Compaction Procedures and Associated Environmental Impacts Analysis for Application of Steel Slag in Road Base Layer

Abstract

:1. Introduction

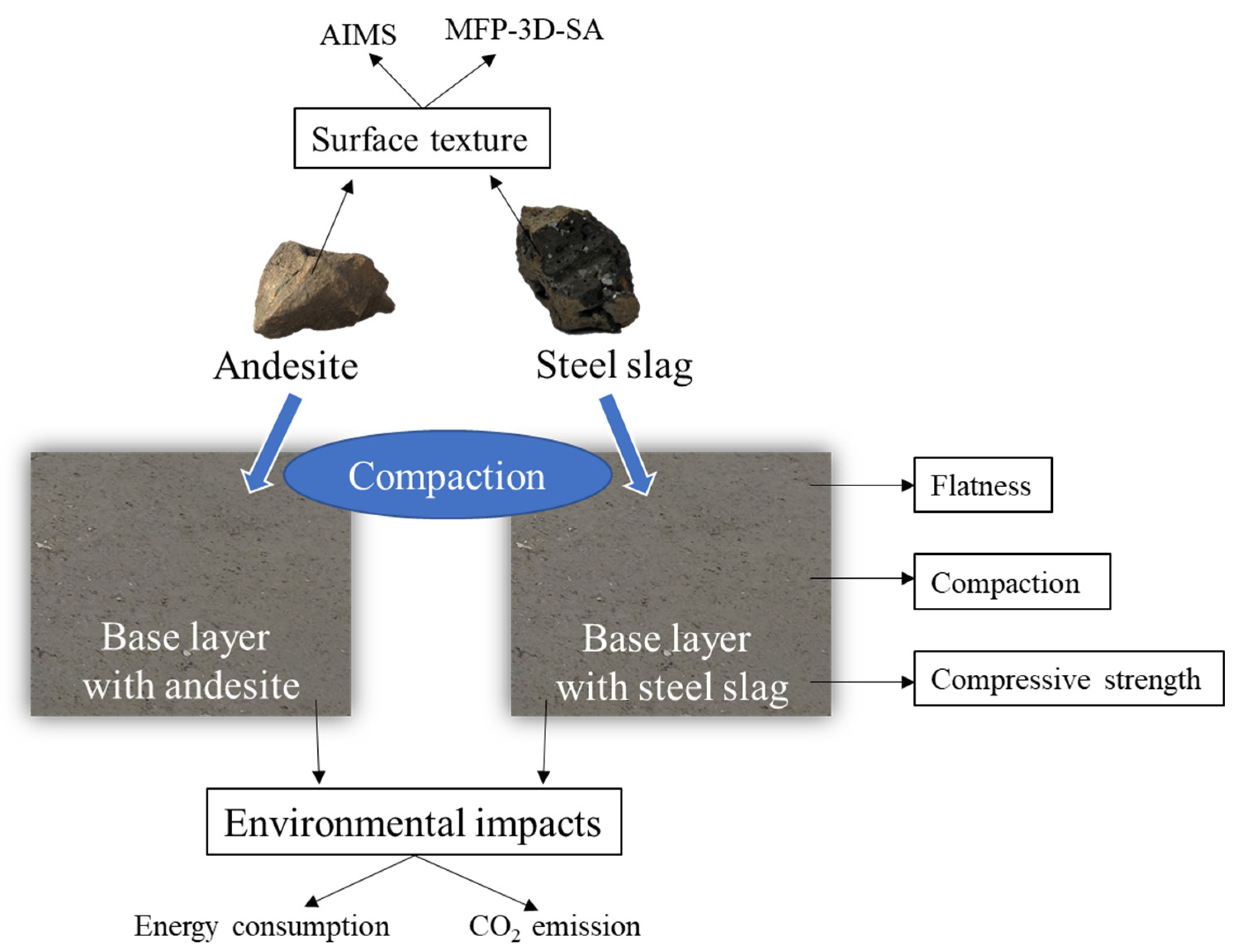

2. Materials and Methods for the Case Study

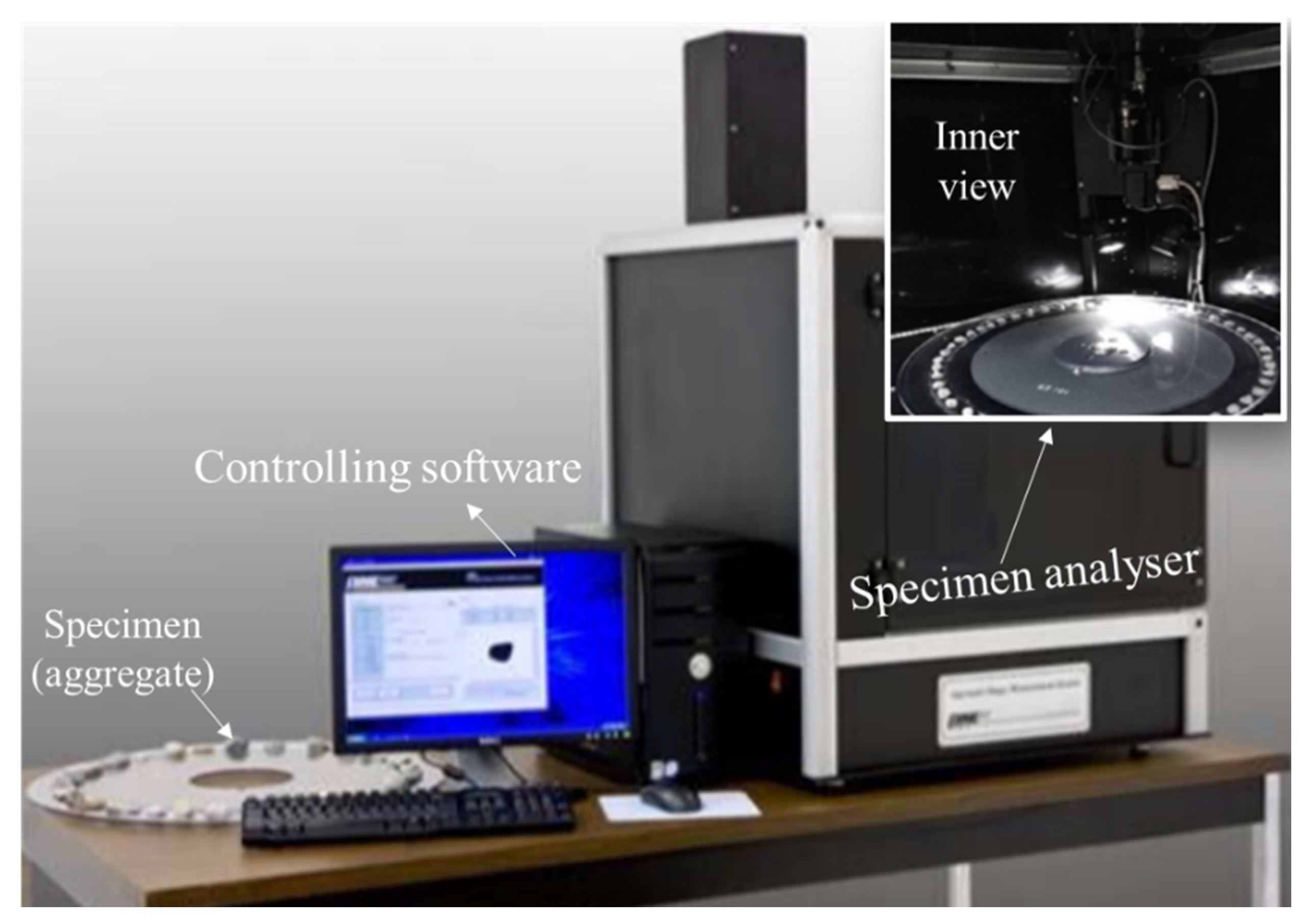

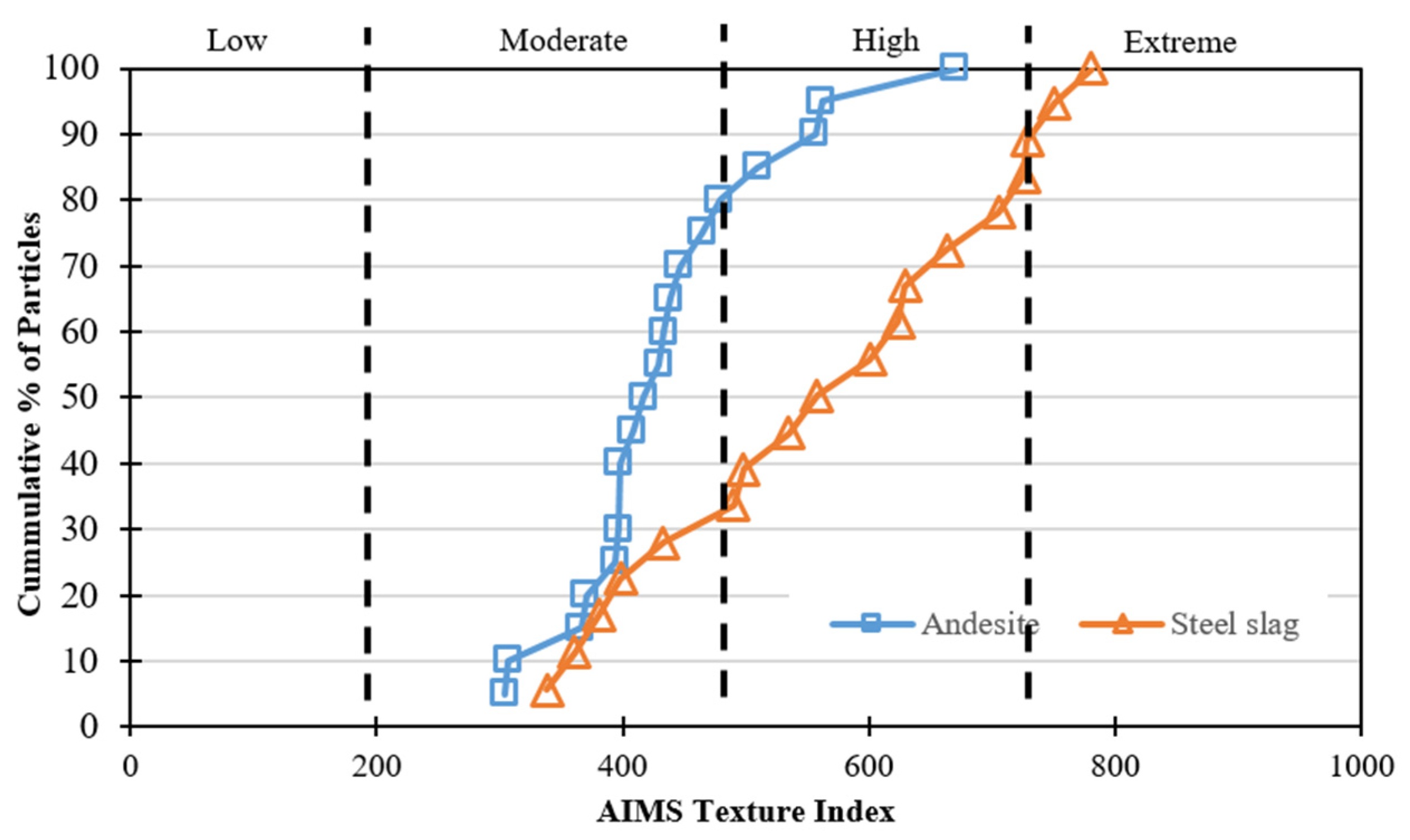

2.1. Physical Properties of Steel Slag and Andesite

2.2. Study Methods

3. Results and Discussion

3.1. Mechanical Properties of Base Layer

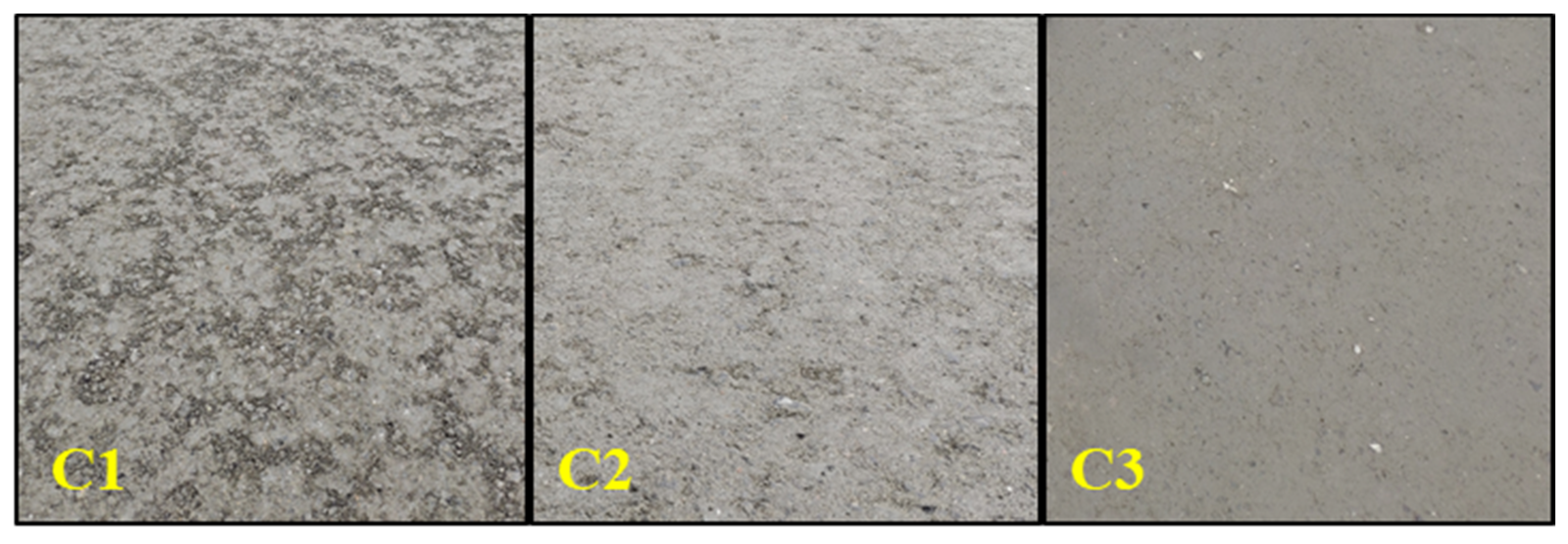

3.1.1. Optimization of Compaction Procedure

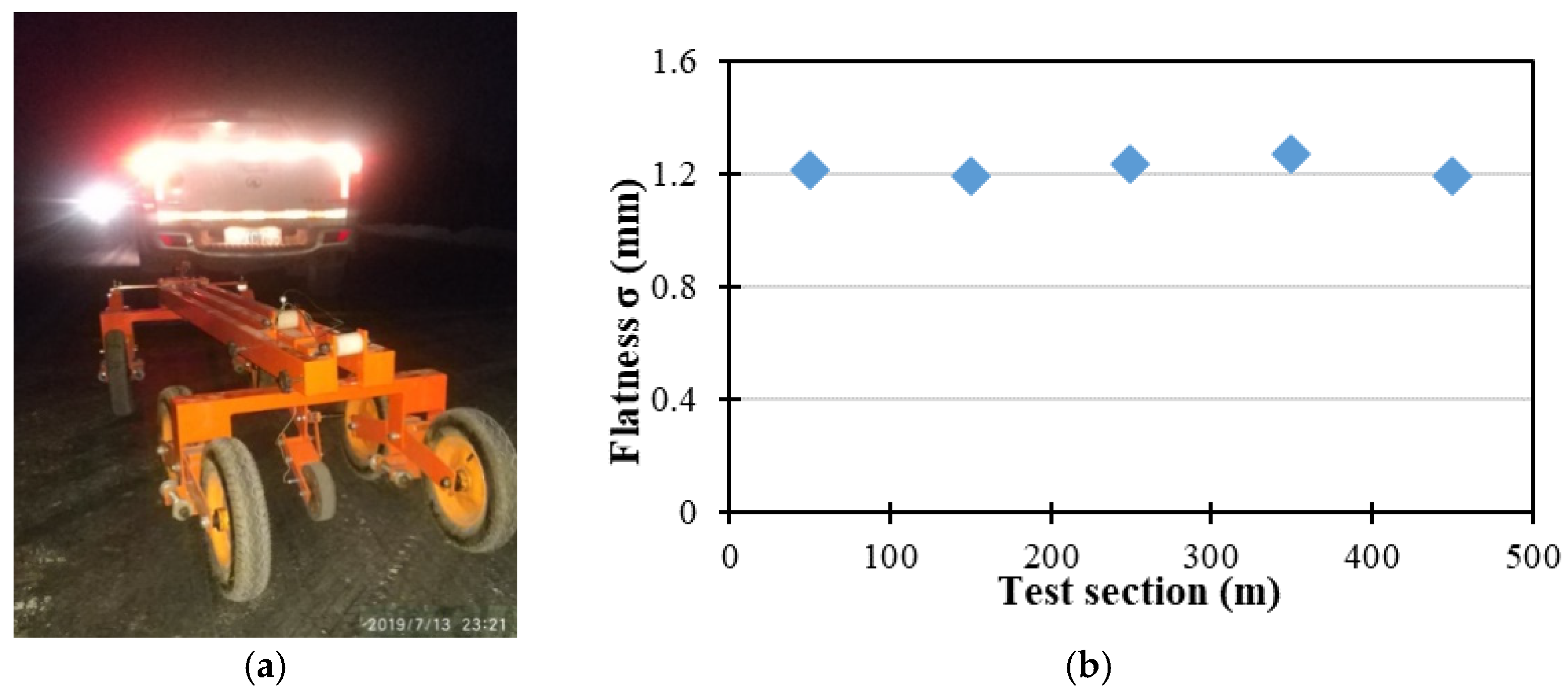

3.1.2. Surface Flatness

3.1.3. Hydraulically Bound Mixture Strength

3.2. Environmental Impacts

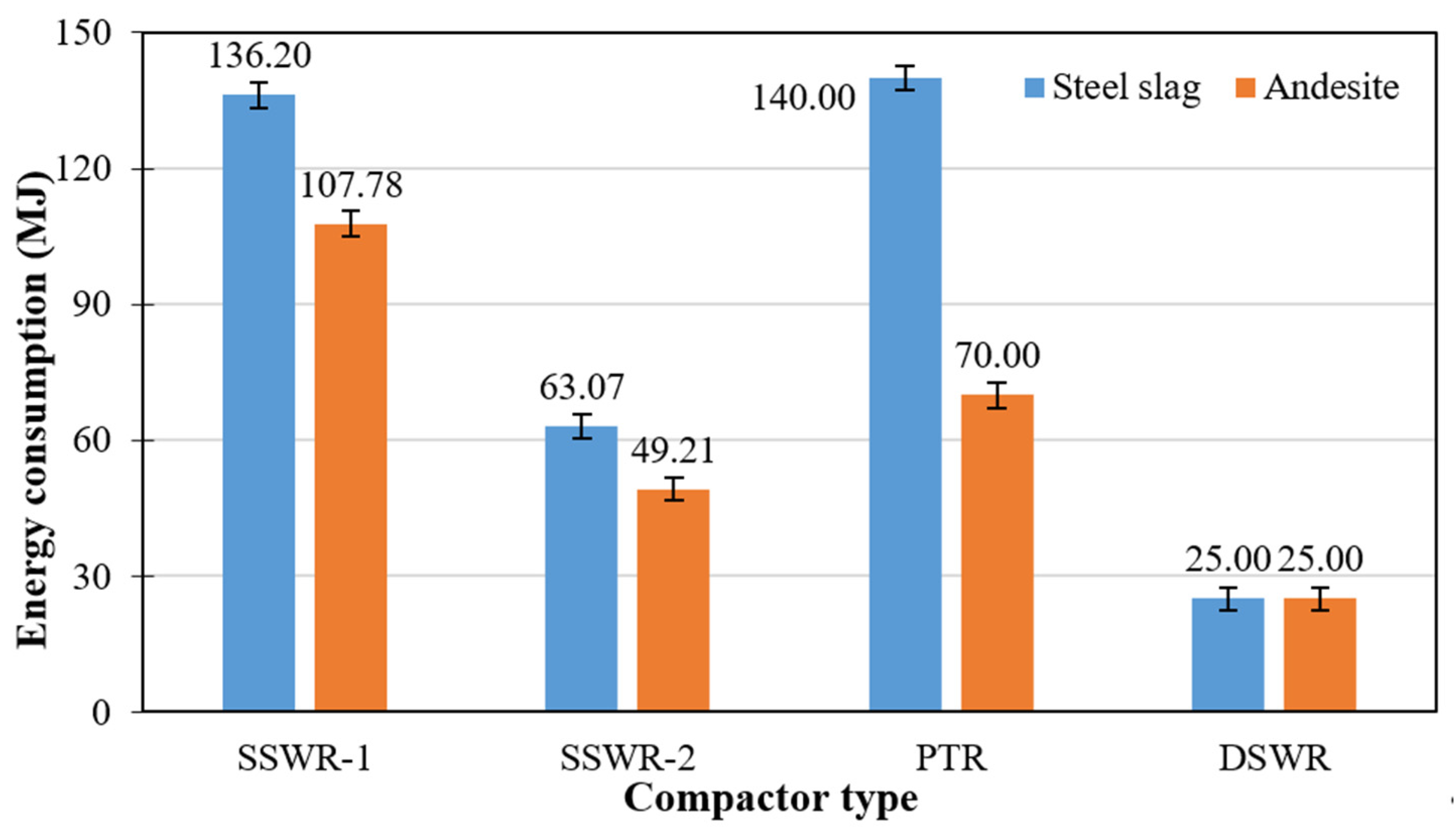

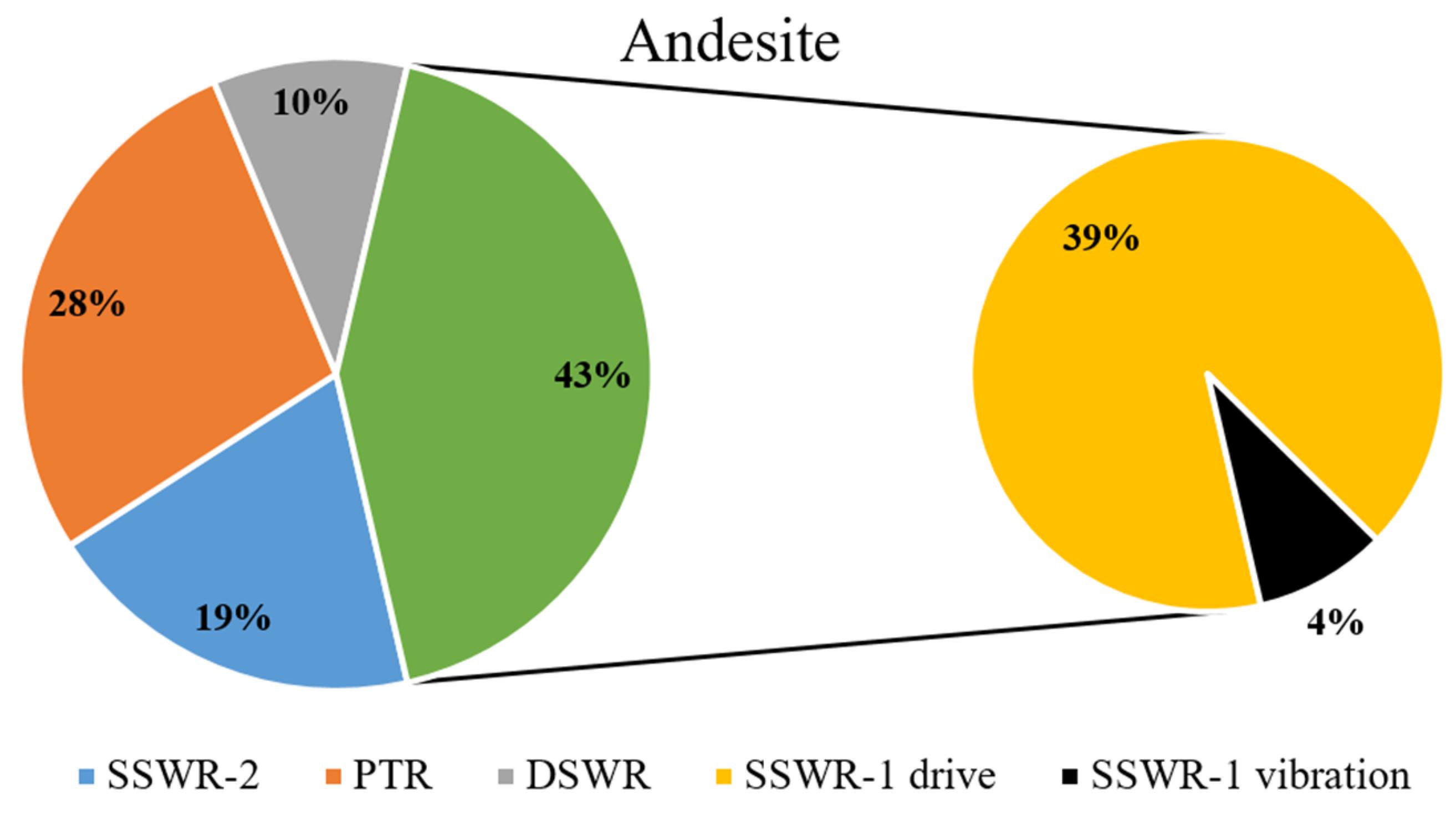

