Building Envelope Thermal Defects in Existing and Under-Construction Housing in the UAE; Infrared Thermography Diagnosis and Qualitative Impacts Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Thermal Imaging and Building Envelope

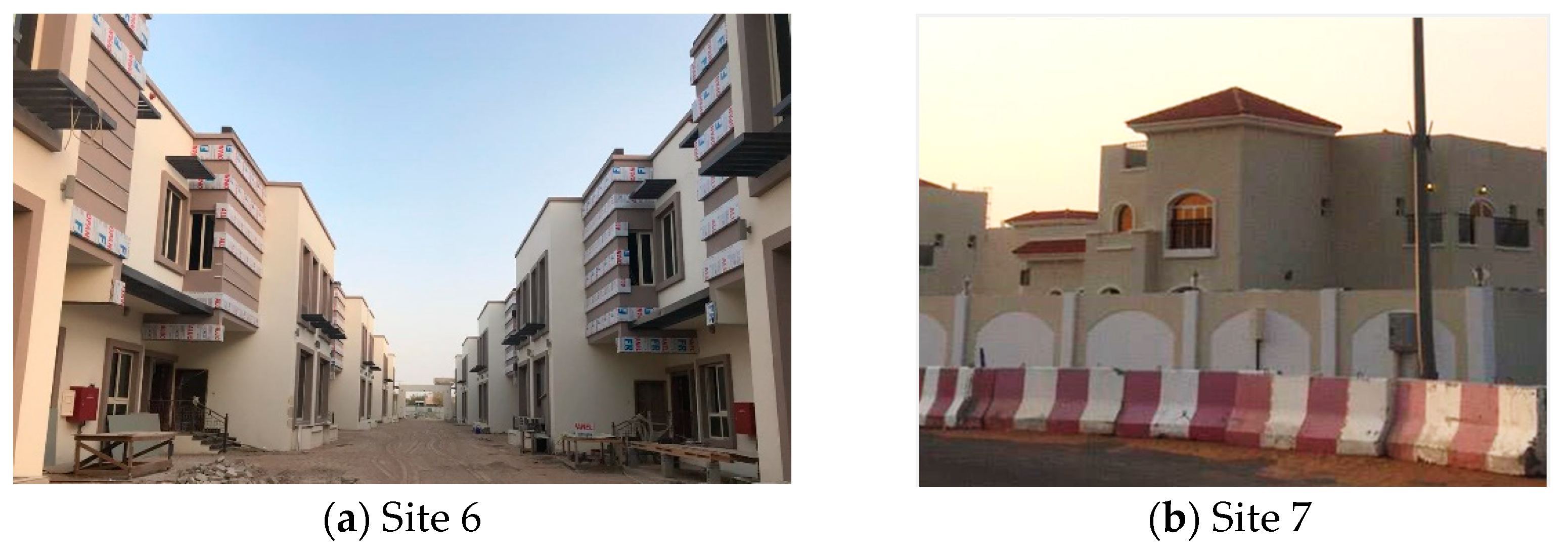

2.2. Case Studies

2.3. Testing Procedure

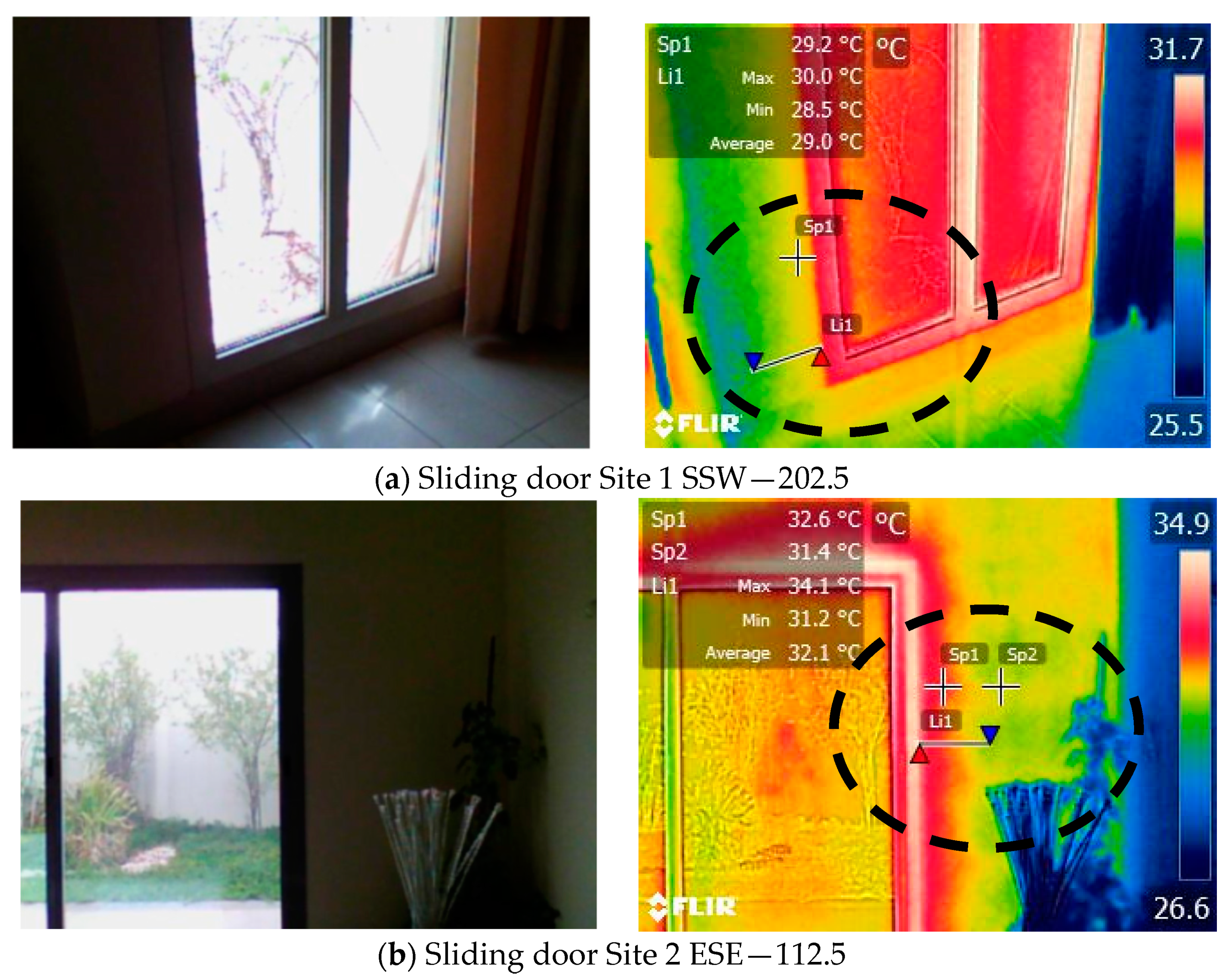

3. Results of Field Investigation: Building Defects Detection through Thermal Imaging

3.1. Construction Quality in Existing Buildings

3.2. Uninsulated Structural Elements

3.3. Blockwork Defects

3.4. Design Discrepencies

4. Qualitative Impacts Analysis of Identified Building and Construction Defects

4.1. Non-Insulated Building Envelope

4.2. Thermal Bridging

4.2.1. Impacts on Energy

4.2.2. Impacts on Health and User Comfort

4.3. Construction Quality and Workmanship

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Berardi, U. A Cross-Country Comparison of the Building Energy Consumptions and Their Trends. Resour. Conserv. Recycl. 2017, 123. [Google Scholar] [CrossRef]

- Bidwai, P. The Emerging Economies and Climate Change: A Case Study of the BASIC Grouping. In Shifting Power—Critical Perspectives on Emerging Economies. 2014. Available online: https://www.tni.org/en/search/field_publication_series/shifting-power-critical-perspectives-on-emerging-economies-44/language/en (accessed on 30 October 2020).

