Abstract

The development of ecological circular agriculture has been highly encouraged to recycle agricultural wastes, reduce mineral fertilizer input, and protect the environment. Biogas slurry (BS), a by-product of biogas production generated from anaerobic digestion of animal waste and crop residues, is often considered a substitute to reduce mineral fertilizer input. Being a cheap source of organic matter and plant nutrients, its application may improve soil fertility and yield quality and quantity. The field experiments were conducted in 2016 and 2017 to study the plant growth responses and forage quality by applying biogas slurry to replace chemical synthetic fertilizer (CSF). Results revealed that biogas slurry combination with chemical synthetic fertilizer significantly (p < 0.05) improved the growth of Italian ryegrass on treatment with T2, and the Italian ryegrass dry matter was increased by more than 9.00%, while the stem-to-leaf ratio was decreased by more than 12% (second cutting), in comparison with only chemical synthetic fertilizer group. In the case of forage quality, the crude protein (CP) and crude fiber (CF) content had a significant difference was observed between the T0 and T2 treatment group. Compare with the chemical synthetic fertilizer group, the CP content improved by 10.35%, and the CF content decreased about 10.00%. Based on these results, it was concluded that the application of 37.5 kg/ha CSF + 100.5 t/ha BS could improve the production of biomass and forage quality in Italian ryegrass.

1. Introduction

As number of livestock has increased all around the world, the amount of animal manure has increased simultaneously. From 2006 to 2016, the number of total livestock increased from 293.48 to 374.99 million in Bangladesh [1]. In China, the livestock population is estimated to be 9.03 million cattle and buffaloes, 0.61 million horses and donkeys, 44.06 million goats and sheep, and 74.66 million hogs in 2017 [2]. However, the increasing amounts of the livestock wastes, such as feces and urine, were difficulty in disposing of as it induced extensive environmental pollution [3,4]. Besides, economical reason is also important for avoiding over-fertilization. Holm-Nielsen et al. [5] have suggested that increasing animal production areas need suitable manure management and to optimize their recycling. For sustainable development, it is necessary to find out a cost-effective way to dispose of these wastes.

Anaerobic digestion is one of the effective solutions for livestock wastes and satisfies growing concerns on energy supply [6,7,8]. Among the alternative energy generation technologies, anaerobic digestion is an efficient way to transform waste into resources and it benefits by improving fertilizer qualities, reducing odors and pathogens of livestock wastes. The main product of anaerobic digestion is biogas, which is an important and clean energy source. The biogas could be used for human activity like cooking or lighting, thereby replacing other fuels. Several research studies are reported on the utilization of farm waste as feedstock to produce biogas. In Malaysia, it was found that the amount of biogas could be generated for the year 2012 (4589.49 million m3) from animal farm waste [9]. In Thailand, approximately 620 million m3 biogas can be generated from that animal waste [10]. Similar kinds of studies were also conducted in Laos and Myanmar [11]. Besides, biogas could be sent to a biogas upgrading system for the production of bio-methane further, which plays an important role in agriculture development [12]. Meanwhile, the by-product biogas slurry is also an environmentally friendly organic fertilizer which could be used in agricultural production [5,13]. Recently, the use of biogas slurry has been recognized as an important kind of fertilizer owing to its high nutrient components, environmentally friendly and lower costs than chemical fertilizers [14,15]. It was reported that more than 450 million tons of biogas slurry have been used in China each year [16] to popularize ecological circular agriculture, recycle agricultural wastes, reduce chemical fertilizer input, and protect the environment. However, the increasing popularity of anaerobic digestion has created another challenge of how to deal with large quantities of biogas slurry generated during this process. An 800 m3 volume biogas system needs to discharge 15 tons of biogas slurry daily. Therefore, this condition will become an environmental issue if improperly managed.

As a kind of bio fertilizer, biogas slurry has plenty of nitrogen (N), phosphorus (P), potassium (K), and other trace elements. Further, biogas slurry could use as a biological pesticide due to its high levels of amino acids, as well as growth hormones, and antibiotics that promote plant growth [17,18,19,20,21,22]. It was reported that dry slurry contained lower levels of nitrogen (less than 0.5%), while the wet slurry contained more than 1.6% nitrogen as readily available nutrients. Based on the fermentation process, the concentration of carbon (C) from the dry matter reduced, while the ammonium ion (NH4+) content of the biogas slurry increased, which induced the C/N ratio decreased [23,24]. Furthermore, biogas slurry supplies more plant readily available nitrogen than common chemical fertilizers [25]. Generally, the available forms of N contained nitrate (NO3), ammonium (NH4+), and simple structured organic partly from the degradation of organic matter, which could directly be absorbed by plants. Besides, biogas slurry also supplied varied nutrients, including some micronutrients, auximones, vitamins, and humic acid, which could not only retain water as well as regulate soil fertility, soil environment, gas and heat, but were also beneficial to plant growth [26,27]. It had been reported that biogas slurry could efficiently be utilized for crops, such as Triticum aestivum [28], Hordeum vulgare [23], Oryza sativa [20,29], Allium porrum [30], Zea mays [31], Arachis hypogaea [32], and Brassica rapa [33]. However, different standards are required for various crops based on plant nutrient utilization efficiency, soil conditions, as well as environmental release.

Italian ryegrass (lolium multiflorum L.) is one of the most important annual forage grasses worldwide and it has been cultivated for hay, grazing, or silage owing to its easy to establish, high productivity and palatability, excellent resistance to mow, and adapted to a wide range of soil types [34,35,36]. Italian ryegrass was always planted and mixed with small grains and clovers (Trifolium sp.) to provide forage for animals during winter and spring. Additionally, it is widely used for the cereal-forage rotation system or economic crop intercropping in south of China. The forage quality could directly influence the animal performance, while various factors directly or indirectly decided forage quality. Among them, the most key factors are forage species and stage of maturity at harvest. Followed, soil fertility, fertilization, and temperatures during forage growth period are all important [37]. For grasses species, it is well-known that nitrogen fertilization directly contributes to the quantity and quality of forage production. However, inappropriate or excessive use of chemical fertilizers induced adverse effect on the soil, causing a decrease in organic carbon, as well as environment pollution [38]. Additionally, Italian ryegrass can promote the purification of domestic sewage, aquaculture wastewater, and other sewage, and has good environmental, ecological, and economic effects [39], which makes it become a good plant with absorbing biogas slurry to reduce environmental pollution.

