Waste to Wealth: Value Recovery from Bakery Wastes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Collection of Feedstocks

2.2. Characteristics of the Feedstock

2.3. Composting Bin

2.4. Preparation of Microbial Inoculant

2.5. Composting

2.6. Physicochemical Analysis of Compost

2.6.1. Determination of pH and Electrical Conductivity

2.6.2. Determination of Moisture Content

2.6.3. Determination of Temperature

2.6.4. Determination of Water Holding Capacity (WHC)

2.6.5. Nitrogen, Phosphorus, Potassium (N,P,K), and Total Organic Carbon (TOC) Analysis of End Product

2.6.6. Color Intensity of Water Extract

2.6.7. Determination of Phytotoxicity

2.7. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Properties

3.1.1. Analysis of Compost Feedstocks

3.1.2. Temperature Analysis of Compost Trials

3.1.3. pH Analysis of Compost Trials

3.1.4. Moisture Content Analysis of Compost Trials

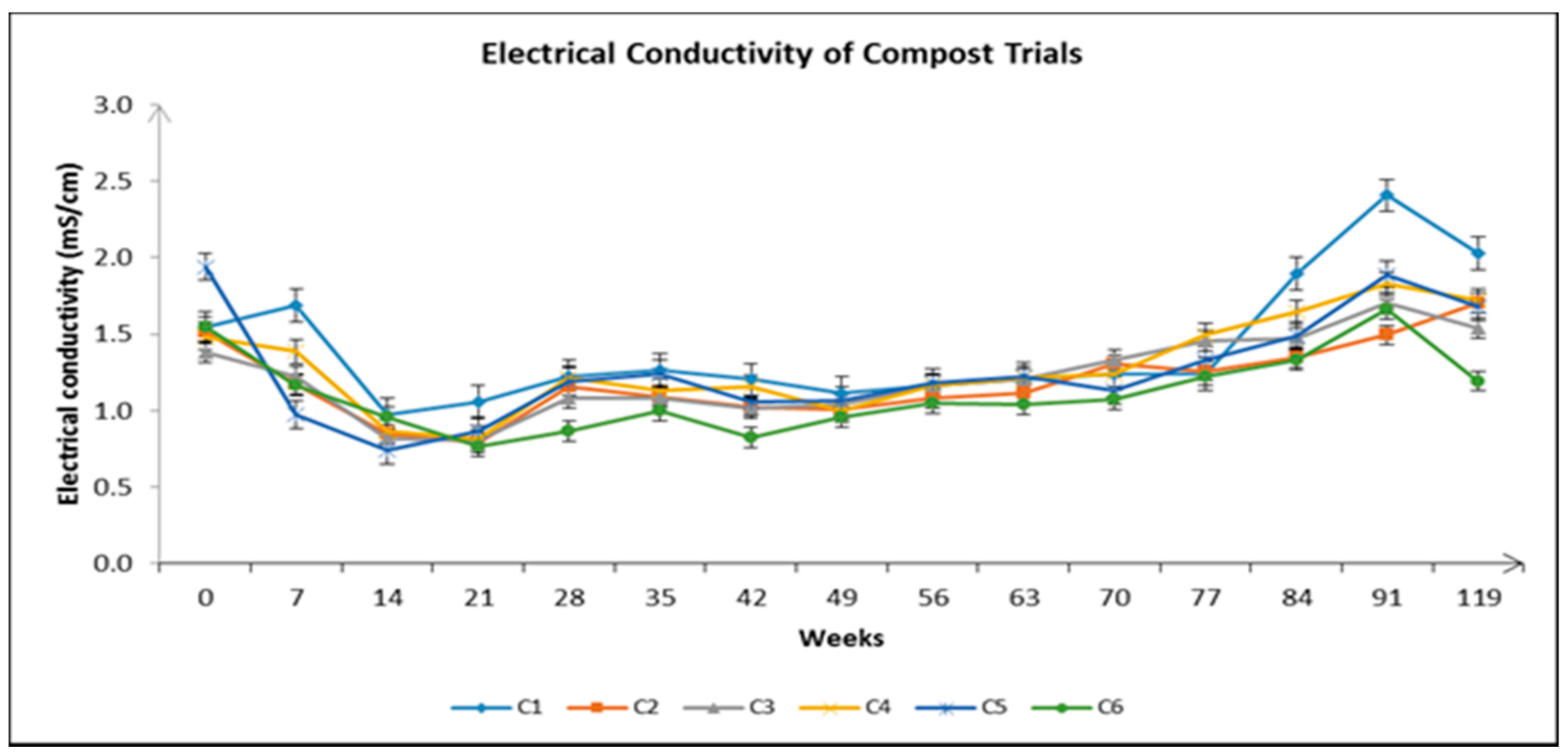

3.1.5. Electrical Conductivity Analysis of Compost Trials

3.1.6. Water Holding Capacity (WHC) Analysis of Compost Trials

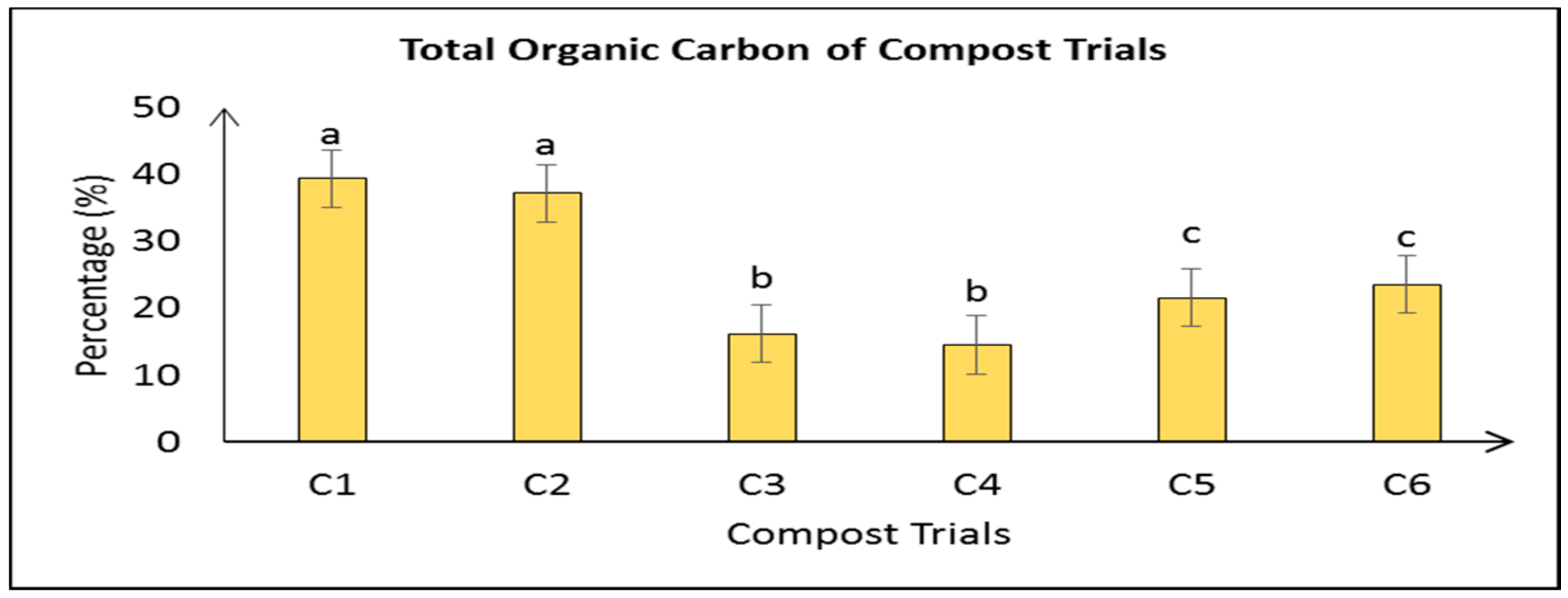

3.1.7. NPK and TOC Analysis on Compost Trials

3.1.8. C/N Ratio of Compost Trials

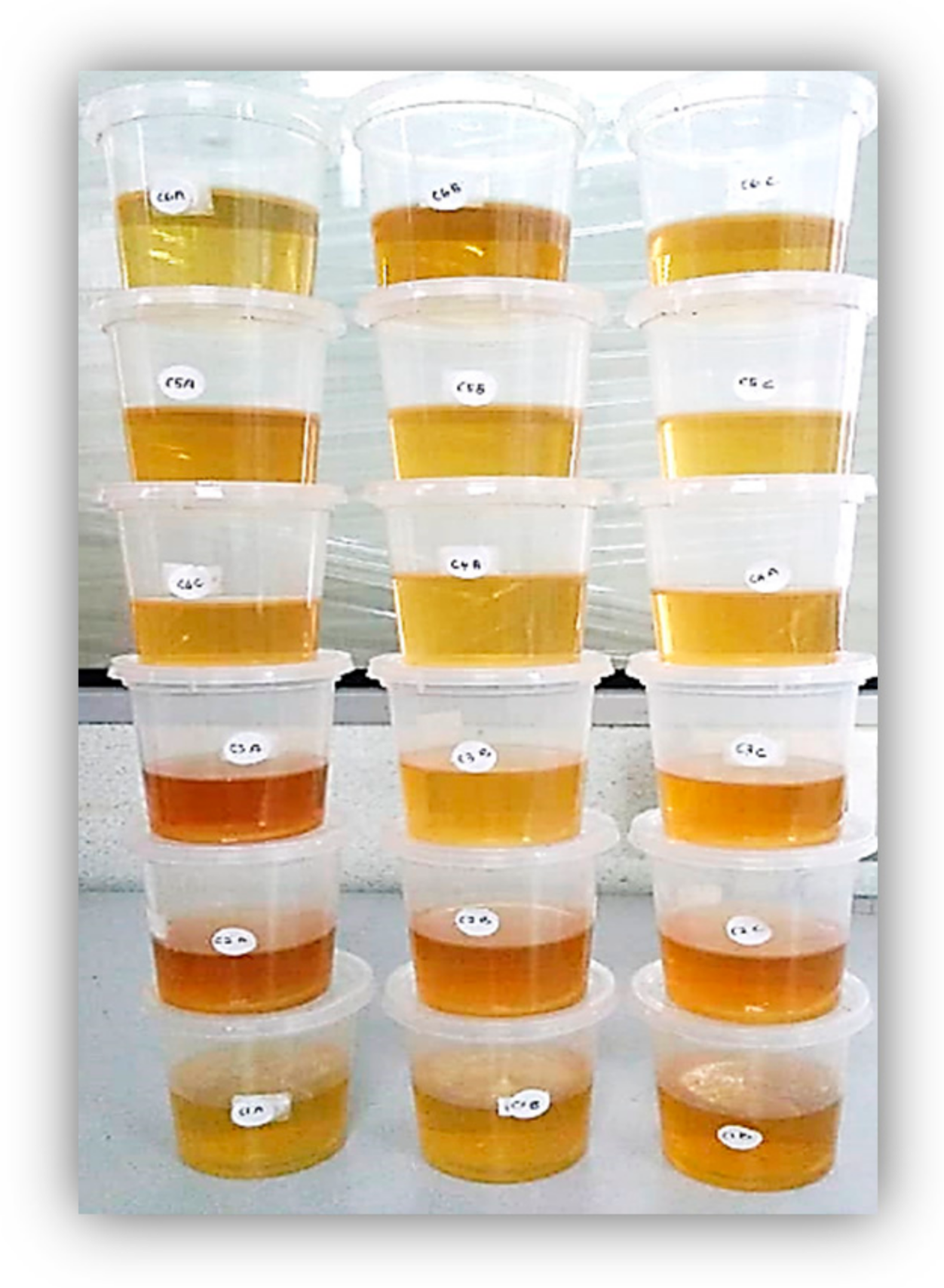

3.1.9. The Color Intensity of Water Extract of Compost Trials

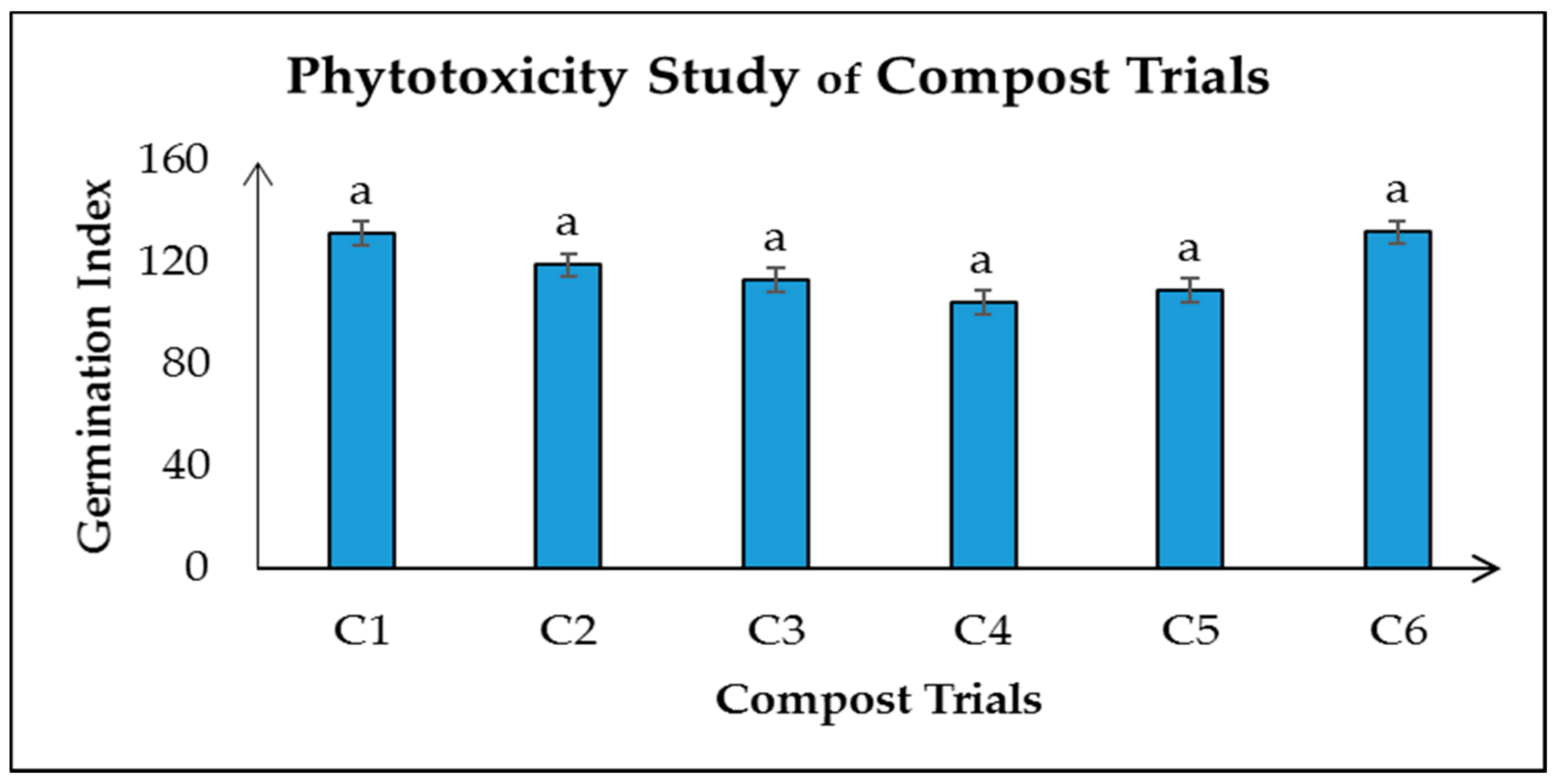

3.2. Phytotoxicity Analysis of Compost Trials

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ferronato, N.; Torretta, V. Waste Mismanagement in Developing Countries: A Review of Global Issues. IJERPH 2019, 16, 1060. [Google Scholar] [CrossRef] [Green Version]

- FAO. Towards the Future We Want: End Hunger and Make the Transition to Sustainable Agricultural and Food Systems; Food and Agriculture Organization of the United Nations: Rome, Italy, 2012. [Google Scholar]

