Water-to-Cement Ratio of Magnesium Oxychloride Cement Foam Concrete with Caustic Dolomite Powder

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw and Processed Materials

2.2. Brine Test

2.3. MOCFC Test

3. Results and Discussion

3.1. Derivation of Formula (DF)

3.2. Modification of Formula (MF)

3.3. Relationship between the Amount of Water in Brine and Bischofite

3.4. Water-to-Cement Ratio (W/C) with Caustic Dolomite MOC

3.5. Calculation Example

4. Conclusions

- The physical properties of salt lake bischofite dissolved in water were first studied in this research. The P and Ba of MgCl2–H2O formed by bischofite dissolved in water showed a linear growth trend at ambient temperature (20 °C), and the average difference between the two was 0.9.

- The ratio relationship between the mBr and mMO in MOC with dolomite was obtained using the mean difference (Avg.(Bai − Pi = 0.9)) and the MF: mBr/mMO = 2.375 [(x a1 + y a2)/n P (x + y)]. Then, the proportional relationship between the mf added to bischofite was deduced, and the proportional relationship function was obtained: f(mf/mBi) = 1/0.021368 (Ba − 0.9) − 1.

- According to the MF, f(mBr/mMO) and the proportional relation function (f(mf/mBi)), the W/C relation formula for MOC with CDP was summarized: f(W/C) = f(Ba) + f(mt). It was verified through experiments that the W/C relationship of CDP–MOC can reflect the dosage relationship between the brine and powder in MOCFC under the conditions of real raw material ratios.

