Battery Electric Bus Network: Efficient Design and Cost Comparison of Different Powertrains

Abstract

:1. Introduction

2. Materials and Methods

2.1. Methodology

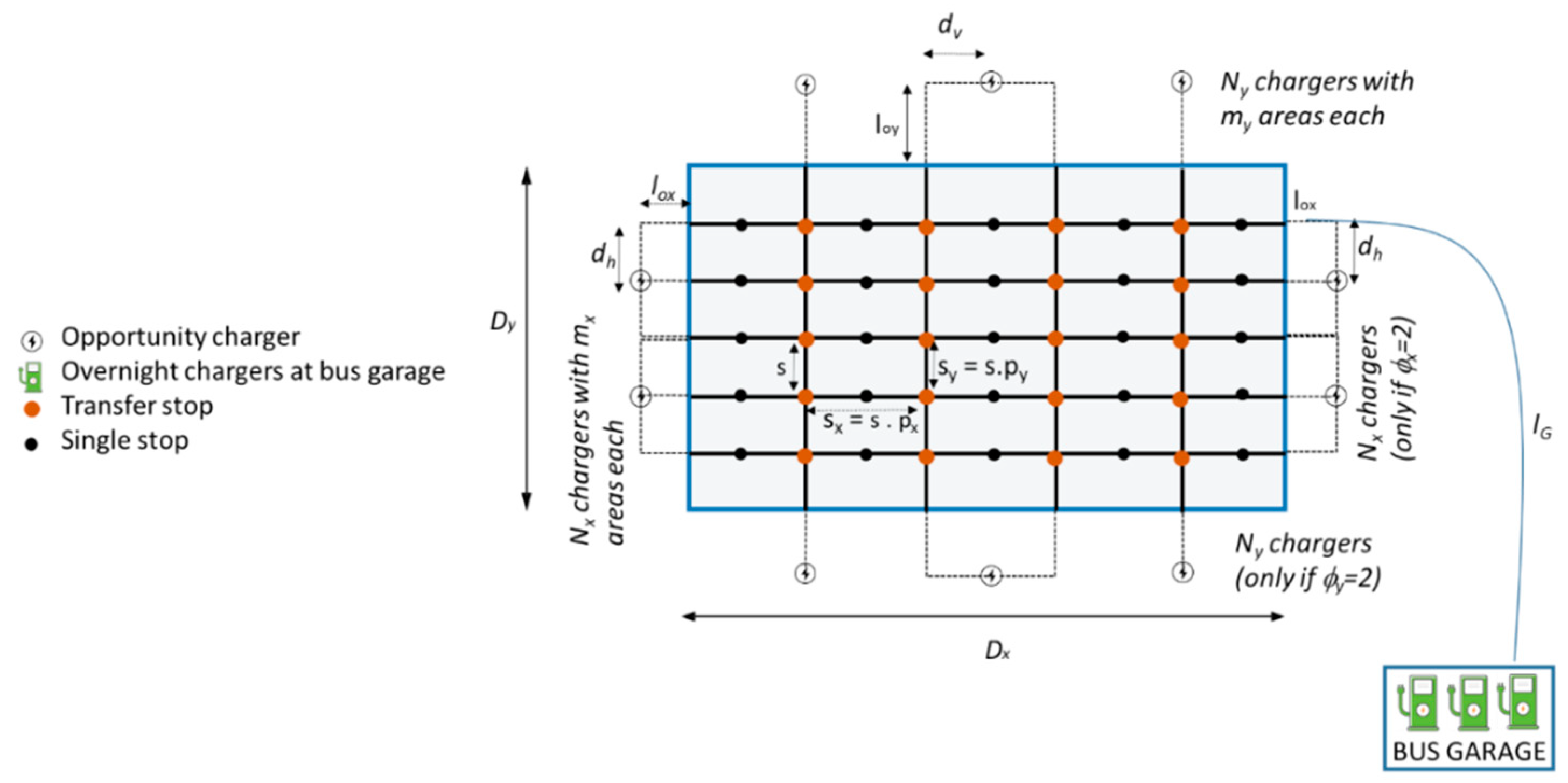

- Street network and bus corridor structure: It was assumed that buses follow a perfect grid configuration. Another assumption is that the city is covered by orthogonal bus corridors, traveling in the west–east and north–south axis and operated in two directions of service (see Figure 1). The headways of the corridors running along the horizontal and vertical directions (x and y axes) are denoted by Hx and Hy respectively. Moreover, the route spacing between the vertical or horizontal lines are respectively sx = px·s and sy = py·s, where s is the stop spacing and px, py two integer variables. Finally, there is a transfer stop at each intersection between vertical and horizontal routes. Hence, users can move in the network from any point to any other point with one transfer.

- User behavior and service characteristics: The network is designed to minimize the total cost at the peak hour, serving a total of Λ passengers with origins and destinations uniformly distributed in the service area Dx and Dy (in Estrada [25] it is stated that the agreement between the cost and performance estimations of continuous approximation models with OD simulation techniques is within 85%). However, the bus service will also be provided during Ω hours along the day, with an average hourly demand λ(pax/h). The door-to-door travel time of users integrates: the access and egress time spent at a vw walking speed to/from the closest stop, waiting time at stops, riding time and the transfer time to overcome the distance δ between the loading platforms of orthogonal routes.

