Preliminary Proposal for an Alternative Wall Lining Panel Based on Molded Recycled Cellulose and Designed for Home Wiring Refurbishment of Building Interior Partitions

Abstract

:1. Introduction

- (1)

- Periodic changes in the user of the housing stock (rent and purchase);

- (2)

- Home-scale renewal, aligned with buildings and city refurbishment policies:

- (3)

- The growing need for more wired services (energy, security, sensors, lighting, communication, etc.) at home, which does not seem to be slowing;

- (4)

- New “green” refurbishment technologies to make the circular economy a reality [5].

2. Literature

2.1. Current Situation of Electrical and Wire Services in Housing

- (1)

- 23.87% of living room switches have been modified from the original layout;

- (2)

- 25.4% of bedroom switches have been modified from the original layout;

- (3)

- 23.6% of kitchen switches have been modified from the original layout;

- (4)

- 35.13% of living room sockets have been modified from the original layout;

- (5)

- 40.93% of socket outlets are hidden by furniture;

- (6)

- 35.20% of plug positions have been modified from the original layout;

- (7)

- 38.07% of bedroom sockets are hidden by furniture;

- (8)

- 29.6% of kitchen plugs have been modified from the original layout;

- (9)

- 77.67% of plugs in living rooms connect adaptors, spools or extension cables;

- (10)

- 64.20% of plugs in bedrooms have spools or extensions connected.

- (1)

- 31.7% of telephone connections are modified from the original layout;

- (2)

- 16.7% of telephony connections in living rooms have been modified from the original layout;

- (3)

- 38.5% of telephone connections in bedrooms have been modified from the original layout;

- (4)

- 12.7% of telephone connections in bedrooms have been hidden by furniture;

- (5)

- 33.3% of data and TV connections in living rooms have been modified from the original layout;

- (6)

- 18.1% of data and TV connections in living rooms have been hidden by furniture;

- (7)

- 40.7% of data connections and TV in bedrooms have been modified from the original layout;

- (8)

- 13.8% of data and TV connections in bedrooms are hidden by furniture.

2.2. Commercial State of the Art

2.3. Industrial State of the Art

- (1)

- Patents for invention and utility models of the Spanish Patent and Trademark Office (SPTO), INVENES;

- (2)

- European Patent Office, ESPACENET;

- (3)

- GOOGLE SCHOLAR, patent portal.

- (1)

- E04B2 walls, for example, partitions for buildings, the structure of the walls regarding insulation, specific mounts for walls;

- (2)

- E04C2 construction elements of relatively little thickness to construct parts of buildings.

- (1)

- Most of the patented solutions start from using a previous structure of uprights and crossbars;

- (2)

- Most of the solutions are designed to resolve cross conflicts between ducts and frames;

- (3)

- No solution is focused on the insertion of an insulation panel for thermal or acoustic purposes;

- (4)

- Most systems take advantage of the opportunities offered by cold-rolled profiles due to their folds and gaps;

- (5)

- No concerns about reducing environmental impact are addressed;

- (6)

- There is no consensus about where to fix sockets and switches: on board or on the frame;

- (7)

- There does not seem to be the same interest in guaranteeing access to installations in the selected solutions;

- (8)

- There is marked conflict between the stiffness of the walls and the flexibility of the wiring;

- (9)

- Solutions do not seem to consider in general the opportunities presented by the wall lining in combination with a previous masonry wall;

- (10)

- The proposed innovation does not, in general, involve the board but rather the relationship between the metal profiles and the electrical wiring;

- (11)

- Most of the solutions present the primacy of the upright profiles, and only some raise the possibility of prefabricating all the panels in the workshop.

3. Objectives of the Investigation

- Time, cost and quality adjustments, due to increasing industrialization and modulation;

- A reduction in environmental impact through using recycled materials.

- 3.

- A reduction in run time and low waste generation through using small modules that are stackable and light;

- 4.

- Facilitation of work processes through using materials that are easily cut, nailed, screwed, drilled and fixed on the existing support and to each other;

- 5.

- Facilitation of the fitting of wired networks;

- 6.

