Abstract

A city as a system that constitutes one of the most important areas of human activities. The significant role to fulfill their expectations pay the goods transport and deliveries. These issues are the subject of urban logistics. In broad terms, urban logistics may be construed as a number of processes focused on freight flows, which are completed in cities, including deliveries, supply, goods transfer, services, etc. Due to the different urban logistics stakeholders’ expectations, these systems generate many challenges for managers, especially in the context of city users’ needs and their quality of life. Today, there is a lack of broadened approach and methodology to support them from the processes’ efficiency perspective. To fulfill this gap, the purpose of this paper is to apply the Six Sigma method as a support in last mile delivery management. Six Sigma method plays important role in production systems processes management. However, it could be useful in much wider perspective, including transport and logistics processes. The Authors emphasize that the Six Sigma method could be efficient approach in the last mile delivery processes’ analysis in the context of their efficiency. It helps positioning the customer satisfaction level and quantify the delivery processes defects, related to the undelivered goods. Following that it could improve significantly the last mile delivery processes efficiency. The concept is illustrated by a sample evaluation of one of the urban logistics processes: completion of deliveries. To this end, urban logistics processes were defined. In particular, the delivery completion process was mapped, and the process client was defined along with their expectations. The defects that occurred in the process were identified and analyzed. A DPMO (Defect per Million Opportunities) indicator was established for three randomly selected months. In addition, a root cause analysis of errors was performed. The sigma level for the studied process ranged from 2.61 to 2.89. The factor that had the greatest impact on the number of defects defined as failed deliveries was customer’s absence. The obtained results indicate that the delivery process should be examined in more detail.

1. Introduction

A city as a system constitutes an important area of functioning for people. It provides space for work, living, leisure, and shopping, as well as cultural life. Predominantly, it may facilitate fulfillment of many life needs of its residents, as well as other city users (visitors or entrepreneurs), ensuring appropriate conditions for that [1]. Such life needs in particular include the need for efficient transport and access to a wide range of consumer goods, as well as resources. Due to that, the transport function is one of the major tasks of any city.

Contemporary cities constitute a huge market for distribution companies focused on meeting the needs in the area of deliveries of goods, parcels/consignments, and stocks replenishment, among other things [2]. Most measures taken by the public sector with regard to urban freight transport are aimed at reducing the negative social and environmental effects resulting from transport activities. To that end, decision-makers dealing with the transport policy take up numerous initiatives that concentrate on the physical infrastructure, road traffic, vehicle design, or basic logistic operations. However, the organization of freight traffic is often chaotic and uncoordinated, which is a result of the lack of analyses regarding, e.g., the traffic levels in specific hours [3]. It is the task of urban logistics to address any problems related to deliveries made within city areas. Properly organized deliveries of goods and services, which form the basis of commercial activity, can make urban transport an important element that ensures the city’s economic development. An efficient freight transport system plays a fundamental role in increasing the region’s competitiveness. It also streamlines the functioning of supply chains, where the basic factor of success (achieving a competitive advantage) is meeting the timeliness requirements of the customers. The majority of transport in urbanized areas is generated by industrial, commercial, and service companies [3].

