Research for Risk Management of Construction Projects in Taiwan

Abstract

:1. Introduction

2. Literature Review of Risk in Construction Projects

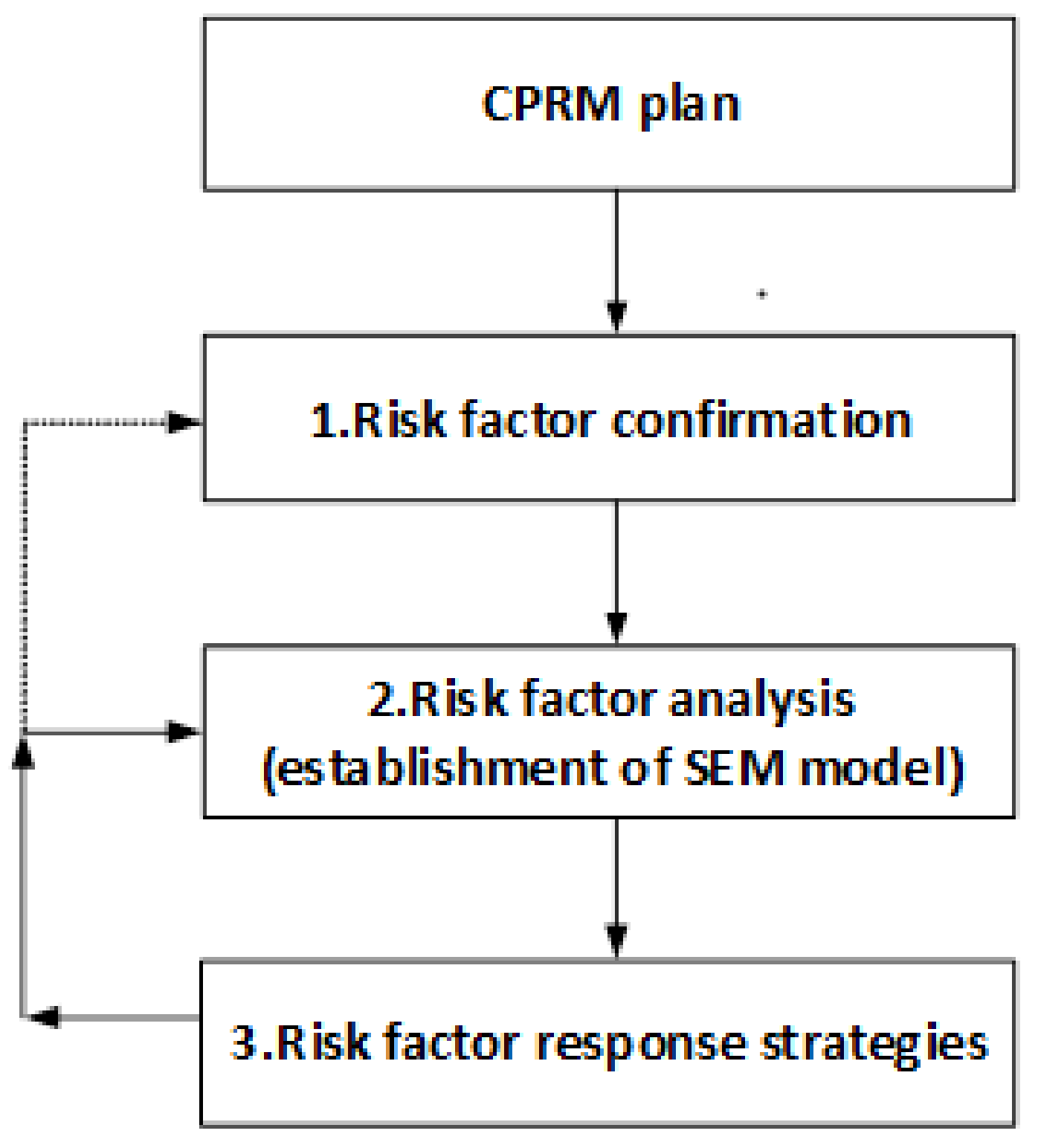

3. Research Methodology

4. Application of SEM to Risk Management

5. Sample Data Analysis

5.1. Application of SEM

