Development of an Ignition System and Assessment of Engine Performance and Exhaust Characteristics of a Marine Gas Engine

Abstract

:1. Introduction

2. Gas Engine Development

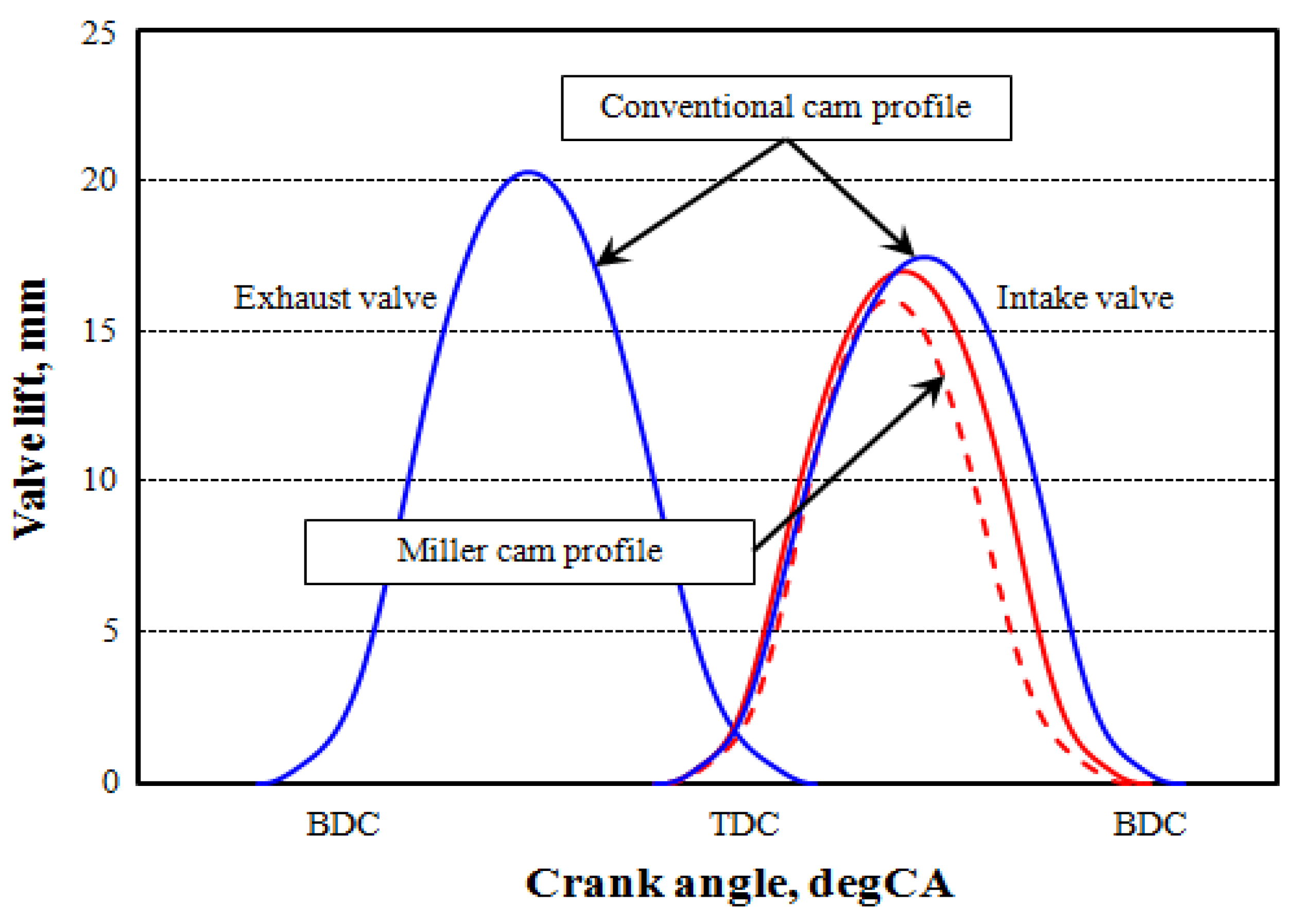

2.1. Concept of the Target Gas Engine

2.2. Components of the Main Gas Engine

2.2.1. Cylinder Heads and Precombustion Chamber

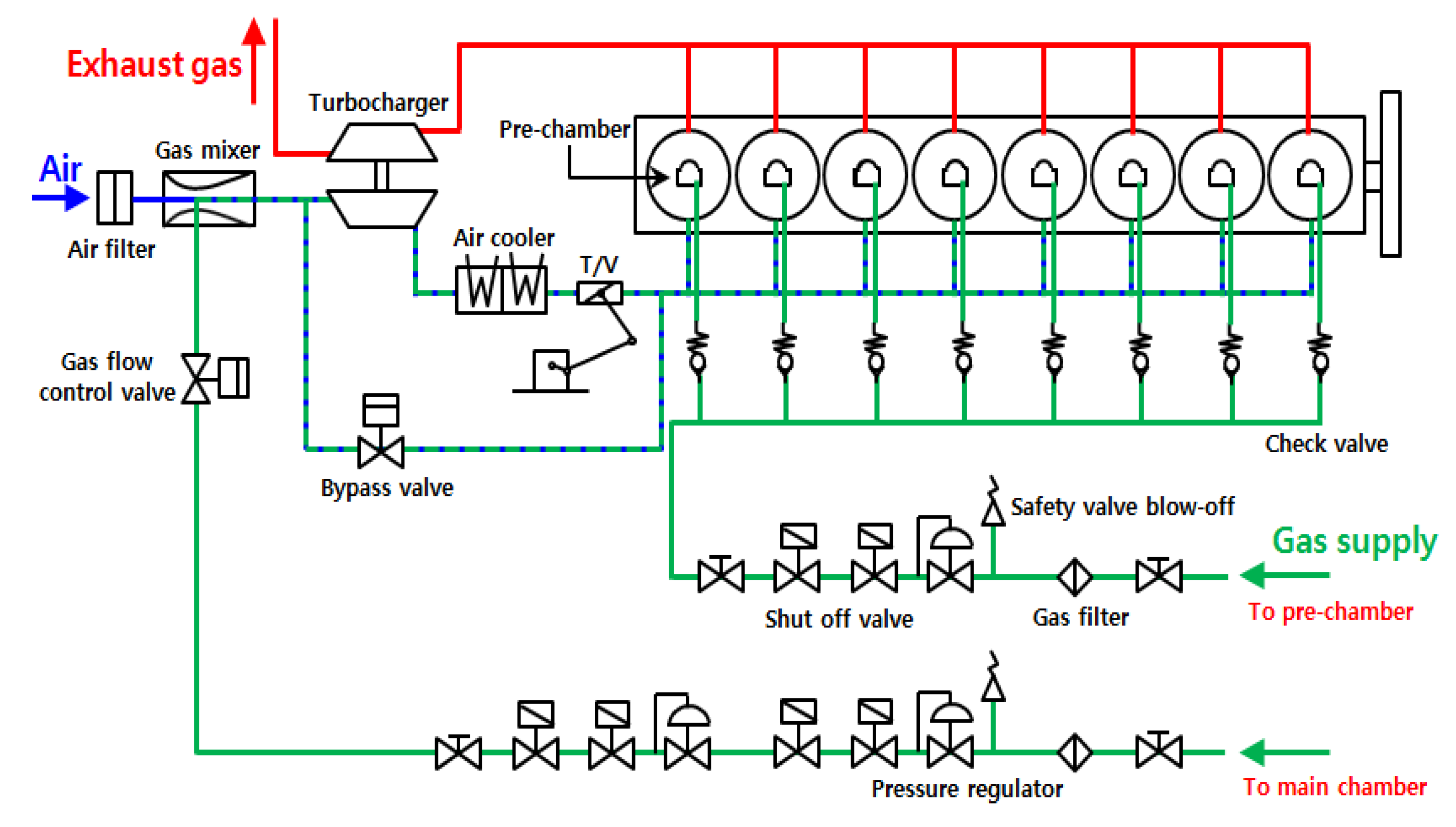

2.2.2. Fuel Supply

2.2.3. Ignition System

2.2.4. Engine Control System

