1. Introduction

In December 2015, the European Commission adopted a Circular Economy Action Plan [

1] to give a new boost to employment, growth and investment, and to develop a carbon neutral, resource-efficient and competitive economy. The EU’s publication on the implementation of the Circular Economy Action Plan [

2] mentions that “

design stands at the beginning of products’ lifecycle and is essential for ensuring circularity”. Thus, depending on the products to be re-circulated, the processes controlled, and the actors involved, especially designers, the requirements to be reported at design level are very diverse and the concept of lifecycle engineering [

3] takes on its full meaning.

Our overall research deals with the engineering design methods used to implement circular economy (CE) solutions. The time of prevailing products that are designed to be used, and then discarded is behind us. Consciousness of the primacy of in-use performance and resource scarcity, far beyond product ownership and ostentation, has allowed new behaviors and expectations. It has started to be, and will be very soon in many areas, good practice to upgrade and update products several times throughout their lifetime. If the initial objective was clearly to extend the lifespan of products by repair strategies and then by resale to different users, the novel objective is to design a long-life product that will serve one or more users, at the same time or in a row, with the experiences of the same or different users. We call this type of products “immortal products”, meaning that when the product seems to have finished its life, it rebounds to another life following circularity principles and a novel usage. Theoretically, this usage loop could be infinite, hence the expression used in this article. However, nowadays, product design and material regeneration are not optimal for such an objective.

Circular economy has been widely studied in the literature mainly to promote its environmental [

4] and business [

5] advantages. However, the design and engineering perspective is missing since the product is considered first and “just adapted” to meet environmental and business perspectives. The methods proposed in these papers cannot be exploited in practical situations because they do not support implementation due to their lack of tools and quantitative methods [

6,

7]. Design of immortal products requires the design of lifecycle scenarios for immortality, aligned with circular economy business strategies and enabling actual environmental gains. The main design-oriented papers highlighted the movement from product to value-in-use service-oriented offers [

8]. This paper aims at proposing a practical engineering method with corresponding engineering tools for the design of “immortal products”, easily usable by small and medium-sized enterprises (SMEs). According to our aim, we pose the following research question:

How can engineering design tools be used to design “immortal products” within the circular economy scenarios framework in companies?

Our goal here is to ensure that, when implementing circular economy scenarios, the lifecycle scenarios actually integrate the skills, methods and tools able to contribute to the involvement of the numerous stakeholders, as well as to the socio-technical system and to positive impacts on society. The novelty in the engineering design method proposed is two-fold. First, it clearly balances technology, business and environmental concerns, supporting all three perspectives at the same time. Second, it relies on legacy tools to design, select and validate industrial scenarios. Those tools are already well known and used by engineers and designers, including in SMEs.

The outline of this paper is as follows: after the introduction,

Section 2 highlights the theoretical background of the new role and position of designers in solving not only issues related to the product, but also issues meeting society’s expectations.

Section 3 analyses the methodological frameworks proposed to help designers and business strategists to come up with viable circular economy solutions. It also presents a theoretical proposal in order to implement “immortal products”. Three industrial design cases presented in

Section 4 illustrate the method. Finally,

Section 5 discusses the results and concludes the paper.

2. Theoretical Background

This section highlights the theoretical background of the new role and position of engineering designers in solving not only issues related to the product, but also issues meeting society’s expectations. Product end-of-life was first considered in design affairs on the adoption of Extended Producer Responsibility in Europe, in 2005. The main tool was a hierarchy for waste management, moving from prevention of waste (the preferred option), to reuse, recycle, energy recover, and dispose (the least preferred option) [

9]. The circular economy (CE), also referred to as the closed-loop economy, is a dynamic industrial and social concept that aims to achieve comprehensive sustainability goals through a culture of “no waste” [

10].

