Engineering Design Process of Face Masks Based on Circularity and Life Cycle Assessment in the Constraint of the COVID-19 Pandemic

Abstract

1. Introduction

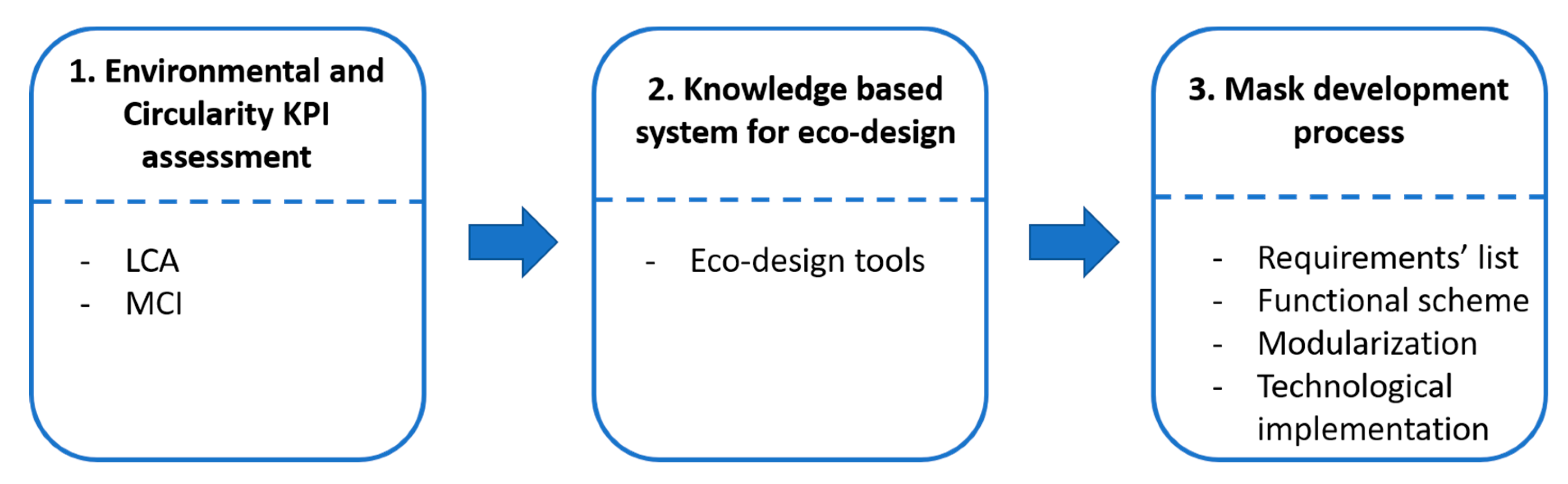

2. Materials and Methods

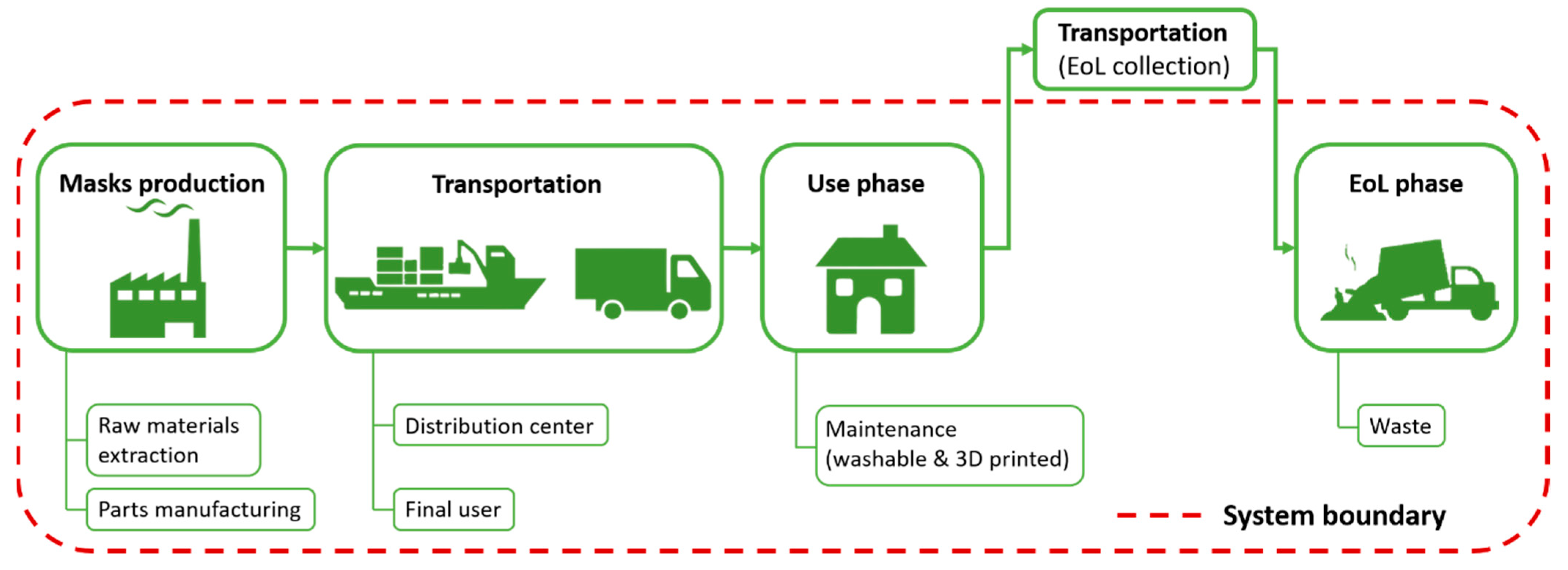

2.1. Environmental and Circularity KPI Assessment

- Goal and scope definition;

- Life cycle inventory (LCI);

- Life cycle impact assessment (LCIA);

- Interpretation.

- M1—3D-printed model. This commercial mask uses disposable FFP2 filters. This technology is very widespread on the market for masks with a reusable structure. The 3D-printed part has to be disinfected to ensure that it is safe to use. FFP2 filters guarantee a filtration efficiency of at least 94% and must be changed every 8 h of use [41].

- M2—surgical mask. This type of device is for single use only and acts as a barrier to prevent droplets from being transmitted during breathing or speaking. They mainly protect other people, not the wearer, although they can help to prevent the user from coming into contact with a stream of liquid. They must be discarded every 4 h of use [41].

- M3—FFP2 with exhalation valve. This mask is for single use and is designed to facilitate breathing through its valve. It protects the user from possible external contamination, but it does not protect others. They must be discarded every 8 h of use [41].

- M4—FFP2 without an exhalation valve. As in the previous case, it is for single use but, since it does not have an exhalation valve, it protects both the user and others. It needs to be discarded every 8 h of use [41].

- M5—washable mask. Mask can be reused several times, maintaining its filtering efficiency for at least 50 washes. In this case, maintenance consists of washing the product in a washing machine at a recommended temperature between 40 °C and 75 °C [42].

- L represents the useful life of the product;

- Lav refers to the average useful life of the industry.

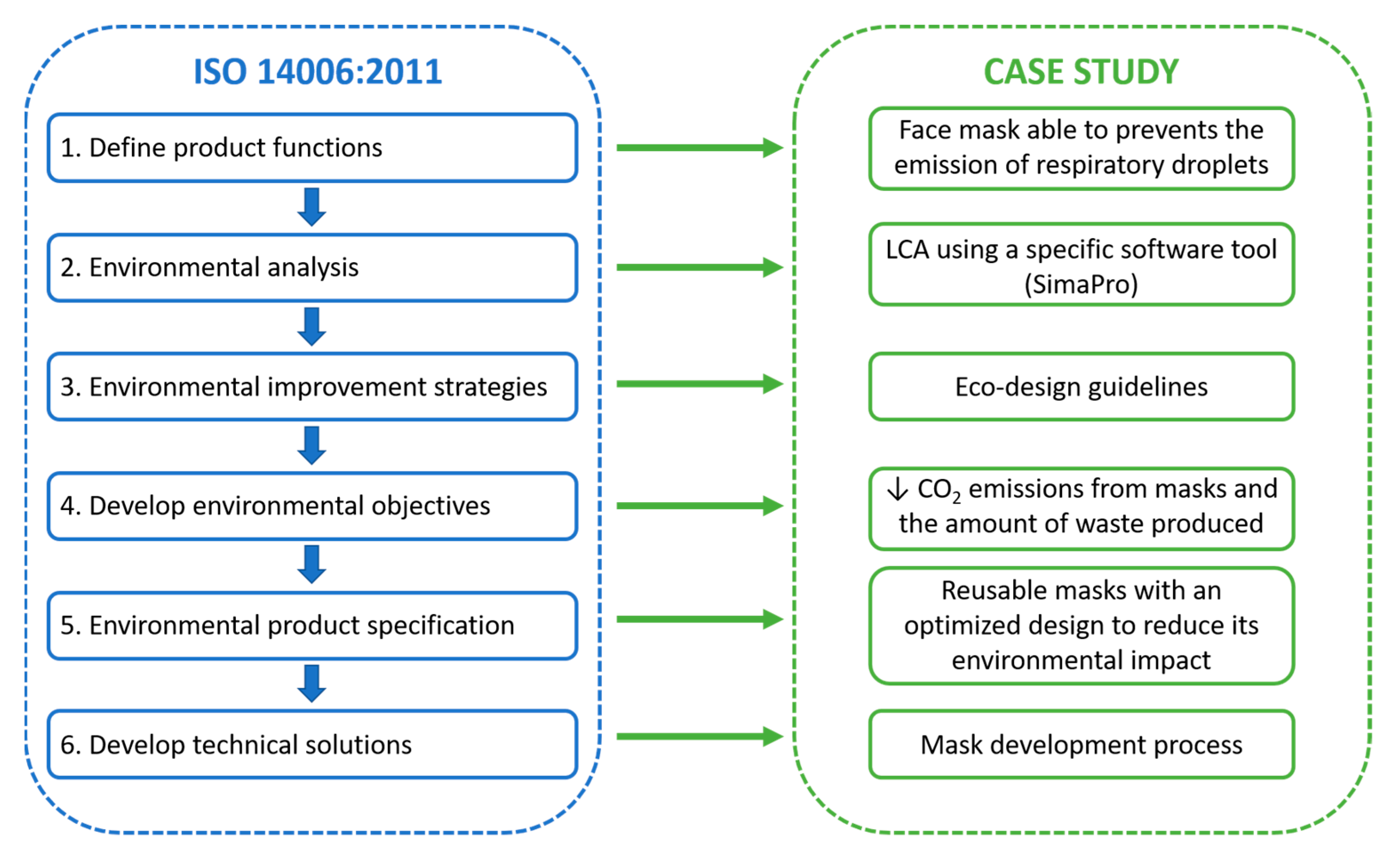

2.2. Knowledge-Based System for Eco-Design

- Define product functions;

- Environmental analysis;

- Environmental improvement strategies;

- Develop environmental objectives;

- Environmental product specification;

- Develop technical solutions.

