Smart Green Prefabrication: Sustainability Performances of Industrialized Building Technologies

Abstract

:1. Introduction

- Predictability, because construction activities are led within a controlled environment where it is possible to carry out tight quality controls over prefabricated components;

- Time and cost reduction, because construction activities are no longer affected by external conditions (e.g., weather, site accessibility, etc.)

- Increased safety because workers carry out their activities in a safe and protected environment;

- Reduction of the impact of the construction site on the surrounding activities.

- COP21 Conference agreements (Paris Agreement, 2015) and the European Green Deal (2020) that addressed zeroing of emissions by 2050;

- Green Paper for Integrated Product Policy (COM (2001) 68) that aims to reduce the economic and environmental impact of buildings life-cycle;

- Industrial Strategy 2050 of the European Commission (COM (2020) 102) and the Horizon Europe Framework Program Pillar 2 (Cluster Digital, Industry and Space) to enhance the competitiveness of the prefabrication sector through digital transformation.

Research question (RQ)—Which product-process innovations in prefabricated buildings enhance sustainability?

- Analysis of 13 case studies of prefabricated building technologies in Europe;

- Evaluation and comparison of their performances according to sustainability qualitative parameters.

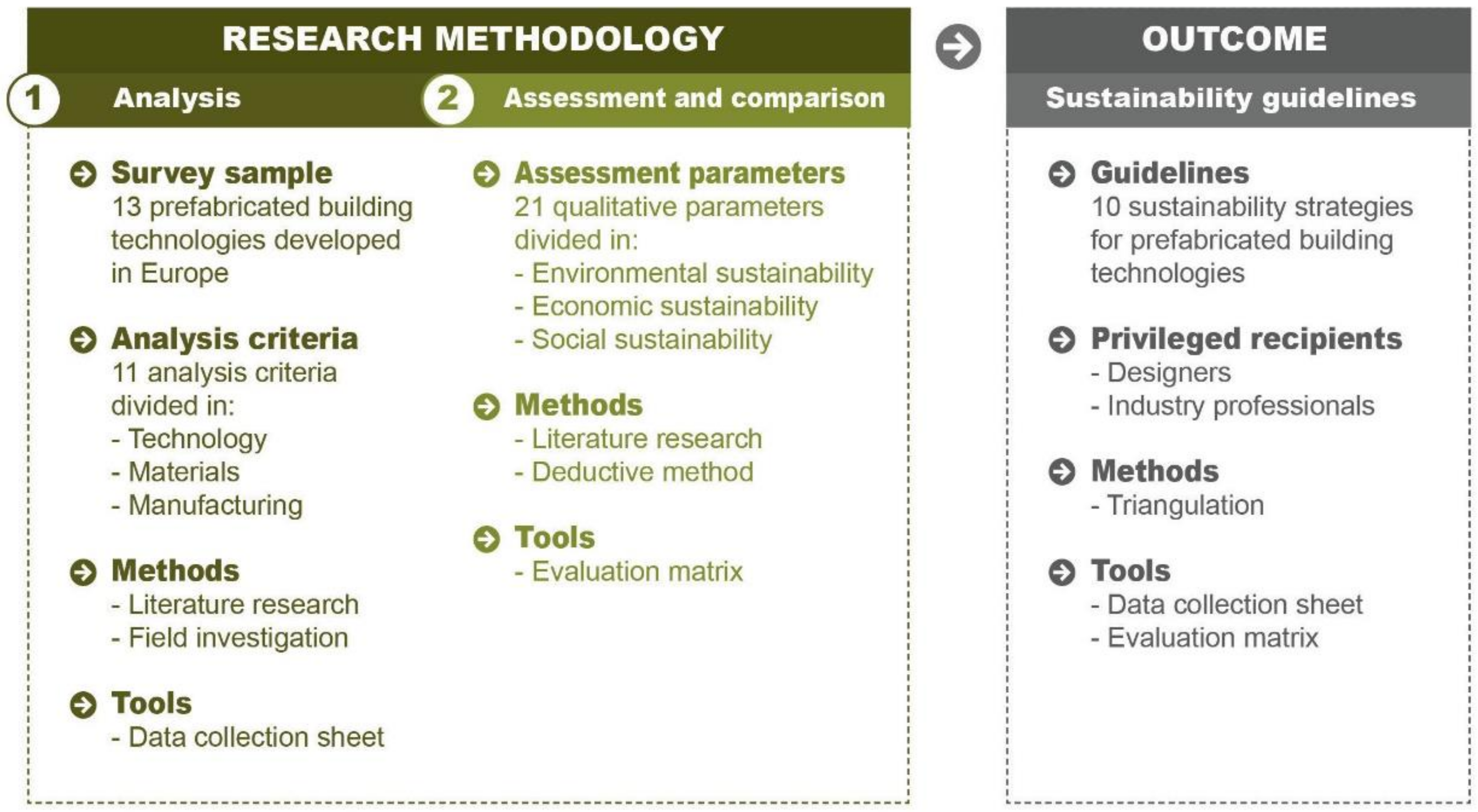

2. Materials and Methods

- Analysis of 13 prefabricated building processes of modular units and prefabricated panel systems developed in Europe. The analysis has been carried out through three subsequent phases, namely:

- 1.1.

- Definition of the investigation sample: the sample includes 13 prefabrication technologies, divided into three macro-categories according to the classification of the MHCLG Joint Industry Working Group (UK) [27]. The prefabrication technologies analyzed are listed in Table 1 and their description is provided in Appendix A;

- 1.2.

- Definition of analysis criteria and preparation of a data collection sheet. A total of 11 qualitative criteria have been identified (Table 2) and divided into three investigation categories:

- –

- Technology, referring to construction features of the building;

- –

- Materials, referring to the type of resources employed;

- –

- Manufacturing, concerning production techniques and methods.

Criteria selected for the analysis refer to common characteristics of prefabricated technologies, that is to say, they do not depend on specific organizations and/or commercial strategies adopted by manufacturers. To facilitate data systematization a synthetic filing sheet model has been developed; the sheet is structured in four sections according to the criteria categories that are being analyzed (Figure 2): (1) Overview, (2) Technology, (3) Materials, (4) Manufacturing. - 1.3.

- Data collection and filing: descriptive and qualitative data have been collected through bibliographic research—articles in scientific journals, manuals, and publications accessible in open repositories such as Scopus, Mendeley, Web of Science, and Google Scholar. References for each case study are collected in Table 1, column (c). Information collected through the bibliographic research has been integrated by the direct experience of the authors who acquired, in the field, supplementary information that was necessary to complete the survey.

