Structural Performance and Reinforcement Improvement of Structural Walls Using Strain-Hardening Cementitious Composites

Abstract

:1. Introduction

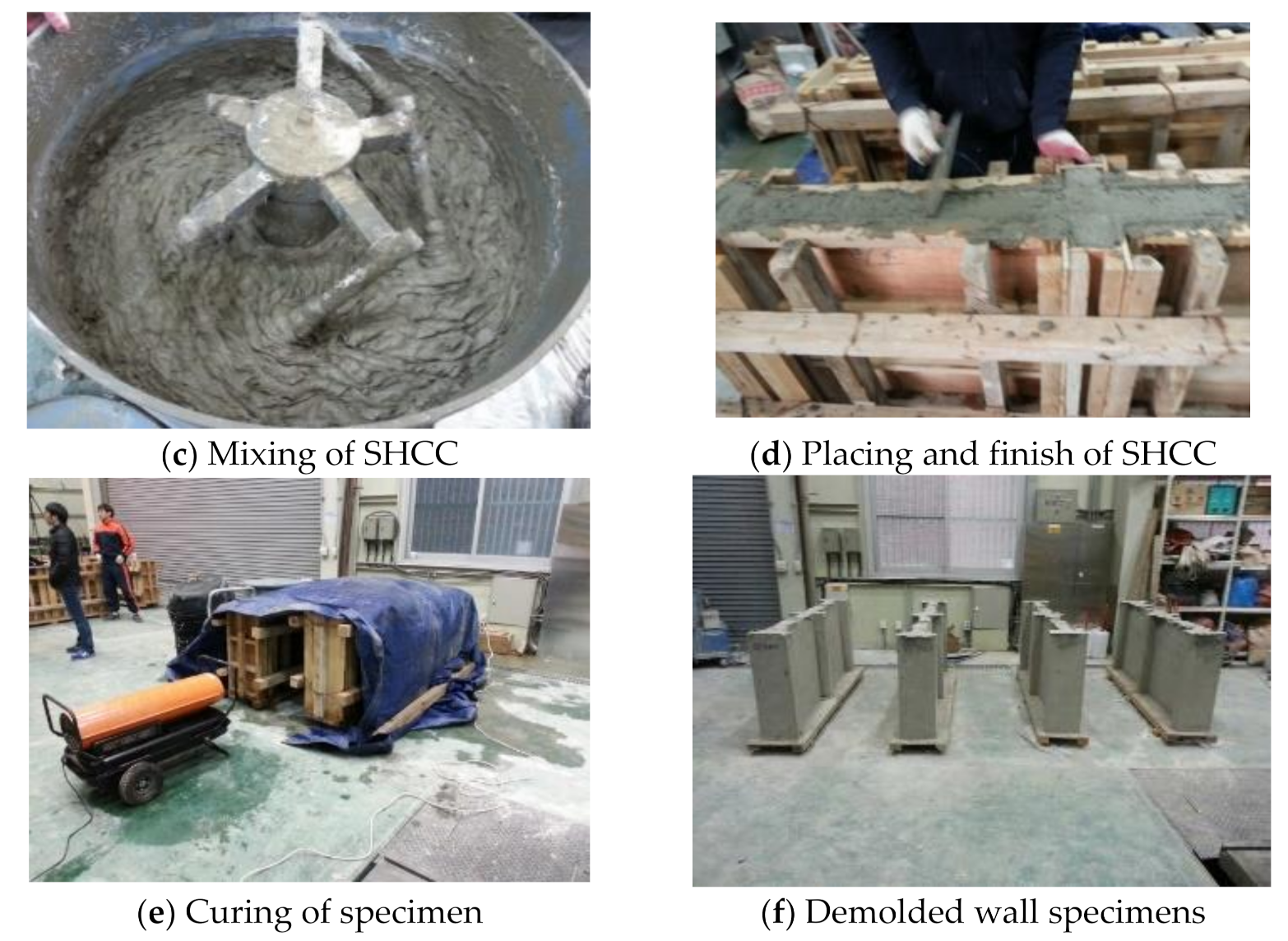

2. Manufacture, Material, and Mechanical Characteristics of SHCC

2.1. Mixing of SHCC

2.2. Mechanical Characteristics of SHCC

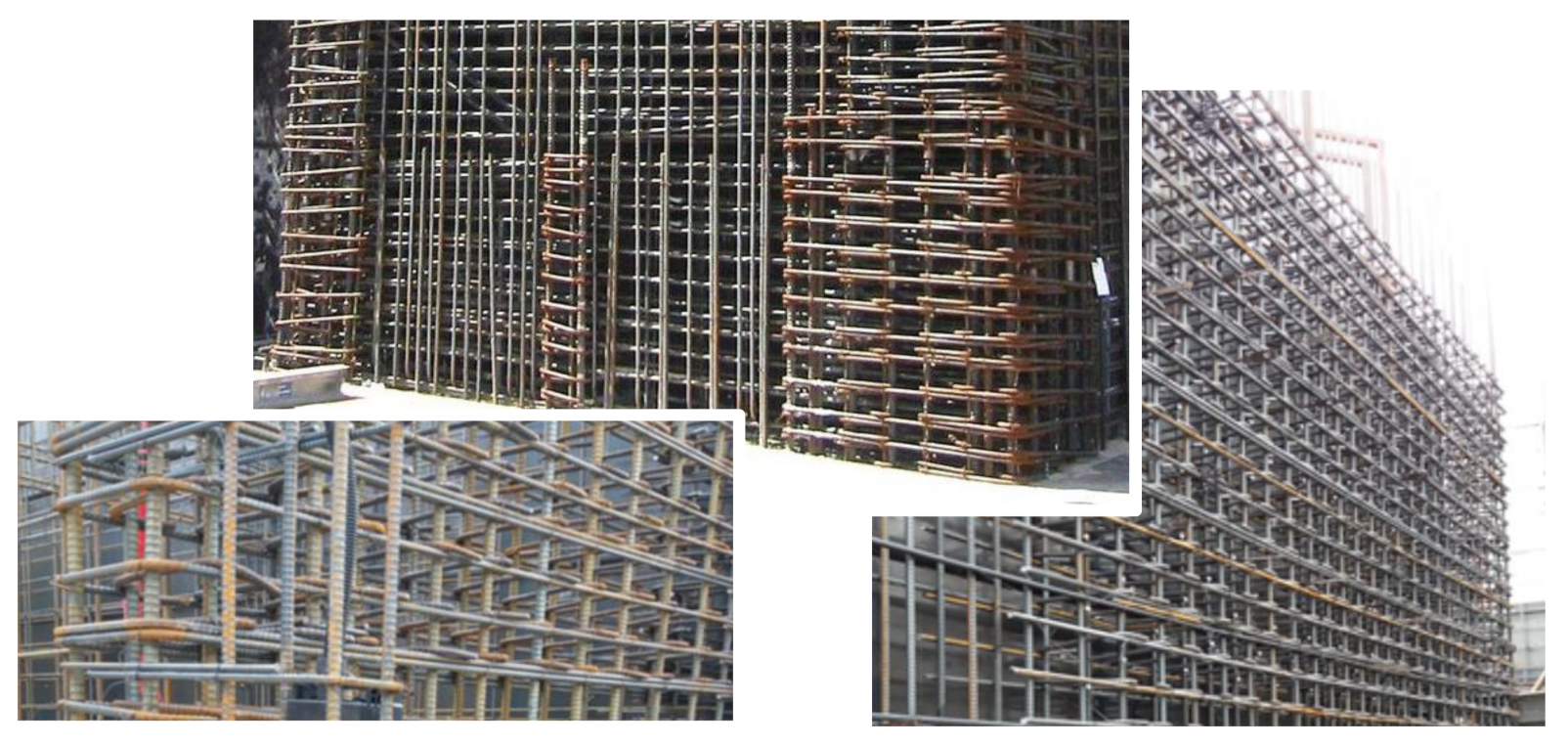

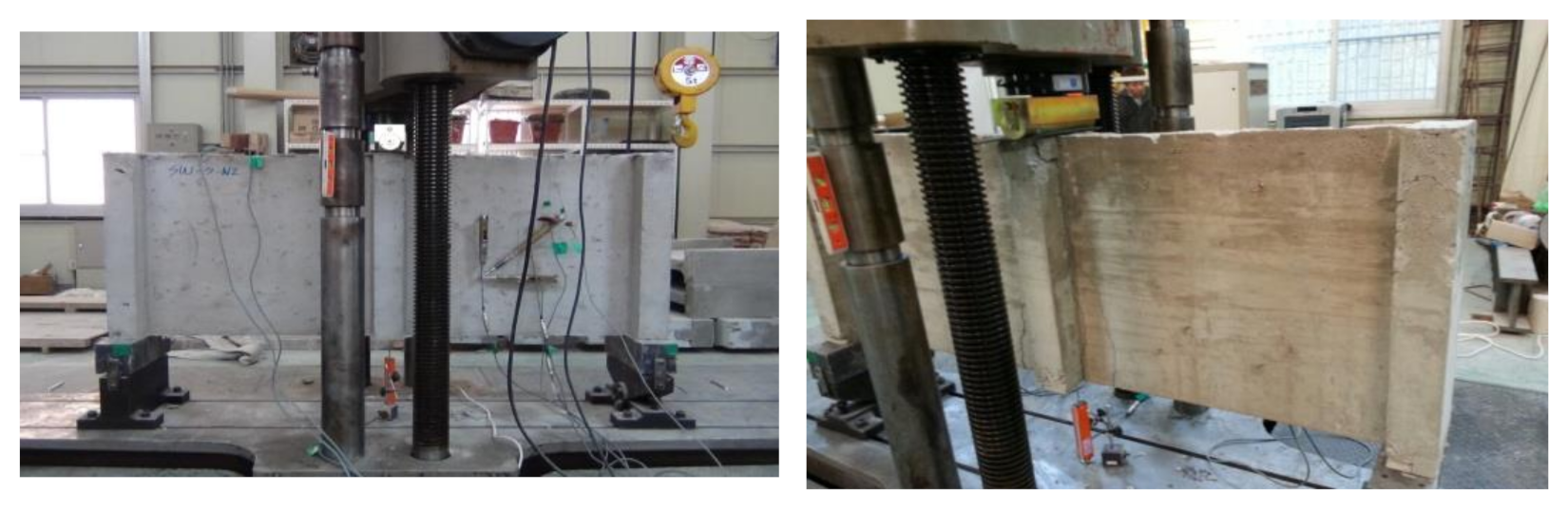

3. Manufacture and Experiment of R-SHCC Structural Wall Specimens