Recently, more and more studies have focused on the effects of biogas slurry on crop biomass yield, soil properties, and fertility. Balance of the useage of biogas slurry is not only avoiding environmental risk of over-fertilization, but also for optimum plant growth. However, environmental factors were selected only as their treatment, and the integrated effects that related to crop growth, yield, and quality by applying biogas slurry are rarely investigated. Additionally, previous studies mainly focused on cereal crops or conventional vegetables, research on Italian ryegrass (lolium multiflorum) were reported rarely, which account for a large proportion of the total cool-season forages planting area [34,36]. In brief, there is little information available related to dealing with the use of biogas slurry and synthetic chemical fertilizer as an alternative to only synthetic fertilizer application in Italian ryegrass production. The objective of the study was to evaluate the effects of biogas slurry in combination with synthetic chemical fertilizer on biomass yield production and nutritional status of Italian ryegrass, and find the optimal ratio of synthetic fertilizer and biogas slurry to dissolve baogass slurry and reduce the synthetic fertilizer application. On the other hand, this study can provide basic information about that the balance of Italian ryegrass biomas yield and biogas slurry assimilating capacity.

2. Materials and Methods

2.1. Experimental Materials and Procedures

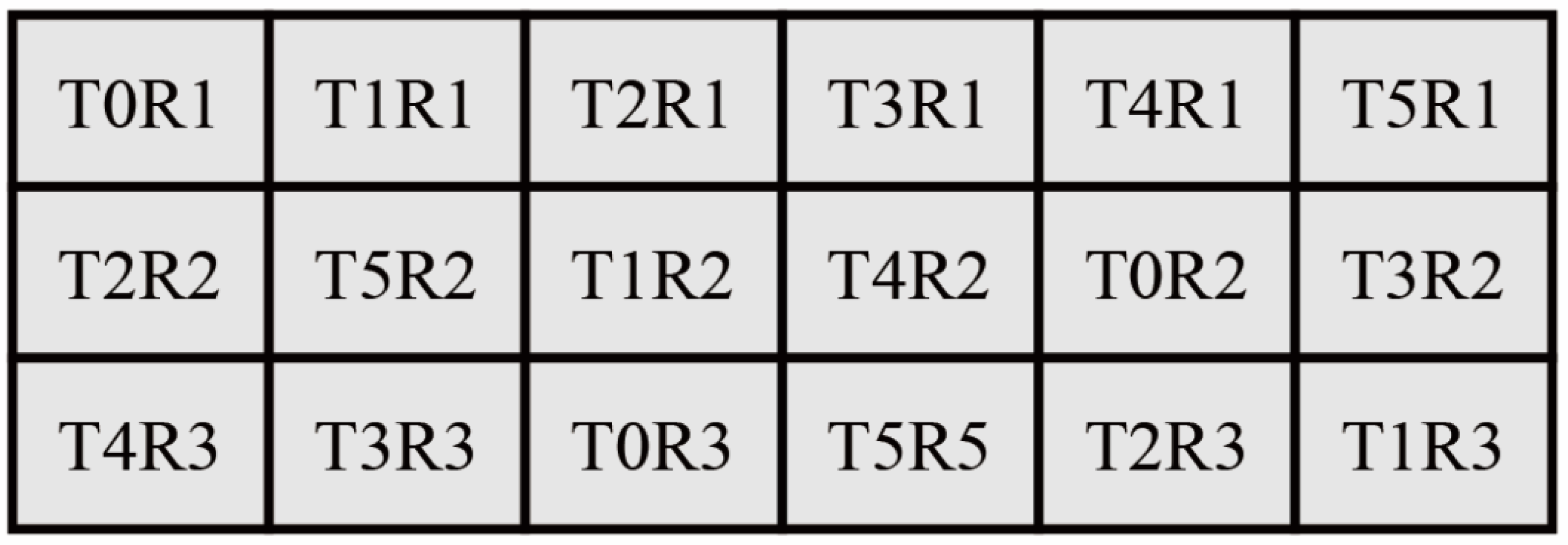

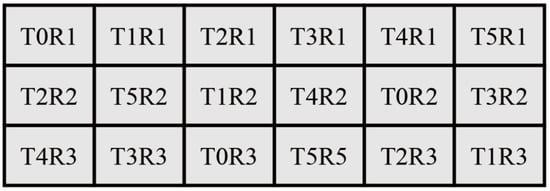

The experiment was conducted in Sichuan Academy of Agricultural Sciences farm (Hong Ya, Sichuan, China; N 29°32′, E 103°15′, 442 m) and the soil at the site was identified as viscous yellow soil. The land was prepared well and weeds were carefully removed. The land was divided into 18 plots (each plot was 15 m2 with 3 m wide and 5 m length) according to the layout of the experiment (Figure 1). The experiment was performed by two growth seasons, the first growth season from October 2016 to April 2017, and the second growth season from October 2017 to April 2018. Italian ryegrass was sowed in September each growth season and the biogas slurry treatment was applied between October and April in each growth season.

Figure 1.

The design of experiment in the field. Three replicates were applied for each treatment and T represents treatment and R represents replication.

The experiment was conducted in a randomized block design comprising 6 levels of fertilizer treatment: 112.4 kg/ha chemical synthetic fertilizer (CSF), 74.9 kg/ha CSF + 49.5 t/ha biogas slurry (BS), 37.5 kg/ha CSF + 100.5 t/ha BS, 150 t/ha2 BS, 300 t/ha BS, 450 t/ha BS, referred to treatments T0, T1, T2, T3, T4, and T5, respectively. The physicochemical properties of the soil, chemical fertilizer, and biogas slurry are given in Table 1. The biogas slurry used for this study was collected from a commercial biogas plant, named Modern animal husbandry Hongya Ranch, which was produced by fermentation of cow dung. The biogas plant has a special pipeline to transport the biogas slurry to the test site.

Table 1.

Characteristics of the experimental soil and biogas slurry.

For observing the efficiency of biogas slurry, the Italian ryegrass variety ‘Splendor’ was selected for this experiment, which was normally used for fodder production in China. The Italian ryegrass seeds were sown using a line sowing method, maintaining row-to-row spacing of 30 cm with the long side of plot, and sown 10 line per plot. The seed rate was 30 kg/ha and the seed germination rate was 90%. No irrigation or insecticide was applied during the experimental period. The plant height of Italian ryegrass was measured (cm) before harvesting every time. After second and third cutting of the Italian ryegrass plants each growth season, the stem and leaf weight were measured from 1 kg plants, then the stem-to-leaf ratio was calculated. The Italian ryegrass was harvested when the plants are grown to 50–60 cm. Harvesting was performed manually and samples were kept for further analysis. The biomass yield of the forage from each plot was recorded using a weighing balance, immediately.