- Allouhi, A.; El Fouih, Y.; Kousksou, T.; Jamil, A.; Zeraouli, Y.; Mourad, Y. Energy Consumption and Efficiency in Buildings: Current Status and Future Trends. J. Clean. Prod. 2015, 109. [Google Scholar] [CrossRef]

- World Population Review. United Arab Emirates Population. Available online: https://worldpopulationreview.com/countries/united-arab-emirates-population. (accessed on 14 November 2020).

- Elessawy, F.M. The Boom: Population and Urban Growth of Dubai City. Horizons Hum. Soc. Sci. 2017, 2. [Google Scholar] [CrossRef]

- The World Bank. Urban Population (% of Total Population). United Arab Emirates. Available online: https://data.worldbank.org/indicator/SP.URB.TOTL.IN.ZS?locations=AE. (accessed on 14 November 2020).

- Shahbaz, M.; Sbia, R.; Hamdi, H.; Ozturk, I. Economic Growth, Electricity Consumption, Urbanization and Environmental Degradation Relationship in United Arab Emirates. Ecol. Indic. 2014, 45. [Google Scholar] [CrossRef]

- World Energy Council. World Energy Trilemma Index|2020. Available online: https://www.worldenergy.org/publications/entry/world-energy-trilemma-index-2020 (accessed on 1 December 2020).

- A.C. Overview. UAE Construction Analytic Reports & Forecasts. Available online: https://www.bncnetwork.net/Access-UAE-Construction-Projects-News-Analytic-Reports-and-Forecasts (accessed on 1 December 2020).