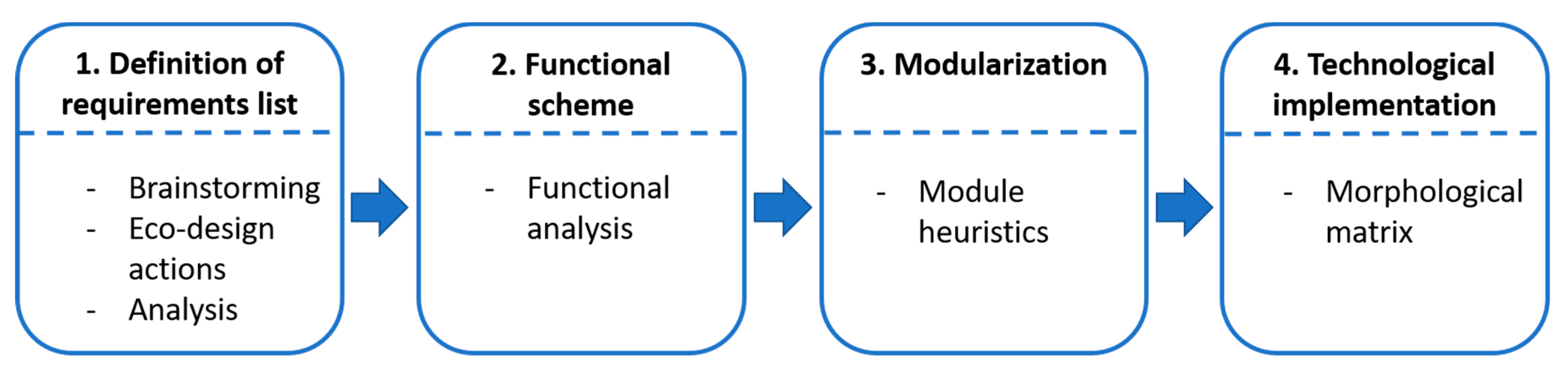

2.3. Mask Development process

3. Results

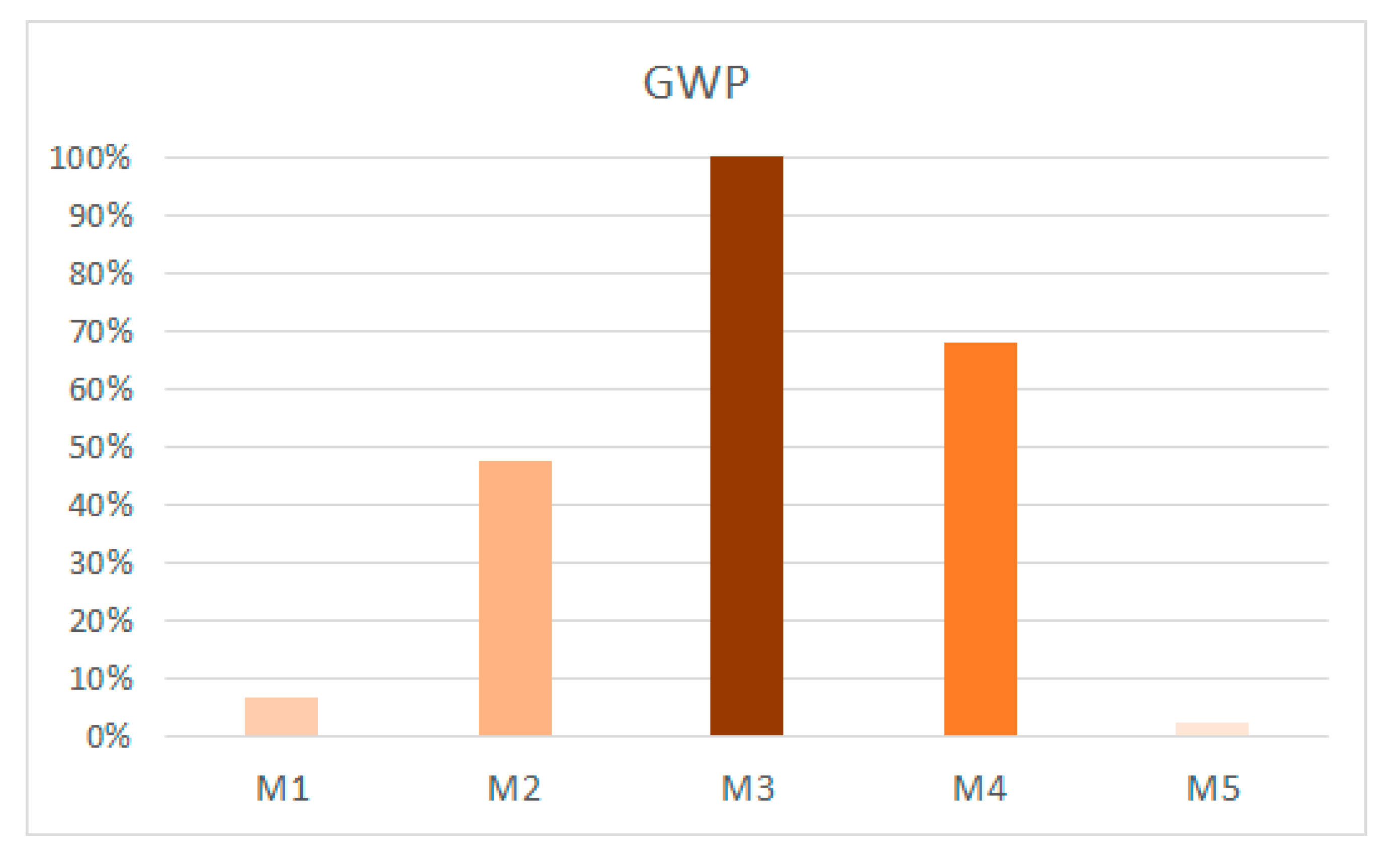

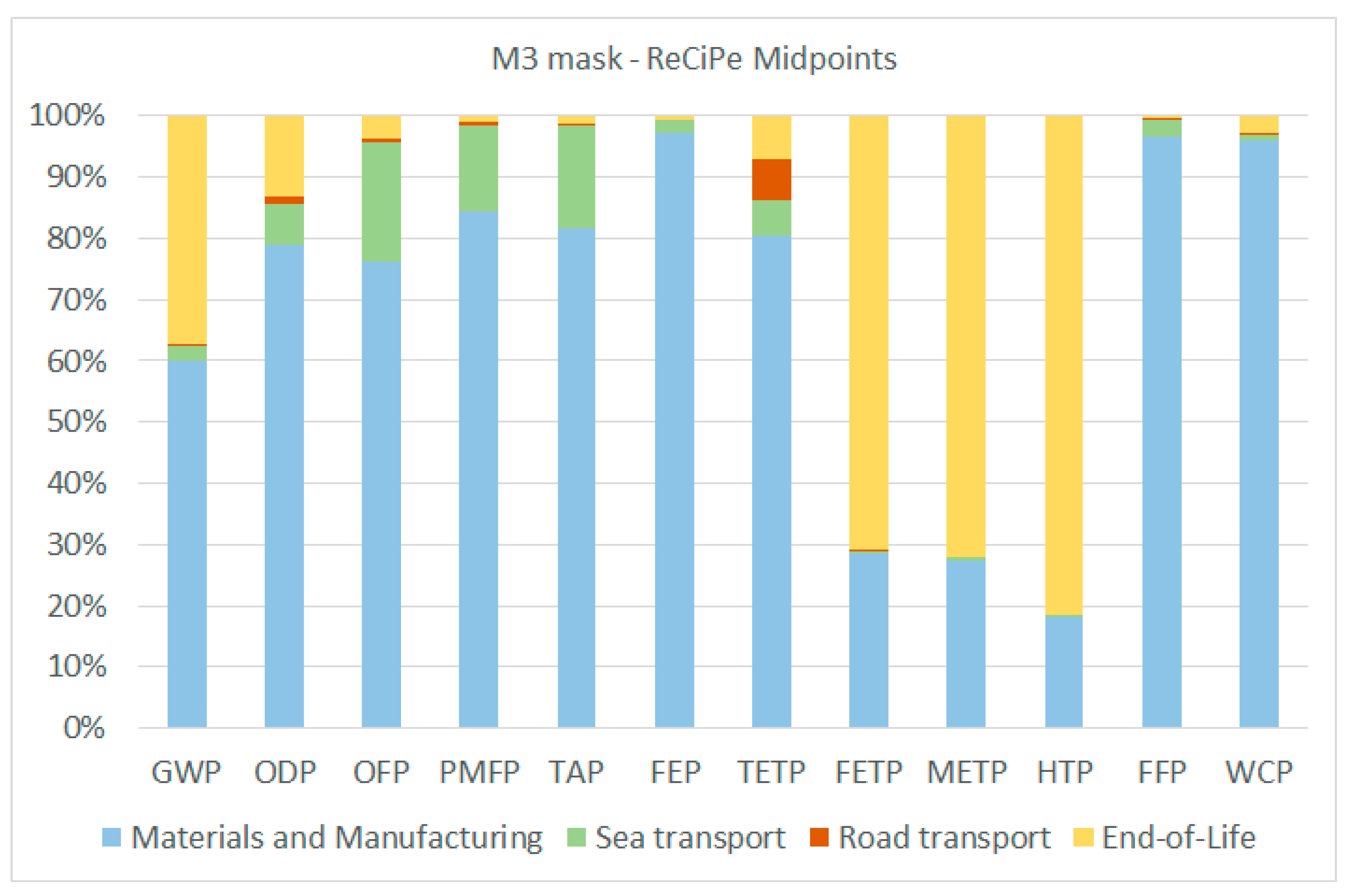

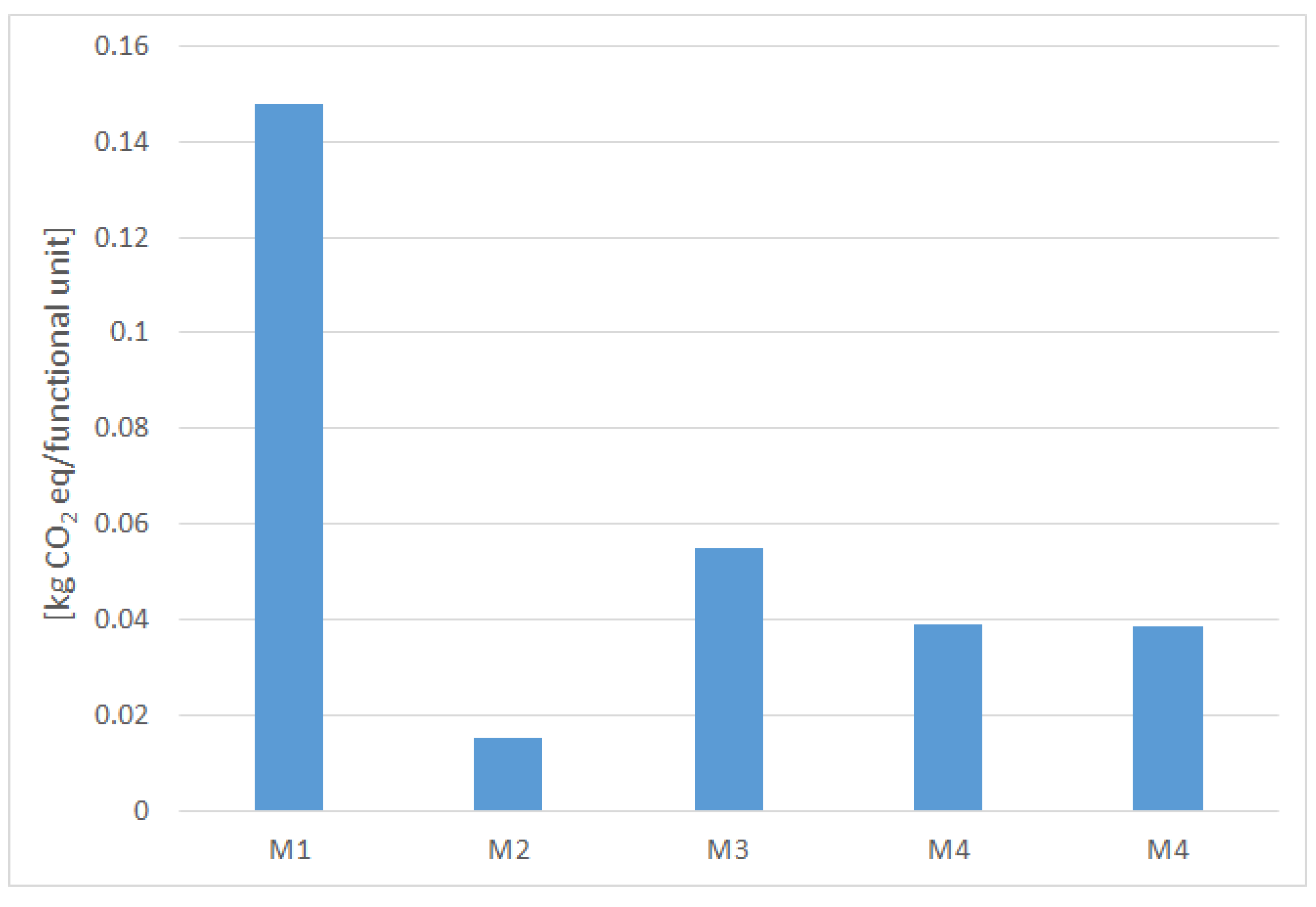

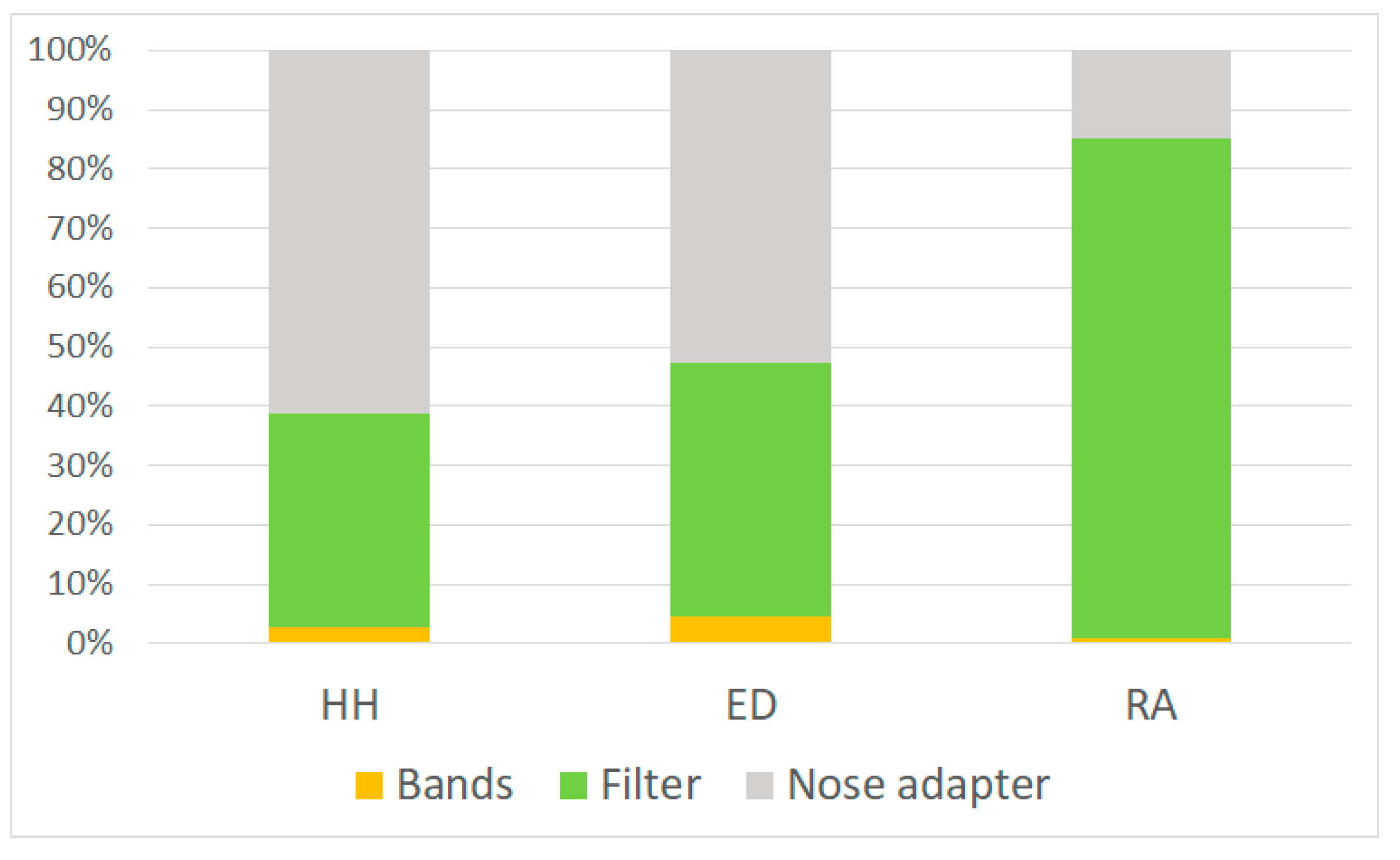

