Striding towards Sustainability: A Framework to Overcome Challenges and Explore Opportunities through Industry 4.0

Abstract

1. Introduction

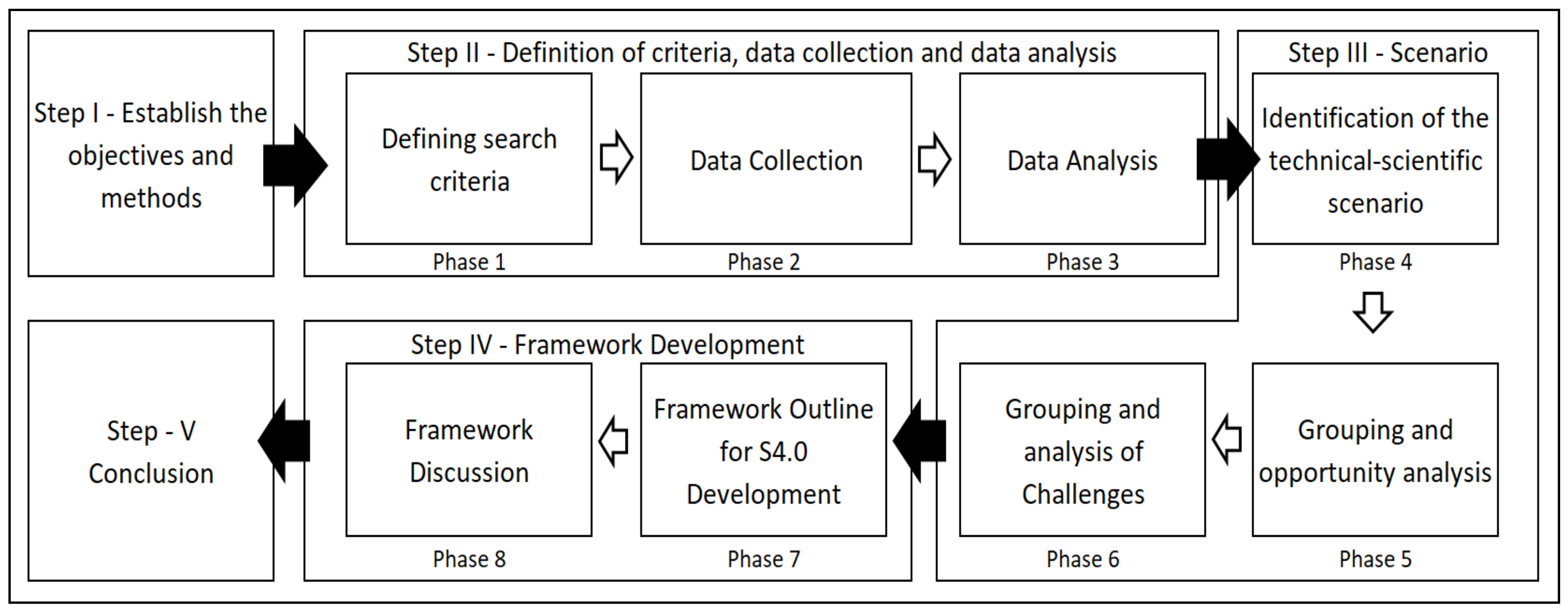

2. Scientific Method

3. Scientific-Technical Scenario

3.1. India

3.1.1. Government

3.1.2. Organizations

3.1.3. Academy

3.2. United States of America

3.2.1. Government

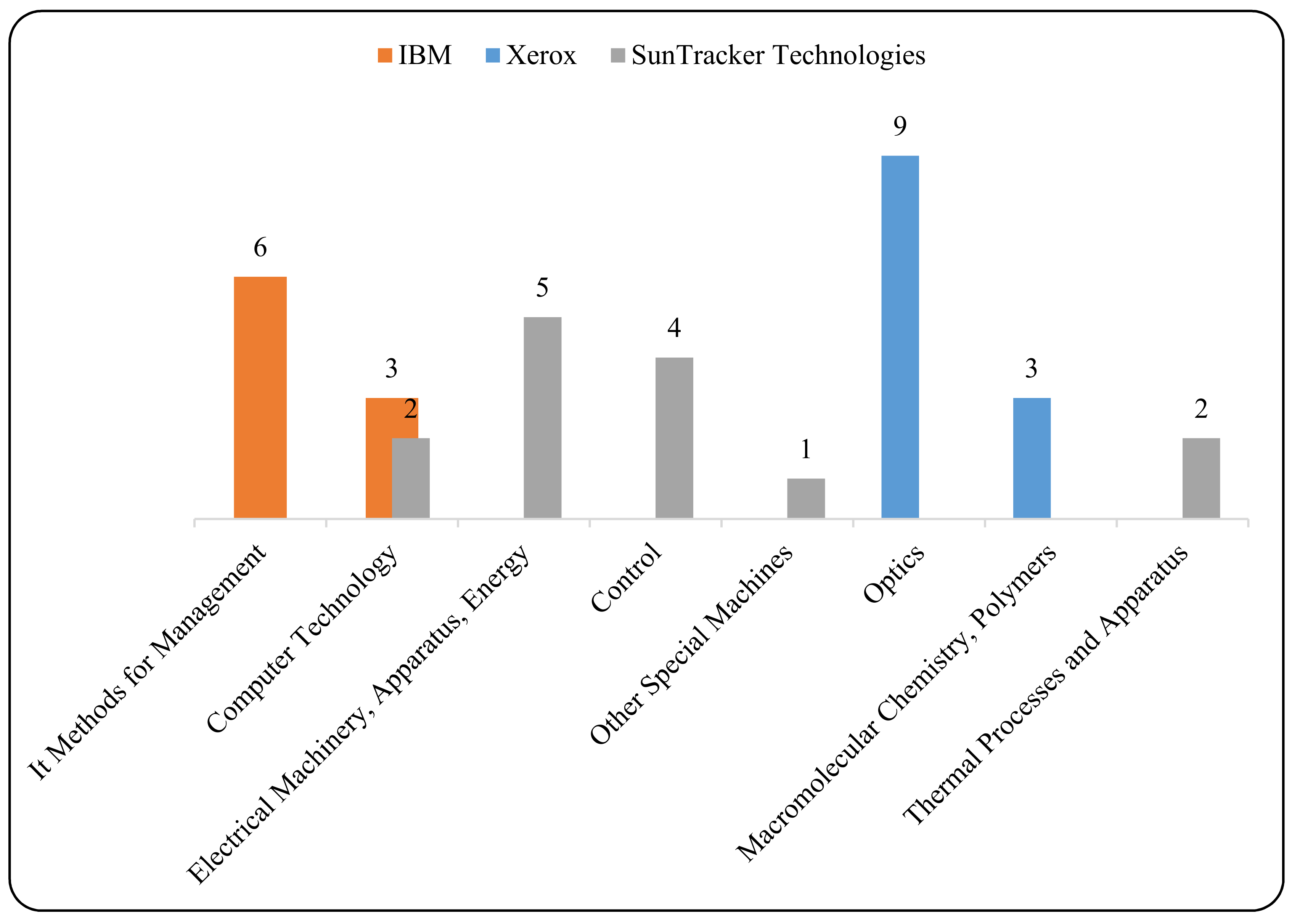

3.2.2. Organizations

3.2.3. Academy

3.3. China

3.3.1. Government

3.3.2. Organizations

3.3.3. Academy

3.4. Germany

3.4.1. Government

3.4.2. Organizations

3.4.3. Academy

4. Opportunities and Challenges to Develop S4.0

5. Framework for Developing S4.0

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

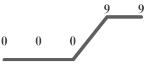

| Countries, H-Index | Total Citations—Documents | Citations | Documents | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2015 | 2016 | 2017 | 2018 | 2019 | 2015 | 2016 | 2017 | 2018 | 2019 | ||