- Improvement in the final technical quality of the set without altering the initial architectural appearance: facilitation of the fitting of standard laminate base gypsum board as a finishing layer;

- 7.

- Facilitation of the fitting of thermal and acoustic insulation products.

4. Methods

- (1)

- Replacing the differentiated support elements (uprights) with a continuous structure should reduce the thickness of the gypsum board that finally coats the liner;

- (2)

- Looking for a recycling material with low environmental impact to materialize this continuous structure;

- (3)

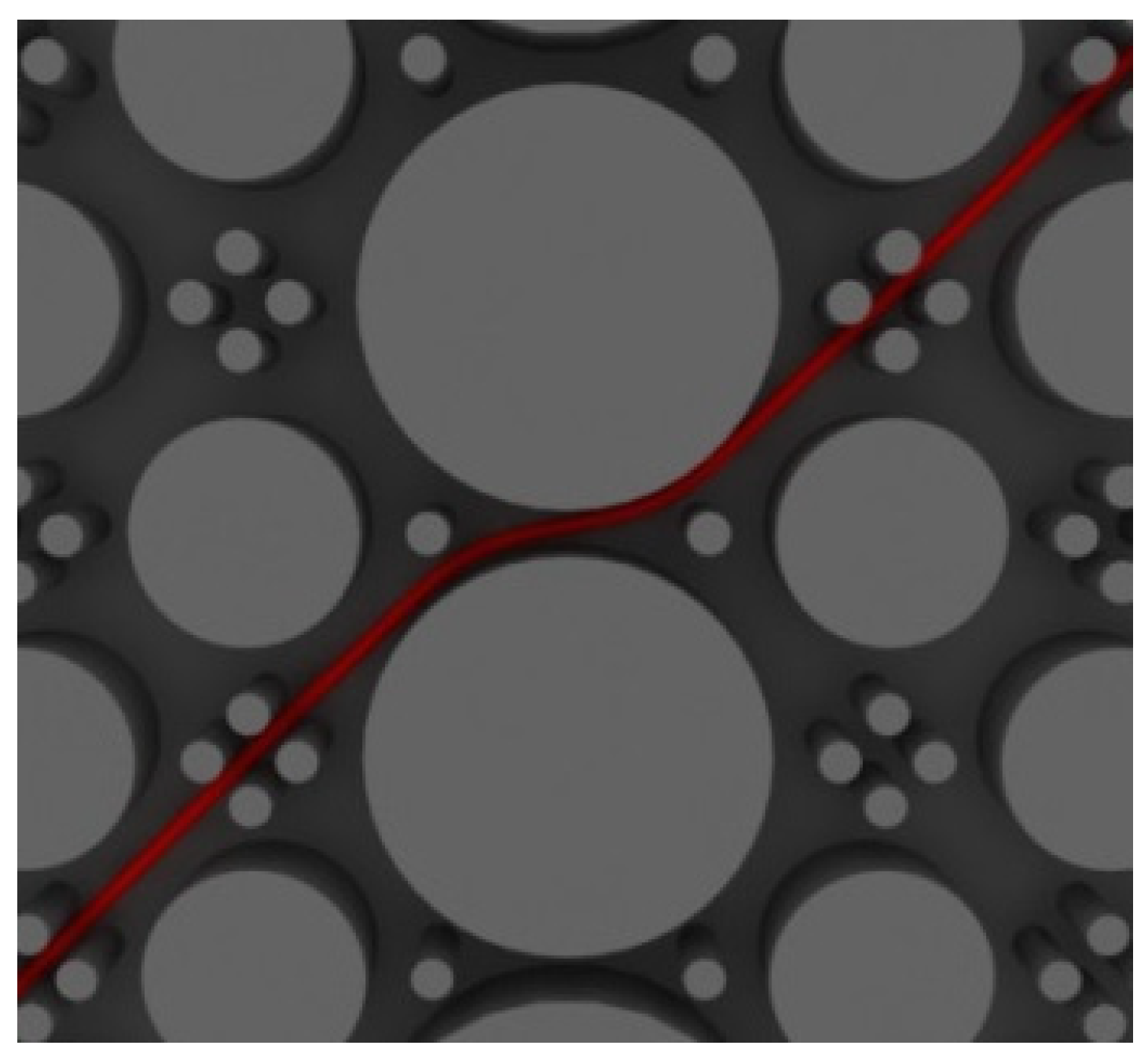

- Providing this continuous structure with relief gives it greater rigidity and the ability to insert the wiring without needing to use point fixings.