- Melikoglu, M.; Lin, C.; Webb, C. Analysing Global Food Waste Problem: Pinpointing the Facts and Estimating the Energy Content. Open Eng. 2013, 3, 157–164. [Google Scholar] [CrossRef]

- Paritosh, K.; Kushwaha, S.K.; Yadav, M.; Pareek, N.; Chawade, A.; Vivekanand, V. Food Waste to Energy: An Overview of Sustainable Approaches for Food Waste Management and Nutrient Recycling. BioMed Res. Int. 2017, 2017, 2370927. [Google Scholar] [CrossRef]

- Katami, T.; Yasuhara, A.; Shibamoto, T. Formation of Dioxins from Incineration of Foods Found in Domestic Garbage. Environ. Sci. Technol. 2004, 38, 1062–1065. [Google Scholar] [CrossRef] [PubMed]

- Ma, H.; Wang, Q.; Qian, D.; Gong, L.; Zhang, W. The Utilization of Acid-Tolerant Bacteria on Ethanol Production from Kitchen Garbage. Renew. Energy 2009, 34, 1466–1470. [Google Scholar] [CrossRef]

- Macgregor, C.A. Directory of Feeds & Feed Ingredients, 3rd ed.; Hoard’s Dairyman; W.D. Hoard & Sons: Fort Atkinson, WI, USA, 2000. [Google Scholar]

- Quested, T.; Johnson, H. Household Food and Drink Waste in the UK: Final Report; Wastes & Resources Action Programme (WRAP): Banbury, UK, 2009. [Google Scholar]

- Zhang, A.Y.; Sun, Z.; Leung, C.C.J.; Han, W.; Lau, K.Y.; Li, M.; Lin, C.S.K. Valorisation of Bakery Waste for Succinic Acid Production. Green Chem. 2013, 15, 690. [Google Scholar] [CrossRef]

- Han, W.; Lam, W.C.; Melikoglu, M.; Wong, M.T.; Leung, H.T.; Ng, C.L.; Yan, P.; Yeung, S.Y.; Lin, C.S.K. Kinetic Analysis of a Crude Enzyme Extract Produced via Solid State Fermentation of Bakery Waste. ACS Sustain. Chem. Eng. 2015, 3, 2043–2048. [Google Scholar] [CrossRef]

- Neves, L.; Ferreira, V.; Oliveira, R. Co-Composting Cow Manure with Food Waste: The Influence of Lipids Content. World Acad. Sci. Eng. Technol. 2009, 58, 986–991. [Google Scholar]

