Design of a Database of Case Studies and Technologies to Increase the Diffusion of Low-Temperature Waste Heat Recovery in the Industrial Sector

Abstract

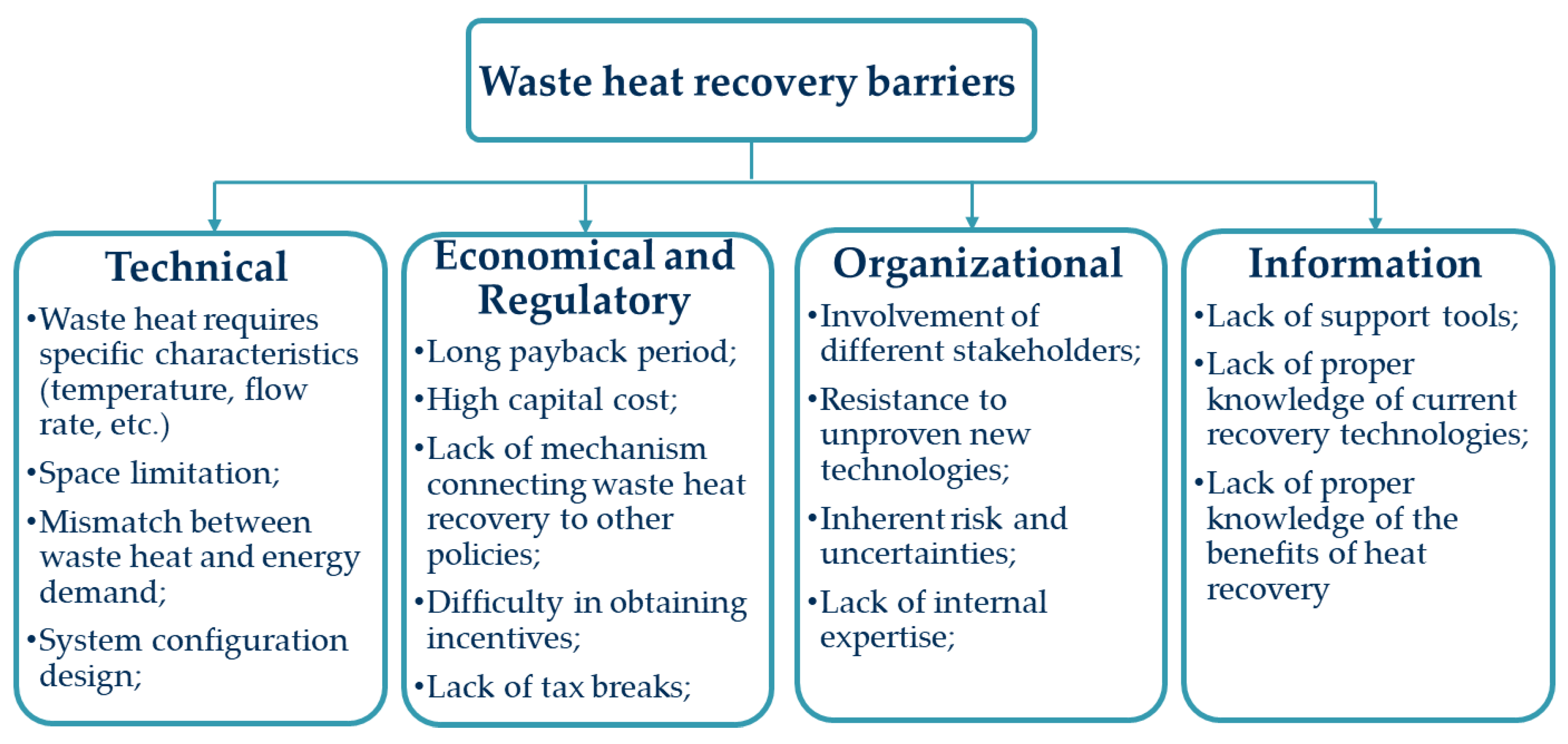

:1. Introduction and Background

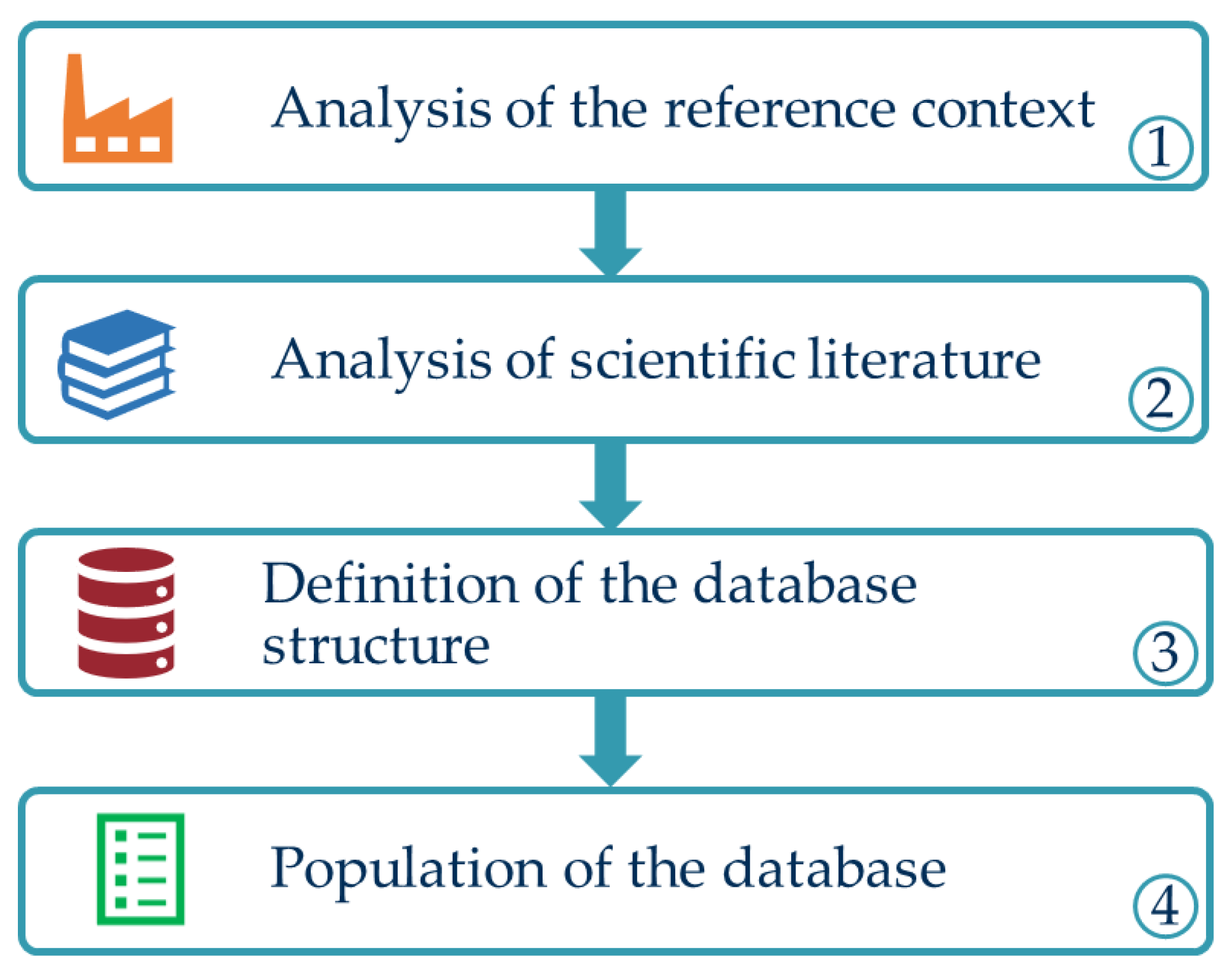

2. Database Design Methodology

- Analysis of the reference context: preliminary analysis of the reference scenario and formulation of the research keywords.

- Analysis of the scientific literature: search and preliminary analysis of the literature sources, to select the most representative studies to be used as input for the definition of the database structure.

- Definition of the database structure: in this phase, thanks to the results of the literature analysis, the database fields and the information to be collected are defined.

- Population of the database: the last phase involves further analysis of the sources found and their use for the database’s preliminary population.

- WHR case studies and technologies at ultra-low and low temperatures (temperature lower than 230 °C);

- Relevance and applicability to the industrial sector (for example, applications in the residential sector were not considered).

- Test the effectiveness of the two databases in containing all the information necessary to adequately characterize the various technologies (Technology database) and applications (Case study database);

- Verify the correctness of the data contained in the databases and evaluate the correspondence of the information collected, in terms of technologies available and effective applications in the industrial scenario;

- Test the usability of the tools in their role of supporting the identification of heat recovery opportunities.

