Stabilising Rural Roads with Waste Streams in Colombia as an Environmental Strategy Based on a Life Cycle Assessment Methodology

Abstract

:1. Introduction

1.1. Low Traffic Roads in Colombia and Its Stabilisation

1.2. Assessing Environmental Impacts and Life Cycle Assessment (LCA)

2. Materials and Methods

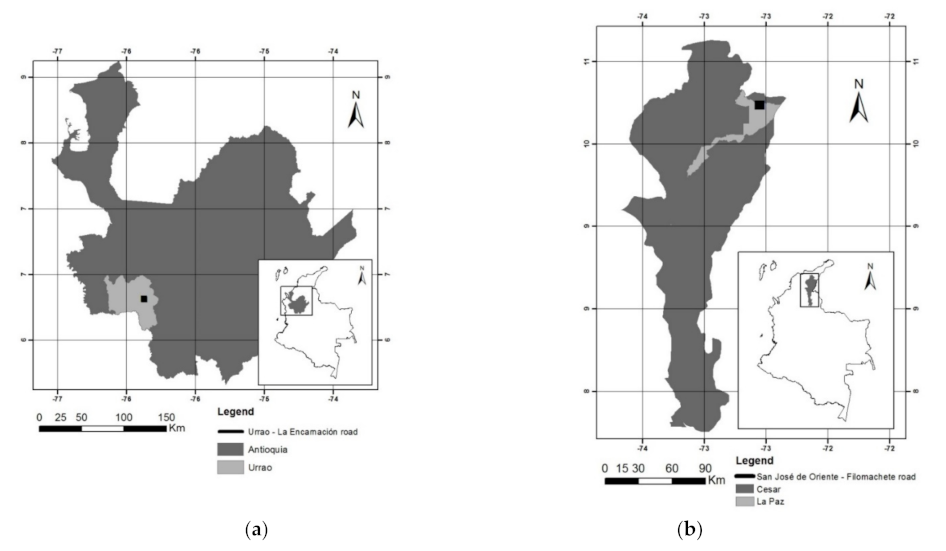

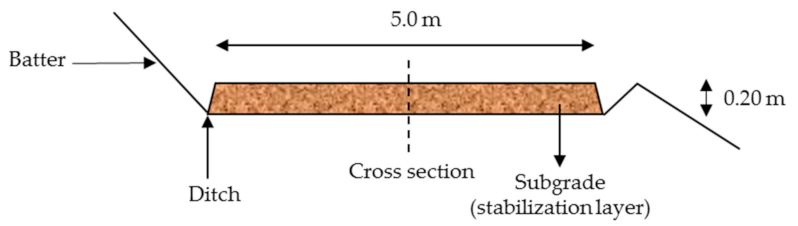

2.1. Roads Being Studied

2.2. Stabilising Materials

2.3. LCA Methodology

3. Life Cycle Assessment Methodology

3.1. Goal and Scope Definition

- -

- The transformation of the polymer and sulphonated oil into stabilisers.

- -

- The ash and brick dust taken as delivered by the industrial facility where they were produced as waste, without any additional processing of the material. Lime was used as an alkali activator in both cases, during stabilisation process.

- -

- The preliminary activities stage included all the necessary processes before the stabilisation process. Among these activities, we included the transport of machinery and materials necessary for the stabilisation of the road, identifying its origin, time (in hours) and distances travelled (in km) from its origin to the study area.

- -

- In the stabilisation process, the following activities are considered: scarification, stabiliser application, compaction, wetting, and curing depending on the case; as well as diesel consumption by each machine that was used in the process (see Figure 3).

- -

- Machinery manufacture, because the impact assigned to the time used for this system is very small in relation to the useful life of the machines.

- -

- The maintenance stage, because it was beyond the scope of the Red Innovial, and is a stage that takes longer to be performed and evaluated than the duration of the project. As indicated above, this is an LCA from “cradle to gate” and, therefore, the use stage was not considered.

- -

3.2. Inventory Analysis: Inputs and Outputs

3.2.1. Stabilisers

- -

- The “cut-off rule” [38] was applied and, therefore, wastes such as ash and brick dust entered the system with no environmental impact other than their transformation, if needed, and their transport to site.

- -

- The polymer and the sulphonated oil were of waste origin, but they were mixed with virgin chemical compounds to be transformed into stabilisers. For instance, for the sulphonated oil manufacture, the following processes were used to model the substances used and obtained from the GaBi database. The needed amounts are presented in Table 3.

- ○

- Silicone–resin plaster; technology mix; production mix, at plant; based on mineral fillers and a silicone bonding agent (en) from Germany; 100 mL;

- ○

- Deionised water; highly pure, via ion exchange, from hydrochloric acid and caustic soda; single route, at plant from the U.S.; 1 kg/L (en);

- ○

- Phenol; hock process, oxidation of cumene; single route, at plant; 1.07 g/cm3, 94 g/mol (en) from Germany;

- ○

- Propylene glycol; via Propylene oxide (PO)-hydrogenation; single route, at plant; 1.04 g/cm3, 76.10 g/mol (en) from Germany;

- ○

- Polyvinyl alcohol (from vinyl acetate) (PVAL); technology mix; production mix, at plant; without additives from the U.S.;

- ○

- Antistatic agent (quaternary ammonium compound); technology mix; production mix, at plant; quaternary ammonium compound (en) Global;

- ○

- Sulphuric acid aq. (96%); concentrated, sulphur dioxide route; single route, at plant; 96%, 1.84 g/cm3 (en) from the U.S.