2.3. Gas Fuel Characteristics

3. Results and Discussion

3.1. Combustion Performance Evaluation

3.2. Performance Evaluation

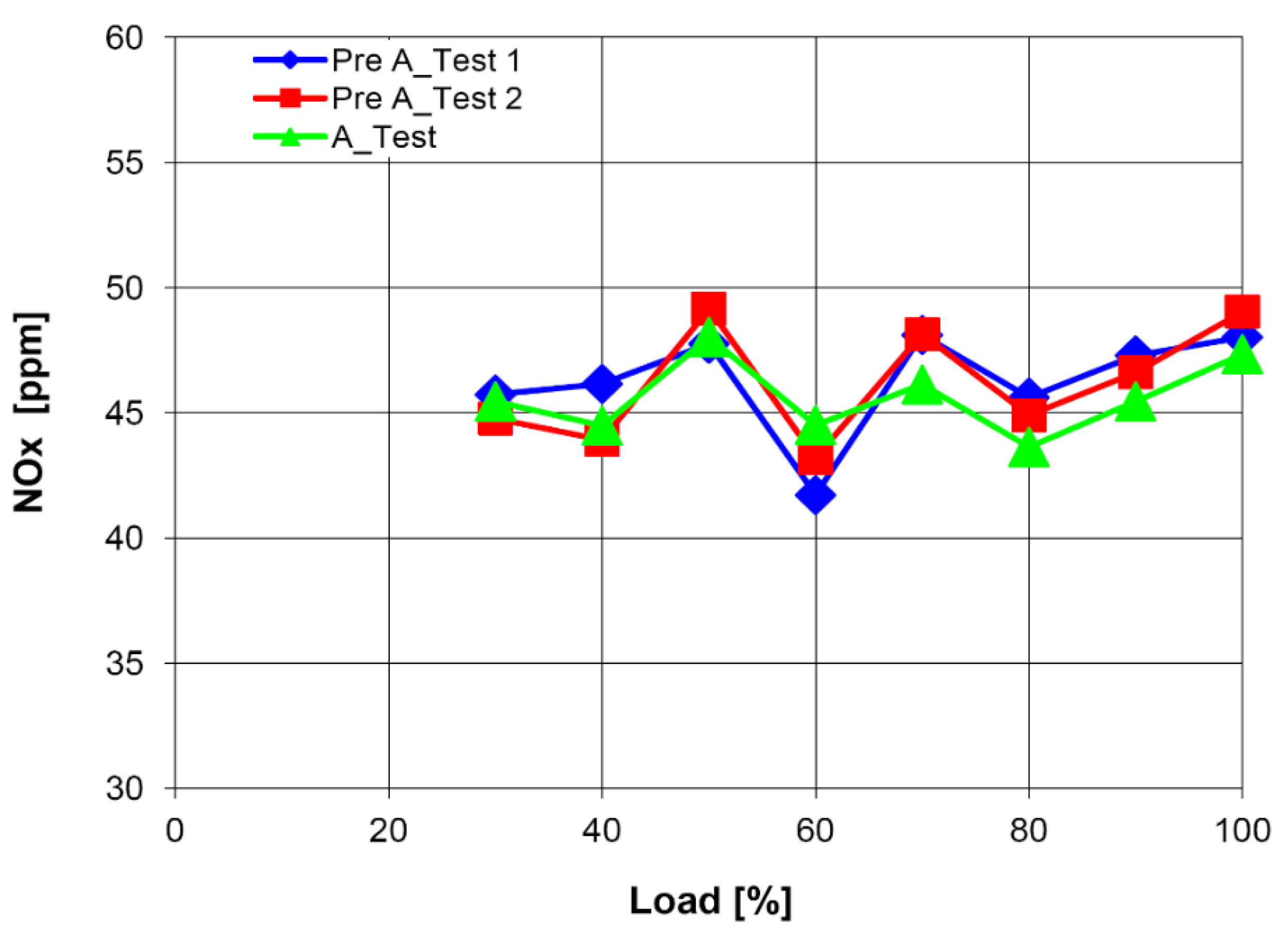

3.2.1. NOx Emission Characteristics

3.2.2. Thermal Efficiency Characteristics

3.2.3. Mean Effective Pressure

4. Conclusions

- A 1.6 MW dedicated gas engine was developed based on a diesel engine with bore 220, stroke 300. The developed gas engine had a precombustion chamber and exhibited excellent performance—2.1 MPa brake mean effective pressure at 1000 rpm and 50 ppm NOx emissions under 15% O2. In particular, it demonstrated excellent fuel economy with a thermal efficiency of 45%; its carbon dioxide emissions were ~75% of those of diesel engines, enabling greenhouse gas reduction. These results indicated that suitably developed gas engines can provide a low-cost and energy-efficient alternative to diesel engines.

