatzer.com/first-photos-spencer-dock-bridge-dublin (accessed on 1 March 2020).

- Design to Production. Available online: https://www.designtoproduction.com/en/ (accessed on 1 February 2020).

- Gramazio, F.; Kohler, M.; Willmann, J.; Oesterle, S.; Vansteenkiste, A.; Mirjan, A. Zero Waste Free-Form Formwork. In Proceedings of the Second International Conference on Flexible Formwork; University of Bath: Bath, UK, 2012; pp. 258–267. [Google Scholar]

- Pedersen, T.H.; Lenau, T.A. Variable geometry casting of concrete elements using pin-type tooling. J. Manuf. Sci. Eng. 2010, 132. [Google Scholar] [CrossRef]

- Munro, C.; Walczyk, D. Reconfigurable pin-type tooling: A survey of prior art and reduction to practice. J. Manuf. Sci. Eng. 2007, 129, 551–565. [Google Scholar] [CrossRef]

- Vedel-Smith, N.K.; Lenau, T.A. Casting traceability with direct part marking using reconfigurable pin-type tooling based on paraffin–graphite actuators. J. Manuf. Syst. 2012, 31, 113–120. [Google Scholar] [CrossRef]

- Im, Y.T.; Walczyk, D.F.; Schwarz, R.C.; Papazian, J.M. A comparison of pin actuation schemes for large-scale discrete dies. J. Manuf. Process. 2000, 2, 247–257. [Google Scholar] [CrossRef]

- Tan, F.X.; Li, M.Z.; Cai, Z.Y. Research on the process of multi-point forming for the customized titanium alloy cranial prosthesis. J. Mater. Process. Technol. 2007, 187, 453–457. [Google Scholar] [CrossRef]

- Savvides, A. Free Form Formwork System Technology for Concrete Structures. Master’s Thesis, Budapest University of Technology and Economics, Budapest, Hungary, 2012. [Google Scholar]

- Lee, D.; Kim, S. Energy and CO2 reduction of aluminum powder molds for producing free-form concrete panels. Sustainability 2020, 12, 9613. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.G.; Kim, S. Composite phase-change material mold for cost-effective production of free-form concrete panels. JCEM 2017, 143, 04017012. [Google Scholar] [CrossRef]

- Kim, S. An experimental study for quality assurance of free-form concrete panels produced by CNC machine. JCEM 2018, 24, 145–154. [Google Scholar] [CrossRef]

- Southcape. Available online: http://www.southcape.co.kr/ (accessed on 1 March 2020).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).