4.1. Find a Material That Meets Objectives 2, 4 & 7

4.2. Find a Molded Form That Meets Objectives 1, 3, 5 & 6

- (1)

- The thickness of the cellulose pulp moldings is similar to that of cardboard paper and does not exceed 1mm, so it acquires its rigidity due to the double relief on both sides obtained from a central core. This central core also has slight ribbing;

- (2)

- The relief, conical trunks or prismatic trunks have a slight inclination to facilitate demolding;

- (3)

- At its edges, it is always additionally reinforced by bending to prevent perimeter tearing;

- (4)

- Most of the moldings are stackable, which significantly reduces their volume and deterioration during transport and storage processes;

- (5)

- The thickness achieved is in most cases around the 50 mm objective set;

- (6)

- Modular molded parts can be obtained, but it is also possible to obtain custom-made parts for special uses;

- (7)

- Molded cellulose is compatible with wet sprayed cellulose and injected cellulose wool used in thermal insulation applications in enclosed air chambers;

- (8)

- All collected patents and specimens feature flat ends on both reliefs to facilitate support on flat surfaces;

- (9)

- There are no sharp edges to avoid damage to the items themselves and to people who handle them without gloves;

- (10)

- It is not difficult to obtain polygonal or curved surfaces;

- (11)

- A lateral union between moldings is not provided;

- (12)

- Most of the moldings require the need to generate boxes, an aspect that is not important for use in buildings.

5. Development of the Molded Panel

5.1. Modulation and Relief of the Panels

- (1)

- Outputs to support the laminated base gypsum board (LGB);

- (2)

- Channels between the outputs to facilitate the insertion and anchorage of electrical elements. Channels of diverse width are provided: channels for wiring as described (Table 2), channels for electrical control boxes (superior and inferior) and channels for electrical connection and junction boxes (Figure 17).

5.2. Jointing of the Panels

5.3. Insertion of Electrical Control and Junction Boxes

- (1)

- 100 mm channel width for insertion of junction electrical boxes located from the lower end of the module;

- (2)

- 74 mm channel width for insertion of switches located at 20 cm from the lower end of the module;

- (3)

- 74 mm channel width for the insertion of socket boxes, located from the lower end of the module;

- (4)

- The casket for fitting the mechanisms of the electrical installation is in the perimeter relief of the area designed to accommodate it.

5.4. Location of Wires

5.5. Fixing Laminate Base Gypsum Board

6. Discussion of Preliminary Results

7. Future Challenges

- (1)

- Guarantee the performance of fixing anchors between the laminated base gypsum board and the molded panel and between the molded panel and the pre-existing wall;

- (2)

- Facilitate the mechanization and manipulation of the molded panel with single tools to facilitate insert connection and junction boxes of the wired installation;

- (3)

- This molded panel can complement specific insulating materials that can also be derived from cellulose fiber. Non-agglomerated cellulose fiber is a type of thermal and acoustic insulation. It can be applied either blown dry or sprayed wet. It is essential to ensure the proper performance of the molded panel in contact with thermal insulation of fiber cellulose that is directly projected on the backside of the molded panel;

- (4)

- Assessment of using boric salts to give fire retardant, fungicidal and insecticidal properties to the panel;

- (5)

- Adjustment of the thickness of the molded layer of cellulose fibers to ensure medium-term dimensional stability;

- (6)

- Adaption of the molded panel design to water supply ducts.

