1. Introduction

1.1. Context and the Importance of Developing the Field of Research

Today we are facing many challenges and concerns associated with pollution, global warming, and natural resource depletion. Consequently, research is focusing on more sustainable development, especially regarding energy production. It is only a matter of time before the only existing sources for energy production are renewables, and new opportunities will be created for processing various non-recyclable waste, vegetal waste, and biomass.

The mission to develop innovative, mature, and viable technologies that can sustainably convert biomass-based resources into high-quality biofuels and chemicals is not just an important stage in industrial development, but also a milestone for redesigning the world in a safer environment for future generations.

Global research objectives are aimed at including plant waste in the processes of producing efficient biofuels and overcoming difficulties related to biomass characteristics such as high moisture content, low calorific value, and increased loosening, or increased processing and transportation costs, making it difficult to successfully produce and use biofuels in large-scale applications [

1,

2].

The establishment of various intensive energy crops has long been considered an opportunity to reduce the widespread use of fossil fuels and chemicals. However, industrial-scale cultivation of these crops is achieved to the detriment of food production and has proven to generate long-term environmental negative effects on the ecosystem, drastically reducing their expected benefits [

3,

4].

One possible approach to offset competition with food production would be to plant various crops with special characteristics and high potential for biomass production on marginal, contaminated, or nutrient-depleted lands, carefully analyzing aspects related to productivity and production cost. Particular attention must be paid to the conversion efficiency since the total biofuel costs on production and processing often ends up being higher than the cost of synthesizing petroleum fuels. Therefore, the technologies employed for planting, harvesting, transporting, and processing must produce qualitative biofuels or chemicals with special valuable applications [

5,

6].

One energy crop suitable for planting on difficult soils is sweet sorghum (

Sorghum bicolor (L.) Moench), because of its characteristics of easy adaptability in various climatic conditions, disease resistance, good biological productivity [

7], and higher stress efficiency than other traditional crops. Sweet sorghum juice is rich in sugars and has a rich plant mass, and has significant potential to be used for chemicals and biofuel production [

8].

A crop established on degraded or polluted soils cannot be used in human nutrition or to produce animal feed, and it is not considered a very advantageous factor in restoring soil quality, either. One of the preferred areas of use for this potentially contaminated biomass is the renewable fuel industry, after applying different types of heat treatments and processes that would increase its value.

Sweet sorghum juice obtained by pressing the stems can be subjected to a process of alcoholic fermentation and distillation to produce bioethanol [

9], and the bagasse and the plant leaves resulting as waste from the process can be considered raw material for the pyrolysis process [

10].

Integration into the agricultural use of degraded and contaminated soils to obtain high-quality fuels that can be used in internal combustion engines, using both the juice obtained by pressing sweet sorghum stems in the production of bioethanol and the pyrolysis of plant mass to obtain bio-oils, is an extremely important direction both for environmental protection and for the transition from fossil fuels to renewable ones.

1.2. Efficient Use of Marginal Lands for Food and Bioenergy Production

The potential of marginal lands to enhance food security and promote bioenergy production has attracted a lot of attention. However, various environmental concerns, ecosystem service drawbacks, and long-term viability issues have been questioned in relation to the usage of marginal lands [

10,

11]. In Europe, agricultural marginal lands have been characterized as land uses that are on the edge of economic viability—areas where cost-effective production is not possible under the given site conditions, cultivation techniques, agricultural policies, or macro-economic conditions [

12,

13].

Marginal lands are therefore characterized by low productivity and reduced economic return, which might produce serious limitations for agricultural use [

14,

15]. These lands generally refer not only to low production, but also to several other limitations that make them unsuitable for agricultural practices and ecosystem function, such as low accessibility, soil erosion, the existence of ecologically sensitive areas, chemical contamination, the inability to carry out agricultural work, or easy floodability [

16]. Some land limitations may not be directly associated with crop production, at least in the short term, but they might be considered marginal for biodiversity purposes. The USDA-NRCS made a classification of marginal lands according to some indicators of damage [

17] associated with land suitability, considering that in most cases land limitations cause a reduction in agricultural value. Crops produced from marginal lands could be worth less than the total cost incurred for the agricultural works of establishing and harvesting, processing works, transport, or possible rents paid to have access to the respective area.