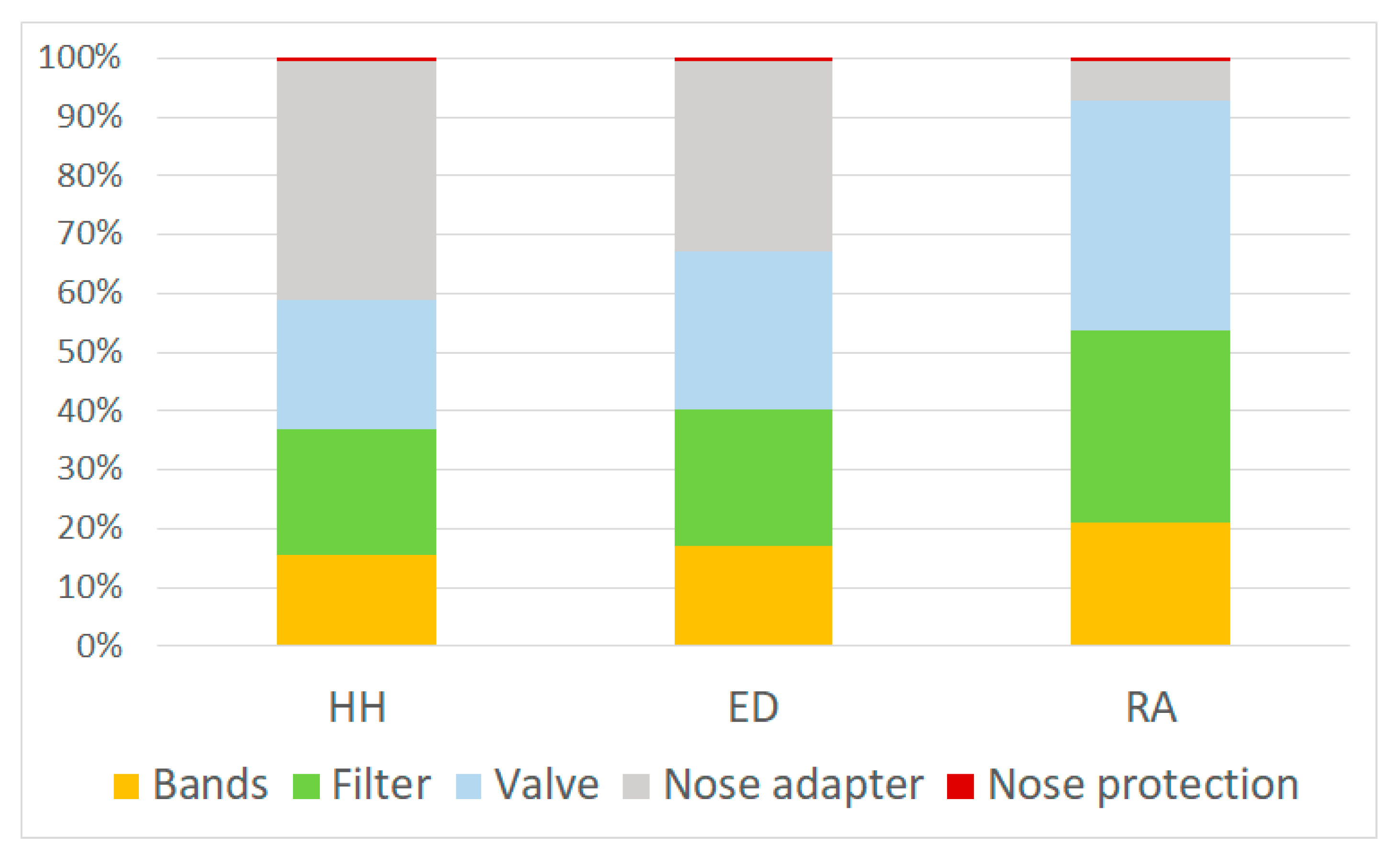

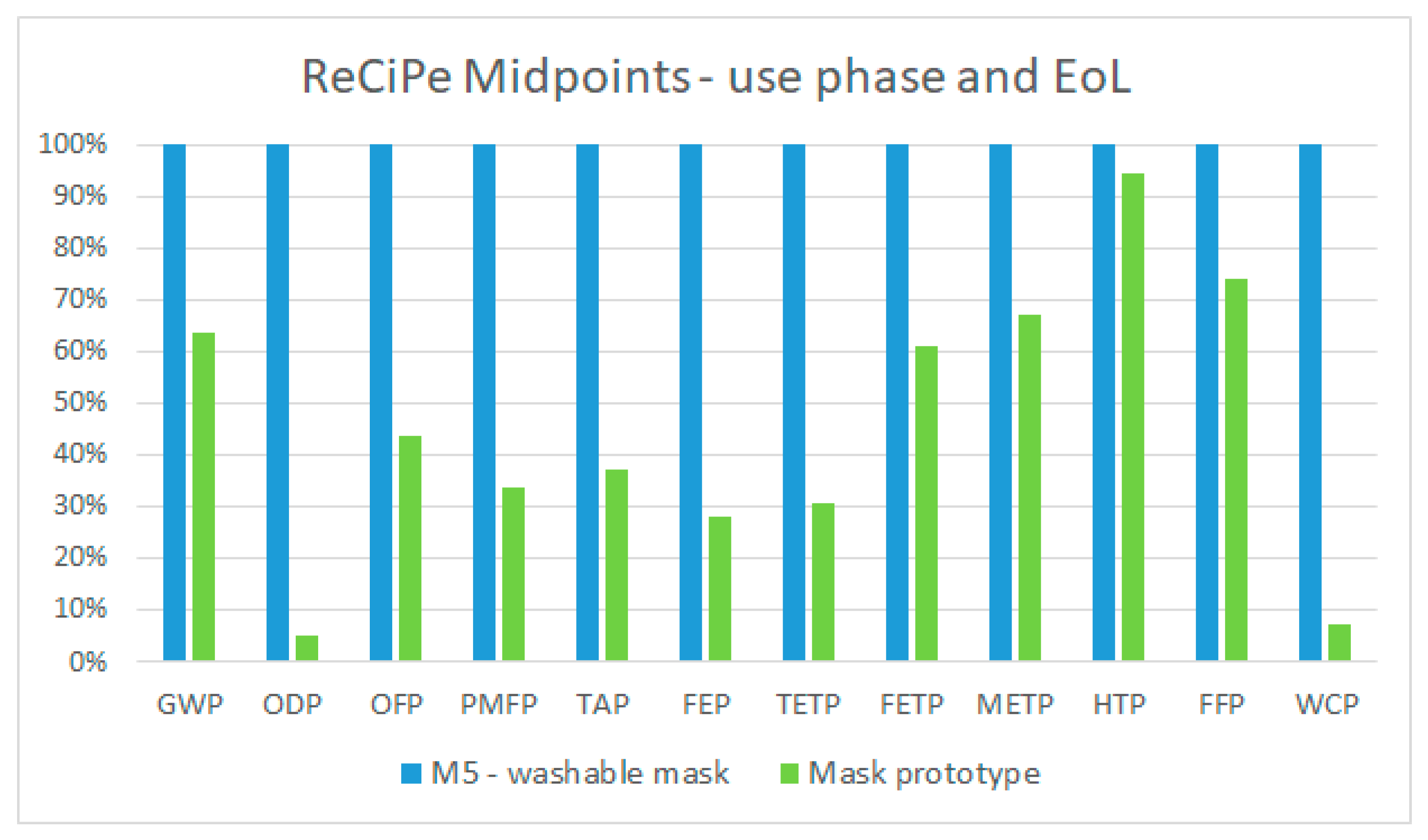

3.1. Environmental and Circularity KPI Assessment

3.2. Knowledge-Based System for Eco-Design

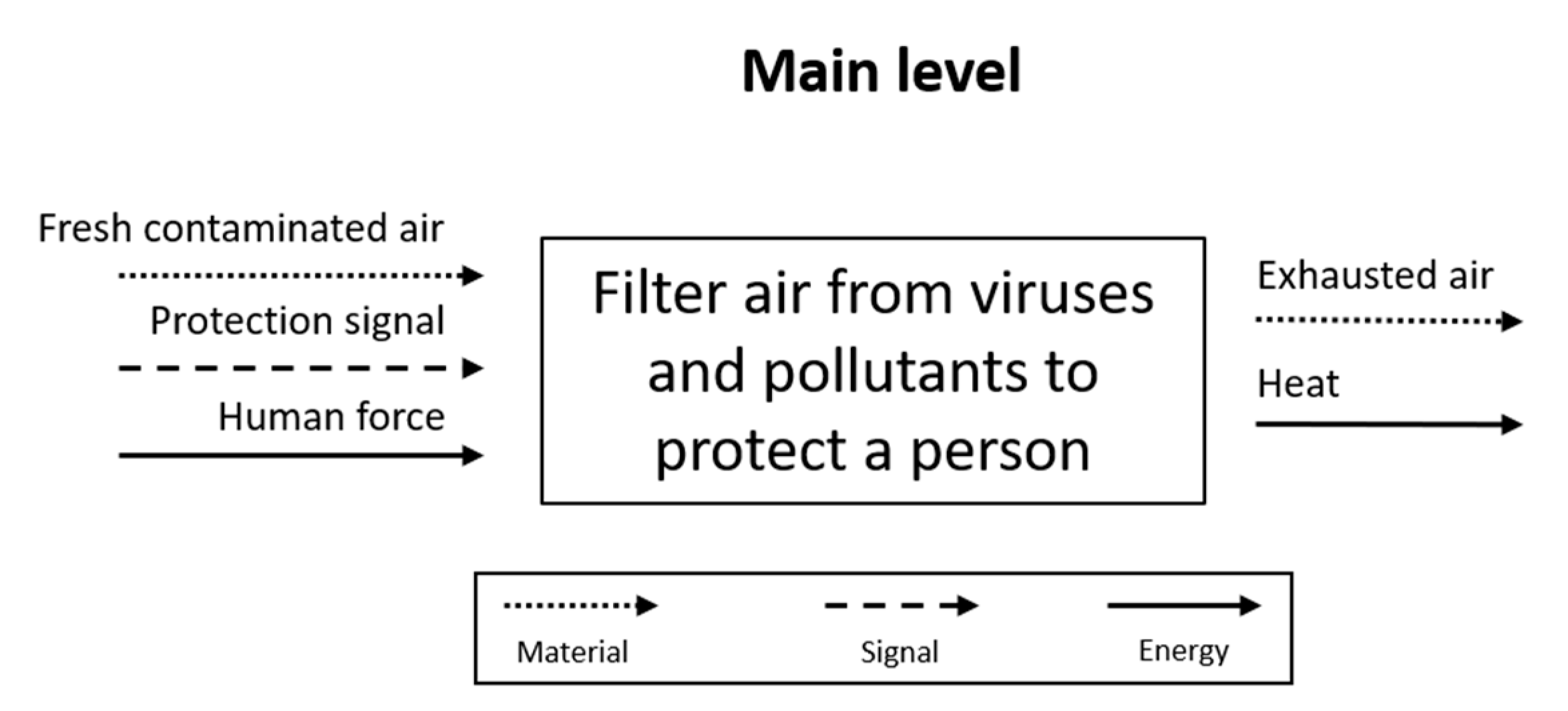