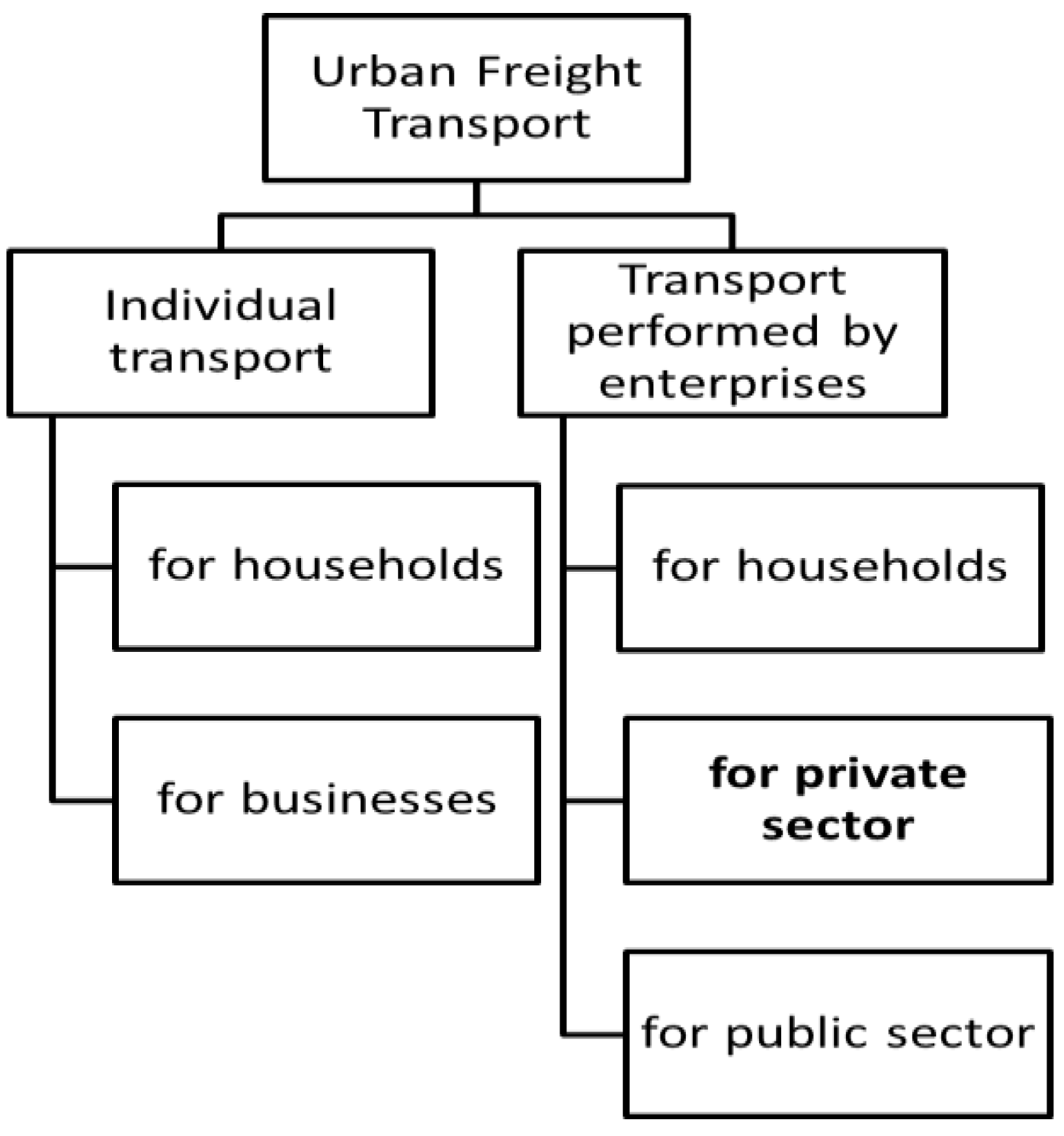

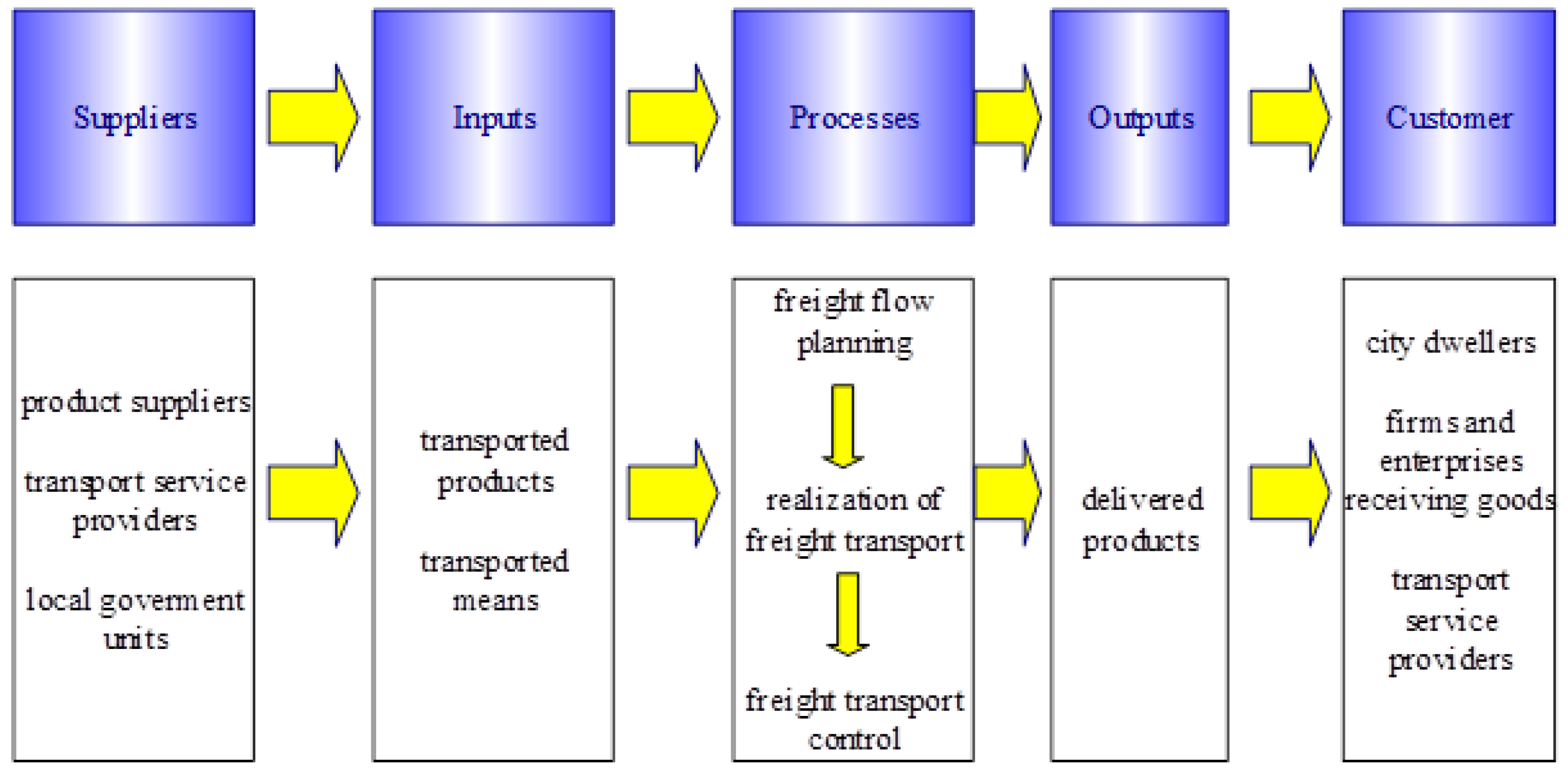

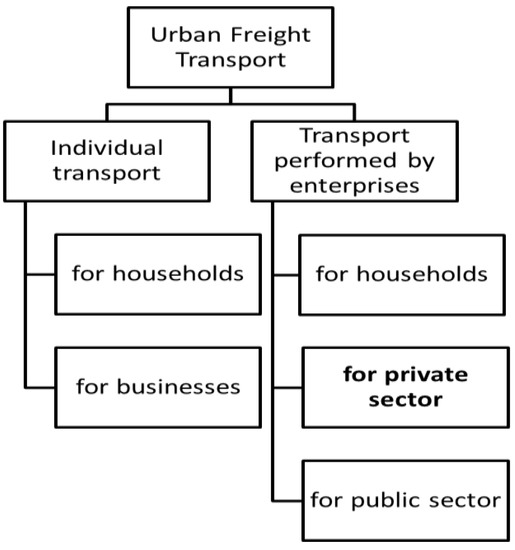

For the purposes of this article, the adopted definition of urban logistics is the one conceived by E. Taniguchi [4], according to which it is the process for totally optimizing the logistics and transport activities by private companies in city areas, considering the traffic environment, the traffic congestion and the energy savings within the framework of a market economy. Urban deliveries play a key role in the functioning of cities, being a decisive factor of their competitiveness, and they have a direct impact on the life quality perceived by city residents and users [5,6]. Following that, urban logistics is focused on urban freight transport (UFT), defined as “the delivery of consumer goods (not only by retail but also by other sectors, such as manufacturing) in city and suburban areas, including the reverse flow of used goods in terms of clean waste” [7]. Nevertheless, urban logistics significantly constitutes the last element of a supply chain which comprises deliveries to the end consumer, referred as last mile deliveries. It should be underlined that last mile deliveries focus on both household deliveries being the outcome of commercial transactions (most often online shopping) and deliveries necessary for day-to-day business of enterprises operating within the city (i.e., deliveries of goods, components, parts, consumables, documents, postal delivery services, etc.) [8,9]. Considering the delivery realization, urban freight transport may be divided into two main categories (Figure 1):

Figure 1.

Classification of urban freight transport (UFT) [8].

- individual transport, including transport:

- ○

- to meet the needs of households (which usually pertains to deliveries of products purchased by individual consumers and made to their home addresses);

- ○

- to meet the needs of businesses (predominantly deliveries of supplies to shops, service outlets, catering outlets, etc., made individually by owners of such entities);

- commercial transport (provided by third-party, commercial carriers), including:

- ○

- deliveries of goods to households (i.e., delivering the products purchased by individual customers in online stores);

- ○

- deliveries to meet the needs of the private sector, including any and all deliveries made to business entities (shops, enterprises, service outlets, etc.);

- ○

- deliveries to meet the needs of the public sector, including any and all deliveries made to administration entities and other non-commercial entities (schools, colleges, hospitals, etc.).

Despite many problems generated by freight transport within the cities (like congestion, pollution, noise, etc.), it cannot be eliminated. Due to that, it must be managed in a systemic manner, while bearing in mind that any activities taken within cities should be performed in compliance with the principles of sustainability [10,11]. The tasks faced by urban logistics stakeholders include, first and foremost, improvement of life quality for the city community in economic, social, and ecological terms [1]. The research studies completed over the past several years have confirmed that sustainable UFT should, therefore, be defined as a system that meets the following objectives [12]:

- guarantees transport accessibility for UFT;

- reduces pollutant emissions and noise to the level that does not have an adverse effect on human health and the natural environment;

- seeks energy efficiency and cost efficiency of urban freight transport, taking into account the external costs;

- participates in improving the attractiveness and quality of living in a city by reducing the number of accidents.

The objectives mentioned above are one of the most important challenges for urban logistics stakeholders, especially considering the increasing number of home deliveries, realized under e-commerce.

It should be mentioned that different expectations of e-commerce stakeholders generates many problems for urban logistics managers, especially in the context of city users’ needs and their quality of life. The clients expect that the parcels will be delivered directly to their household fast and on preferred delivery times; on the other hand, it is hard for freight carriers to establish the delivery schedules to fully fulfill that [13,14]. It resulting with significant number of failed deliveries. Next, it influences on lower efficiency of delivery processes. Today, there is a lack of broaden approach and methodology to support urban logistics managers in this context. To fulfill this gap, the purpose of this paper is to apply the Six Sigma method as a support in last mile delivery management.

Six Sigma is considered to be one of the latest quality management concepts. It was developed by Bob Galvin and Bill Smith, who, in the 1980s, implemented it in Motorola [15]. Management based on the Six Sigma principles was first applied in production operations [16], but, now, it is successfully used in other areas, such as: hotel industry [17], services [18], and finance [19], as well as logistics. The in-depth analysis of the studies of Tjahjano [20] or De Carvalho [21] provides for a possibility of applying the Six Sigma method in logistics processes. The examples of logistic processes management on the basis of Six Sigma are related particularly to production logistics [22] or supply chain management [23,24]. Additionally, Cheng described the use of Six Sigma in process assessment by the Chinese postal service provider China Express [25]. In addition, the use of Six Sigma in process improvement is declared by, among others, DHL or FedEx [26]. Moreover, taking to the account the city environment and sustainability, in 2000, the city of Fort Wayne was the first that successfully implemented the Six Sigma concept in city management [27]. In addition,, Shokri [28] pointed out the implementation of Six Sigma in green production. It should be mentioned that utilization of Six Sigma method brings significant financial benefits to the organization. Interesting results related to the usefulness of Six Sigma in service delivery were introduced in [29,30]. Nevertheless, the examples mentioned above are not directly related to the urban logistics, especially considering the last mile deliveries specificity. Since it is possible to manage a city according to Six Sigma, as well as logistics processes, there are reasons to verify the possibility of managing urban logistics processes based on Six Sigma in the context of deliveries to the final client on the last mile of delivery process.

The Authors express their conviction that the Six Sigma method could be efficient approach in the last mile delivery processes’ analysis in the context of their efficiency. It helps positioning the customer satisfaction level and quantify the delivery processes defects, related to the failed deliveries. The presented case study will make it possible to introduce the possibilities of applying some selected tools used in Six Sigma method to evaluate some processes taking place in last mile delivery. Implementation of this method may bring numerous benefits, such as increased customer satisfaction, higher quality of goods, greater reliability and stability of processes, elimination of time wasting, and improved efficiency and enhanced flexibility of the system, as well as reduced operating costs.

The structure of the paper is based on four sections. Firstly, the Authors introduced the methodological assumptions. Next, the general Six Sigma background has been presented. The research section includes the chosen case study related to the last mile delivery in the chosen city: Szczecin, Poland. The last part of the paper is focused on general conclusions and case study analysis results, as well as the future work direction.

2. Research Methodology

The general methodological assumptions for the work introduced in the paper was to analyze the chosen last mile delivery processes in the context of their efficiency. In the process quality context, the major quantifier of the mentioned above processes efficiency is the number of failed deliveries. According to that, this aspect was taken to the account as a reference for the analysis realized in the research.

During the first stage of the work, the urban logistics processes were mapped, and the processes client and its needs were defined. To that end, a SIPOC (Supplier Input Process Output Client) diagram was applied along with BPMN (Business Process Model and Notation) mapping and a CTQ (Critical to Quality) tree. The client’s needs were defined based on the literature review.