- The maximum pressure in the combustion chamber was ~16.9 MPa, which satisfied the designed pressure limits of the piston; the maximum pressure deviation between the cylinders was ~0.2–0.4 MPa, which was acceptable in accordance with engine stability.

- Ultra-lean combustion with an excess air ratio of 2.0 or higher was implemented to achieve the target thermal efficiency.

- The dedicated gas engine development goals of NOx emissions, thermal efficiency, and brake mean effective pressure were effectively achieved, and the values are as follows:

- NOx emissions: 50 ppm or less at 15% O2.

- Thermal efficiency: 45.04% at 50 ppm NOx.

- Brake mean effective pressure: 2.1 MPa.

- Specifically, NOx and CO2 emissions were significantly reduced compared to diesel engines:

- NOx emissions: 0.85 g/kWh (~9.4% of IMO Tier II emissions).

- CO2 emissions: 460 g/kWh (~75% of diesel engine emissions).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Okamoto, K. Development of a 350 kW High-Efficiency (over 43%) Lean Burn Gas Engine for Co-Generation Systems. In Proceedings of the 24th CIMAC Congress, Kyoto, Japan, 7–11 June 2004. [Google Scholar]

- Tanaka, K. Development of Lean Burn Miller Cycle Gas Engine. In Proceedings of the 24th CIMAC Congress, Kyoto, Japan, 7–11 June 2004. [Google Scholar]

- Kalam, M.A.; Masjuki, H.H.; Maleque, M.A.; Amalina, M.A.; Abdesselam, H.; Mahlia, T.M.I.; Aslam, M.U.; Varman, M. Power improvement of a modified natural gas engine. In Proceedings of the 1st Conference & Exhibition on Natural Gas for Vehicles (ANGVA 2005), Kuala Lumpur, Malaysia, 26–28 July 2005. [Google Scholar]

- Klimkiewicz, D.; Teodorczyk, A. An experimental study of SI engine combustion system with direct methane injection. In Proceedings of the Third European combustion meeting ECM, Crete, Greece, 11–13 April 2007. [Google Scholar]

- Evans, R.L.; Blaszczyk, J. A compartive study of the performance and exhaust emissions of a spark ignition engine fuelled by natural gas and gasoline. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 1996, 211, 39–47. [Google Scholar] [CrossRef]

- Miller, R.H. Supercharging and internal cooling cycle for high output. Trans. ASME 1947, 69, 453–457. [Google Scholar]

- Al-Sarkhi, A.; Jaber, J.; Probert, S. Efficiency of a Miller engine. Appl. Energy 2006, 83, 343–351. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, J. Performance analysis of an irreversible Miller heat engine and its optimum criteria. Appl. Therm. Eng. 2007, 27, 2051–2058. [Google Scholar] [CrossRef]

- Endo, H.; Tanaka, K.; Kakuhama, Y.; Goda, Y.; Fujiwaka, T.; Nishigaki, M. Development of the lean burn Miller cycle gas engine. In Proceedings of the 5th International Symposium on Diagnostics and Modeling of Combustion in Internal Combustion Engines (COMODIA 2001), Nagoya, Janpan, 1–4 July 2001. [Google Scholar]

- Gheorghiu, V.; Ueberschar, D. Enhancement potential of the thermal conversion efficiency of ICE cycles especially for use in hybrid vehicles. In Proceedings of the 5th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics (HEFEAT2007), Sun City, South Africa, 1–4 July 2007. [Google Scholar]

- Wang, Y.; Ruxton, T. An experimental investigation of NOx emission reduction from automotive engine using the Miller cycle. In Proceedings of the ASME 2004 Fall Technical Conference, Long Beach, CA, USA, 24–27 October 2004. [Google Scholar]

- Wang, Y.; Lin, L.; Roskilly, A.P.; Zeng, S.; Huang, J.; He, Y.; Huang, X.; Huang, H.; Wei, H.; Li, S.; et al. An analytic study of applying Miller cycle to reduce NOx emission from petrol engine. Appl. Therm. Eng. 2007, 27, 1779–1789. [Google Scholar] [CrossRef] [Green Version]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Inc.: New York, NY, USA, 1988. [Google Scholar]