2.2. Biochemical Analysis

To determine dry matter (DM) content of Italian ryegrass, the fresh samples were inactivated in oven at 105 °C for 30 min, and then dried at 65 °C to a constant weight. Finally, the dried samples of the first cutting of first growth season were stored in a dry container until used for analysis of crude protein (CP), ether extract (EE), and fiber fractions (crude fiber (CF), neutral detergent fiber (NDF), and acid detergent fiber (ADF)).

The CP content was determined by wet chemistry analysis according to the Kjeldahl method [40] with the KjeltecTM 8400 analyzer unit (FOSS, Hoganas, Sweden). Briefly, the ground samples (0.5 g) were added into a 250 mL TKN digestion tube with 10 mL concentrated sulfuric acid and two digestive tablets (Beijing Jinyuanxingke Technology, Beijing, China). Blanks containing all these reagents were simultaneously processed. All tubes were digested in the preheated digestion block (TecatorTM digestor auto; FOSS, Ho-ganas, Sweden) at 420 °C for 90 min or until the samples were green and clear. The CP content was calculated using the following equation:

where:

- V1 = volume (mL) of standard HCl required for sample;

- V2 = volume (mL) of standard HCl required for blank;

- C = molarity of standard HCl;

- 1.4007 = milliequivalent weight of N × 100;

- 6.25 = average coefficient of nitrogen conversion into proteins;

- M = sample weight in grams.

The crude fat (ether extracts, EE) content was determined using the ether extraction method after acid-hydrolysis [40] with a Soxtherm apparatus (Gerhardt, Bonn, Germany). Briefly, a total of 2 g samples were placed in a degreased filter paper package and placed in a flask with carborundum dried to a constant weight (M2) at 70 °C. Then, the extraction was carried out in a Soxtherm apparatus (Gerhardt, Bonn, Germany). After ether extract, the sample package was placed in a flask with carborundum and dried to a constant weight (M1) at 70 °C. The contents of EE were calculated using the following equation:

where:

- M = sample weight;

- M1 = weight of flask with carborundum;

- M2 = weight of flask with carborundum and weight of dry residue after the ether extract.

The CF, NDF, and ADF contents were measured by using the methods described by Goering and Van Soest [41] and Van Soest, et al. [42] in an automatic fiber analyzer (ANKOM 2000 Fiber Analyzer, ANKOM Technology, NY, USA). Briefly, for CF analysis, a total of 1 g pulverized samples were placed into the fiber filter bag (F57, ANKOM Technology, NY, USA) and preextracted in a beaker with ether. Then, they were placed into the automatic fiber analyzer for digesting the samples with 0.255 N H2SO4 (FCFA20, ANKOM Technology, NY, USA) and 0.313 N NaOH (FCFB20, ANKOM Technology, NY, USA) solutions. For NDF analysis, a total 0.5 g pulverized samples were placed into the fiber filter bag (F57, ANKOM Technology, NY, USA) and placed into the automatic fiber analyzer for digesting the samples with dilutes solutions of neutral detergent dry concentrate with triethylene glycol (FND20C, ANKOM Technology, NY, USA). The residues obtained after the deter-mination of NDF can be directly digested by the solution of acid detergent concentrate-dry CTAB powder (FAD20C, ANKOM Technology, NY, USA) for ADF determination.The contents of CF, NDF, and ADF were calculated using the following equation:

where:

- M = sample weight;

- M1 = bag tare weight;

- M2 = weight of organic matter after extraction by neutral detergent;

- M3 = weight of organic matter after extraction by acid detergent;

- C = loss in weight on ignition of bag/sample;

- C1 = ash-corrected blank bag factor (a running average of the loss of weight after extraction of the blank bag/original blank bag).

2.3. Statistical Analysis

All data obtained were analyzed using a one-way analysis of variance (ANOVA) with SPSS 18.0 (IBM, Armonk, NY, USA). A mean comparison was performed using Fisher’s least significant difference test (LSD) and the Duncan multiple range test with a significance level of p < 0.05.

3. Results

3.1. The Plant Height of Italian Ryegrass with the Biogas Slurry Applied

Plant height is an important component for biomass production in Italian ryegrass. Table 2 showed that the plant height of Italian ryegrass varied at different harvest times and different levels of biogas slurry treatment. The application of different levels of biogas slurry was non-significantly different at the first cutting in two growth seasons. However, for the second and third cutting, the plant height of Italian ryegrass treated with T2 were 102.52 and 97.00 cm, respectively, which was significantly higher than that treated with T1, T3, T4, and T5 in the 1st growth season (p < 0.05). In the 2nd growth season, the plant height of Italian ryegrass was non-significantly changed with the increased biogas slurry at second and third cutting, while T2 was obviously higher than T0 which was no biogas slurry applied.

Table 2.

The effect of biogas slurry in place of chemical fertilizer on plant height in Italian ryegrass.

3.2. The Biomass Yield of Italian Ryegrass with the Biogas Slurry Applied Subsection

Table 3 showed the fresh weight of biomass yield of Italian ryegrass under CSF with different BS ratios at different harvest times. The significant differences (p < 0.05) were found among all treatment groups. Specially, the Italian ryegrass treated with T2 displayed the highest fresh weight at different harvest times in the 1st growth season, which were 36647.54 kg/ha, 54663.61 kg/ha, and 42956.58 kg/ha, respectively. The recorded improvements were 7.64%, 7.99%, and 6.96% than that of T0 treatment at first cutting, second cutting, and third cutting. In the 2nd growth season, the biomass yield of Italian ryegrass with T2 treatment has higher fresh weight than T0 at different cutting times, and the yields improvements were 4.71%, 23.60%, and 17.70% at first cutting, second cutting, and third cutting, respectively. It was worth mentioning that by increasing the BS ratio to two or three folds in the 2nd growth season, the fresh weight of the second cutting and third cutting increased more significantly than the treatment of T2, which could be the drought in spring at the location.

Table 3.

The effect of chemical fertilizer and biogas slurry on fresh biomass yield in Italian ryegrass.

3.3. The Stem-to-Leaf Ratio of Italian Ryegrass with the Biogas Slurry Applied

Stem-to-leaf ratio is a component of canopy architecture that determines diet selection and forage intake in forages. Increased stem-to-leaf ratio is a major cause of the decline in forage quality, and also the loss in quality under adverse hay curing conditions [31]. Table 4 illustrates the ratio of the stem and leaf in Italian ryegrass under CSF and different BS ratios at different cutting times. By increasing the biogas slurry fertilizer ratios to 2/3 (T2 treatment), the ratio of stem and leaf reduced to the minimum value at second cutting and third cutting in the 1st and 2nd growth season, respectively.