Next, the case study method has been applied as a research approach for the work. Case study method helps to identify and analyze the processes in the real environment. This method gives the practical drivers and better analyzed area understanding. Moreover, considering in the analysis the quantitative indicators, it allows general conclusions to be drawn on the basis of only one case [31]. In addition to the research carried out to describe a certain community, so-called holistic case studies [32], the embedded case studies are mentioned, as well [33]. This kind of research could be realized as a single-case designs, especially in a situation where the theory does not exist and the study is pilot and aimed at verifying the initial concept [34]. The case introduced in the paper was chosen on the basis of the data availability. The courier company analyzed under this work cooperated with the Authors in the European Project EUFAL (Electric Urban Freight and Logistics), which was focused on the utilization of electric vehicles for last mile delivery. Due to that, it was possible to collect the data related to the delivery processes in the context of their successes or failures. which resulted in the case study approach being identified as the most interesting and valuable for that research work.

It is important to note that the analyzed company has not implemented the Six Sigma management system. The data used in the process evaluation were obtained from the operating IT (Information Technology) system. The analysis covered three months chosen randomly from year 2018. The purpose of the analysis was to specify the delivery process capability, which eventually meant designation of the Sigma process level. Source data received from the company’s IT system included the delivery date, courier’s identification number and the delivery status (“effective delivery” or “undelivered”). In addition, in the case of undelivered status, the reason for failed delivery was given. As the process defect consisting in failed delivery is a datum described as a feature, the Sigma level should be specified based on the DPMO (Defect per Million Opportunities) ratio. For this purpose, the total number of deliveries was calculated for each of the analyzed months. The number of defects was identified and calculated. The number of possible faults was determined. The DPMO index was calculated, and, on its basis, the process Sigma level was calculated. The Sigma level allowed to determine to what extent the process meets the customer’s requirements. It should be noted that the benefits of Six Sigma are obtained by meeting customer satisfaction. Therefore, the information about the Sigma level is also an indicator of the effectiveness of the process. At the same time, the analysis also considered the reasons for delivery failures. All the diagrams were prepared using Microsoft Visio 2016; Microsoft Excel was used to calculate the DPMO, and the Sigma level was read from the Statistica calculator.

3. Six Sigma as a Processes Management Method

The Six Sigma methodology focuses on process improvement so as to eliminate any defects, losses and any quality issues found on the basis of actual data [35,36]. One of the main assumptions is that quality may cost nothing, in terms of comparing quality assurance costs and costs resulting from bad quality. Outlays made to cover the former will help avoid losses resulting from the latter. At the same time, it should be emphasized that quality should not be an end in itself. With Six Sigma, any and all activities should focus on increased capability of the process to satisfy the customer needs, as well as to maintain the process stability, which consequently will lead to increased profits. Besides, this regards both the external customer and the internal process. Moreover, the process should be correctly completed the first time around, and any possible mistakes should be identified and eliminated as early as possible. Information on whether or not the process is able to meet the customer’s requirements, or if and where wastage is taking place, is obtained via continuous measurement and control of the process. The idea behind it is that, if something is not measured, its functioning cannot be evaluated. Any observed irregularities in the process should be the starting point for streamlining it.

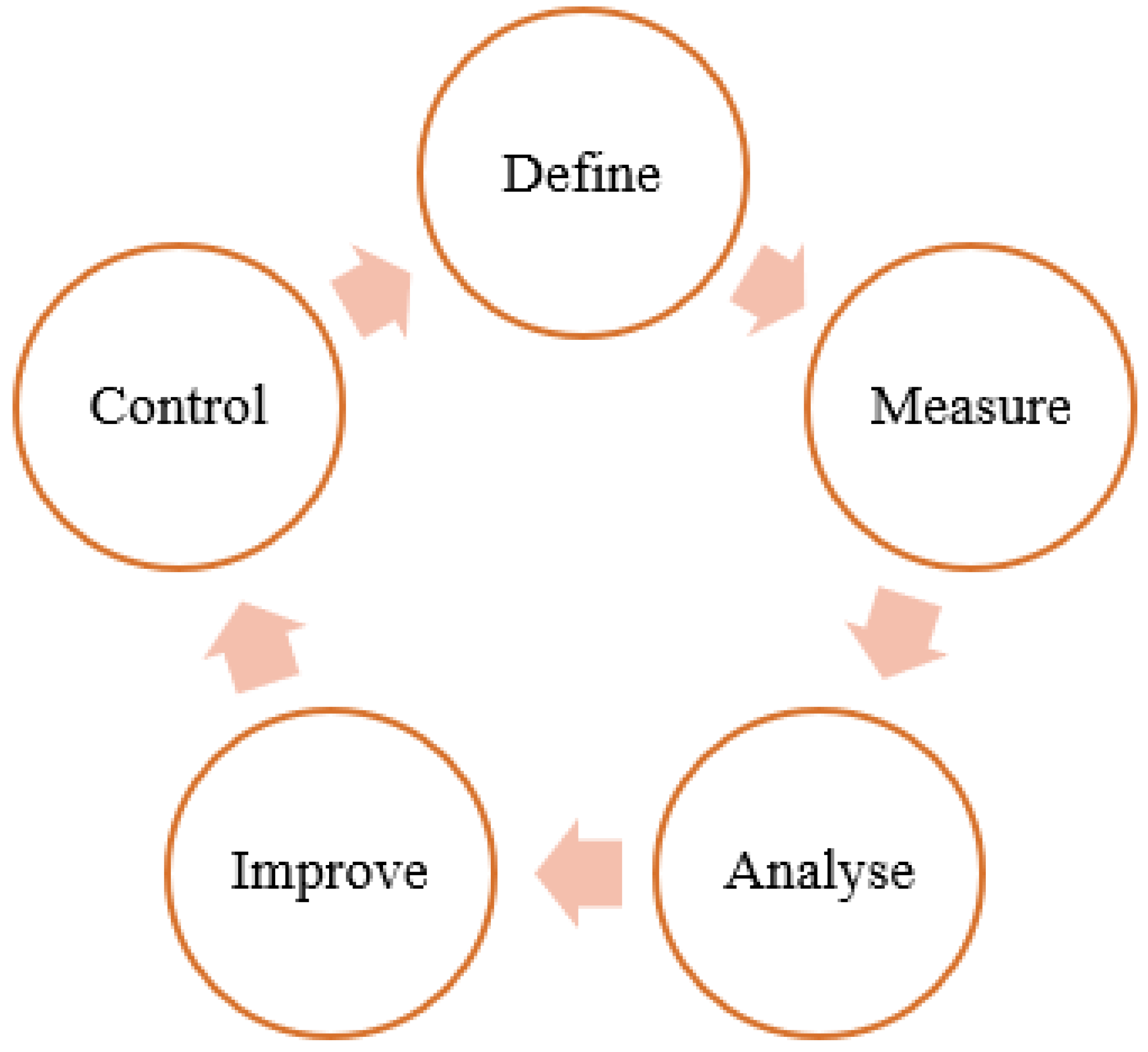

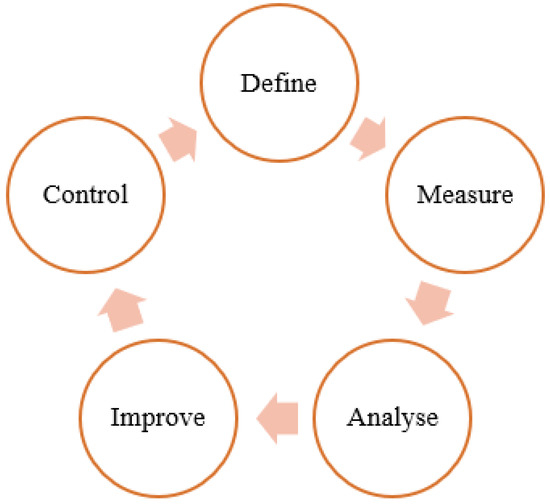

3.1. DMAIC (Define, Measure, Analyze, Improve, Control) Cycles with Six Sigma

It is recommended to manage the processes via projects carried out in accordance with the DMAIC cycle (Figure 2). The cycle name is the acronym of its subsequent phases: Define, Measure, Analyze, Improve, and Control. This approach enables integration of the three key areas in Six Sigma: customer, process, and employees [37].

Figure 2.

DMAIC cycle.

At this point, it should be noted that in accordance with the rules of each management cycle, a signal to commence another cycle (which in Six Sigma means the project commencement) is its last phase. In DMIAC, it is the control phase, during which durability of the effects of the solutions generated and implemented in the previous phases is evaluated. Should there be any deviations from the desired outcomes, the problem definition phase is recommenced, and the cycle is restarted. At each stage of the DMAIC cycle, the project team have at their disposal a number of tools (Table 1).

Table 1.

Sample tools in DMAIC (Define, Measure, Analyse Analyze, Improve, Control).