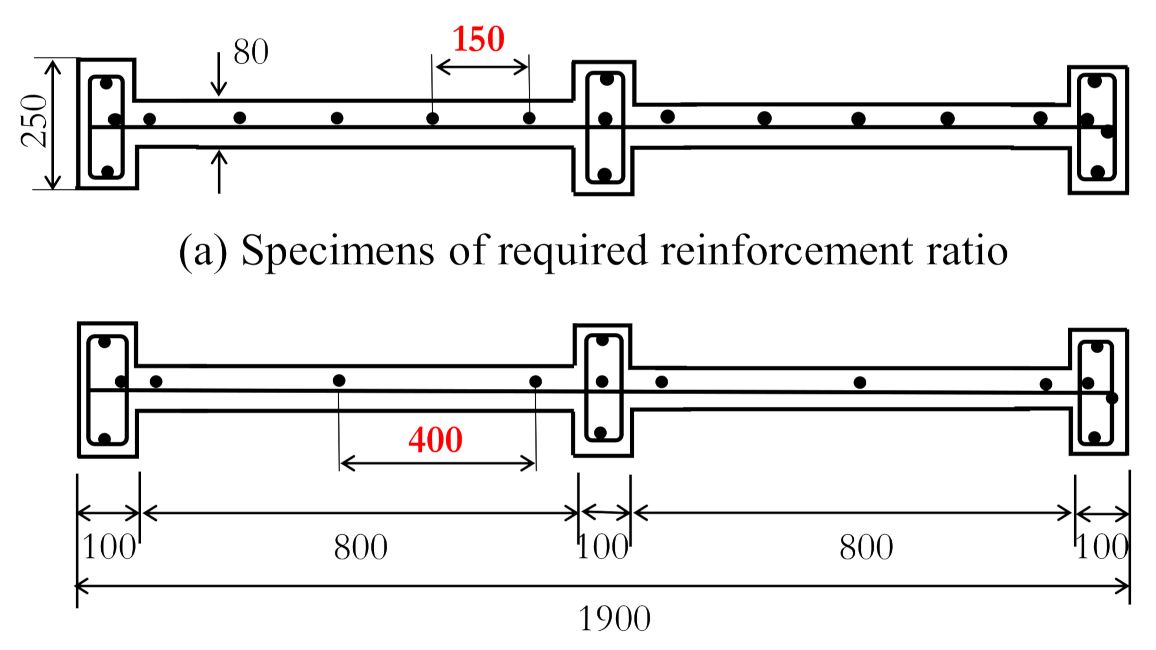

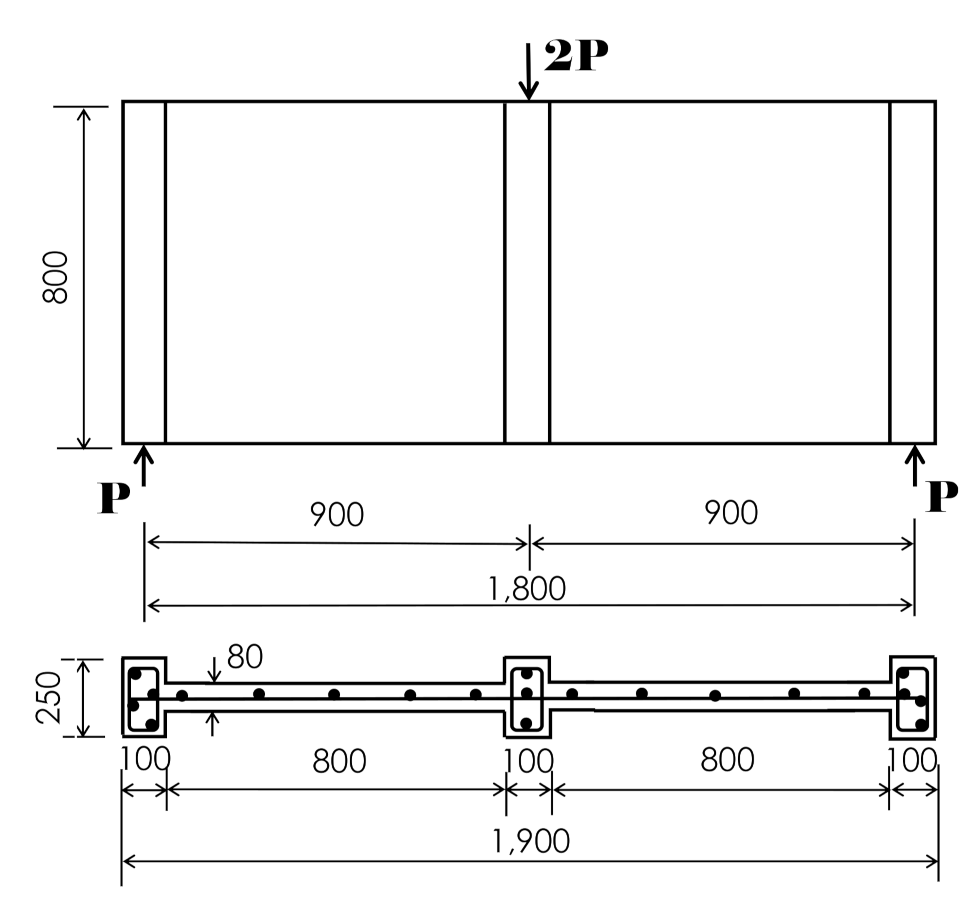

3.1. Design and Details of Wall Specimens

3.2. Splitting Tensile Strength

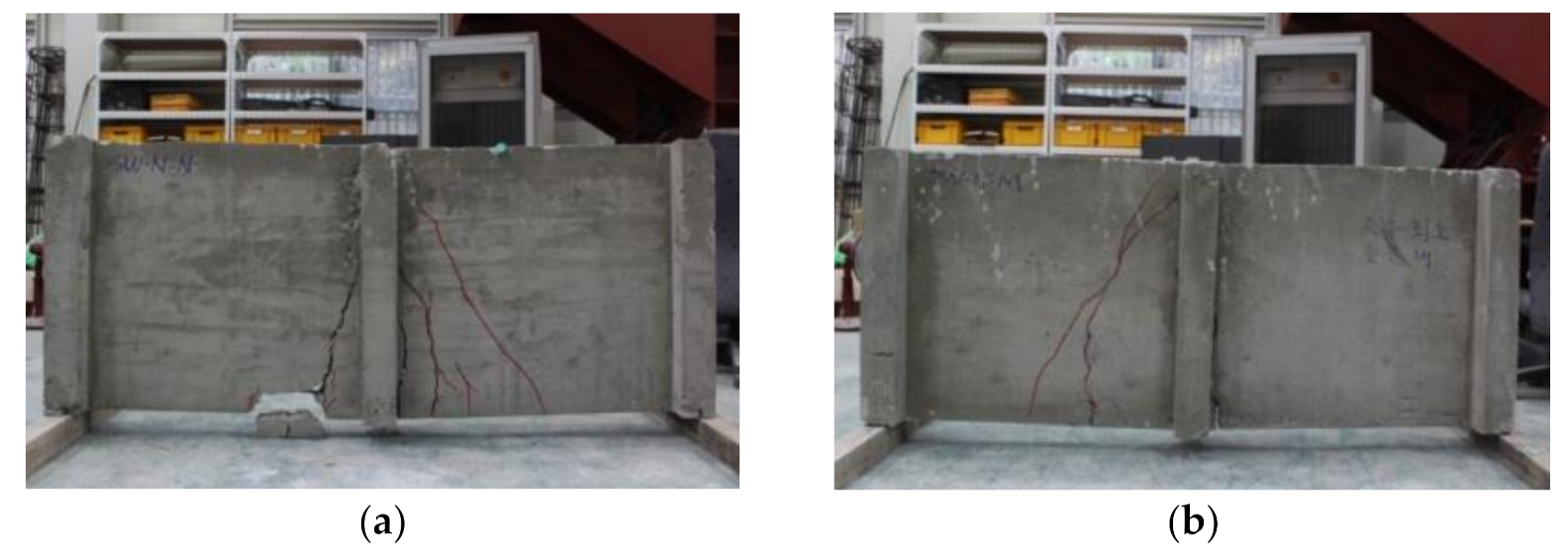

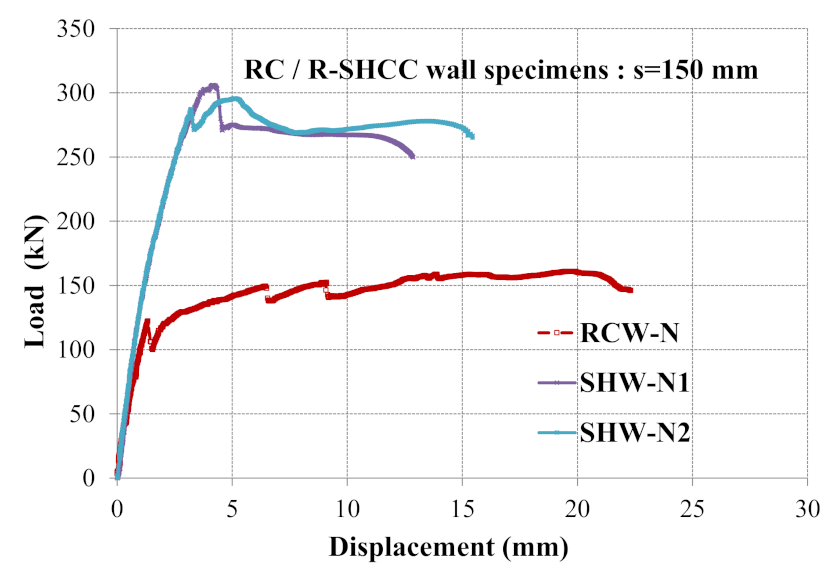

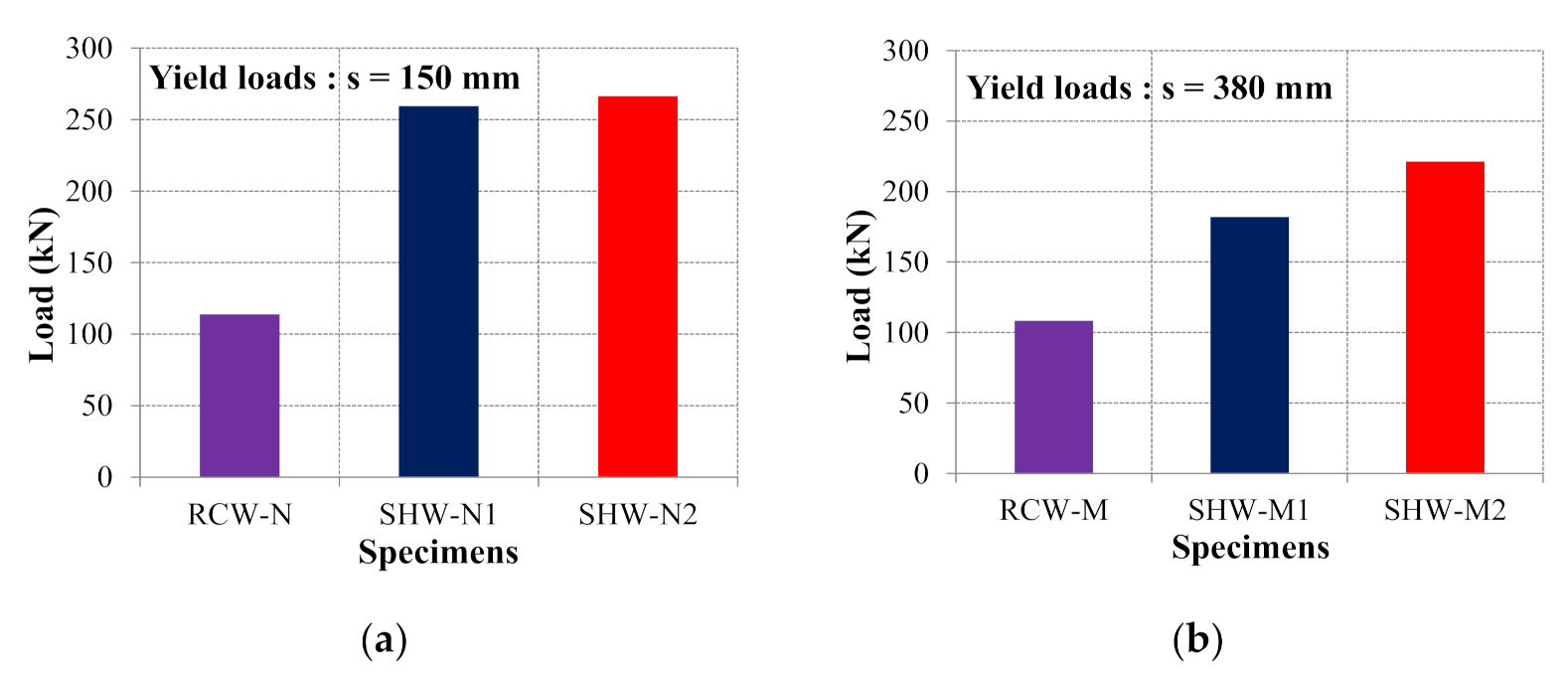

4. Summaries and Discussions on Wall Load Test

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ACI. Building Code Requirements for Structural Concrete (ACI 318-19); American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