8. Conclusions

- (1)

- New social, technical and environmental challenges force current construction products to evolve to reap benefits on these three fronts. The knowledge acquired in the past decades will serve as a basis for redefining current products and improving their suitability;

- (2)

- The product design methodology can benefit the construction sector, especially in the interior rehabilitation of homes that are usually slower, more expensive and with a higher environmental impact;

- (3)

- This research contributes to improving the applications of molded panels designed for the refurbishment and using recycled cellulose fibers in the building industry;

- (4)

- The possibility of designing reliefs for every specific purpose is an opportunity for the future integration of home services and building elements and reducing mutual disturbance in various situations;

- (5)

- The authors are confident that small but extensive technical problems linked to improving interior building quality, such as the one raised here, will gradually emerge. These challenges are an opportunity for co-design based on better use of existing industrial potential.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Santangelo, A.; Tondelli, S. Occupant behaviour and building renovation of the social housing stock: Current and future challenges. Energy Build. 2017, 145, 276–283. [Google Scholar] [CrossRef]

- Gohardani, N.; Björk, F. Sustainable refurbishment in building technology. Smart Sustain. Built Environ. 2012, 1, 241–252. [Google Scholar] [CrossRef]

- European Commission. Communication from de Commission Europe 2020: A Strategy for Smart, Sustainable and Inclusive Growth; European Commission: Brussels, Belgium, 2020; Available online: https://ec.europa.eu/eip/ageing/file/225/download_en%3Ftoken=Ff9OHs4J (accessed on 7 April 2021).

- Holck Sandberg, N.; Sartori, I.; Richard Dawson, O.; Dascalaki, E.; Dimitriou, S.; Vimm-r, T.; Filippidou, F.; Stegnar, G.; ŠijanecZavrl, M.; Brattebø, H. Dynamic building stock modelling: Application to 11 European countries to support the energy efficiency and retrofit ambitions of the EU. Energy Build. 2016, 132, 26–38. [Google Scholar] [CrossRef] [Green Version]

- Report on Access to Decent and Affordable Housing for All (2019/2187(INI)). Available online: https://www.europarl.europa.eu/doceo/document/A-9-2020-0247_EN.html (accessed on 7 April 2021).

- White Paper Residential Electrical Safety How to Ensure Progress Forum for European Electrical Safety (Feeds). May 2017. Available online: https://www.iut.nu/wp-content/uploads/2018/06/Feeds-Forum-White-Paper-2017.pdf (accessed on 7 April 2021).

- Gasca, J.C.T.; de las Casas Ayala, J.M.; Frutos, C.B. Diseño y ubicación de los mecanismos eléctricos en las viviendas: Análisis y soluciones. Segur. y Medio Ambiente 2010, 120, 30–31. Available online: https://documentacion.fundacionmapfre.org/documentacion/publico/i18n/catalogo_imagenes/grupo.do?path=1062520 (accessed on 7 April 2021).

- International Electrotechnical Commission IEC 60364-8-1:2019 IEC 60364-5-52:2009 Low-Voltage Electrical Installations-Part 5-52: Selection and Erection of Electrical Equipment-Wiring Systems. Available online: https://webstore.iec.ch/publication/1878 (accessed on 7 April 2021).

- CEC. Catálogo de Elementos Constructivos del CTE. 2010. Available online: https://www.codigotecnico.org/pdf/Programas/CEC/CAT-EC-v06.3_marzo_10.pdf (accessed on 7 April 2021).

- NHBC. National House Building Council Standards. 2021. Available online: https://nhbc-standards.co.uk/9-finishes/9-2-wall-and-ceiling-finishes/9-2-4-dry-lining/ (accessed on 7 April 2021).

- EC. Manual of Standard Building Specifications. 2011. Available online: https://eeas.europa.eu/archives/docs/business-tenders/docs/20151209/3-4-annex-4-mit-standard-building-specifications_en.pdf (accessed on 7 April 2021).

- CSTB. Tests by Product. Available online: https://evaluation.cstb.fr/en/tests/product/doublage-de-mur/ (accessed on 7 April 2021).

- Hispalam® Large Size Clay Bricks + Drywall Board System. Available online: http://www.hispaplano.com/Uploads/docs/Informacio%20Basica%2002%2010%2008%20Ingles.pdf (accessed on 7 April 2021).

- Muralit® Large Size Clay Bicks + Drywall Board System. Available online: https://muralit.es/ (accessed on 7 April 2021).