- Kadir, A.A.; Azhari, N.W.; Jamaludin, S.N. Evaluation of Physical, Chemical and Heavy Metal Concentration of Food Waste Composting. MATEC Web Conf. 2017, 103, 5014. [Google Scholar] [CrossRef] [Green Version]

- Hassen, A.; Belguith, K.; Jedidi, N.; Cherif, A.; Cherif, M.; Boudabous, A. Microbial Characterization during Composting of Municipal Solid Waste. Bioresour. Technol. 2001, 80, 217–225. [Google Scholar] [CrossRef]

- Frimpong, K.; Asare-Bediako, E.; Amissah, R.; Okae-Anti, D. Influence of Compost on Incidence and Severity of Okra Mosaic Disease and Fruit Yield and Quality of Two Okra (Abelmoschus esculentus L. Moench) Cultivars. IJPSS 2017, 16, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Khater, E.S. Some Physical and Chemical Properties of Compost. Int. J. Waste Resour. 2015, 5. [Google Scholar] [CrossRef]

- Misra, R.V.; Roy, R.N.; Hiraoka, H. On-Farm Composting Methods; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013. [Google Scholar]

- Zhang, M.; Wang, N.; Xu, Q.; Harlina, P.W.; Ma, M. An Efficient Method for Co-Purification of Eggshell Matrix Proteins OC-17, OC-116, and OCX-36. Korean J. Food Sci. Anim. Resour. 2016, 36, 769–778. [Google Scholar] [CrossRef] [Green Version]

- Wolka, K.; Melaku, B. Exploring Selected Plant Nutrient in Compost Prepared from Food Waste and Cattle Manure and Its Effect on Soil Properties and Maize Yield at Wondo Genet, Ethiopia. Environ. Syst. Res. 2015, 4, 9. [Google Scholar] [CrossRef] [Green Version]

- Ong, H.K.; Chew, B.H.; Suhaimi, M. Effect of Effective Microorganisms on Composting Characteristics of Chicken Manure. J. Trop. Agric. Food Sci. 2001, 2, 189–196. [Google Scholar]

- Kumar, M.; Ou, Y.L.; Lin, J.G. Co-Composting of Green Waste and Food Waste at Low C/N Ratio. Waste Manag. 2010, 30, 602–609. [Google Scholar] [CrossRef] [PubMed]

- EMRO Malaysia Sdn Bhd. How to Produce EMAS (EM Activated Solution), EMRO Malaysia Sdn Bhd. 2020. Available online: https://www.emromalaysia.my/index.php?ws=showproducts&products_id=2294283 (accessed on 28 February 2021).

- Mathews, S.; Gowrilekshmi, R. Solid Waste Management Using Effective Microorganism (EM) Technology. Int. J. Curr. Microbiol. Appl. Sci. 2016, 5, 804–815. [Google Scholar] [CrossRef]

- Jusoh, M.L.; Manaf, L.A.; Latiff, P.A. Composting of Rice Straw with Effective Microorganisms (EM) and Its Influence on Compost Quality. J. Environ. Health Sci. Eng. 2013, 10, 17. [Google Scholar] [CrossRef] [Green Version]

- Selim, S.M.; Zayed, M.S.; Atta, H.M. Evaluation of Phytotoxicity of Compost during Composting Process. Nat. Sci. 2011, 10, 69–77. [Google Scholar]

- Ameen, A.; Raza, S.; Ahmad, J. Effect of PH and Moisture Content on Composting of Municipal Solid Waste. Int. J. Sci. Res. Publ. 2016, 6, 35–37. [Google Scholar]

- Waqas, M.; Nizami, A.S.; Aburiazaiza, A.S.; Barakat, M.A.; Ismail, I.M.I.; Rashid, M.I. Optimization of Food Waste Compost with the Use of Biochar. J. Environ. Manag. 2018, 216, 70–81. [Google Scholar] [CrossRef]

- Mat Saad, N.F.; Ma’min, N.N.; Md Zain, S.; Ahmad Basri, N.E.; Md Zaini, N.S. Composting of Mixed Yard and Food Wastes with Effective Microbes. J. Teknol. 2013, 65, 89–95. [Google Scholar] [CrossRef] [Green Version]

- Cyrille, T.; Patrick, E.A.; Lyde, T.A.; Mama, D.; Boko, M. Physico- Chemical Characteristics of Compost (Cotonou, Benin, West Africa). J. Appl. Sci. Environ. Manag. 2014, 18, 301–306. [Google Scholar] [CrossRef] [Green Version]

- Rynk, R. Top Soil Bulk Compost Suppliers, Logs and Firewood. In Science of Composting; Olus Environmental Ltd. Company: Henfield, UK, 2008; pp. 24–30. [Google Scholar]