Our first assumption is that designers must develop the entire lifecycle of immortal products, including the numerous loops, as a driver for actual product and service designs. The construction of key lifecycle scenarios is part of the design activity. In an attempt to unify the approaches, Den Hollander et al. [

9] emphasize that circular product design encompasses two approaches: design for product integrity and design for recycling. The first approach aims at preventing and reversing obsolescence at product and component levels, while the second has the same aims but at a material level. Immortal products clearly prioritize product integrity in the very long term. This means a fundamental change in the practice of design, since circular economy transforms the systems of production and consumption, and how companies do business, particularly in the manufacturing sector. Lifecycle simulation methods are also good and efficient methods to support engineers in addressing lifecycle issues in design. It is based on modular lifecycle models and support their assessment for service economy [

11] and the planning of activities [

12].

Our second assumption is that engineering design and business design are so closely intertwined that they have become one. As products and services are also under planetary limits, we consider design as a blended activity of engineering, business and environment. While examining different case studies, De los Rios and Charnley [

10] identified changes in design processes, revealing a growing necessity for the industry to rely on new skills for their employees which support closure of material loops. The transition to closed loop systems could result in product design requirements that contrast sharply from those for the linear “take-make-waste” economy [

9], strengthening the current importance of the product designer’s role. Zwolinski and Brissaud connect remanufacturing to design/re-design strategies [

13]. Sumter et al. [

14] identify and map designers’ roles and associated design competencies for the creation of circular business models. It is clear that the role of product design will, and must, expand to assist businesses in their transition toward CE. Therefore, they list the different roles that product designers can assume (i.e., functional, coordinating, and strategic), and the competencies for each role (in concordance with De los Rios and Charnley [

10]), within the context of sustainability, sustainable design and circular design. From a holistic perspective, Joore et al. [

15] state that “

the role of designers is broadening, from the creators of physical artefacts to the potential role of facilitators of complex societal change processes”. Within the same holistic perspective, Trevisan and Brissaud [

16] proposed a supportive model that integrates product and service engineering requirements in product-service systems (PSS) engineering. Nevertheless, they also state that current design and innovation models are insufficient to support designers, because they are either excessively oriented towards the development of one specific new product or service, or they are too abstract and conceptual to be used potentially to structure future design-based initiatives.

Our third assumption is that designers are pioneers in societal transformations. They have to design the behavior of a system composed of systems, where their own “small” contribution (the design of a product or a service) interacts and influences the overall system. Practically, the design process must be structured and flexible simultaneously.

From the literature, we assume that immortal products will emerge from the new role that engineering designers must play from now: life cycle scenario design is the key driver; engineering and business design are totally intertwined; societal transformations make sense.

3. Method to Support Immortal Product Design Implementation

The method used in this article is based on the analysis of different circular economy methodological frameworks available in the literature in regards to the three hypotheses set out in the introductory section. A framework is then proposed in order to support the design of lifecycle scenarios integrating engineering tools used by most companies. Finally, the analysis of three case studies is made in order to check the validity of the proposed framework and highlight the lessons learned.

3.1. Conceptual Frameworks to Design for the Circular Economy

Considering the practical implementation of circular economy, several authors agree on the fact that business models and design strategies will need to go hand in hand. According to Den Hollander et al. [

9] and Alamerew et al. [

17], a business built around product life extension and resource recovery cannot operate without products specifically designed to support that strategy. Therefore, different framework propositions emerged in the literature to consider both business and design strategies.

Bocken et al. [

18], proposed a “

framework of strategies to guide designers and business strategists in the move from a linear to a circular economy”. The taxonomy of slowing, closing and shortening resource loops was suggested to classify circular strategies. Examples of case studies of lifecycle scenarios aligned with CE were provided to show a synergistic combination between business model strategies and product design strategies. This framework highlighted the need for new business models, design strategies, approaches, and tools to help in the transition toward CE.

Moreno et al. proposed a Conceptual Framework for Circular Design integrating a Taxonomy of Design for X (DfX) approaches [

19] mapped out against circular business model archetypes. Thus, several design strategies were found in the literature to help identify a strategy toward circular economy: Design for resource recovery, design for long life use of products, design for reliability and durability, design for product attachment and trust, design for product life extension, design for dematerializing products. This framework described a close relationship between appropriate DfX strategies and business strategies for moving from a linear scenario to CE.