| Germany, 6 | 220-6 |  |  | ||||||||

| India, 5 | 109-9 |  |  | ||||||||

| Brazil, 4 | 151-6 |  |  | ||||||||

| United States of America, 4 | 86-13 |  |  | ||||||||

| France, 3 | 110-3 |  |  | ||||||||

| China, 3 | 47-3 |  |  | ||||||||

| United Kingdom, 3 | 46-6 |  |  | ||||||||

| Malaysia, 2 | 111-3 |  |  | ||||||||

| Estonia, 2 | 70-2 |  |  | ||||||||

| Sweden, 2 | 54-3 |  |  | ||||||||

Appendix B

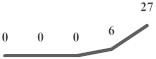

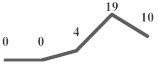

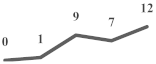

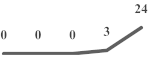

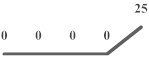

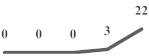

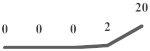

| # | Title | Authors (Year) | Journal (ISSN) | Opportunities | Challenges | Total Citations (18/02/20) | Evolution of Citations | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2015 | 2016 | 2017 | 2018 | 2019 | |||||||

| 1 | Industry 4.0: A Solution Towards Technology Challenges Of Sustainable Business Performance | Haseeb et al. (2019) [33] | Social Sciences (2076-0760) | Mapping How Industry 4.0 Is Benefiting Sustainable Performance In Multinationals | Financial Challenges For SMEs To Acquire Cutting-Edge Technologies | 109 |  | ||||

| 2 | What drives the implementation of industry 4.0? The role of opportunities and challenges in the context of sustainability | Müller et al. (2018) [38] | Sustainability (2071-1050) | Analyze The Benefits Of Industry 4.0 Within The Field Of Sustainability | Lack Of Know-How For Implementing Industry 4.0 Technologies | 75 |  | ||||

| 3 | When titans meet – can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors | Jabbour et al. (2018a) [25] | Technological Forecasting And Social Change (0040-1625) | Identify The Synergies And Dissonances Between Industry 4.0 And Sustainability | Challenges In Integrating Industry 4.0 With Organizations Sustainability Goals | 54 |  | ||||

| 4 | Industry 4.0 And The Circular Economy: A Proposed Research Agenda And Original Roadmap For Sustainable Operations | Jabbour et al. (2018b) [126] | Annals Of Operations Research (0254-5330) | Propose Best Practices With Industry 4.0 Technologies That Enhance Circular Economy In Organizations | Coordinate Actions In Different Organizational Areas And Cybersecurity Concerns | 49 |  | ||||

| 5 | Sustainable Industrial Value Creation: Benefits And Challenges Of Industry 4.0 | Kiel et al. (2017) [29] | International Journal Of Innovation Management (1363-9196) | Measure The Cost Benefit Of Integrating Industry 4.0 And Sustainability | High Cost To Adapt The Technological Infrastructure For Connection And Data Exchange Within The Organization | 48 |  | ||||

| 6 | Sustainable Industry 4.0 Framework: A Systematic Literature Review Identifying The Current Trends And Future Perspectives | Kamble et al. (2018) [37] | Process Safety And Environmental Protection (0957-5820) | Identify Trends In Scientific Research On Sustainable Industry 4.0 | Lack Of Initial Data On The Benefits Of Industry 4.0 For Organizational Sustainability | 46 |  | ||||

| 7 | Sustainable Business Models And Structures For Industry 4.0 | Prause (2015) [47] | Journal Of Security And Sustainability Issues (2029-7017) | Identify Opportunities For New Sustainable Business Models In The Industrie 4.0 Age | Challenges With The New Normalizations For Sustainability With The Insertion Of Industry 4.0 | 37 |  | ||||

| 8 | Evaluating Challenges To Industry 4.0 Initiatives For Supply Chain Sustainability In Emerging Economies | Luthra and Mangla (2018) [65] | Process Safety And Environmental Protection (0957-5820) | Investigate The Impacts On Sustainability In Emerging Economies That Have Implemented Industry 4.0 In Supply Chains | Lack Of Knowledge Of The Impacts Of Industry 4.0 For Sustainability | 33 |  | ||||

| 9 | On Sustainable Production Networks For Industry 4.0 | Prause and Atari (2017) [30] | Entrepreneurship And Sustainability Issues (2345-0282) | Evaluate The Benefits For Sustainability In Implementing Industry 4.0 Technologies | Lack Of Infrastructure For Integration Of Value Chains | 33 |  | ||||

| 10 | From Automated Home To Sustainable, Healthy And Manufacturing Home: A New Story Enabled By The Internet-Of-Things And Industry 4.0 | Branger and Pang (2015) [48] | Journal Of Management Analytics (2327-0012) | Identify Opportunities To Make People’s Daily Lives More Sustainable Through Industry 4.0 | Difficulty In Balancing Production And High Energy Demand With Industry 4.0 Technologies | 29 |  | ||||

| 11 | Industry 4.0 As Enabler For A Sustainable Development: A Qualitative Assessment Of Its Ecological And Social Potential | Stock et al. (2018) [129] | Process Safety And Environmental Protection (0957-5820) | Evaluate The Sustainable Potential Of Industry 4.0 Within Organizations | Lack Of Skilled Labor And Challenges In Specializing The Labor Force | 27 |  | ||||

| 12 | A Comprehensive Review Of Big Data Analytics Throughout Product Lifecycle To Support Sustainable Smart Manufacturing: A Framework, Challenges And Future Research Directions | Ren et al. (2019) [106] | Journal Of Cleaner Production (0959-6526) | Measuring the impact of industry 4.0 technologies (cyber-physical systems etc.) On sustainability | Lack Of Adequate Data Management Infrastructure | 25 |  | ||||

| 13 | Sustainable Industrial Value Creation In SMEs: A Comparison Between Industry 4.0 And Made In China 2025 | Müller and Voigt (2018) [94] | International Journal Of Precision Engineering And Manufacturing-Green Technology (2288-6206) | Identify Which Jobs Have Emerged And Which Will Be Discontinued With Industry 4.0 | Challenges In Finding Suitable Partners And Suppliers With Industry 4.0 Technologies | 25 |  | ||||

| 14 | Industry 4.0 And Sustainability Implications: A Scenario-Based Analysis Of The Impacts And Challenges | Bonilla et al. (2018) [26] | Sustainability (2071-1050) | Identify Opportunities For Industry 4.0’s Contribution To Environmental Sustainability | Lack Of Knowledge Of Industry 4.0 Technologies | 22 |  | ||||