- Sánchez-Monedero, M.; Urpilainen, S.T.; Cabañas-Vargas, D.D.; Kamilaki, A.; Stentiford, E.I. Assessing the Stability and Maturity of Compost at Large-Scale Plants. Interam. Sanit. Environ. Eng. Assoc. 2005, 9, 25–30. [Google Scholar]

- Der Wurff, A.; Fuchs, J.G.; Raviv, M.; Termorshuizen, A. Handbook for Composting and Compost Use in Organic Horticulture; BioGreenhouse COST Action FA1105: Bleiswijk, The Netherlands, 2016. [Google Scholar]

- Masó, M.A.; Blasi, A.B. Evaluation of Composting as a Strategy for Managing Organic Wastes from a Municipal Market in Nicaragua. Bioresour. Technol. 2008, 99, 5120–5124. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.V.; Lee, C.T.; Leow, C.W.; Chua, L.S.; Sarmidi, M.R. Physico-Chemical and Biological Changes During Co-Composting of Model Kitchen Waste, Rice Bran and Dried Leaves with Different Microbial Inoculants. MJAS 2016, 20, 1447–1457. [Google Scholar] [CrossRef]

- Zucconi, F.; Pera, A.M.F.; Bertoldi, M.D. Evaluating Toxicity of Immature Compost. BioCycle 1981, 22, 54–57. [Google Scholar]

- Monson, C.C.; Murugappan, A. Developing Optimal Combination of Bulking Agents in an In-Vessel Composting of Vegetable Waste. E-J. Chem. 2010, 7, 93–100. [Google Scholar] [CrossRef]

- Cooperband, L. The Art and Science of Composting Science of Composting; University of Wisconsin-Madison: Madison, WI, USA, 2002. [Google Scholar]

- Irshad, M.; Eneji, A.E.; Hussain, Z.; Ashraf, M. Chemical Characterization of Fresh and Composted Livestock Manures. J. Soil Sci. Plant Nutr. 2013, 13, 115–121. [Google Scholar] [CrossRef] [Green Version]

- Hunton, P. Research on Eggshell Structure and Quality: An Historical Overview. Rev. Bras. Cienc. Avic. 2005, 7, 67–71. [Google Scholar] [CrossRef] [Green Version]

- McSweeney, J. Analytically Based Recipe Development; Agency of Natural Resources, Department of Environmental Conservation: Fairfield, NJ, USA, 2015. [Google Scholar]

- Palaniveloo, K.; Amran, M.A.; Norhashim, N.A.; Mohamad-Fauzi, N.; Peng-Hui, F.; Hui-Wen, L.; Kai-Lin, Y.; Jiale, L.; Chian-Yee, M.G.; Jing-Yi, L.; et al. Food Waste Composting and Microbial Community Structure Profiling. Processes 2020, 8, 723. [Google Scholar] [CrossRef]

- Ozores-Hampton, M. Guidelines for Assessing Compost Quality for Safe and Effective Utilization in Vegetable Production. hortte 2017, 27, 162–165. [Google Scholar] [CrossRef]

- Chaher, N.E.; Chakchouk, M.; Engler, N.; Nassour, A.; Nelles, M.; Hamdi, M. Optimization of Food Waste and Biochar In-Vessel Co-Composting. Sustainability 2020, 12, 1356. [Google Scholar] [CrossRef] [Green Version]

- Bernal, M.P.; Alburquerque, J.A.; Moral, R. Composting of Animal Manures and Chemical Criteria for Compost Maturity Assessment. A Review. Bioresour. Technol. 2009, 100, 5444–5453. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Zhang, L.; Sun, X. Improvement of Two-Stage Composting of Green Waste by Addition of Eggshell Waste and Rice Husks. Bioresour. Technol. 2021, 320, 124388. [Google Scholar] [CrossRef] [PubMed]

- Trautmann, N.M.; Krasny, M.E. The Science of Composting. In Composting in the Classroom; Soil Wealth Integrated Crop. Protection; Kendall/Hunt Publishing Company: Dubuque, IA, USA, 2015. [Google Scholar]

- Sundberg, C.; Smars, S.; Jonsson, H. Low PH as an Inhibiting Factor in the Transition from Mesophilic to Thermophilic Phase in Composting. Bioresour. Technol. 2004, 95, 145–150. [Google Scholar] [CrossRef]

- Epstein, E. The Science of Composting; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Hashemi, S.; Boudaghpour, S.; Han, M. Evaluation of Different Natural Additives Effects on the Composting Process of Source Separated Feces in Resource-Oriented Sanitation Systems. Ecotoxicol. Environ. Saf. 2019, 185, 109667. [Google Scholar] [CrossRef]