- Assessment and comparison of 13 prefabricated technologies. The evaluation is developed according to 21 qualitative parameters of environmental, economic, and social sustainability (Table 3, column (b)). The parameters describe expected performances related to sustainability, i.e., product-process features that are proven to be directly linked to the achievement of sustainability goals (Table 3, column (a)) [3,22,25,28,29,30,31,32,33,34,35,36]. For each technology, the achievement of the identified parameters has been verified through an analytical comparison of information and data collected in Phase 1. Hence, the results of the evaluation are reported in a summary matrix (Table 4) and discussed in Section 3.

3. Results

- Environmental sustainability

- Material circularity:

- –

- SP. (01) Structural material can be recycled at the end of the building use without losing its performance.

- –

- SP. (02) Structural material supplied from recycled sources.

- –

- SP. (03) Building components or sub-components can be relocated after their use.

- Product-process predictability:

- –

- SP. (04) Possibility to perform tight quality controls over the final product.

- –

- SP. (05) Possibility to control the building process (times and costs certainty).

- Reduction of material wastes:

- –

- SP. (6) Optimization of orders.

- –

- SP. (7) Optimization of material use in the manufacturing process.

- Reduction of emissions:

- –

- SP. (8) Low energy demand and CO2 emissions from processing.

- –

- SP. (9) Structural material supplied from sustainably managed sources.

- –

- SP. (10) Widespread material availability.

- Economy

- Speed of construction:

- –

- SP. (11) Reduction of construction time compared to traditional buildings.

- Ease of construction:

- –

- SP. (12) Building components can be easily handled and installed by workers without using crane equipment.

- –

- SP. (13) Stocking and installation of components do not require specific site protection measures against weather.

- Economy of construction:

- –

- SP. (14) Building components are optimized for transport.

- Society

- Product-process adaptability

- –

- SP. (15) Technology can be easily integrated with other building systems and components.

- –

- SP. (16) Technology ensure space flexibility (variable space configuration, adaptation to specific design program).

- –

- SP. (17) Components can be integrated and/or modified after manufacturing.

- –

- SP. (18) Components can be removed and/or to accommodate further changes in the space program.

- –

- SP. (19) Flexible manufacturing, i.e., changes in the building product requires minimum changes in the production chain.

- Work safety and health

- –

- SP. (20) Manufacture processing requires minimum interaction with workers (limited to machine setting and control).

- Inclusion and collaboration

- –

- SP. (21) Design adopts an “open system” approach to ensure customization and integration of different specifications (structural, energetic, costs, etc.).

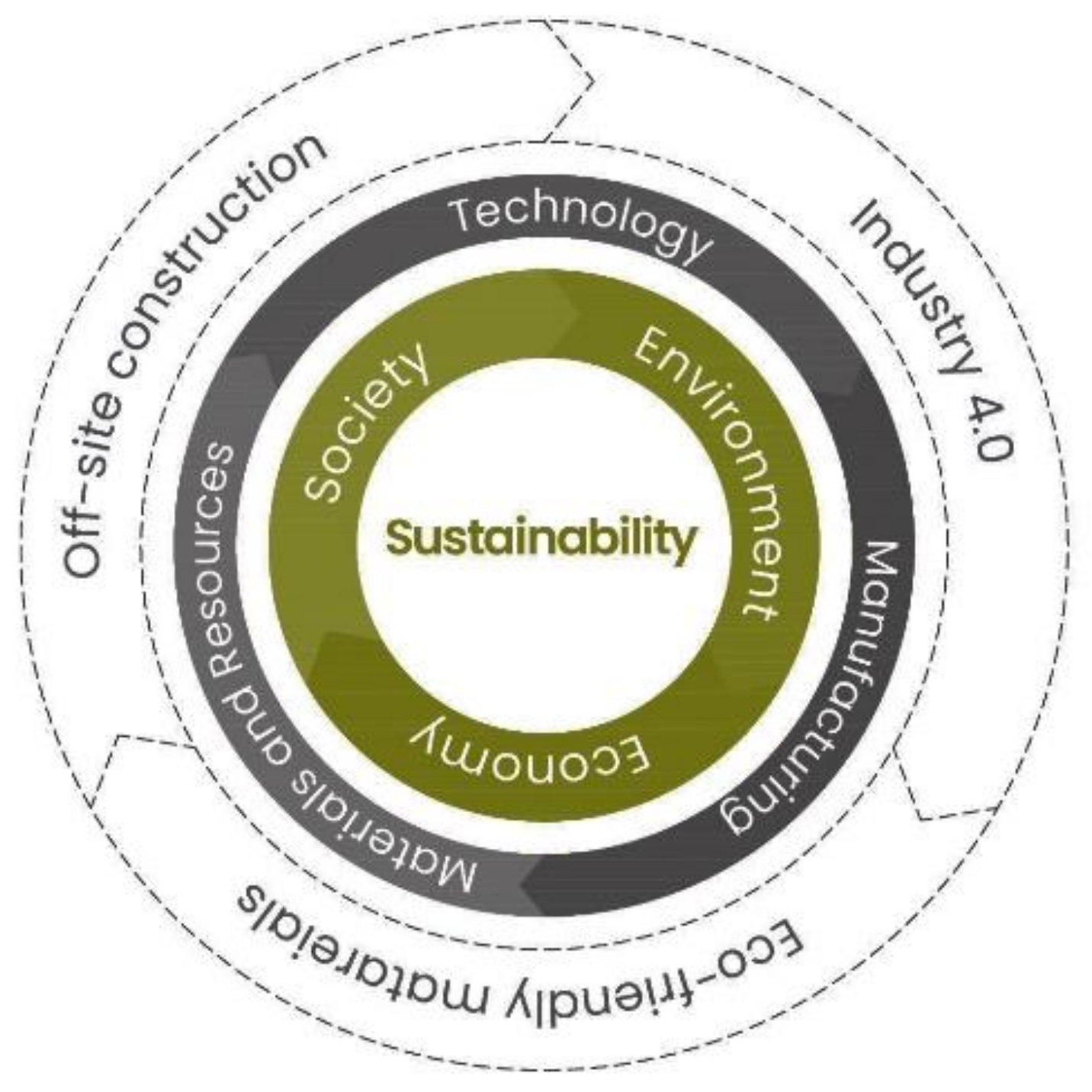

4. Discussion

- S.1—Material and technology

- S.2—Assembly and construction

- S.3—Transport

- S.4—Industrialized manufacturing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