- -

- On the other hand, the environmental data for the chemical products added to the polymer were obtained from the GaBi database of the United States, and the processes for the compounds used in the production of the stabiliser are mentioned below (see Table 4 for quantities):

- ⯀

- Acrylic acid (Propene); oxidation of propene; production mix, at plant; 1.05 g/cm3, 72.06 g/mol (en; Dipropylene glycol by product propylene glycol via PO hydrogenation; hydration of propylene oxide; single route, at plant; 1.02 g/cm3, 134 g/mol (en);

- ⯀

- Dipropylene glycol by product propylene glycol via PO hydrogenation; hydration of propylene oxide; single route, at plant; 1.02 g/cm3, 134 g/mol (en) from the U.S.;

- ⯀

- Polycarbonate–acrylonitrile–butadiene–styrene compound (80% PC, 20% ABS); mixing, pelletising and compounding; single route, at plant; 80% polycarbonate, 20% acrylonitrile–butadiene–styrene (en);

- ⯀

- Ethylene vinylacetate copolymer (E/VA) (72% ethylene, 28% vinylacetate); co-polymerisation of ethylene and vinyl acetate; production mix, at plant; without additives, 72% ethylene, 28% vinyl acetate (en);

- ⯀

- Sodium chloride (rock salt); salt mining and leaching; production mix, at plant; 2.17 g/cm3, 58.44 g/mol (en).

- -

- For the alkaline activator (lime) model, the process used was: “Limestone flour (0.115 mm), production mix, at producer; grain size 0.115 mm”, from the GaBi database.

3.2.2. Material Transportation

- -

- The distance travelled by each material from the production site to the corresponding road (Table 5);

- -

- Material weight (Table 2), which depended on the type of soil at each road;

- -

- In addition, for ash and brick dust, lime was used as an activator (Table 2);

- -

- For any material transportation, the type of truck was chosen from the GaBi database, based on the amounts of materials needed to be transported: Truck-Heavy Heavy-duty Diesel Truck/53.333 lb payload-8b; Unit process, not pre-allocated; consumption mix;

- -

3.2.3. Machinery Transportation

- -

- The distances for machinery acquisition were calculated based on the closer city to each stabilised road: 2 km for Urrao (Antioquia region) and 14 km for La Paz (Cesar region);

- -

- -

- The machinery was transported in a low bed truck, taken from GaBi database, and chosen based on the capacity to support the weight of each machine: “Flatbed, platform, etc./49,000 lb payload-8b; Unit process, not pre-allocated; consumption mix”.

3.2.4. Stabilisation Stage

- -

- Performances obtained from the manufacturers of: the motor grader (2080 L/h); the roller (1510 L/h); and the water tanker (3581 km/L);

- -

- Distances used to perform each activity within the stabilisation stage (including scarification, application of stabiliser (depending on the case), wetting/curing and compaction): calculated based on the number of times the relevant machinery was to pass over each cell, multiplied by the length of the cell;

- -

- The time to carry the materials to each place was calculated taking the distance travelled in km and the speed used by each type of transport, for each material or machinery;

- -

- Amount of water in the mixtures of lime + ash and lime + brick powder, calculated according to the proportion of the material used in each of the sections (See Table 8);

- -

- Environmental impacts of diesel production: calculated using the GaBi data set for the United States (USA), because no Colombian diesel data were available (Diesel at refinery; from crude oil; production mix, at refinery; 15 ppm sulphur);

- -

- Water consumption, which was measured in the field, adding up the amounts used for the curing and wetting activities, which depended on each type of soil and its moisture requirements (Table 8);

- -

- Environmental impacts of water production calculated using the U.S. GaBi dataset (Tap water from groundwater; filtration, disinfection, ion removal, etc.; production mix, at plant; 1000 kg/m3, 18 g/mol from the U.S.).

3.3. Impact Assessment

4. Results and Discussion

4.1. Results for Urrao

4.2. Results for La Paz

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- DNP. Política para la Gestión de la Red Terciaria: Presupuesto Informado por Resultados; Departamento Nacional de Planeación: Bogotá, Colombia, 2017.

- Muñoz, F.; Arias, Y.P.; Hidalgo, C. Evaluación del polvo de ladrillo como estabilizante de suelo perteneciente a vías terciarias. Proceedings from: Simposio Colombiano Sobre Ingeniería de Pavimentos; Santa Marta, Colombia, 2015; pp. 1–10. [Google Scholar]

- La República. Del Total de la red vial terciaria con la que cuenta Colombia, 96% está en mal estado. 2017. Available online: https://www.larepublica.co/infraestructura/del-total-de-la-red-vial-terciaria-con-la-que-cuenta-colombia-96-esta-en-mal-estado-2828335 (accessed on 27 September 2019).

- Muñoz, F. Evaluación de las Propiedades Hidráulicas de Suelos Estabilizados con Polvo de Ladrillo Utilizados en vías de Bajos Volúmenes de Tránsito; Universidad de Medellín: Medellín, Colombia, 2016. [Google Scholar]

- IDU. Guía para el Diseño y la Construcción de Capas Estructurales de Pavimentos Estabilizados Mediante Procesos Químicos; Instituto de Desarrollo Urbano: Bogotá, Colombia, 2005.