- Ayilara, M.; Olanrewaju, O.; Babalola, O.; Odeyemi, O. Waste Management through Composting: Challenges and Potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Cofie, O.; Nikiema, J.; Impraim, R.; Adamtey, A.; Paul, J.; Kone, D. Co-Composting of Solid Waste and Fecal Sludge for Nutrient and Organic Matter Recovery; International Water Management Institute (IWMI): Gujarat, India, 2016. [Google Scholar] [CrossRef]

- Manga, M.; Camargo-Valero, M.A.; Anthonj, C.; Evans, B.E. Fate of Faecal Pathogen Indicators during Faecal Sludge Composting with Different Bulking Agents in Tropical Climate. Int. J. Hyg. Environ. Health 2021, 232, 113670. [Google Scholar] [CrossRef]

- Benito, M.; Masaguer, A.; Moliner, A.; Arrigo, N.; Palma, R.M. Chemical and Microbiological Parameters for the Characterisation of the Stability and Maturity of Pruning Waste Compost. Biol. Fertil. Soils 2003, 37, 184–189. [Google Scholar] [CrossRef]

- Lasaridi, K.; Protopapa, I.; Kotsou, M.; Pilidis, G.; Manios, T.; Kyriacou, A. Quality Assessment of Composts in the Greek Market: The Need for Standards and Quality Assurance. J. Environ. Manag. 2006, 80, 58–65. [Google Scholar] [CrossRef] [PubMed]

- A&L Canada Laboratories. Compost Analysis for Available Nutrients and Soil Suitability Criteria and Evaluation; A&L Canada Laboratories: London, ON, Canada, 2004. [Google Scholar]

- Carvalho, J.; Araujo, J.; Castro, F. Alternative Low-Cost Adsorbent for Water and Wastewater Decontamination Derived from Eggshell Waste: An Overview. Waste Biomass Valor 2011, 2, 157–167. [Google Scholar] [CrossRef] [Green Version]

- Farahana, R.N.; Supri, A.G.; Teh, P.L. Tensile and Water Absorption Properties of Eggshell Powder Filled Recycled High-Density Polyethylene/Ethylene Vinyl Acetate Composites: Effect of 3-Aminopropyltriethoxysilane. J. Adv. Res. Mater. Sci. 2015, 5, 1–9. [Google Scholar]

- Daur, I. Study of Commercial Effective Microorganism on Composting and Dynamics of Plant Essential Metal Micronutrients. J. Environ. Biol. 2016, 37, 937–941. [Google Scholar]

- Mutairi, S.; Ghoneim, A.; Modaihsh, A.; Alotaibi, K.; Al-Barakah, F.; Noor, M. Deriving Compost from Municipal OrganicWastes in Saudi Arabia. Pol. J. Environ. Stud. 2019, 28, 1839–1845. [Google Scholar] [CrossRef]

- Eitbrecht, K.; Müller, K.; Gerhard, L.-M. First off the Mark: Early Seed Germination. J. Exp. Bot. 2011, 62, 3289–3309. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elamin, E.A.; El-Tilib, A.M.; El-Gaziri, M.M. Effects of Nitrogen Fertilization and Calcium Carbonate on Soil Nitrogen, Phosporus, Potassium, Calcium and Magnesium. Univ. Khartoum J. Agric. Sci. 2007, 15, 259–272. [Google Scholar]

- Monteith, N.H.; Sherman, G.D. The Comparative Effects of Calcium Carbonate and of Calcium Silicate on the Yield of Sudan Grass Grown in a Ferruginous Latosol and a Hydrol Humic Latosol; University of Hawaii, College of Tropical Agriculture: Honolulu, HI, USA, 1963. [Google Scholar]

- Najafi-Ghiri, M.; Abtahi, A. Potassium Fixation in Soil Size Fractions of Arid Soils. Soil Water Res. 2013, 8, 49–55. [Google Scholar] [CrossRef] [Green Version]

- Iglesias-Jimenez, E.; Perez-Garcia, V. Determination of Maturity Indices for City Refuse Composts. Agric. Ecosyst. Environ. 1992, 38, 331–343. [Google Scholar] [CrossRef]

- Adi, A.J.; Noor, Z.M. Waste Recycling: Utilization of Coffee Grounds and Kitchen Waste in Vermicomposting. Bioresour. Technol. 2009, 100, 1027–1030. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Kalamdhad, A.S. Reduction of Heavy Metals during Composting—A Review. Int. J. Environ. Prot. 2012, 2, 36–43. [Google Scholar]

- Emino, E.R.; Warman, P.R. Biological Assay for Compost Quality. Compos. Sci. Util. 2004, 12, 342–348. [Google Scholar] [CrossRef]

- Tiquia, S.M.; Tam, N.F.Y.; Hodgkiss, I.J. Effects of Composting on Phytotoxicity of Spent Pig-Manure Sawdust Litter. Environ. Pollut. 1996, 93, 249–256. [Google Scholar] [CrossRef]