With a view to drawing a parallel between business strategic planning and eco-design, Mendoza et al. [

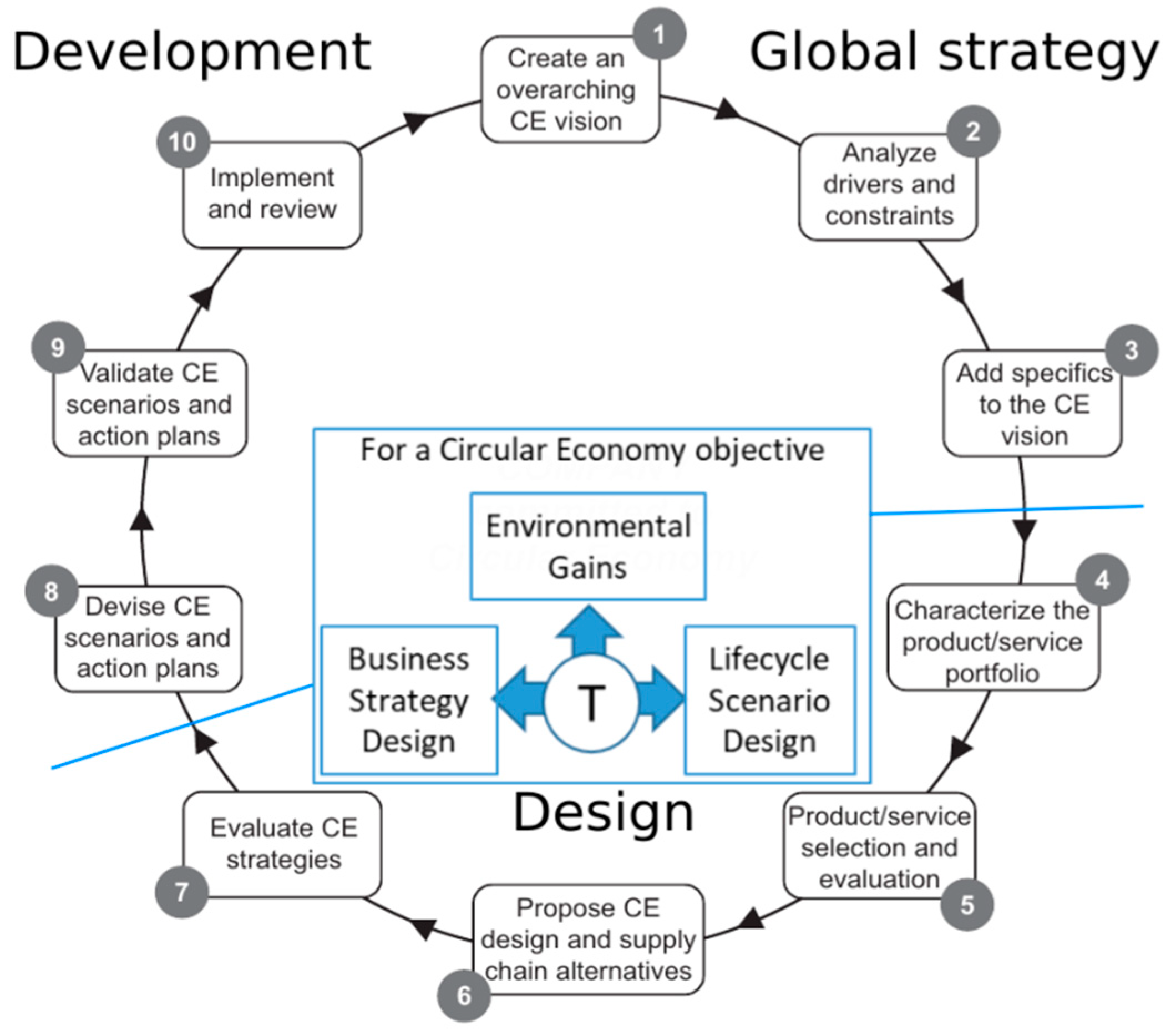

20] proposed the Backcasting and Eco-design for the Circular Economy (BECE) framework aimed at supporting companies to develop sustainable business models that transform circular economy paradigms into industrial application. Along with the coordinated role of design and business models for CE, the BECE framework highlighted the importance of setting up a strategy for implementation of CE scenarios on the one hand, and assessing the environmental benefits using eco-design on the other hand. Ten stages were developed by combining the relevant steps of backcasting and eco-design (