- AIK. Korean Building Code and Commentary (KBC 2016); Architectural Institute of Korea: Seoul, Korea, 2016. [Google Scholar]

- Cervenka, V.; Gerstle, K.H. Inelastic Analysis of Reinforced Concrete Panels, Part I: Experimental Verification and Application. Int. Assoc. Bridge Struct. Eng. Publ. 1972, 32, 25–39. [Google Scholar]

- Darwin, D.; Pecknold, D.A. Analysis of RC Shear Panels under Cyclic Loading. J. Struct. Eng. ASCE 1976, 102, 355–369. [Google Scholar]

- Massone, L.M.; Wallace, J.W. Load-Deformation Responses of Slender Reinforced Concrete Walls. ACI Struct. J. 2004, 101, 103–113. [Google Scholar]

- Segura, C.L.; Wallace, J.W. Seismic performance limitations and detailing of slender reinforced concrete walls. ACI Struct. J. 2018, 115, 849–859. [Google Scholar] [CrossRef]

- Zhang, H.M.; Lu, X.L.; Duan, Y.F.; Zhu, Y. Experimental study on failure mechanism of RC walls with different boundary elements under vertical and lateral loads. Adv. Struct. Eng. 2014, 17, 361–379. [Google Scholar] [CrossRef]

- Abdullah, S.A.; Wallace, J.W. Reliability-Based Design Methodology for Reinforced Concrete Structural Walls with Special Boundary Elements. ACI Struct. J. 2020, 117, 17–29. [Google Scholar] [CrossRef]

- Paulay, T.; Priestley, M.J.N. Seismic Design of Reinforced Concrete and Masonry Buildings; Wiley & Sons: New York, NY, USA, 1992; p. 744. [Google Scholar]