In view of the purpose and scope of this article, it addresses only some of the DMAIC cycle phases, and it discusses some selected tools applied there. In the “Define” phase, the problem and project objectives are specified [38]. Projects are most often focused on cost reduction, improving the customer satisfaction, increasing the efficiency or waste elimination. At this stage, customers and their needs are also specified. The particularly helpful tools and techniques include VoC (Voice of Client) or CTQ (Critical to Quality) tree applied in the further analysis of the case study. At this point, the process map is developed, which is to help to obtain a precise specification of the customer needs to make sure that what the customer gets is what the customer needs. It is important that the course of the process, as well as its inputs and outputs, be defined. At the same time, the map should present the current state rather than a representation of the process. In many cases, any errors in the process may be noticed already at the stage of developing such a map. However, no corrections to the process are allowed before finishing the DMAIC cycle. A too fast attempt to implement solutions to improve the process without a prior in-depth analysis of the process is one of the more frequent causes of Six Sigma project failures.

3.2. Measure of Process

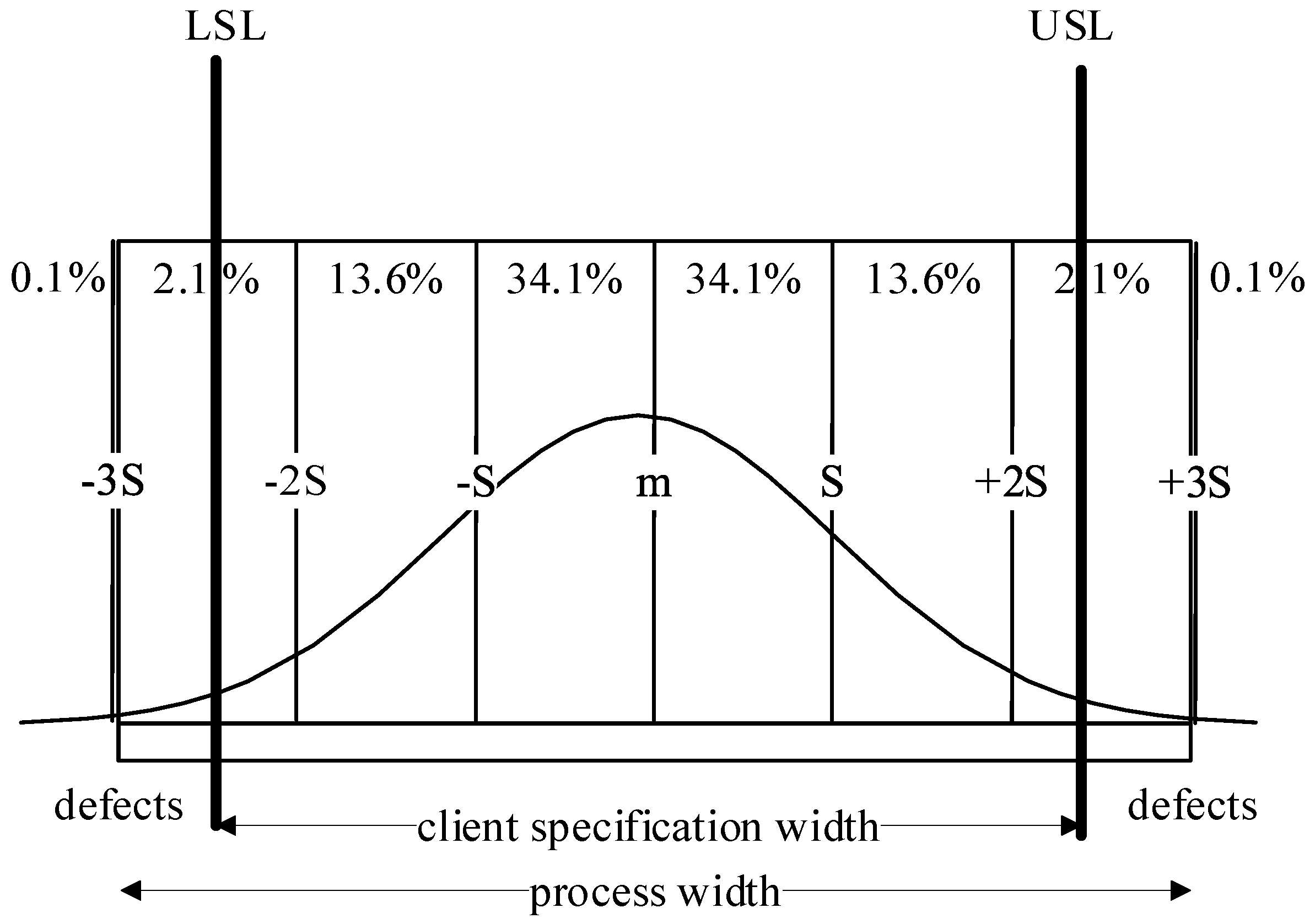

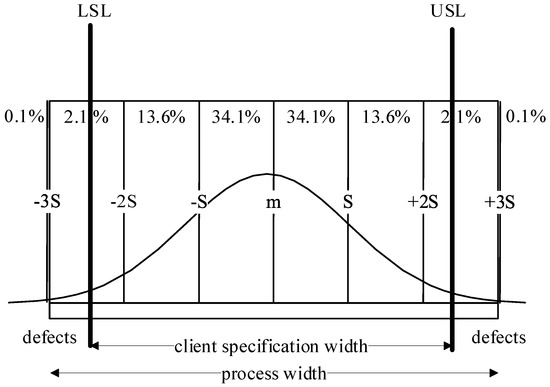

Having recognized the problem, the customer and the process, it is time to move on to the next step in the DMAIC cycle, i.e., “Measure”, where the process output is measured and evaluated. The measures selected for further analysis should be critical for the process and overlap with the customer’s expectations specified in the “Define” phase. Having determined the measures, as well as the values expected by the customer, it is now possible to move on to source the needed data and carry out an in-depth analysis of the process output. In the Six Sigma concept, the basic indicator in evaluating the process output is its capability. The measure of the process capability is referred to as the process sigma (or sigma level). The procedure for determining and evaluating the process capability differs depending on the characteristics of the evaluated data. In the case of continuous data, such as delivery time or consumed fuel, it is advisable to analyze the frequency graph. Assuming that the process is characterized by normal distribution, over 90% measurements of the given measure will show values falling within the range of plus/minus three standard deviations from the mean (Figure 3).

Figure 3.

Six Sigma chart.

The process capability may be evaluated by putting the lower and upper customer specification limits (marked as LSL and USL in Figure 3) on the normal distribution curve. All the values of the measured process output, which fall between LSL and USL, are considered to be acceptable for the customer. Any values of the process output measure, which fall outside the range of the customer specifications, are considered to be defects. In the context of the process capability, a correct process is the one where half of the graph falls within the range from the mean to the nearer limit of the customer specification. Moreover, the mean of the graph is the same as the mean of the customer specification. Such a process is referred to as a 3-sigma level process, whereas 6 sigma means a situation where a half of the graph can fit twice within the band from the mean to the nearer customer specification limit. Such a graph demonstrates a smaller dispersion, and dispersion is more perceptible to customers. Making a process graph narrower is considered to be much more difficult than shifting its mean. Visual analysis of graphs is very useful and often applied, as it makes it possible to evaluate the process quite quickly in terms of its purposefulness and coherence. Nevertheless, a process graph analysis should be supported by computation of potential process capability (Cp, Equation (1)) and actual process capability index (Cpk, Equation (2)) [39].

where:

USL—Upper Specification Limit,

LSL—Lower Specification Limit,

σ—standard deviation,

µ—mean value.

The process capability analysis assumes that its distribution is more or less normal [40]. In the literature on the subject, any process with a value of Cp < 1 is considered a low capability process. The chart width is greater than the client’s specification width. The processes with the Cp ratio falling between 1 and 1.33 are considered to be of medium capability, whereas Cp > 1.33 means a high process capability [41]. The Cpk ratio value informs where the process mean is located in relation to the specification’s limits. Interpretation of the Cpk ratio is shown in Table 2 [42].

Table 2.

Cpk interpretation.

However, a full picture of the process can be obtained via combined interpretation of Cp and Cpk ratios. Comparing the values of Cp and Cpk, it is possible to draw conclusions on overlapping the chart mean with the specification mean [43]. Table 3 shows how the ratio should be interpreted.

Table 3.

Relationship between Cp and Cpk.

The process sigma level can be found in the process capability table, based on Process Capability Index (Cpk) [44]. A 6-sigma level is achieved by a process described by the equation expressed by Formula (3).

The process is not only coherent, but also the mean of its graph falls in the middle of the customer specifications. At this point, it should be noted that many processes, especially transaction or service processes, do not follow the normal distribution. Aldowaisan proposed a method for evaluating such processes [45].

A different course of action should be taken when the process is evaluated on the basis of discrete data such as, e.g., damaged parcel. In this case, the customer does not care to which extent the parcel was damaged; the only thing that matters is that it has been damaged. This is a zero-one option. In this case, a DPMO (Defects Per Million Opportunities) indicator should be determined (Equation (4)) [46] and used as the basis for identifying the sigma level in the process capability table [44].

where:

D—number of defects,

U—number of units,

OPU—number of defects opportunities per unit.

