Quality 4.0: The EFQM 2020 Model and Industry 4.0 Relationships and Implications

Abstract

1. Introduction

- RQ1. What are the novel features of the EFQM 2020 model?

- RQ2. What are the relationships and implications between the EFQM 2020 model and Industry 4.0?

- RQ3. Is the EFQM 2020 model a novel Quality 4.0 management system?

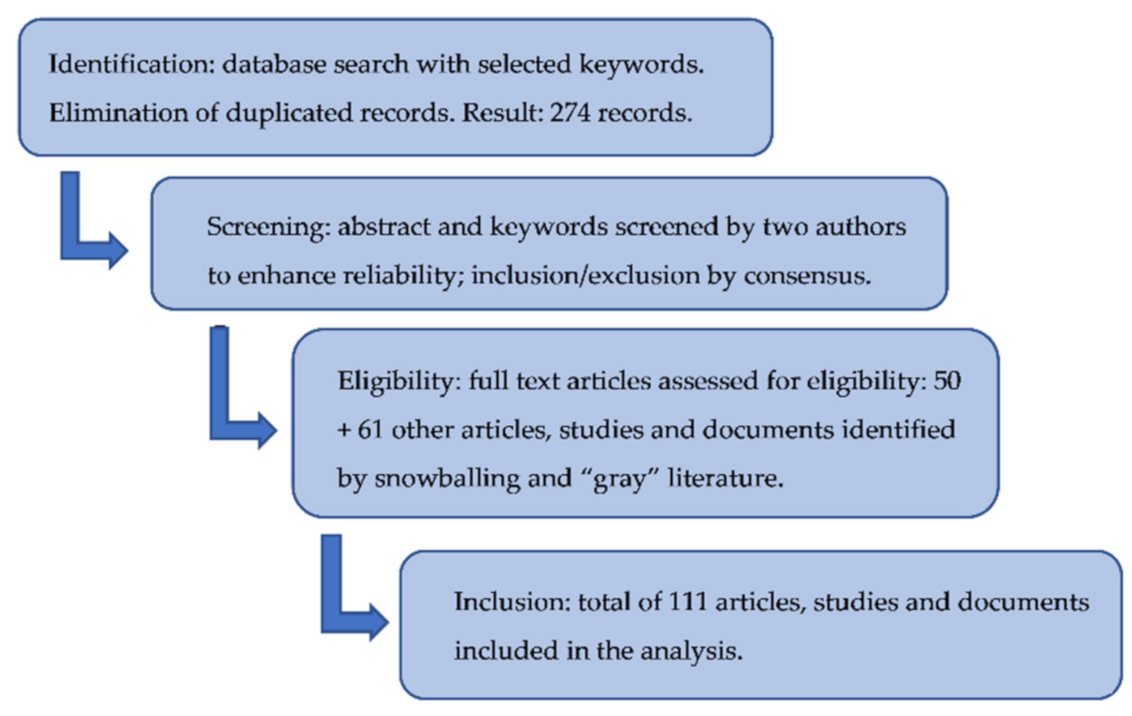

2. Materials and Methods

3. Literature Review

3.1. The EFQM 2020 Model

3.2. Industry 4.0

- The industrial Internet of Things (IoT) allows people and things to be always interconnected, digitalizing all physical systems towards ensuring transformational solutions that will be foundational for future complex business ecosystems [43].

- Cloud computing, using cloud applications and services conveniently combined towards enhancing systems interoperability, data sharing, and the improvement of systems’ performance over time [63].

- Big data: “large volumes of high velocity, complex and variable data requiring advanced techniques to enable the capture, storage, distribution, management and analysis of the information” [64].

- Simulation: the development of digital twin models to better understand the dynamics of simulations in business systems applicable to all product lifecycle phases. The combination of real-life data with simulation models improves productivity and maintenance performance, based on realistic data [65,66].

- Additive manufacturing is a technology, also known as rapid prototyping, digital manufacturing, or 3D printing, that enables the development of new products and business models [68].

- Horizontal and vertical system integration, with collaborative scenarios of system integration and real-time sharing [69].

- Autonomous robots with AI and improved adaptation and flexibility can support different manufacturing processes and decrease production costs [69].