- Cadavid, L.; Restrepo, F. Evaluación del Efecto de la Erosión por Escorrentía Superficial en Suelos Residuales Arenosos Estabilizados con Cemento o cal; Universidad de Medellín: Medellín, Colombia, 2007. [Google Scholar]

- Cardona, C.; Ruiz, N. Determinación de la Dosificación de cal para la Estabilización de Suelos Granulares de Dioritas, bajo Análisis de Pruebas Estadísticas; Universidad de Medellín: Medellín, Colombia, 2005. [Google Scholar]

- Echavarria, J.; Arroyave, N. Diseño de Mezclas de Suelo-Cemento para Estructuras Ingenieriles, Utilizando Suelo Residual Proveniente de Diorite; Universidad de Medellín: Medellín, Colombia, 2006. [Google Scholar]

- Gómez, C.; Osorio, J. Análisis del Comportamiento Estático de un Suelo Tipo Granular Adicionado con Cal; Universidad de Medellín: Medellín, Colombia, 2004. [Google Scholar]

- Ortiz, C.; Barreto, J. Mejoramiento de Suelos con cal Fase III; Universidad de Medellín: Medellín, Colombia, 2005. [Google Scholar]

- INVIAS. Especificaciones Generales de Construcción de Carreteras; Instituto Nacional de Vías: Bogotá, Colombia, 2012.

- Da Rocha, C.G.; Passuello, A.C.; Consoli, N.C.; Samaniego, R.A.Q.; Kanazawa, N.M. Life cycle assessment for soil stabilization dosages: A study for the Paraguayan Chaco. J. Clean. Prod. 2016, 139, 309–318. [Google Scholar] [CrossRef]

- Larrea-Gallegos, G.; Vázquez-Rowe, I.; Gallice, G. Life cycle assessment of the construction of an unpaved road in an undisturbed tropical rainforest area in the vicinity of Manu National Park, Peru. Int. J. Life Cycle Assess. 2016, 22, 1109–1124. [Google Scholar] [CrossRef]

- Kneese, A.V.; Ayres, R.U.; D’Arge, R.C. Economics and the Environment: A Materials Balance Approach; RFF Resources for the Future: New York, NY, USA, 2015. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Fullana-i-Palmer, P.; Puig, R.; Bala, A.; Baquero, G.; Riba, J.; Raugei, M. From Life Cycle Assessment to Life Cycle Management. J. Ind. Ecol. 2011, 15, 458–475. [Google Scholar] [CrossRef]

- De Larriva, R.A.; Rodríguez, G.C.; López, J.M.C.; Raugei, M.; I Palmer, P.F. A decision-making LCA for energy refurbishment of buildings: Conditions of comfort. Energy Build. 2014, 70, 333–342. [Google Scholar] [CrossRef]

- Bloom, E.F.; Horstmeier, G.J.; Pakes Ahlman, A.; Edil, T.B.; Whited, G. Assessing the Life Cycle Benefits of Recycled Material in Road Construction. GeoChicago-Conference-Paper-I-94-and-Beltline-LCA. 2017. Available online: http://rmrc.wisc.edu/wp-content/uploads/2017/05/GeoChicago-Conference-Paper-I-94-and-Beltline-LCA.pdf (accessed on 30 December 2020).

- Chiu, C.-T.; Hsu, T.-H.; Yang, W.-F. Life cycle assessment on using recycled materials for rehabilitating asphalt pavements. Resour. Conserv. Recycl. 2008, 52, 545–556. [Google Scholar] [CrossRef]

- Chowdhury, R.; Apul, D.; Fry, T. A life cycle based environmental impacts assessment of construction materials used in road construction. Resour. Conserv. Recycl. 2010, 54, 250–255. [Google Scholar] [CrossRef]

- Hung, M.-L.; Ma, H.-W.; Chao, C.-W. Screening the Life Cycle Impact Assessment Methods and Modifying Environmental Impact Model to Determine Environmental Burdens. J. Environ. Eng. Manag. 2009, 19, 155–164. Available online: http://ser.cienve.org.tw/download/19-3/jeeam19-3_155-164.pdf (accessed on 30 December 2020).

- Aldaco, R.; Margallo, M.; Fullana-i-Palmer, P.; Bala, A.; Gazulla, C.; Irabien, A.; Aldaco, R. Introducing life cycle thinking to define best available techniques for products: Application to the anchovy canning industry. J. Clean. Prod. 2017, 155, 139–150. [Google Scholar] [CrossRef] [Green Version]

- Lasvaux, S.; Gantner, J.; Wittstock, B.; Bazzana, M.; Schiopu, N.; Saunders, T.; Gazulla, C.; Mundy, J.A.; Sjöström, C.; Fullana-i-Palmer, P.; et al. Achieving consistency in life cycle assessment practice within the European construction sector: The role of the EeBGuide InfoHub. Int. J. Life Cycle Assess. 2014, 19, 1783–1793. [Google Scholar] [CrossRef]