- Abu Dhabi Government Statistics Center. Statistical Yearbook Energy and Water. Available online: https://www.scad.gov.ae/Release Documents/Statistical Yearbook Energy and Water_2019_Annual_Yearly_en.pdf (accessed on 30 October 2020).

- Energy Information Administration. Country Analysis Executive Summary: United Arab Emirates. Available online: https://www.eia.gov/international/content/analysis/countries_long/United_Arab_Emirates/uae_2020.pdf (accessed on 30 October 2020).

- St. Clair, P. Low-Energy Design in the United Arab Emirates—Building Principles; Royal Australian Institute of Architects: Melbourne, Australia, 2009. [Google Scholar]

- Friess, W.A.; Rakhshan, K.; Hendawi, T.A.; Tajerzadeh, S. Wall Insulation Measures for Residential Villas in Dubai: A Case Study in Energy Efficiency. Energy Build. 2012, 44. [Google Scholar] [CrossRef]

- Department of Municipalities and Transport. Pearl Building Rating System. Available online: https://www.dmt.gov.ae/en/Urban-Planning/Pearl-Building-Rating-System (accessed on 30 October 2020).

- Department of Urban Planning and Municipalities. Estidama Insulation Products and Systems for PEARL Villa Rating. Available online: http://estidama.upc.gov.ae/estidama-villa-products-database/insulationproducts (accessed on 14 November 2020).

- Efird, B.; Griffiths, S.; Mollet, P.; Al-Mubarak, I.; Sgouridis, S.; Tsai, I. The Political Feasibility of Policy Options for the UAE’s Energy Transition; King Abdullah Petroleum Studies and Research Center: Riyadh, Saudi Arabia, 2017. [Google Scholar]

- Motaleb, O.; Kishk, M. An Investigation into Causes and Effects of Construction Delays in UAE. Association of Researchers in Construction Management, ARCOM 2010. In Proceedings of the 26th Annual Conference, Leeds, UK, 24 January 2010. [Google Scholar]

- AL Mousli, M.H.; El-Sayegh, S.M. Assessment of the Design–Construction Interface Problems in the UAE. Archit. Eng. Des. Manag. 2016, 12. [Google Scholar] [CrossRef]

- Johnson, R.M.; Babu, R.I.I. Time and Cost Overruns in the UAE Construction Industry: A Critical Analysis. Int. J. Constr. Manag. 2020, 20. [Google Scholar] [CrossRef]

- Tabet Aoul, K.A.; Hagi, R.; Abdelghani, R.; Akhozheya, B.; Karaouzene, R.; Syam, M. The Existing Residential Building Stock in UAE: Energy Efficiency and Retrofitting Opportunities. Proc. Annu. Int. Conf. Archit. Civil. Eng. 2018. [Google Scholar] [CrossRef]

- Mwasha, A.; Williams, R.G.; Iwaro, J. Modeling the Performance of Residential Building Envelope: The Role of Sustainable Energy Performance Indicators. Energy Build. 2011, 43. [Google Scholar] [CrossRef]

- Alencastro, J.; Fuertes, A.; de Wilde, P. The Relationship between Quality Defects and the Thermal Performance of Buildings. Renew. Sustain. Energy Rev. 2018. [Google Scholar] [CrossRef]

- Gupta, R.; Kotopouleas, A. Magnitude and Extent of Building Fabric Thermal Performance Gap in UK Low Energy Housing. Appl. Energy 2018, 222. [Google Scholar] [CrossRef]

- Macarulla, M.; Forcada, N.; Casals, M.; Gangolells, M.; Fuertes, A.; Roca, X. Standardizing Housing Defects: Classification, Validation, and Benefits. J. Constr. Eng. Manag. 2013. [Google Scholar] [CrossRef]

- Forcada, N.; Macarulla, M.; Gangolells, M.; Casals, M. Handover Defects: Comparison of Construction and Post-Handover Housing Defects. Build. Res. Inf. 2016, 44, 279–288. [Google Scholar] [CrossRef]

- Forcada, N.; Macarulla, M.; Gangolells, M.; Casals, M.; Fuertes, A.; Roca, X. Posthandover Housing Defects: Sources and Origins. J. Perform. Constr. Facil. 2013. [Google Scholar] [CrossRef]

- Josephson, P.E.; Hammarlund, Y. Causes and Costs of Defects in Construction a Study of Seven Building Projects. Autom. Constr. 1999. [Google Scholar] [CrossRef]

- Forcada, N.; Macarulla, M.; Love, P.E.D. Assessment of Residential Defects at Post-Handover. J. Constr. Eng. Manag. 2013, 139. [Google Scholar] [CrossRef]

- Bianchi, F.; Pisello, A.L.; Baldinelli, G.; Asdrubali, F. Infrared Thermography Assessment of Thermal Bridges in Building Envelope: Experimental Validation in a Test Room Setup. Sustainability 2014, 6. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A.; Christou, P.; Kalogirou, S.A. Infrared Thermography (IRT) Applications for Building Diagnostics: A Review. Appl. Energy 2014. [Google Scholar] [CrossRef]