Table 4.

The effect of chemical fertilizer and biogas slurry on stem-to-leaf ratio in Italian ryegrass.

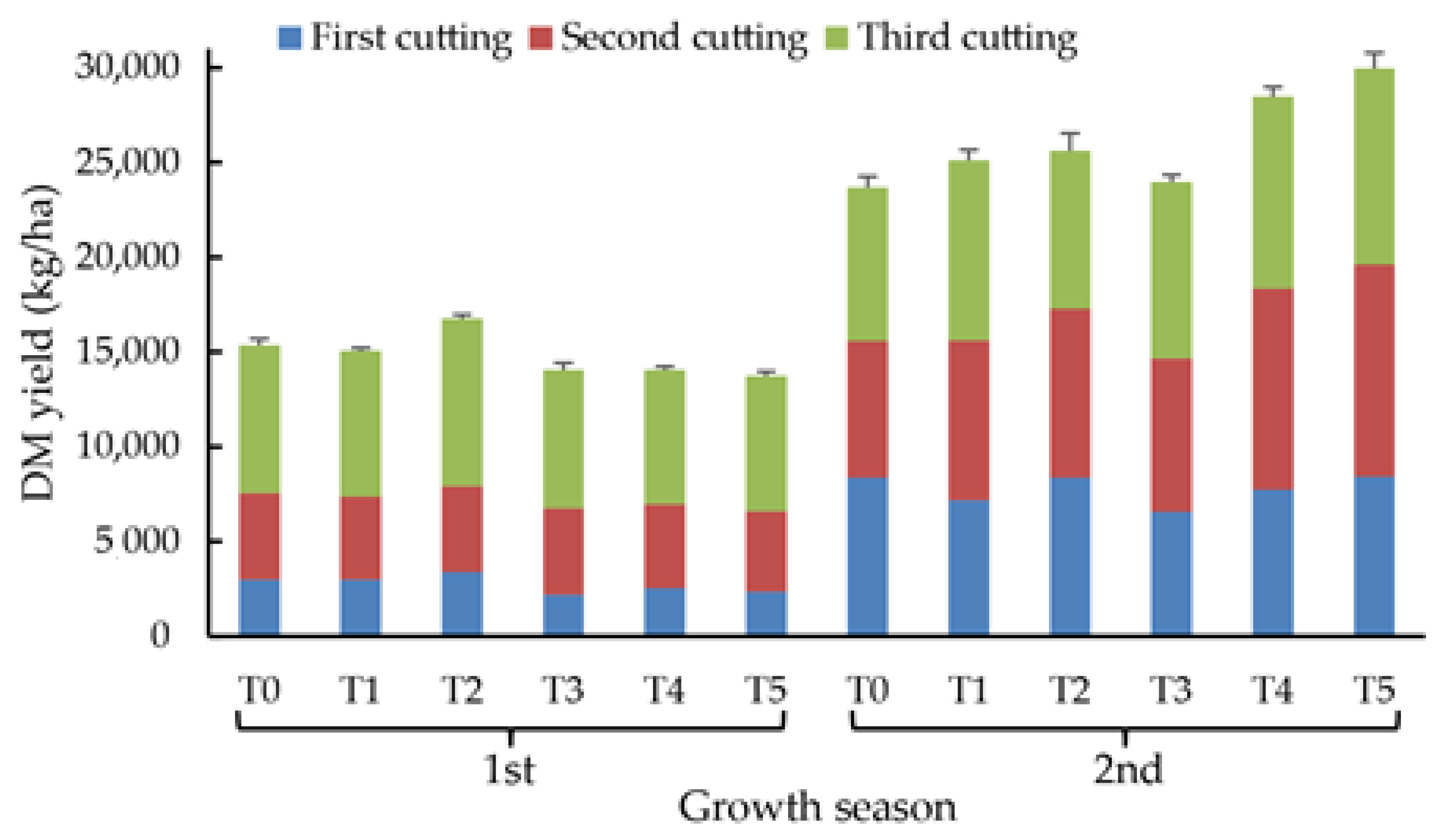

3.4. Dry Matter Yield of Italian Ryegrass with the Biogas Slurry Applied

Figure 2 shows the dry matter (DM) accumulation in above-ground parts of Italian ryegrass plants in two growth seasons. The DM accumulation of Italian ryegrass with T2 treatment was significantly higher than other treatments in the 1st growth season (p < 0.05). However, in the 2nd growth season, the Italian ryegrass DM accumulation treated with T2 occupied third place in all treatments, and the treatment of T4 and T5 were significantly higher than others (p < 0.05). Analyzing the total DM yield, contributing characters according to the DM accumulation of Italian ryegrass at every cutting time, it could be found that the Italian ryegrass hay yield of the third cutting contributed a lot to the DM accumulation in the 1st growth season, and the same results were also found in the 2nd growth season.

Figure 2.

The effect of chemical fertilizer and biogas slurry on dry matter (DM) yield of Italian ryegrass in different growth seasons.

3.5. Nutritional Status of Italian Ryegrass with the Biogas Slurry Applied

The nutritional status of Italian ryegrass in the different biogas slurry treatment groups was presented in Table 5. Crude protein (CP) content of T2 (25.06% DM) was significantly higher (p < 0.05) than T0 (22.71% DM), T1 (23.85% DM), T3 (23.11% DM), T4, and T5 (both with 23.68% DM), and CP content gradually increased in T1 and T2, but decreased in T3, T4, and T5. Ether extract (EE) content was higher for T2 (6.40% DM) than for the other treatment groups, but there was no significant difference except T5. In the case of CF content, significant differences (p < 0.05) were between the treatment groups. The lowest CF content was in T2 (15.50% DM), and CF gradually decreased in T1 and T2, but increased in T3, T4, and T5. For the neutral detergent fiber (NDF) and acid detergent fiber (ADF) content, there were no statistically significant differences between treatment groups, indicating that biogas slurry had no effect on the NDF and ADF.

Table 5.

The effect of chemical fertilizer and biogas slurry on the nutrient content in Italian ryegrass.

4. Discussion

With the growing energy demand and inadequate natural resource availability, biogas technology has been considered a new renewable energy alternative, obtained by using cattle dung, poultry litter, and other wastes [43]. However, with the synthesis of biogas through anaerobic digestion, solids and other wastes are released as slurry, which is commonly considered a waste product and potential caused environmental pollution. An optimized level of BS fertilizer is a good source of plant nutrients and can significantly improve soil properties and crop productivities [44], providing an opportunity to treat and reutilize various organic wastes and minimize greenhouse gas emissions [14,45].