3.3. Quality 4.0

4. Discussion of the EFQM 2020 Model and Industry 4.0 Relationships and Implications

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peters, T.; Waterman, R.H., Jr. In Search of Excellence. Lessons from American Best-Run Companies; Harper & Row: New York, NY, USA, 1982. [Google Scholar]

- Hussain, T.; Edgeman, R.; Eskildsen, J.K. Knowledge-based intellectual structure of research in business excellence (1995–2015). Total. Qual. Manag. Bus. Excell. 2018, 1, 1–24. [Google Scholar] [CrossRef]

- Fonseca, L.M. Relationship between ISO 9001 certification and EFQM Business Excellence Model results. Qual. Innov. Prosper. 2015, 19, 85–102. [Google Scholar] [CrossRef]

- Nair, A. Meta-analysis of the relationship between quality management practices and firm performance implications for quality management theory development. J. Oper. Manag. 2006, 24, 948–975. [Google Scholar] [CrossRef]

- Vora, M.K. Business excellence through quality management. Total Qual. Manag. 2002, 13, 1151–1159. [Google Scholar] [CrossRef]

- Ghafoor, S.; Grigg, N.P.; Mathrani, S.; Mann, R. A bibliometric and thematic review of business excellence journal papers from 1990 to 2020. Total. Qual. Manag. Bus. Excell. 2020. [Google Scholar] [CrossRef]

- Nenadál, J. The New EFQM Model: What is Really New and Could Be Considered as a Suitable Tool with Respect to Quality 4.0 Concept? Qual. Innov. Prosper. 2020, 24, 17–28. [Google Scholar] [CrossRef]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J.P. Industry 4.0 implies lean manufacturing: Research activities in industry 4.0 function as enablers for lean manufacturing. J. Ind. Eng. Manag. (JIEM) 2016, 9, 811–833. [Google Scholar] [CrossRef]

- Fonseca, L.M.; Domingues, J.P. The best of both worlds? Use of Kaizen and other continuous improvement methodologies within Portuguese ISO 9001 certified organization. TQM J. 2018, 30, 321–334. [Google Scholar] [CrossRef]

- Kolesar, P.J. Juran’s lectures to Japanese executives in 1954: A perspective and some contemporary lessons. Qual. Manag. J. 2008, 15, 5–12. [Google Scholar] [CrossRef]

- Bergman, B.; Klefsjö, B. Quality from Customer Needs to Customer Satisfaction; Studentlitteratur: Stockholm, Sweden, 2010. [Google Scholar]

- Siva, V.; Gremyr, I.; Bergquist, B.; Garvare, R.; Zobel, T.; Isaksson, R. The support of Quality Management to sustainable development: A literature review. J. Clean. Prod. 2016, 138, 148–157. [Google Scholar] [CrossRef]

- Abbas, J. Impact of total quality management on corporate sustainability through the mediating effect of knowledge management. J. Clean Prod. 2020, 244, 118806. [Google Scholar] [CrossRef]

- Küpper, D.; Knizek, C.; Ryeson, D.; Noecker, J. Quality 4.0 Takes More than Technology. In Boston Consulting Group (BCG). 2019. Available online: https://www.bcg.com/publications/2019/quality-4.0-takes-more-than-technology.aspx (accessed on 5 February 2021).

- Sony, M.; Antony, J.; Douglas, J.A. Essential ingredients for the implementation of Quality 4.0: A narrative review of literature and future directions for research. TQM J. 2020, 32, 779–793. [Google Scholar] [CrossRef]

- Vial, G. Understanding digital transformation: A review and a research agenda. In J. Strateg. Inf. Syst. 2019. [Google Scholar] [CrossRef]

- Qin, J.; Liu, Y.; Grosvenor, R. A categorical framework of manufacturing for industry 4.0 and beyond. Procedia CIRP 2016, 52, 173–178. [Google Scholar] [CrossRef]

- Prinz, C.; Kreggenfeld, N.; Kuhlenkötter, B. Lean meets industrie 4.0—A practical approach to interlink the method world and cyber-physical world. Procedia Manuf. 2018, 23, 21–26. [Google Scholar] [CrossRef]

- Shin, W.S.; Dahlgaard, J.J.; Dahlgaard-Park, S.M.; Kim, M.G. A quality scorecard for the era of industry 4.0. Total. Qual. Manag. Bus. Excell 2018, 29, 959–976. [Google Scholar] [CrossRef]