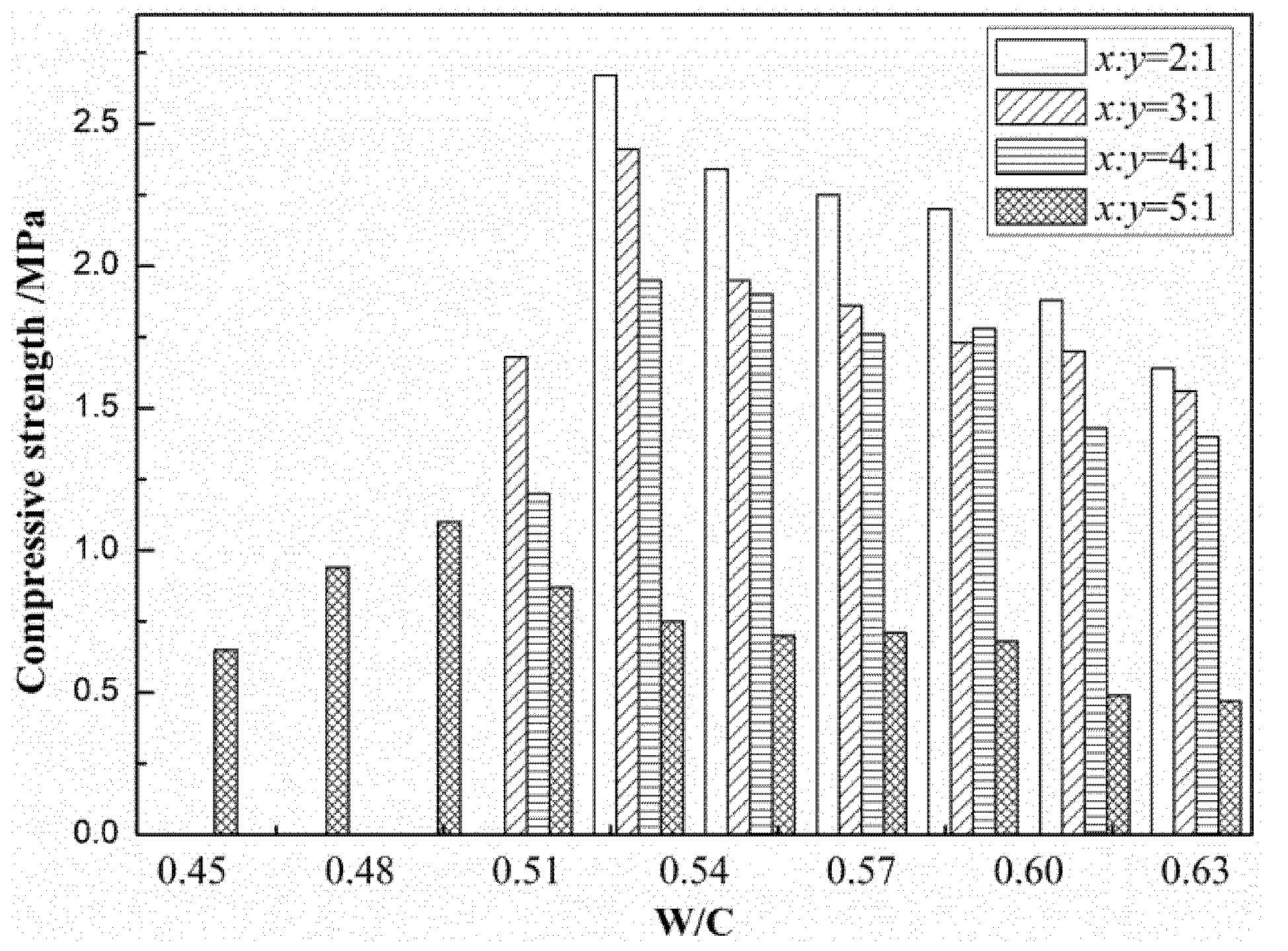

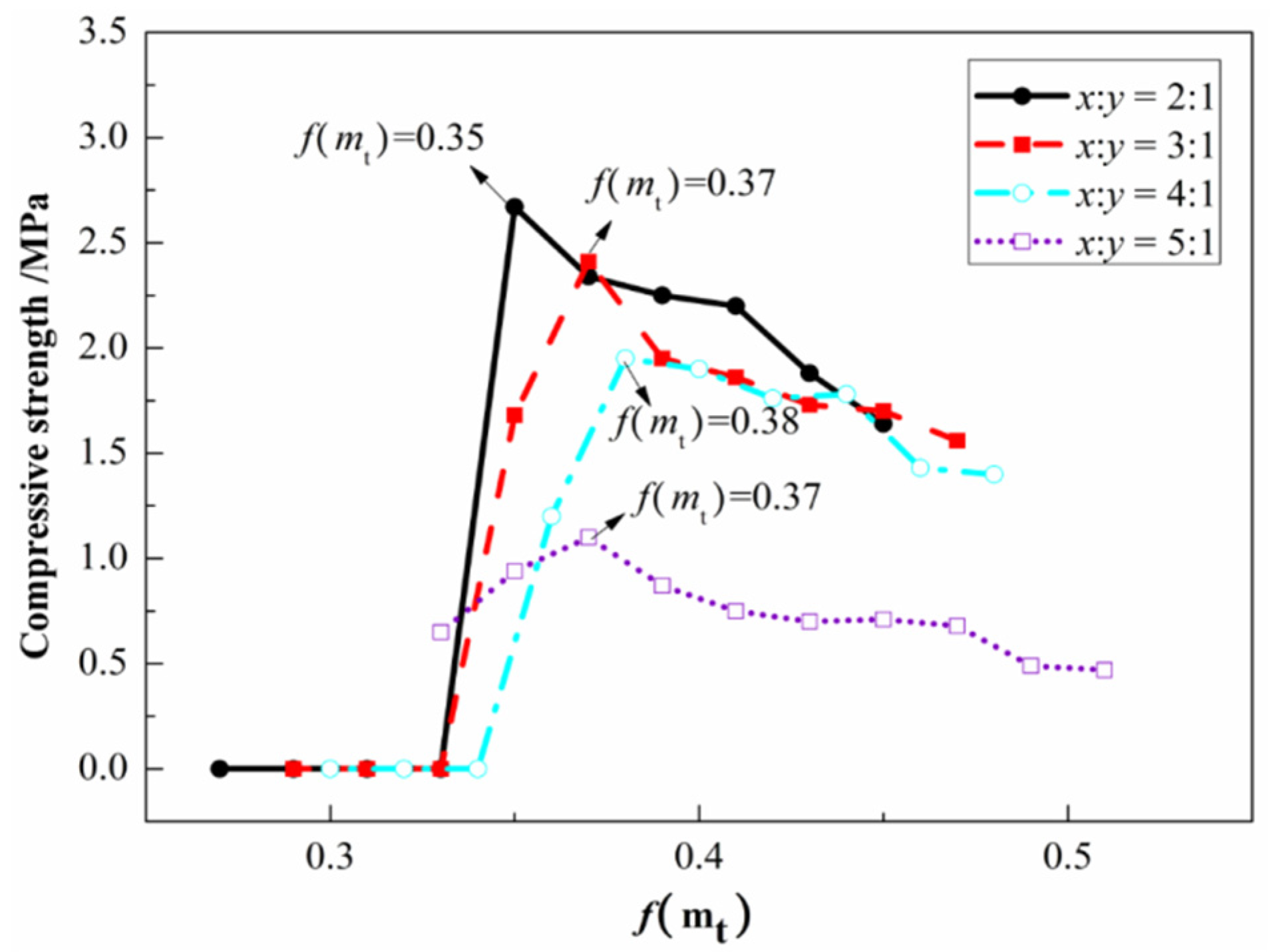

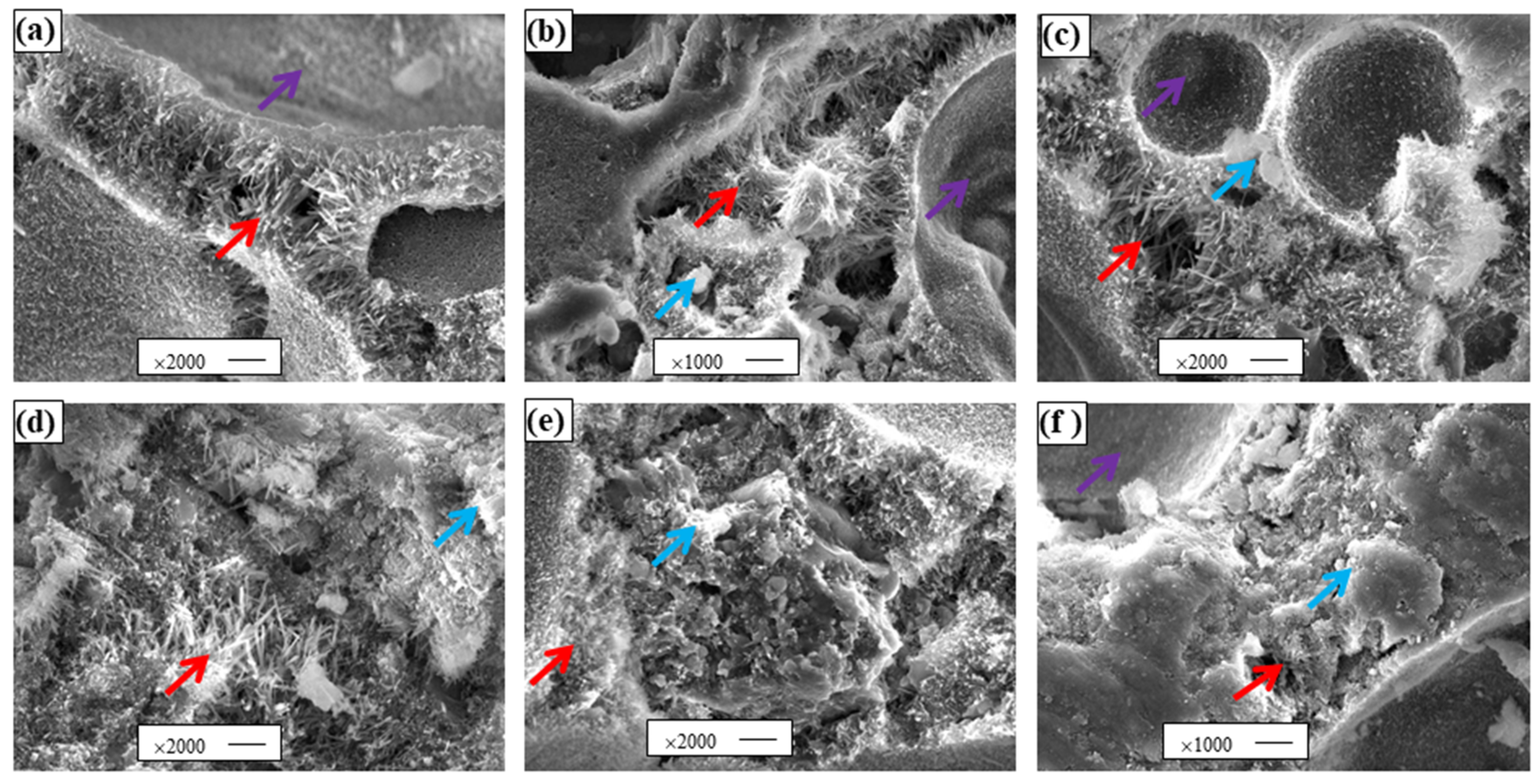

- The derived MF formula and W/C relationship were verified in the practical production of MOCFC, and the optimum W/C range for MOCFC was obtained by using the W/C formula. It can be concluded that, for MOCFC with CDP and LMP being the raw materials, MOCFC with the best performance can be obtained when W/C = 0.45–0.63. The MgOa among the four mixing ratios was of the following order: 2:1 > 3:1 > 4:1 > 5:1, which was consistent with the W/C trend obtained in the experiment. As f(mt) increased, the 5·1·8 phase in the bubble wall gradually decreased, while the Mg(OH)2 gradually increased. This happened because with excessive