Figure 1). The starting point is the application of backcasting, i.e., a roadmap in order to take a company from the current practice to a challenging vision of the future where environmental benefits are obtained. On the other hand, eco-design determines practical steps in order to achieve the CE vision and to reduce environmental impacts. The final steps of the framework aim at implementing the business strategy and CE scenarios.

Analyzing the use of each of these three frameworks [

18,

19,

20] in regards to the three hypotheses outlined in the previous section, we note that none of the frameworks alone allows us to highlight all three hypotheses at once. In fact, the taxonomy of DfX strategies proposed within the framework of Moreno et al. helps designers to shift their role from product developers to regenerative system creators by considering the entire lifecycle of products. This is in line with the first assumption of our study. The framework of Bocken et al. highlights a complementarity between product design and business considerations, which is compliant with the hypothesis 2. Then due to its backcasting process, the BECE framework is well suited to the exploration of complex long-term societal scenarios emerging in circular economy, which is in line with our third assumption. Therefore, we can consider that the three frameworks are complementary and helpful in defining a macroscopic and conceptual scope to carry out immortal product design projects.

3.2. Theoretical Proposal for Supporting Immortal Product Design Implementation by Manufacturing Companies

The smart combination of the three framework aims at supporting the design of lifecycle scenarios and the integration of business perspectives in a societal development. However, they may be difficult to apply in practice, especially for SMEs as they are not supported with hands-on engineering tools. This paper claims that circular economy scenarios could be implemented through the integration of engineering tools that are already acknowledged and used by most companies, including SMEs. Our focus is on the effective use of the method by industrial practitioners in an integrated approach.

The theoretical proposal for this research consists in the characterization of a design for circularity method supported by the adaptation and use of well-established engineering tools. The proposed method could support the construction of CE scenarios, including the products and services needed, in engineering design, simultaneously with the definition of the business strategy and the evidence of the environmental gains to be expected. Since SMEs are already aware of the engineering tools used, they can easily adopt the approach.

The framework (

Figure 2) is based on the 10 steps of Mendoza’s approach [

20] featured in three macro steps: global strategy, design and development. It also embeds Bocken’s framework [

18] to support the global strategy step and Moreno’s DfX approaches [

19] to support the development phase. Our main add-on is the integration of the three perspectives from the lifecycle scenario construction and the support of the product and service design phase within a set of engineering tools.

Immortal product design projects mainly consist in designing three elements simultaneously: the business strategy, the lifecycle scenario (including system definition and the products and services needed), and the environmental profile of the solution. The business strategy relies on the initial knowledge of the company and its business culture in order to secure the business change. In most cases, the economic department is in charge of this aspect. The product and service lifecycle scenario is generally based on the organizational expertise of the company and its technology background and is at the core of the R&D job, even if embedding the whole lifecycle is quite a new activity. Assessment of the environmental gains of the solution against circularity and other impacts is key because it gives evidence for the ecological image of the company. This activity continues to be frequently outsourced to experts. The challenge is to support modelling of the solution designed so that the three design processes perform concurrently in a holistic and integrated approach.

Thus, the general objective of our research is to provide R&D engineers with a design method structured around well-known engineering tools and lifecycle scenarios to assist company in the implementation of their Circular Economy strategy. This approach was developed around the three main properties needed for a successful implementation.

The first property is an effective design method, shared by all the design stakeholders. Practically, we rely on the Mendoza’s ten steps that integrate properly the business-, technology- and environment-oriented approaches. This method could support engineers working in SMEs who take charge of the three perspectives by themselves (global strategy, design and development), as well as engineers in large companies that are structured by many different departments.