An ideal process is the one which generates maximum 3.4 DPMO [47]. The sigma level for this process is 6 in the short term and 4.5 in the long run [48].

Having completed the detailed examination of the process output, it is possible to move to another phase of the DMAIC cycle, i.e., “Analyze”. The final result of this step is determining the root cause of the problem specified in the “Define” phase. The search starts with finding potential causes, even those least probable. The useful methods to help create an extensive list of possible causes could be brainstorm, Ishikawa diagram, or 5Why. Next, the list is shortened to a few causes which are subject to a further quantitative analysis. Correlations between the result and any individual cause are identified. Ultimately, there should be one cause left, which then should be eliminated via proposing an improvement solution in the next step of the DMAIC cycle. The “Improve” phase ends with implementing the solution that eliminates the root cause and consequently the problem. We could say that this is where the Six Sigma project comes to an end. The last phase of the DMAIC cycle—“Control”—is a systematic measurement of the process and verification whether or not the proposed solution has brought a durable effect. At this stage, actions are simultaneously taken so as to maintain the improved process at the right level.

Further on, this article presents a concept of applying the Six Sigma methodology in urban logistics processes management. The issue of the process evaluation will be discussed in detail on the basis of a case study of a courier company.

4. The Case Study Analysis Results

4.1. Define Processes of City Logistics

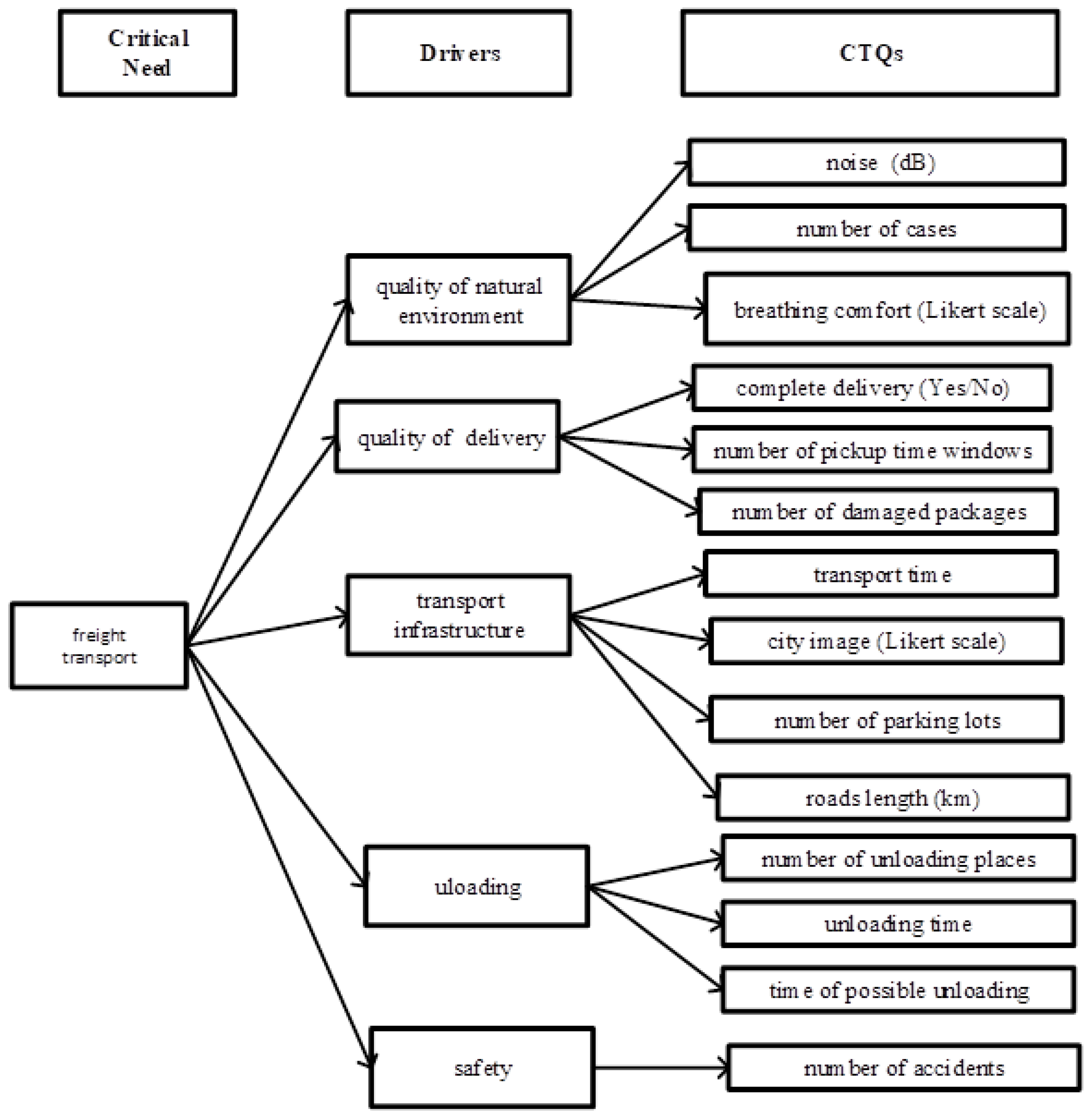

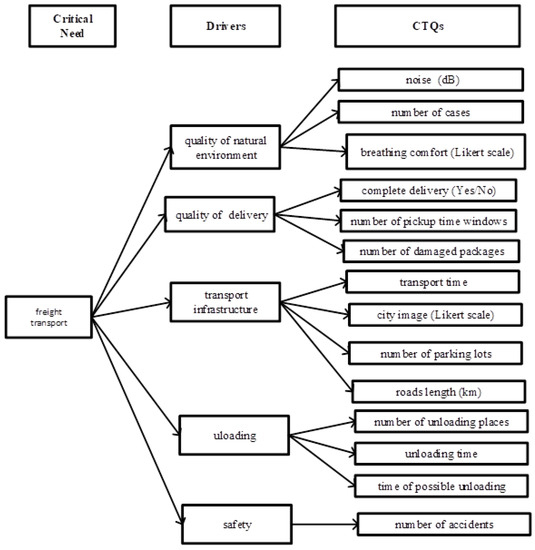

Based on the above considerations, it is possible to notice that any process evaluation in the first place requires identification of customers’ expectations. Customers of urban logistics processes are both city residents and enterprises operating within a city. Both enterprises and residents expect that urban logistics provide sustainable transport. This factor is considered critical, and the whole CTQ tree for the customer is presented in Figure 4.

Figure 4.

CTQ (Critical to Quality) of city logistics process.

In this context, properly completed deliveries are no less important than the quality of the natural environment or safety. Moreover, transport services providers have expectations regarding the transport infrastructure, particularly with respect to unloading operations. Many indicators proposed for evaluation of sustainable transport in urban logistics are connected with life quality of city residents. According to Dąbrowska [49], life quality is assessed in the context of factors, such as subjective well-being, material living conditions, main kind of activity, work, health, education, leisure time and social relations, economic and physical security, the state and state laws, as well as civic participation, and quality of natural environment at the place of residence.

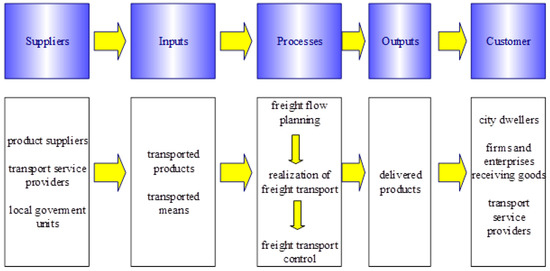

Having identified the urban logistics client, it is now possible to move to defining the process. In the earlier deliberations on urban logistics, it was found that it is a process of optimizing (or improving) logistic and transport operations completed within a city. It should be noted that the said operations are also processes. Thus, urban logistics processes should be construed not as a set of actions to be taken in order to improve logistic or transport processes, but as logistic or transport processes themselves, which are carried out within cities. What is more, the processes are completed by various entities. Nevertheless, it is possible to identify a set of activities, which is coherent for all performers of urban logistics processes. To map the processes of urban logistics, the SIPOC (Suppliers, Inputs, Process, Outputs, Customer) diagram was applied (Figure 5).

Figure 5.

SIPOC (Suppliers, Inputs, Process, Outputs, Customer) diagram: processes of city logistics.

It should be noted that the SIPOC diagram is designed in the reverse order, which meant that the first step was to define the client. In further steps of the diagram development, it was necessary to define the process output and the activities that enable generating the output. The activities shown in the diagram are compliant with the ones listed by CLM (Council of Logistics Management) [50]. At the next stage, the outputs necessary for completing the process and finally suppliers of the outputs were specified. Transport companies are assigned the roles of both suppliers and process clients, which is related to the broad sense of flow planning. This is not limited merely to specifying the route for the transported cargo. Flow planning also includes any activities that secure transport of goods, such as, e.g., development of infrastructure. In the SIPOC diagram, suppliers of this activity may also be self-government units.