- Kinematic characteristics of buses: The maximal cruising speed on both horizontal and vertical lines is assumed to be identical and equal to v. Boarding and alighting time per passenger at stops is τ’. On the other hand, vehicles have a constant acceleration rate a and a maximal instantaneous speed of vmax. Therefore, the additional driving time to perform one stop with regard to one vehicle cruising at maximal speed (without stopping) is τ = vmax/a.

- Vehicle powertrains and energy provision: It was assumed that ICE-powered buses (diesel) or battery electric buses (BEB) would operate the service. In the case of diesel vehicles, the auxiliary facility to provide energy will be a set of fuel dispensers (fuel station) to be located in the bus garage.

2.2. Materials

- C-12. Standard bus with diesel engine (12 m long, conventional environmental label);

- C-18. Articulated bus with diesel engine (18 m long, conventional environmental label);

- EuroVI-12. Standard bus with diesel engine (12 m long, Euro VI environmental label);

- EuroVI-18. Articulated bus with diesel engine (18 m long, Euro VI environmental label);

- BEB-12 Ov. Standard battery-electric bus with overnight charging (12 m long);

- BEB-12 Opp. Standard battery-electric bus with opportunity charging (12 m long);

- BEB-12 Day. Standard battery-electric bus with charging at the bus garage during service (12 m long);

- BEB-18. Articulated battery-electric bus with opportunity charging (18 m long).