- Benveniste, G.; Gazulla, C.; Fullana-i-Palmer, P.; Celades, I.; Ros, T.; Zaera, V.; Godes, B. Análisis de ciclo de vida y reglas de categoría de producto en la construcción. El caso de las baldosas cerámicas. Informes de la Construcción 2011, 63, 71–81. [Google Scholar] [CrossRef] [Green Version]

- Mroueh, U.-M.; Eskola, P.; Laine-Ylijoki, J. Life-cycle impacts of the use of industrial by-products in road and earth construction. Waste Manag. 2001, 21, 271–277. [Google Scholar] [CrossRef]

- Rajendran, S.; Gambatese, J. Solid Waste Generation in Asphalt and Reinforced Concrete Roadway Life Cycles. J. Infrastruct. Syst. 2007, 13, 88–96. [Google Scholar] [CrossRef]

- Birgisdottir, H.; Bhander, G.; Hauschild, M.; Christensen, T. Life cycle assessment of disposal of residues from municipal solid waste incineration: Recycling of bottom ash in road construction or landfilling in Denmark evaluated in the ROAD-RES model. Waste Manag. 2007, 27, S75–S84. [Google Scholar] [CrossRef] [PubMed]

- Celauro, C.; Corriere, F.; Guerrieri, M.; Casto, B.L. Environmentally appraising different pavement and construction scenarios: A comparative analysis for a typical local road. Transp. Res. Part D Transp. Environ. 2015, 34, 41–51. [Google Scholar] [CrossRef]

- Balaguera, A.; Carvajal, G.I.; Albertí, J.; Fullana-i-Palmer, P. Life cycle assessment of road construction alternative materials: A literature review. Resour. Conserv. Recycl. 2018, 132, 37–48. [Google Scholar] [CrossRef]

- Bala, A.; Raugei, M.; Benveniste, G.; Gazulla, C.; Fullana-i-Palmer, P.; Bala, A. Simplified tools for global warming potential evaluation: When ‘good enough’ is best. Int. J. Life Cycle Assess. 2010, 15, 489–498. [Google Scholar] [CrossRef]

- Navarro, A.; Puig, R.; Fullana-I-Palmer, P. Product vs corporate carbon footprint: Some methodological issues. A case study and review on the wine sector. Sci. Total Environ. 2017, 581–582, 722–733. [Google Scholar] [CrossRef]

- Puig, R.; Fullana-i-Palmer, P.; Baquero, G.; Riba, J.-R.; Bala, A. A Cumulative Energy Demand indicator (CED), life cycle based, for industrial waste management decision making. Waste Manag. 2013, 33, 2789–2797. [Google Scholar] [CrossRef]

- Mackie, P.; Nellthorp, J.; Laird, J. Low Volume Rural Roads. 1 January 2005. pp. 1–9. Available online: http://documentos.bancomundial.org/curated/es/286811468339867486/Low-volume-rural-roads (accessed on 30 December 2020).

- Balaguera, A.; Carvajal, G.I.; Jaramillo, Y.P.A.; Albertí, J.; Fullana-i-Palmer, P. Technical feasibility and life cycle assessment of an industrial waste as stabilizing product for unpaved roads, and influence of packaging. Sci. Total. Environ. 2018, 651, 1272–1282. [Google Scholar] [CrossRef]

- Paez, D. Efectos de la estabilización electroquímica de suelos finos. Rev. Ing. UPTC 2005, 18, 83–96. [Google Scholar]

- Camacho-Tauta, J.; Ortiz, O.J.R.; Mayorga, C. Efecto de la radiación UV en arcillas expansivas tratadas con aceite sulfonado. Ingeniería y Competitividad 2011, 12, 41–50. [Google Scholar] [CrossRef]

- ISO. ISO 14044:2006(E)—Environmental management—Life cycle assessment—Requirements and guidelines. English, 2006. p. 42. Available online: https://www.iso.org/standard/38498.html (accessed on 28 January 2021).

- ISO 14040. Environmental management—Life cycle assessment—Principles and framework. In Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar] [CrossRef] [Green Version]

- Baitz, M.; Albrecht, S.; Brauner, E.; Broadbent, C.; Castellan, G.; Conrath, P.; Fava, J.; Finkbeiner, M.; Fischer, M.; I Palmer, P.F.; et al. LCA’s theory and practice: Like ebony and ivory living in perfect harmony? Int. J. Life Cycle Assess. 2013, 18, 5–13. [Google Scholar] [CrossRef] [Green Version]

- ISO. ISO 14025—Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures. 2006. Available online: https://www.normativa-iso-une-pdf.com/descarga/pdf/une-en-iso-140252010/ (accessed on 28 January 2021).

- Barthel, M.; Fava, J.; James, K.; Khan, S. Hotspots Analysis an Overarching Methodological Framework and Guidance for Product and Sector Level Application. 2017. Available online: www.lifecycleinitiative.org (accessed on 30 December 2020).