3.2.1. Energy Consumption

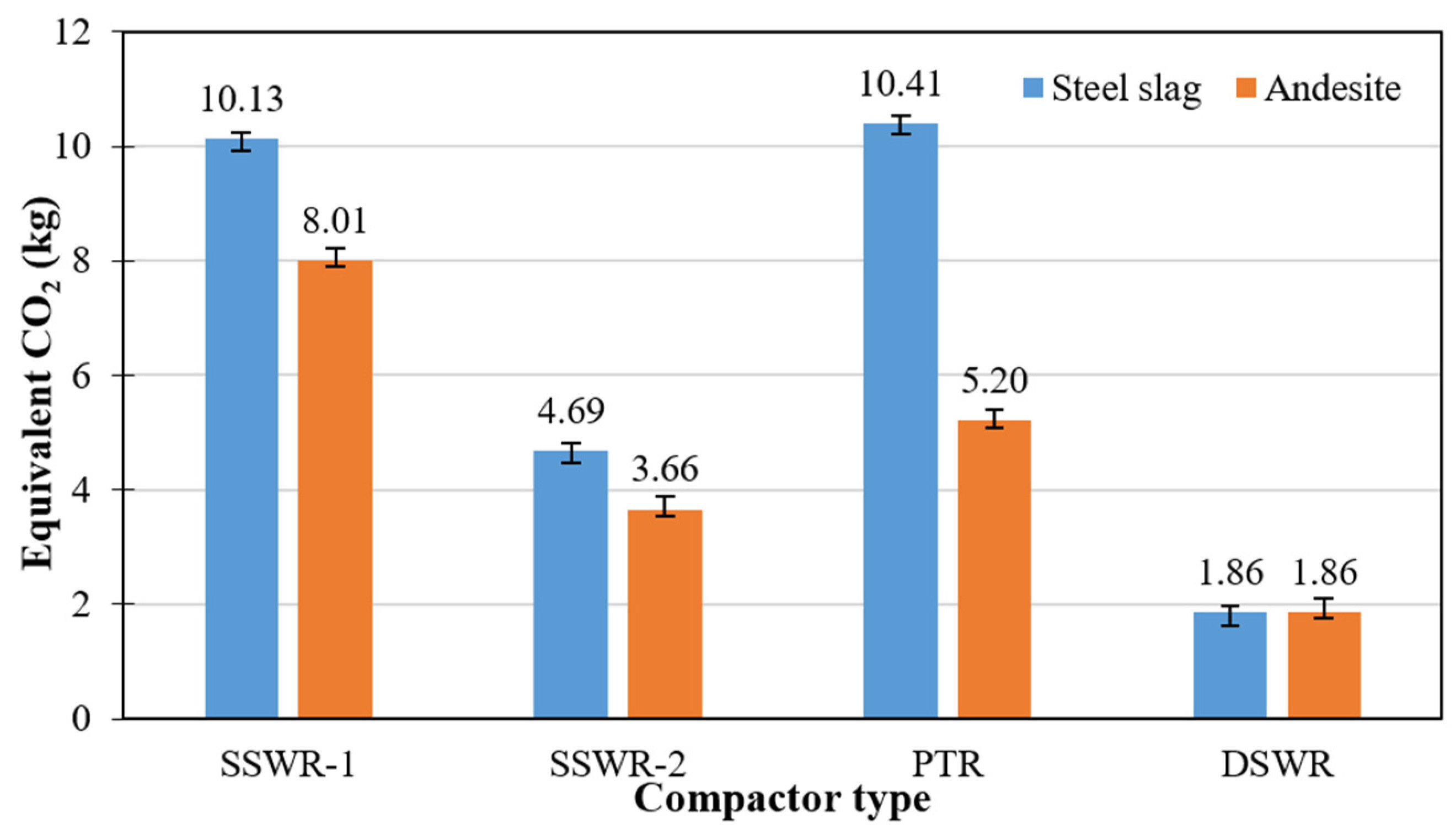

3.2.2. Equivalent CO2 Emission

4. Conclusions

- (1)

- Steel slag aggregate offers better roughness and surface micro-morphology properties than andesite aggregate in this investigated case.

- (2)

- The base layer containing steel slag aggregate fulfils the road construction requirements specified by the standard code, namely compactness, surface flatness and compressive strength of the hydraulically bound mixture.

- (3)

- Strong vibrations should be avoided or reduced during compaction to mitigate the adverse “hard-to-hard” effect between adjacent steel slag particles; the static pressure exerted by the rolling compactors should be increased.

- (4)