- Fuentes, A. Phytotoxicity and Heavy Metals Speciation of Stabilised Sewage Sludges. J. Hazard. Mater. 2004, 108, 161–169. [Google Scholar] [CrossRef]

- Luo, Y.; Liang, J.; Zeng, G.; Chen, M.; Mo, D.; Li, G.; Zhang, D. Seed Germination Test for Toxicity Evaluation of Compost: Its Roles, Problems and Prospects. Waste Manag. 2018, 71, 109–114. [Google Scholar] [CrossRef]

- Qian, X.; Shen, G.; Wang, Z.; Guo, C.; Liu, Y.; Lei, Z.; Zhang, Z. Co-Composting of Livestock Manure with Rice Straw: Characterization and Establishment of Maturity Evaluation System. Waste Manag. 2014, 34, 530–535. [Google Scholar] [CrossRef] [Green Version]

- Bazrafshan, E.; Zarei, A.; Kord Mostafapour, F.; Poormollae, N.; Mahmoodi, S.; Zazouli, M.A. Maturity and Stability Evaluation of Composted Municipal Solid Wastes. Health Scope 2016, 5, e33202. [Google Scholar] [CrossRef] [Green Version]

| Trials | Non-Creamy BW | Creamy BW | CD | DL | PB | ES | EM Culture |

|---|---|---|---|---|---|---|---|

| C1 | 1 kg | − | 1.5 kg | 1 kg | 0.5 kg | − | − |

| C2 | − | 1 kg | 1.5 kg | 1 kg | 0.5 kg | − | − |

| C3 | − | 1 kg | 1.5 kg | 1 kg | 0.5 kg | − | 1 L |

| C4 | 1 kg | − | 1.5 kg | 1 kg | 0.5 kg | − | 1 L |

| C5 | 1 kg | − | 1.5 kg | 1 kg | 0.5 kg | 1 kg | 1 L |

| C6 | − | 1 kg | 1.5 kg | 1 kg | 0.5 kg | 1 kg | 1 L |

| Feedstocks | Moisture Content (%) | pH | EC (ms/cm) | TOC (%) | N (%) | P (%) | K (%) | C/N Ratio |

|---|---|---|---|---|---|---|---|---|

| Non-creamy bakery waste | 21.80 (±0.32) | 6.54 (±0.04) | 1.85 (±0.02) | 40.60 (±0.15) | 1.45 (±0.02) | 0.49 (±0.02) | 0.18 (±0.01) | 28.07 (±0.24) |

| Creamy bakery waste | 32.23 (±0.35) | 6.01 (±0.02) | 1.59 (±0.02) | 31.47 (±0.09) | 1.21 (±0.02) | 0.30 (±0.01) | 0.17 (±0.01) | 26.09 (±0.47) |

| Dry leaves | 11.53 (±0.20) | 4.34 (±0.02) | 1.07 (±0.01) | 31.70 (±0.10) | 0.73 (±0.02) | 0.15 (±0.01) | 0.34 (±0.01) | 43.46 (±0.81) |

| Paper boxes | 0.00 (±0.00) | 7.14 (±0.02) | 0.35 (±0.02) | 34.57 (±0.18) | 0.24 (±0.01) | 0.00 (±0.00) | 0.02 (±0.00) | 147.10 (±8.57) |

| Cow dung | 71.40 (±0.83) | 9.16 (±0.02) | 2.44 (±0.03) | 14.53 (±0.15) | 1.71 (±0.01) | 0.43 (±0.02) | 0.53 (±0.03) | 8.48 (±0.11) |

| Eggshells | 0.00 (±0.00) | 9.06 (±0.03) | 0.14 (±0.01) | 1.80 (±0.06) | 0.79 (±0.01) | 0.36 (±0.01) | 0.05 (±0.00) | 2.29 (±0.10) |

| p-value | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Govindaraju, M.; Sathasivam, K.V.; Marimuthu, K. Waste to Wealth: Value Recovery from Bakery Wastes. Sustainability 2021, 13, 2835. https://doi.org/10.3390/su13052835

Govindaraju M, Sathasivam KV, Marimuthu K. Waste to Wealth: Value Recovery from Bakery Wastes. Sustainability. 2021; 13(5):2835. https://doi.org/10.3390/su13052835

Chicago/Turabian StyleGovindaraju, Mugilan, Kathiresan V. Sathasivam, and Kasi Marimuthu. 2021. "Waste to Wealth: Value Recovery from Bakery Wastes" Sustainability 13, no. 5: 2835. https://doi.org/10.3390/su13052835

APA StyleGovindaraju, M., Sathasivam, K. V., & Marimuthu, K. (2021). Waste to Wealth: Value Recovery from Bakery Wastes. Sustainability, 13(5), 2835. https://doi.org/10.3390/su13052835