- Dall’O’, G.; Sarto, L.; Panza, A. Infrared Screening of Residential Buildings for Energy Audit Purposes: Results of a Field Test. Energies 2013, 6. [Google Scholar] [CrossRef]

- Fox, M.; Goodhew, S.; De Wilde, P. Building Defect Detection: External versus Internal Thermography. Build. Environ. 2016, 105. [Google Scholar] [CrossRef]

- O’Grady, M.; Lechowska, A.A.; Harte, A.M. Infrared Thermography Technique as an In-Situ Method of Assessing Heat Loss through Thermal Bridging. Energy Build. 2017, 135. [Google Scholar] [CrossRef]

- Hopper, J.; Littlewood, J.R.; Taylor, T.; Counsell, J.A.M.; Thomas, A.M.; Karani, G.; Geens, A.; Evans, N.I. Assessing Retrofitted External Wall Insulation Using Infrared Thermography. Struct. Surv. 2012, 30. [Google Scholar] [CrossRef]

- Taylor, T.; Counsell, J.; Gill, S. Energy Efficiency Is More than Skin Deep: Improving Construction Quality Control in New-Build Housing Using Thermography. Energy Build. 2013, 66. [Google Scholar] [CrossRef]

- Littlewood, R.J. Chapter 4—Assessing and Monitoring the Thermal Performance of Dwellings. In Architectural Technology: Research in Practice; Emmitt, S., Ed.; Wiley-Blackwell: Oxford, UK, 2013. [Google Scholar]

- FLIR Systems. Thermal Imaging Guidebook for Building and Renewable Energy Applications; FLIR: Wilsonville, OR, USA, 2011. [Google Scholar]

- Bauer, E.; Pavón, E.; Barreira, E.; De Castro, E.K. Analysis of Building Facade Defects Using Infrared Thermography: Laboratory Studies. J. Build. Eng. 2016, 6. [Google Scholar] [CrossRef]

- British Standard BS EN. Thermal Performance of Buildings. Qualitative Detection of Thermal Irregularities in Building Envelopes. Infrared Method; BSI: Brussels, Belgium, 1999. [Google Scholar]

- Mathur, S.S.; Umesh, G.; Seth, A.K.; Sharma, R.P.; Kaushik, S.C. Periodic Heating/Cooling by Solar Radiation. In Sun: Mankind’s Future Source of Energy; Elsevier: Amsterdam, The Netherlands, 1978. [Google Scholar]

- Kirimtat, A.; Krejcar, O. A Review of Infrared Thermography for the Investigation of Building Envelopes: Advances and Prospects. Energy Build. 2018. [Google Scholar] [CrossRef]

- Yu, S.; Liu, Y.; Wang, D.; Bahaj, A.B.S.; Wu, Y.; Liu, J. Review of Thermal and Environmental Performance of Prefabricated Buildings: Implications to Emission Reductions in China. Renew. Sustain. Energy Rev. 2020. [Google Scholar] [CrossRef]

- Radhi, H.; Eltrapolsi, A.; Sharples, S. Will Energy Regulations in the Gulf States Make Buildings More Comfortable—A Scoping Study of Residential Buildings. Appl. Energy 2009, 86. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M.F. Effect of Thermal Bridges on Transmission Loads and Thermal Resistance of Building Walls under Dynamic Conditions. Appl. Energy 2012, 98. [Google Scholar] [CrossRef]

- Bojić, M.; Djordjević, S.; Stefanović, A.; Miletić, M.; Cvetković, D. Decreasing Energy Consumption in Thermally Non-Insulated Old House via Refurbishment. Energy Build. 2012, 54. [Google Scholar] [CrossRef]

- AlNaqbi, A.; AlAwadhi, W.; Manneh, A.; Kazim, A.; Abu-Hijleh, B. Survey of the Existing Residential Buildings Stock in the UAE. Int. J. Environ. Sci. Dev. 2012. [Google Scholar] [CrossRef]

- Ibrahim, M.; Biwole, P.H.; Wurtz, E.; Achard, P. Limiting Windows Offset Thermal Bridge Losses Using a New Insulating Coating. Appl. Energy 2014, 123. [Google Scholar] [CrossRef]

- Evangelisti, L.; Guattari, C.; Gori, P. Energy Retrofit Strategies for Residential Building Envelopes: An Italian Case Study of an Early-50s Building. Sustainability 2015, 7, 445. [Google Scholar] [CrossRef]