The second property is that a specific engineering tool supports simultaneous model design, from the expert tools they use to application on business, technology and environment-friendly designs. Designers in SMEs are reluctant to accept new tools and need to be supported in improving and adapting the tools they are used to. We have not developed any new tools but have stated that we should adapt already-used tools that helped perspectives converge. As an example, the tools that were adapted in the application cases were Failure Modes Effect and Criticality Analysis (FMECA), functional analysis and Structured Analysis and Design Technique (SADT): these are widely used in manufacturing companies, including SMEs.

The third property is that only knowledge is unified to design, but not the engineering tools. Industrial and societal contexts enable specific innovative solutions for the same CE objective, developed by a company with their specific background. In practical terms, the most adapted tool supports expert company knowledge and practices at the right time and in the right context.

4. Design of Immortal Products: Three Industrial Design Cases to Illustrate Different Ways to Identify CE Scenarios

The G-SCOP design framework was applied on different and various cases to design immortal products for services and businesses in a circular economy approach. Because the approach is really scenario dependent, the industrial design cases cover a large variety of situations aiming at extending lifecycle durations at product and component levels as long as possible (hence the term “immortal”). Two common elements stand out in each of these cases studied, independently from companies’ sizes, business sectors, and skills. The first is their overarching motivation to improve their sustainable image. The second is their common need for a shared representation model of the system to design able to ensure a detailed view of the usage and expected fate of the products. Our proposal of product lifecycle scenarios to structure the reasoning was easily accepted.

Table 1 presents the results from the three industrial design cases. Column 1 characterizes the company type and column 2 its activity domain. The engineering tool that structured the design process in the company (column 4), was adapted to support the design of the lifecycle scenarios to be studied (column 3). The success of the method was tested during its implementation in each case study. Columns 5 to 7 summaries the main design elements that were studied based on the lifecycle scenario modelled. In the following

Section 4.1,

Section 4.2 and

Section 4.3, the cases are explained from the engineering/business process design points of view. How engineering methods were used is detailed, focusing on their influence on decision making on the different scenarios.

4.1. Case A: Design for Continuous Remanufacturing (In a SME)

The company (SME) sells sanitation equipment and services to professionals and private individuals. Customers can find, on an online shop, all the components, spare parts and accessories for the approved micro-sanitation stations and for their maintenance. As the installed systems were starting to age, a renewal of the current installations was expected in the near future, in addition to an expansion of the market. The company’s strategy was to reuse customers’ equipment after remanufacturing instead of landfilling discarded products. The company had no previous R&D experience. The description of the remanufacturing process was formalized and furthered from qualitative simulations. It highlighted the weak points for the new business and environment-friendly impacts. FMECA enabled the proposal of a tool dedicated to the diagnosis of returned products, and which could assist technicians in appropriation of knowledge of the product operation, its potential malfunctions, and the remanufacturability of components. This tool is a formalized analytical method for the systematic identification of failures and the estimation of the related risks (effect and criticality). It implies a direct analysis of failures, their consequences and causes.

Thus, the main goal of the company was to exploit its expertise in maintenance to extend its market and to reduce its dependence towards its suppliers. In so doing, it could propose additional services. The first issue that had risen was the significant number of products returned due to failure, independently to the company activity, which was due to the products themselves. Therefore, it sought a way to create value from these returned products with the creation of a remanufacturing activity while considering environmental considerations. It launched a project based on this end-of-life strategy, assessing the cases when recovering used products, which had broken down or had reached their end of life, to rebuild spare products. These reconstructed products would then be sold as new remanufactured products. Consequently, most of the products would have a new life while the unusable parts and materials would be revalorized (recycling among other valorizing strategies).

The first issue that this company had to deal with was to identify the remanufacturing scenarios when parts could be reused. In this aspect, it had diagnosed the feasibility, thanks to FMECA as a backbone tool. It enabled to analyze all possible situations when recovering used products, and to build a decision tree helping operators to decide which parts could be recovered. It served as an intermediate tool between procurement and method personnel to set the required disassembly levels based on negotiable component prices and labor costs. If a part was too expensive to replace, additive manufacturing was considered to remanufacture it.