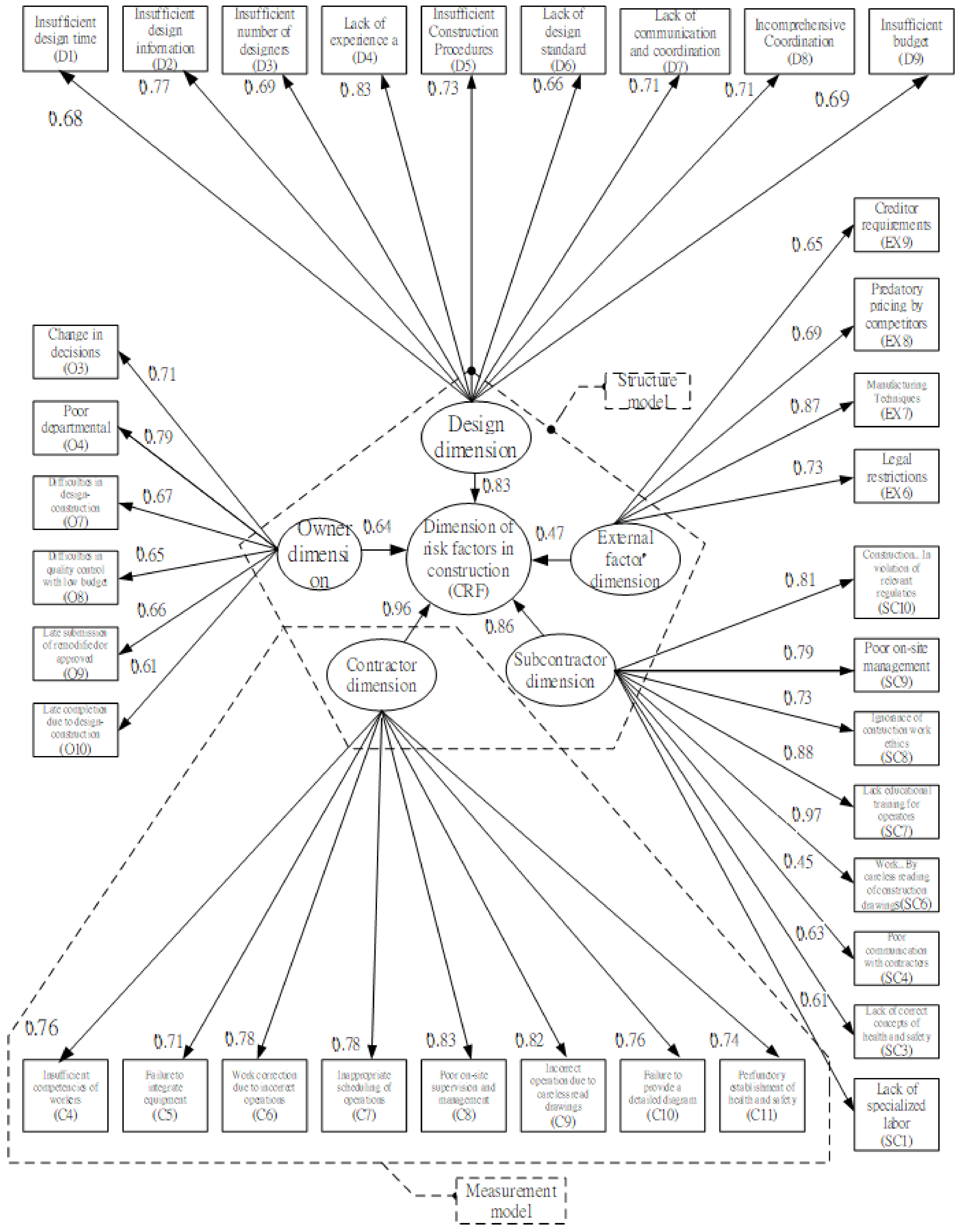

5.2. Establishment of the SEM Model of CPRM

5.2.1. SEM Model Specification

5.2.2. Goodness-of-Fit Verification and Modification of SEM

6. SEM Model of CPRM

7. Conclusions and Recommendations

- Contractors should practice thorough on-site supervision and management.