- Chomkhamsri, K.; Wolf, M.-A.; Pant, R. International Reference Life Cycle Data System (ILCD) Handbook: Review Schemes for Life Cycle Assessment. In Towards Life Cycle Sustainability Management; Springer: Cham, Switzerland, 2011; pp. 107–117. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Tarrés, Q.; Pèlach, M.À.; Mutjé, P.; Fullana-i-Palmer, P. Are Cellulose Nanofibers a Solution for a More Circular Economy of Paper Products? Environ. Sci. Technol. 2015, 49, 12206–12213. [Google Scholar] [CrossRef]

- Guinée, J.B. Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Kluwer Academic Publishers: New York, NY, USA, 2002. [Google Scholar]

- BRE. Product Category Rules for Type III Environmental Product Declaration of Construction Products to EN 15804: 2012. 2013. Available online: http://www.bre.co.uk/filelibrary/materials/bre_en_15804_pcr.pn514.pdf (accessed on 30 December 2020).

- Rashid, A.F.A.; Idris, J.; Sumiani, Y. Environmental Impact Analysis on Residential Building in Malaysia Using Life Cycle Assessment. Sustainability 2017, 9, 329. [Google Scholar] [CrossRef] [Green Version]

- Quintero, A.B.; Cano, D.G.; Peláez, G.C.; Arias, Y.P. Technical and Environmental Assessment of an Alternative Binder for Low Traffic Roads with LCA Methodology. In Proceedings of the 3rd Pan American Materials Congress; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

- Bueno, C.; Hauschild, M.Z.; Rossignolo, J.; Ometto, A.R.; Crespo-Mendes, N. Sensitivity analysis of the use of Life Cycle Impact Assessment methods: A case study on building materials. J. Clean. Prod. 2016, 112, 2208–2220. [Google Scholar] [CrossRef] [Green Version]

- Huarachi, D.A.R.; Gonçalves, G.; De Francisco, A.C.; Canteri, M.H.G.; Piekarski, C.M. Life cycle assessment of traditional and alternative bricks: A review. Environ. Impact Assess. Rev. 2020, 80, 106335. [Google Scholar] [CrossRef]

- Araújo, J.P.C.; Oliveira, J.R.; Da Silva, H.M.R.D. The importance of the use phase on the LCA of environmentally friendly solutions for asphalt road pavements. Transp. Res. Part D Transp. Environ. 2014, 32, 97–110. [Google Scholar] [CrossRef] [Green Version]

- Santos, J.; Ferreira, A.; Flintsch, G.W. A life cycle assessment model for pavement management: Road pavement construction and management in Portugal. Int. J. Pavement Eng. 2014, 16, 315–336. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, F.; Lou, W.; Li, D.; Chen, J. Chemical characterization and toxicity assessment of fine particulate matters emitted from the combustion of petrol and diesel fuels. Sci. Total Environ. 2017, 605–606, 172–179. [Google Scholar] [CrossRef]

- Ingersoll Rand. Ficha Técnica Vibrocompactador. 2015. Available online: http://maquqam.com/tecnicas/carreteras-3337/ingersoll-rand/sd70d.html (accessed on 30 December 2020).

- John Deere. Ficha Técnica Motoniveladora. 2015. Available online: http://maquqam.com/tecnicas/construccion-6735/john-deere/570b.html (accessed on 30 December 2020).

- Ministerio de Ambiente y Desarrollo Sostenible. Estrategia Nacional de Economía Circular 2018–2022. 2018. Available online: https://id.presidencia.gov.co/Paginas/prensa/2019/190614-Presidente-Duque-Estrategia-Nacional-Economia-Circular-primera-politica-ambiental-de-este-tipo-en-America-Latina.aspx#:~:text=La%20Estrategia%20Nacional%20de%20Econom%C3%ADa%20Circular%20transformar%C3%A1%20las%20cadenas%20de,Am%C3%A9rica%20Latina%20para%20el%20203057 (accessed on 30 December 2020).

- CEPAL. Agua para el siglo XXI para América del Sur. De la División a la Acción. 2016. Available online: https://www.cepal.org/samtac/noticias/documentosdetrabajo/5/23345/InCo00200.pdf (accessed on 30 December 2020).

- Siracusa, V.; Ingrao, C.; Giudice, A.L.; Mbohwa, C.; Rosa, M.D. Environmental assessment of a multilayer polymer bag for food packaging and preservation: An LCA approach. Food Res. Int. 2014, 62, 151–161. [Google Scholar] [CrossRef]

- Muench, S.T. Roadway Construction Sustainability Impacts. Transp. Res. Rec. J. Transp. Res. Board 2010, 2151, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Johnson, D.; Heltzel, R.; Nix, A.C.; Clark, N.; Darzi, M. Greenhouse gas emissions and fuel efficiency of in-use high horsepower diesel, dual fuel, and natural gas engines for unconventional well development. Appl. Energy 2017, 206, 739–750. [Google Scholar] [CrossRef]