| 15 | A Cross-Strait Comparison Of Innovation Policy Under Industry 4.0 And Sustainability Development Transition | Lin et al. (2017) [39] | Sustainability (2071-1050) | Propose New Strategic Interactions Between Industry 4.0 And Sustainability | Propose New Interactions Between Industry 4.0 And Corporate Sustainability | 18 |  | ||||

| 16 | Development Of A Risk Framework For Industry 4.0 In The Context Of Sustainability For Established Manufacturers | Birkel et al. (2019) [99] | Sustainability (2071-1050) | Investigate Opportunities In Industry 4.0 Management Risks Related To Sustainability | High Costs With Long And Unclear Amortization With The Implementation Of Industry 4.0 Technologies | 12 |  | ||||

| 17 | IoT Heterogeneous Mesh Network Deployment For Human-In-The-Loop Challenges Towards A Social And Sustainable Industry 4.0 | Garrido-Hidalgo et al. (2018) [124] | IEEE Access (2169-3536) | assessing the impact of the internet of things on sustainable productivity growth | lack of expertise of smart technologies in organizations | 12 |  | ||||

| 18 | Industry 4.0 And Supply Chain Sustainability: Framework And Future Research Directions | Bag et al. (2018) [118] | Benchmarking (1463-5771) | Identify Opportunities For Industry 4.0’s Contribution To Supply Chain Sustainability | Lack Of Skilled Labor To Implement Industry 4.0 Technologies | 11 |  | ||||

| 19 | Pharma Industry 4.0: Literature Review And Research Opportunities In Sustainable Pharmaceutical Supply Chains | Ding (2018) [122] | Process Safety And Environmental Protection (0957-5820) | Evaluate Sustainable Results By Implementing Fourth Industrial Revolution Concepts In Chemical Industries | Difficulty In Adapting Workers With Industry 4.0 Technologies | 8 |  | ||||

| 20 | Sustainable Development Of Industry 4.0: The Case Of High-Tech Products System Design | Batkovskiy et al. (2019) [128] | Entrepreneurship And Sustainability Issues (2345-0282) | Propose Best Practices For Integrating Industry 4.0 In Sustainable Product Development | Lack Of Infrastructure For Data Collection | 7 |  | ||||

| 21 | Maintenance For Sustainability In The Industry 4.0 Context: A Scoping Literature Review | Franciosi et al. (2018) [123] | IFAC-Papers Online (2405-8963) | Analyze The Concepts Of Industry 4.0 That Enhance Sustainable Manufacturing | Lack Of Knowledge Of The Impacts Of Industry 4.0 On The Value Chain | 7 |  | ||||

| 22 | Sustainable Robust Layout Using Big Data Approach: A Key Towards Industry 4.0 | Kumar et al. (2018) [120] | Journal Of Cleaner Production (0959-6526) | Assessing The Impact Of Smart Factory Layout On Sustainability In Organizations | Challenges In Integrating Industry 4.0 Into A Sustainable Layout | 6 |  | ||||

| 23 | Optimization Of Municipal Waste Collection Routing: Impact Of Industry 4.0 Technologies On Environmental Awareness And Sustainability | Bányai et al. (2019) [127] | International Journal Of Environmental Research And Public Health (1661-7827) | Propose The Integration Of Industry 4.0 In Water And Solid Waste Treatment In Organizations | Lack Of Infrastructure To Implement Industry 4.0 Technologies In Waste Collection | 6 |  | ||||

| 24 | Sustainable And Flexible Industrial Human Machine Interfaces To Support Adaptable Applications In The Industry 4.0 Paradigm | Ardanza et al. (2019) [125] | International Journal Of Production Research (0020-7543) | Implement The Human Machine Interface Model To Solve Sustainability Problems In Mass Production Customizations | Lack Of Knowledge Of The Impacts Of Smart Technologies On Production In Organizations | 6 |  | ||||

| 25 | Enhancing Sustainability And Energy Efficiency In Smart Factories: A Review | Meng et al. (2018) [41] | Sustainability (2071-1050) | Map The Concepts Of Industry 4.0 That Contribute To Sustainability | Lack Of Basic Infrastructure To Implement Industry 4.0 Technologies | 6 |  | ||||

| 26 | Industry 4.0 And Lean Manufacturing Practices For Sustainable Organisational Performance In Indian Manufacturing Companies | Kamble et al. (2019) [84] | International Journal Of Production Research (0020-7543) | Identify The Synergies And Dissonances Between Industry 4.0 And Lean Manufacturing In The Context Of Sustainability | Weak Administrative Support, Low Awareness, Reluctant Behavior And Lack Of Competence | 5 |  | ||||

| 27 | A Review Of Internet Of Things (IoT) Embedded Sustainable Supply Chain For Industry 4.0 Requirements | Manavalan and Jayakrishna (2019) [42] | Computers And Industrial Engineering (0360-8352) | Identifying Synergies And Dissonances When Implementing The Internet Of Things In Supply Chain Management | Financial Challenges To Implement Industry 4.0 Technologies | 5 |  | ||||

| 28 | Sustainable Production Scheduling In Open Innovation Perspective Under The Fourth Industrial Revolution | Shim et al. (2018) [121] | Journal Of Open Innovation: Technology, Market And Complexity (2199-8531) | Assess The Impact On Sustainability By Implementing Industry 4.0 Concepts In Production Scheduling | Lack Of Knowledge About The Impacts Of Industry 4.0 On Organizations | 5 |  | ||||

| 29 | An Empirical Investigation Of The Relationship Between Overall Equipment Efficiency (OEE) And Manufacturing Sustainability In Industry 4.0 With Time Study Approach | Yazdi et al. (2018) [119] | Sustainability (2071-1050) | Identify integration opportunities between industry 4.0 technologies (cyber-physical systems etc.) And supply chain management | High Investment To Implement Industry 4.0 Technologies | 5 |  | ||||

| 30 | Intelligent Sustainable Supplier Selection Using Multi-Agent Technology: Theory And Application For Industry 4.0 Supply Chains | Ghadimi et al. (2019) [56] | Computers And Industrial Engineering (0360-8352) | Assessing The Risks In The Transition From An Ordinary Factory To A Smart Factory | Lack Of Expertise In Industry 4.0 Technologies | 4 |  | ||||

References

- United Nations Sustainable Development Goals. Available online: https://www.un.org/sustainabledevelopment/sustainable-development-goals/ (accessed on 16 June 2020).

- World Health Organization. Available online: https://www.who.int/heli/risks/en/ (accessed on 16 June 2020).

- Borowiecki, M.; Machado, D.; Paunov, C.; Planes-Satorra, S. Supporting Research for Sustainable Development; OECD Science, Technology and Industry Policy Papers; OECD iLibrary: Paris, France, 2019; 71p. [Google Scholar] [CrossRef]

- Elkington, J. Accounting for the Triple Bottom Line. Meas. Bus. Excell. 1998, 2, 18–22. [Google Scholar] [CrossRef]

- Klewitz, J.; Hansen, E.G. Sustainability-oriented innovation of SMEs: A systematic review. J. Clean. Prod. 2014, 65, 57–75. [Google Scholar] [CrossRef]

- Isaksson, R. Creating a sense of urgency for sustainable development—Testing two system models. J. Clean. Prod. 2019, 227, 1173–1184. [Google Scholar] [CrossRef]

- Isaksson, R.; Buregyeya, A. Understanding sustainability—The case of building blocks in Tanzania and Uganda. TQM J. 2020. [Google Scholar] [CrossRef]

- Cöster, M.; Dahlin, G.; Isaksson, R. Are They Reporting the Right Thing and Are They Doing It Right?—A Measurement Maturity Grid for Evaluation of Sustainability Reports. Sustainability 2020, 12, 10393. [Google Scholar] [CrossRef]

- United Nations Transforming our world: The 2030 Agenda for Sustainable Development. Available online: https://www.un.org/ga/search/view_doc.asp?symbol=A/RES/70/1&Lang=E (accessed on 16 June 2020).