- Subcontractors should enhance on-site workers’ ability to read construction drawings and improve the educational training for these operators.

- Designers’ professional knowledge should be respected and information updates be followed closely.

- Interdepartmental communication and coordination with clients should be enhanced to reduce unnecessary changes in decisions.

- Regarding on-site operations, construction techniques should be improved, and relevant legal restrictions and legal changes should be followed closely and responded to in a timely manner.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Odeyinka, H.A.; Oladapo, A.A.; Dada, J.O. An assessment of risk in construction in the Nigerian construction industry. Int. Symp. Global. Constr. Const. Dev. Econ. 2005, 107, 359–368. [Google Scholar]

- Ehsan, N.; Alam, M.; Mirza, E.; Ishaque, A. Risk Management in Construction Industry. In Proceedings of the The 3rd IEEE International Conference on Computer Science and Information Technology, Chengdu, China, 9–11 July 2010. [Google Scholar]

- Kaur, M.; Singh, R. Risk and risk-handling strategies in construction projects. Int. J. Manage. Stud. 2018, 5, 1–7. [Google Scholar] [CrossRef]

- Kishan, P.; Bhatt, R. A study of risk factors affecting building construction projects. Int. J. Eng. Res. Technol. 2014, 3, 831–835. [Google Scholar]

- Flanagan, R.; Norman, G.; Chapman, R. Risk Management and Construction, 2nd ed.; Blackwell Publication: Hoboken, NJ, USA, 2006. [Google Scholar]

- Algahtany, M.; Alhammadi, Y.; Kashiwagi, D. Introducing a new risk management model to the Saudi Arabian construction industry. Procedia Eng. 2016, 145, 940–947. [Google Scholar] [CrossRef]

- Adeleke, A.Q.; Bahaudin, A.Y.; Kamaruddeen, A.M.; Bamgbade, J.A.; Salimon, M.G.; Khan, M.W.A.; Sorooshian, S. The influence of organizational external factors on construction risk management among Nigerian construction companies. Saf. Health Work 2018, 9, 115–124. [Google Scholar] [CrossRef]

- Nawaz, A.; Waqar, A.; Shah, S.A.R.; Sajid, M.; Khalid, M.I. An innovative framework for risk management in construction projects in developing countries: Evidence from Pakistan. Risks 2019, 7, 24. [Google Scholar] [CrossRef] [Green Version]

- Tipili, L.G.; Yakubu, I. Identification and assessment of key risk factors affecting public construction projects in Nigeria: Stakeholders perspectives. Int. J. Eng. Adv. Technol. Stud. 2016, 4, 20–32. [Google Scholar]

- Hubbard, D.W. The Failure of Risk Management: Why It’s Broken and How to Fix It, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2009. [Google Scholar]

- Fan, M.; Lin, N.P.; Sheu, C. Choosing a project risk-handling strategy: An analytical model. Int. J. Prod. Econ. 2008, 112, 700–713. [Google Scholar] [CrossRef]

- Rehacek, P. Risk Management in Construction Projects. J. Eng. Appl. Sci. 2017, 12, 5347–5352. [Google Scholar]

- Dey, P.K. Project risk management: A combined analytic hierarchy process and decision tree approach. Cost Eng. 2002, 44, 13–26. [Google Scholar]

- Mills, A. A systematic approach to risk management for construction. Struct. Surv. 2001, 19, 245–252. [Google Scholar] [CrossRef] [Green Version]

- Choudhry, R.M.; Iqbal, K. Identification of risk management system in construction industry in Pakistan. J. Manag. Eng. 2013, 29, 42–49. [Google Scholar] [CrossRef]

- Akintoye, A.S.; MacLeod, M.J. Risk analysis and management in construction. Int. J. Project Manag. 1997, 15, 31–38. [Google Scholar] [CrossRef]