Analysis of variance (ANOVA) is the most efficient method available for the analysis of experimental data, and it is a technique for analyzing the way in which the mean of a variable is affected by different types and combinations of factors. One-way analysis of variance is the simplest form. It is an extension of the independent samples t-test [46] and can be used to compare any number of groups or treatments. This method is widely used in agricultural research. Previous study showed that ANOVA was used to compare changes in the phenological properties, yield, and phytochemical composition of guar (Cyamopsis tetragonoloba L.) landaraces under various irrigation regimes and planting dates [47]. In the present study, we designed a randomized block experiment to compare the effects of CSF + BS on the biomass yield and forage quality of Italian ryegrass with ANOVA, which could have statistical meaning for agriculture application.

It has been proved that the application of biogas slurry as fertilizer could effectively stimulate the growth of plants and is the ideal substitute of chemical synthetic fertilizer. As a kind of biofertilizer with abundant nutrients, bioslurry has been reported to have significantly increased yields in S. tuberosum L. [48], Spinacia oleracea L. [49], Capsicum annuum L. [49], Abelmoschus esculentus (L.) Moench [50], and Lactuca sativa L. [51] compared with only the application of synthetic fertilizer. However, in order to obtain optimized growth and be environment friendly, the suitable application rate of biogas slurry should be study. Based on this study, approximately 37.5 kg/ha CSF + 100.5 t/ha BS is the optimum level for Italian ryegrass growth, and the yield greater than the yield of traditional farmer practice (only used the chemical synthetic fertilizer), which was consistent with previous study in tomato by Ferdous et al. [52]. Marino et al. [53] reported that the nitrogen fertilizer significantly increased the forage dry matter and N accumulation. Although Wentzel and Joergensen [54] reported the positive effect of biogas slurry fertilizer on Italian ryegrass plant biomass, the biomass yield was non-significantly increased with the excess use of biogas slurry. Similarly, in order to obtain the maximum growth of maize fodder, an optimal level of biogas slurry (70 kg of slurry N ha−1) was suggested to be applied, while excessive use beyond this optimal level might induce adverse effects [27]. Other factors like genetic makeup of plant, soil fertility, and environment conditions were all important to plant height of forage.

It has been demonstrated that BS might increase the availability of macro- and micronutrients, particularly nitrogen, which in turn promotes meristematic growth, leading to higher bioactive compounds like anthocyanin and vitamin. BS is the rich source of nitrogen which holds prime importance since it is the key element in all proteins including enzymes which regulate all the metabolic processes in plants [27]. Nitrogen also has a direct correlation with the important metabolic pathways such as growth, photosynthesis, and consequently affects the light energy efficiency and yield because it is the main element of leaf chlorophyll content [55,56]. The plant photosynthetic rate may be linear in correlation to leaf nitrogen content but the continuous lack of nitrogen reduces photosynthesis rate, soluble protein, enzymes, and chlorophyll [57]. The observed increase in forage yield in response to slurry nitrogen might be owing to its positive effect on cell elongation, cell division, and increasing photosynthetic surface, resulting in more production and accumulation of photosynthetic compounds.

Usually, crops can directly use soil-available NH4 + -N, P, and K in biogas slurry [8,58]. Further, it has been reported that the use of biogas slurry in combination with chemical fertilizer could effectively increase soil organic matter, nutrient concentrations, and N use efficiency [59]. The increase in nitrogen use efficiency could promote root and shoot growth, and increase the crop biomass yield [52]. Katuwal and Bohara [60] reported an increase in vegetable crop yields among 68% of farming households, along with an increase in revenue among 42% households after use of biogas slurry. Muhmood et al. [49] reported that synthetic fertilizer in combination with biogas slurry applied could increase economic returns from spinach (Spinacia oleracea) and chilli (Capsicum frutescens) production. In this study, the results showed that the optimum level of biogas slurry for Italian ryegrass could benefit plant growth, and the yield, which was similar to those reported by Daudén and QuíLez [61], who conducted a maize yield experiment using different levels of slurry. However, these studies mainly explored the effect of BS on yield, rather than both the yield and quality of productions.

Forage DM content is also an indicator of its quality according to variety, stage of forage maturity, season, temperature, and environment conditions. In the current study, due to soil fertilizer residues in the 1st growth season and the improvement of soil structure by biogas slurry, dry matter production in the 2nd growth season was higher than that of the previous year [62]. Interestingly, the DM content of the second and third cutting were higher than other treatments results where the DM production of T4 and T5 in 2017 were higher than others. When the Italian ryegrass suffered drought stress during the second and third growth, the treatment of T4 and T5 can provide enough water for Italian ryegrass to grow. Besides, the CP and CF content of forage is the most important indicator contributing to its forage quality. Generally speaking, it has a direct effect on milk production in dairy animals and body growth in cattle. Sarker [63] reported that the increased use of nitrogen fertilizer could effectively increase the CP content in Zamboo grass (Hybrid jowar). The previous study of mixed sown pasture in North Wales indicated that application of digestate leads to a similar response in pasture yield as when compound inorganic fertilizer is applied, and better than straight N organic fertilizer [64]. In this study, application of 37.5 kg/ha chemical synthetic fertilizer and 100.5 t/ha biogas slurry significantly increased the CP content. In addition, the CF content of Italian ryegrass decreased when the biogas slurry was used in combination with chemical fertilizer. The reason may be that biogas slurry had the potential to increase Italian ryegrass yield and improve the forage quality. Additionally, use of chemical fertilizer with biogas slurry could be a viable input for production of high yield and high quality forage. Similar results were also reported in switchgrass by the University of Life Sciences in Lublin where the biogas digestate can increase the biomass yield, the content of protein, P, and Mg of switchgrass [65]. The present study provides guidance for the use of BS to grow Italian ryegrass, especially in the dairy farm and the developed area of animal husbandry. Italian ryegrass can provide feed for cow, and the cow dung is used to produce biogas to provide energy, and BS as a by-product can provide nutrients for Itanlian ryegrass. Due to an 800 m3 volume, the biogas system needs to discharge 15 tons of biogas slurry daily; this circulation model can be applied on a large scale to reduce environmental pollution. The biogas slurry produced by a scale farm can be supplied to Italian ryegrass planting for animal feed. However, the biogas slurry transportation seems troublesome, and it is best to have pipeline laying as a cost-effective way, which sometimes requires government financial supply.