- United Nations Page and The Sustainable Development Goals. Available online: https://www.un-page.org/page-and-sustainable-development-goals (accessed on 16 June 2020).

- World Economic Forum. Davos Manifesto 2020: The Universal Purpose of a Company in the Fourth Industrial Revolution. Available online: https://www.weforum.org/agenda/2019/10/davos-2020-wef-world-economic-forum-theme/ (accessed on 15 June 2020).

- Bonavolonta, F.; Tedesco, A.; Moriello, R.S.L.; Tufano, A. Enabling wireless technologies for industry 4.0: State of the art. In Proceedings of the 2017 IEEE International Workshop on Measurement and Networking (M&N), Naples, Italy, 27–29 September 2017. [Google Scholar]

- Thoben, K.; Wiesner, S.; Wuest, T. “Industrie 4.0” and Smart Manufacturing—A Review of Research Issues and Application Examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef]

- Roblek, V.; Meško, M.; Krapež, A. A Complex View of Industry 4.0. SAGE Open 2016, 6, 215824401665398. [Google Scholar] [CrossRef]

- Ciffolilli, A.; Muscio, A. Industry 4.0: National and regional comparative advantages in key enabling technologies. Eur. Plan. Stud. 2018, 26, 2323–2343. [Google Scholar] [CrossRef]

- Bigliardi, B.; Bottani, E.; Casella, G. Enabling technologies, application areas and impact of industry 4.0: A bibliographic analysis. Procedia Manuf. 2020, 42, 322–326. [Google Scholar] [CrossRef]

- Bortolini, M.; Ferrari, E.; Gamberi, M.; Pilati, F.; Faccio, M. Assembly system design in the Industry 4.0 era: A general framework. IFAC PapersOnLine 2017, 50, 5700–5705. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S. Do Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- IIConsortium. The Industrial Internet Consortium: A Global Nonprofit Partnership Of Industry, Government and Academia. Available online: https://www.iiconsortium.org/about-us.htm (accessed on 23 June 2020).

- Li, L. China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0.”. Technol. Forecast. Soc. Chang. 2018, 135, 66–74. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef]

- Braccini, A.; Margherita, E. Exploring Organizational Sustainability of Industry 4.0 under the Triple Bottom Line: The Case of a Manufacturing Company. Sustainability 2018, 11, 36. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Godinho Filho, M. When titans meet—Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Bonilla, S.; Silva, H.; Terra da Silva, M.; Franco Gonçalves, R.; Sacomano, J. Industry 4.0 and Sustainability Implications: A Scenario-Based Analysis of the Impacts and Challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef]

- Lardo, A.; Mancini, D.; Paoloni, N.; Russo, G. The perspective of capability providers in creating a sustainable I4.0 environment. Manag. Decis. 2020, 58, 1759–1777. [Google Scholar] [CrossRef]

- Brozzi, R.; Forti, D.; Rauch, E.; Matt, D.T. The Advantages of Industry 4.0 Applications for Sustainability: Results from a Sample of Manufacturing Companies. Sustainability 2020, 12, 3647. [Google Scholar] [CrossRef]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.-I. Sustainable Industrial Value Creation: Benefits and Challenges of Industry 4.0. Int. J. Innov. Manag. 2017, 21, 1740015. [Google Scholar] [CrossRef]

- Prause, G.; Atari, S. On sustainable production networks for Industry 4.0. Entrep. Sustain. Issues 2017, 4, 421–431. [Google Scholar] [CrossRef]

- Lozano, R. Analysing the use of tools, initiatives, and approaches to promote sustainability in corporations. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 982–998. [Google Scholar] [CrossRef]

- Bajic, B.; Rikalovic, A.; Suzic, N.; Piuri, V. Industry 4.0 Implementation Challenges and Opportunities: A Managerial Perspective. IEEE Syst. J. 2020, 1, 1–14. [Google Scholar] [CrossRef]

- Haseeb, M.; Hussain, H.I.; Ślusarczyk, B.; Jermsittiparsert, K. Industry 4.0: A Solution towards Technology Challenges of Sustainable Business Performance. Soc. Sci. 2019, 8, 154. [Google Scholar] [CrossRef]

- Kimatu, J.N. Evolution of strategic interactions from the triple to quad helix innovation models for sustainable development in the era of globalization. J. Innov. Entrep. 2016, 5, 16. [Google Scholar] [CrossRef]

- Leydesdorff, L.; Meyer, M. Triple Helix indicators of knowledge-based innovation systems: Introduction to the special issue. Res. Policy 2006, 35, 1441–1449. [Google Scholar] [CrossRef]

- Ranga, M.; Etzkowitz, H. Triple Helix Systems: An Analytical Framework for Innovation Policy and Practice in the Knowledge Society. Ind. High. Educ. 2013, 27, 237–262. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Lin, K.; Shyu, J.; Ding, K. A Cross-Strait Comparison of Innovation Policy under Industry 4.0 and Sustainability Development Transition. Sustainability 2017, 9, 786. [Google Scholar] [CrossRef]

- Birkel, H.; Müller, J.M. Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability—A systematic literature review. J. Clean. Prod. 2021, 289, 125612. [Google Scholar] [CrossRef]

- Meng, Y.; Yang, Y.; Chung, H.; Lee, P.-H.; Shao, C. Enhancing Sustainability and Energy Efficiency in Smart Factories: A Review. Sustainability 2018, 10, 4779. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Nunhes, T.V.; Oliveira, O.J. Analysis of Integrated Management Systems research: Identifying core themes and trends for future studies. Total Qual. Manag. Bus. Excell. 2018, 31, 1–23. [Google Scholar] [CrossRef]

- Alvarenga, A.B.C.d.; Espuny, M.; Reis, J.S.d.; Silva, F.d.; Sampaio, N.A.d.; Nunhes, T.V.; Barbosa, L.C.F.M.; Santos, G.; de Oliveira, O.J. The Main Perspectives of The Quality of Life of Students In The Secondary Cycle: An Overview of The Opportunities, Challenges and Their Greatest Impact Elements. Int. J. Qual. Res. 2021, 15. [Google Scholar] [CrossRef]

- Hsieh, H.-F.; Shannon, S.E. Three Approaches to Qualitative Content Analysis. Qual. Health Res. 2005, 15, 1277–1288. [Google Scholar] [CrossRef]

- Swarnima, C.; Mehra, P.; Dasot, A. India’s Readiness for Industry 4.0—A Focus on Automotive Sector. Available online: http://www.grantthornton.in/insights/articles/indias-readiness-for-industry-4.0--a-focus-on-automotive-sector/ (accessed on 18 August 2020).