- Kartam, N.A.; Kartam, S.A. Risk and its management in the Kuwaiti construction industry: A contractor’s perspective. Int. J. Project Manag. 2001, 19, 325–335. [Google Scholar] [CrossRef]

- Dziadosz, A.; Rejment, M. Risk analysis in construction project-chosen methods. Procedia Eng. 2015, 122, 258–265. [Google Scholar] [CrossRef] [Green Version]

- Fernando, C.K.; Hosseini, M.R.; Zavadskas, E.K.; Perera, B.A.K.S.; Rameezdeen, R. Managing the financial risks affecting construction contractors: Implementing hedging in Sri Lanka. Int. J. Strateg. Prop. Manag. 2017, 21, 212–224. [Google Scholar] [CrossRef]

- Park, K.; Lee, S.; Ahn, Y. Construction management risk system (CMRS) for construction management (CM) firms. Future Internet 2017, 9, 5. [Google Scholar] [CrossRef] [Green Version]

- Carmer, S.G.; Swanson, M.R. Detection of differences between means: A Monte Carlo study of five pair-wise multiple comparison procedures. Agronomy J. 1971, 63, 940–945. [Google Scholar] [CrossRef]

- Modarres, M. Risk Analysis in Engineering-Techniques, Tools, and Trends, 1st ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Hoyle, R.H. The structural equation modeling approach: Basic concepts and fundamental issues. In Structural Equation Modeling Concepts, Issues and Applications; Hoyle, R.H., Ed.; Sage: Thousand Oaks, CA, USA, 1995; pp. 1–15. [Google Scholar]

- Kline, R.B. Principles and Practice of Structural Equation Modeling, 3rd ed.; The Guilford Publications: New York, NY, USA, 2011. [Google Scholar]

- Byrne, B.B. Structural Equation Modeling with AMOS: Basic Concepts, Applications, and Programming, 2nd ed.; Routledge: New York, NY, USA, 2010. [Google Scholar]

- Wan Mohamed Radzi, C.W.J.B.; Salarzadeh Jenatabadi, H.; Hasbullah, M.B. Firm Sustainability performance index modeling. Sustainability 2015, 7, 16196–16212. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.-L.; Jeng, C.-H. Exploring interface problems in Taiwan’s construction projects using structural equation modeling. Sustainability 2017, 9, 822. [Google Scholar] [CrossRef] [Green Version]

- PMI (Project Management Institute). A Guide to the Project Management Body of Knowledge: PMBOK; Project Management Institute: Philadelphia, PA, USA, 2000. [Google Scholar]

- SLAC National Accelerator Laboratory. Risk Management Plan. Research Support Building and Infrastructure Modernization; LAC: Menlo Park, CA, USA, 2009. [Google Scholar]

- Vlăduț-Severian, I.A.C.O.B. Risk management and evaluation and qualitative method within the projects. Ecoforum 2014, 3, 1–10. [Google Scholar]

- Abazid, M.; Harb, H. An overview of risk management in the construction projects. Acad. Res. Int. 2018, 9, 75–76. [Google Scholar]

- Leo-Olagbaye, F.; Odeyinka, H.A. Evaluation of risk factors and their impact on road projects. J. Constr. Bus. Manag. 2018, 2, 24–35. [Google Scholar]

- Marzouk, M.; Aboushady, M. Modeling risks in real estate development projects. Int. J. Strateg. Prop. Manag. 2018, 22, 447–456. [Google Scholar] [CrossRef] [Green Version]

- Banaitienė, N.; Banaitis, A.; Norkus, A. Peculiarities of lithuanian construction companies. Int. J. Strateg. Prop. Manag. 2011, 15, 60–73. [Google Scholar] [CrossRef]

- Marsh, H.W.; Hau, K.T. Confirmatory factor analysis: Strategies for small sample sizes. In Statistical Strategies for Small Sample Research, Hoyle, R.H., Ed.; Sage: Thousand Oaks, CA. USA, 1999; pp. 252–284. [Google Scholar]