- Karavalakis, G.; Hajbabaei, M.; Jiang, Y.; Yang, J.; Johnson, K.C.; Cocker, D.R.; Durbin, T.D. Regulated, greenhouse gas, and particulate emissions from lean-burn and stoichiometric natural gas heavy-duty vehicles on different fuel compositions. Fuel 2016, 175, 146–156. [Google Scholar] [CrossRef] [Green Version]

| Properties | Standard | Urrao | La Paz |

|---|---|---|---|

| Type of soil | Lime | Sandy-clay | |

| Unified Soil Classification System (USCS) | MH 1 | SC 2 | |

| AASHTO classification | A-7-5 | A-6 | |

| Natural humidity (%) | INV E 3-122 | 27 | 9 |

| Specific gravity (Gs) | INV E-128 | 2.71 | 2.70 |

| Liquid limit (%) | INV E-25 | 66 | 36 |

| Plastic limit (%) | INV E-126 | 48 | 20 |

| Plastic index (%) | INV E-126 | 18 | 16 |

| Maximum size of particle (mm) | 19 | 9.5 | |

| Clay (%) | 23 | 14 | |

| Dry unit weight (kN/m3) | INV E-142 | 14.8 | 19.5 |

| Optimal humidity (%) | 25.8 | 11.8 |

| Material | Quantity of Material for Urrao (t/m3) | Quantity of Soil for Stabilisation Urrao (t/m3) | Quantity of Material for La Paz (t/m3) | Quantity of Soil for Stabilisation La Paz (t/m3) |

|---|---|---|---|---|

| Fly ash | 97.4 | 997.6 | 155 | 1272.8 |

| Lime (Fly ash) | 65 | 51.8 | ||

| Brick dust | 113 | 1049.2 | 162 | 1272.8 |

| Lime (brick dust) | 534 | 45.6 | ||

| Sulphonated oil | 0.426 | 1280 | 1.12 | 1480 |

| Polymer | 33.3 | 1280 | 50 | 1480 |

| Silicone–Resin Plaster (kg) | Deionised Water (kg) | Phenol (kg) | Propylene Glycol (kg) | Antistatic Agent (Quaternary Ammonium Compound) (kg) | Polyvinyl Alcohol (kg) | Sulphuric Acid Aq. (96%) (kg) |

|---|---|---|---|---|---|---|

| 0.2 | 0.093 | 0.06 | 0.01 | 0.02 | 0.6 | 0.0004 |

| Acrylic Acid (kg) | Dipropylene Glycol (kg) | Polycarbonate-Acrylonitrile-Butadiene-Styrene (kg) | Sodium Chloride (kg) | Ethylene Vinylacetate Copolymer (kg) |

|---|---|---|---|---|

| 0.08 | 0.004 | 0.5 | 0.002 | 0.5 |

| Material | Urrao | La Paz | ||

|---|---|---|---|---|

| Distance (km) | Time (h) | Distance (km) | Time (h) | |

| Ash | 159 | 3.5 | 234 | 5.9 |

| Lime (ash) | 159 | 3.5 | 25 | 0.7 |

| Brick dust | 159 | 3.5 | 322 | 8.1 |

| Lime (brick dust) | 159 | 3.5 | 25 | 0.7 |

| Sulphonated oil | 159 | 3.5 | 25 | 0.7 |

| Polymer | 159 | 3.5 | 25 | 0.7 |

| Activity | Diesel Consumption per Material (kg) | |||

|---|---|---|---|---|

| Sulphonated Oil | Polymer | Brick Dust | Ash | |

| Scarification | 12,300 | 67,700 | 49,100 | 106,000 |

| Stabiliser application | 4.08 | 14.6 | * | * |

| Mixing | 27,800 | 57,300 | 40,900 | 63,900 |

| Compaction | 16,700 | 16,900 | 13,300 | 15,000 |

| Wetting/curing | 2.04 | 1.36 | 6.12 | 8.16 |

| Activity | Diesel Consumption per Material (kg) | |||

|---|---|---|---|---|

| Sulphonated Oil | Polymer | Brick Dust | Ash | |

| Scarification | 82,900 | 27,200 | 53,000 | 21,600 |

| Stabiliser application | 4.42 | 2.04 | * | * |

| Mixing | 29,200 | 10,300 | 19,200 | 45,800 |

| Compaction | 26,400 | 41,400 | 15,000 | 10,000 |

| Wetting/curing | ** | ** | 1.02 | 2.38 |

| Material | Urrao kg | La Paz kg |

|---|---|---|

| Ash | 57,000 | 15,400 |

| Ash + lime | 38,000 | 10,200 |

| Brick dust | 11,800 | 17,500 |

| Brick dust + lime | 5570 | 8220 |

| Sulphonated oil | 23,200 | 102,000 |

| Polymer | 20,300 | 50,300 |

| Impact Categories | Polymer | Sulphonated Oil | ||||||

|---|---|---|---|---|---|---|---|---|

| Material Production | Preliminaries Activities | Stabilisation | Total | Material Production | Preliminaries Activities | Stabilisation | Total | |

| ADP elements 4 kg Sb-Equiv. | 0.362 | 7.21 × 10 −5 | 24,100 | 0.362 | 0.00565 | 6.10 × 10 −7 | 9.76 × 10 −5 | 0.00575 |

| ADP fossil 5 MJ | 3.41 × 10 6 | 5930 | 7.30 × 10 6 | 1.07 × 10 7 | 1.64 × 10 8 | 50.2 | 2.92 × 10 6 | 1.67 × 10 8 |

| AP 6 kg SO2-Equiv. | 259 | 0.212 | 1060 | 1320 | 58.000 | 0.00179 | 424 | 58.400 |

| EP 7 kg Phosphate-Equiv. | 36.2 | 0.0705 | 73.2 | 110 | 4880 | 5.96 × 10 −4 | 29.3 | 4910 |