- Akhozheya, B.; Syam, M.; Abdelghani, R.; Aoul, K.A.T. Retrofit Evaluation of a Residential Building in UAE: Energy Efficiency and Renewable Energy. In Proceedings of the 5th International Conference on Renewable Energy: Generation and Application, ICREGA 2018, Al Ain, United Arab Emirates, 26–28 February 2018. [Google Scholar]

- Khoukhi, M.; Darsaleh, A.F.; Ali, S. Retrofitting an Existing Office Building in the UAE towards Achieving Low-Energy Building. Sustainability 2020, 12, 2573. [Google Scholar] [CrossRef]

- Jahed, N.; Aktaş, Y.D.; Rickaby, P.; Altinöz, A.G.B. Policy Framework for Energy Retrofitting of Built Heritage: A Critical Comparison of UK and Turkey. Atmosphere 2020, 11, 674. [Google Scholar] [CrossRef]

- Aktacir, M.A.; Büyükalaca, O.; Yilmaz, T. A Case Study for Influence of Building Thermal Insulation on Cooling Load and Air-Conditioning System in the Hot and Humid Regions. Appl. Energy 2010, 87. [Google Scholar] [CrossRef]

- Brannigan, A.; Booth, C.A. Building Envelop Energy Efficient Retrofitting Options for Domestic Buildings in the UK. WIT Trans. Ecol. Environ. 2013, 179. [Google Scholar] [CrossRef]

- Altun, M.; Akgul, C.M.; Akcamete, A. Effect of Envelope Insulation on Building Heating Energy Requirement, Cost and Carbon Footprint from a Life Cycle Perspective. J. Fac. Eng. Archit. Gazi Univ. 2020, 35. [Google Scholar] [CrossRef]

- Zedan, M.F.; Al-Sanea, S.; Al-Mujahid, A.; Al-Suhaibani, Z. Effect of Thermal Bridges in Insulated Walls on Air-Conditioning Loads Using Whole Building Energy Analysis. Sustainability 2016, 8, 560. [Google Scholar] [CrossRef]

- Erdem, C.; Pinar, M.C. The Impact of Internal Aerogel Retrofitting on the Thermal Bridges of Residential Buildings: An Experimental and Statistical Research. Energy Build. 2016. [Google Scholar] [CrossRef]

- Theodosiou, T.; Tsikaloudaki, K.; Bikas, D. Analysis of the Thermal Bridging Effect on Ventilated Facades. Procedia Environ. Sci. 2017. [Google Scholar] [CrossRef]

- Johnston, D.; Miles-Shenton, D.; Farmer, D. Quantifying the Domestic Building Fabric “Performance Gap”. Build. Serv. Eng. Res. Technol. 2015, 36. [Google Scholar] [CrossRef]

- Real, S.; Gomes, M.G.; Moret Rodrigues, A.; Bogas, J.A. Contribution of Structural Lightweight Aggregate Concrete to the Reduction of Thermal Bridging Effect in Buildings. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Theodosiou, T.; Tsikaloudaki, K.; Tsoka, S.; Chastas, P. Thermal Bridging Problems on Advanced Cladding Systems and Smart Building Facades. J. Clean. Prod. 2019. [Google Scholar] [CrossRef]

- Kiil, M.; Käärid, M.S.; Klõšeiko, P.; Võsa, K.V.; Simson, R.; Sarevet, H.; Thalfeldt, M.; Kurnitski, J. PCSP’s Diagonal Tie Connectors Thermal Bridges Impact on Energy Performance and Operational Cost: Case Study of a High-Rise Residential Building in Estonia. In E3S Web of Conferences; EDP Sciences: London, UK, 2020. [Google Scholar]

- Liu, Y.; Li, B.; Cao, X. The Research on the Influence of Building Air Tightness to Energy Consumption of Residential Building in a Hot Summer and Cold Winter Zone in China. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 609. [Google Scholar]

- Cappelletti, F.; Gasparella, A.; Romagnoni, P.; Baggio, P. Analysis of the Influence of Installation Thermal Bridges on Windows Performance: The Case of Clay Block Walls. Energy Build. 2011. [Google Scholar] [CrossRef]

- Marincioni, V.; Altamirano-Medina, H.; May, N.; Sanders, C. Estimating the Impact of Reveals on the Transmission Heat Transfer Coefficient of Internally Insulated Solid Wall Dwellings. Energy Build. 2016. [Google Scholar] [CrossRef]

- Jedidi, M.; Benjeddou, O. Effect of Thermal Bridges on the Heat Balance of Buildings. IJSRCE 2018, 2, 41–49. [Google Scholar]

- Al-Sayed Omar, E. Impact of Columns and Beams on the Thermal Resistance of the Building Envelope; Energy Systems Laboratory: College Station, TX, USA, 2002; Available online: http://esl.tamu.edu (accessed on 30 October 2020).