4.2. Assessment of the Delivery Process

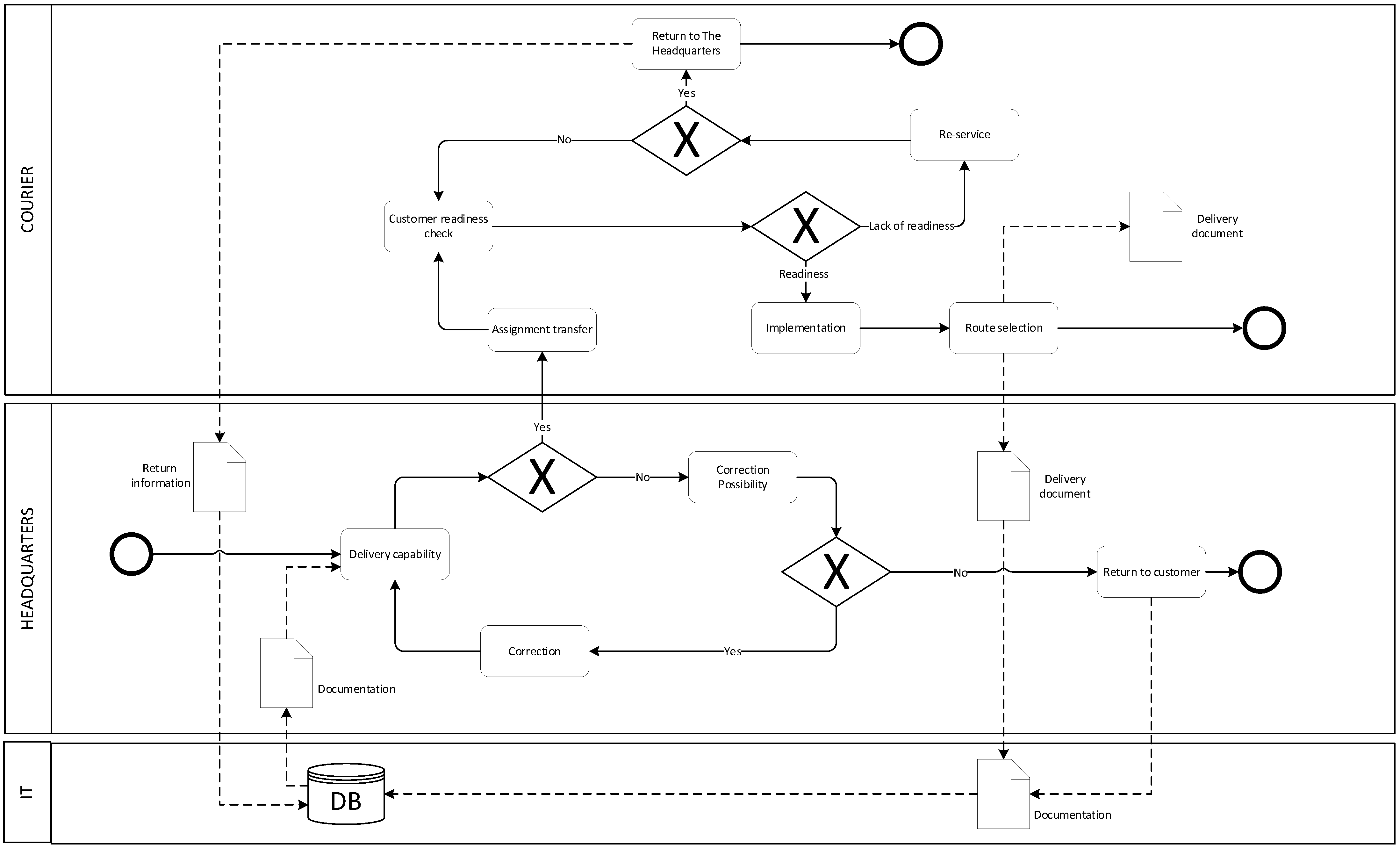

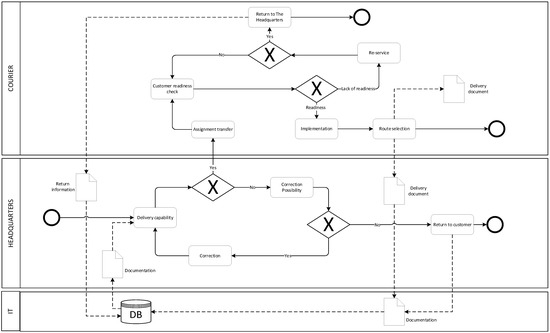

It is important to notice that a SIPOC diagram defines the so-called major processes. This means that subprocesses may also be defined for each of them. The delivery completion process was subject to further analyses. Figure 6 presents a map of the delivery making process for the case study in question.

Figure 6.

Delivery process.

In process monitoring, it is important to choose the data to be observed. It is assumed that 2–3 measures at the input and output of the process, and 1 key measure of the process itself, should be regularly monitored. In this case study, the key measure of the process was assumed to be its effectiveness. Based on the collected data, the analyzed process efficiency has been identified (Table 4).

Table 4.

Performance of delivery process.

In the analyzed company, couriers “checks the customer’s readiness” the moment they collect the parcels to be delivered. Recipients are often notified of the consignment when the delivery vehicle is standing in front of the building. In case the parcel cannot be delivered, the courier notes down the reason for failure to deliver the consignment. In the analyzed months, eight causes of unsuccessful deliveries were identified; moreover, a parcel delivered with incorrect documents was considered a defect (see Table 5).

Table 5.

Performance of delivery process.

The IT system, in which the causes of failed deliveries are entered, enables selection of only one option per parcel. The courier selects the cause of non-delivery marked as “missing or incorrect documents” in a situation where there are non-compliances in the documents other than those related to the address, which should be prepared by the customer of the courier company or the recipient of the shipment. The customer of the courier company is the one who orders the transport service. This includes, among others, the inability to confirm the recipient’s identity (e.g., no ID card), the lack of a GRN (Goods Received Note) prepared by the client (external receipt) or the client’s or recipient’s failure to prepare other documents required for a specific shipment. The courier has the right to release the parcel to the recipient, if the so-called return documents (reason “Parcel delivered-documents incorrect”).

Particular attention should be paid to recipient’s absence. Over 60% of parcels were not delivered due to the customers’ absence. Another reason for failed delivery was a later delivery date. In both cases, it means a need to repeat the journey to the customer. Consequently, the delivery lead times get longer and also environmental pollution is increased as a result of unnecessary combustion of fuel.

In view of the earlier defined CTQ tree for urban logistics processes, the process was measured and evaluated on the basis of the following measures: completeness of deliveries. A delivery is when a courier departs with a consignment to be delivered, whereas a complete delivery means that a consignment was received by the customer without any objections. This is a feature; therefore, the evaluation and determination of the sigma level for the process was based on the DPMO indicator. It should be remembered that for one delivery, the courier may indicate only one reason for its failure. This means that the number of defects is equal to the number of undelivered parcels. Therefore, for the purposes of DPMO computation, it was assumed that it is possible to make one error per consignment (Table 6).

Table 6.

DPMO (Defect per Million Opportunities) and Sigma level of delivery process.

The established process sigma level indicates that the process should be deemed as approximately correct. In particular, in Month 3, the sigma level almost equaled 3. In Six Sigma, particular attention is paid to added value of the process. If activities are repeated, as in the case of redelivery, the process is not assigned any added value. Therefore, for the purposes of delivery making process evaluation, including determination of the DPMO indicator and the process sigma level, correct deliveries are only those which were completed the first time around. It should be noted that there was no possibility of generating transport in relation to any specific consignment. Table 7 shows the value of the process sigma level, based on the assumption that all consignments undelivered due to the recipient’s absence and a later delivery time were delivered the second time round.

Table 7.

DPMO and Sigma level without repeated deliveries.

In order to calculate the actual number of consignments (rather than the number of trips made by a courier with the same parcel), it was necessary to subtract, from the number of units in Table 5, a half of the consignments undelivered due to recipients’ absence and later delivery time. An analogical action should be taken in the case of effective deliveries. As a result of this adjustment, all the indicators deteriorated. It should be underlined that evaluation of the process may also be disturbed by inability to indicate more than one defect for a single consignment. It is possible to imagine a situation where the delivery is not completed the first time round due to the recipient’s absence, and, although it is collected the second time round, there are errors in the documents or when the customer refuses to accept the parcel due to damage, and the additional personal data on the contract does not match the recipient’s data. In these cases, the number of errors equals 2.