- Hyun Park, S.; Seon Shin, W.; Hyun Park, Y.; Lee, Y. Building a new culture for quality management in the era of the Fourth Industrial Revolution. Total. Qual. Manag. Bus. Excell. 2017, 28, 934–945. [Google Scholar] [CrossRef]

- Rowlands, H. Manufacturing Quality 4.0. In Proceedings of the 21st QMOD-ICQSS Conference, Cardiff University, Cardiff, UK, 22–24 August 2018. [Google Scholar]

- Rowlands, H.; Milligan, S. Future Research Agenda for Quality 4.0. In Proceedings of the 22nd QMOD-ICQSS Conference: Leadership and Strategies for Quality, Sustainability and Innovation in the 4th Industrial Revolution, Kraków, Poland, 13–15 October 2019. [Google Scholar]

- Tortorella, G.L.; Fettermann, D. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Group, P. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed]

- Torraco, R.J. Writing integrative literature reviews: Using the past and present to explore the future. Hum. Resour. Dev. Rev. 2016, 15, 404–428. [Google Scholar] [CrossRef]

- Adams, R.J.; Smart, P.; Huff, A.S. Shades of grey: Guidelines for working with the grey literature in systematic reviews for management and organizational studies. Int. J. Manag. Rev. 2017, 19, 432–454. [Google Scholar] [CrossRef]

- Conti, T.A. A history and review of the European Quality Award Model. TQM Mag. 2007, 19, 112–128. [Google Scholar] [CrossRef]

- Talwar, B. Business excellence models and the path ahead. TQM J. 2011, 23, 21–35. [Google Scholar] [CrossRef]

- Boon, O.K.; Arumugam, V.; Safa, M.S.; Bakar, N.A. HRM and TQM: Association with job involvement. Pers. Rev. 2007, 36, 939–962. [Google Scholar] [CrossRef]

- Bolboli, S.A.; Reiche, M. Development of an instrument for assessing corporate culture in the context of EFQM excellence model. Organ. Cult. Int. J. 2016, 16, 37–50. [Google Scholar] [CrossRef]

- Aras, G.; Crowther, D. Sustaining business excellence. Total. Qual. Manag. Bus. Excell. 2010, 21, 565–576. [Google Scholar] [CrossRef]

- Sadikoglu, E.; Olcay, H. The effects of total quality management practices on performance and the reasons of and the barriers to TQM practices in Turkey. Adv. Decis. Sci. 2014. [Google Scholar] [CrossRef]

- Carvalho, A.M.; Sampaio, P.; Rebentisch, E.; Saraiva, P. 35 years of excellence, and perspectives ahead for excellence 4.0. Total. Qual. Manag. Bus. Excell. 2019. [Google Scholar] [CrossRef]

- Bendell, T. Does Investing in Excellence Pay? 2007. Available online: http://slideplayer.com/slide/5789976/ (accessed on 11 October 2020).

- Edgeman, R. Excellence models as complex management systems: An examination of the shingo operational excellence model. Bus. Process Manag. J. 2018, 24, 1321–1338. [Google Scholar] [CrossRef]

- Boulter, L.; Bendell, T.; Dahlgaard, J. Total quality beyond North America: A comparative analysis of the performance of European excellence award winners. Int. J. Oper. Prod. Manag. 2013, 33, 197–215. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Subramanian, N.; Ngai, W.T.E. Quality management in the 21st century enterprises: Research pathway towards Industry 4.0. Int. J. Prod. Econ. 2019. [Google Scholar] [CrossRef]

- EFQM. EFQM Excellence Model; European Foundation for Quality Management: Brussels, Belgium, 2013. [Google Scholar]

- EFQM. The Fundamental Concepts of Excellence; European Foundation for Quality Management: Brussels, Belgium, 2003. [Google Scholar]

- EFQM. The EFQM Model; EFQM: Brussels, Belgium, 2019; ISBN 978-90-5236-845-0. [Google Scholar]

- EFQM. EFQM 2020 Model—EFQM. 2020. Available online: https://www.efqm.org/index.php/efqm-model/download-your-free-short-copy-of-the-efqm-model/ (accessed on 20 May 2020).