- Prause, G. Sustainable Business Models and Structures for Industry 4.0. J. Secur. Sustain. Issues 2015, 5, 159–169. [Google Scholar] [CrossRef]

- Branger, J.; Pang, Z. From automated home to sustainable, healthy and manufacturing home: A new story enabled by the Internet-of-Things and Industry 4.0. J. Manag. Anal. 2015, 2, 314–332. [Google Scholar] [CrossRef]

- Hirsch, J.E. Does the h index have predictive power? Proc. Natl. Acad. Sci. USA 2007, 104, 19193–19198. [Google Scholar] [CrossRef]

- Nunhes, T.V.; Garcia, E.V.; Espuny, M.; de Melo Santos, V.H.; Isaksson, R.; José de Oliveira, O. Where to Go with Corporate Sustainability? Opening Paths for Sustainable Businesses through the Collaboration between Universities, Governments, and Organizations. Sustainability 2021, 13, 1429. [Google Scholar] [CrossRef]

- Scopus Scopus. Available online: https://www.scopus.com/home.uri (accessed on 8 July 2020).

- Orbit Patent. Available online: https://www32.orbit.com/ (accessed on 17 July 2020).

- Schneider Electric about Us. Available online: https://www.se.com/in/en/about-us/company-profile/ (accessed on 20 August 2020).

- Schneider Electric EcoStruxureTM. Available online: https://www.se.com/in/en/work/campaign/innovation/overview.jsp (accessed on 20 August 2020).

- Schneider Electric EcoStruxureTM Building. Available online: https://www.se.com/in/en/work/campaign/innovation/buildings.jsp (accessed on 20 August 2020).

- Ghadimi, P.; Wang, C.; Lim, M.K.; Heavey, C. Intelligent sustainable supplier selection using multi-agent technology: Theory and application for Industry 4.0 supply chains. Comput. Ind. Eng. 2019, 127, 588–600. [Google Scholar] [CrossRef]

- VST Mobility Solutions about Us. Available online: https://vstmobility.com/about.php (accessed on 28 August 2020).

- VST Mobility Solutions IoT Services. Available online: https://vstmobility.com/ser_iot.php (accessed on 28 August 2020).

- VST Mobility Solutions BIN-19. Available online: https://vstmobility.com/bin-19.php (accessed on 28 August 2020).

- Da Motta Reis, J.S.; Silva, F.d.; Espuny, M.; Alexandre, L.G.L.; Barbosa, L.C.F.M.; Bonassa, A.C.M.; Faria, A.M.; Sampaio, N.A.d.; Santos, G.; de Oliveira, O.J. The Rapid Escalation of Publications on Covid-19: A Snapshot of Trends in the Early Months to Overcome the Pandemic and to Improve Life Quality. Int. J. Qual. Res. 2020, 14, 951–968. [Google Scholar] [CrossRef]

- Chung, M.; Bernheim, A.; Mei, X.; Zhang, N.; Huang, M.; Zeng, X.; Cui, J.; Xu, W.; Yang, Y.; Fayad, Z.A.; et al. CT Imaging Features of 2019 Novel Coronavirus (2019-nCoV). Radiology 2020, 295, 202–207. [Google Scholar] [CrossRef] [PubMed]

- National Institute of Industrial Engineering Vision e Mission. Available online: https://www.nitie.ac.in/vision-mission (accessed on 30 August 2020).

- Yadav, G.; Kumar, A.; Luthra, S.; Garza-Reyes, J.A.; Kumar, V.; Batista, L. A framework to achieve sustainability in manufacturing organisations of developing economies using industry 4.0 technologies’ enablers. Comput. Ind. 2020, 122, 103280. [Google Scholar] [CrossRef]

- Yadav, G.; Luthra, S.; Jakhar, S.K.; Mangla, S.K.; Rai, D.P. A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. J. Clean. Prod. 2020, 254, 120112. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Indian Institute of Technology Delhi Departments. Available online: https://home.iitd.ac.in/departments.php (accessed on 3 September 2020).

- United States Environmental Protection Agency. EPA Celebrates 50 Years of Research for a Healthier Environment. Available online: https://www.epa.gov/newsreleases/epa-celebrates-50-years-research-healthier-environment (accessed on 9 August 2020).

- Dernbach, J.C.; Mintz, J.A. Environmental Laws and Sustainability: An Introduction. Sustainability 2011, 3, 531–540. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Smart City Air Challenge Resource Pages: Community Case Studies. Available online: https://developer.epa.gov/city-case-studies/ (accessed on 12 August 2020).

- OECD Greenhouse Gas Emissions by Source. Available online: https://www.oecd-ilibrary.org/environment/data/oecd-environment-statistics/greenhouse-gas-emissions_data-00594-en (accessed on 24 June 2020).

- IBM About IBM. Available online: https://www.ibm.com/ibm/us/en/?lnk=fai-maib-usen (accessed on 10 August 2020).

- IBM Energy and Environment. Available online: https://www.ibm.com/ibm/green/ (accessed on 10 August 2020).

- Xerox about Xerox. Available online: https://www.xerox.com/en-us/about (accessed on 11 August 2020).

- Xerox Xerox DocuShare Flex. Available online: https://www.xerox.com/pt-br/servicos-empresariais/solucoes-de-gestao-de-conteudo-corporativo/docushare-flex (accessed on 18 August 2020).

- Xerox Como a Xerox® DocuShare® Ajudou um Fabricante de Móveis de 99 anos a Digitalizar 500.000 Documentos. Available online: https://www.xerox.com/pt-br/servicos-empresariais/solucoes-de-gestao-de-conteudo-corporativo/docushare-estudo-de-caso-sobre-eficiencia-do-fluxo-de-trabalho (accessed on 18 August 2020).

- Newell, J.P.; Vos, R.O. “Papering” Over Space and Place: Product Carbon Footprint Modeling in the Global Paper Industry. Ann. Assoc. Am. Geogr. 2011, 101, 730–741. [Google Scholar] [CrossRef]

- SunTracker Technologies Our Company. Available online: https://www.suntrackertech.com/about/ (accessed on 11 August 2020).

- Moschetti, R.; Mazzarella, L.; Nord, N. An overall methodology to define reference values for building sustainability parameters. Energy Build. 2015, 88, 413–427. [Google Scholar] [CrossRef]

- Banani, R.; Vahdati, M.M.; Shahrestani, M.; Clements-Croome, D. The development of building assessment criteria framework for sustainable non-residential buildings in Saudi Arabia. Sustain. Cities Soc. 2016, 26, 289–305. [Google Scholar] [CrossRef]

- SunTracker Technologies Horticultural Lighting Design. Available online: https://www.suntrackertech.com/horticultural/ (accessed on 18 August 2020).

- United Nations Goal 2: Zero Hunger. Available online: https://www.un.org/sustainabledevelopment/hunger/ (accessed on 16 June 2020).

- California State University Bakersfield CSUB Sustainability. Available online: https://www.csub.edu/sustainability/ (accessed on 18 August 2020).