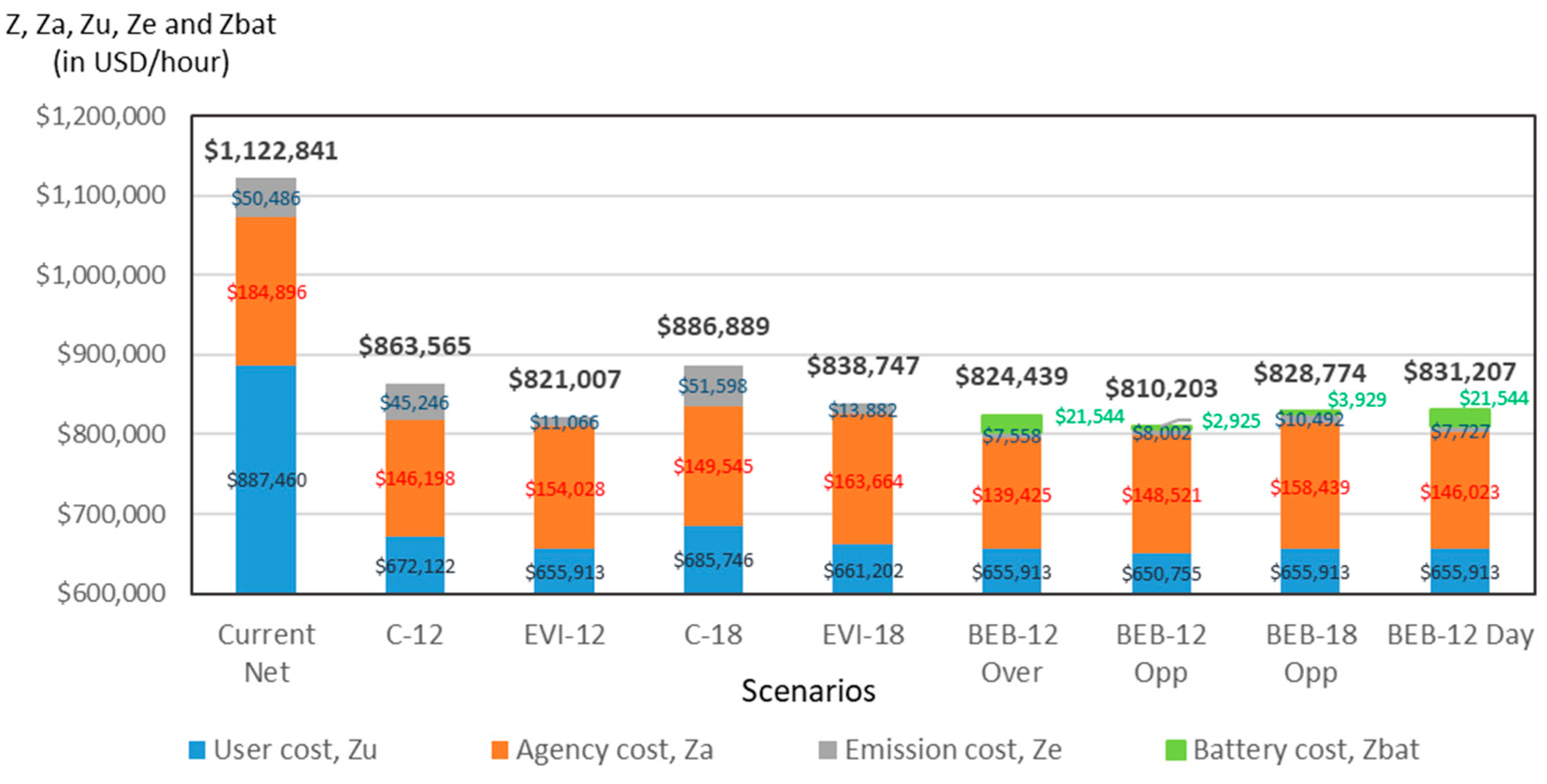

3. Results

3.1. Sensitivity Analysis

3.1.1. Hourly Demand

3.1.2. City Size

3.1.3. Electric Vehicle and Charging Infrastructure Costs

4. Discussions

4.1. Discussion of the Performance Metrics

4.2. Discusion of the Sensitivity Analysis

4.2.1. Discussion of Sensitivity Analysis of Hourly Demand

4.2.2. Discussion of Sensitivity Analysis of City Size

4.2.3. Discussion of Sensitivity Analysis of Electric Vehicle and Charging Infrastructure Costs

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| CO2 | PM10 | NOX | CO | SOX | VOC | NH3 | ||

|---|---|---|---|---|---|---|---|---|

| C-12 | Monetization x (USD/g polluntant x) | 1.12 × 10−4 | 1.38 ×10−1 | 2.39 × 10−2 | 1.34 × 10−3 | 1.22 × 10−2 | 1.34 × 10−3 | 1.96 × 10−2 |

| Tank to Wheel, EF,x (g/km) | 1.67 × 103 | 1.21 | 2.23 × 101 | 8.42 | 3.14 × 10−3 | 2.88 | 2.90 × 10−3 | |

| Well to Tank, EE,x (g/kWh) | 5.51 × 101 | 1.13 × 10−2 | 9.76 × 10−2 | 4.49 × 10−2 | 3.27 × 10−2 | 2.63 × 10−2 | ||