water, the MgOa generates more Mg(OH)2, which leads to a decrease in the intensity of the samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, J.; Ge, S.; Wang, H.; Chen, R. Study on Preparation and Properties of Intrinsic Super-Hydrophobic Foamed Magnesium Oxychloride Cement Material. Appl. Sci. 2020, 10, 8134. [Google Scholar] [CrossRef]

- Zaleska, M.; Pavlikova, M.; Jankovsky, O.; Lojka, M.; Pivak, A.; Pavlik, Z. Experimental Analysis of MOC Composite with a Waste-Expanded Polypropylene-Based Aggregate. Materials 2018, 11, 931. [Google Scholar] [CrossRef]

- Zaleska, M.; Pavlikova, M.; Jankovsky, O.; Lojka, M.; Antoncik, F.; Pivak, A.; Pavlik, Z. Influence of Waste Plastic Aggregate and Water-Repellent Additive on the Properties of Lightweight Magnesium Oxychloride Cement Composite. Appl. Sci. 2019, 9, 5463. [Google Scholar] [CrossRef]

- Kastiukas, G.; Ruan, S.; Unluer, C.; Liang, S.; Zhou, X. Environmental Assessment of Magnesium Oxychloride Cement Samples: A Case Study in Europe. Sustainability 2019, 11, 6957. [Google Scholar] [CrossRef]

- Jin, S.; Li, K.; Li, J.; Chen, H. A Low-Cost, Formaldehyde-Free and High Flame Retardancy Wood Adhesive from Inorganic Adhesives: Properties and Performance. Polymers 2017, 9, 513. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Provis, J.L.; Tsang, D.C.W.; Poon, C.S. Accelerated carbonation of reactive MgO and Portland cement blends under flowing CO2 gas. Cem. Concr. Compos. 2020, 106, 103489. [Google Scholar] [CrossRef]