- Reis, J.S.d.; Costa, A.C.F.; Espuny, M.; Batista, W.J.; Francisco, F.E.; Gonçalves, G.S.; Tasinaffo, P.M.; Dias, L.A.V.; da Cunha, A.M.; de Oliveira, O.J. Education 4.0: Gaps Research Between School Formation and Technological Development. In Proceedings of the 17th International Conference on Information Technology–New Generations (ITNG 2020); Latifi, S., Ed.; Springer: Cham, Switzerland, 2020; pp. 415–420. ISBN 978-3-030-43020-7. [Google Scholar]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2019, 58, 1–19. [Google Scholar] [CrossRef]

- Tuffnell, C.; Král, P.; Durana, P.; Krulicky, T. Industry 4.0-based Manufacturing Systems: Smart Production, Sustainable Supply Chain Networks, and Real-Time Process Monitoring. J. Self-Gov. Manag. Econ. 2019, 7, 7–12. [Google Scholar]

- Ainsworth-Rowen, E. Networked, Smart, and Responsive Devices in Sustainable Internet-of-Things-based Manufacturing Systems: Industrial Value Creation, Cognitive Decision-Making Algorithms, and Operational Performance Improvement. Econ. Manag. Financ. Mark. 2019, 14, 9. [Google Scholar]

- Tuffnell, C.; Král, P.; Siekelova, A.; Horák, J. Cyber-Physical Smart Manufacturing Systems: Sustainable Industrial Networks, Cognitive Automation, and Data-Centric Business Models. Econ. Manag. Financ. Mark. 2019, 14, 58. [Google Scholar]

- Fielden, A.; Michalkova, L.; Vrbka, J.; Lyakina, M. Smart Sustainable Data-driven Manufacturing: Cyber-Physical Production Systems and Internet of Things Sensing Networks. J. Self-Gov. Manag. Econ. 2019, 7, 7–13. [Google Scholar]

- Felstead, M. Cyber-Physical Production Systems in Industry 4.0: Smart Factory Performance, Innovation-driven Manufacturing Process Innovation, and Sustainable Supply Chain Networks. Econ. Manag. Financ. Mark. 2019, 14, 37. [Google Scholar]

- American Association for Economic Research ISBDA. Available online: https://aa-er.org/isbda?fbclid=IwAR18WjYSm6LqAMtXhvWDR_mlNLP9TjP5KraHAPmODcYhSWm5viZHqoB0tg8 (accessed on 19 August 2020).

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- International Monetary Fund. The People’s Republic of China: 2016 Article IV Consultation-Press Release; Staff Report; and Statement by the Executive Director for The People’s Republic of China. Available online: https://www.imf.org/en/Publications/CR/Issues/2016/12/31/The-People-s-Republic-of-China-2016-Article-IV-Consultation-Press-Release-Staff-Report-and-44181 (accessed on 7 September 2020).

- Asian Development Bank People’s Republic of China: Country Partnership Strategy (2016–2020). Available online: https://www.adb.org/documents/peoples-republic-china-country-partnership-strategy-2016-2020 (accessed on 10 September 2020).

- Müller, J.M.; Voigt, K.-I. Sustainable Industrial Value Creation in SMEs: A Comparison between Industry 4.0 and Made in China 2025. Int. J. Precis. Eng. Manuf. Technol. 2018, 5, 659–670. [Google Scholar] [CrossRef]

- The People’s Republic of China Made in China 2025. Available online: http://english.www.gov.cn/2016special/madeinchina2025/ (accessed on 7 September 2020).

- Institute for Security and Development Policy Made in China 2025. Available online: https://isdp.eu/publication/made-china-2025/ (accessed on 8 September 2020).

- Southeast University About SEU. Available online: https://www.seu.edu.cn/english/_t1875/22456/list.psp (accessed on 8 September 2020).

- National Mobile Communications Research Laboratory Main Scientific Research Results. Available online: https://ncrl.seu.edu.cn/15596/list.htm (accessed on 9 August 2020).

- Birkel, H.; Veile, J.; Müller, J.M.; Hartmann, E.; Voigt, K.-I. Development of a Risk Framework for Industry 4.0 in the Context of Sustainability for Established Manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef]

- China Datang Company Profile. Available online: http://www.cccme.org.cn/shop/cccme8991/introduction.aspx (accessed on 10 September 2020).

- Zhejiang Haikang Technology Company Profile. Available online: http://www.hiklife.com/Corporate/Company-Profile (accessed on 12 September 2020).

- Zhejiang Haikang Technology Awake. Available online: http://www.hiklife.com/solution/Alert-series (accessed on 12 September 2020).

- Dalian University of Technology about DUT. Available online: https://en.dlut.edu.cn/Research/Research_Overview.htm (accessed on 12 September 2020).

- Beijing University of Technology about BJUT. Available online: http://english.bjut.edu.cn/About/About_BJUT.htm (accessed on 25 September 2020).

- Chongqing University an Overview. Available online: http://english.cqu.edu.cn/ (accessed on 25 September 2020).

- Ren, S.; Zhang, Y.; Liu, Y.; Sakao, T.; Huisingh, D.; Almeida, C.M.V.B. A comprehensive review of big data analytics throughout product lifecycle to support sustainable smart manufacturing: A framework, challenges and future research directions. J. Clean. Prod. 2019, 210, 1343–1365. [Google Scholar] [CrossRef]

- Bundestag, D. Bundesbericht Forschung und Innovation 2020. Available online: https://dip21.bundestag.de/dip21/btd/19/193/1919310.pdf (accessed on 26 June 2020).

- Bundestag, D. Integrierter Nationaler Energie- und Klimaplan. Available online: https://dip21.bundestag.de/dip21/btd/19/203/1920364.pdf (accessed on 31 June 2020).

- Hannover Messe about Us. Available online: https://www.hannovermesse.de/en/about-us/about-the-show/ (accessed on 1 July 2020).

- Tao, F.; Wang, Y.; Zuo, Y.; Yang, H.; Zhang, M. Internet of Things in product life-cycle energy management. J. Ind. Inf. Integr. 2016, 1, 26–39. [Google Scholar] [CrossRef]

- Odd.Bot agRobotics for a Sustainable Future. Available online: https://www.hannovermesse.de/exhibitor/odd-bot/N1449701 (accessed on 1 July 2020).

- Elahi, E.; Weijun, C.; Zhang, H.; Nazeer, M. Agricultural intensification and damages to human health in relation to agrochemicals: Application of artificial intelligence. Land Use Policy 2019, 83, 461–474. [Google Scholar] [CrossRef]

- Cybus Cybus Connectware Gateway and Integration Platform. Available online: https://www.messe.de/apollo/hannover_messe_2020/obs/Binary/A1020767/Cybus_Connectware_OnePager_FO_2019.pdf (accessed on 1 July 2020).

- Friedrich-Alexander-Universität Erlangen-Nürnberg Seven Unique Research Areas. Available online: https://www.wiso.rw.fau.eu/research/research-profile/research-focus-areas/ (accessed on 25 June 2020).

- Bauhütte 4.0 Bauhütte 4.0. Available online: https://www.bauhuette40.com/ (accessed on 25 June 2020).

- Abgeordnetenhaus von Berlin Nachhaltigkeit auf dem Bau: Berlin baut mit Holz. Available online: https://www.parlament-berlin.de/ados/18/IIIPlen/vorgang/d18-2225.pdf (accessed on 1 August 2020).