The scenarios considered for each component were thus identified and an environmental impact study was carried out in parallel, which also guided corporate choices. In particular, the application of FMECA enabled the creation of a workshop that would be integrated into the company as a circular economy center. This project was mainly carried out within the pillar of “extension of the duration of use” inside the circular economy model. It is planned to find a way of inducing motivation to the customers and professionals, from all around France and often in rural areas, to return the end-of-life products to the company. In addition to these objectives of “diversion of waste”, it existed the possibility of developing a new activity with the potential of local recruitment, thus having positive social impacts for the community.

After the diagnosis of the returned products, it was decided to focus on auxiliary machines in water sanitation micro-stations: air compressors, electric motors with high humidity resistance and water pumps. They were indeed the products with the highest remanufacturing potential and economic viability. Changes in the company organization occurred to integrate this new remanufacturing activity and to promote the new products and services: experience feedback from customer and corporate services on technical, economic and environmental assessment; recruitment to ensure the durability of the activity that enabled to generate an additional income with a higher margin.

4.2. Case B: Design for Anticipated Repurposing (in a Start-Up)

The start-up is an intermediary consultant with previous expertise in the development of electric vehicle battery technology. Its aim is to look for multiple possible consecutive lifecycles to extend battery lifetime. Its skills are mostly related to innovation and design, while their objective is to address the life extension of batteries from the design phase. The practical project consisted in designing an electric battery used first on construction machinery and then repurposed for a second application: forklift trucks [

21]. Repurposing could be defined as “

a strategy that preserves the value of used products by reusing them in different applications and fields, potentially for different new markets” [

22].

The functional analysis was used as the backbone of the project to help the design of the novel organization and to describe the immortal scenario. It made it possible to identify contributors to the battery lifecycle, which included a battery recycler, an R&D center working on energy production technologies, researchers working on battery technologies, and the start-up experts.

Then, several rounds of interviews and a workshop with the main stakeholders were organized in order to investigate technical issues and determine key technological functions of the battery system that should be redesigned for repurposing. The requirements allowing a better design of multiple-uses batteries were gathered. They included different functional aspects of the battery design, such as product integration, electric and electronic architectures, power management and evaluation of state of health of the battery at the end of the lifecycle.

In addition to technical issues, business model implementation and repurposing processes were also discussed. The outcomes of the functional analysis study were validated and tested during a workshop that gathered all the stakeholders. It helped in determining the main characteristics of the repurposed product allowing at least two usages. For the first characteristic related to business strategy, the stakeholders pointed out the need to design a successful business model that takes into consideration intellectual propriety, legal issues, partnership with the mains partners during the value chain (including Original Equipment Manufacturers (OEM), repurposing company and the retailer).

The quantity of repurposed batteries was also highlighted as a key challenge because a minimum volume of products will be required in order to enable the standardization of operations and thus reach a break-even point. The second characteristic regarding the system design is related to the battery technology on the one hand and the repurposing process on the other hand.

The recycler and the researchers come to the conclusion that not all battery technologies are relevant for repurposing. Several constraints were determined and included among others, the battery chemistry, architecture and dimensional specifications, charging and discharging cycles, and safety considerations for the different uses. To overcome these constraints, the stakeholders agreed on the importance of controlling the battery during its lifecycle. This will help in the evaluation of its state of health at the end of each usage cycle and in determining the necessary diagnosis to be carried out, which will eventually facilitate repurposing. Regarding the repurposing process, the stakeholders pointed out that it is rather similar to remanufacturing process with specific technology for re-produce. It should be composed of reverse logistics, repurposing operations (which include control, disassembly, cleaning, repurposing, reassembly, storage and final testing) and redistribution. The most important operation was identified to be the control of the past performance of the battery and the evaluation of the state of health.