- Compared to the andesite base course, the base layer containing steel slag entails a higher diesel consumption used by the compactors: an additional 2.67 MJ/m3 of energy and 0.20 kg/m3 equivalent CO2 emissions were generated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- U.S. Department of Transportation. Highway Finance Data Collection. Our Nation’s Highways: 2011; Federal Highway Administration: Washington, DC, USA, 2014.

- Improving America’s Transportation Infrastructure: The Road Forward; U.S. Department of Transportation: Washington, DC, USA, 2017.

- Development Statistics Bulletin of Transportation Industry in 2018; Ministry of Transport of China: Beijing, China, 2019.

- Statistical Bulletin of Transportation Industry Development in 2019; Ministry of Transport of China: Beijing, China, 2020.

- Laurance, W.F.; Clements, G.R.; Sloan, S.; O’Connell, C.S.; Mueller, N.D.; Goosem, M.; Venter, O.; Edwards, D.P.; Phalan, B.; Balmford, A.; et al. A global strategy for road building. Nat. Cell Biol. 2014, 513, 229–232. [Google Scholar] [CrossRef]

- Gao, D.; Wang, F.-P.; Wang, Y.-T.; Zeng, Y.-N. Sustainable utilization of steel slag from traditional industry and agriculture to catalysis. Sustainability 2020, 12, 9295. [Google Scholar] [CrossRef]

- Skaf, M.; Manso, J.M.; Aragón, Á.; Fuente-Alonso, J.A.; Ortega-López, V. EAF slag in asphalt mixes: A brief review of its possible re-use. Resour. Conserv. Recycl. 2017, 120, 176–185. [Google Scholar] [CrossRef]