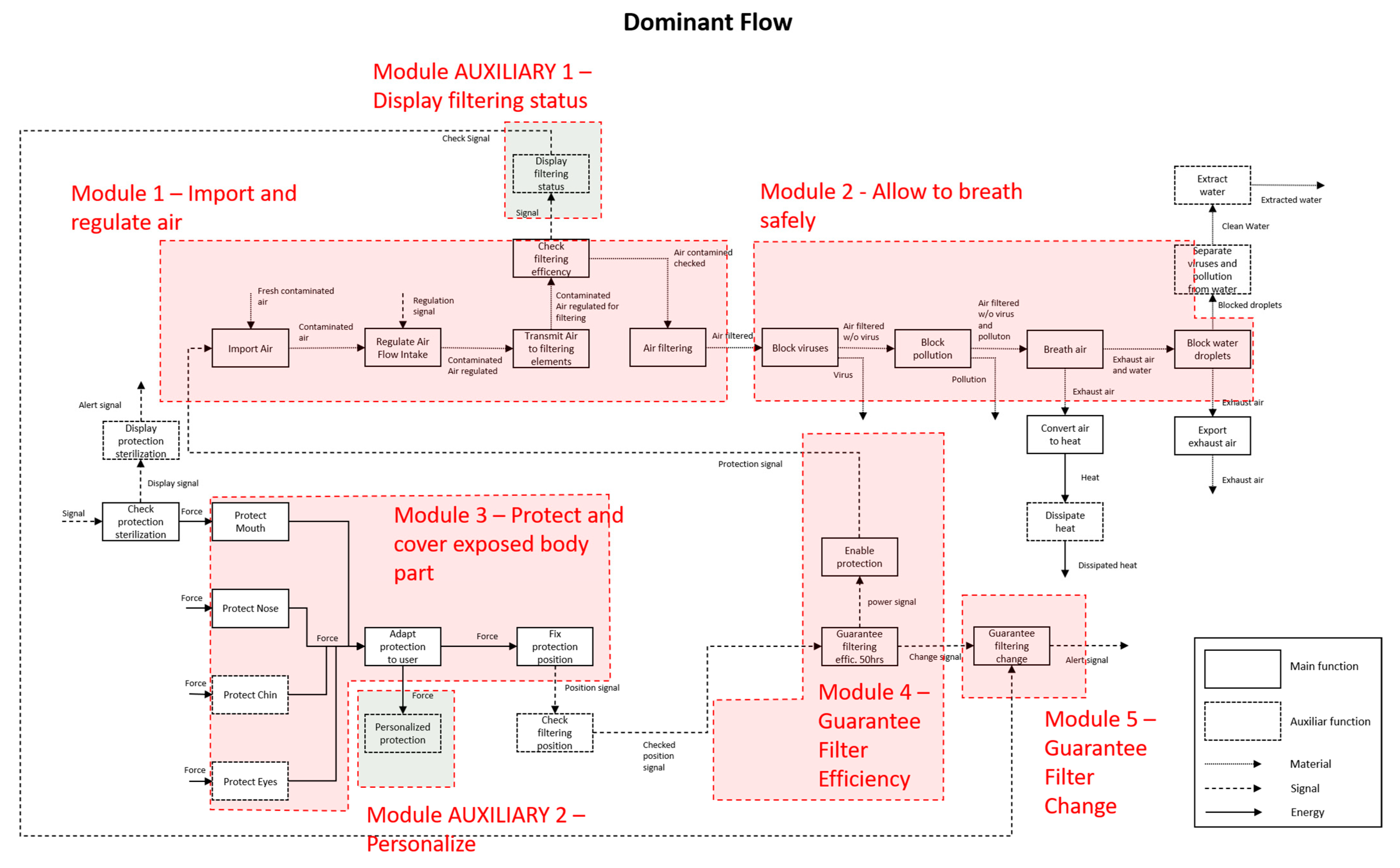

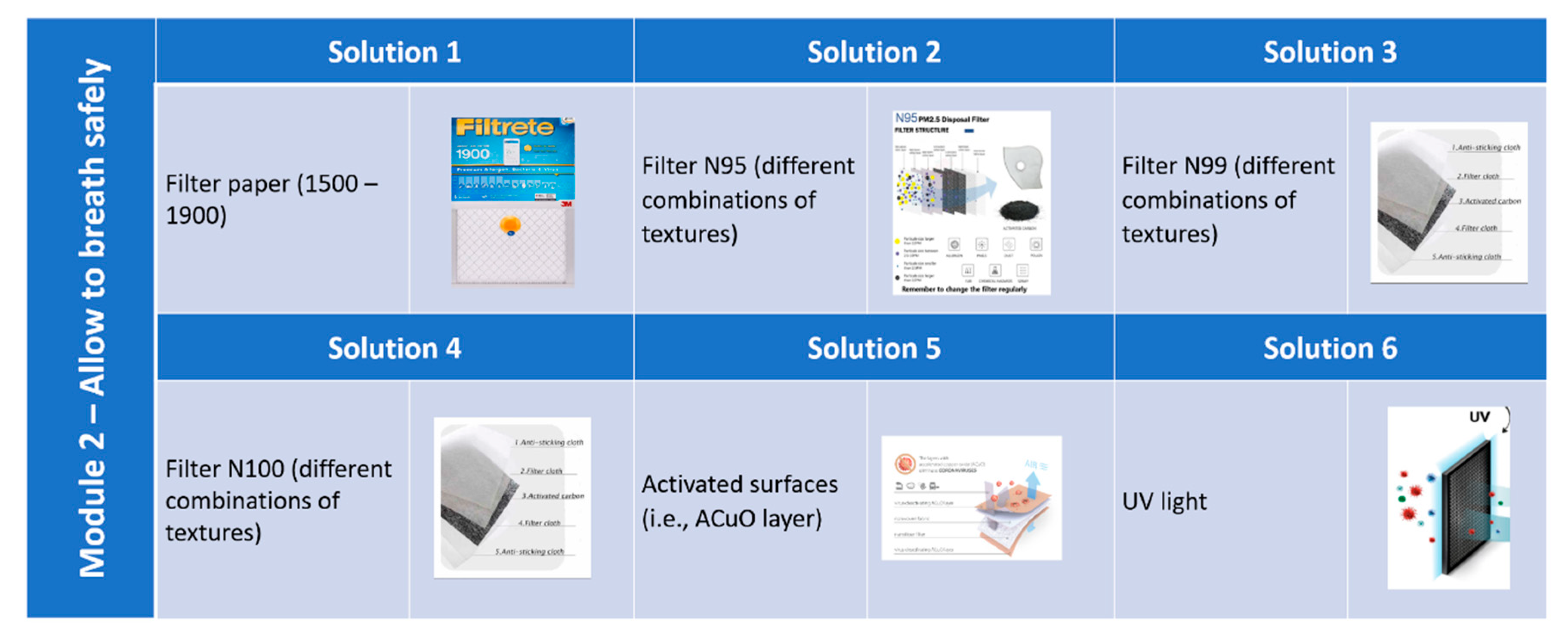

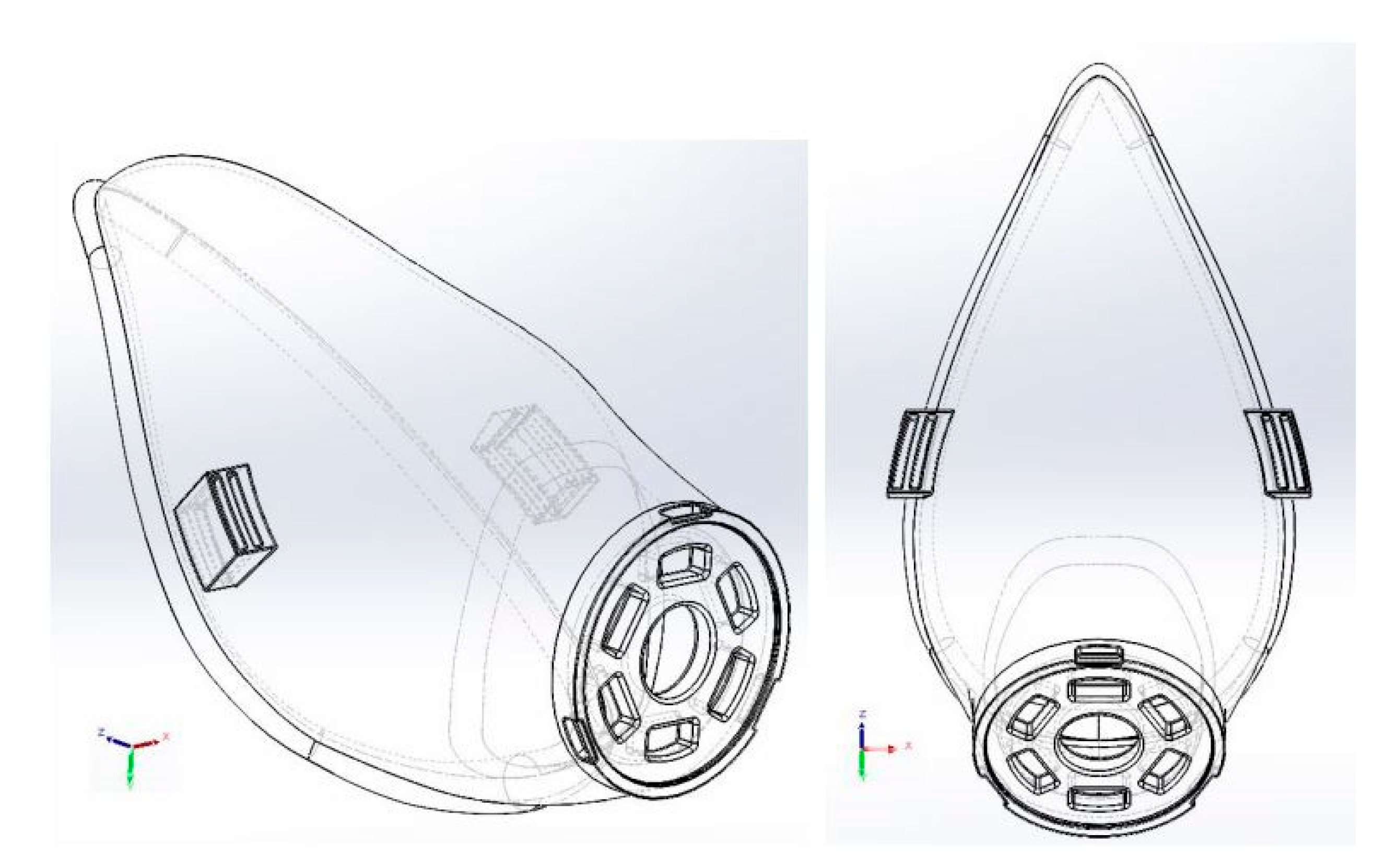

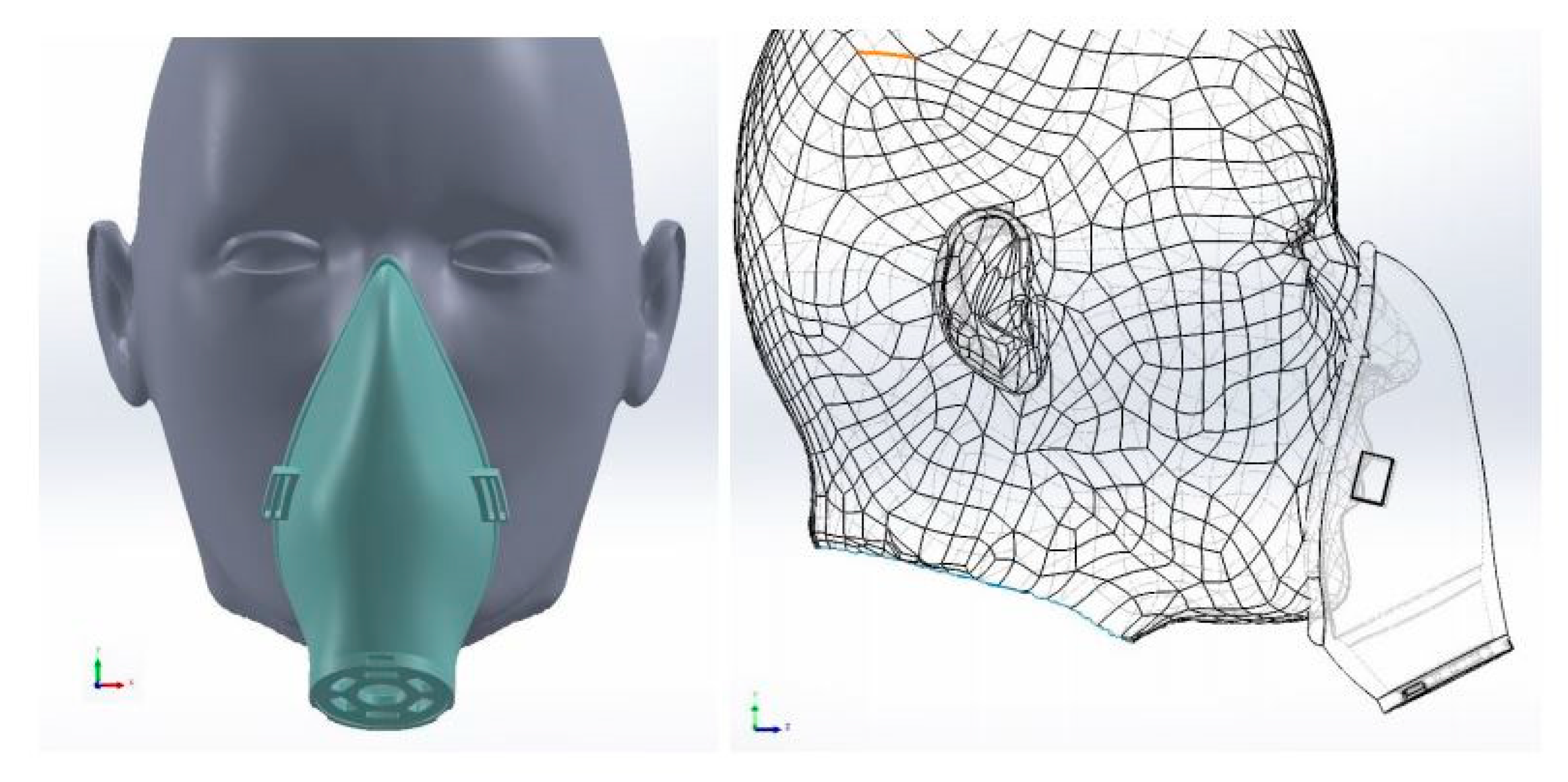

3.3. Mask Development Process

- Fresh contaminated air: the material needed for breathing;

- Protection signal: the signal to activate the protection;

- Human force: the force required to apply the protection.

- Exhausted air: represents the result of the breathing process (contaminated air);

- Heat: generated by the breathing process.