- Levinskyte, A.; Banionis, K.; Geleziunas, V. The Influence of Thermal Bridges for Buildings Energy Consumption of “A“ Energy Efficiency Class. J. Sustain. Archit. Civ. Eng. 2016, 15, 47–58. [Google Scholar] [CrossRef][Green Version]

- Dynamic Effect of Thermal Bridges on the Energy Performance of Residential Buildings; Concordia University: Montreal, QC, Canada, 2015.

- Kotti, S.; Teli, D.; James, P.A.B. Quantifying Thermal Bridge Effects and Assessing Retrofit Solutions in a Greek Residential Building. Procedia Environ. Sci. 2017. [Google Scholar] [CrossRef]

- Karabulut, K.; Buyruk, E.; Fertelli, A. Numerical Investigation of Heat Transfer for Thermal Bridges Taking into Consideration Location of Thermal Insulation with Different Geometries. Stroj. Časopis Teor. Praksu Stroj. 2009, 51, 431–439. [Google Scholar]

- Evola, G.; Margani, G.; Marletta, L. Energy and Cost Evaluation of Thermal Bridge Correction in Mediterranean Climate. Energy Build. 2011. [Google Scholar] [CrossRef]

- Kaymaz, E.; Sezer, F.S. Thermal Performance Assessment of Existing Buildings: A Case Study from Turkey. Int. J. Humanit. Soc. Sci. 2015, 6, 43–54. [Google Scholar]

- Collins, M.; Dempsey, S. Residential Energy Efficiency Retrofits: Potential Unintended Consequences. J. Environ. Plan. Manag. 2019. [Google Scholar] [CrossRef]

- Ilomets, S.; Kalamees, T. Evaluation of the Criticality of Thermal Bridges. J. Build. Pathol. Rehabil. 2016. [Google Scholar] [CrossRef]

- Miasik, P.; Lichołai, L. The Influence of a Thermal Bridge in the Corner of the Walls on the Possibility of Water Vapour Condensation. In E3S Web of Conferences; EDP Sciences: London, UK, 2018. [Google Scholar]

- Willand, N.; Ridley, I.; Maller, C. Towards Explaining the Health Impacts of Residential Energy Efficiency Interventions—A Realist Review. Part 1: Pathways. Soc. Sci. Med. 2015. [Google Scholar] [CrossRef] [PubMed]

- Al-Alili, A.; Al Qubaisi, A. Efficient Residential Buildings in Hot and Humid Regions: The Case of Abu Dhabi, UAE. Int. J. Therm. Environ. Eng. 2018, 17. [Google Scholar] [CrossRef]

- Ali, M.; Oladokun, M.O.; Osman, S.B.; Samsuddin, N.; Hamzah, H.A. Moisture Condensation on Building Envelopes in Differential Ventilated Spaces in the Tropics: Quantitative Assessment of Influencing Factors. In MATEC Web of Conferences; EDP Sciences: London, UK, 2016; Volume 66. [Google Scholar]

- WHO Regional Office for Europe. WHO Guidelines for Indoor Air Quality: Dampness and Mould—WHO Regional Office for Europe, World Health Organization—Google Books; Heseltine, E., Rosen, J.J., Eds.; World Health Organisation: Geneva, Switzerland, 2009. [Google Scholar]

- Choudhry, R.M.; Gabriel, H.F.; Khan, M.K.; Azhar, S. Causes of Discrepancies between Design and Construction in the Pakistan Construction Industry. J. Constr. Dev. Ctries 2017, 22. [Google Scholar] [CrossRef]

- Han, S.; Love, P.; Peña-Mora, F. A System Dynamics Model for Assessing the Impacts of Design Errors in Construction Projects. Math. Comput. Model 2013. [Google Scholar] [CrossRef]

- Oyewobi, L.O.; Oke, A.A.; Ganiyu, B.O.; Shittu, A.A.; Isa, R.B.; Nwokobia, L. The Effect of Project Types on the Occurrence of Rework in Expanding Economy. J. Civ. Eng. Constr. Technol. 2011, 2, 119–124. [Google Scholar]

- Love, P.E.D.; Li, H. Quantifying the Causes and Costs of Rework in Construction. Constr. Manag. Econ. 2000, 18. [Google Scholar] [CrossRef]

- Fayek, A.R.; Dissanayake, M.; Campero, O. Developing a Standard Methodology for Measuring and Classifying Construction Field Rework. Can. J. Civ. Eng. 2004. [Google Scholar] [CrossRef]

- Josephson, P.-E.; Larsson, B.; Li, H. Illustrative Benchmarking Rework and Rework Costs in Swedish Construction Industry. J. Manag. Eng. 2002. [Google Scholar] [CrossRef]

- Georgiou, J. Verification of a Building Defect Classification System for Housing. Struct. Surv. 2010. [Google Scholar] [CrossRef]