Biogas slurry used in crop cultivations is an agricultural eco-circulatory system for the reuse of livestock and poultry waste and reduction of chemical syntheic fertilizer input. Although this study explored the appropriate amount of biogas slurry to improve the yield of Italian ryegrass, there is much more to be learned. Uncertain chemical characteristics of biogas slurry including liquidity, high pH, high ammonium (NH4+) content, and potentially high heavy metal content [20,29,31], which are very different with traditional mineral fertilizers, could induce biology security risks. Thus, necessary evaluating studies must be performed to elucidate the effects of biogas slurry on crop development and environment before its extensive application. Especially, the accumulation of heavy metals in plants and soil to prevent them from affecting human health through the food chain.

5. Conclusions

Biogas slurry, a by-product of biogas production generated from anaerobic digestion of animal waste and crop residues, is often considered a substitute to reduce mineral fertilizer input. The results of the present study showed that biogas slurry in combination with chemical synthetic fertilizer significantly (p < 0.05) improved the growth of Italian ryegrass on treatment with T2, and the Italian ryegrass dry matter increased by more than 9.00%, while the stem-to-leaf ratio decreased by more than 12% (second cutting), in comparison with only chemical synthetic fertilizer group (T0). The forage quality index of CP and CF also had a significant difference and was observed between the T0 and T2 treatment group. Compare with the chemical synthetic fertilizer group, the CP content improved by 10.35%, and the CF content decreased by about 10.00%. Based on these results, it was concluded that the application of 37.5 kg/ha CSF + 100.5 t/ha BS could improve the production of biomass and forage quality in Italian ryegrass, but also replace part of the chemical fertilizer applied in agriculture.

Author Contributions

W.X. and C.L., Conceived the idea, analyzed, and interpreted the data, drafted and revised the manuscript; X.W., H.W. and L.Y., Collected and analyzed the data; Y.Z. and L.J., revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the National Key Research and Development Program (2018YFD0200707), the Financial Innovation Capacity Improvement Project in Sichuan Province (2016GYSH-022), China Agriculture Research System (NO. CARS-34), Sichuan forage innovation team.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data has been shared in this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Abbreviations

The abbreviation were used in this study.

| CSF | Chemical synthetic fertilizer |

| BS | Biogas slurry |

| DM | Dry matter |

| CP | Crude protein |

| EE | Ether extract |

| CF | Crude fiber |

| NDF | Neutral detergent fiber |

| ADF | Acid detergent fiber |

References

- Chowdhury, T.; Chowdhury, H.; Hossain, N.; Ahmed, A.; Hossen, M.S.; Chowdhury, P.; Thirugnanasambandam, M.; Saidur, R. Latest advancements on livestock waste management and biogas production: Bangladesh’s perspective. J. Clean. Prod. 2020, 272, 122818. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China. China Statistical Yearbook 2018; China Statistics Press: Beijing, China, 2018.

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Mulka, R.; Szulczewski, W.; Szlachta, J.; Prask, H. The influence of carbon content in the mixture of substrates on methane production. Clean Technol. Environ. Policy 2016, 18, 807–815. [Google Scholar] [CrossRef][Green Version]

- Holm-Nielsen, J.B.; Al Seadi, T.; Oleskowicz-Popiel, P. The future of anaerobic digestion and biogas utilization. Bioresour. Technol. 2009, 100, 5478–5484. [Google Scholar] [CrossRef]

- Ebenezer Rajkumar, A.; Sethumadhavan, R.; Velraj, R. Biogas: Can it be an important source of energy? Environ. Sci. Pollut. Res. Int. 2007, 14, 67–71. [Google Scholar]

- Arthurson, V. Closing the Global Energy and Nutrient Cycles through Application of Biogas Residue to Agricultural Land—Potential Benefits and Drawback. Energies 2009, 2, 226–242. [Google Scholar] [CrossRef]

- Yu, F.B.; Luo, X.P.; Song, C.F.; Zhang, M.X.; Shan, S.D. Concentrated biogas slurry enhanced soil fertility and tomato quality. Acta Agric. Scand. 2010, 60, 262–268. [Google Scholar] [CrossRef]

- Abdeshahian, P.; Lim, J.S.; Ho, W.S.; Hashim, H.; Lee, C.T. Potential of biogas production from farm animal waste in Malaysia. Renew. Sustain. Energy Rev. 2016, 60, 714–723. [Google Scholar] [CrossRef]

- Prasertsan, S.; Sajjakulnukit, B. Biomass and biogas energy in Thailand: Potential, opportunity and barriers. Renew. Energy 2006, 31, 599–610. [Google Scholar] [CrossRef]

- Sadettanh, K. Renewable energy resources potential in Lao PDR. Energy Sour. 2004, 26, 9–18. [Google Scholar] [CrossRef]

- O’Shea, R.; Wall, D.; Murphy, J. Modelling a demand driven biogas system for production of electricity at peak demand and for production of biomethane at other times. Bioresour. Technol. 2016, 216, 238–249. [Google Scholar] [CrossRef] [PubMed]

- D’Imporzano, G.; Pilu, R.; Corno, L.; Adani, F. Arundo donax L. can substitute traditional energy crops for more efficient, environmentally-friendly production of biogas: A Life Cycle Assessment approach. Bioresour. Technol. 2018, 267, 249–256. [Google Scholar] [CrossRef] [PubMed]

- Surendra, K.; Takara, D.; Hashimoto, A.G.; Khanal, S.K. Biogas as a sustainable energy source for developing countries: Opportunities and challenges. Renew. Sustain. Energy Rev. 2014, 31, 846–859. [Google Scholar] [CrossRef]

- Li, J.; Duan, N.; Guo, S.; Shao, L.; Lin, C.; Wang, J.; Hou, J.; Hou, Y.; Meng, J.; Han, M. Renewable resource for agricultural ecosystem in China: Ecological benefit for biogas by-product for planting. Ecol. Inform. 2012, 12, 101–110. [Google Scholar] [CrossRef]

- Mao, C.; Feng, Y.; Wang, X.; Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 2015, 45, 540–555. [Google Scholar] [CrossRef]

- Banik, S.; Nandi, R. Effect of supplementation of rice straw with biogas residual slurry manure on the yield, protein and mineral contents of oyster mushroom. Ind. Crop. Prod. 2004, 20, 311–319. [Google Scholar] [CrossRef]

- Insam, H.; Gómez-Brandón, M.; Ascher, J. Manure-based biogas fermentation residues–Friend or foe of soil fertility? Soil Biol. Biochem. 2015, 84, 1–14. [Google Scholar] [CrossRef]