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Muhuri, P.K.; Shukla, A.K.; Abraham, A. Industry 4.0: A bibliometric analysis and detailed overview. Eng. Appl. Artif. Intell. 2019, 78, 218–235. [Google Scholar] [CrossRef]

- Bandyopadhyay, P.K.; Leonard, D. The value of using the Baldrige performance excellence framework in manufacturing organizations. J. Qual. Particip. 2016, 39, 10–14. [Google Scholar]

- Jankalová, M.; Jankal, R. How to Characterize Business Excellence and Determine the Relation between Business Excellence and Sustainability. Sustainability 2020, 12, 6198. [Google Scholar] [CrossRef]

- Fonseca, L.; Carvalho, F. The Reporting of SDGs by Quality, Environmental, and Occupational Health and Safety-Certified Organizations. Sustainability 2019, 11, 5797. [Google Scholar] [CrossRef]

- Chesbrough, H.; Rosenbloom, R.S. The role of the business model in capturing value from innovation: Evidence from Xerox Corporation’s technology spin-off companies. Ind. Corp. Chang. 2002, 11, 529–555. [Google Scholar] [CrossRef]

- Magretta, J. Why business models matter. Harv. Bus. Rev. 2002, 80, 86–92. [Google Scholar]

- Arend, R.J. The business model: Present and future-beyond a skeumorph. Strateg. Organ. 2013, 11, 390–402. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; Milgrom, P. Complementarity in organizations. In The Handbook of Organizational Economics; Gibbons, R., Roberts, J., Eds.; Princeton University Press: Princeton, NJ, USA, 2013; pp. 11–55. [Google Scholar]

- Baden-Fuller, C.; Morgan, M.S. Business models as models. Long Range Plan. 2010, 43, 156–171. [Google Scholar] [CrossRef]

- Amit, R.; Zott, C. Creating Value through business model innovation. MIT Sloan Manag. Rev. 2012, 2012, 41–49. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239. [Google Scholar] [CrossRef]

- Valdez, A.C.; Brauner, P.; Schaar, A.K.; Holzinger, A.; Zieflea, M. Reducing Complexity with simplicity-Usability Methods for Industry 4.0. In Proceedings of the 19th Triennial Congress of the IEA, Melbourne, Australia, 9–14 August 2015; RWTH Publications: Aachen, Germany, 2015; pp. 9–14. [Google Scholar]

- Müller, J.M.; Kiel, D.; Voigt, K.I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Galati, F.; Bigliardi, B. Industry 4.0: Emerging themes and future research avenues using a text mining approach. Comput. Ind. 2019, 109, 100–113. [Google Scholar] [CrossRef]

- Ejsmont, K.; Gladysz, B.; Kluczek, A. Impact of Industry 4.0 on Sustainability—Bibliometric Literature Review. Sustainability 2020, 12, 5650. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Quiver, F.H. Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104583. [Google Scholar] [CrossRef]

- Fonseca, L.M. Industry 4.0 and the digital society: Concepts, dimensions and envisioned benefits. Proc. Int. Conf. Bus. Excell. 2017, 12, 386–397. [Google Scholar] [CrossRef]

- Lorenz, M.; Rüßmann, M.; Waldner, M.; Engel, P.; Harnisch, M.; Justus, J. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries. Boston Consulting Group. 2015. Available online: https://www.bcg.com/publications/2015/engineered_products_project_business_industry_4_future_productivity_growth_manufacturing_industries (accessed on 20 May 2020).

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Cemernek, D.; Gursch, H.; Kern, R. Big Data as a promoter of industry 4.0: Lessons of the semiconductor industry. In Proceedings of the IEEE 15th International Conference on Industrial Informatics (INDIN), Emden, Germany, 24–26 July 2017; pp. 239–244. [Google Scholar] [CrossRef]

- Zezulka, F.; Marcon, P.; Vesely, I.; Sajdl, O. Industry 4.0—An Introduction in the phenomenon. IFAC-PapersOnLine 2016, 49, 8–12. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control 2020. [Google Scholar] [CrossRef]

- Palmarini, R.; Erkoyuncu, J.A.; Roy, R. An Innovate Process to Select Augmented Reality (AR) Technology for Maintenance. Procedia CIRP 2017, 59, 23–28. [Google Scholar] [CrossRef]

- Chong, L.; Ramakrishna, S.; Singh, S. A review of digital manufacturing-based hybrid additive manufacturing processes. Int. J. Adv. Manuf. Tecnol. 2018, 95, 2281–2300. [Google Scholar] [CrossRef]