- Zheng, W.; Xiao, X.; Chang, C.; Dong, J.; Wen, J.; Huang, Q.; Zhou, Y.; Li, Y. Characterizing properties of magnesium oxychloridecement concrete pavement. J. Cent. South Univ. 2019, 26, 3410–3419. [Google Scholar] [CrossRef]

- Pivak, A.; Pavlikova, M.; Zaleska, M.; Lojka, M.; Jankovsky, O.; Pavlik, Z. Magnesium Oxychloride Cement Composites with Silica Filler and Coal Fly Ash Admixture. Materials 2020, 13, 2537. [Google Scholar] [CrossRef] [PubMed]

- Liska, M.; Al-Tabbaa, A. Performance of magnesia cements in pressed masonry units with natural aggregates: Production parameters optimisation. Constr. Build. Mater. 2008, 22, 1789–1797. [Google Scholar] [CrossRef]

- Luong, V.T.; Amal, R.; Scott, J.A.; Ehrenberger, S.; Tran, T. A comparison of carbon footprints of magnesium oxide and magnesium hydroxide produced from conventional processes. J. Clean. Prod. 2018, 202, 1035–1044. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Zhang, S.; Yang, P. Recycling of Spent Pot Lining First Cut from Aluminum Smelters by Utilizing the Two-Step Decomposition Characteristics of Dolomite. Materials 2020, 13, 5283. [Google Scholar] [CrossRef]

- Srinivasan, S.; Dodson, D.; Charles, M.J.; Wallen, S.L.; Albarelli, G.; Kaushik, A.; Hickman, N.; Chaudhary, G.R.; Stefanakos, E.; Dhau, J. Energy Storage in Earth-Abundant Dolomite Minerals. Appl. Sci. 2020, 10, 6679. [Google Scholar] [CrossRef]

- Yu, J.; Qian, J.; Wang, F.; Qin, J.; Dai, X.; You, C.; Jia, X. Study of using dolomite ores as raw materials to produce magnesium phosphate cement. Constr. Build. Mater. 2020, 253, 119147. [Google Scholar] [CrossRef]

- Wang, F.; Zhu, X.; Liu, H.; Lei, S.; Huang, D. Influence of Superhydrophobic Coating on the Water Resistance of Foundry Dust/Magnesium Oxychloride Cement Composite. Materials 2020, 13, 3431. [Google Scholar] [CrossRef]

- Azimi, A.H. Experimental investigations on the physical and rheological characteristics of sand–foam mixtures. J. Non-Newton. Fluid Mech. 2015, 221, 28–39. [Google Scholar] [CrossRef]

- Altiner, M.; Yildirim, M. Influence of filler on the properties of magnesium oxychloride cement prepared from dolomite. Emerg. Mater. Res. 2017, 6, 417–421. [Google Scholar] [CrossRef]

- Chen, Y.J.; Wu, C.Y.; Yu, H.F.; Chen, W.H.; Chen, C.; Zhang, S.H.; Chen, F.Y. Study of using light-burned dolomite ores as raw material to produce magnesium oxysulfate cement. Adv. Cem. Res. 2018, 30, 437–450. [Google Scholar] [CrossRef]

- Ruan, S.Q.; Liu, J.W.; Yang, E.H.; Unluer, C. Performance and microstructure of calcined dolomite and reactive magnesia-based concrete samples. J. Mater. Civ. Eng. 2017, 29, 04017236. [Google Scholar] [CrossRef]

- Mironyuk, I.F.; Gun’ko, V.M.; Povazhnyak, M.O.; Zarko, V.I.; Chelyadin, V.M.; Leboda, R.; Skubiszewska-Zieba, J.; Janusz, W. Magnesia formed on calcination of Mg(OH)2 prepared from natural bischofite. Appl. Surf. Sci. 2006, 252, 4071–4082. [Google Scholar] [CrossRef]