- Branyon, D.; Simpson, D. Miller Cycle Application to the Scuderi Split Cycle Engine (by Downsizing the Compressor Cylinder); SAE Technical Paper 2012-01-0419; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Wu, C.; Puzinauskas, P.V.; Tsai, J.S. Performance analysis and optimization of a supercharged Miller cycle Otto engine. Appl. Therm. Eng. 2003, 23, 511–521. [Google Scholar] [CrossRef]

- Hatamura, K.; Hayakawa, M.; Goto, T.; Hitomi, M. A study of the improvement effect of Miller-cycle on mean effective pressure limit for high-pressure supercharged gasoline engines. JSAE Rev. 1997, 18, 101–106. [Google Scholar] [CrossRef]

- Martins, J.J.G.; Uzuneanu, K.; Ribeiro, B.S.; Jasasky, O. Thermodynamic Analysis of an Over-Expanded Engine. SAE Trans. 2004, 113, 476–490. [Google Scholar]

- Al-Sarkhi, A.; Akash, B.A.; Jaber, J.O.; Mohsen, M.S.; Abu-Nada, E. Efficiency of Miller engine at maximum power density. Int. Commun. Heat Mass Transf. 2002, 29, 1159–1167. [Google Scholar] [CrossRef]

- Ebrahimi, R. Thermodynamic modeling of performance of a Miller cycle with engine speed and variable specific heat ratio of working fluid. Comput. Math. Appl. 2011, 62, 2169–2176. [Google Scholar] [CrossRef] [Green Version]

- Mikalsen, R.; Wang, Y.; Roskilly, A. A comparison of Miller and Otto cycle natural gas engines for small scale CHP applications. Appl. Energy 2009, 86, 922–927. [Google Scholar] [CrossRef] [Green Version]

- Anderson, M.K.; Assanis, D.N.; Filipi, Z.S. First and second law analyses of a naturalaspirated, Miller cycle, SI engine with late intake valve closure. SAE Trans. 1998, 107, 1355–1370. [Google Scholar]

- Kesgin, U. Efficiency improvement and NOx emission reduction potentials of two-stage turbocharged Miller cycle for stationary natural gas engines. Int. J.Energy Res. 2005, 29, 189–216. [Google Scholar] [CrossRef]

- Chen, L.; Lin, J.; Sun, F.; Wu, C. Efficiency of an Atkinson engine at maximum power density. Energy Convers. Manag. 1998, 39, 337–341. [Google Scholar] [CrossRef]

- Gonca, G.; Hocaoglu, M.F. Performance Analysis and Simulation of a Diesel-Miller Cycle (DiMC) Engine. Arab J Sci Eng 2019, 44, 5811–5824. [Google Scholar] [CrossRef]

- Sahin, B.; Kesgin, U.; Kodal, A.; Vardar, N. Performance optimization of a new combined power cycle based on power density analysis of the dual cycle. Energy Convers. Manag. 2002, 43, 2019–2031. [Google Scholar] [CrossRef]

- Benajes, J.; Molina, S.; Martín, J.; Novella, R. Effect of advancing the closing angle of the intake valves on diffusion-controlled combustion in a HD diesel engine. Appl. Therm. Eng. 2009, 29, 1947–1954. [Google Scholar] [CrossRef] [Green Version]

- Martins, M.E.S.; Lanzanova, T.D. Full-load Miller cycle with ethanol and EGR: Potential benefits and challenges. Appl. Therm. Eng. 2015, 90, 274–285. [Google Scholar] [CrossRef]

- Lin, J.C.; Hou, S.S. Performance analysis of an air-standard Miller cycle with considerations of heat loss as a percentage of fuel’s energy, friction and variable specific heats of working fluid. Int. J.Therm. Sci. 2008, 47, 182–191. [Google Scholar] [CrossRef]

- Ge, Y.; Chen, L.; Sun, F.; Wu, C. Effects of heat transfer and variable specific heats of working fluid on performance of a Miller cycle. Int. J. Ambient. Energy 2005, 26, 203–214. [Google Scholar] [CrossRef]

- Gonca, G.; Sahin, B.; Ust, Y. Performance maps for an air-standard irreversible DualeMiller cycle (DMC) with late inlet valve closing (LIVC) version. Energy 2013, 54, 285–290. [Google Scholar] [CrossRef]

- Gonca, G.; Sahin, B.; Parlak, A.; Ust, Y.; Ayhan, V.; Cesur, I.; Boru, B. The effects of steam injection on the performance and emission parameters of a Miller cycle diesel engine. Energy 2014, 78, 266–275. [Google Scholar] [CrossRef]