| FAETP 8 kg DCB-Equiv. | 822 | 3.54 | 163,000 | 1.63 × 10 5 | 3.69 × 10 6 | 0.0299 | 65.000 | 3.76 × 10 6 |

| GWP 100 years 9 kg CO2-Equiv. | 1.50 × 10 5 | 53.0 | 78,000 | 2.28 × 10 5 | 1.32 × 10 7 | 0.448 | 31.300 | 1.32 × 10 7 |

| HTP 10 kg DCB-Equiv. | 7650 | 44.7 | 459,000 | 4.66 × 10 5 | 1.19 × 10 7 | 0.379 | 1.84 × 10 5 | 1.21 × 10 7 |

| MAETP 11 kg DCB-Equiv. | 3.63 × 10 6 | 6720 | 6.16 × 10 8 | 6.20 × 10 8 | 1.40 × 10 10 | 56.9 | 2.47 × 10 8 | 1.42 × 10 10 |

| ODP 12 kg R11-Equiv. | 1.35 × 10 −5 | 2.73 × 10 −9 | 2.18 × 10 −5 | 3.53 × 10 −5 | 4.92 × 10 −4 | 2.31 × 10 −11 | 8.72 × 10 −6 | 5.01 × 10 −4 |

| POCP 13 kg Ethene-Equiv. | 34.6 | 0.0474 | 170 | 204 | 5490 | 4.01 × 10 −4 | 68.0 | 5560 |

| TETP 14 kg DCB-Equiv. | 60.5 | 0.159 | 28.7 | 89.4 | 8430 | 0.00135 | 11.5 | 8440 |

| Impact Categories | Brick Dust + Lime | Ash + Lime | ||||||

|---|---|---|---|---|---|---|---|---|

| Material Production | Preliminaries Activities | Stabilisation | Total | Material Production | Preliminaries Activities | Stabilisation | Total | |

| ADP elements 4 kg Sb-Equiv. | 6.44 × 10 −7 | 2.31 × 10 −4 | 1.76 × 10 −4 | 4.07 × 10 −4 | 6.44 × 10 −7 | 2.31 × 10 −4 | 3.18 × 10 −4 | 5.49 × 10 −4 |

| ADP fossil 5 MJ | 15.5 | 19,000 | 5.32 × 10 6 | 5.34 × 10 6 | 15.5 | 19,000 | 9.48 × 10 6 | 9.50 × 10 6 |

| AP 6 kg SO2-Equiv. | 0.00429 | 0.676 | 773 | 773 | 0.00429 | 0.676 | 1380 | 1380 |

| EP 7 kg Phosphate-Equiv. | 9.90 × 10 −4 | 0.226 | 53.3 | 53.5 | 9.90 × 10 −4 | 0.226 | 95.2 | 95.4 |

| FAETP 8 kg DCB-Equiv. | 0.00415 | 11.3 | 118,000 | 118,000 | 0.00415 | 11.3 | 211,000 | 211,000 |

| GWP 100 years 9 kg CO2-Equiv. | 1.50 | 170 | 56,900 | 57,000 | 1.50 | 170 | 102,000 | 102,000 |

| HTP 10 kg DCB-Equiv. | 0.0624 | 143 | 334,000 | 334,000 | 0.0624 | 143 | 596,000 | 596,000 |

| MAETP 11 kg DCB-Equiv. | 135 | 21.500 | 4.49 × 10 8 | 4.49 × 10 8 | 135 | 21,500 | 8.00 × 10 8 | 8.00 × 10 8 |

| ODP 12 kg R11-Equiv. | 5.41 × 10 −12 | 8.74× 10 −9 | 1.59 × 10 −5 | 1.59 × 10 −5 | 5.41 × 10 −12 | 8.74 × 10 −9 | 2.83 × 10 −5 | 2.83 × 10 −5 |

| POCP 13 kg Ethene-Equiv. | 3.79 × 10 −4 | 0.152 | 124 | 124 | 3.79 × 10 −4 | 0.152 | 221 | 221 |

| TETP 14 kg DCB-Equiv. | 0.00494 | 0.510 | 21.0 | 21.5 | 0.00494 | 0.510 | 37.5 | 38.0 |

| Impact Categories | Polymer | Sulphonated Oil | ||||||

|---|---|---|---|---|---|---|---|---|

| Material Production | Preliminaries Activities | Stabilisation | Total | Material Production | Preliminaries Activities | Stabilisation | Total | |

| ADP elements 4 kg Sb-Equiv. | 0.542 | 2.25 × 10 −5 | 1.34 × 10 −4 | 0.542 | 0.0150 | 6.31 × 10 −6 | 2.41 × 10 −4 | 0.0152 |

| ADP fossil 5 MJ | 5.11 × 10 6 | 1850 | 4.04 × 10 6 | 9.15 × 10 6 | 4.36 × 10 8 | 518 | 7.12 × 10 6 | 4.43 × 10 8 |

| AP 6 kg SO2-Equiv. | 389 | 0.0661 | 587 | 976 | 154,000 | 0.0185 | 1030 | 155,000 |

| EP 7 kg Phosphate-Equiv. | 54.4 | 0.0220 | 40.6 | 95.0 | 12,900 | 0.00616 | 71.5 | 13,000 |

| FAETP 8 kg DCB-Equiv. | 1230 | 1.11 | 90,000 | 91,300 | 9.78 × 10 6 | 0.309 | 159,000 | 9.94 × 10 6 |