- Salkin, C.; Oner, M.; Ustundag, A.; Cevikcan, E. A Conceptual Framework for Industry 4.0. In Industry 4.0: Managing the Digital Transformation; Springer Series in Advanced Manufacturing; Springer: Cham, Switzerland, 2018; pp. 3–23. [Google Scholar] [CrossRef]

- Pereira, T.; Barreto, L.; Amaral, A. Network and information security challenges within Industry 4.0 paradigm. Procedia Manuf. 2017, 13, 1253–1260. [Google Scholar] [CrossRef]

- Piedrahita, A.F.M.; Piedrahita, V.; Gaur, J.; Giraldo, A.A.; Cardenas, S.J. Rueda, Virtual incident response functions in control systems. Comput. Netw. 2018, 135, 147–159. [Google Scholar] [CrossRef]

- World Economic Forum. 2018. Available online: http://www3.weforum.org/docs/WEF_Future_of_Jobs_2018.pdf (accessed on 9 December 2020).

- Wan, J.; Yan, H.; Suo, H.; Li, F. Advances in Cyber-Physical Systems Research. KSII Trans. Internet Inf. Syst. 2011, 5, 1891–1908. [Google Scholar] [CrossRef]

- Bonilla, S.; Silva, H.; Terra, M.; Franco, G.R.; Sacomano, J. Industry 4.0 and Sustainability Implications: A Scenario-Based Analysis of the Impacts and Challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef]

- O’Rielly, K.; Jeswiet, J. Strategies to improve industrial energy efficiency. Procedia Cirp 2014, 15, 325–330. [Google Scholar] [CrossRef][Green Version]

- Daki, H.; El Hannani, A.; Aqqal, A.; Haidine, A.; Dahbi, A. Big Data management in smart grid: Concepts, requirements and implementation. J. Big Data 2017, 4, 1–19. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Kiel, D.; Arnold, C.; Collisi, M.; Voigt, K. The impact of the industrial internet of things on established business models. In Proceedings of the 25th International Association for Management of Technology (IAMOT) Conference, Orlando, FL, USA, 15–19 May 2016; pp. 673–695. [Google Scholar]

- Napolitano, F.; Girolami, A.; Faraone, D.; Chaudhry, M.; Braghieri, A. Appearance, consumer liking and preferences of Lucanian ‘Soppressata’salami. Meat Sci. 2020, 167, 1–7. [Google Scholar] [CrossRef]

- Ferreira, F.; Putnik, G.D.; Lopes, N.; Garcia, W.; Cruz-Cunha, M.M.; Castro, H.; Varela, M.L.R.; Moura, J.M.; Shaha, V.; Alves, C.; et al. Disruptive data visualization towards zero-defects diagnostics. Procedia CIRP 2018, 67, 374–379. [Google Scholar] [CrossRef]

- Biagi, F.; Falk, M. The impact of ICT and e-commerce on employment in Europe. J. Policy Modeling 2017, 39, 1–18. [Google Scholar] [CrossRef]

- Antonelli, D.; D’Addona, D.M.; Maffei, A.; Modrak, V.; Putnik, G.; Stadnicka, D.; Stylos, C. Tiphys: An Open Networked Platform for Higher Education on Industry 4.0. Procedia CIRP 2019, 79, 706–711. [Google Scholar] [CrossRef]

- Canadasa, N.; Machado, J.; Soares, F.; Barrosa, C.; Varela, L. Simulation of cyber physical systems behaviour using timed plant models. Mechatronics 2018, 54, 175–185. [Google Scholar] [CrossRef]

- Gunal, M.M. Simulation for Industry 4.0: Past, Present, and Future; Springer: Cham, Switzerland, 2019. [Google Scholar]

- De Sousa Jabbour, A.; Jabbour, C.; Foropon, C.; Godinho Filho, M. When titans meet–Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Wang, L.; Törngren, M.; Onori, M. Current status and advancement of cyberphysical systems in manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Linder, C. Customer orientation and operations: The role of manufacturing capabilities in small- and medium-sized enterprises. Int. J. Prod. Econ. 2019, 216, 105–117. [Google Scholar] [CrossRef]