- Forcada, N.; MacArulla, M.; Gangolells, M.; Casals, M. Assessment of Construction Defects in Residential Buildings in Spain. Build. Res. Inf. 2014, 42. [Google Scholar] [CrossRef]

- Aïssani, A.; Chateauneuf, A.; Fontaine, J.P.; Audebert, P. Quantification of Workmanship Insulation Defects and Their Impact on the Thermal Performance of Building Facades. Appl. Energy 2016, 165. [Google Scholar] [CrossRef]

- de Wilde, P.; Tian, W.; Augenbroe, G. Longitudinal Prediction of the Operational Energy Use of Buildings. Build. Environ. 2011, 46. [Google Scholar] [CrossRef]

- Zero Carbon Hub. Closing the Gap between Design and As-Built Performance, End of Term Report. 2014. Available online: https://www.zerocarbonhub.org/sites/default/files/resources/reports/Closing_the_Gap_Bewteen_Design_and_As-Built_Performance_Interim_Report.pdf (accessed on 30 October 2020).

- Zero Carbon Hub. Closing the Gap between Design and As-Built Performance—Evidence Review Report. 2014. Available online: https://www.zerocarbonhub.org/sites/default/files/resources/reports/Closing_the_Gap_Between_Design_and_As-Built_Performance-Evidence_Review_Report_0.pdf (accessed on 30 October 2020).

- Oreszczyn, T.; Mumovic, D.; Davies, M.; Ridley, I.; Bell, M.; Smith, M.; Miles-Shenton, D. ‘Condensation Risk—Impact of Improvements to Part L and Robust Details on Part C’, Final Report; Office of the Deputy Prime Minister: London, UK, 2005. [Google Scholar]

- The “Warm Houses” Program: Insulating Existing Buildings through Compulsory Retrofits. Sustain. Energy Technol. Assess. 2015, 9. [CrossRef]

- Lucchi, E. Applications of the Infrared Thermography in the Energy Audit of Buildings: A Review. Renew. Sustain. Energy Rev. 2018. [Google Scholar] [CrossRef]

- Underhill, L.J.; Milando, C.W.; Levy, J.I.; Dols, W.S.; Lee, S.K.; Fabian, M.P. Simulation of Indoor and Outdoor Air Quality and Health Impacts Following Installation of Energy-Efficient Retrofits in a Multifamily Housing Unit. Build. Environ. 2020. [Google Scholar] [CrossRef]

- Al-Homoud, M.S. The Effectiveness of Thermal Insulation in Different Types of Buildings in Hot Climates. J. Build. Phys. 2004, 27. [Google Scholar] [CrossRef]

- Sustainability and Green Building Rating Systems: LEED, BREEAM, GSAS and Estidama Critical Analysis. J. Build. Eng. 2017. [CrossRef]

- Zhang, L.; Liu, Z.; Hou, C.; Hou, J.; Wei, D.; Hou, Y. Optimization Analysis of Thermal Insulation Layer Attributes of Building Envelope Exterior Wall Based on DeST and Life Cycle Economic Evaluation. Case Stud. Therm. Eng. 2019. [Google Scholar] [CrossRef]

- Baba, F.; Ge, H. Dynamic Effect of Balcony Thermal Bridges on the Energy Performance of a High-Rise Residential Building in Canada. Energy Build. 2016, 116. [Google Scholar] [CrossRef]

- Finch, G.; Wilson, M.; Higgins, J. Thermal Bridging Of Masonry Veneer Claddings & Energy Code Compliance; ASTM International: Philadelphia, PA, USA, 2013. [Google Scholar]

- Özdeniz, M.B.; Hançer, P. Suitable Roof Constructions for Warm Climates—Gazimǎusa Case. Energy Build. 2005. [Google Scholar] [CrossRef]

- Seppänen, O.; Kurnitski, J. Moisture Control and Ventilation. In WHO Guidelines for Indoor Air Quality: Dampness and Mould; WHO: Geneva, Switzerland, 2009. [Google Scholar]

- Bani Mfarrej, M.F.; Qafisheh, N.A.; Bahloul, M.M. Investigation of Indoor Air Quality inside Houses From UAE. Air Soil Water Res. 2020, 13. [Google Scholar] [CrossRef]

- Mohamad, M.I.; Nekooie, M.A.; Al-Harthy, A.B.S. Design Changes in Residential Reinforced Concrete Buildings: The Causes, Sources, Impacts and Preventive Measures. J. Constr. Dev. Ctries 2012, 17, 23–44. [Google Scholar]

- van Dronkelaar, C.; Dowson, M.; Spataru, C.; Mumovic, D. A Review of the Regulatory Energy Performance Gap and Its Underlying Causes in Non-Domestic Buildings. Front. Mech. Eng. 2016, 1. [Google Scholar] [CrossRef]