- Rinaldini, C.A.; Mattarelli, E.; Golovitchev, V.I. Potential of the Miller cycle on a HSDI diesel automotive engine. Appl. Energy 2013, 112, 102–119. [Google Scholar] [CrossRef]

- Dexter, S.G.; Ennemoser, C. Fire Not Misfire in Pre-Chamber Gas Engines. In Proceedings of the 21st CIMAC Congress, Interlaken, Switzerland, 15–18 May 1995. [Google Scholar]

- Herdin, G.R.; Gruber, F.; Henkel, W.; Fahringer, A. The New High Efficiency 1.5 MW Engine of Jenbacher AG, High Efficiency Concept–HEC. In Proceedings of the 23rd CIMAC Congress, Hamburg, Germany, 7–10 May 2001; pp. 966–975. [Google Scholar]

- Takemoto, T. Development of High Efficiency Gas Engine Improvement of Knocking Limit by Optimized Engine System. In Proceedings of the 24th CIMAC Congress, Kyoto, Japan, 7–11 June 2004. [Google Scholar]

- Herdin, G.R.; Gruber, F. Miller Cycle-Efficiency Potentials for Gas Engines. In Proceedings of the 24th CIMAC congress, Kyoto, Japan, 7–11 June 2004. [Google Scholar]

- Kondo, M. Development of the 1000 kW-Class Gas Engine (MD20G). In Proceedings of the 25th CIMAC Congress, Vienna, Austria, 21–24 May 2007. [Google Scholar]

- Edwards, K.D.; Wagner, R.M.; Daw, C.S. Adaptive Control for Extending the Effective Lean Limit in a Spark-Ignition Engine Model. In Proceedings of the 24th CIMAC Congress, Kyoto, Japan, 7–11 June 2004. [Google Scholar]

- Murakami, S.; Baufeld, T. Current Status and Future Strategies of Gas Engine Development. In Proceedings of the CIMAC 2013, Shanghai, China, 13–17 May 2013. [Google Scholar]

| Phase | Target |

|---|---|

| Power | 1.6 MW |

| Brake mean effective pressure | 2.1 MPa |

| Thermal efficiency | 45% (acc. to ISO 3046-1) |

| NOx | ≤50 ppm at 15% O2 |

| Ambient temperature | 25 °C |

| Ambient pressure | 0.1 MPa |

| Intake depression | 5.0 kPa |

| Charged air temperature | 40 °C |

| Exhaust back pressure | 4.0 kPa |

| Phase | Specification |

|---|---|

| Bore/stroke | 200/300 |

| Arrangement of cylinder | 8 in-line |

| Engine speed | 1000 rpm |

| Compression ratio | 12.0 |

| Fuel | Natural gas |

| Fuel admission | Central gas mixer |

| Engine speed control | Throttle valve |

| Ignition | Spark plug with PC |

| Phase | Unit | Quality |

|---|---|---|

| CH4 composition | % | >90 |

| Lower heating value | MJ/Nm3 | 39.33 |

| Density | kg/m3 | 0.7976 |

| Stoichiometric ratio | - | 16.87 |

| Molecular weight | kg/kmol | 17.77 |

| Methane number | - | 73 |

| Gas supply pressure, (g) | MPa | >0.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noh, K.; Lee, C. Development of an Ignition System and Assessment of Engine Performance and Exhaust Characteristics of a Marine Gas Engine. Sustainability 2021, 13, 4097. https://doi.org/10.3390/su13084097

Noh K, Lee C. Development of an Ignition System and Assessment of Engine Performance and Exhaust Characteristics of a Marine Gas Engine. Sustainability. 2021; 13(8):4097. https://doi.org/10.3390/su13084097

Chicago/Turabian StyleNoh, Kichol, and Changhee Lee. 2021. "Development of an Ignition System and Assessment of Engine Performance and Exhaust Characteristics of a Marine Gas Engine" Sustainability 13, no. 8: 4097. https://doi.org/10.3390/su13084097

APA StyleNoh, K., & Lee, C. (2021). Development of an Ignition System and Assessment of Engine Performance and Exhaust Characteristics of a Marine Gas Engine. Sustainability, 13(8), 4097. https://doi.org/10.3390/su13084097