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.K.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Bag, S.; Telukdarie, A.; Pretorius, J.H.C.; Gupta, S. Industry 4.0 and supply chain sustainability: Framework and future research directions. Benchmarking Int. J. 2018. [Google Scholar] [CrossRef]

- Yazdi, P.G.; Azizi, A.; Hashemipour, M. An Empirical Investigation of the Relationship between Overall Equipment Efficiency (OEE) and Manufacturing Sustainability in Industry 4.0 with Time Study Approach. Sustainability 2018, 10, 3031. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, S.P.; Lamba, K. Sustainable robust layout using Big Data approach: A key towards industry 4.0. J. Clean. Prod. 2018, 204, 643–659. [Google Scholar] [CrossRef]

- Shim, S.-O.; Park, K.; Choi, S. Sustainable Production Scheduling in Open Innovation Perspective under the Fourth Industrial Revolution. J. Open Innov. Technol. Mark. Complex. 2018, 4, 42. [Google Scholar] [CrossRef]

- Ding, B. Pharma Industry 4.0: Literature review and research opportunities in sustainable pharmaceutical supply chains. Process Saf. Environ. Prot. 2018, 119, 115–130. [Google Scholar] [CrossRef]

- Franciosi, C.; Iung, B.; Miranda, S.; Riemma, S. Maintenance for Sustainability in the Industry 4.0 context: A Scoping Literature Review. IFAC PapersOnLine 2018, 51, 903–908. [Google Scholar] [CrossRef]

- Garrido-Hidalgo, C.; Hortelano, D.; Roda-Sanchez, L.; Olivares, T.; Ruiz, M.C.; Lopez, V. IoT Heterogeneous Mesh Network Deployment for Human-in-the-Loop Challenges Towards a Social and Sustainable Industry 4.0. IEEE Access 2018, 6, 28417–28437. [Google Scholar] [CrossRef]

- Ardanza, A.; Moreno, A.; Segura, Á.; de la Cruz, M.; Aguinaga, D. Sustainable and flexible industrial human machine interfaces to support adaptable applications in the Industry 4.0 paradigm. Int. J. Prod. Res. 2019, 57, 4045–4059. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar]

- Bányai, T.; Tamás, P.; Illés, B.; Stankevičiūtė, Ž.; Bányai, Á. Optimization of Municipal Waste Collection Routing: Impact of Industry 4.0 Technologies on Environmental Awareness and Sustainability. Int. J. Environ. Res. Public Health 2019, 16, 634. [Google Scholar] [CrossRef]

- Batkovskiy, A.M.; Leonov, A.V.; Pronin, A.Y.; Semenova, E.G.; Fomina, A.V.; Balashov, V.M. Sustainable development of Industry 4.0: The case of high-tech products system design. Entrep. Sustain. Issues 2019, 6, 1823–1838. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Fatimah, Y.A.; Govindan, K.; Murniningsih, R.; Setiawan, A. Industry 4.0 based sustainable circular economy approach for smart waste management system to achieve sustainable development goals: A case study of Indonesia. J. Clean. Prod. 2020, 269, 122263. [Google Scholar] [CrossRef]

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Tiwari, K.; Khan, M.S. Sustainability accounting and reporting in the industry 4.0. J. Clean. Prod. 2020, 258, 120783. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Kumar, S. Industry 4.0 adoption and 10R advance manufacturing capabilities for sustainable development. Int. J. Prod. Econ. 2021, 231, 107844. [Google Scholar] [CrossRef]

- Bai, X.; Ren, X.; Khanna, N.Z.; Zhou, N.; Hu, M. Comprehensive water footprint assessment of the dairy industry chain based on ISO 14046: A case study in China. Resour. Conserv. Recycl. 2018, 132, 369–375. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, A.; Zavadskas, E.K.; Mangla, S.K.; Garza-Reyes, J.A. Industry 4.0 as an enabler of sustainability diffusion in supply chain: An analysis of influential strength of drivers in an emerging economy. Int. J. Prod. Res. 2020, 58, 1505–1521. [Google Scholar] [CrossRef]

- Leng, J.; Ruan, G.; Jiang, P.; Xu, K.; Liu, Q.; Zhou, X.; Liu, C. Blockchain-empowered sustainable manufacturing and product lifecycle management in industry 4.0: A survey. Renew. Sustain. Energy Rev. 2020, 132, 110112. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K.; Kumar, V. Managing supply chains for sustainable operations in the era of industry 4.0 and circular economy: Analysis of barriers. Resour. Conserv. Recycl. 2021, 164, 105215. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.S.; Zkik, K.; Cherrafi, A.; Touriki, F.E. The integrated effect of Big Data Analytics, Lean Six Sigma and Green Manufacturing on the environmental performance of manufacturing companies: The case of North Africa. J. Clean. Prod. 2020, 252, 119903. [Google Scholar] [CrossRef]

- Sharma, M.; Kamble, S.; Mani, V.; Sehrawat, R.; Belhadi, A.; Sharma, V. Industry 4.0 adoption for sustainability in multi-tier manufacturing supply chain in emerging economies. J. Clean. Prod. 2021, 281, 125013. [Google Scholar] [CrossRef]

- Gupta, H.; Kumar, A.; Wasan, P. Industry 4.0, cleaner production and circular economy: An integrative framework for evaluating ethical and sustainable business performance of manufacturing organizations. J. Clean. Prod. 2021, 295, 126253. [Google Scholar] [CrossRef]

| Clusters | Associated Words SCOPUS | Associated Words ORBIT |

|---|---|---|

| Sustainability | Sustainability; Sustainable | Sustainability; Sustainable |

| Industry 4.0 | Industry 4.0; Industrial 4.0; Industrie 4.0; Manufacturing 4.0; The Fourth Industrial Revolution; 4.0; Smart Factory; Smart Manufacturing; Smart Factories | Smart Machine; Smart Manufacturing; Smart Factories; Smart Factory; Cyber-physical Systems; Internet of Things; Internet of Services; Cloud; Big Data; Machine Learning; Deep Learning; Artificial Intelligence; Intelligent Manufacturing |

| Research Opportunities | Authors |

|---|---|

| Identifying the impacts of the Integration between Sustainability and Industry 4.0 in the Supply Chain | Bag et al. (2018) [118]; Luthra and Mangla (2018) [65]; Manavalan and Jayakrishna (2019) [42]; Yazdi et al. (2018) [119] |

| Proposing strategies to integrate Sustainability with Industry 4.0 | Jabbour et al. (2018a) [25]; Kiel et al. (2017) [29]; Kumar et al. (2018) [120]; Lin et al. (2017) [39]; Meng et al. (2018) [41]; Prause and Atari (2017) [30]; Ren et al. (2019) [106]; Shim et al. (2018) [121] |

| Integrating Risk Management with S4.0 | Birkel et al. (2019) [99]; Ghadimi et al. (2019) [56] |

| Proposing new models of sustainable production processes using the technologies of Industry 4.0 | Ding (2018) [122]; Franciosi et al. (2018) [123]; Garrido-Hidalgo et al. (2018) [124]; Kamble et al. (2019) [84]; Prause (2015) [47] |

| Identifying and assessing the impacts of implementing I4.0 on TBL | Ardanza et al. (2019) [125]; Müller and Voigt (2018) [94] |