- Wang, X.; Miller, J.D.; Cheng, F.; Cheng, H. Potash flotation practice for carnallite resources in the Qinghai Province, PRC. Miner. Eng. 2014, 66–68, 33–39. [Google Scholar]

- Liu, X.; Zhong, M.; Chen, X.; Li, J.; He, L.; Zhao, Z. Enriching lithium and separating lithium to magnesium from sulfate type salt lake brine. Hydrometallurgy 2020, 92, 105247. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Q.; Wang, Y.; Yun, R.; Xiang, X. Recent advances in magnesium/lithium separation and lithium extraction technologies from salt lake brine. Sep. Purif. Technol. 2021, 56, 117807. [Google Scholar] [CrossRef]

- Jiříčková, A.; Lojka, M.; Lauermannová, A.M.; Antončík, F.; Sedmidubský, D.; Pavlíková, M.; Záleská, M.; Pavlík, Z.; Jankovský, O. Synthesis, Structure, and Thermal Stability of Magnesium Oxychloride 5Mg(OH)2·MgCl2·8H2O. Appl. Sci. 2020, 10, 1683. [Google Scholar] [CrossRef]

- Lojka, M.; Jankovský, O.; Jiříčková, A.; Lauermannová, A.M.; Antončík, F.; Sedmidubský, D.; Pavlík, Z.; Pavlíková, M. Thermal Stability and Kinetics of Formation of Magnesium Oxychloride Phase 3Mg(OH)2·MgCl2·8H2O. Materials 2020, 13, 767. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Luo, R.Y.; Zhang, W.; Jin, M.M.; Tang, S.W. Effects of Fineness and Content of Phosphorus Slag on Cement Hydration, Permeability, Pore Structure and Fractal Dimension of Concrete. Fractals 2021. [Google Scholar] [CrossRef]

- Wang, L.; Jin, M.M.; Guo, F.X.; Wang, Y.; Tang, S.W. Pore Structural and Fractal Analysis of the Influence of FLY ASH and Silica Fume on the Mechanical Property and Abrasion Resistance of Concrete. Fractals 2021. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.X.; Yang, H.M.; Wang, Y.; Tang, S.W. Comparison of FLY ASH, PVA Fiber, MgO and Shrinkage-reducing Admixture on the Frost Resistance of Face Slab Concrete via Pore Structural and Fractal Analysis. Fractals 2021. [Google Scholar] [CrossRef]

- Li, Z.; Chau, C.K. Influence of molar ratios on properties of magnesium oxychloride cement. Adv. Cem. Res. 2007, 37, 866–870. [Google Scholar] [CrossRef]

- Wang, F.; Yang, L.; Guan, L.; Hu, S. Microstructure and properties of cement foams prepared by magnesium oxychloride cement. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2015, 30, 331–337. [Google Scholar] [CrossRef]

- Zheng, W.; Xiao, X.; Wen, J.; Dong, J.; Chang, C.; Huang, Q.; Man, Y.; Zhou, Y. Application of a new computational method to calculate the mixture composition of magnesium osychloride cement. Ceramics-Silikáty 2019, 63, 157–163. [Google Scholar] [CrossRef]

- Liu, G.; Ma, L.; Liu, J. Huaxue Huagong Wuxing Shuju Shouce; Chemical Industry Press: Beijing, China, 2003; pp. 475, 485. [Google Scholar]

- Li, Y.; Yu, H.; Zheng, L.; Wen, J.; Wu, C.; Tan, Y. Compressive strength of fly ash magnesium oxychloride cement containing granite wastes. Constr. Build. Mater. 2013, 38, 1–7. [Google Scholar] [CrossRef]

- Dai, M.; Zhang, H. Study on magnesium oxychloride cement material with porous with orthogonal experiment. Concrete 2013, 3, 134–140. [Google Scholar]