4. Discussion

5. Conclusions

- LCA analysis refinements: an extension of the environmental and circularity analyses, which include additional details (e.g., specific inventory for the nonwoven fabrics manufacturing, the inclusion of the waste collection phase within the system boundaries, etc.) will help in a definition of more specific guidelines and actions;

- LCA analysis scenarios: additional scenarios (e.g., sanitary landfill EoL, different typologies of washable masks, etc.) will allow defining a larger set of design guidelines ad to provide the best solution for policymakers in this complex context;

- Consequential LCA: since the production and disposal of anti-SARS-CoV-2 masks are becoming of global importance for the socioeconomic management of the pandemic, an additional consequential LCA will be able to estimate how the global environmental burdens are affected by the production and use of this product. Consequential LCA could bring some additional important conclusions to couple with the results of this study.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

List of Acronyms

| Abbreviation | |

| BF | Branching flows |

| BFE | Bacteria Filtration Efficiency |

| CED | Cumulative Energy Demand |

| CTM | Conversion-transmission modules |

| DF | Dominant flow |

| ED | Ecosystem |

| EoL | End of Life |

| EU | European Union |

| FEP | Freshwater eutrophication potential |

| FETP | Freshwater ecotoxicity potential |

| GHG | Greenhouse gas |

| GWP | Global warming potential |

| HH | Human Health |

| HTP | Human toxicity potential |

| KPI | Key Performance Indicator |

| LCA | Life Cycle Assessment |

| LCE | Life Cycle Engineering |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| LCT | Life Cycle Thinking |

| M1 | Mask type 1 |

| M2 | Mask type 2 |

| M3 | Mask type 3 |

| M4 | Mask type 4 |

| M5 | Mask type 5 |

| MCI | Material Circularity Indicator |

| METP | Marine ecotoxicity potential |

| ODP | Ozone depletion potential |

| OFP | Photochemical oxidant formation potential |

| PE | Polyester |

| PFE | Particle Filtration Efficiency |

| PLA | Polylactic acid |

| PMFP | Particulate matter formation potential |

| PP | Polypropylene |

| PPE | Personal Protective Equipment |

| PU | Polyurethane |

| RA | Resources |

| TAP | Terrestrial acidification potential |

| TETP | Terrestrial ecotoxicity potential |

| UV | Ultraviolet |

| WCP | Water consumption potential |

| WHO | World Health Organization |

References

- World Health Organization Archived: WHO Timeline—COVID-19. Available online: https://www.who.int/news/item/27-04-2020-who-timeline—covid-19 (accessed on 4 February 2021).

- Worldometer Real Time World Statistics. Available online: https://www.worldometers.info/coronavirus/ (accessed on 4 February 2021).

- Kutter, J.S.; Spronken, M.I.; Fraaij, P.L.; Fouchier, R.A.; Herfst, S. Transmission routes of respiratory viruses among humans. Curr. Opin. Virol. 2018, 28, 142–151. [Google Scholar] [CrossRef]

- Chaudhuri, S.; Basu, S.; Kabi, P.; Unni, V.R.; Saha, A. Modeling the role of respiratory droplets in Covid-19 type pandemics. Phys. Fluids 2020, 32, 063309. [Google Scholar] [CrossRef]

- Huang, H.; Fan, C.; Li, M.; Nie, H.L.; Wang, F.B.; Wang, H.; Wang, R.; Xia, J.; Zheng, X.; Zuo, X.; et al. COVID-19: A Call for Physical Scientists and Engineers. ACS Nano 2020, 14.4, 3747–3754. [Google Scholar] [CrossRef]

- Anderson, E.L.; Turnham, P.; Griffin, J.R.; Clarke, C.C. Consideration of the Aerosol Transmission for COVID-19 and Public Health. Risk Anal. 2020, 40, 902–907. [Google Scholar] [CrossRef]

- Prather, K.A.; Wang, C.C.; Schooley, R.T. Reducing transmission of SARS-CoV-2. Science 2020, 368, 6498, 1422–1424. [Google Scholar] [CrossRef]

- World Health Organization Advice on the use of masks in the context of COVID-19. Available online: https://www.who.int/publications. (accessed on 22 January 2021).

- Gobierno de España Real Decreto 463/2020, de 14 de Marzo, Por el que se Declara el Estado de Alarma Para la Gestión de la Situación de Crisis Sanitaria Ocasionada por el COVID-19. Available online: https://www.boe.es/buscar/doc.php?id=BOE-A-2020-3692. (accessed on 4 February 2021).

- Governo Italiano Coronavirus, Conte Firma il Dpcm 11 Marzo. 2020. Available online: http://www.governo.it/it/articolo/coronavirus-conte-firma-il-dpcm-11-marzo-2020/14299. (accessed on 4 February 2021).

- Ippolito, M.; Vitale, F.; Accurso, G.; Iozzo, P.; Gregoretti, C.; Giarratano, A.; Cortegiani, A. Medical masks and Respirators for the Protection of Healthcare Workers from SARS-CoV-2 and other viruses. Pulmonology 2020, 26, 204–212. [Google Scholar] [CrossRef] [PubMed]

- Teesing, G.R.; van Straten, B.; de Man, P.; Horeman-Franse, T. Is there an adequate alternative to commercially manufactured face masks? A comparison of various materials and forms. J. Hosp. Infect. 2020, 106, 246–253. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Li, Y.; Zhang, A.L.; Wang, Y.; Molina, M.J. Identifying airborne transmission as the dominant route for the spread of COVID-19. Proc. Natl. Acad. Sci. USA 2020, 117, 14857–14863. [Google Scholar] [CrossRef] [PubMed]

- Leung, N.H.L.; Chu, D.K.W.; Shiu, E.Y.C.; Chan, K.H.; McDevitt, J.J.; Hau, B.J.P.; Yen, H.L.; Li, Y.; Ip, D.K.M.; Peiris, J.S.M.; et al. Respiratory virus shedding in exhaled breath and efficacy of face masks. Nat. Med. 2020, 26, 676–680. [Google Scholar] [CrossRef]

- European Center for Disease Prevention and Control. Using Face Masks in the Community; European Center for Disease Prevention and Control: Stockholm, Sweden, 2020. [Google Scholar]

- World Health Organization Shortage of Personal Protective Equipment Endangering Health Workers Worldwide. Available online: https://www.who.int/news/item/03-03-2020-shortage-of-personal-protective-equipment-endangering-health-workers-worldwide (accessed on 25 January 2021).

- World Health Organization Rational Use of Personal Protective Equipment for COVID-19 and Considerations during Severe Shortages. 2020, pp. 1–32. Available online: https://apps.who.int/iris/bitstream/handle/10665/338033/WHO-2019-nCoV-IPC_PPE_use-2020.4-eng.pdf (accessed on 10 March 2021).

- Chiang, J.; Hanna, A.; Lebowitz, D.; Ganti, L. Elastomeric respirators are safer and more sustainable alternatives to disposable N95 masks during the coronavirus outbreak. Int. J. Emerg. Med. 2020, 13, 39. [Google Scholar] [CrossRef] [PubMed]

- Ji, D.; Fan, L.; Li, X.; Ramakrishna, S. Addressing the worldwide shortages of face masks. BMC Mater. 2020, 2, 1. [Google Scholar] [CrossRef] [PubMed]

- Pu, Y.; Zheng, J.; Chen, F.; Long, Y.; Wu, H.; Li, Q.; Yu, S.; Wang, X.; Ning, X. Preparation of Polypropylene Micro and Nanofibers by Electrostatic-Assisted Melt Blown and Their Application. Polymers 2018, 10, 959. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, S.; Kumar, S.; Sahu, R.K.; Nayar, S. PVA-graphene-hydroxyapatite electrospun fibres as air-filters. Mater. Res. Express 2019, 6, 125366. [Google Scholar] [CrossRef]

- Lazzaro, B.P.; Zasloff, M.; Rolff, J. Antimicrobial peptides: Application informed by evolution. Science 2020, 368, 6490. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.; Lee, S.; Dou, X.; Kwon, E.E. Valorization of disposable COVID-19 mask through the thermo-chemical process. Chem. Eng. J. 2021, 405, 126658. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Aragaw, T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020, 159, 111517. [Google Scholar] [CrossRef] [PubMed]

- Fadare, O.O.; Okoffo, E.D. Covid-19 face masks: A potential source of microplastic fibers in the environment. Sci. Total Environ. 2020, 737, 140279. [Google Scholar] [CrossRef] [PubMed]

- Govern of Canada COVID-19: Compostable Disposable Surgical Masks and Compostable Disposable Respirators Used in the Canadian Healthcare System. Available online: https://www.ic.gc.ca/eic/site/101.nsf/eng/00117.html (accessed on 25 January 2021).

- Ertz, M.; Patrick, K. The future of sustainable healthcare: Extending product lifecycles. Resour. Conserv. Recycl. 2020, 153, 104589. [Google Scholar] [CrossRef]

- Ministerio para la Transición Ecológica y el Reto Demográfico, Gobierno de España. Prevención y gestión de residuos. Available online: https://www.miteco.gob.es/es/ministerio/medidas-covid19/residuos/prevencionygestionderesiduos_tcm30-509666.pdf (accessed on 4 February 2021).

- Murrieta-Rico, F.N.; Yocupicio-Gaxiola, R.I.; Petranovskii, V.; Sánchez, P.; Antúnez-García, J.; Alonso-Núñez, G.; Galván, D.H. Prospects for Further Development of Face Masks to Minimize Pandemics—Functionalization of Textile Materials with Biocide Inorganic Nanoparticles: A Review. IEEE Lat. Am. Trans. 2020, 14, 1–14. [Google Scholar]

- Livinguard Livinguard Technology scientifically proven to destroy >99.9% of SARS-CoV-2. Available online: https://livinguard.com/products (accessed on 25 January 2021).

- McGain, F.; Story, D.; Lim, T.; McAlister, S. Financial and environmental costs of reusable and single-use anaesthetic equipment. Br. J. Anaesth. 2017, 118, 862–869. [Google Scholar] [CrossRef] [PubMed]

- Klemeš, J.J.; Van Fan, Y.; Jiang, P. The energy and environmental footprints of COVID-19 fighting measures–PPE, disinfection, supply chains. Energy 2020, 211. [Google Scholar] [CrossRef]

- Kumar, H.; Azad, A.; Gupta, A.; Sharma, J.; Bherwani, H.; Labhsetwar, N.K.; Kumar, R. COVID-19 Creating another problem? Sustainable solution for PPE disposal through LCA approach. Environ. Dev. Sustain. 2020. [Google Scholar] [CrossRef] [PubMed]

- Allison, A.L.; Ambrose-Dempster, E.; Domenech Aparsi, T.; Bawn, M.; Casas Arredondo, M.; Chau, C.; Chandler, K.; Dobrijevic, D.; Hailes, H.; Lettieri, P.; et al. The environmental dangers of employing single-use face masks as part of a COVID-19 exit strategy. UCL Open Environ. 2020. [Google Scholar] [CrossRef]

- Schmutz, M.; Hischier, R.; Batt, T.; Wick, P.; Nowack, B.; Wäger, P.; Som, C. Cotton and surgical masks—what ecological factors are relevant for their sustainability? Sustainatibility 2020, 12, 245. [Google Scholar] [CrossRef]

- Boix Rodríguez, N.; Formentini, G.; Favi, C.; Marconi, M. Environmental implication of personal protection equipment in the pandemic era: LCA comparison of face masks typologies. Procedia CIRP. 2021, 98, 306–311. [Google Scholar] [CrossRef] [PubMed]

- Sousa, A.C.; Veiga, A.; Maurício, A.C.; Lopes, M.A.; Santos, J.D.; Neto, B. Assessment of the environmental impacts of medical devices: A review. Environ. Dev. Sustain. 2020, 1–26. [Google Scholar] [CrossRef]

- Lee, A.W.L.; Neo, E.R.K.; Khoo, Z.-Y.; Yeo, Z.; Tan, Y.S.; Chng, S.; Yan, W.; Lok, B.K.; Low, J.S.C. Life cycle assessment of single-use surgical and embedded filtration layer (EFL) reusable face mask. Resour. Conserv. Recycl. 2021, 170, 105580. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization ISO 14040:2006. Environmental Management–Life Cycle Assessment–Principles and Framework; International Organization for Standarization: Geneva, Switzerland, 2006. [Google Scholar]

- Lepelletier, D.; Grandbastien, B.; Romano-Bertrand, S.; Aho, S.; Chidiac, C.; Géhanno, J.F.; Chauvin, F. What face mask for what use in the context of the COVID-19 pandemic? The French guidelines. J. Hosp. Infect. 2020, 105, 414–418. [Google Scholar] [CrossRef] [PubMed]

- Jonel Elsanek Olefine 150. Available online: http://www.jonelsl.com/wp-content/uploads/2020/07/fitxa_150_Olefine_2020.pdf (accessed on 4 February 2021).