- Palmer, J.; Godoy-Shimizu, D.; Tillson, A.; Mawditt, I. Building Performance Evaluation Programme: Findings from Domestic Projects—Making Reality Match Design; Innovate: London, UK, 2016. [Google Scholar]

- Qi, Y.; Qian, Q.K.; Meijer, F.M.; Visscher, H.J. Identification of Quality Failures in Building Energy Renovation Projects in Northern China. Sustainability 2019, 11, 4203. [Google Scholar] [CrossRef]

| Building Status | General Information | Building Phase | N. of Tested Units | Construction Method | |

|---|---|---|---|---|---|

| Existing Buildings (pre-energy efficiency code) | Site 1 | Attached and semi-attached units/residential compound/196 units | Existing building competed in 1999 | 5 units | Non-insulated concrete blockwork infill with reinforced concrete post and beam structural system |

| Site 2 | Semi-attached units/residential compound/30 units | Existing building completed in 2011 | 2 units | ||

| Under-construction buildings (post-energy efficiency code) | Site 3 | Single-family house/two levels | Under construction—blockwork stage | 1 unit | Insulated concrete blockwork infill with reinforced concrete post and beam structural |

| Site 4 | Single-family house/Three levels | Under construction—finishing stage | 1 unit | ||

| Site 5 | Single-family house/two levels | Under construction—blockwork stage | 1 unit | ||

| Site 6 | Semi-attached units/residential compound/80 units | Under construction—blockwork stage | 6 units | ||

| Site 7 | Detached unit/residential compound/300 units | Handover stage | 3 units | Insulated precast concrete panel and frame |

| Construction Defects | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Site | Construction Quality | Non-Insulated Structural Elements | Blockwork Defects | Design Change/ Discrepancies | |||||||||

| Existing buildings | Site 1 | ||||||||||||

| Site 2 | |||||||||||||

| Buildings under construction | Site 3 | ||||||||||||

| Site 4 | |||||||||||||

| Site 5 | |||||||||||||

| Site 6 | |||||||||||||

| Site 7 | |||||||||||||

| Defect Type | Location | Origin | Source of Error | Impact |

|---|---|---|---|---|

| Missing insulation | Exterior Walls Roof | Lack of code (existing building prior to energy code implementation in 2010) | Heat gain | |

| Insulation discontinuity | Design change Workmanship | Using non-insulated blocks | Thermal bridging | |

| Structural–wall junction | Exterior Walls | Non-insulated structural elements (column, beam) | Thermal bridging | |

| Window–wall junction | Exterior Walls | Workmanship | Poor sealing | Thermal bridging |

| Blockwork defects | Exterior Walls | Workmanship | Oversize electric services Oversize mortar joints between blocks | Thermal bridging |

| Construction Defects | Impacts | References |

|---|---|---|

| Lack of insulation and energy standards | Energy | [13,20,45,46,47,48,49,50,51] |

| Cost | [52,53,54] | |

| Comfort | [13] | |

| Thermal bridging | Energy through walls | [55,56,57,58,59,60,61] |

| Energy through windows and openings | [47,62,63,64] | |

| Energy through building junctions | [29,65,66,67,68,69,70,71,72] | |

| Comfort and health | [56,72,73,74,75,76,77,78,79] | |

| Design discrepancies | Workmanship quality | [24,28,58,80,81,82,83,84,85,86,87,88,89,90,91,92] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tabet Aoul, K.A.; Hagi, R.; Abdelghani, R.; Syam, M.; Akhozheya, B. Building Envelope Thermal Defects in Existing and Under-Construction Housing in the UAE; Infrared Thermography Diagnosis and Qualitative Impacts Analysis. Sustainability 2021, 13, 2230. https://doi.org/10.3390/su13042230

Tabet Aoul KA, Hagi R, Abdelghani R, Syam M, Akhozheya B. Building Envelope Thermal Defects in Existing and Under-Construction Housing in the UAE; Infrared Thermography Diagnosis and Qualitative Impacts Analysis. Sustainability. 2021; 13(4):2230. https://doi.org/10.3390/su13042230

Chicago/Turabian StyleTabet Aoul, Kheira Anissa, Rahma Hagi, Rahma Abdelghani, Monaya Syam, and Boshra Akhozheya. 2021. "Building Envelope Thermal Defects in Existing and Under-Construction Housing in the UAE; Infrared Thermography Diagnosis and Qualitative Impacts Analysis" Sustainability 13, no. 4: 2230. https://doi.org/10.3390/su13042230

APA StyleTabet Aoul, K. A., Hagi, R., Abdelghani, R., Syam, M., & Akhozheya, B. (2021). Building Envelope Thermal Defects in Existing and Under-Construction Housing in the UAE; Infrared Thermography Diagnosis and Qualitative Impacts Analysis. Sustainability, 13(4), 2230. https://doi.org/10.3390/su13042230