- Jena, M.C.; Mishra, S.K.; Moharana, H.S. Application of Industry 4.0 to enhance sustainable manufacturing. Environ. Prog. Sustain. Energy 2020, 39, 13360. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.P.; Ribeiro da Silva, E.H.D. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Bogle, I.D.L. A perspective on smart process manufacturing research challenges for process systems engineers. Engineering 2017, 3. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2020, 58, 1319–1337. [Google Scholar] [CrossRef]

- Beier, G.; Ullrich, A.; Niehoff, S.; Reißig, M.; Habich, M. Industry 4.0: How it is defined from a sociotechnical perspective and how much sustainability it includes A literature review. J. Clean. Prod. 2020, 229, 120856. [Google Scholar] [CrossRef]

- Nara, E.O.B.; Becker da Costa, M.; Baierle, I.C.; Schaefer, J.L.; Benitez, G.B.; Lima do Santos, L.M.A.; Benitez, L.B. Expected impact of industry 4.0 technologies on sustainable development: A study in the context of Brazil’s plastic industry. Sustain. Prod. Consum. 2021, 25, 102–122. [Google Scholar] [CrossRef]

- Davies, R. EPRS|European Parliamentary Research Service. Members’ Research Service PE 568.337. 2015. Available online: https://www.europarl.europa.eu/thinktank/en/document.html?reference=EPRS_BRI%282015%29568337 (accessed on 12 December 2020).

- Brous, P.; Janssen, M.; Herder, P. The dual effects of the Internet of Things (IoT): A systematic review of the benefits and risks of IoT adoption by organizations. Int. J. Inf. Manag. 2020, 51, 101952. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 40. In Proceedings of the 13th Global Conference on Sustainable Manufacturing-Decoupling Growth from Resource Use, Berlin, Germany, 16–18 September 2011; pp. 536–541. [Google Scholar]

- Yaseen, H.; Alhusban, M.D.; Alhosban, A.; Dingley, K. Making Sense of E-Commerce Customers Awareness in a Developing Country Context: A Framework for Evaluation. Electron. J. Inf. Syst. Eval. 2017, 20, 102–115. [Google Scholar]

- Dang, L.M.; Piran, M.; Han, D.; Min, K.; Moon, H. A survey on internet of things and cloud computing for healthcare. Electronics 2019, 8, 768. [Google Scholar] [CrossRef]

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Delić, M.; Radlovački, V.; Kamberović, B.; Vulanović, S.; Hadžistević, M. Exploring the impact of quality management and application of information technologies on organisational performance—The case of Serbia and the wider region. Total. Qual. Manag. Bus. Excell 2014, 25, 776–789. [Google Scholar] [CrossRef]

- Lee, J.; Kao, H.-A.; Yang, S. Service Innovation and Smart Analytics for Industry 4.0and Big Data Environment. Procedia CIRP 2014, 16, 3–8. [Google Scholar] [CrossRef]

- Turisova, R.; Sinay, J.; Pacaiova, H.; Kotianavova, Z.; Glatz, J. Application of the EFQM Model to Assess the Readiness and Sustainability of the Implementation of I4.0 in Slovakian Companies. Sustainability 2020, 12, 5591. [Google Scholar] [CrossRef]

- 2020 World Manufacturing Report: Manufacturing in the Age of Artificial Intelligence. Available online: https://worldmanufacturing.org/wp-content/uploads/WorldManufacturingForum2020_Report.pdf (accessed on 5 February 2021).

- Barbier, E.B.; Burgess, J.C. Sustainable development goal indicators: Analyzing trade-offs and complementarities. World Dev. 2019, 122, 295–305. [Google Scholar] [CrossRef]

- Facchini, F.; Oleśków-Szłapka, J.; Ranieri, L.; Urbinati, A. A Maturity Model for Logistics 4.0: An Empirical Analysis and a Roadmap for Future Research. Sustainability 2020, 12, 86. [Google Scholar] [CrossRef]

- Wirtz, B.W.; Pistoia, A.; Ullrich, S.; Gottel, V. Business models: Origin, development and future research perspectives. Long Range Plan. 2016, 49, 36–54. [Google Scholar] [CrossRef]

- Zonnenshain, A.; Kenett, R.S. Quality 4.0—the challenging future of quality engineering. Qual. Eng. 2020, 32, 614–626. [Google Scholar] [CrossRef]