- ISPRA – Istituto Superiore per la Protezione e la Ricerca Ambientale. I rifiuti costituiti da DPI usati. Available online: https://www.isprambiente.gov.it/files2020/notizie/rapporto-ispra-dpi-usati.pdf (accessed on 5 January 2021).

- Huijbregts, M.; Steinmann, Z.J.N.; Elshout, P.M.F.M.; Stam, G.; Verones, F.; Vieira, M.D.M.; Zijp, M.; van Zelm, R. ReCiPe 2016–A harmonized life cycle impact assessment method at midpoint and endpoint level. Report I: Characterization. Natl. Inst. Public Heal. Environ. 2017, 22, 138–147. [Google Scholar]

- Althaus, H.-J.; Bauer, C.; Doka, G.; Dones, R.; Frischknecht, R.; Hischier, R.; Hellweg, S.; Humbert, S.; Jungbluth, N.; Köllner, T.; et al. Implementation of Life Cycle Impact Assessment Methods; Ecoinvent Report No. 3, v2.2; Hischier, R., Weidema, B., Eds.; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2010. [Google Scholar]

- European Commission Communication from the Commission to the European Parliament, the Council, the Economic and Social Committee and the Committee of the Regions. A new Circular Economy Action Plan For a cleaner and more competitive Europe. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020DC0098 (accessed on 13 January 2021).

- Ellen MacArthur Foundation Circularity Indicators. An Approach to Measure Circularity. Methodology; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Goddin, J. A free Calculator for the Materials Circularity Indicator. Available online: https://www.hoskinscircular.com/blog/calculator-material-circularity-simple (accessed on 3 February 2021).

- Jeswiet, J.; Hauschild, M. EcoDesign and future environmental impacts. Mater. Des. 2005, 26, 629–634. [Google Scholar] [CrossRef]

- Luttropp, C.; Lagerstedt, J. EcoDesign and The Ten Golden Rules: Generic advice for merging environmental aspects into product development. J. Clean. Prod. 2006, 14, 1396–1408. [Google Scholar] [CrossRef]

- International Organization for Standarization. ISO 1400:2011 Environmental Management Systems–Guidelines for Incorporating Ecodesign; International Organization for Standarization: Geneva, Switzerland, 2011. [Google Scholar]

- Bovea, M.D.; Wang, B. Identifying environmental improvement options by combining life cycle assessment and fuzzy set theory. Int. J. Prod. Res. 2003, 41, 593–609. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Giacchetta, G. Integration of Design for Environmental Concepts in Product Life Cycle. In Design for Environment as a Tool for the Development of a Sustainable Sypply Chain; Springer: London, UK, 2012; pp. 11–32. [Google Scholar]

- Navajas, A.; Uriarte, L.; Gandía, L.M. Application of eco-design and life cycle assessment standards for environmental impact reduction of an industrial product. Sustainatibility 2017, 9, 1724. [Google Scholar] [CrossRef]

- Formentini, G.; Boix Rodríguez, N.; Favi, C.; Marconi, M. Challenging the engineering design process for the development of facial masks in the constraint of the COVID-19 pandemic. In Proceedings of the 31st CIRP Design Conference 2021 (CIRP Design 2021), Online, 19–20 May 2021. in press. [Google Scholar]

- Alenezi, H.; Cam, M.E.; Edirisinghe, M. A novel reusable anti-COVID-19 transparent face respirator with optimized airflow. Bio Des. Manuf. 2021, 4, 1–9. [Google Scholar] [CrossRef]

- Yi, H.; Pingsterhaus, A.; Song, W. The Adverse Effect of Wearing a Face Mask During the COVID-19 Pandemic and Benefits of Wearing Transparent Face Masks and Using Clear Speech on Speech Intelligibility. 2021. Available online: https://doi.org/10.31234/osf.io/z9c4k. (accessed on 15 January 2021).

- Caniato, M.; Marzi, A.; Gasparella, A. How much COVID-19 face protections influence speech intelligibility in classrooms? Appl. Acoust. 2021, 178, 108051. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Product Development Process. In Engineering Design; Springer: London, UK, 2007. [Google Scholar]

- Stone, R.B.; Wood, K.L.; Crawford, R.H. A heuristic method for identifying modules for product architectures. Des. Stud. 2000, 21, 5–31. [Google Scholar] [CrossRef]

- Fargnoli, M.; Rovida, E.; Troisi, R. The morphological matrix: Tool for the development of innovative design solutions. In Proceedings of the 4th International Conference on Axiomatic design, Firenze, Italy, 13–16 June 2006; ICAD Nashua: Nashua, NH, USA, 2006. [Google Scholar]

- Blanco, I.; Ingrao, C.; Siracusa, V. Life-cycle assessment in the polymeric sector: A comprehensive review of application experiences on the Italian scale. Polymers 2020, 12, 1212. [Google Scholar] [CrossRef]

- Ramesh, P.; Vinodh, S. State of art review on Life Cycle Assessment of polymers. Int. J. Sustain. Eng. 2020, 13, 411–422. [Google Scholar] [CrossRef]

- Gomes, T.S.; Visconte, L.L.Y.; Pacheco, E.B.A.V. Life Cycle Assessment of Polyethylene Terephthalate Packaging: An Overview. J. Polym. Environ. 2019, 27, 533–548. [Google Scholar] [CrossRef]

- Perelshtein, I.; Applerot, G.; Perkas, N.; Wehrschuetz-Sigl, E.; Hasmann, A.; Guebitz, G.; Gedanken, A. CuO–cotton nanocomposite: Formation, morphology, and antibacterial activity. Surf. Coat. Technol. 2009, 204, 54–57. [Google Scholar] [CrossRef]

- Zhou, J.; Hu, Z.; Zabihi, F.; Chen, Z.; Zhu, M. Progress and Perspective of Antiviral Protective Material. Adv. Fiber Mater. 2020, 2, 123–139. [Google Scholar] [CrossRef]

- Li, Y.; Leung, P.; Yao, L.; Song, Q.W.; Newton, E. Antimicrobial effect of surgical masks coated with nanoparticles. J. Hosp. Infect. 2006, 62, 58–63. [Google Scholar] [CrossRef] [PubMed]

- Brace, V.; Cheutet, V. A Framework to Support Requirements Analysis in Engineering Design. J. Eng. Des. 2012, 23, 876–904. [Google Scholar] [CrossRef]

- Kukharev, G.A.; Kaziyeva, N. Digital Facial Anthropometry: Application and Implementation. Pattern Recognit. Image Anal. 2020, 30, 496–511. [Google Scholar] [CrossRef]

- Madival, S.; Auras, R.; Singh, S.P.; Narayan, R. Assessment of the environmental profile of PLA, PET and PS clamshell containers using LCA methodology. J. Clean. Prod. 2009, 17, 1183–1194. [Google Scholar] [CrossRef]

- Hartanto, B.W.; Mayasari, D.S. Environmentally friendly non-medical mask: An attempt to reduce the environmental impact from used masks during COVID 19 pandemic. Sci. Total Environ. 2021, 760, 144143. [Google Scholar] [CrossRef] [PubMed]

- Van Straten, B.; Ligtelijn, S.; Droog, L.; Putman, E.; Dankelman, J.; Sperna Weiland, N.; Horeman, T. A Life Cycle Assessment of reprocessing face masks during the Covid-19 pandemic. Res. Sq. 2021. preprint version. [Google Scholar] [CrossRef]

| Type | Image | Component | Weight [g] | Material | Manufacturing Process |

|---|---|---|---|---|---|

| M1 |  | Filter | 0.50 | PP—Polypropylene | N.A. |

| 0.50 | PE—Polyester | ||||

| Structure | 30.00 | PLA | 3D printing | ||

| Bands | 3.00 | Synthetic rubber | N.A. | ||

| M2 |  | Filter | 1.28 | PP—Polypropylene | N.A. |

| 1.28 | PE—Polyester | ||||

| Nose adapter | 0.44 | Aluminum | Wire drawing | ||

| Bands | 0.02 | Cotton | N.A. | ||

| M3 |  | Filter | 5.00 | PP—Polypropylene | N.A. |

| Valve | 5.00 | PP—Polypropylene | Injection molding | ||

| Nose adapter | 0.95 | Aluminum | Wire drawing | ||

| Nose protection | 0.05 | PU—Polyurethane foam | N.A. | ||

| Bands | 3.00 | Synthetic rubber | N.A. | ||

| M4 |  | Filter | 5.00 | PP—Polypropylene | N.A. |

| Nose adapter | 0.95 | Aluminum | Wire drawing | ||

| Bands | 3.00 | Synthetic rubber | N.A. | ||

| M5 |  | Filter | 2.70 | PP—Polypropylene | N.A. |

| 2.70 | PE—Polyester | ||||

| Bands | 1.00 | Cotton | N.A. |

| Type | Lifespan | Units [million] | |

| M1 | Mask | - | 40 |

| Filter | 8 h | 600 | |

| M2 | 4 h | 1200 | |

| M3 | 8 h | 600 | |

| M4 | 8 h | 600 | |

| M5 | 50 washes | 40 | |

| LCIA Method | Indicator | Acronym | Unit |

|---|---|---|---|

| ReCiPe Midpoints | Global warming potential | GWP | [Kg CO2 eq] |

| Ozone depletion potential | ODP | [kg CFC11 eq] | |

| Photochemical oxidant formation potential | OFP | [kg NOx eq] | |

| Particulate matter formation potential | PMFP | [kg PM2.5 eq] | |

| Terrestrial acidification potential | TAP | [kg SO2 eq] | |

| Freshwater eutrophication potential | FEP | [kg P eq] | |

| Terrestrial ecotoxicity potential | TETP | [kg 1.4-DCB] | |

| Freshwater ecotoxicity potential | FETP | [kg 1.4-DCB] | |

| Marine ecotoxicity potential | METP | [kg 1.4-DCB] | |

| Human toxicity potential | HTP | [kg 1.4-DCB] | |

| Fossil fuel potential | FFP | [kg oil eq] | |

| Water consumption potential | WCP | [m3] | |

| ReCiPe Endpoints | Human Health | HH | [-] |

| Ecosystem | ED | [-] | |

| Resources | RA | [-] | |

| Single Issue | Cumulative energy demand | CED | [MJ] |

| Type | Requirement |

|---|---|

| Wish | Might be made of sustainable materials |

| Demand | Might be reusable |

| Demand | Might be durable |

| Wish | Might provide filtering status information |

| Wish | Might be recyclable |

| Demand | Need to allow to see the face |

| Wish | Might be personalized |

| Wish | Need to be cheap for daily use |

| Demand | Need to be available for each person in very constrained time |

| Impact Category | Unit | M1 | M2 | M3 | M4 | M5 |

|---|---|---|---|---|---|---|

| GWP | [Kg CO2 eq] | 3.9 × 106 | 2.7 × 107 | 5.6 × 107 | 3.8 × 107 | 1.5 × 106 |