Finally, the third characteristic regarding environment assessment, the experts, supported by the literature, pointed out numerous limitations to Life Cycle Assessment (LCA) performed on repurposed systems. In particular, the experts admitted that different functional units, divergent hypotheses on second use, distinct system boundaries could be considered for the first usage and for the repurposed one. Therefore, a generic framework for the LCA of repurposed products was proposed, composed of seven major steps inspired by the classical literature and the specificities of reuse strategies (remanufacturing in particular). Beyond this framework, several recommendations were made for the collection of the information necessary for its completion [

23].

4.3. Case C: Design for Continuous Upgrades (at OEM)

This company is a leading OEM on the consumer electronic product market. It designs and manufactures a wide range of appliances. Its specific goal was to change its business model thanks to the addition of upcycling possibilities in its portfolio. Immortality is targeted by upgrading the product continuously.

The challenge here is to offer a target market products whose lifespan can be extended through upgrades and avoid replacement. The objective, by extending the life of products while proposing improvements on these products, is to avoid functional or aesthetic obsolescence and/or to make improvements on the product according to the actual uses made of it, which is particularly important for resource-consuming products in the use phase. It allows introducing innovation at any upgrade.

Upgradability implies to consider the whole system (product + service + supply chain etc. on multiple use-cycles) with an “extended” multidisciplinary design team and in a large view the environmental dimension (lifetime improvement by upgrades of modules and services, user consciousness with eco-learning service, business model including end-of-life treatment) [

24].

The approach started with the marketing department that wished to propose product upgrades throughout its life in order to extend its usage and thus reduce its environmental impacts. Different categories of upgrades were initially proposed depending on their effect on the global value of the solution: upgrades to increase utility value, sensory and aesthetic value, environmental and ethical value, or upgrades to improve the performance or to enable new functions. Based on those new elements, focus groups were organized with customers to identify the target in terms of customers’ needs to satisfy. Then, SADT formalized the specific process of upgrade cycles that were new scenarios for everybody.

SADT is a system engineering tool for describing systems as a hierarchy of functions. It is a structured analysis modeling language, which uses two types of diagrams: activity models and data models. Thus, it is a method aimed to model the decisions, actions, and activities of an organization or system.

It was necessary to create a completely new eco-system and to determine the upgradable modules that constitute the basics of the idea. Based on the possible element able to compose the new offer, a great number of possibilities were simulated and micro-tools used to calculate certain indicators automatically to ensure a wide spectrum exploration. SADT also supported the specification of those new indicators and their calculations. The processes and solution elements described and characterized in SADT formed also a good basis for the first environmental assessments of the upgraded solutions.

Finally, the modelling has highlighted a range of possible options in terms of products, processes and organizations. Scenarios such as additive manufacturing at the customer’s site were explored, for example, as were pure service solutions for which scenario building played a key role.

5. Discussion and Conclusions

5.1. Conclusion on the Implementation of the Method

The research question was: How can engineering design tools be used to design “immortal products” within the circular economy scenarios framework in companies? At the end of the paper, we can draw some interesting conclusions on the practical use of the actual engineering design tools in a circular economy context. Several lessons have been learned from the application of the method on the complementary industrial cases. First of all, it is clear that formalizing the entire product lifecycle scenarios helps designers to focus on hot spots.

A long-term perspective on products is required, which is a new and not obvious activity. Because it reverses the design approach that has been dominant so far, the immortal product concept needs time for acculturation. Secondly, the capability to handle business, engineering and environment from the same model was appreciated, even in Case C in which different departments were involved. The issue is mainly to choose the right tool during implementation of the method, which does not seem to be limited by cultural barriers.

Moreover, the method is simple enough to ensure its robustness, even if its genericity cannot be proven with only three cases, however different they are. Nevertheless, the tools are flexible enough to be adapted by the practitioners themselves to the scenario studied. More precisely, we should say the set of tools because the method must be supported coherently from the beginning to the end. It was not possible to deploy the tools partially because the circular economy scenario needs to focus on all the facets of the lifecycle to be complete and validated. The full deployment of the tool (design method) is fundamental to succeed.

Finally, as the implementation of immortal loops and the associated industrial systems are extremely dependent on the industrial context and lifecycle scenarios, it was crucial that designers and corporate culture were directed towards the relevant engineering tool in each case. The limits are mainly focused on two points: support tool capacity and engineers’ skills. These are discussed as perspectives.