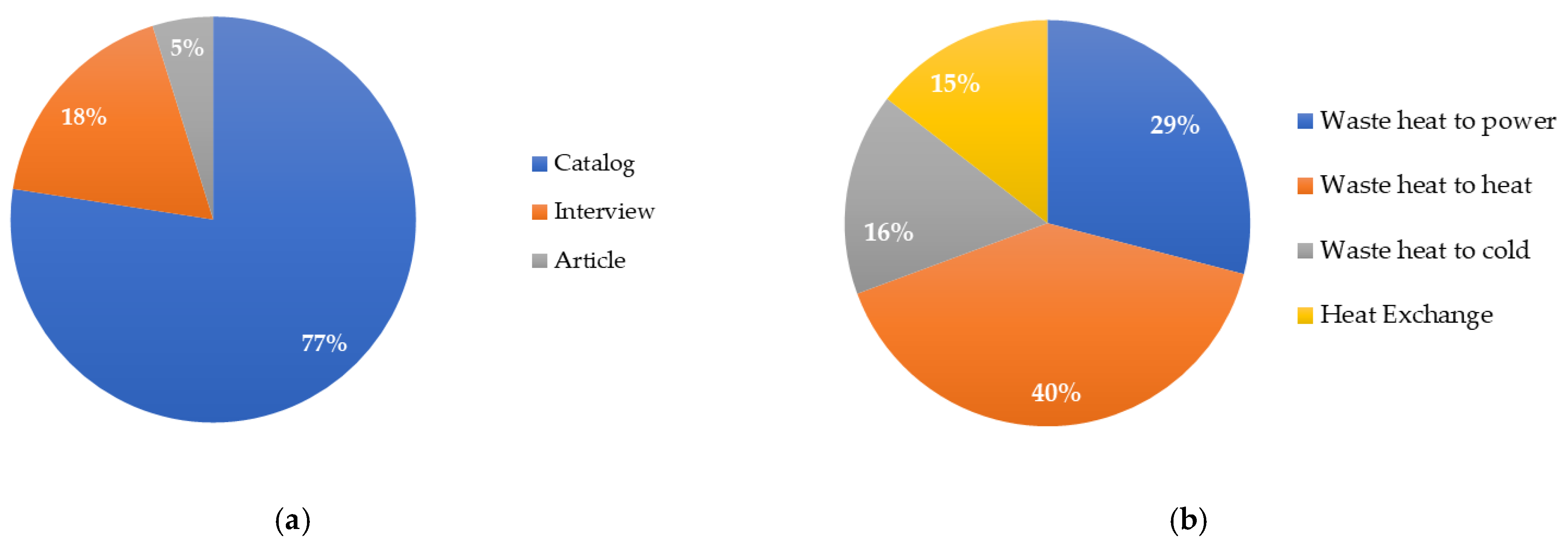

3. The Technology Database

3.1. Analysis of the Reference Context

- Waste Heat to Heat: technologies through which the waste heat recovered is used to produce thermal energy at a higher temperature level (heat pumps, mechanical vapor compression, absorption heat pumps, etc.).

- Waste Heat to Cold: technologies that utilize the waste heat recovered to produce cooling energy (absorption and adsorption chiller, etc.).

- Waste Heat to Power: technologies that convert the waste heat recovered to electricity (organic Rankine cycles, Kalina cycles, etc.).

- Heat Exchange: technologies through which the waste heat recovered is used directly at the same or a lower temperature. Heat exchangers and thermal energy storage are the two dominant technologies of this category.

3.2. Analysis of the Scientific Literature

3.3. Definition of the Database Structure

- Identification: includes fields to locate the technology within the database. Different technologies can be associated with each technology provider.

- Source: contains information relating to the source from which the technology was identified to guarantee its retrieval.

- Technology provider: contains the information necessary to identify the manufacturer of the technology under investigation.

- Technology information: identifies the technology, its state of maturity, and the type of recovery it allows to obtain. It also contains the main technical characteristics and ranges of application of this technology.

- Other information: includes other technical or economic information not recorded in the previous fields that may help the user evaluate and understand the technology.