| Vehicle manufacturing, EM,x (g/veh-h) | 1.43 × 103 | |||||||

| Infrastructure, EI,x (g/km-h) | 6.19 × 102 | 3.24 | ||||||

| Euro-VI 12 | Tank to Wheel, EF,x (g/km) | 1.28 × 103 | 8.11 × 10−3 | 5.28 × 10−1 | 3.64 × 10−1 | 2.40 × 10−3 | 5.70 × 10−2 | 9.00 × 10−3 |

| Well to Tank (g/kWh) | 5.51 × 101 | 1.13 × 10−2 | 9.76 × 10−2 | 4.49 × 10−2 | 3.27 × 10−2 | 2.63 × 10−2 | ||

| Vehicle manufacturing, EM,x (g/veh-h) | 1.43 × 103 | |||||||

| Infrastructure, EI,x (g/km-h) | 6.19 × 102 | 3.24 | ||||||

| C-18 | Tank to Wheel, EF,x (g/km) | 2.07 × 103 | 1.52 | 2.87 × 101 | 1.11 × 101 | 3.89 × 10−3 | 2.99 | 2.90 × 10−3 |

| Well to Tank, EE,x (g/kWh) | 5.51 × 101 | 1.13 × 10−2 | 9.76 × 10−2 | 4.49 × 10−2 | 3.27 × 10−2 | 2.63 × 10−2 | ||

| Vehicle manufacturing, EM,x (g/veh-h) | 1.93 × 103 | |||||||

| Infrastructure, EI,x (g/km-h) | 6.19 × 102 | 3.24 | ||||||

| Euro VI 18 | Tank to Wheel, EF,x (g/km) | 1.70 × 103 | 9.15 × 10−3 | 4.38 × 10−1 | 4.14 × 10−1 | 3.19 × 10−3 | 6.5 × 10−2 | 9.0 × 10−3 |

| Well to Tank, EE,x (g/kWh) | 5.51 × 101 | 1.13 × 10−2 | 9.76 × 10−2 | 4.49 × 10−2 | 3.27 × 10−2 | 2.63 × 10−2 | ||

| Vehicle manufacturing, EM,x (g/veh-h) | 1.93 × 103 | |||||||

| Infrastructure, EI,x (g/km-h) | 6.19 × 102 | 3.24 | ||||||

| BEB 12 Ov and Opp. | Tank to Wheel, EF,x (g/km) | |||||||

| Well to Tank, EE,x (g/kWh) | 5.14 × 102 | 8.58 × 10−2 | 8.02 × 10−1 | 2.55 × 10−1 | 6.90 × 10−1 | 6.29 × 10−2 | ||

| Vehicle manufacturing, EM,x (g/veh-h) | 1.79 × 103 | |||||||

| Infrastructure, EI,x (g/km-h) | 6.19 × 102 | 3.24 | ||||||

| Chargers (g/charger), EC,x (g/charger-h) | 1.12 × 102 | 1.04 × 10−6 | 1.24 × 10−1 | 1 × 10−1 | 1.16 × 10−1 | 8.16 × 10−6 | 2.78 × 10−6 | |

| BEB-18 Opp | Tank to Wheel, EF,x (g/km) | |||||||

| Well to Tank, EE,x (g/kWh) | 5.14 × 102 | 8.58 × 10−2 | 8.02 × 10−1 | 2.55 × 10−1 | 6.90 × 10−1 | 6.29 × 10−2 | ||

| Vehicle manufacturing, EM,x (g/veh-h) | 2.42 × 103 | |||||||

| Infrastructure, EI,x (g/km-h) | 6.19 × 102 | 3.24 | ||||||

| Chargers (g/charger), EC,x (g/charger-h) | 1.12 × 102 | 1.04 × 10−6 | 1.24 × 10−1 | 1 × 10−1 | 1.16 × 10−1 | 8.16 × 10−6 | 2.78 × 10−6 |

References

- Ibarra-Rojas, O.J.; Delgado, F.; Giesen, R.; Muñoz, J.C. Planning, operation, and control of bus transport systems: A literature review. Transp. Res. Part B Methodol. 2015, 77, 38–75. [Google Scholar] [CrossRef]

- Magnanti, T.L.; Wong, R.T. Network design and transportation planning: Models and algorithms. Transp. Sci. 1984, 18, 1–55. [Google Scholar] [CrossRef] [Green Version]