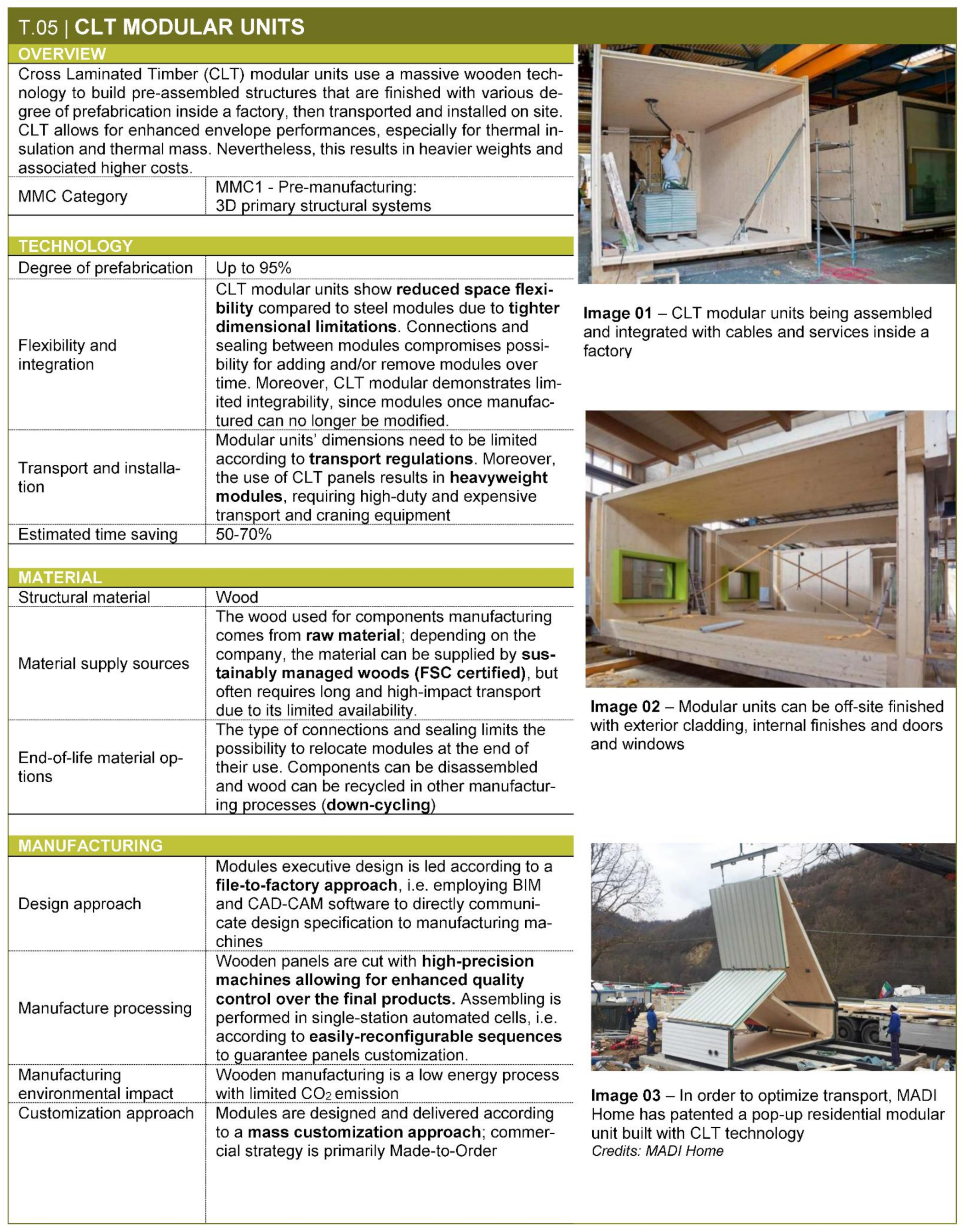

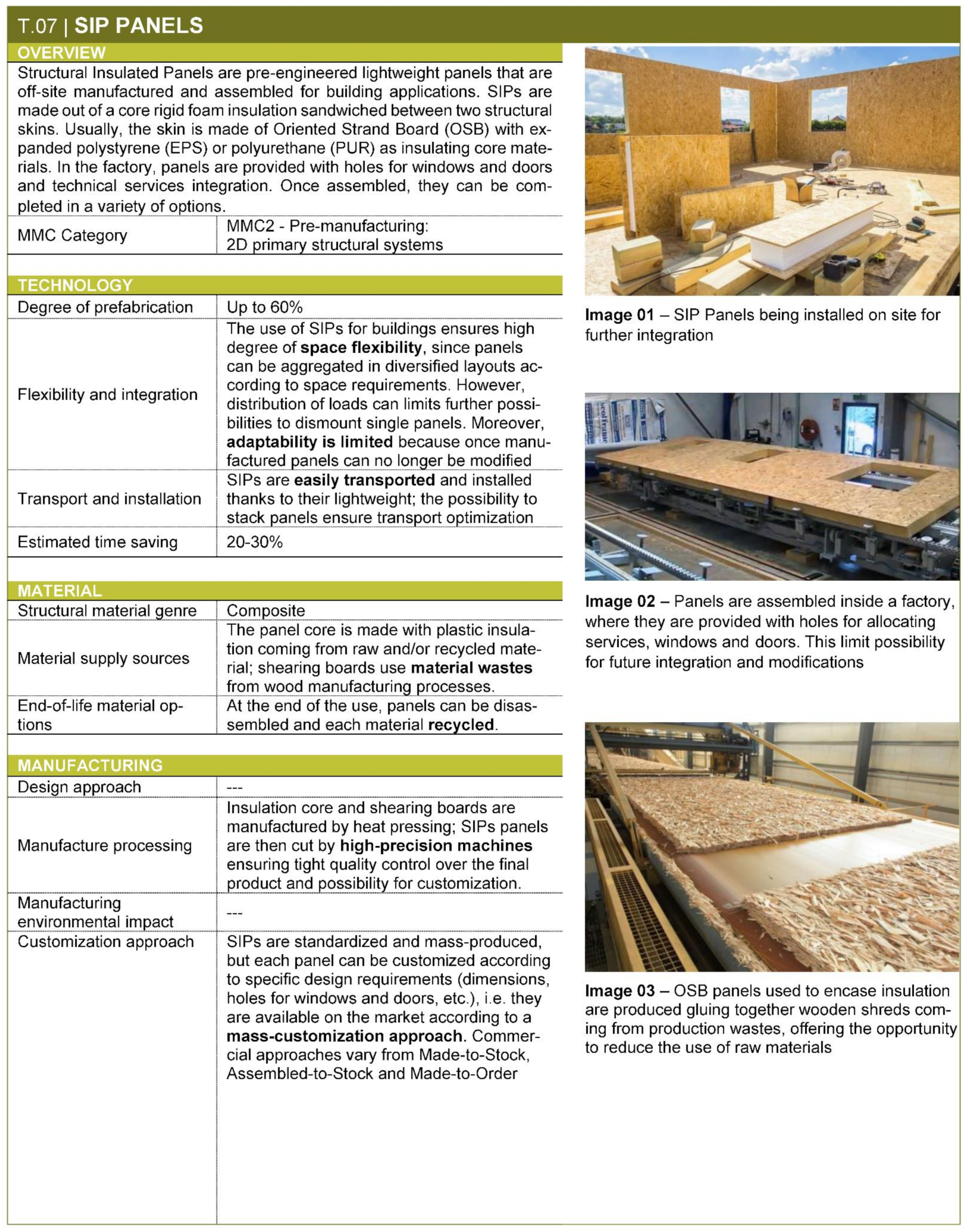

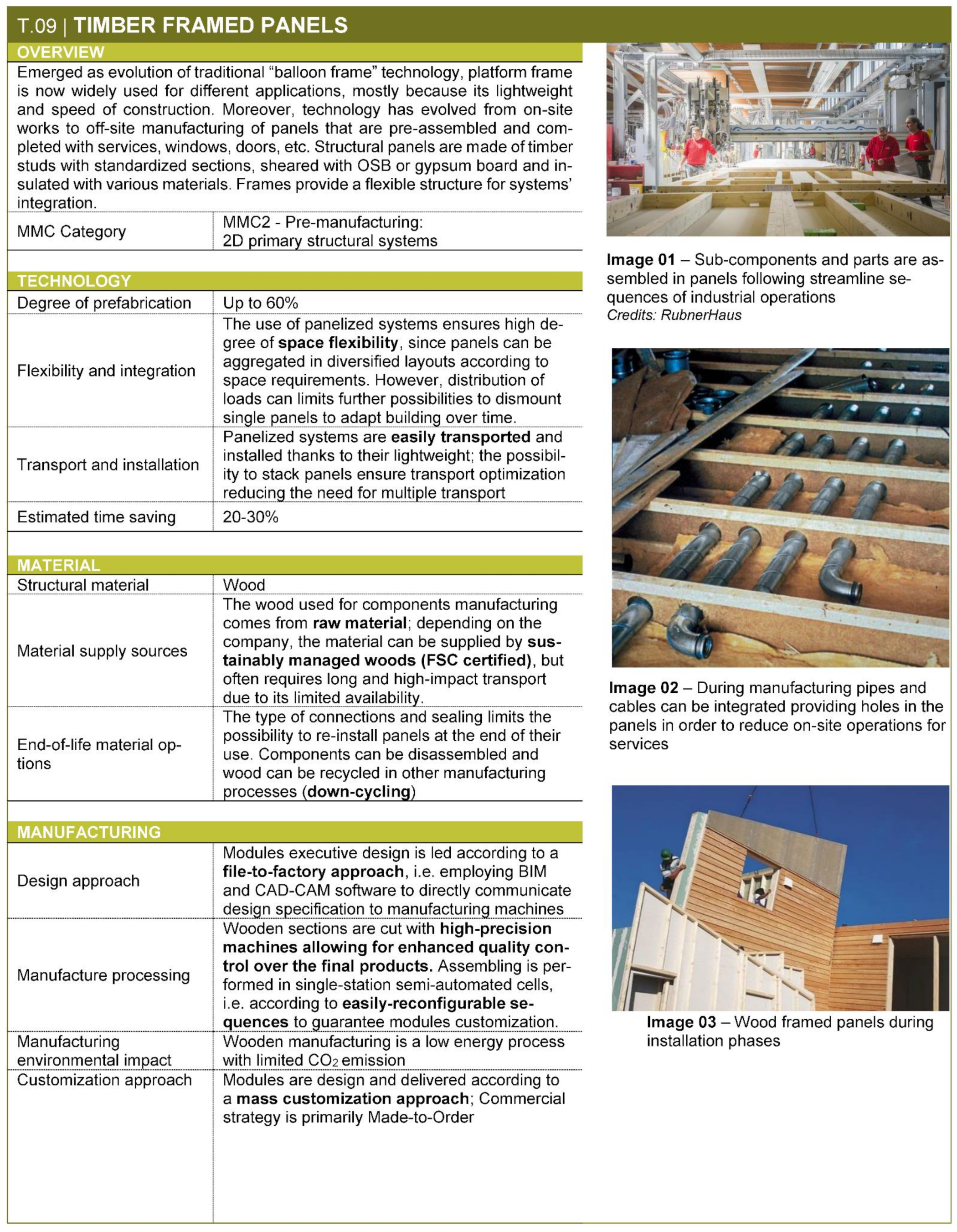

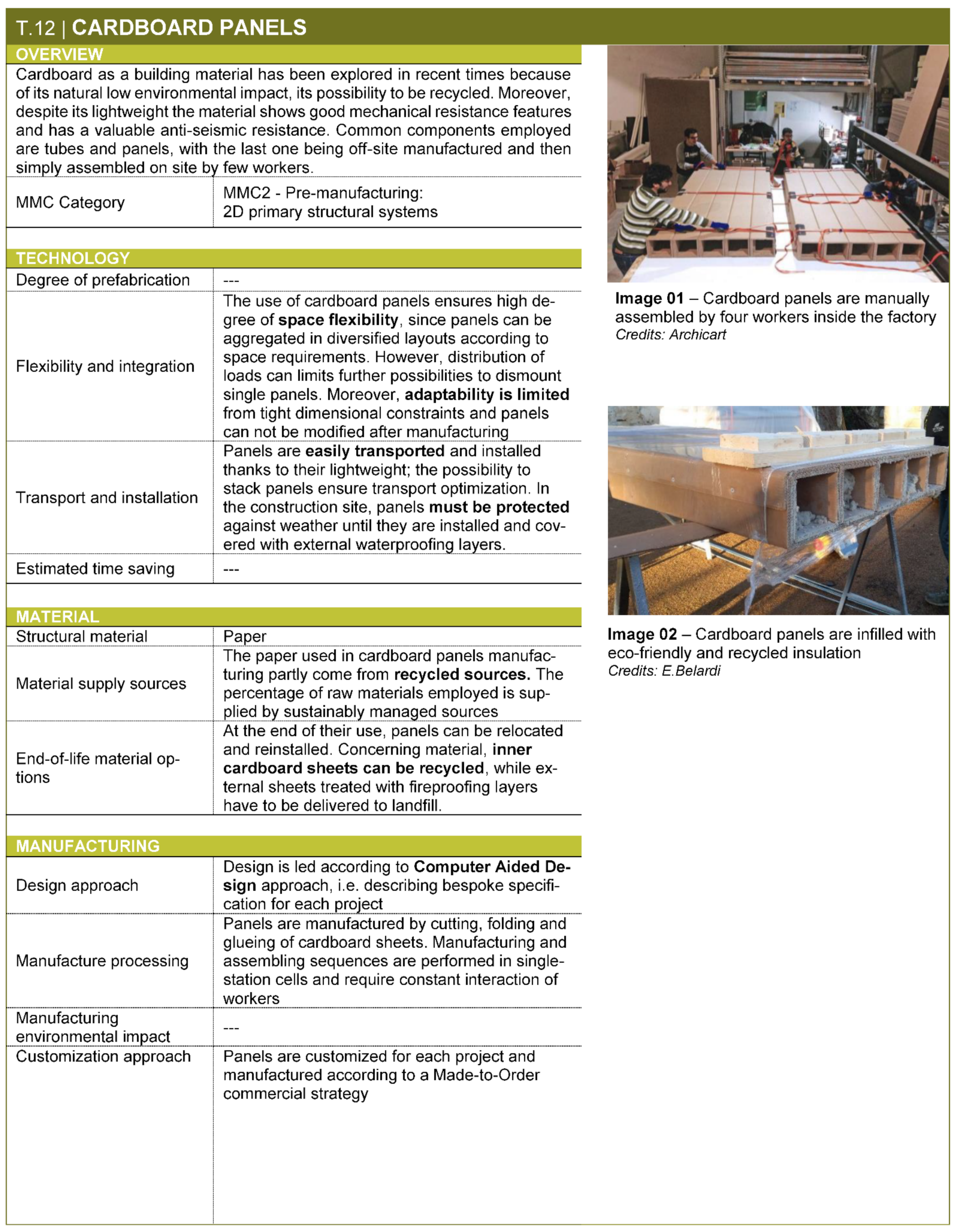

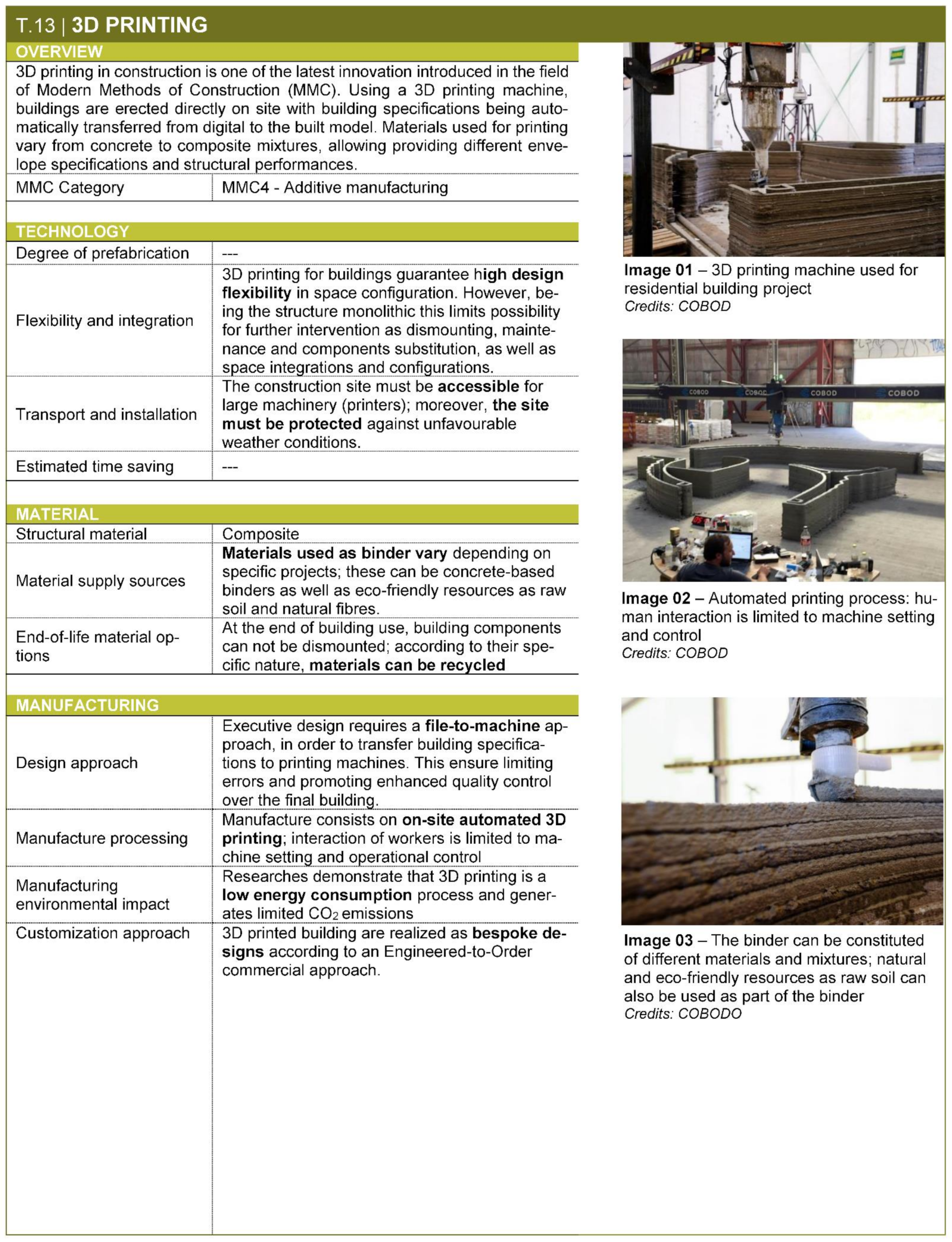

Appendix A. Analysis of Prefabricated Building Technologies: Reading Sheets

References

- Mapston, M.; Westbrook, C. Prefabricated building units and modern methods of construction (MMC). Mater. Energy Effic. Therm. Comf. Build. 2010, 427–454. [Google Scholar] [CrossRef]

- Arif, M.; Egbu, C. Making a case for offsite construction in China. Eng. Constr. Arch. Manag. 2010, 17, 536–548. [Google Scholar] [CrossRef]

- Krug, D.; Miles, J. Off-Site Construction: Sustainability Characteristics. 2013. Available online: https://www.buildoffsite.com/content/uploads/2015/03/BoS_offsiteconstruction_1307091.pdf (accessed on 5 January 2021).