- Huang, T.; Yuan, Q.; Deng, D. The role of phosphoric acid in improving the strength of magnesium oxychloride cement pastes with large molar ratios of H2O/MgCl2. Cem. Concr. Compos. 2019, 97, 379–386. [Google Scholar] [CrossRef]

| Component | MgCl2 | KCl | NaCl | CaCl2 | MgSO4 | Water Insolubles | Crystal Water |

|---|---|---|---|---|---|---|---|

| Bischofite | 46.10 | 0.38 | 0.46 | 0.11 | 0.09 | 0.45 | 52.41 |

| Component | MgO | SiO2 | CaO | Al2O3 | Fe2O3 | Loss on Ignition |

|---|---|---|---|---|---|---|

| LMP * | 85.96 | 6.03 | 1.29 | 1.28 | 0.57 | 4.87 |

| CDP * | 20.15 | 1.46 | 33.20 | 0.85 | 0.47 | 43.87 |

| mf/mBi | Ba (°Be’) | Ρ (kg/m3) | P (%) |

|---|---|---|---|

| 0.55 | 31.0 | 1276 | 29.7 |

| 0.69 | 28.0 | 1256 | 27.9 |

| 0.80 | 26.5 | 1239 | 26.3 |

| 0.84 | 25.5 | 1224 | 24.9 |

| 1.00 | 24.2 | 1212 | 23.6 |

| 0.99 | 23.0 | 1201 | 22.4 |

| 1.11 | 22.0 | 1191 | 21.4 |

| 1.30 | 21.0 | 1182 | 20.5 |

| 1.33 | 20.0 | 1167 | 19.6 |

| 1.45 | 19.5 | 1165 | 18.8 |

| 1.50 | 19.0 | 1158 | 18.0 |

| P * (%) | ρ * (kg/m3) | Ba * (°Be’) | Bai * − Ci * |

|---|---|---|---|

| 2 | 1014.6 | 2.1 | 0.1 |

| 4 | 1031.1 | 3.3 | −0.7 |

| 6 | 1047.8 | 6.6 | 0.6 |

| 8 | 1064.6 | 8.8 | 0.8 |

| 10 | 1081.6 | 10.9 | 0.9 |

| 12 | 1098.9 | 13.0 | 1.0 |

| 14 | 1116.4 | 15.0 | 1.0 |

| 16 | 1132.4 | 16.8 | 0.8 |

| 18 | 1152.3 | 19.0 | 1.0 |

| 20 | 1170.6 | 21.1 | 1.1 |

| 25 | 1218.4 | 25.8 | 0.8 |

| 30 | 1268.8 | 30.6 | 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, W.; Xiao, X.; Wen, J.; Chang, C.; An, S.; Dong, J. Water-to-Cement Ratio of Magnesium Oxychloride Cement Foam Concrete with Caustic Dolomite Powder. Sustainability 2021, 13, 2429. https://doi.org/10.3390/su13052429

Zheng W, Xiao X, Wen J, Chang C, An S, Dong J. Water-to-Cement Ratio of Magnesium Oxychloride Cement Foam Concrete with Caustic Dolomite Powder. Sustainability. 2021; 13(5):2429. https://doi.org/10.3390/su13052429

Chicago/Turabian StyleZheng, Weixin, Xueying Xiao, Jing Wen, Chenggong Chang, Shengxia An, and Jingmei Dong. 2021. "Water-to-Cement Ratio of Magnesium Oxychloride Cement Foam Concrete with Caustic Dolomite Powder" Sustainability 13, no. 5: 2429. https://doi.org/10.3390/su13052429

APA StyleZheng, W., Xiao, X., Wen, J., Chang, C., An, S., & Dong, J. (2021). Water-to-Cement Ratio of Magnesium Oxychloride Cement Foam Concrete with Caustic Dolomite Powder. Sustainability, 13(5), 2429. https://doi.org/10.3390/su13052429