- Wan, Q.K.; Lo, H.K. A Mixed Integer Formulation for Multiple-Route Transit Network Design. J. Math. Model. Algorithms 2003, 2, 299–308. [Google Scholar] [CrossRef]

- Hasselström, D. Public Transportation Planning—A Mathematical Programming Approach. Ph.D. Thesis, University of Göteborg, Göteborg, Sweden, 1981. [Google Scholar]

- Ceder, A.; Wilson, N.H.M. Bus network design. Transp. Res. Part B 1986, 20, 331–344. [Google Scholar] [CrossRef]

- Baaj, M.H.; Mahmassani, H.S. TRUST: A LISP Program for the Analysis of Transit Route Configurations. Transp. Res. Rec. 1990, 1283, 125–135. [Google Scholar]

- Baaj, M.H.; Mahmassani, H.S. Hybrid route generation heuristic algorithm for the design of transit networks. Transp. Res. Part C 1995, 3, 31–50. [Google Scholar] [CrossRef]

- van Nes, R.; Hamerslag, R.; Immers, B.H. Design of public transport networks. Transp. Res. Rec. 1988, 1202, 74–83. [Google Scholar] [CrossRef]

- Foletta, N.; Estrada, M.; Roca-Riu, M.P. Martí, New Modifications to Bus Network Design Methodology. J. Transp. Res. Rec. 2010, 2197, 43–53. [Google Scholar] [CrossRef]

- Pattnaik, S.B.; Mohan, S.; Tom, V.M. Urban bus transit route network design using genetic algorithm. J. Transp. Eng. 1998, 124, 368–375. [Google Scholar] [CrossRef]

- Zhao, F.; Zeng, X. Optimization of transit route network, vehicle headways and timetables for large-scale transit networks. Eur. J. Oper. Res. 2008, 186, 841–855. [Google Scholar] [CrossRef]

- Fan, W.; Machemehl, R.B. Using a simulated annealing algorithm to solve the transit route network design problem. J. Transp. Eng. 2006, 132, 122–132. [Google Scholar] [CrossRef]

- Fan, W.; Machemehl, R.B. Optimal transit route network design problem with variable transit demand: Genetic algorithm approach. J. Transp. Eng. 2006, 132, 40–51. [Google Scholar] [CrossRef]

- Fan, W.; Machemehl, R.B. Tabu search strategies for the public transportation network optimizations with variable transit demand. Comput. Aided Civ. Infrastruct. Eng. 2008, 23, 502–520. [Google Scholar] [CrossRef]

- Holroyd, E.M. The Optimum Bus Service: A Theoretical Model for A Large Uniform Urban Area. In Proceedings of the Third International Symposium on the Theory of Traffic Flow, New York, NY, USA, 1967; Available online: https://trid.trb.org/Results?q=&serial=%22Proceedings%20of%20the%20Third%20International%20Symposium%20on%20the%20Theory%20of%20Traffic%20Flow%22#/View/693339 (accessed on 21 April 2021).

- Newell, G.F. Some issues relating to the optimal design of bus routes. Transp. Sci. 1979, 13, 20–35. [Google Scholar] [CrossRef]

- Daganzo, C.F. Structure of competitive transit networks. Transp. Res. Part B Methodol. 2010, 44, 434–446. [Google Scholar] [CrossRef] [Green Version]

- Badia, H.; Estrada, M.; Robusté, F. Competitive transit network design in cities with radial street patterns. Transp. Res. Part B Methodol. 2014, 59, 161–181. [Google Scholar] [CrossRef]

- Chen, H.; Gu, W.; Cassidy, M.J.; Daganzo, C.F. Optimal transit service atop ring-radial and grid street networks: A continuum approximation design method and comparisons. Transp. Res. Part B Methodol. 2015, 81, 755–774. [Google Scholar] [CrossRef] [Green Version]

- Badia, H.; Estrada, M.; Robusté, F. Bus network structure and mobility pattern: A monocentric analytical approach on a grid street layout. Transp. Res. Part B Methodol. 2016, 93, 37–56. [Google Scholar] [CrossRef] [Green Version]