- Jansen van Vuuren, T.; Middleton, C. Methodology for Quantifying the Benefits of Offsite Construction. Buildoffsite, CIRIA. 2020. Available online: https://www.ciria.org/ItemDetail?iProductCode=C792F&Category=FREEPUBS&WebsiteKey=3f18c87a-d62b-4eca-8ef4-9b09309c1c91 (accessed on 5 January 2021).

- Cuadrado, J.; Zubizarreta, M.; Rojí, E.; Larrauri, M.; Álvarez, I.; Chandro, E.R. Sustainability assessment methodology for industrial buildings: Three case studies. Civ. Eng. Environ. Syst. 2016, 33, 106–124. [Google Scholar] [CrossRef]

- IEA. Transition to Sustainable Buildings. 2013. Available online: https://webstore.iea.org/download/direct/745 (accessed on 5 January 2021).

- IEA. 2019 Global Status Report for Buildings and Construction. 2019. 224. Available online: https://www.iea.org/reports/global-status-report-for-buildings-and-construction-2019 (accessed on 5 January 2021).

- Directive 2010/31/EU of the European Parliament and the Council of 19 May 2010 on the Energy Performance of Buildings. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32010L0031&from=EN (accessed on 5 January 2021).

- ISPRA. Fattori Di Emissione Atmosferica Di CO2 e Altri Gas a Effetto Serra Nel Settore Elettrico. 2017. Available online: https://www.isprambiente.gov.it/files2017/pubblicazioni/rapporto/R_257_17.pdf (accessed on 5 January 2021).

- Abanda, F.; Tah, J.; Cheung, F. BIM in off-site manufacturing for buildings. J. Build. Eng. 2017, 14, 89–102. [Google Scholar] [CrossRef] [Green Version]

- Mc Kinsey. Global, Imagining Construction’s Digital Future. 2016. Available online: https://www.mckinsey.com/business-functions/operations/our-insights/imagining-constructions-digital-future (accessed on 5 January 2021).

- Osservatorio Sicurezza sul Lavoro di VEGA Engineering. Elaborazione Statistica degli Infortuni Mortali sul Lavoro. Base dati INAIL. 2019. Available online: https://www.vegaengineering.com/dati-osservatorio/allegati/Statistiche-Morti-Lavoro-Osservatorio-Sicurezza-Lavoro-Vega-Engineering-31-10-20.pdf (accessed on 5 January 2021).

- Schwatka, N.V.; Butler, L.M.; Rosecrance, J.R. An Aging Workforce and Injury in the Construction Industry. Epidemiol. Rev. 2012, 34, 156–167. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kagermann, H.; Wahlster, W.; Helbig, J. Securing the Future of German Manufacturing Industry: Recommendations for Imple-menting the Strategic Initiative INDUSTRIE 4.0. 2013. Available online: https://www.din.de/blob/76902/e8cac883f42bf28536e7e8165993f1fd/recommendations-for-implementing-industry-4-0-data.pdf (accessed on 5 January 2021).

- Qin, J.; Liu, Y.; Grosvenor, R. A Categorical Framework of Manufacturing for Industry 4.0 and Beyond. Procedia CIRP 2016, 52, 173–178. [Google Scholar] [CrossRef] [Green Version]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J. Construction 4.0: A Literature Review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- You, Z.; Feng, L. Integration of Industry 4.0 Related Technologies in Construction Industry: A Framework of Cyber-Physical System. IEEE Access 2020, 8, 122908–122922. [Google Scholar] [CrossRef]

- Newman, C.; Edwards, D.; Martek, I.; Lai, J.; Thwala, W.D.; Rillie, I. Industry 4.0 deployment in the construction industry: A bibliometric literature review and UK-based case study. Smart Sustain. Built Environ. 2020. [Google Scholar] [CrossRef]

- Rivera, F.M.-L.; Mora-Serrano, J.; Valero, I.; Oñate, E. Methodological-Technological Framework for Construction 4.0. Arch. Comput. Methods Eng. 2020. [Google Scholar] [CrossRef]

- Tezel, A.; Taggart, M.; Koskela, L.; Tzortzopoulos, P.; Hanahoe, J.; Kelly, M. Lean Construction and BIM in Small and Medium-Sized Enterprises (SMEs) in Construction: A Systematic Literature Review. Can. J. Civ. Eng. 2019, 47, 186–201. [Google Scholar] [CrossRef]

- Ejsmont, K.; Gladysz, B.; Kluczek, A. Impact of Industry 4.0 on Sustainability—Bibliometric Literature Review. Sustainability 2020, 12, 5650. [Google Scholar] [CrossRef]

- Giglio, F. Low Tech and unconventional materials. Measure, Time, Place. Techne 2018, 16, 122–130. [Google Scholar] [CrossRef]

- Setyowati, E.; Pandelaki, E.E. The concept of sustainable prefab modular housing made of natural fiber reinforced polymer (NFRP). IOP Conf. Ser. Mater. Sci. Eng. 2018, 316. [Google Scholar] [CrossRef]

- Barreca, F.; Tirella, V. A self-built shelter in wood and agglomerated cork panels for temporary use in Mediterranean climate areas. Energy Build. 2017, 142, 1–7. [Google Scholar] [CrossRef]

- Distefano, D.; Gagliano, A.; Naboni, E.; Sapienza, V.; Timpanaro, N. Thermophysical characterization of a cardboard emergency kit-house. Math. Model. Eng. Probl. 2018, 5, 168–174. [Google Scholar] [CrossRef] [Green Version]

- MHCLG. Joint Industry Working Group on MMC. Modern Methods of Construction. Introducing the MMC Definition Framework. 2019. Available online: http://www.cast-consultancy.com/wp-content/uploads/2019/03/MMC-I-Pad-base_GOVUK-FINAL_SECURE.pdf (accessed on 5 January 2021).