5.2. Creating Scenarios towards Immortal Products

It is also necessary to discuss whether the circular scenarios studied lead to immortal products. Continuous remanufacturing in case A is the classical process of remanufacturing that re-produces products as they were initially. In a theoretical point of view, this continuous process could conduct to a very long life of products; life stopped more by business obsolescence than technical issues. In practice, the re-transformation process is not perfect and there are performance losses that conduct to achieve the end of life sooner than expected. The limit is given when the re-transformation process stops giving environmental gains.

Repurposing is a specific remanufacturing case where the product is re-produced to be used in a new application. Here also, repurposing is open to be continuous and conducts theoretically to very long product lives. The performances losses can be overpassed by moving to new applications where the performances expected are different. Nevertheless, the conclusion is similar: the product life is less than expected. It is mainly due that products must be designed to meet the requirements of the application; it is what is done with the anticipated repurposing scenario developed in case B.

The second application is known when the first application is developed and can be integrated in the design decisions to meet both the first and second application expectations. The anticipation of applications is limited and in case B, we had no vision on where the product will go after its second live, meaning that it will not be optimize for it and consequently not relevant. Practically to achieve immortality, continuous redesignable products should support repurposing. However, it is another story to develop design method to those kinds of products.

Continuous upgrading in case C is certainly the best candidate today to go to immortal products. As the other scenarios, it is done theoretically with the opportunity to include innovation at any time, ensuring its continuous relevance to market.

5.3. Perspectives: Effort to Put on Tooling Engineers

The main changes in product design are not yet well supported. Only a few researchers [

25] have started working on the simulation of lifecycle scenarios, which is the key for designing within a circular economy paradigm. This is a difficult task because we need a multiple level (system and details) modelling system to ensure correct implementation and performance, and a multiple systems approach since the product will be part of different systems throughout its lifetime.

The concept of full digital twin [

26] is very promising since it supports the whole lifecycle with the unique and continuously updated model, while also enabling optimization in real time. It already supports easily redesign and continuous improvement activities that are at the core of immortal products. It would be much powerful with predictive abilities. AI techniques are very promising and attractive to develop predictions and should enrich digital twin very soon. Prediction functions availability will deeply transform the design activity and will definitively enable the shift from designing a product to designing behaviors.

Nevertheless, the main issue is the training of people, for newly graduated engineers and during life-long learning. The skills needed are quite different from the present ones: systems thinking of embedded and networked systems of products and services, and integration skills of many technologies across disciplines, including data sciences and entrepreneurship development along with material and social disciplines. Two aspects need to be addressed to meet these engineers’ skills challenges. First, it is important for engineers to be able to navigate fluently with simulations and overcome any cultural difficulties preventing them from being confident with data to replace or complement expertise and experience. Second, social and environmental challenges are the design objectives instead of optimization pure company objectives. It calls for a very different training of engineering designers.

5.4. Perspectives: Potential Limitations of Immortal Products

Although the concept of immortal products was applied to three case studies, conditions of applicability should be considered. In particular, immortal products may be confronted with outdated technologies which would question the relevance of continuing. Maybe this would lead to a point where immortality would mean the recyclability of materials more than usage loops.

From a more social perspective, acceptability by consumers could also become an issue after a certain time with inevitable aesthetic differences with newer similar products that would make them less desirable, despite functional upgrades. More generally, this issue highlights the limitation of this engineering approach which is essentially based on a technical approach. Furthermore, a shift in the business models, including prices could be expected. In this case, it would be necessary to consider changes of demand and consumption patterns.

Although the environmental impacts were assessed in the case study and some economic information were available, the consequences of a broad diffusion of immortal products have not been studied yet. However, several rebound effects could be expected. For example, less labor in production could be induced but it might shift towards to activities for the repairing or remanufacturing of the products.

These three limitations would need to be explored in future researches and require the addition of social aspects to go further than the technical approach described in this article and to propose a comprehensive assessment anticipating potential adverse effects of a massive shift toward immortal products.