- Boomsma, A. The robustness of LISREL against small sizes in factor analysis models. In Systems Under Indirect Observation: Causality, Structure, Prediction (Part I); Wold, H., Jöreskog, K.G., Eds.; Journal of Econometrics: North-Holland, Amsterdam, The Netherlands, 1982; pp. 149–173. [Google Scholar]

- Kline, R.B. Principles and Practice of Structural Equation Modelling, 2nd ed.; The Guilford Publications: New York, NY, USA, 2005. [Google Scholar]

- Cronbach, L.J. Coefficient alpha and the internal structure of tests. Psychometrika 1951, 16, 297–334. [Google Scholar] [CrossRef] [Green Version]

- Schumacker, R.E.; Lomax, R.G. A Beginner’s Guide to Structural Equation Modeling, 2nd ed.; Erlbaum: Mahwah, NJ, USA, 2004. [Google Scholar]

- Jöreskog, K.G.; Sörbom, D. LISREL VI: Analysis of Linear Structural Relationships by the Method of Maximum Likelihood, 3rd ed.; National Educational Resources: Chicago, IL, USA, 1984. [Google Scholar]

- Bentler, P.M. Comparative fit indexes in structural models. Psychol. Bull. 1990, 107, 238–246. [Google Scholar] [CrossRef] [PubMed]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Market. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Jöreskog, K.G. Testing structural equation models. In Testing Structural Equation Models; Bollen, K.A., Long, J.S., Eds.; Sage: Thousand Oaks, CA, USA, 1993; pp. 392–416. [Google Scholar]

- Rigdon, E.E. Structural equation modeling: Nontraditional alternatives. In Encyclopedia of Statistics in Behavioral Science; Everitt, B.S., Howell, D.C., Eds.; Wiley: New York, NY, USA, 2005. [Google Scholar]

| Item | Measurement Models and Risk Factors | FL * (I = FL) (2) | Influence Level and Ranking of Risk Factors | Influence Level and Ranking of Models | |||

|---|---|---|---|---|---|---|---|

| P(1) | (3) | Rank | Rank | ||||

| I | Measurement model for the client dimension L L = 0.64 (coefficient of path) | ||||||

| O3 | Change in decisions | 0.71 | 0.31 | 0.22 | 3 | 0.141 | 3 |

| O4 | Poor…communication | 0.79 | 0.32 | 0.25 | 1 | 0.162 | 2 |

| O7 | Difficulties in design–construction coordination | 0.67 | 0.34 | 0.23 | 2 | 0.146 | 4 |

| O8 | Difficulties in quality control with low budget | 0.65 | 0.31 | 0.20 | 4 | 0.129 | 5 |

| O9 | Late submission of remodified or approved documents | 0.66 | 0.35 | 0.23 | 2 | 0.148 | 1 |

| O10 | Late completion due to design–construction interface problems | 0.61 | 0.33 | 0.20 | 4 | 0.129 | 5 |

| II | Measurement model for the design dimension L L = 0.83 (coefficient of path) | ||||||

| D1 | Insufficient design time | 0.68 | 0.27 | 0.18 | 8 | 0.149 | 9 |

| D2 | Insufficient design information | 0.77 | 0.35 | 0.27 | 2 | 0.224 | 2 |

| D3 | Insufficient number of designers | 0.69 | 0.34 | 0.23 | 5 | 0.195 | 6 |

| D4 | Lack of experience and knowledge | 0.83 | 0.30 | 0.25 | 4 | 0.207 | 4 |

| D5 | Insufficient understanding of the actual construction procedures | 0.73 | 0.36 | 0.26 | 3 | 0.218 | 3 |

| D6 | Lack of a design standard | 0.66 | 0.35 | 0.23 | 6 | 0.192 | 7 |

| D7 | Lack of communication and coordination in the design–construction interface | 0.71 | 0.40 | 0.28 | 1 | 0.236 | 1 |

| D8 | Incomprehensive coordination in the design–construction interface | 0.71 | 0.35 | 0.25 | 4 | 0.206 | 5 |