- Chester, M.V.; Horvath, A. Environmental assessment of passenger transportation should include infrastructure and supply chains. Environ. Res. Lett. 2009, 4. [Google Scholar] [CrossRef]

- Griswold, J.B.; Madanat, S.; Horvath, A. Tradeoffs between costs and greenhouse gas emissions in the design of urban transit systems. Environ. Res. Lett. 2013, 8, 044046. [Google Scholar] [CrossRef] [Green Version]

- Cheng, H.; Mao, C.; Madanat, S.; Horvath, A. Minimizing the total costs of urban transit systems can reduce greenhouse gas emissions: The case of San Francisco. Transp. Policy 2018, 66, 40–48. [Google Scholar] [CrossRef]

- Griswold, J.B.; Sztainer, T.; Lee, J.; Madanat, S.; Horvath, A. Optimizing urban bus transit network design can lead to greenhouse gas emissions reduction. Front. Built Environ. 2017, 3. [Google Scholar] [CrossRef] [Green Version]

- Estrada, M.; Roca-Riu, M.; Badia, H.; Robusté, F.; Daganzo, C.F. Design and implementation of efficient transit networks: Procedure, case study and validity test. Transp. Res. Part A Policy Pract. 2011, 45, 935–950. [Google Scholar] [CrossRef]

- Griswold, J.B.; Cheng, H.; Madanat, S.; Horvath, A. Unintended greenhouse gas consequences of lowering level of service in urban transit systems. Environ. Res. Lett. 2014, 9, 124001. [Google Scholar] [CrossRef] [Green Version]

- Cheng, H.; Madanat, S.; Horvath, A. Planning hierarchical urban transit systems for reductions in greenhouse gas emissions. Transp. Res. Part D Transp. Environ. 2016, 49, 44–58. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Madanat, S. Optimal policies for greenhouse gas emission minimization under multiple agency budget constraints in pavement management. Transp. Res. Part D Transp. Environ. 2017, 55, 39–50. [Google Scholar] [CrossRef] [Green Version]

- EEA. Passenger cars, light commercial trucks, heavy-duty vehicles including buses and motor cycles. In EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019; European Environment Agency: Copenhagen, Denmark, 2019; Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2019 (accessed on 21 April 2021).

- UChicago Argonne. The Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET®) Model. Fuel Cycle Model GREET1; Argonne National Laboratory: Lemont, IL, USA, 2019. Available online: https://greet.es.anl.gov/greet_1_series (accessed on 21 April 2021).

- Zhou, B.; Wu, Y.; Zhou, B.; Wang, R.; Ke, W.; Zhang, S.; Hao, J. Real-world performance of battery electric buses and their life-cycle benefits with respect to energy consumption and carbon dioxide emissions. Energy 2016, 96, 603–613. [Google Scholar] [CrossRef]

- Lajunen, A. Lifecycle costs and charging requirements of electric buses with different charging methods. J. Clean. Prod. 2018, 172, 56–67. [Google Scholar] [CrossRef]

- He, X.; Zhang, S.; Ke, W.; Zheng, Y.; Zhou, B.; Liang, X.; Wu, Y. Energy consumption and well-to-wheels air pollutant emissions of battery electric buses under complex operating conditions and implications on fleet electrification. J. Clean. Prod. 2018, 171, 714–722. [Google Scholar] [CrossRef]

- Correa, G.; Muñoz, P.M.; Rodriguez, C.R. A comparative energy and environmental analysis of a diesel, hybrid, hydrogen and electric urban bus. Energy 2019, 187, 115906. [Google Scholar] [CrossRef]

- Nordelöf, A.; Romare, M.; Tivander, J. Life cycle assessment of city buses powered by electricity, hydrogenated vegetable oil or diesel. Transp. Res. Part D Transp. Environ. 2019, 75, 211–222. [Google Scholar] [CrossRef]

- Wang, S.; Lu, C.; Liu, C.; Zhou, Y.; Bi, J.; Zhao, X. Understanding the Energy Consumption of Battery Electric Buses in Urban Public Transport Systems. Sustainability 2020, 12, 7. [Google Scholar] [CrossRef]