- Nelson, J.A.; Pritchard, M.J. Removable Non-Load-Bearing Partitions; Partitions with a Free Upper Edge Modular Coordination Assembled Using Frames with Infill Panels or Coverings Only; Made-Up of Panels and a Support Structure Incorporating Posts with Panels and Support Posts, Extending from Floor to Ceiling with Wallboards Attached to the Outer Faces of the Posts, Parallel to the. Partition. Patent No. EP 0778376 B1, 11 June 1997. [Google Scholar]

- Reuter, R.E.; Bullwinkle, W.C.; Reuter, R.D. U.S. Lay-In Wireways for a Space Divider System. Patent 5918433 A, 6 July 1999. [Google Scholar]

- Waalkes, M.; Pressnell, M.; Slager, M.; Shields, M.; Kane, B.; Christopher, R.; Boyle, D.; Seiber, C.; Skillman, P.; Chang, J.; et al. Knock-Down Portable Partition System. U.S. Patent 20070227079 A1, 4 October 2007. [Google Scholar]

- Parshad, D.; Woronecki, P.; Liu, I. Office Partition System. U.S. Patent 7975445 B2, 12 July 2011. [Google Scholar]

- Wild, R.L. U.S. Transmission Media Patch Panel Modular Cabinetry System. Patent 6322176 B1, 27 November 2001. [Google Scholar]

- MacDonald, D.B.; Sanders, S.E.; Dykstra, J.R. U.S. Stacking Connector for Partitions. Patent 6351917 B1, 5 March 2002. [Google Scholar]

- Parshad, D.; Edwards, J.R.; Woronecki, P. Electrified Lockable Double Sided Storage Cabinet. U.S. Patent 8387314 B2, 5 March 2013. [Google Scholar]

- Liu, I.; Parshad, D.; Woronecki, P. Variable Width Module Office Furniture Partition. U.S. Patent 8534021 B2, 17 September 2013. [Google Scholar]

- Henriott, J.M.; Metcalf, K.E. Partition System. U.S. Patent 20110197519 A1, 18 August 2011. [Google Scholar]

- Bates, M.; Boyce, A.J.; Kang, C.M.; Katje, M.J.; Lyons, S.R.; Porter, K.E.; Roetman, J.D.; Sellers, P.L.; Zaccai, G.D. Wall Mounted Assembly. U.S. Patent 20110219706 A1, 15 September 2011. [Google Scholar]

- Baier, H. Wandverkleidungsmodul. Patent No. EP 2450500 A2, 9 May 2012. [Google Scholar]

- Sutton, T.A.; Bodkins, N.J. Wall-Mounted Modular Accessory System. U.S. Patent 12/713,547, 11 December 2012. [Google Scholar]

- NaturboTherm® Wall Heating. Available online: https://www.naturbo.co.uk/wall-heating-system (accessed on 7 April 2021).

- Schlüter®-KERDI-BOARD. Available online: https://www.kerdi-board.co.uk/ (accessed on 7 April 2021).

- Aabyaa® SNK 50 KIT. Available online: https://aabyaa.com/wp-content/uploads/2019/07/Manual-SNK50-KIT-AABYAA.pdf (accessed on 7 April 2021).

- The Gypsum Construction Handbook. 2009. Available online: http://www.macopa.com/sites/default/files/documentos-catalogos-manuales/2_gypsum_construction_handbook_usg_ingles.pdf (accessed on 7 April 2021).

- TOSCA. Available online: https://etsavupc.wixsite.com/tosca/2014-bcn (accessed on 7 April 2021).

- IMFA International Molded Fiber Association. Available online: https://www.imfa.org/ (accessed on 7 April 2021).

- Andrés, F.N.; Beltramini, L.B.; Guilarducci, A.G.; Romano, M.S.; Ulibarrie, Waste of Molded Pulp Industry. Filler Panel Production for Construction. In Proceedings of the International Congress of Science and Technology of Metallurgy and Materials, Puerto Iquazu, Argentina, 20–23 August 2013; pp. 824–830. [Google Scholar]

- Biprocel (Honext®). Available online: https://honextmaterial.com/material/ (accessed on 7 April 2021).