- Guo, J.; Bao, Y.; Wang, M. Steel slag in China: Treatment, recycling, and management. Waste Manag. 2018, 78, 318–330. [Google Scholar] [CrossRef]

- Yi, H.; Xu, G.; Cheng, H.; Wang, J.; Wan, Y.; Chen, H. An overview of utilization of steel slag. Procedia Environ. Sci. 2012, 16, 791–801. [Google Scholar] [CrossRef] [Green Version]

- Horii, K.; Kato, T.; Sugahara, K.; Tsutsumi, N.; Kitano, Y. Overview of iron/steel slag application and development of new utilization technologies. Nippon Steel Sumitomo Tech. Rep. 2015, 109, 5–11. [Google Scholar]

- Jullien, A.; Proust, C.; Martaud, T.; Rayssac, E.; Ropert, C. Variability in the environmental impacts of aggregate production. Resour. Conserv. Recycl. 2012, 62, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Barišić, I.; Grubeša, I.N.; Kutuzović, B.H. Multidisciplinary approach to the environmental impact of steel slag reused in road construction. Road Mater. Pavement Des. 2017, 18, 897–912. [Google Scholar] [CrossRef]

- Moustakas, K.; Mavropoulos, A.; Katsou, E.; Haralambous, K.-J.; Loizidou, M. Leaching properties of slag generated by a gasification/vitrification unit: The role of pH, particle size, contact time and cooling method used. J. Hazard. Mater. 2012, 207–208, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Chand, S.; Paul, B.; Kumar, M. Short-term leaching study of heavy metals from LD slag of important steel industries in Eastern India. J. Mater. Cycles Waste Manag. 2016, 19, 851–862. [Google Scholar] [CrossRef]