5. Discussion and Conclusions

Transport of goods within cities usually takes place in an uncoordinated and chaotic manner [2,51]. This is mainly due to the fact that urban freight transport is carried out by individual entities focused predominantly on fulfilling their own needs, without taking into account other UFT stakeholders; they are also unwilling to share knowledge with each other [52,53]. It results with the significant impact on the city environment, especially in the context of congestion and pollution [12]. The important part of the city freight movements is realized by couriers under the last mile delivery processes. Year-by-year, it becomes more significant issue due to the increase of e-commerce [53,54]. Among other problems related to the last mile delivery, like traffic congestion, unsustainable delivery modes, or limited parking availability [55], the important issue is the number of failed deliveries. It could be called as a major defect of the last mile delivery processes. This issue seems to be the most important challenge for the urban logistics managers. Failure deliveries result in a negative impact on congestion and environmental pollution. Due to that, improvement of the processes aimed at reducing undelivered parcels, in addition to financial benefits for the company, should also bring benefits to the city and its users.

It should be noted that the optimization of urban logistics activities should be applied by various entities, including local authorities or partnerships, as well as by individual enterprises. In addition, it should be emphasized that even though optimization enables to achieve the best measure from among the possible ones under the given restrictive conditions, development of optimizing models is often costly and time-consuming, and, due to the fast-changing external conditions, they quickly become obsolete. Although there is no certainty that a specific improvement will be the best solution, a consistent analysis of the process and implementation of improvement projects in a long run may lead to the same results as in the case of optimization, but at a lower cost.

The example presented in the paper illustrates the effective, structured and process-oriented way to streamline the functioning of urban logistics, so as to achieve the expected outcomes. The presented analysis shows application of Six Sigma in the process of deliveries made by a courier company within a city. The research study was carried out in order to exemplify the possibilities of applying Six Sigma in urban logistics processes management. The focus was on the process evaluation. The case study analysis emphasized the significance of the quality of data sourced for the purposes of the process evaluation. In the introduced case study, the process with a level equal to 3 is considered to be a process that meets the client’s expectations. One could agree that when the sigma level is from 2.6 to 2.8, the company is close to success. However, the management should not feel complacent. Firstly, the result is below the critical level of 3, which means that (assuming the normal distribution for that process) more than 0.2% of deliveries are expected to fail. Secondly, the company should persistently continue to improve its process and strive to obtain the sigma level of 6 for the process. For the purposes of comparison, a Chinese delivery company in 2016 obtained a DPMO ratio of 31,250, which means a sigma level of 3.36 [25]. In order to streamline the process, it would be necessary to analyze it in more depth. It would also be advisable to analyze the process variability. To this end, it is possible to use control charts (p-charts). Moreover, it is necessary to have a closer look at the reasons for failed deliveries. In this context, particular attention should be paid to recipient’s absence. On average, 2193 deliveries a month are not made for that reason. This is more than 6% of all deliveries. It is advisable to find the root cause of recipient’s absence.

When implementing Six Sigma management in the analyzed courier company, it would be necessary to modify the IT system so that it makes it possible to identify the number of deliveries completed correctly the first time around, as well as the number of various defects per consignment. In relation to this courier company, it should be considered whether the chosen research sample is representative. Moreover, including just one company in a case study limits the possibility of generalization of any conclusions to the whole urban logistics process. Examination of similar processes at other courier service providers may indicate a problem other than the absence of the recipient of the delivery. Six Sigma is a comprehensive approach to management. This means that all processes taking place in the organization can be managed in accordance with this method [56]. Therefore, indicating the usefulness of Six Sigma in the management of urban logistics processes requires further research on other processes, such as the transport planning process or the transport control process. Therefore, the Authors plan to extend the research to include other entities that represent UFT stakeholders. The future studies will make it possible to run a complete DMAIC cycle. In particular, it is expected that problems occurring in urban logistics processes will be identified, and the measures which are critical to the process and require continuous monitoring will be specified in more detail. At this point, it is especially important to avoid the mistake of “measuring everything that moves”. At the same time, a Six Sigma implementation model is expected to be developed in entities which carry out the urban logistics processes. It should be noted that many Six Sigma projects fail to deliver the desired result. The reasons for the failure include, among others, the lack of commitment of leaders and management, lack of competences, incorrect selection of projects for implementation, resistance to change or mistakes in understanding the client’s needs [57,58]. Furthermore, applying Six Sigma in urban logistics processes management is hindered by lack of data, while the concept effectiveness relies on the data quality. A rational solution in this respect would be developing an IT system that gathers the necessary data via, e.g., a system that monitors the streets, which enables generation of correct data necessary for process evaluation in real time. Application of Six Sigma may be successful provided that cooperation is assured in each link of a supply chain. A hallmark in this respect is the automotive industry. Development of solutions that would encourage the entities involved in urban logistics processes to implement Six Sigma and to cooperate with each other seems to be indispensable for successful urban logistics management in accordance with the Six Sigma concept.

Author Contributions

Conceptualization, J.L. and K.K.; methodology, J.L.; validation, J.L., K.K., and S.I.; formal analysis, J.L., K.K., T.D.; investigation, J.L. and K.K.; resources, K.K. and S.I.; data curation, K.K., J.L.; writing-original draft preparation, J.L., K.K., S.I., and T.D.; writing-review and editing, J.L., K.K., T.D., and S.I.; All authors have read and agreed to the published version of the manuscript.

Funding

This paper was funded under the grant No 1/S/KZiL/21 “Implementation of sustainable supply chain systems in the conditions of the new economy” financed from subsidy of the Ministry of Education and Science for statutory activities.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Witkowski, J.; Kiba-Janiak, M. Correlation between City Logistics and Quality of Life as an Assumption for Referential Model, Procedia—Social and Behavioral Sciences; Elsevier: Amsterdam, The Netherlands, 2012; Volume 39, pp. 568–581. [Google Scholar]

- Joerss, M.; Nehuaus, F.; Schroeder, J. How Customers Demands Are Reshaping Last Mile Delivery; McKinsey & Company: New York, NY, USA, 2016. [Google Scholar]

- Iwan, S. Wdrażanie Dobrych Praktyk w Obszarze Transport Dostawczego w Miastach; Wydawnictwo Naukowe Akademii Morskiej w Szczecinie: Szczecin, Poland, 2013. [Google Scholar]

- Taniguchi, E.; Thompson, R.G.; Yamada, T.; van Duin, R. City Logistics—Network Modelling and Intelligent Transport. Systems; Elsevier Science Ltd: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Russo, F.; Comi, A. Urban freight transport planning towards green goals: Synthetic environmental evidence from tested results. Sustainability 2016, 8, 381. [Google Scholar] [CrossRef]

- Çalışkan, A.; Kalkan, M.; Ozturkoglu, Y. City logistics: Problems and recovery proposals. Int. J. Logist. Syst. Manag. 2017, 26, 145–162. [Google Scholar] [CrossRef]

- OECD Working Group on Urban Freight Logistics. Delivering the Goods—21st Century Challenges to Urban Goods Transport; OECD Publications: Paris, France, 2003; p. 7. [Google Scholar]

- Dablanc, L. Freight Transport. for Development Toolkit: Urban. Freight, The International Bank for Reconstruction and Development; The World Bank: Washington, DC, USA, 2009. [Google Scholar]

- Kijewska, K. Procesy Dystrybucyjne w Zrównoważonej Logistyce Miejskiej; BEL Studio: Warszawa, Poland, 2016. [Google Scholar]

- Kiba-Janiak, M. Urban freight transport in city strategic planning. In Research in Transportation Business & Management; Elsevier Science Ltd: Amsterdam, The Netherlands, 2017; pp. 4–16. [Google Scholar] [CrossRef]

- Tavasszy, L.; Piecyk, M. Sustainable freight transport. Sustainability 2018, 10, 3624. [Google Scholar] [CrossRef]

- Behrends, S.; Lindholm, M.; Woxenius, J. The Impact of Urban Freight Transport a Definition of Sustainability from Actor’s Perspectives. Transp. Plan. Technol. 2008, 31, 698–703. [Google Scholar] [CrossRef]

- Rai, H.B.; Verlinde, S.; Macharis, C. Unlocking the failed delivery problem? Opportunities and challenges for smart locks from a consumer perspective. Res. Transp. Econ. 2019. in Press. [Google Scholar]

- Apex Insight Ltd. Global Parcels Market Insight Report 2020; Apex Insight Ltd: London, UK, 2020. [Google Scholar]

- Helmers, S.A. Microsoft Visio 2016 Step by Step, Pearson Education; Microsoft Press: Redmond, WA USA, 2015. [Google Scholar]

- Vivekanathamoothy, N.; Ankar, S. Lean Six Sigma. In Six Sigma—Projects and Personal Experiences; Coskun, A., Ed.; Available online: www.intechopecn.com (accessed on 19 March 2020).

- Prabu, K.; Makesh, J.; Naveen, R.; Devadasan, S.R. Six Sigma Implementation Trough DMIAC: A case study. Int. J. Process. Manag. Benchmarking 2013, 3, 386–400. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, D. Implementing 8D Model of Problem Solving in Emploee Turnover: A case Study of Selected Hotels in Delhi and Rajastan. J. Kashmir Tour. Cater. Technol. 2015, 2, 1–10. [Google Scholar]

- Chakraborty, A.; Tan, K.C. Case Study analysis of Six Sigma implementation in service organizations. Bus. Process Manag. J. 2012, 18, 992–1019. [Google Scholar] [CrossRef]

- Ansari, A.; Lockwood, D.; Thies, E.; Modarress, B.; Nino, J. Application of Six-Sigma in finance: A case study. J. Case Res. Bus. Econ. 2010, 1–13. Available online: www.semanticscholar.org (accessed on 15 September 2020).