- Jensen, K.; Nielsen, K.; Brunoe, T. Application of Mass Customization in the Construction Industry. In Proceedings of the IFIP International Conference on Advances in Production Management Systems (APMS), Tokyo, Japan, 7–9 September 2015; pp. 161–168. [Google Scholar]

- Jiang, Y.; Zhao, D.; Wang, D.; Xing, Y. Sustainable Performance of Buildings through Modular Prefabrication in the Construction Phase: A Comparative Study. Sustainability 2019, 11, 5658. [Google Scholar] [CrossRef] [Green Version]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Generalova, E.M.; Generalov, V.P.; Kuznetsova, A.A. Modular Buildings in Modern Construction. Procedia Eng. 2016, 153, 167–172. [Google Scholar] [CrossRef] [Green Version]

- Musa, M.F.; Mohammad, M.F.; Mahbub, R.; Yusof, M.R. Enhancing the Quality of Life by Adopting Sustainable Modular Industrialised Building System (IBS) in the Malaysian Construction Industry. Procedia Soc. Behav. Sci. 2014, 153, 79–89. [Google Scholar] [CrossRef] [Green Version]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef] [Green Version]

- Soriano, B.S.; Gimeno, P.V.; Segura, A.D.; De La Maza, R.M. Assembling sustainable ideas: The construction process of the proposal SMLsystem at the Solar Decathlon Europe 2012. Energy Build. 2014, 83, 186–194. [Google Scholar] [CrossRef]

- Boafo, F.E.; Kim, J.-H.; Kim, J.-T. Performance of Modular Prefabricated Architecture: Case Study-Based Review and Future Pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef] [Green Version]

- Pons, O. Assessing the sustainability of prefabricated buildings. In Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Elsevier: Amsterdam, The Netherlands, 2013; pp. 434–456. [Google Scholar] [CrossRef]

- Knaack, U.; Chung-Klatte, S.; Hasselbach, R. Prefabricated Systems. In Principles of Construction; Birkhauser: Cham, Switzerland, 2012. [Google Scholar]

- Shen, J.; Copertaro, B.; Zhang, X.; Koke, J.; Kaufmann, P.; Krause, S. Exploring the Potential of Climate-Adaptive Container Building Design under Future Climates Scenarios in Three Different Climate Zones. Sustainability 2019, 12, 108. [Google Scholar] [CrossRef] [Green Version]

- Dara, C.; Hachem-Vermette, C.; Assefa, G. Life cycle assessment and life cycle costing of container-based single-family housing in Canada: A case study. Build. Environ. 2019, 163, 163. [Google Scholar] [CrossRef]

- Smith, R.S. Prefab Architecture. In A Guide to Modular Design and Construction; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Ermolli, S.R.; Galluccio, G. Industrializzazione edilizia e prefabbricazione tra materialità e immaterialità. AGATHÓN Int. J. Archit. Art Des. 2019, 5, 93–100. [Google Scholar] [CrossRef]

- Staib, G.; Dörrhöfer, A.; Rosenthal, M. Components and Systems. In Modular Construction. Design, Structure, New Technologies; Detail: Munchen, Germany, 2007. [Google Scholar]

- Tavares, V.; Lacerda, N.; Freire, F. Embodied energy and greenhouse gas emissions analysis of a prefabricated modular house: The “Moby” case study. J. Clean. Prod. 2019, 212, 1044–1053. [Google Scholar] [CrossRef]

- Lawson, M.; Ogden, R.; Goodier, C. Design in Modular Construction; Group T&F: Abingdon, UK, 2014. [Google Scholar]

- Structural Insulated Panel Association. Available online: https://www.sips.org/ (accessed on 5 January 2021).

- Lehmann, S. Low carbon construction systems using prefabricated engineered solid wood panels for urban infill to significantly reduce greenhouse gas emissions. Sustain. Cities Soc. 2013, 6, 57–67. [Google Scholar] [CrossRef]

- Distefano, D.L. Prefab Lightness. Cardboard Architecture Responds to Emergency. Design, Prototyping and Testing of a High Performance Emrgency House-Kit. Ph.D. Thesis, University of Catania, Catania, Italy, July 2019. [Google Scholar]

- Eekhout, M. Cardboard in Architecture, Research. In Architectural Engineering Series; IOS Press: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Perrot, A. 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction Revolution; Wiley: Hoboken, NJ, USA, 2019. [Google Scholar]

- Sanjan, J.G.; Nazari, A.; Nematollahi, B. 3D Concrete Printing Technology: Construction and Building Applications; Butterworth-Heinemann Elsevier: Oxford, UK, 2019. [Google Scholar]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef] [Green Version]

| MMC Category (a) [27] | Prefabrication Technologies (b) | References (c) |

|---|---|---|

| MMC Category 1: Pre-manufacturing, 3D primary structural systems A systemized approach based on volumetric construction involving the production of three-dimensional units in controlled factory conditions before final installation. Volumetric units can be brought to the final site in a variety of forms ranging from a basic structure only to a structure with all internal and external finishes and services installed, all ready for installation | T.01—Portable buildings | [1,37] |

| T.02—ISO Shipping containers | [38,39] | |

| T.03—Light gauge steel modular units | [40,41,42,43] | |

| T.04—Timber-framed modular units | [40,42,43] | |

| T.05—CLT modular unit | [40,42,43] | |

| T.06—Concrete modular units | [40,43,44] | |

| MMC Category 2: Pre-manufacturing, 2D primary structural systems A systemized approach using flat-panel units used for basic floor, wall, and roof structures of varying materials which are produced in a factory environment and assembled at the final workforce to produce a final three-dimensional structure | T.07—SIP panels | [40,45] |

| T.08—Lightgauge steel panels | [37,40,41] | |

| T.09—Timber-framed panels | [37,40,42] | |

| T.10—CLT panels | [37,40,42,46] | |

| T.11—Precast concrete panels | [37,40] | |

| T.12—Cardboard panels | [26,47,48] | |

| MMC Category 4: Additive manufacturing, structural and non-structural The remote, site-based, or final workforce-based printing of parts of buildings through various materials based on digital design and manufacturing techniques (The category MMC 4—Additive manufacturing is not directly applicable to the concept of prefabrication, as it does not imply the assembly of components inside a factory. Nonetheless, for this work the technology T.13—3D printing is analyzed because the scientific literature promotes additive manufacturing as one of the ‘enabling technologies’ (Key Enabling Technologies, KETs) for industry 4.0 [15].) | T.13—3D printing | [49,50,51] |

| Analysis Criteria (a) | Criteria Description (b) | |

|---|---|---|

| Technology | Degree of prefabrication | Describes the maximum degree of prefabrication of the building components, (i.e., the percentage of completion of the work inside the factory evaluated compared to the final building |

| Flexibility and integration | Analyzes flexibility features of the technological system (i.e., the capability to be integrated with technical systems and/or other technologies and to be adapted during the time: additions, selective demolitions, replacement, etc.) | |

| Transport and installation | Analyzes the technological features related to the transport and installation of building components and parts, that is to say, the prefabrication strategies adopted to reduce transport and installation costs, identifying critical areas | |

| Estimated time saving | Describes the expected percentage of time construction saving compared to the use of traditional construction techniques | |

| Materials | Structural material | Identifies the structural material employed |

| Material supply sources | Analyzes the material supply sources highlighting the use of recycled materials and/or reused components as well as the supply sources management | |