- Xie, J.; Wu, S.; Zhang, L.; Xiao, Y.; Ding, W. Evaluation the deleterious potential and heating characteristics of basic oxygen furnace slag based on laboratory and in-place investigation during large-scale reutilization. J. Clean. Prod. 2016, 133, 78–87. [Google Scholar] [CrossRef]

- Euroslag & Eurofer. Position Paper on the Status of Ferrous Slag complying with the Waste Framework Directive (Articles 5/6) and the REACH Regulation; European Slag Association: Duisburg, Germany, 2012. [Google Scholar]

- Monshi, A.; Asgarani, M.K. Producing Portland cement from iron and steel slags and limestone. Cem. Concr. Res. 1999, 29, 1373–1377. [Google Scholar] [CrossRef]

- Maslehuddin, M.; Sharif, A.M.; Shameem, M.; Ibrahim, M.; Barry, M. Comparison of properties of steel slag and crushed limestone aggregate concretes. Constr. Build. Mater. 2003, 17, 105–112. [Google Scholar] [CrossRef]

- Reddy, A.S.; Pradhan, R.; Chandra, S. Utilization of Basic Oxygen Furnace (BOF) slag in the production of a hydraulic cement binder. Int. J. Miner. Process. 2006, 79, 98–105. [Google Scholar] [CrossRef]

- Altun, I.A.; Yilmaz, I. Study on steel furnace slags with high MgO as additive in Portland cement. Cem. Concr. Res. 2002, 32, 1247–1249. [Google Scholar] [CrossRef]

- Lee, K.-M.; Park, P.-J. Estimation of the environmental credit for the recycling of granulated blast furnace slag based on LCA. Resour. Conserv. Recycl. 2005, 44, 139–151. [Google Scholar] [CrossRef]

- Saade, M.R.M.; da Silva, M.G.; Gomes, V. Appropriateness of environmental impact distribution methods to model blast furnace slag recycling in cement making. Resour. Conserv. Recycl. 2015, 99, 40–47. [Google Scholar] [CrossRef]

- Pasetto, M.; Pasquini, E.; Giacomello, G.; Baliello, A. Life-cycle assessment of road pavements containing marginal materials: Comparative analysis based on a real case study. In Pavement Life-Cycle Assessment; CRC Press: London, UK, 2017. [Google Scholar]

- Václavík, V.; Ondová, M.; Dvorský, T.; Eštoková, A.; Fabiánová, M.; Gola, L. Sustainability potential evaluation of concrete with steel slag aggregates by the LCA method. Sustainability 2020, 12, 9873. [Google Scholar] [CrossRef]

- Anastasiou, E.; Liapis, A.; Papayianni, I. Comparative life cycle assessment of concrete road pavements using industrial by-products as alternative materials. Resour. Conserv. Recycl. 2015, 101, 1–8. [Google Scholar] [CrossRef]

- Wang, F.; Hoff, I.; Yang, F.; Wu, S.; Xie, J.; Li, N.; Zhang, L. Comparative assessments for environmental impacts from three advanced asphalt pavement construction cases. J. Clean. Prod. 2021, 297, 126659. [Google Scholar] [CrossRef]

- Ministry of Transport of China. Test Methods of Aggregate for Highway Engineering (JTG E42–2005); China Communications Press: Beijing, China, 2005.

- Kandhal, P.S.; Hoffman, G.L. Evaluation of steel slag fine aggregate in hot-mix asphalt mixtures. Transp. Res. Rec. J. Transp. Res. Board 1997, 1583, 28–36. [Google Scholar] [CrossRef]

- Frías, M.; De Rojas, M.S.; Uría, A. Study of the instability of black slags from electric arc furnace steel industry. Mater. Constr. 2002, 52, 79–83. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Wang, D.; Zhuang, S. The soundness of steel slag with different free CaO and MgO contents. Constr. Build. Mater. 2017, 151, 138–146. [Google Scholar] [CrossRef]

- Nallathambi, P.; Karihaloo, B.L.; Heaton, B.S. Effect of specimen and crack sizes, water/cement ratio and coarse aggregate texture upon fracture toughness of concrete. Mag. Concr. Res. 1984, 36, 227–236. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, F.; Cui, P.; Lei, L.; Lin, J.; Yi, M. Evaluation of fine aggregate morphology by image method and its effect on skid-resistance of micro-surfacing. Materials 2018, 11, 920. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cui, P.; Xiao, Y.; Yan, B.; Li, M.; Wu, S. Morphological characteristics of aggregates and their influence on the performance of asphalt mixture. Constr. Build. Mater. 2018, 186, 303–312. [Google Scholar] [CrossRef]

- Ministry of Transport of China. Code for Field Test of Highway Subgrade and Pavement (JTGE 60-2008); China Communications Press: Beijing, China, 2008.

- Winter, M. The Determination of the Acceptability of Selected Fragmenting Materials for Earthworks Compaction: Prepared for National Roads Directorate, Scottish Office Development Department; Thomas Telford: Lomdon, UK, 1999. [Google Scholar]

- Shen, J.; Li, F.; Lv, G. JTJ059-95 Highway Subgrade Pavement Field Test Procedures; People’s Communications Press: Beijing, China, 1995. [Google Scholar]

- Ministry of Transport of China. Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering (JTG E51–2009); China Communications Press: Beijing, China, 2009.

- Huang, Y.H. Pavement Analysis and Design; Pearson: London, UK, 2004. [Google Scholar]

- Edwards, C.F.; Teh, K.-Y.; Miller, S.L. Low exergy loss chemical engines. In Global Climate & Energy Project; Stanford University: Stanford, CA, USA, 2006. [Google Scholar]

- Tebbe, P. DIESEL ENGINE. 2015. Available online: https://cset.mnsu.edu/engagethermo/components_diesel.html (accessed on 1 January 2021).