- Montero, A.; Zamora, J.L. Aplicaciones de MaterialesFibrososMoldeadosProcedentes de Reciclaje: Caso: TrasdosadosenRehabilitación de Edificios; TFMMáster de Tecnología de la Arquitectura (UPC): Barcelona, Spain, 2014; Available online: http://hdl.handle.net/2099.1/24537 (accessed on 7 April 2021).

- Schechter, A. Packing or Supporting Tray. U.S. Patent 3360150A, 26 December 1967. [Google Scholar]

- Grant, J.R. Egg Tray and Cover. U.S. Patent 2656945A, 27 October 1953. [Google Scholar]

| Strategies | Weaknesses | Strenuous | Threats | Opportunities |

|---|---|---|---|---|

| Wall chasing | Affects the basic performance of the wall (isolation, stability) | Produces noise, dust and waste, affects workers’ safety, and requires a great deal of time to do and undo activities | Very cheap | No need to forecast future needs |

| Surface technical channels | No flatness | Alters the visible architectural appearance | Easy handling | Available everywhere and with various kinds of accessories |

| Wall lining | Loss of habitable volume | More expensive | Not visible | Improves other aspects of wall performance: acoustic, fire, thermal, etc. |

| Cables | Comments |

|---|---|

| RZ1-K 0.6/1 kV, nominal sections of 1.5 and 2.5 mm2 | Reference standards:

|

| Effective voltage (U) of 1 kV for use in fixed installations | |

| Rated voltage 0.6/kV test voltage 3.5 kV C.A (5 min) | |

| Cross-linked polyethylene (XLPE) insulation, type DIX3 according to HD 603-1. Cover made of polyolefin PO | According to Annex 1, UNE 21123-4 |

| Minimum radius of curvature 4Ø if Ø ˂ 25 mm and 5Ø if 5 mm ≤ Ø ≤ 50 mm | The nominal section of 1.5 mm2 is suitable for the supply of 10 A consumer lighting; The nominal section of 2.5 mm2 is suitable for feeding bases between 16 and 20 A; The outer Ø of these nominal sections is 5.7 mm and 6.2 mm, which means that the most restrictive radius of curvature is 24.8 mm. |

| Electrolytically twisted flexible copper conductor class 5 according to UNE 21022/IEC 228 | It is substantially cheaper than using a “hose”. |

| Telephone conductors: cables of 1 pair EV 0.51 mm with an outer diameter of 3.7 mm are taken as a reference. | It is comparable to most drivers used in pre-existing telephone installations in the study area. |

| Data conductors of 6.1 mm outer diameter FTP Class D, Cat5e cables are taken as reference. | It is comparable to most of the conductors used in pre-existing telephone installations in the study area. |

| Coaxial 75 Ω, 6.6 mm outer diameter cables are taken as reference for television drivers. | It is comparable to most drivers used in pre-existing television installations in the study area. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serra-Fabregà, R.; Zamora-Mestre, J.-L. Preliminary Proposal for an Alternative Wall Lining Panel Based on Molded Recycled Cellulose and Designed for Home Wiring Refurbishment of Building Interior Partitions. Sustainability 2021, 13, 4643. https://doi.org/10.3390/su13094643

Serra-Fabregà R, Zamora-Mestre J-L. Preliminary Proposal for an Alternative Wall Lining Panel Based on Molded Recycled Cellulose and Designed for Home Wiring Refurbishment of Building Interior Partitions. Sustainability. 2021; 13(9):4643. https://doi.org/10.3390/su13094643

Chicago/Turabian StyleSerra-Fabregà, Raül, and Joan-Lluís Zamora-Mestre. 2021. "Preliminary Proposal for an Alternative Wall Lining Panel Based on Molded Recycled Cellulose and Designed for Home Wiring Refurbishment of Building Interior Partitions" Sustainability 13, no. 9: 4643. https://doi.org/10.3390/su13094643

APA StyleSerra-Fabregà, R., & Zamora-Mestre, J.-L. (2021). Preliminary Proposal for an Alternative Wall Lining Panel Based on Molded Recycled Cellulose and Designed for Home Wiring Refurbishment of Building Interior Partitions. Sustainability, 13(9), 4643. https://doi.org/10.3390/su13094643