- Quarles, N.; Kockelman, K.M.; Mohamed, M. Costs and Benefits of Electrifying and Automating Bus Transit Fleets. Sustainability 2020, 12, 3977. [Google Scholar]

- Bie, Y.; Hao, M.; Guo, M. Optimal Electric Bus Scheduling Based on the Combination of All-Stop and Short-Turning Strategies. Sustainability 2021, 13, 1827. [Google Scholar] [CrossRef]

- Piccioni, C.; Musso, A.; Guida, U. Training material for University workshops. Deliverable n°42.6. Zero Emission Urban Bus System Project. In Seventh Framework Programme for Directorate General Mobility & Transport; European Commission: Brussels, Belgium, 2018; Available online: https://zeeus.eu/ (accessed on 21 April 2021).

- van Essen, H.; van Wijngaarden, L.; Schroten, A.; de Bruyn, S.; Sutter, D.; Bieler, C.; Maffii, S.; Brambilla, M.; Fiorello, D.; Fermi, F.; et al. Handbook on the External Costs of Transport: Version 2019; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- IIEG. Alcanza Área Metropolitana de Guadalajara los 5 Millones de Habitantes. 2017. Available online: https://iieg.gob.mx/strategos/alcanza-area-metropolitana-de-guadalajara-los-5-millones-de-habitantes/ (accessed on 21 April 2021).

- Parada, G. Estudio de Demanda Multimodal de Desplazamientos de la Zona Metropolitana de Guadalajara; Laboratorio Nacional de Políticas Públicas, Gobierno de México: Mexico City, Mexico, 2008; Available online: http://datos.cide.edu/handle/10089/16392 (accessed on 21 April 2021).

- Conasami. Salario Promedio Asociado a Trabajadores Asegurados al IMSS; Comisión Nacional de Salarios Mínimos; Gobierno de México: Mexico City, Mexico, 2018; Available online: https://www.gob.mx/cms/uploads/attachment/file/321592/Salarios-abril2018.pdf (accessed on 21 April 2021).

- Vuchic, V.R. Urban Transit Systems and Technology; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar] [CrossRef]

- OECD-IEA. Global EV Outlook 2018; Towards cross-modal electrification; International Energy Agency: Paris, France, 2018. [Google Scholar]

- TMB. Total Cost of Ownership of Diesel, Hybrid and Electric Vehicles in Barcelona. Transports Metropolitans de Barcelona. Available online: https://www.tmb.cat/en/home (accessed on 21 April 2021).

- IEA. Mexico Energy Outlook; International Energy Agency: Paris, France, 2016; Available online: https://www.iea:publications/freepublications/publication/MexicoEnergyOutlook.pdf (accessed on 21 April 2021).

- Wayman, M.; Sköld, Y.A.; Bergman, R.; Huang, Y.; Parry, T.; Raaberg, J.; Enell, A. Life Cycle Assessment of Reclaimed Asphalt. Deliverable 3.4. Re-Road—End-of-Life Strategies of Asphalt Pavements; FP7 Collaborative Project; European Commission: Brussels, Belgium, 2008. [Google Scholar]

- Nansai, K.; Tohno, S.; Kono, M.; Kasahara, M.; Moriguchi, Y. Life-cycle analysis of charging infrastructure for electric vehicles. Appl. Energy 2001, 70, 251–265. [Google Scholar] [CrossRef]

- CRE. Factor de Emisión del Sector Eléctrico Nacional 2017; Comisión Reguladora de la Energía; Gobierno de México: Mexico City, Mexico, 2017; Available online: https://www.gob.mx/cms/uploads/attachment/file/304573/Factor_de_Emisi_n_del_Sector_El_ctrico_Nacional_1.pdf (accessed on 21 April 2021).