- Priestley, M.J.N.; Seible, F.; Calvi, G.M. Seismic Design and Retrofit of Bridges; John Wiley & Sons: New York, NY, USA, 1996; p. 686. [Google Scholar]

- Li, V.C. From Micromechanics to Structural Engineering—The Design of Cementitious Composites for Civil Engineering Applications. J. Struc. Mech. Earth Eng. 1993, 10, 37–48. [Google Scholar]

- Blanco, I.; Poggetto, G.D.; Morrone, B.; Tranquillo, E.; Barrino, F.; Catauro, M. Fly Ash Filled Geopolymers: Preparation and Thermal Study. Macromol. Symp. 2020, 389, 1900052. [Google Scholar] [CrossRef]

- Cho, C.G.; Ha, G.J.; Kim, Y.Y. Nonlinear Model of Reinforced Concrete Frames Retrofitted by In-Filled HPFRCC Walls. Struct. Eng. Mech. 2008, 30, 211–223. [Google Scholar] [CrossRef]

- Cho, C.G.; Kim, Y.Y.; Feo, L.; Hui, D. Cyclic Responses of Reinforced Concrete Composite Columns Strengthened in the Plastic Hinge Region by HPFRC Mortar. Compos. Struct. 2012, 94, 2246–2253. [Google Scholar] [CrossRef]