- Tjahjono, B.; Ball, B.; Vitanov, V.I.; Scorzafave, C.; Nogueira, J.; Calleja, J.; Minguet, M.; Narasimha, L.; Rivas, A. Six Sigma: A Literature Review. Int. J. Lean Six Sigma 2010, 1, 216–233. [Google Scholar] [CrossRef]

- Constantin, F.; Di Gravio, G.; Romitelli, A. Lean Six Sigma for Logistics process reengineering Conference. In Proceedings of the XVI Summer School Francesco Turco, Abano Terme, Padova, Italy, 14–16 September 2011; Available online: www.researchgate.net (accessed on 25 February 2021).

- Mitchell, E.M.; Kovach, J.V. Improving Supply Chain Information sharing using Design for Six Sigma. Eur. Res. Manag. Bus. Econ. 2016, 22, 147–154. [Google Scholar] [CrossRef]

- Gutiérrez, L.J.; De Leeuw, S.; Dubbers, R. Logistics Services and Lean Six Sigma Implementation: A Case Study. Int. J. Lean Six Sigma 2016, 7, 324–342. [Google Scholar] [CrossRef]

- Cheng, M. Research on the Improvement Strategy of Express Service Quality Based on Six Sigma Method. Am. J. Theor. Appl. Bus. 2018, 4, 27–36. [Google Scholar] [CrossRef]

- Zahng, A.; Luo, W.; Shi, Y.; Chia, S.T.; Sim, Z.H.X. Lean and Six Sigma in Logistics: A Pilot Survey Study in Singapore. Int. J. Oper. Prod. Manag. 2016, 36, 1625–1643. [Google Scholar] [CrossRef]

- De Carvalho, E.R.; de Mota, A.E.A.S.; de Souza Martins, G.M.; Bastos, L.D.S.L.; Melo, A.C.S. The Current Contex of Lean and Six Sigma Logistics Applications in Literature: A Systematic Review. Braz. J. of Oper. Prod. Manag. 2017, 14, 586–602. [Google Scholar] [CrossRef]

- Quality Digest Fort Wayne’s Sis Sigma Success. 2007. Available online: www.qualitydigest.com (accessed on 11 May 2020).

- Antony, J.; Jiju Antony, F.; Kumar, M.; Rae Cho, B. Six sigma in service organisations: Benefits, challenges and difficulties, common myths, empirical observations and success factors. Int. J. Qual. Reliab. Manag. 2007, 24, 294–311. [Google Scholar] [CrossRef]

- Thawani, S. Six Sigma—strategy for organizational excellence. Total Qual. Manag. 2004, 15, 655–664. [Google Scholar] [CrossRef]

- Silverman, D. Doing Qualitative Research; A Practical Handbook; SAGE Publications Ltd: Thousand Oaks, CA USA, 2009. [Google Scholar]

- Creswell, J.W. Qualitative Inquiry and Research Design. Choosing among Five Approaches; Sage Publications Thousand Oaks: London, UK; New Delhi, India, 2007. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods; Sage Publications Thousand Oaks: London, UK; New Delhi, India, 2009. [Google Scholar]

- Zaidah, Z. Case Study as a Research Method. J. Kemanus. 2007, 9, 1–6. [Google Scholar]

- Shokri, A.; Li, G. Green implementation of Lean Six Sigma projects in the manufacturing sector. Int. J. Lean Six Sigma 2020, 11, 711–729. [Google Scholar] [CrossRef]

- Jiraskuprasert, P.; Garaza-Reyes, J.A.; Kumar, V.; Lim, M.K. A Six Sigma and DMAIC application for the reduction of the defects in rubber gloves manufacturing process. Int. J. Lean Six Sigma 2014, 5, 2–21. [Google Scholar] [CrossRef]

- Antony, J.; Kumar, M.; Madu, C.N. Six Sigma in Small and Medium Sized UK Manufacturing Enterprises. Int. J. Qual. Reliab. Manag. 2005, 22, 860–874. [Google Scholar] [CrossRef]

- Sánchez, J.; Valles-Chavez, A. Successful Projects from the Application of Six Sigma Methodology. In Six Sigma Projects and Personal Experiences; IntechOpen: London, UK, 2011. [Google Scholar]

- Czarski, A.; Matusewicz, P. Influence of Measurement System Quality on the Evaluation of Processes Capability Indices. Metall. Eng. 2012, 38, 25–31. [Google Scholar]

- Yerriswamy, W.; Swamy, D.R.; Nagesh, P. The Process Capability Analysis—A Tool for Process Performance Measures and Metrics—A Case Study. Int. J. Qual. Res. 2014, 8, 399–416. [Google Scholar]

- Stefanow, P. Analiza zdolności procesu. Folia Oeconomica Crac. 2013, 54, 117–132. [Google Scholar]

- Ozlem, S.; Hakan, T. Process Capability and Six Sigma Methodology Including Fuzzy and Lean Approaches. In Products and Services; from R&D to Final Solutions, 2nd ed.; Fuerstner, I., Ed.; IntechOpen: London, UK, 2010. [Google Scholar] [CrossRef]

- Montgomery, D.C. Statistical Quality Control—A Modern Introduction; Willey: Hoboken, NJ, USA, 2009. [Google Scholar]

- Hayen, R.L. Six Sigma Information Systems: A Payroll Application. Issuess Inf. Syst. 2008, 9, 479–488. [Google Scholar]

- Aldowaisan, T.A.; Nourelfath, M.; Hassan, J. Six Sigma performance for non-normal processes. Eur. J. Oper. Res. 2015, 247, 968–977. [Google Scholar] [CrossRef]

- Sujova, A.; Simanova, L.; Marcinekova, K. Sustainable Process Performance by Application of Six Sigma Concepts: The Research Study of Two Industrial Cases. Sustainability 2016, 8, 260. [Google Scholar] [CrossRef]

- Banuleas, R.; Antony, J. Six Sigma or Design for Six Sigma. TQM Mag. 2004, 16, 250–263. [Google Scholar] [CrossRef]

- Nicolai, M.; Totolici, S. Six Sigma—A New Approach of Quality. In The Annalas of Dunarea de Jos University Fasicicle I: Economics and Informatics; Dunarea de Jos University of Galati: Galați, Romania, 2005; Volume 1, pp. 91–99. [Google Scholar]

- Dąbrowska, A. Jakość życia.—aspekty definicyjno—badawcze. In Pomiar Jakości Życia na Poziomie Lokalnym Rozprawy i Studia 2017 T. (MLV) 981; Błoński, K., Burlita, A., Witek, J., Eds.; Wydawnictwo Naukowe Uniwersytetu Szczecińskiego: Szczecin, Poland, 2017; pp. 11–18. [Google Scholar]

- Pasternak, Ł.; Sadowski, A. Bariery i ograniczenia w logistyce miejskie. Studia Miej. 2014, 15, 9–19. [Google Scholar]

- Dablanc, L. City distribution, a key element of the urban economy: Guidelines for practitioners. In City Distribution and Urban Freight Transport; Macharis, C., Melo, S., Eds.; Edward Elgar Publishing Ltd: Camberley, UK, 2011. [Google Scholar]

- Taniguchi, E.; Thompson, R.G. City logistics: Mapping the future; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Olsson, J.; Hellström, D.; Pålsson, H. Framework of Last Mile Logistics Research: A Systematic Review of the Literature. Sustainability 2019, 11, 7131. [Google Scholar] [CrossRef]

- Morganti, E.; Dablanc, L.; Fortin, F. Final deliveries for online shopping: The deployment of pickup point networks in urban andsuburban areas. Res. Transp. Bus. Manag. 2014, 11, 23–31. [Google Scholar] [CrossRef]

- Rosenberg, L.; Balouka, N.; Herer, Y.; Dani, E.; Gasparin, P.; Dobers, K.; Rüdiger, D.; Pättiniemi, P.; Portheine, P.; van Uden, S. Introducing the Shared Micro-Depot Network for Last-Mile Logistics. Sustainability 2021, 13, 2067. [Google Scholar] [CrossRef]

- Kumar, D.; Kaushis, D. A Rewiev of Six Sigma Approach: Methodology Obstacles and Benefits Global. J. Eng. Des. Technol. 2014, 3, 1–5. [Google Scholar]

- Atakan, G.; Firuzan, A.R. Reasons of Failure in Lean Six Sigma Projects. Int. J. Multidiscip. Thought 2012, 2, 123–130. [Google Scholar]

- Antony, J. A SWOT analysis on Six Sigma: Some perspectives from leading academics and practitioners. Int. J. Prod. Perform. Manag. 2012, 61, 691–698. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).