| D9 | Insufficient budget | 0.69 | 0.27 | 0.19 | 7 | 0.155 | 8 |

| III | Measurement model for the contractor dimension L L = 0.96 (coefficient of path) | ||||||

| C4 | Insufficient competencies of construction workers | 0.76 | 0.34 | 0.26 | 5 | 0.249 | 5 |

| C5 | Failure to integrate construction equipment, materials, and techniques | 0.71 | 0.41 | 0.29 | 2 | 0.279 | 3 |

| C6 | Work correction due to incorrect construction operations | 0.78 | 0.36 | 0.28 | 3 | 0.269 | 4 |

| C7 | Inappropriate scheduling of construction operations | 0.78 | 0.34 | 0.27 | 4 | 0.254 | 6 |

| C8 | Poor on-site supervision and management | 0.83 | 0.39 | 0.32 | 1 | 0.311 | 1 |

| C9 | Incorrect construction operations due to careless reading of construction drawings | 0.82 | 0.36 | 0.29 | 2 | 0.283 | 2 |

| C10 | Failure to provide a detailed construction diagram | 0.78 | 0.33 | 0.26 | 5 | 0.247 | 7 |

| C11 | Perfunctory establishment of health and safety facilities | 0.74 | 0.32 | 0.24 | 6 | 0.227 | 8 |

| IV | Measurement model for the subcontractor dimension L L = 0.86 (coefficient of path) | ||||||

| SC1 | Lack of specialized labor | 0.61 | 0.35 | 0.21 | 5 | 0.184 | 7 |

| SC3 | Lack of correct concepts of health and safety | 0.63 | 0.38 | 0.24 | 3 | 0.206 | 4 |

| SC4 | Poor communication and coordination with contractors | 0.45 | 0.38 | 0.17 | 6 | 0.147 | 8 |

| SC6 | Work correction due to incorrect construction operations caused by careless reading of construction drawings | 0.97 | 0.42 | 0.41 | 1 | 0.350 | 1 |

| SC7 | Lack of educational training for operators | 0.88 | 0.34 | 0.30 | 2 | 0.257 | 2 |

| SC8 | Ignorance of construction work ethics | 0.73 | 0.31 | 0.23 | 4 | 0.195 | 6 |

| SC9 | Poor on-site management | 0.79 | 0.38 | 0.30 | 2 | 0.248 | 3 |

| SC10 | Construction operations conducted according to personal experience and in violation of relevant regulations | 0.81 | 0.29 | 0.23 | 4 | 0.202 | 5 |

| V | Measurement model for the external factor dimension L L = 0.47 (coefficient of path) | ||||||

| Ex6 | Legal restrictions | 0.73 | 0.36 | 0.26 | 2 | 0.123 | 2 |

| Ex7 | Manufacturing techniques | 0.87 | 0.31 | 0.27 | 1 | 0.127 | 1 |

| Ex8 | Predatory pricing by competitors | 0.69 | 0.25 | 0.17 | 4 | 0.081 | 4 |

| Ex9 | Creditor requirements | 0.65 | 0.27 | 0.18 | 3 | 0.082 | 3 |

| Item | Measurement Models and Risk Factors | FL * (I = FL) (2) | Influence Level and Ranking of Risk Factors | Reliab-Ility (α) | ||

|---|---|---|---|---|---|---|

| P(1) | Rank | |||||

| I | Measurement model for the client dimension | |||||

| O1 | Unclear definition of requirement | 0.57 | 0.28 | 0.16 | 5 | 0.877 |

| O2 | Lack of personnel | 0.36 | 0.31 | 0.11 | 8 | |

| O3 | Change in decisions | 0.67 | 0.31 | 0.21 | 3 | |

| O4 | Poor departmental communication | 0.72 | 0.32 | 0.23 | 2 | |

| O5 | Delayed schedule and late payment | 0.55 | 0.26 | 0.14 | 6 | |

| O6 | Complex contracting procedures | 0.61 | 0.33 | 0.20 | 4 | |

| O7 | Difficulties in design–construction coordination | 0.69 | 0.34 | 0.23 | 2 | |