3.4. Population of the Database

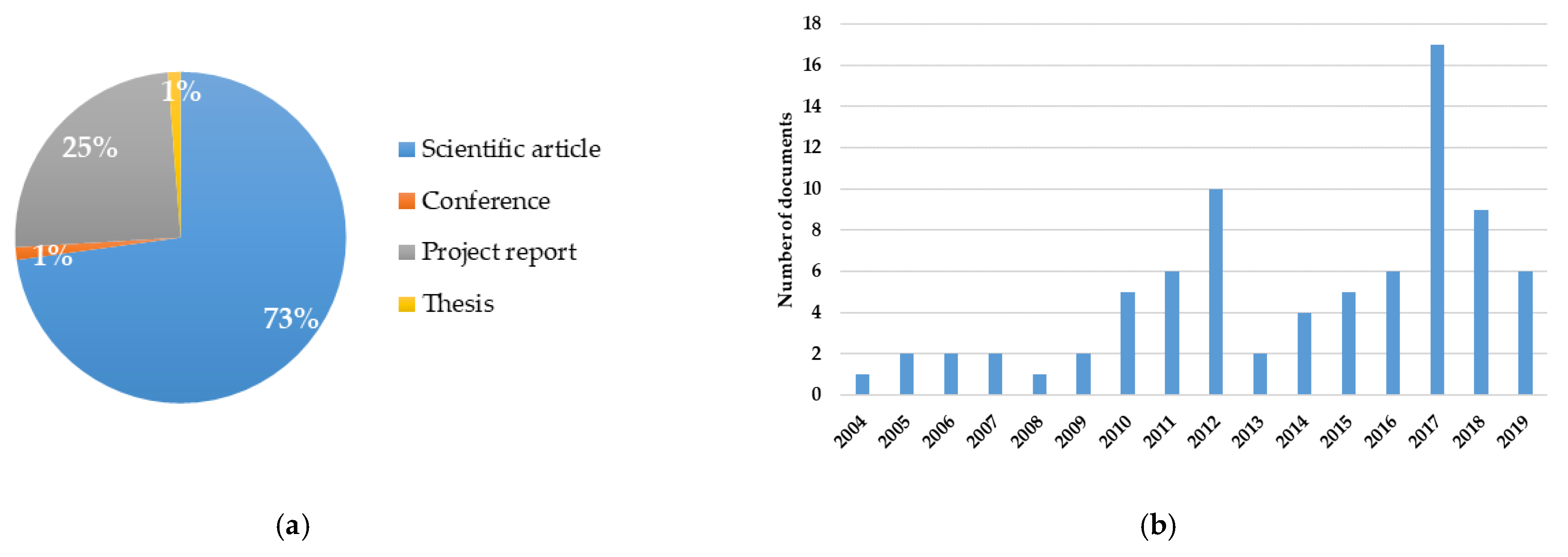

4. The Case Study Database

4.1. Analysis of the Reference Context

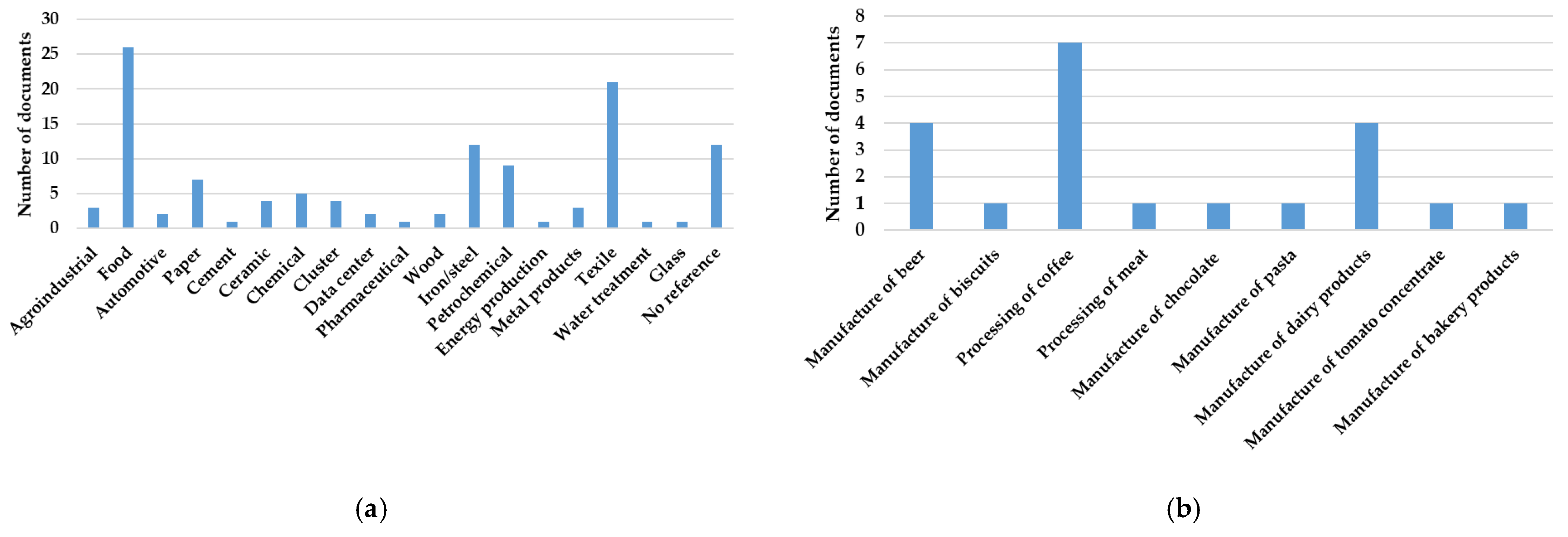

4.2. Analysis of the Scientific Literature

4.3. Definition of the Database Structure

- Identification: identification of each single case study within the database. For each source, there can be multiple WHR case collected.

- Source: reference to the document in which the case study is described.

- Company: this category geographically locates the heat recovery project and includes the industrial sectors and subsectors involved.

- Waste heat: includes all the information necessary to characterize the available waste heat source.

- Recovery process: includes information about the type of recovery intervention performed and the technology used, following the structure defined by the Technology database.

- Waste heat utilization: contains information describing how the recovered waste heat is used.

- Other information: refers to other technical, economic, and general information not recorded in the previous fields that may help the user to evaluate and understand the WHR application.

4.4. Population of the Database

5. Use of the Databases

- (a)

- User A consults the Case study database searching for heat recovery applications in a specific sector or sub-sector;

- (b)

- User B consults the Technology database looking for a technology suitable for the available waste heat characteristics.

6. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moran, E.F.; Lopez, M.C.; Moore, N.; Müller, N.; Hyndman, D.W. Sustainable Hydropower in the 21st Century. Proc. Natl. Acad. Sci. USA 2018, 115, 11891–11898. [Google Scholar] [CrossRef] [Green Version]

- Okot, D.K. Review of Small Hydropower Technology. Renew. Sustain. Energy Rev. 2013, 26, 515–520. [Google Scholar] [CrossRef]

- Kumar, Y.; Ringenberg, J.; Depuru, S.S.; Devabhaktuni, V.K.; Lee, J.W.; Nikolaidis, E.; Andersen, B.; Afjeh, A. Wind Energy: Trends and Enabling Technologies. Renew. Sustain. Energy Rev. 2016, 53, 209–224. [Google Scholar] [CrossRef]

- Tiwari, R.; Babu, N.R. Recent Developments of Control Strategies for Wind Energy Conversion System. Renew. Sustain. Energy Rev. 2016, 66, 268–285. [Google Scholar] [CrossRef]

- Santolamazza, A.; Dadi, D.; Introna, V. A Data-Mining Approach for Wind Turbine Fault Detection Based on SCADA Data Analysis Using Artificial Neural Networks. Energies 2021, 14, 1845. [Google Scholar] [CrossRef]

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.-H. Solar Energy: Potential and Future Prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Gong, J.; Li, C.; Wasielewski, M.R. Advances in Solar Energy Conversion. Chem. Soc. Rev. 2019, 48, 1862–1864. [Google Scholar] [CrossRef] [PubMed]

- Sundaram, M.M.; Appadoo, D. Traditional Salt-in-Water Electrolyte vs. Water-in-Salt Electrolyte with Binary Metal Oxide for Symmetric Supercapacitors: Capacitive vs. Faradaic. Dalton Trans. 2020, 49, 11743–11755. [Google Scholar] [CrossRef] [PubMed]

- Minakshi, M.; Mitchell, D.R.G.; Jones, R.T.; Pramanik, N.C.; Jean-Fulcrand, A.; Garnweitner, G. A Hybrid Electrochemical Energy Storage Device Using Sustainable Electrode Materials. ChemistrySelect 2020, 5, 1597–1606. [Google Scholar] [CrossRef]

- Sharma, P.; Minakshi, M.; Whale, J.; Jean-Fulcrand, A.; Garnweitner, G. Effect of the Anionic Counterpart: Molybdate vs. Tungstate in Energy Storage for Pseudo-Capacitor Applications. Nanomaterials 2021, 11, 580. [Google Scholar] [CrossRef] [PubMed]

- Braff, W.A.; Mueller, J.M.; Trancik, J.E. Value of Storage Technologies for Wind and Solar Energy. Nat. Clim. Chang. 2016, 6, 964–969. [Google Scholar] [CrossRef]

- Firth, A.; Zhang, B.; Yang, A. Quantification of Global Waste Heat and Its Environmental Effects. Appl. Energy 2019, 235, 1314–1334. [Google Scholar] [CrossRef]

- Brunner, C.; Muster, B.; Heig, E.; Schweiger, H.; Vannoni, C. Einstein—Expert System for an Intelligent Supply of Thermal Energy in Industry—Audit Methodology and Software Tool. Chem. Eng. Trans. 2010, 21, 685–690. [Google Scholar] [CrossRef]

- EINSTEIN II. Available online: https://www.einstein-energy.net/index.php/about-einstein/fundedprojects/einstein-ii (accessed on 23 March 2021).

- Glatzl, W.; Brunner, C.; Fluch, J. GREENFOODS—Energy Efficiency in the Food and Beverage Industry. In Proceedings of the Eceee Summer Study on Energy Efficiency, Toulon/Hyères, France, 1–6 June 2015. [Google Scholar]

- SEEnergies Project. Available online: https://www.seenergies.eu (accessed on 23 March 2021).

- Forman, C.; Muritala, I.K.; Pardemann, R.; Meyer, B. Estimating the Global Waste Heat Potential. Renew. Sustain. Energy Rev. 2016, 57, 1568–1579. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Wang, R.Z.; Yang, C. Perspectives for Low-Temperature Waste Heat Recovery. Energy 2019, 176, 1037–1043. [Google Scholar] [CrossRef]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste Heat Recovery Technologies and Applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Martin, M.; Harris, S. Prospecting the Sustainability Implications of an Emerging Industrial Symbiosis Network. Resour. Conserv. Recycl. 2018, 138, 246–256. [Google Scholar] [CrossRef]

- Dénarié, A.; Fattori, F.; Spirito, G.; Macchi, S.; Cirillo, V.F.; Motta, M.; Persson, U. Assessment of Waste and Renewable Heat Recovery in DH through GIS Mapping: The National Potential in Italy. Smart Energy 2021, 1, 100008. [Google Scholar] [CrossRef]

- Wheatcroft, E.; Wynn, H.; Lygnerud, K.; Bonvicini, G.; Leonte, D. The Role of Low Temperature Waste Heat Recovery in Achieving 2050 Goals: A Policy Positioning Paper. Energies 2020, 13, 2107. [Google Scholar] [CrossRef] [Green Version]