| GWP 100 years 9 kg CO2-Equiv. | 225,000 | 16.5 | 43,200 | 268,000 | 3.51 × 10 7 | 4.63 | 76,200 | 3.52 × 10 7 |

| HTP 10 kg DCB-Equiv. | 11,500 | 14.0 | 254,000 | 266,000 | 3.16 × 10 7 | 3.91 | 448,000 | 3.20 × 10 7 |

| MAETP 11 kg DCB-Equiv. | 5.45 × 10 6 | 2100 | 3.42 × 10 8 | 3.47 × 10 8 | 3.73 × 10 10 | 587 | 6.02 × 10 8 | 3.79 × 10 10 |

| ODP 12 kg R11-Equiv. | 2.03 × 10 −5 | 8.54 × 10 −10 | 1.21 × 10 −5 | 3.24 × 10 −5 | 0.0013 | 2.38 × 10 −10 | 2.13 × 10 −5 | 0.00132 |

| POCP 13 kg Ethene-Equiv. | 51.8 | 0.0148 | 94.2 | 146 | 14,600 | 0.00414 | 166 | 14,800 |

| TETP 14 kg DCB-Equiv. | 90.8 | 0.0498 | 16.0 | 107 | 22,400 | 0.0139 | 28.2 | 22,400 |

| Impact Categories | Brick Dust + Lime | Ash + Lime | ||||||

|---|---|---|---|---|---|---|---|---|

| Material Production | Preliminaries Activities | Stabilisation | Total | Material Production | Preliminaries Activities | Stabilisation | Total | |

| ADP elements 4 kg Sb-Equiv. | 6.44 × 10 −7 | 7.26 × 10 −4 | 1.49 × 10 −4 | 8.76 × 10 −4 | 6.44 × 10 −7 | 5.32 × 10 −4 | 1.33 × 10 −4 | 6.65 × 10 −4 |

| ADP fossil 5 MJ | 15.5 | 59,800 | 4.48 × 10 6 | 4.54 × 10 6 | 15.5 | 43,700 | 3.98 × 10 6 | 4.03 × 10 6 |

| AP 6 kg SO2-Equiv. | 0.000429 | 2.13 | 651 | 653 | 0.00429 | 1.56 | 578 | 580 |

| EP 7 kg Phosphate-Equiv. | 9.90 × 10 −4 | 0.710 | 45.0 | 45.7 | 9.90 × 10 −4 | 0.520 | 40.0 | 40.5 |

| FAETP 8 kg DCB-Equiv. | 0.00415 | 35.6 | 99,800 | 99,900 | 0.00415 | 26.1 | 88,700 | 88,800 |

| GWP 100 years 9 kg CO2-Equiv. | 1.50 | 533 | 48,000 | 48,500 | 1.50 | 390 | 42,600 | 43,000 |

| HTP 10 kg DCB-Equiv. | 0.0624 | 451 | 282,000 | 282,000 | 0.0624 | 330 | 250,000 | 251,000 |

| MAETP 11 kg DCB-Equiv. | 135 | 67,700 | 3.78 × 10 8 | 3.78 × 10 8 | 135 | 49,500 | 3.36 × 10 8 | 3.36 × 10 8 |

| ODP 12 kg R11-Equiv. | 5.41 × 10 −12 | 2.75 × 10 −8 | 1.34 × 10 −5 | 1.34 × 10 −5 | 5.41 × 10 −12 | 2.02 × 10 −8 | 1.19 × 10 −5 | 1.19 × 10 −5 |

| POCP 13 kg Ethene-Equiv. | 3.79 × 10 −4 | 0.478 | 104 | 105 | 3.79 × 10 −4 | 0.349 | 92.8 | 93.1 |

| TETP 14 kg DCB-Equiv. | 0.00494 | 1.61 | 17.7 | 19.3 | 0.0494 | 1.17 | 15.7 | 16.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balaguera, A.; Alberti, J.; Carvajal, G.I.; Fullana-i-Palmer, P. Stabilising Rural Roads with Waste Streams in Colombia as an Environmental Strategy Based on a Life Cycle Assessment Methodology. Sustainability 2021, 13, 2458. https://doi.org/10.3390/su13052458

Balaguera A, Alberti J, Carvajal GI, Fullana-i-Palmer P. Stabilising Rural Roads with Waste Streams in Colombia as an Environmental Strategy Based on a Life Cycle Assessment Methodology. Sustainability. 2021; 13(5):2458. https://doi.org/10.3390/su13052458

Chicago/Turabian StyleBalaguera, Alejandra, Jaume Alberti, Gloria I. Carvajal, and Pere Fullana-i-Palmer. 2021. "Stabilising Rural Roads with Waste Streams in Colombia as an Environmental Strategy Based on a Life Cycle Assessment Methodology" Sustainability 13, no. 5: 2458. https://doi.org/10.3390/su13052458

APA StyleBalaguera, A., Alberti, J., Carvajal, G. I., & Fullana-i-Palmer, P. (2021). Stabilising Rural Roads with Waste Streams in Colombia as an Environmental Strategy Based on a Life Cycle Assessment Methodology. Sustainability, 13(5), 2458. https://doi.org/10.3390/su13052458