| O8 | Difficulties in quality control with low budget | 0.68 | 0.31 | 0.21 | 3 | |

| O9 | Late submission of re-modified or approved documents | 0.77 | 0.35 | 0.27 | 1 | |

| O10 | Late completion due to design–construction interface problems | 0.70 | 0.33 | 0.23 | 2 | |

| O11 | Insufficient information on health and safety facilities | 0.43 | 0.31 | 0.13 | 7 | |

| II | Measurement model for the design dimension | |||||

| D1 | Insufficient design time | 0.76 | 0.27 | 0.21 | 7 | 0.907 |

| D2 | Insufficient design information | 0.83 | 0.35 | 0.29 | 1 | |

| D3 | Insufficient number of designers | 0.75 | 0.34 | 0.26 | 3 | |

| D4 | Lack of experience and knowledge | 0.81 | 0.30 | 0.24 | 5 | |

| D5 | Insufficient understanding of the actual construction procedures | 0.73 | 0.36 | 0.26 | 3 | |

| D6 | Lack of a design standard | 0.67 | 0.35 | 0.23 | 6 | |

| D7 | Lack of communication and coordination in the design–construction interface | 0.69 | 0.40 | 0.28 | 2 | |

| D8 | Incomprehensive coordination in the design–construction interface | 0.71 | 0.35 | 0.25 | 4 | |

| D9 | Insufficient budget | 0.70 | 0.27 | 0.19 | 8 | |

| D10 | Interference from commissioned designers | 0.62 | 0.30 | 0.19 | 9 | |

| D11 | Un-quantified health and safety facilities | 0.55 | 0.31 | 0.17 | 10 | |

| III | Measurement model for the contractor dimension | |||||

| C1 | Insufficient construction time | 0.56 | 0.39 | 0.22 | 7 | 0.917 |

| C2 | Low-price contracting | 0.58 | 0.42 | 0.24 | 6 | |

| C3 | Lack of communication and coordination in the design–construction interface | 0.62 | 0.41 | 0.25 | 5 | |

| C4 | Insufficient competencies of construction workers | 0.79 | 0.34 | 0.27 | 4 | |

| C5 | Failure to integrate construction equipment, materials, and techniques | 0.77 | 0.41 | 0.32 | 1 | |

| C6 | Work correction due to incorrect construction operations | 0.81 | 0.36 | 0.29 | 2 | |

| C7 | Inappropriate scheduling of construction operations | 0.80 | 0.34 | 0.27 | 4 | |

| C8 | Poor on-site supervision and management | 0.81 | 0.39 | 0.32 | 1 | |

| C9 | Incorrect construction operations due to careless reading of construction drawings | 0.79 | 0.36 | 0.28 | 3 | |

| C10 | Failure to provide a detailed construction diagram | 0.73 | 0.33 | 0.24 | 5 | |

| C11 | Perfunctory establishment of health and safety facilities | 0.72 | 0.32 | 0.23 | 6 | |

| C12 | Insufficient finances | 0.64 | 0.27 | 0.17 | 8 | |

| IV | Measurement model for the subcontractor dimension | |||||

| SC1 | Lack of specialized labor | 0.70 | 0.35 | 0.25 | 5 | 0.893 |

| SC2 | Lack of on-site workers | 0.57 | 0.34 | 0.19 | 7 | |

| SC3 | Lack of correct concepts of health and safety | 0.73 | 0.38 | 0.28 | 3 | |

| SC4 | Poor communication and coordination with contractors | 0.71 | 0.38 | 0.27 | 4 | |

| SC5 | Late payment requests | 0.45 | 0.29 | 0.13 | 8 | |

| SC6 | Work correction due to incorrect construction operations caused by careless reading of construction drawings | 0.75 | 0.42 | 0.32 | 1 | |