- Department of Energy (DOE). Waste Heat Recovery Systems. Chapter 6: Innovating Clean Energy Technologies in Advanced Manufacturing-Technology Assessments. In Quadrennial Technology Review 2015-An Assessment of Energy Technologies and Research Opportunities; DOE: Washington, DC, USA, 2015. [Google Scholar]

- Haddad, C.; Périlhon, C.; Danlos, A.; François, M.-X.; Descombes, G. Some Efficient Solutions to Recover Low and Medium Waste Heat: Competitiveness of the Thermoacoustic Technology. Energy Procedia 2014, 50, 1056–1069. [Google Scholar] [CrossRef]

- Simeone, A. A Decision Support System for Waste Heat Recovery in Manufacturing. CIRP Ann. 2016, 65, 21–24. [Google Scholar] [CrossRef] [Green Version]

- Ling-Chin, J.; Bao, H.; Ma, Z.; Taylor, W.; Paul Roskilly, A. State-of-the-Art Technologies on Low-Grade Heat Recovery and Utilization in Industry. In Energy Conversion—Current Technologies and Future Trends; Al-Bahadly, I.H., Ed.; IntechOpen: Londone, UK, 2019; ISBN 978-1-78984-904-2. [Google Scholar]

- Kovala, T.; Wallin, F.; Hallin, A. Factors Influencing Industrial Excess Heat Collaborations. Energy Procedia 2016, 88, 595–599. [Google Scholar] [CrossRef] [Green Version]

- Grönkvist, S.; Sandberg, P. Driving Forces and Obstacles with Regard to Co-Operation between Municipal Energy Companies and Process Industries in Sweden. Energy Policy 2006, 34, 1508–1519. [Google Scholar] [CrossRef]

- Broberg Viklund, S.; Karlsson, M. Industrial Excess Heat Use: Systems Analysis and CO2 Emissions Reduction. Appl. Energy 2015, 152, 189–197. [Google Scholar] [CrossRef] [Green Version]

- The EU-MERCI Project. Available online: http://www.eumerci.eu (accessed on 23 March 2021).

- Maggiore, S.; Realini, A.; Zagano, C. ’Good Practices’ to Improve Energy Efficiency in the Industrial Sector. Int. J. Energy Prod. Manag. 2020, 5, 259–271. [Google Scholar] [CrossRef]

- IAC: Industrial Assessment Centers. Available online: https://iac.university (accessed on 23 March 2021).

- MAESTRI Project. Available online: http://maestri-spire.eu/ (accessed on 23 March 2021).

- SHIP Plants. Available online: http://ship-plants.info (accessed on 23 March 2021).

- AEE—Institut Für Nachhaltige Technologien—“Matrix of Industrial Process Indicators”. Available online: http://wiki.zero-emissions.at/index.php?title=Main_Page (accessed on 23 March 2021).

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial Waste Heat Recovery Technologies: An Economic Analysis of Heat Transformation Technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Papapetrou, M.; Kosmadakis, G.; Cipollina, A.; La Commare, U.; Micale, G. Industrial Waste Heat: Estimation of the Technically Available Resource in the EU per Industrial Sector, Temperature Level and Country. Appl. Therm. Eng. 2018, 138, 207–216. [Google Scholar] [CrossRef]

- Dadi, D.; Introna, V.; Cesarotti, V.; Benedetti, M. Design and Development of a Database to Identify and Evaluate Waste Heat Recovery Opportunities. In Proceedings of the Summer School Francesco Turco, Bergamo, Italy, 9–11 September 2020. [Google Scholar]

- Johnson, I.; Choate, W.T.; Davidson, A. Waste Heat Recovery: Technology and Opportunities in U.S. Industry; BCS, Inc.: Laurel, MD, USA; Washington, DC, USA, 2008; p. 112. [Google Scholar]

- L. 10/1991 Norme per L’attuazione del Piano Energetico Nazionale in Materia di uso Razionale Dell’energia, di Risparmio Energetico e di Sviluppo Delle Fonti Rinnovabili di Energia. 1991. Available online: https://www.gazzettaufficiale.it/eli/id/1991/01/16/091G0015/sg (accessed on 23 March 2021).

- Berlin, J.; Motro, A. Database Schema Matching Using Machine Learning with Feature Selection. Semin. Contrib. Inf. Syst. Eng. 2013, 15, 315–329. [Google Scholar]

- Rahm, E.; Bernstein, P.A. A Survey of Approaches to Automatic Schema Matching. VLDB J. 2001, 10, 334–350. [Google Scholar] [CrossRef] [Green Version]