- Dahiya, A.K.; Vasudevan, P. Biogas plant slurry as an alternative to chemical fertilizers. Biomass 1986, 9, 67–74. [Google Scholar] [CrossRef]

- Lu, J.; Jiang, L.; Chen, D.; Toyota, K.; Strong, P.J.; Wang, H.; Hirasawa, T. Decontamination of anaerobically digested slurry in a paddy field ecosystem in Jiaxing region of China. Agric. Ecosyst. Environ. 2012, 146, 13–22. [Google Scholar] [CrossRef]

- Sheets, J.P.; Liangcheng, Y.; Xumeng, G.; Zhiwu, W.; Yebo, L. Beyond land application: Emerging technologies for the treatment and reuse of anaerobically digested agricultural and food waste. Waste Manag. 2015, 44, 94–115. [Google Scholar] [CrossRef]

- Tan, F.; Wang, Z.; Zhouyang, S.; Li, H.; Xie, Y.; Wang, Y.; Zheng, Y.; Li, Q. Nitrogen and phosphorus removal coupled with carbohydrate production by five microalgae cultures cultivated in biogas slurry. Bioresour. Technol. 2016, 221, 385–393. [Google Scholar] [CrossRef]

- Terhoeven-Urselmans, T.; Scheller, E.; Raubuch, M.; Ludwig, B.; Joergensen, R.G. CO2 evolution and N mineralization after biogas slurry application in the field and its yield effects on spring barley. Appl. Soil Ecol. 2009, 42, 297–302. [Google Scholar] [CrossRef]

- Hansen, M.N.; Henriksen, K.; Sommer, S.G. Observations of production and emission of greenhouse gases and ammonia during storage of solids separated from pig slurry: Effects of covering. Atmos. Environ. 2006, 40, 4172–4181. [Google Scholar] [CrossRef]

- Möller, K.; Müller, T. Effects of anaerobic digestion on digestate nutrient availability and crop growth: A review. Eng. Life Sci. 2012, 12, 242–257. [Google Scholar] [CrossRef]

- Liu, W.K.; Yang, Q.C.; Du, L.F. Soilless cultivation for high-quality vegetables with biogas manure in China: Feasibility and benefit analysis. Renew. Agric. Food Syst. 2009, 24, 300–307. [Google Scholar] [CrossRef]

- Islam, M.R.; Rahman, S.M.E.; Rahman, M.M.; Deog Hwan, O.H.; Chang, S.R. The effects of biogas slurry on the production and quality of maize fodder. Turk. J. Agric. For. 2010, 34, 91–99. [Google Scholar]

- Garg, R.N.; Pathak, H.; Das, D.K.; Tomar, R.K. Use of Flyash and Biogas Slurry for Improving Wheat Yield and Physical Properties of Soil. Environ. Monit. Assess. 2005, 107, 1–9. [Google Scholar] [CrossRef]

- Hou, H.; Zhou, S.; Hosomi, M.; Toyota, K.; Yosimura, K.; Mutou, Y.; Nisimura, T.; Takayanagi, M.; Motobayashi, T. Ammonia Emissions from Anaerobically-digested Slurry and Chemical Fertilizer Applied to Flooded Forage Rice. Water Air Soil Pollut. 2007, 183, 37–48. [Google Scholar] [CrossRef]

- Elfstrand, S.; Båth, B.; Mårtensson, A. Influence of various forms of green manure amendment on soil microbial community composition, enzyme activity and nutrient levels in leek. Appl. Soil Ecol. 2007, 36, 70–82. [Google Scholar] [CrossRef]

- Svoboda, N.; Taube, F.; Wienforth, B.; Kluß, C.; Kage, H.; Herrmann, A. Nitrogen leaching losses after biogas residue application to maize. Soil Tillage Res. 2013, 130, 69–80. [Google Scholar] [CrossRef]

- Zheng, X.; Fan, J.; Jian, C.; Yi, W.; Jing, Z.; Mao, Y.; Sun, M. Effects of biogas slurry application on peanut yield, soil nutrients, carbon storage, and microbial activity in an Ultisol soil in southern China. J. Soils Sediments 2016, 16, 449–460. [Google Scholar] [CrossRef]

- Zhu, K.; Choi, H.L.; Yao, H.Q.; Suresh, A.; Oh, D.I. Effects of anaerobically digested pig slurry application on runoff and leachate. Chem. Ecol. 2009, 25, 359–369. [Google Scholar] [CrossRef]

- Carámbula, M.; Carámbula, M. Producción y Manejo de Pasturas Sembradas; Editorial Agropecuaria Hemisferio Sur: Montevideo, Uruguay, 1977. [Google Scholar]

- Evers, G.; Smith, G.; Hoveland, C. Ecology and production of annual ryegrass. Ecol. Prod. Manag. Lolium Forage USA 1997, 24, 29–43. [Google Scholar]

- Maia, M. Secagem de Sementes de Azevém Anual (Lolium moltiflorum L.) com ar em Ambiente Controlado; Universidade Federal de Pelotas: Pelotas, Brazil, 1995. [Google Scholar]

- Ball, D.M.; Collins, M.; Lacefield, G.; Martin, N.; Mertens, D.; Olson, K.; Putnam, D.; Undersander, D.; Wolf, M. Understanding Forage Quality; American Farm Bureau Federation Publication: Park Ridge, IL, USA, 2001. [Google Scholar]

- Rahman, S.; Islam, M.; Rahman, M.; Oh, D.-H. Effect of cattle slurry on growth, biomass yield and chemical composition of maize fodder. Asian-Aust. J. Anim. Sci. 2008, 21, 1592–1598. [Google Scholar] [CrossRef]

- Yin, Y.; Xing, X.; Tang, H.; Li, Z.; Liu, M.; Xu, H.; Guo, Y. Nutrient assimilating capacity of lolium multiflorum pasture for dairy farm biogas slurry. Acta Pratac. Sin. 2013, 22, 333–338. [Google Scholar]

- AOAC. Official Methods of Analysis, 15th ed.; Association Official Analytical Chemists: Arlington, VA, USA, 1990. [Google Scholar]

- Goering, H.K.; Van Soest, P.J. Forage Fiber Analyses: Apparatus, Reagents, Procedures, and Some Applications; Agricultural Research Service, US Department of Agriculture: Washington, DC, USA, 1970. [Google Scholar]