| SC7 | Lack of educational training for operators | 0.84 | 0.34 | 0.29 | 2 | |

| SC8 | Ignorance of construction work ethics | 0.70 | 0.31 | 0.22 | 6 | |

| SC9 | Poor on-site management | 0.77 | 0.38 | 0.29 | 2 | |

| SC10 | Construction operations conducted according to personal experience and in violation of relevant regulations | 0.75 | 0.29 | 0.22 | 6 | |

| V | Measurement model for the external factor dimension | |||||

| Ex1 | Political environment | 0.52 | 0.29 | 0.15 | 6 | 0.882 |

| Ex2 | Economic environment | 0.51 | 0.27 | 0.14 | 7 | |

| Ex3 | Force majeure events | 0.48 | 0.36 | 0.17 | 5 | |

| Ex4 | Source of material supply | 0.64 | 0.35 | 0.22 | 3 | |

| Ex5 | Client requirements | 0.59 | 0.32 | 0.19 | 5 | |

| Ex6 | Legal restrictions | 0.66 | 0.36 | 0.24 | 1 | |

| Ex7 | Manufacturing techniques | 0.75 | 0.31 | 0.23 | 2 | |

| Ex8 | Predatory pricing by competitors | 0.67 | 0.25 | 0.17 | 5 | |

| Ex9 | Creditor requirements | 0.73 | 0.27 | 0.20 | 4 | |

| Ex10 | Contractors’ low cash flow caused by late payment | 0.61 | 0.25 | 0.15 | 6 | |

| Model Fit Index | Acceptable Range (No Fit to Perfect Fit) | SEM Measurement Models for the Five Dimensions | Structural Model for the Five Dimensions | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Client Dimension | Design Dimension | Contractor Dimension | Subcontractor Dimension | External Factor Dimension | ||||||||

| Initial Model | Final Model | Initial Model | Final Model | Initial Model | Final Model | Initial Model | Final Model | Initial Model | Final Model | |||

| χ2/df | 5 to 1 | 4.454 | 1.579 | 7.491 | 2.358 | 4.214 | 2.985 | 6.365 | 1.351 | 6.308 | 2.502 | 2.216 |

| GFI | 0 to 1 | 0.853 | 0.986 | 0.768 | 0.953 | 0.831 | 0.942 | 0.787 | 0.977 | 0.834 | 0.988 | 0.760 |

| CFI | 0 to 1 | 0.828 | 0.993 | 0.801 | 0.978 | 0.887 | 0.968 | 0.838 | 0.995 | 0.769 | 0.990 | 0.879 |

| RMR | 1 to 0 | 0.090 | 0.030 | 0.095 | 0.046 | 0.080 | 0.040 | 0.091 | 0.028 | 0.113 | 0.037 | 0.095 |

| SRMR | 1 to 0 | 0.071 | 0.024 | 0.075 | 0.036 | 0.064 | 0.033 | 0.079 | 0.023 | 0.083 | 0.026 | 0.074 |

| CR | ~ ≧ 0.7 | 0.872 | 0.856 | 0.914 | 0.916 | 0.910 | 0.919 | 0.894 | 0.895 | 0.861 | 0.823 | ~ |

| AVE | ~ ≧ 0.5 | 0.413 | 0.503 | 0.532 | 0.548 | 0.508 | 0.588 | 0.462 | 0.520 | 0.387 | 0.543 | ~ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.-L.; Chen, B.-K. Research for Risk Management of Construction Projects in Taiwan. Sustainability 2021, 13, 2034. https://doi.org/10.3390/su13042034

Lin C-L, Chen B-K. Research for Risk Management of Construction Projects in Taiwan. Sustainability. 2021; 13(4):2034. https://doi.org/10.3390/su13042034

Chicago/Turabian StyleLin, Chien-Liang, and Bey-Kun Chen. 2021. "Research for Risk Management of Construction Projects in Taiwan" Sustainability 13, no. 4: 2034. https://doi.org/10.3390/su13042034

APA StyleLin, C.-L., & Chen, B.-K. (2021). Research for Risk Management of Construction Projects in Taiwan. Sustainability, 13(4), 2034. https://doi.org/10.3390/su13042034