- Benedetti, M.; Dadi, D.; Introna, V.; Santolamazza, A. Proposal of a Methodology for the Preliminary Assessment of Low Temperature Heat Recovery Opportunities for Industrial Applications. In Proceedings of the International Conference on Applied Energy 2020 (ICAE 2020), Bangkok/Virtual, Thailand, 1–10 December 2020. [Google Scholar]

| Range of Waste Heat | Temperature |

|---|---|

| Ultra-low temperature | <120 °C |

| Low temperature | 120–230 °C |

| Medium temperature | 230–650 °C |

| High temperature | 650–870 °C |

| Ultra-high temperature | >870 °C |

| Category | Consolidated Technologies | Emerging Technologies | ||

|---|---|---|---|---|

| <120 °C | 120–250 °C | <120 °C | 120–250 °C | |

| Waste heat to heat | Heat pumps | Heat pumps | Thermoacoustic HP 1 | Heat transformer |

| Absorption HP 1 | High temperature HP 1 | High temperature HP 1 | ||

| Waste heat to cold | Absorption chiller | - | Adsorption chiller | Thermoacoustic Chiller |

| Waste heat to power | ORC 2 | ORC 2 | Electrochemical systems | Thermoelectric generator |

| Kalina cycle | Piezoelectric and pyroelectric systems | |||

| Heat Exchange | Shell, tube and plate heat exchangers | Shell, tube and plate heat exchangers | Non-metallic and corrosion-resistant heat exchangers | Recuperators with innovative geometries |

| Air preheaters | Heat pipe exchanger | Membrane type systems for latent heat recovery | Advanced design of metallic heat wheel heat pipe exchanger | |

| Direct contact water heaters | Metallic heat wheel | Desiccant systems for latent heat recovery | Self-recuperative burners | |

| Non-metallic heat exchangers | Convection recuperator | Systems with phase change material | Systems with phase change material | |

| Category | Field | Description |

|---|---|---|

| Identification | Provider ID | A unique progressive number assigned to the WHR 1 provider technology |

| Technology ID | A unique progressive number assigned to the WHR 1 specific technology | |

| Source | Source type | Scientific article, project report, catalog, interview, etc. |

| Provider/Authors | Name of the technology provider or authors | |

| Link | Source reference (e.g., DOI 2, website, etc.) | |

| Year | Time reference (e.g., year of publication, year of the catalog, year of the interview with the supplier, etc.) | |

| Technology provider | Geographical reference | The country or countries in which the technology provider works |

| Contact info | Useful information to contact the technology provider (e.g., email address) | |

| Type of provider | Manufacturer, retailer or both | |

| Technology information | Recovery type | Indicates the type of heat recovery (e.g., waste heat to electricity, waste heat to cooling, etc.) |

| Technology | type of technology (e.g., ORC 3, heat pumps, etc.) | |

| Technology description | Additional information on the technology | |

| State of maturity | It represents the state of maturity of the technology (e.g., consolidated, emerging, etc.) | |

| Applications | Description of the possible primary applications of the technology | |

| Model | If the technology can be identified with a specific model | |

| Vector fluid | Vector fluid used in the recovery process (e.g., water, oil, etc.) | |

| Input temperature | Range of admissible input temperatures of the vector fluid | |

| Minimum input temperature | Minimum admissible input temperatures of the vector fluid | |

| Vector fluid flow rate | Range of vector fluid flow rate that can be processed | |

| Working fluid | Working fluid used by technology (e.g., hydrocarbons, refrigerants, etc.) | |

| Input thermal power | Range or nominal input power | |

| Output type | Type of output energy vector (e.g., electricity, thermal energy, cooling energy) | |

| Output power | Range of nominal output power | |

| Output temperature | Range of output temperatures of the vector fluid | |

| Efficiency | Characteristic performance parameter of the technology (e.g., efficiency, COP 4, etc.) | |

| Dimension | Size required by the technology (e.g., m2/kWh) | |

| Other information | Expected lifetime | The useful life for which the technology was designed |

| Expected PBP 5 | Typical payback time | |

| Notes | Other relevant information about the WHR 1 technology |

| Industrial Sector | Low-Grade Waste Heat Source | Temperature (°C) |

|---|---|---|

| Petrochemical | Stack gas from crude distillation | 156 |

| Stack gas from vacuum distillation | 216 | |

| Exhaust from ethylene furnace | 149 | |

| Iron/steel making | Waste gas from coke oven | 200 |

| Blast furnace gas | 450 | |

| Exhaust gases from Cowper regenerators | 250 | |

| Exhaust gases from electric arc furnaces | 204 | |

| Aluminum | Exhaust from aluminum casting with a stack melter | 121 |

| Food and drink | Extracted air from cooking with fryers or ovens | 150–200 |

| Exhaust from drying with spray/rotary dryers | 110–160 | |

| Water vapor from evaporation and distillation | 100 | |

| Textile | Dyed waste water from drying | 90–94 |

| Stenter exhaust for fabric drying and finishing | 180 | |

| Waste water rejected from heat exchangers | 58–66 | |

| Paper | Waste steam from slag flushing in furnace | 95–100 |

| Waste water from slag flushing in furnace | 65–85 | |

| Cooling water from furnace wall cooling | 35–45 | |

| Cement | Exhaust from cement kilns using 5- or 6-stage preheaters | 204–300 |

| Hot air discharged from clinker coolers | 100 | |

| Chemical and Pharmaceutical | Distillation processes | 100–300 |

| Focused on the Research Subject | Focused on Technologies | Focused on Sectors with High Waste Heat Recovery Potential |