- Kanda, T.; Li, V.C. Interface Property and Apparent Strength of a High Strength Hydrophilic Fiber in Cement Matrix. ASCE J. Mater. Civ. Eng. 1998, 10, 5–13. [Google Scholar] [CrossRef] [Green Version]

- Lee, B.Y.; Cho, C.G.; Lim, H.J.; Song, J.K.; Yang, K.H.; Li, V. Strain Hardening Fiber Reinforced Alkali-Activated Mortar—A Feasibility Study. Constr. Build. Mater. 2012, 37, 15–20. [Google Scholar] [CrossRef]

- Li, V.C.; Hashida, T. Engineering ductile fracture in brittle matrix composites. J. Mater. Sci. Lett. 1993, 12, 898–901. [Google Scholar] [CrossRef] [Green Version]

- Lin, Z.; Li, V.C. Crack Bridging in Fiber Reinforced Cementitious Composites with Slip-hardening Interfaces. J. Mech. Phys. Solids 1997, 45, 763–787. [Google Scholar] [CrossRef]

| Density (g/mm3) | Length (mm) | Diameter (μm) | Young Modulus (GPa) | Surface treatment | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| 1.3 | 12 | 39 | 40 | Oiling agent | 1600 |

| W/B wt % | S/C wt % | FA/B wt % | Slag/B wt % | Unit, kg/m3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W | B | OPC | FA | BFS | Silica Sand | PCSP | HPMC | Defoamer | PVA Vol % | ||||

| 45 | 71 | 20 | 20 | 375 | 883 | 500 | 167 | 167 | 692 | 0.37 | 0.18 | 0.45 | 2.0 |

| SHCC Specimens | Stress at Initial Cracking (MPa) | Max. Tensile Stress (MPa) | Ultimate Tensile Strain (%) |

|---|---|---|---|

| 1 | 3.6 | 4.1 | 3.2 |

| 2 | 2.7 | 3.7 | 3.1 |

| 3 | 3.7 | 4.2 | 4.5 |

| Average | 3.3 | 3.8 | 3.6 |

| Specimen Name | PVA Volume | Main Materials | Horizontal Bars Spacing | Vertical Bars Spacing |

|---|---|---|---|---|

| RCW-N | - | Concrete | 150 mm (0.00597) | 150 mm (0.00583) |

| SHW-N1 | 2.0% | SHCC | 150 mm (0.00597) | 150 mm (0.00583) |

| SHW-N2 | ||||

| RCW-M | - | Concrete | 380 mm (0.0020) | 400 mm (0.0012) |

| SHW-M1 | 2.0% | SHCC | 380 mm (0.0020) | 400 mm (0.0012) |

| SHW-M2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-K.; Cho, C.-G.; Lee, S.-J.; Lee, Y.H.; Kim, T. Structural Performance and Reinforcement Improvement of Structural Walls Using Strain-Hardening Cementitious Composites. Sustainability 2021, 13, 3607. https://doi.org/10.3390/su13073607

Kim H-K, Cho C-G, Lee S-J, Lee YH, Kim T. Structural Performance and Reinforcement Improvement of Structural Walls Using Strain-Hardening Cementitious Composites. Sustainability. 2021; 13(7):3607. https://doi.org/10.3390/su13073607

Chicago/Turabian StyleKim, Hyeong-Ki, Chang-Geun Cho, Sun-Ju Lee, Young Hak Lee, and Taehoon Kim. 2021. "Structural Performance and Reinforcement Improvement of Structural Walls Using Strain-Hardening Cementitious Composites" Sustainability 13, no. 7: 3607. https://doi.org/10.3390/su13073607

APA StyleKim, H.-K., Cho, C.-G., Lee, S.-J., Lee, Y. H., & Kim, T. (2021). Structural Performance and Reinforcement Improvement of Structural Walls Using Strain-Hardening Cementitious Composites. Sustainability, 13(7), 3607. https://doi.org/10.3390/su13073607