- Fonseca, L.M. ISO 9001 quality management systems through the lens of organizational culture. Qual. Access Success 2015, 16, 54–59. [Google Scholar]

- Fonseca, L.C.M.; Domingues, J.P.; Machado, P.B.; Harder, D. ISO 9001:2015 Adoption: A Multi-Country Empirical Research. J. Ind. Eng. Manag. (JIEM) 2019, 12, 27–50. [Google Scholar] [CrossRef]

| Criterion | EFQM 2020 | EFQM 2013 |

| 1. Purpose, Vision & Strategy | 1. Leadership | |

| 2. Strategy | ||

| 2. Organisational Culture & Leadership | 2. Strategy | |

| 3. Engaging Stakeholders | 3. People | |

| 4. Partnerships & Resources | ||

| 4. Creating Sustainable Value | 5. Processes, Products and Services | |

| 5. Driving Performance & Transformation | 4. Partnerships & Resources | |

| 6. Stakeholder Perceptions | 6. Customer Results | |

| 7. People Results | ||

| 8. Society Results | ||

| 7. Strategic & Operational Performance | 9. Business Results | |

| Criterion parts | 23 Criterion Parts and 2 Results Criterion | 32 Criterion parts |

| Criteria weightings | 600 points for Direction and Execution and 400 points for Results | 500 points for Enablers and 500 points for Results |

| High Correlation between Sub-Criteria | |

| Medium correlation between sub-criteria | |

| No correlation between sub-criteria |

| I4.0 Reported Benefits | Author |

|---|---|

| Enhanced integration of business processes across the entire value chain, through data flow and cyber-physical systems (CPSs), promoting more flexible structures and data exchange among all the elements. | Wan et al. [73], Bonilla et al. [74]. |

| Improved productivity and efficiency, enhanced planning and forecasting, reduced cost, improved innovation, flexibility, and agility. | Alcácer and Cruz-Machado [42], O’Rielly et al. [75], Lasi et al. [54], Daki et al. [76], Oesterreich and Teuteberg [77]. |

| Support for new business models that allow new ways of value creation, e.g., cloud-based, service-oriented, process-oriented business models. | Kiel et al. [78]. |

| Improved customization and customer experience. | O’Rielly et al. [75], Kiel at al. [78]. |

| Improved quality products and zero defect diagnostics. | Napolitano et al. [79], Ferreira et al. [80]. |

| Intelligent learning analysis. | Biagi & Falk [81]. |

| Simulation and virtualization. | Antonelli et al. [82], Canadasa et al. [83], Gunal [84]. |

| Ecological sustainability, e.g., more efficient resource utilization, and social sustainability, e.g., workers more supported to do their job. | De Sousa Jabbour et al. [85], Wang et al. [86]. |

| EFQM 2020 Criteria | EFQM 2020 Model Guidance Points Related to I4.0 |

|---|---|

| 1.3 Understand the Ecosystem, Own Capabilities & Major Challenges |

|

| 2.2 Create the Conditions for Realising Change |

|

| 2.3 Enable Creativity and Innovation |

|

| 5.2 Transform the Organisation for the Future |

|

| 5.3 Drive Innovation & Utilise Technology |

|

| 5.4 Leverage Data, Information & Knowledge |

|

| 5.5 Manage Assets & Resources |

|

| 6. Stakeholder Perceptions |

|

| 7. Strategic & Operational Performance |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fonseca, L.; Amaral, A.; Oliveira, J. Quality 4.0: The EFQM 2020 Model and Industry 4.0 Relationships and Implications. Sustainability 2021, 13, 3107. https://doi.org/10.3390/su13063107

Fonseca L, Amaral A, Oliveira J. Quality 4.0: The EFQM 2020 Model and Industry 4.0 Relationships and Implications. Sustainability. 2021; 13(6):3107. https://doi.org/10.3390/su13063107

Chicago/Turabian StyleFonseca, Luis, António Amaral, and José Oliveira. 2021. "Quality 4.0: The EFQM 2020 Model and Industry 4.0 Relationships and Implications" Sustainability 13, no. 6: 3107. https://doi.org/10.3390/su13063107

APA StyleFonseca, L., Amaral, A., & Oliveira, J. (2021). Quality 4.0: The EFQM 2020 Model and Industry 4.0 Relationships and Implications. Sustainability, 13(6), 3107. https://doi.org/10.3390/su13063107