| End-of-life options | Examines the possibility for reuse and/or re-emission of components and/or materials in the same building cycle or other production processes | |

| Manufacturing | Design approach | Describes the methodological approach and operational strategies adopted for design and manufacturing management |

| Manufacture processing | Analyzes the type of processes and equipment used for sub-components and/or components manufacturing and their assembly as well as the productive chain organization | |

| Manufacturing environmental impact | Describes the environmental impact of manufacturing processing regarding energy demand and pollutant emission generated | |

| Customization approach | Describes the approach underlying the product-process regarding the possibility to customize products (i.e., the degree of flexibility of the product-process compared to the need for personalization), as well as the commercial approach and the level of standardization of components (market offer) | |

| Sustainability Goals (a) | Sustainability Parameters (b) | |

|---|---|---|

| Environment | Material circularity | SP. (1) Structural material can be recycled at the end of the building use without losing its performance |

| SP. (2) Structural material supplied from recycled sources | ||

| Building component circularity | SP. (3) Building components or sub-components can be relocated after their use | |

| Product-process predictability | SP. (4) Possibility to perform tight quality controls over the final product | |

| SP. (5) Possibility to control the building process (times and costs certainty) | ||

| Reduction of material wastes | SP. (6) Optimization of material orders | |

| SP. (7) Optimization of material use in the manufacturing process | ||

| Reduction of emissions | SP. (8) Low energy demand and CO2 emissions from processing | |

| SP. (9) Structural material supplied from sustainably managed sources | ||

| SP. (10) Widespread material availability | ||

| Economy | Speed of construction | SP. (11) Reduction of construction time compared to traditional buildings |

| Ease of construction | SP. (12) Building components can be easily handled and installed by workers without using crane equipment | |

| SP. (13) Stocking and installation of components do not require specific site protection measures against weather | ||

| Economy of construction | SP. (14) Building components are optimized for transport | |

| Society | Product-process adaptability | SP. (15) Technology can be easily integrated with other building systems and components |

| SP. (16) Technology ensures space flexibility (variable space configuration, adaptation to specific design program) | ||

| SP. (17) Components can be integrated and/or modified after manufacturing | ||

| SP. (18) Components can be removed and/or to accommodate further changes in the space program | ||

| SP. (19) Flexible manufacturing, i.e., changes in the building product requires minimum changes in the production chain | ||

| Work safety and health | SP. (20) Manufacture processing requires minimum interaction with workers (limited to machine setting and control) | |

| Inclusion and collaboration | SP. (21) Design adopts an “open system” approach to ensure customization and integration of different specifications (structural, energetic, costs, etc.) | |

| Sustainability Goals (a) | Sustainability Parameters (b) | Prefabricated Technologies (Case Studies) (c) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MMC Category 1 | MMC Category 2 | MMC Cat. 4 | |||||||||||||

| T.01 | T.02 | T.03 | T.04 | T.05 | T.06 | T.07 | T.08 | T.09 | T.10 | T.11 | T.12 | T.13 | |||

| Environment | Material circularity | SP. (1) Structural material can be recycled at the end of the building use without losing its performance | • | • | • | • | • | • | • | ||||||

| SP. (2) Structural material supplied from recycled sources | • | • | • | • | • | • | • | • | • | ||||||

| Building component circularity | SP. (3) Building components or sub-components can be relocated after their use | • | • | • | • | • | • | ||||||||

| Product-process predictability | SP. (4) Possibility to perform tight quality controls over the final product | • | • | • | • | • | • | • | • | • | • | • | |||

| SP. (5) Possibility to control the building process (times and costs certainty) | • | • | • | • | • | • | • | • | • | ||||||

| Reduction of material wastes | SP. (6) Optimization of orders | • | • | • | • | • | • | • | • | • | • | ||||

| SP. (7) Optimization of material use in the manufacturing process | • | • | • | • | • | ||||||||||

| Reduction of emissions | SP. (8) Low energy demand and CO2 emissions from processing | • | • | • | • | • | • | ||||||||

| SP. (9) Structural material supplied from sustainably managed sources | • | • | • | • | • | • | |||||||||

| SP. (10) Widespread material availability | • | • | • | • | • | • | • | • | • | ||||||

| Economy | Speed of construction | SP. (11) Reduction of construction time compared to traditional buildings | • | • | • | • | • | • | • | • | • | • | • | • | |

| Ease of construction | SP. (12) Building components can be easily handled and installed by workers without using crane equipment | • | • | • | |||||||||||

| SP. (13) Stocking and installation of components do not require specific site protection measures against weather | • | • | • | • | • | • | |||||||||

| Economy of construction | SP. (14) Building components are optimized for transport | • | • | • | • | ||||||||||

| Society | Product-process adaptability | SP. (15) Technology can be easily integrated with other building systems and components | • | • | • | • | • | ||||||||

| SP. (16) Technology ensures space flexibility (variable space configuration, adaptation to specific design program) | • | • | • | • | • | • | |||||||||

| SP. (17) Components can be integrated and/or modified after manufacturing | • | • | • | • | • | • | |||||||||

| SP. (18) Components can be removed and/or to accommodate further changes in the space program | • | • | • | • | • | ||||||||||

| SP. (19) Flexible manufacturing, i.e. changes in the building product requires minimum changes in the production chain | • | • | • | • | • | • | • | • | • | ||||||

| Work safety and health | SP. (20) Manufacture processing requires minimum interaction with workers (limited to machine setting and control) | • | • | • | |||||||||||

| Inclusion and collaboration | SP. (21) Design adopts an “open system” approach to ensure customization and integration of different specifications (structural, energetic, costs, etc.) | • | • | • | • | • | • | • | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallo, P.; Romano, R.; Belardi, E. Smart Green Prefabrication: Sustainability Performances of Industrialized Building Technologies. Sustainability 2021, 13, 4701. https://doi.org/10.3390/su13094701

Gallo P, Romano R, Belardi E. Smart Green Prefabrication: Sustainability Performances of Industrialized Building Technologies. Sustainability. 2021; 13(9):4701. https://doi.org/10.3390/su13094701

Chicago/Turabian StyleGallo, Paola, Rosa Romano, and Elisa Belardi. 2021. "Smart Green Prefabrication: Sustainability Performances of Industrialized Building Technologies" Sustainability 13, no. 9: 4701. https://doi.org/10.3390/su13094701

APA StyleGallo, P., Romano, R., & Belardi, E. (2021). Smart Green Prefabrication: Sustainability Performances of Industrialized Building Technologies. Sustainability, 13(9), 4701. https://doi.org/10.3390/su13094701