- China Statistical Yearbook; National Bureau of Statistics of China: Beijing, China, 2012.

- Chinese Life Cycle Database; IKE Environmental Technology Sichuan University: Chengdu, China, 2012.

- Leal, D.; Winter, M.G.; Seddon, R.; Nettleton, I.M. A comparative life cycle assessment of innovative highway slope repair techniques. Transp. Geotech. 2020, 22, 100322. [Google Scholar] [CrossRef]

- Gomes Correia, A.; Winter, M.G.; Puppala, A.J. A review of sustainable approaches in transport infrastructure geotechnics. Transp. Geotech. 2016, 7, 21–28. [Google Scholar] [CrossRef] [Green Version]

| Property | Characteristic | Result | Requirement | Standard |

|---|---|---|---|---|

| Fineness | 80 μm (%) | 1.0 | <10 | GB/T1345-2005 |

| Setting time | Initial (min) | 259 | ≥180 | GB/T1346-2011 |

| Final (min) | 420 | ≥360, ≤600 | ||

| Flexural strength | 3d (MPa) | 4.4 | ≥2.5 | GBT17671-1999 |

| 28d (MPa) | 7.5 | ≥5.5 | ||

| Compressive strength | 3d (MPa) | 18.5 | ≥10.0 | |

| 28d (MPa) | 38.4 | ≥32.5 | ||

| Composition content | SO3 (%) | 2.34 | ≤4.0 | GB/T176-2008 |

| MgO (%) | 4.04 | ≤6.0 | ||

| Cl- (%) | 0.01 | ≤0.06 | ||

| Ignition loss (%) | 1.15 | ≤5.0 |

| Property | Size | Result | Requirement | Standard |

|---|---|---|---|---|

| Crushing value (%) | - | 10.3 | ≤26 | T0316 |

| Los Angeles abrasion value (%) | - | 8.5 | ≤28 | T0317 |

| Flake particles content (%) | 4.75–9.5 mm | 10.1 | ≤12 | T0312 |

| ≥9.5 mm | 6.7 | ≤12 | ||

| Weak particles content (%) | - | 0.2 | ≤3 | T0320 |

| f-CaO content (%) | 10–16 mm | 2.42 | ≤3 | YB140-2009 |

| Material | Steel Slag | Andesite | |||

|---|---|---|---|---|---|

| Size (mm) | 19–26.5 | 6–19 | 9.5–16 | 4.75–9.5 | 0–4.75 |

| Mass ratio (%) | 13 | 16 | 18 | 22 | 31 |

| Compactor | SSWR | DSWR | PTR | |

|---|---|---|---|---|

| Wheel Type | Steel | Steel | Rubber | |

| Model | KS225HD-2 | CLG 620H | KP306H | BOMAG203 |

| Vibration frequency, max-min (Hz) | 32/28 | 32/28 | / | 50/40 |

| Vibration force, max-min (kN) | 415/285 | 400/210 | / | 0.69/0.29 |

| Amplitude, max-min (mm) | 1.98/0.99 | 1.90/1.00 | / | 126/84 |

| Power (kW) | 140 | 132 | 140 | 100 |

| Location | Wet Density ρ (g/cm3) | Moisture Content (%) | Dry Density ρd (g/cm3) | Compactness K |

|---|---|---|---|---|

| L1 | 2.875 | 5.5 | 2.725 | 97.8 |

| L2 | 2.904 | 2.753 | 98.8 | |

| L3 | 2.914 | 2.762 | 99.1 |

| Sample Group | A | B |

|---|---|---|

| Average strength (MPa) | 9.4 | 9.9 |

| Standard deviation | 0.23 | 0.26 |

| Coefficient of variation (%) | 2.44 | 2.57 |

| 95% confidence rate (MPa) | 9.0 | 9.5 |

| Compactor | Force (kN) | Frequency (Hz) | Amplitude (mm) | Width (m) | Speed (m/s) | |

|---|---|---|---|---|---|---|

| SSWR-1 | S | 412 | 32 | 1.98 | 1.5 | 2 |

| W | 285 | 28 | 0.99 | 1.5 | 2 | |

| SSWR-2 | S | 400 | 32 | 1.90 | 2.1 | 2 |

| W | 210 | 28 | 1.00 | 2.1 | 2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, B.; Yang, C.; Zou, Y.; Wang, F.; Zhou, X.; Barbieri, D.M.; Wu, S. Compaction Procedures and Associated Environmental Impacts Analysis for Application of Steel Slag in Road Base Layer. Sustainability 2021, 13, 4396. https://doi.org/10.3390/su13084396

Gao B, Yang C, Zou Y, Wang F, Zhou X, Barbieri DM, Wu S. Compaction Procedures and Associated Environmental Impacts Analysis for Application of Steel Slag in Road Base Layer. Sustainability. 2021; 13(8):4396. https://doi.org/10.3390/su13084396

Chicago/Turabian StyleGao, Bo, Chao Yang, Yingxue Zou, Fusong Wang, Xiaojun Zhou, Diego Maria Barbieri, and Shaopeng Wu. 2021. "Compaction Procedures and Associated Environmental Impacts Analysis for Application of Steel Slag in Road Base Layer" Sustainability 13, no. 8: 4396. https://doi.org/10.3390/su13084396

APA StyleGao, B., Yang, C., Zou, Y., Wang, F., Zhou, X., Barbieri, D. M., & Wu, S. (2021). Compaction Procedures and Associated Environmental Impacts Analysis for Application of Steel Slag in Road Base Layer. Sustainability, 13(8), 4396. https://doi.org/10.3390/su13084396