| ODP | [kg CFC11 eq] | 1.8 | 6.1 | 1.0 × 10 | 8.3 | 2.3 |

| OFP | [kg NOx eq] | 1.3 × 104 | 1.0 × 105 | 1.9 × 105 | 1.4 × 105 | 5.7 × 103 |

| PMFP | [kg PM2.5 eq] | 3.7 × 103 | 3.4 × 104 | 5.7 × 104 | 4.5 × 104 | 2.1 × 103 |

| TAP | [kg SO2 eq] | 9.9 × 103 | 8.0 × 104 | 1.5 × 105 | 1.1 × 105 | 4.5 × 103 |

| FEP | [kg P eq] | 5.9 × 102 | 5.3 × 103 | 1.0 × 104 | 7.7 × 103 | 4.2 × 102 |

| TETP | [kg 1.4-DCB] | 4.9 × 106 | 2.9 × 107 | 4.8 × 107 | 4.3 × 107 | 1.9 × 106 |

| FETP | [kg 1.4-DCB] | 1.2 × 105 | 1.0 × 106 | 3.4 × 106 | 3.1 × 106 | 4.5 × 104 |

| METP | [kg 1.4-DCB] | 1.7 × 105 | 1.3 × 106 | 4.7 × 106 | 4.3 × 106 | 5.8 × 104 |

| HTP | [kg 1.4-DCB] | 2.4 × 106 | 1.4 × 107 | 9.6 × 107 | 9.2 × 107 | 7.5 × 105 |

| FFP | [kg oil eq] | 1.2 × 106 | 7.3 × 106 | 1.7 × 107 | 1.1 × 107 | 4.1 × 105 |

| WCP | [m3] | 5.4 × 104 | 2.0 × 105 | 3.9 × 105 | 2.9 × 105 | 7.0 × 104 |

| Impact Category | Unit | M1 | M2 | M3 | M4 | M5 | |

|---|---|---|---|---|---|---|---|

| Non renewable | Fossil | MJ | 5.4 × 107 | 3.3 × 108 | 7.6 × 108 | 4.8 × 108 | 1.9 × 107 |

| Nuclear | MJ | 3.7 × 106 | 1.9 × 107 | 7.3 × 107 | 3.9 × 107 | 2.0 × 106 | |

| Biomass | MJ | 4.2 × 103 | 5.5 × 103 | 1.2 × 104 | 1.1 × 104 | 6.2 × 103 | |

| Renewable | Biomass | MJ | 3.5 × 106 | 3.7 × 106 | 1.3 × 107 | 7.6 × 106 | 1.6 × 106 |

| Wind, solar, geothermal | MJ | 3.0 × 105 | 7.4 × 105 | 3.6 × 106 | 2.0 × 106 | 1.7 × 105 | |

| Water | MJ | 1.1 × 106 | 1.4 × 107 | 2.3 × 107 | 1.8 × 107 | 6.4 × 105 | |

| Total | MJ | 6.3 × 107 | 3.7 × 108 | 8.7 × 108 | 5.5 × 108 | 2.3 × 107 | |

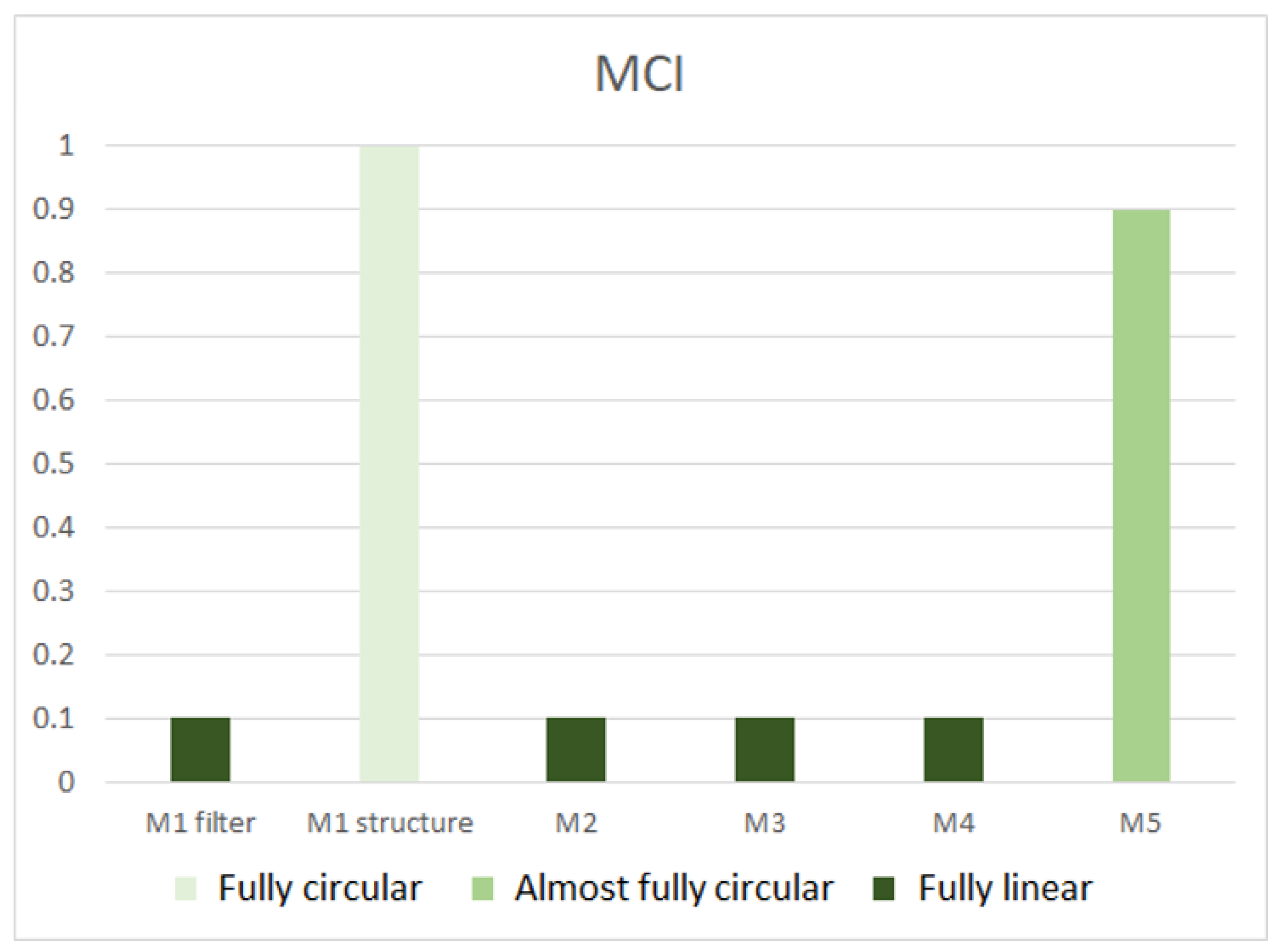

| Type | Utility | MCI |

|---|---|---|

| M1 filter | 1 | 0.1 |

| M1 structure | 300 | 1.0 |

| M2 | 1 | 0.1 |

| M3 | 1 | 0.1 |

| M4 | 1 | 0.1 |

| M5 | 50 | 0.9 |

| Lifecycle Phases | Criticalities | Related Eco-Design Guidelines |

|---|---|---|

| Material and manufacturing | High impacts related to manufacturing process (3D printing) (M1) |

|

| High impacts due to complex structure (M3) |

| |

| High impacts and low circularity due to the use of virgin materials (M1, M2, M3, M4, M5) |

| |

| Use | Disposable products (M2, M3, M4) |

|

| Low duration of filters (M1) |

| |

| End of life | Multimaterial for filters that reduces circularity (M1, M2) |

|

| Difficulties in separating components and materials (M2, M3, M4) |

| |

| Open loop EoL (M1, M2, M3, M4, M5) |

|

| ID | Module | Type | DF | CTM | BF |

|---|---|---|---|---|---|

| A | Import and regulate air | Main | X | ||

| B | Allow safely breathing | Main | X | ||

| C | Protect and cover exposed body parts | Main | X | ||

| D | Guarantee filter efficiency | Main | X | ||

| E | Guarantee filter change | Main | X | ||

| F | Personalize | Auxiliary | X | ||

| G | Display filtering status | Auxiliary | X | ||

| H | Display protection sterilization | Auxiliary | X | ||

| I | Extract water after virus separation | Auxiliary | X | X | |

| L | Monitor protection efficiency | Auxiliary | X | ||

| M | Convert air | Main | X | X | |

| N | Dissipate exhaust air | Main | X | X | |

| O | Block water droplets after breathing | Main | X | X | |

| P | Ergonomic for fixation and adaptation | Main | X | ||

| Q | Dissipate heat | Auxiliary | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boix Rodríguez, N.; Formentini, G.; Favi, C.; Marconi, M. Engineering Design Process of Face Masks Based on Circularity and Life Cycle Assessment in the Constraint of the COVID-19 Pandemic. Sustainability 2021, 13, 4948. https://doi.org/10.3390/su13094948

Boix Rodríguez N, Formentini G, Favi C, Marconi M. Engineering Design Process of Face Masks Based on Circularity and Life Cycle Assessment in the Constraint of the COVID-19 Pandemic. Sustainability. 2021; 13(9):4948. https://doi.org/10.3390/su13094948

Chicago/Turabian StyleBoix Rodríguez, Núria, Giovanni Formentini, Claudio Favi, and Marco Marconi. 2021. "Engineering Design Process of Face Masks Based on Circularity and Life Cycle Assessment in the Constraint of the COVID-19 Pandemic" Sustainability 13, no. 9: 4948. https://doi.org/10.3390/su13094948

APA StyleBoix Rodríguez, N., Formentini, G., Favi, C., & Marconi, M. (2021). Engineering Design Process of Face Masks Based on Circularity and Life Cycle Assessment in the Constraint of the COVID-19 Pandemic. Sustainability, 13(9), 4948. https://doi.org/10.3390/su13094948