|---|---|---|

| Waste heat recovery, low-temperature waste heat, low grade industrial waste heat, low grade industrial waste heat case study, industrial waste heat recovery case study, energy recovery, industrial energy symbiosis, industrial symbiosis | Heat pump, Organic Rankine Cycle, Heat Exchanger Network | Agrifood, Dairy industry, Food, Paper and Pulp Industry, Chemical Industry, Textile industry |

| Category | Field | Description |

|---|---|---|

| Identification | Document ID | A unique progressive number assigned to the source |

| Project ID | A unique progressive number assigned to the heat recovery project | |

| Source | Authors | Name of the authors |

| Year | Year of publication | |

| Source type | Scientific article, project report, etc. | |

| Journal | In the case of a scientific article, it indicates the publication journal | |

| Link | Source reference (e.g., DOI 1, URL 2, etc.) | |

| Company | Geographical reference | The country in which the WHR 3 project is implemented |

| Sectors | Sectors involved in the production of waste heat | |

| Sub-sectors | In the case of a more detailed identification of the sector | |

| Other sectors involved | Sectors involved in the use of waste heat (if different from the previous one) | |

| Waste Heat | Process | Description of the process that produces waste heat |

| Vector | Source from which the heat is recovered (e.g., hot water, exhaust gas) | |

| Quantity | Flow, thermal power or heat produced | |

| Availability | Frequency of waste heat production (e.g., hour per year) | |

| Temperature | Waste heat temperature | |

| Flow rate | Waste heat flow rate | |

| Recovery process | Recovery type | Indicates the type of heat recovery (e.g., waste heat to electricity, waste heat to cooling, etc.) |

| Technology | WHR3 technology used (e.g., ORC 4, heat pumps, etc.) | |

| Technology description | Additional information on the technology used | |

| State of maturity | It represents the state of maturity of the technology (e.g., consolidated, emerging, etc.) | |

| Vector fluid | Vector fluid used in the recovery process (e.g., water, oil, etc.) | |

| Vector fluid quantity | Vector fluid flow rate | |

| Waste heat utilization | Receiving process | The process that receives the recovered energy |

| Internal/External | Specifies the nature of the heat exchange, which can be internal or external to the process | |

| Quantity | Flow, thermal power or heat produced | |

| Use | Frequency of waste heat utilization (e.g., hour per year) | |

| Temperature | The temperature at which the “recovered” energy carrier is used | |

| Other information | Barriers | Main barriers encountered in project implementation |

| Identified solutions | If during the implementation of the project solutions were evaluated to overcome barriers | |

| Notes | Other relevant information about the WHR3 project |

| Case Study Database | ||||||

| Source Type | Sub-Sectors * | Process | Receiving Process | Technology | Quantity | Temperature |

| Project report | Manufacture of dairy products | Process water cooling | Production of hot water for heating of a nearby greenhouse | Heat pump | 7.2 MW | 73 °C |

| Project report | Manufacture of dairy products | Recovery of waste heat from the refrigeration system condenser | Preheating of the air to produce powdered milk | Heat pump | 1.25 MW | 80 °C |

| Technology database | ||||||

| Source type | Recovery type | Technology * | State of maturity | Vector fluid | Output power | Output temperature |

| Catalog | Waste Heat to Heat | Heat pump | Consolidated | Water | 0.6–2.0 MW | 80 |

| Catalog | Waste Heat to Heat | Heat pump | Consolidated | Water | 0.6–10.0 MW | 70–90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benedetti, M.; Dadi, D.; Giordano, L.; Introna, V.; Lapenna, P.E.; Santolamazza, A. Design of a Database of Case Studies and Technologies to Increase the Diffusion of Low-Temperature Waste Heat Recovery in the Industrial Sector. Sustainability 2021, 13, 5223. https://doi.org/10.3390/su13095223

Benedetti M, Dadi D, Giordano L, Introna V, Lapenna PE, Santolamazza A. Design of a Database of Case Studies and Technologies to Increase the Diffusion of Low-Temperature Waste Heat Recovery in the Industrial Sector. Sustainability. 2021; 13(9):5223. https://doi.org/10.3390/su13095223

Chicago/Turabian StyleBenedetti, Miriam, Daniele Dadi, Lorena Giordano, Vito Introna, Pasquale Eduardo Lapenna, and Annalisa Santolamazza. 2021. "Design of a Database of Case Studies and Technologies to Increase the Diffusion of Low-Temperature Waste Heat Recovery in the Industrial Sector" Sustainability 13, no. 9: 5223. https://doi.org/10.3390/su13095223

APA StyleBenedetti, M., Dadi, D., Giordano, L., Introna, V., Lapenna, P. E., & Santolamazza, A. (2021). Design of a Database of Case Studies and Technologies to Increase the Diffusion of Low-Temperature Waste Heat Recovery in the Industrial Sector. Sustainability, 13(9), 5223. https://doi.org/10.3390/su13095223