| Identifying S4.0 contributions to governments, industries and people | Jabbour et al. (2018b) [126]; Bányai et al. (2019) [127]; Batkovskiy et al. (2019) [128]; Bonilla et al. (2018) [26]; Branger and Pang (2015) [48]; Haseeb et al. (2019) [33]; Kamble et al. (2018) [37]; Müller et al. (2018) [38]; Stock et al. (2018) [129] |

| Research Challenges | Authors |

|---|---|

| High cost for the modernization/adaptation of structures and intelligent technologies. | Birkel et al. (2019) [99]; Haseeb et al. (2019) [33]; Kiel et al. (2017) [29]; Lin et al. (2017) [39]; Manavalan and Jayakrishna (2019) [42]; Yazdi et al. (2018) [119] |

| Lack of company know-how and qualified human capital. | Ardanza et al. (2019) [125]; Bag et al. (2018) [118]; Bonilla et al. (2018) [26]; Ding (2018) [122]; Garrido-Hidalgo et al. (2018) [124]; Ghadimi et al. (2019) [56]; Kamble et al. (2018) [37]; Luthra and Mangla (2018) [65]; Müller et al. (2018) [38]; Shim et al. (2018) [121]; Stock et al. (2018) [129] |

| Supply Chain mismatch. | Franciosi et al. (2018) [123]; Müller and Voigt (2018) [94]; Prause and Atari (2017) [30] |

| Divergence of objectives between sustainability and I4.0. | Jabbour et al. (2018a) [25]; Kumar et al. (2018) [120] |

| Lack of infrastructure. | Bányai et al. (2019) [127]; Batkovskiy et al. (2019) [128]; Meng et al. (2018) [41]; Prause (2015) [47]; Ren et al. (2019) [106] |

| Need for organizational alignment. | Branger and Pang (2015); Jabbour et al. (2018b) [126]; Kamble et al. (2019) [84] |

| TH Sectors | Propositions | TH Connection | Benchmarking of Scientific and Technical References |

|---|---|---|---|

| Instituting a national program for the technological and sustainable development of industries. | Organizations | Institute for Security and Development Policy (2020) [96]; Müller and Voigt (2018) [94]; The People’s Republic of China (2020) [95] |

| Instituting a National Plan to develop social connectivity using intelligent technologies. | Organizations and Academy | Haseeb et al. (2019) [33]; Lozano (2020) [31]; Swarnima et al. (2017) [46] | |

| Improving the quality of life by monitoring air quality and noise pollution, using intelligent remote sensing. | Organizations | United States Environmental Protection Agency (2020b) [69] | |

| Developing plans for agricultural development, solid waste management, reduction of factory pollution and increased energy efficiency using I4.0 technologies. | Organizations and Academy | Borowiecki et al. (2019) [3]; Lin et al. (2017) [39]; Odd.Bot (2020) [111]; Tao et al. (2016) [110] | |

| Financing projects for the development of intelligent technologies and infrastructures that take advantage of renewable energy for sustainable development. | Academy | Abgeordnetenhaus von Berlin (2019) [116]; Bauhütte 4.0 (2020) [115] | |

| Fostering S4.0 in civil construction through tax incentives. | Organizations | Abgeordnetenhaus von Berlin (2019) [116]; Bauhütte 4.0 (2020) [115]; Kisku et al. (2017) [117]; Moschetti et al. (2015) [78] | |

| Creating startup financing programs to develop intelligent technologies that ensure the physical integrity of urban and rural workers. | Organizations and Academy | Hannover (2020) [109] | |

| Making it easier for organizations to acquire intelligent structures and technologies. | Organizations | Birkel et al. (2019) [99]; Haseeb et al. (2019) [33]; Kiel et al. (2017) [29]; Lin et al. (2017) [39] | |

| Creating systems with intelligent technologies to improve motor vehicle traffic and reduce CO2 emissions. | Government and Academy | IBM, (2020b) [72]; Haseeb et al. (2019) [33]; Lozano (2020) [31] |

| Using intelligent technologies for the treatment and management of water facilities. | Government and Academy | IBM, (2020b) [72]; Haseeb et al. (2019) [33]; Lozano (2020) [31] | |

| Reducing the consumption of material and energy resources through digitalization, Cloud Computing and IoT. | Government | Lozano (2020) [31]; Newell and Vos (2011) [76]; Xerox (2020b) [74], Xerox (2020c) [75] | |

| Improving the integration of society through collaborative networks with high capacity and speed to exchange information in real-time. | Government | National Mobile Communications Research Laboratory (2020) [98] | |

| Implementing strategies that enable organizational alignment with S4.0. | Academy | Branger and Pang (2015) [48]; Jabbour et al. (2018b) [25]; Kamble et al. (2019) [37] | |

| Using intelligent technologies to disinfect biologically contaminated materials. | Government and Academy | Chung et al. (2020) [61]; Lozano (2020) [31]; VST Mobility Solutions (2020c) [59] | |

| Investigating new sources of clean energy with the help of I4.0. | Government and Organizations | Indian Institute of Technology Delhi (2020) [66]; Kamble et al. (2018) [37]; Manavalan and Jayakrishna (2019) [42] |

| Developing research with I4.0 technologies that enable sustainable management. | Organizations | Bai et al. (2018) [134]; Bonilla et al. (2018) [23]; Esmaeilian et al. (2020) [91] | |

| Prospecting and establishing partnerships between universities and organizations that are advanced in research on Industry 4.0 and Sustainability. | Organizations | Abgeordnetenhaus von Berlin, (2019) [116]; Bauhütte 4.0 (2020) [115] | |

| Developing strategies and tools to integrate Sustainability and Industry 4.0. | Organizations | Kumar et al. (2018) [120] | |

| Proposing models, tools and initiatives for the development of know-how and human capital for S4.0. | Organizations | Kamble et al. (2018) [37]; Müller et al. (2018) [38]; Stock et al. (2018) [129] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reis, J.S.d.M.; Espuny, M.; Nunhes, T.V.; Sampaio, N.A.d.S.; Isaksson, R.; Campos, F.C.d.; Oliveira, O.J.d. Striding towards Sustainability: A Framework to Overcome Challenges and Explore Opportunities through Industry 4.0. Sustainability 2021, 13, 5232. https://doi.org/10.3390/su13095232

Reis JSdM, Espuny M, Nunhes TV, Sampaio NAdS, Isaksson R, Campos FCd, Oliveira OJd. Striding towards Sustainability: A Framework to Overcome Challenges and Explore Opportunities through Industry 4.0. Sustainability. 2021; 13(9):5232. https://doi.org/10.3390/su13095232

Chicago/Turabian StyleReis, José Salvador da Motta, Maximilian Espuny, Thaís Vieira Nunhes, Nilo Antonio de Souza Sampaio, Raine Isaksson, Fernando Celso de Campos, and Otávio José de Oliveira. 2021. "Striding towards Sustainability: A Framework to Overcome Challenges and Explore Opportunities through Industry 4.0" Sustainability 13, no. 9: 5232. https://doi.org/10.3390/su13095232

APA StyleReis, J. S. d. M., Espuny, M., Nunhes, T. V., Sampaio, N. A. d. S., Isaksson, R., Campos, F. C. d., & Oliveira, O. J. d. (2021). Striding towards Sustainability: A Framework to Overcome Challenges and Explore Opportunities through Industry 4.0. Sustainability, 13(9), 5232. https://doi.org/10.3390/su13095232