- Van Soest, P.V.; Robertson, J.; Lewis, B. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Khan, E.U.; Martin, A.R. Review of biogas digester technology in rural Bangladesh. Renew. Sustain. Energy Rev. 2016, 62, 247–259. [Google Scholar] [CrossRef]

- Ahmad, M.; Zahir, Z.A.; Jamil, M.; Nazli, F.; Latif, M.; Akhtar, M. Integrated use of plant growth promoting rhizobacteria, biogas slurry and chemical nitrogen for sustainable production of maize under salt–affected conditions. Pak. J. Bot. 2014, 46, 375–382. [Google Scholar]

- Mengistu, M.G.; Simane, B.; Eshete, G.; Workneh, T.S. A review on biogas technology and its contributions to sustainable rural livelihood in Ethiopia. Renew. Sustain. Energy Rev. 2015, 48, 306–316. [Google Scholar] [CrossRef]

- Whitley, E.; Ball, J. Statistics review 5: Comparison of means. Crit. Care 2002, 6, 1–5. [Google Scholar]

- Meftahizadeh, H.; Ghorbanpour, M.; Asareh, M.H. Changes in phenological attributes, yield and phytochemical compositions of guar (Cyamopsis tetragonoloba L.) landaraces under various irrigation regimes and planting dates. Sci. Hortic. 2019, 256, 108577. [Google Scholar] [CrossRef]

- Garfí, M.; Gelman, P.; Comas, J.; Carrasco, W.; Ferrer, I. Agricultural reuse of the digestate from low-cost tubular digesters in rural Andean communities. Waste Manag. 2011, 31, 2584–2589. [Google Scholar] [CrossRef]

- Muhmood, A.; Javid, S.; Ahmad, Z.; Majeed, A.; Rafique, R. Integrated use of bioslurry and chemical fertilizers for vegetable production. Pak. J. Agric. Sci. 2014, 51, 563–568. [Google Scholar]

- Shahbaz, M.; Akhtar, M.J.; Ahmed, W.; Wakeel, A. Integrated effect of different N-fertilizer rates and bioslurry application on growth and N-use efficiency of okra (Hibiscus esculentus L.). Turk. J. Agric. For. 2014, 38, 311–319. [Google Scholar] [CrossRef]

- Wenke, L.; Lianfeng, D.; Qichang, Y. Biogas slurry added amino acids decreased nitrate concentrations of lettuce in sand culture. Acta Agric. Scand. Sect. B–Soil Plant Sci. 2009, 59, 260–264. [Google Scholar] [CrossRef]

- Ferdous, Z.; Ullah, H.; Datta, A.; Anwar, M.; Ali, A. Yield and Profitability of Tomato as Influenced by Integrated Application of Synthetic Fertilizer and Biogas Slurry. Int. J. Veg. Sci. 2018, 24, 445–455. [Google Scholar] [CrossRef]

- Marino, M.A.; Mazzanti, A.; Assuero, S.G.; Gastal, F.; Echeverría, H.E.; Andrade, F. Nitrogen dilution curves and nitrogen use efficiency during winter–spring growth of annual ryegrass. Agron. J. 2004, 96, 601–607. [Google Scholar] [CrossRef]

- Wentzel, S.; Joergensen, R.G. Effects of biogas and raw slurries on grass growth and soil microbial indices. J. Plant Nutr. Soil Sci. 2016, 179, 215–222. [Google Scholar] [CrossRef]

- Shiratsuchi, H.; Yamagishi, T.; Ishii, R. Leaf nitrogen distribution to maximize the canopy photosynthesis in rice. Field Crops Res. 2006, 95, 291–304. [Google Scholar] [CrossRef]

- Khalid, M.; Bilal, M.; Hassani, D.; Iqbal, H.M.N.; Wang, H.; Huang, D. Mitigation of salt stress in white clover (Trifolium repens) by Azospirillum brasilense and its inoculation effect. Bot. Stud. 2017, 58, 5. [Google Scholar] [CrossRef] [PubMed]

- Boussadia, O.; Steppe, K.; Zgallai, H.; Hadj, S.B.E.; Braham, M.; Lemeur, R.; Labeke, M.C.V. Effects of nitrogen deficiency on leaf photosynthesis, carbohydrate status and biomass production in two olive cultivars ‘Meski’ and ‘Koroneiki’. Sci. Hortic. 2010, 123, 336–342. [Google Scholar] [CrossRef]

- Möller, K.; Stinner, W.; Deuker, A.; Leithold, G. Effects of different manuring systems with and without biogas digestion on nitrogen cycle and crop yield in mixed organic dairy farming systems. Nutr. Cycl. Agroecosyst. 2008, 82, 209–232. [Google Scholar] [CrossRef]

- Akanbi, W.B.; Togun, A.O.; Adediran, J.A.; Ilupeju, E.A.O. Growth, dry matter and fruit yields components of okra under organic and inorganic sources of nutrients. Am. -Eurasian J. Sustain. Agric. 2010, 4, 1–13. [Google Scholar]

- Katuwal, H.; Bohara, A.K. Biogas: A promising renewable technology and its impact on rural households in Nepal. Renew. Sustain. Energy Rev. 2009, 13, 2668–2674. [Google Scholar] [CrossRef]

- Daudén, A.; QuíLez, D. Pig slurry versus mineral fertilization on corn yield and nitrate leaching in a Mediterranean irrigated environment. Eur. J. Agron. 2004, 21, 7–19. [Google Scholar] [CrossRef]

- Du, Z.; Chen, X.; Qi, X.; Li, Z.; Nan, J.; Deng, J. The effects of biochar and hoggery biogas slurry on fluvo-aquic soil physical and hydraulic properties: A field study of four consecutive wheat–maize rotations. J. Soils Sediments 2016, 16, 2050–2058. [Google Scholar] [CrossRef]

- Sarker, V. Effect of Different Doses of Nitrogen Fertilizer on Growth, Yield, Chemical Composition and Degradability of Zamboo Grass (Hybrid jowar). Master’s Thesis, Department of Animal Nutrition, Bangladesh Agricultural University, Mymensingh, Bangladesh, 2000. [Google Scholar]

- Walsh, J.J.; Jones, D.L.; Chadwick, D.; Williams, A. Repeated application of anaerobic digestate, undigested cattle slurry and inorganic fertilizer N: Impacts on pasture yield and quality. Grass Forage Sci. 2018, 73, 758–763. [Google Scholar] [CrossRef]

- Głowacka, A.; Szostak, B.; Klebaniuk, R. Effect of biogas digestate and mineral fertilisation on the soil properties and yield and nutritional value of switchgrass forage. Agronomy 2020, 10, 490. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).