| Cost Parameters | Standard Bus, 12 m Long | Articulated Bus, 18 m Long | ||||||

|---|---|---|---|---|---|---|---|---|

| Diesel Diesel | Electric | Diesel Diesel | Electric | |||||

| Conventional | EURO VI | Over-n./Day | Oppor-tunity | Conventional | EURO VI | Oppor-tunity | ||

| Energy consumption factor (kWh/veh-km) | 6.207 | 4.746 | 1.400 | 7.689 | 6.304 | 1.900 | ||

| Unit energy cost (USD/veh-km) | (a) | 0.685 | 0.524 | 0.112 | 0.849 | 0.696 | 0.152 | |

| Spare parts, maintenance staff cost (USD/veh-km) | (b) | 0.254 | 0.254 | 0.169 | 0.293 | 0.293 | 0.163 | |

| Unit distance cost,(USD/veh-km) | (a + b) | 0.940 | 0.778 | 0.281 | 1.142 | 0.989 | 0.315 | |

| Unit driver cost, (USD/veh-h) | (c) | 9.450 | 9.450 | 9.450 | 9.450 | 9.450 | 9.450 | |

| Vehicle acquisition cost (USD/veh) | 198,000 | 277,500 | 555,000 | 275,000 | 385,000 | 876,900 | ||

| Amortized Vehicle cost (USD/veh-h) | (d) | 2.500 | 3.504 | 7.008 | 3.472 | 4.861 | 11.072 | |

| Refuel workload at bus garage (USD/veh-h) | (e) | 0.183 | 0.083 | 0.000 | 0.183 | 0.183 | 0.000 | |

| Insurances, control, engineering staff (USD/veh-h) | (f) | 2.626 | 2.626 | 2.964 | 2.626 | 2.626 | 2.626 | |

| Unit temporal cost,(USD/veh-h) | (c + d + e + f) | 14.759 | 15.663 | 19.421 | 15.731 | 17.120 | 23.148 | |

| Charger facility/Fuel station invest.(kUSD) | 5550 | 5550 | 95.87 | 777 | 5550 | 5550 | 777 | |

| Vehicle capacity of the charger/station (veh) | (g) | 350 | 350 | 1 | 1 | 350 | 350 | 1 |

| Facility cost (USD/charger-h) | (h) | 35.04 | 35.04 | 0.605 | 5.396 | 35.04 | 35.04 | 5.396 |

| Charger/Refuel station maintenance cost (USD/facility-h) | (i) | 1.354 | 1.354 | 0.625 | 0.625 | 1.354 | 1.354 | 0.625 |

| Unit energy facility cost or refueling station, cN (USD/charger-h) | (h + i)/(g) | 0.104 | 0.104 | 1.230 | 6.021 | 0.104 | 0.104 | 6.021 |

| Unit battery cost, cb (USD/kWh-h) | -- | -- | 0.0190 | -- | -- | 0.019 | ||

| Aggregated Tank to Wheel emission monetization, (USD/veh-km) | 0.9015 | 0.1580 | 0 | 1.1434 | 0.2027 | 0 | ||

| Aggregated Well to Tank emission monetization, (USD/kWh) | 0.0106 | 0.0106 | 0.0974 | 0.0106 | 0.0106 | 0.0974 | ||

| Aggregated Vehicle manuf. emission monetization, (USD/veh-h) | 0.1598 | 0.1598 | 0.2008 | 0.2157 | 0.2157 | 0.2711 | ||

| Aggregated Infrastructure emission monetization, (USD/km-h) | 0.1089 | 0.1089 | 0.1089 | 0.1089 | 0.1089 | 0.1089 | ||

| Aggregated Charger emission monetization, (USD/char-h) | -- | -- | 0.0171 | 0.0171 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barraza, O.; Estrada, M. Battery Electric Bus Network: Efficient Design and Cost Comparison of Different Powertrains. Sustainability 2021, 13, 4745. https://doi.org/10.3390/su13094745

Barraza O, Estrada M. Battery Electric Bus Network: Efficient Design and Cost Comparison of Different Powertrains. Sustainability. 2021; 13(9):4745. https://doi.org/10.3390/su13094745

Chicago/Turabian StyleBarraza, Orlando, and Miquel Estrada. 2021. "Battery Electric Bus Network: Efficient Design and Cost Comparison of Different Powertrains" Sustainability 13, no. 9: 4745. https://doi.org/10.3390/su13094745