Classifications of marginal lands do not allow soil fertility potential to be evaluated. When considering the establishment of highly resistant cultures such as

Miscanthus or different species of

Sorghum, the real productivity of a marginal land can be quantified only in a practical way [

18].

Cultivation of marginal lands is inevitable, considering the limitations related to quality farming land, which is critical in emerging countries due to rising food and energy demand [

19]. According to some research studies [

20], increasing food production would require the conversion of marginal areas to sustainable agricultural management methods, as well as the restoration of degraded soils and ecosystems. Therefore, the importance of identifying new ways of reintegrating marginal lands for agricultural production must be considered, in correlation with the need for land conservation and long-term viability. Heat treatments can also be used to process plants grown on contaminated and hazardous soils, where their use by incineration could cause serious health risks [

21,

22,

23].

1.3. The Current Situation of Technologies Used for Transforming Technical Plants into High-Quality Fuels and Chemicals

There are several techniques commonly used for the thermal processing of agricultural waste. However, practical experiences have shown that using biomass as a fuel in large-scale applications often raises difficulties because the material is bulky, has high humidity levels, and is highly dispersed. These shortcomings usually increase the production cost, making the processing operations financially unprofitable [

24].

Thermo-chemical conversion of biomass includes processes such as gasification, slow pyrolysis, fast pyrolysis, hydro-carbonization, and combustion, which are characterized by differences in oxygen supply, retention time, temperature, and pressure variation. Because slow and rapid pyrolysis are feedstock-flexible possibilities, a variety of biomass sources have been investigated as suitable precursors, due to their reduced cost and availability [

25]. A favorable approach involves obtaining higher-quality fuels using specific thermo-chemical techniques, and pyrolysis is the most intensely studied. Fast pyrolysis is a thermo-chemical conversion method used to produce mainly liquid fuel from biomass, based on thermal decomposition of organic compounds in the absence of oxygen [

25,

26]. Pyrolysis oils are compounds that are preferred as biofuels for their high calorific values, easy transportation and storage, low nitrogen and sulfur content, and the possibility of easy conversion into high-rated chemicals [

27]. Efforts to turn renewable crop biomass into fundamental chemical elements that will be integrated into various common goods have been also intensified in recent years. However, a switch to bio-based polymers is dependent on the availability and consistency of important quantities of feedstock sold at reasonable prices. Commercializing a biobased polymer needs continuous, simultaneous progress in numerous research fields.

Another benefit of pyrolysis is the opportunity to use a wide variety of feedstock, which gives the system flexibility, which is a useful element for agricultural waste, especially when the raw material is not homogeneous.

To obtain products with high energy density and superior energy properties, the variation during thermal decomposition has to be considered and several factors have to be analyzed, such as temperature levels, operating pressures within the reactor, the residence time of the solid, the heating rate, the gaseous environment, the use of catalysts, and the initial properties of the biomass [

28].

Pyrolysis of wastes generated from agriculture can be defined as the controlled de-composition of the organic vegetal mass matrix in the absence of an oxidizing agent, or in an amount so small that gasification does not occur completely, to obtain solid, liquid, and gas as byproducts. Oils obtained by pyrolysis are very valuable, because they can be upgraded by catalysts to produce refined fuels or can potentially be used as highly valuable chemicals [

29,

30].

Biochar is another product obtained by the pyrolysis of sweet sorghum and is considered [

31] an ecofriendly and multifunctional material with significant potential for the remediation of contaminated soils or in the framework of biochar-based water treatment systems. The physical and chemical properties of biochar, such as ash or mineral content, aromaticity, surface structures, pH, and surface functional groups, are mostly determined by the feedstock that is used and the pyrolysis temperature. The alkalinity of biochar usually increases directly proportionally to the pyrolysis temperature [

32], obtaining a higher alkalinity by processing the vegetal mass of the plants than by treating manure. The hydrologic properties of biochar are directly influenced by several aspects, such as the production processing method, the type of feedstock used, the particle size, or the wetting properties [

33,

34], being noted that biochar generated at higher temperatures (400–600 °C) was shown to have the best hydrologic qualities [

35].

Another intensely studied direction [

36,

37] is to process biomass in the presence of various catalysts in order to obtain a densification of the biomass, since the energy content can be improved this way. Although the densification technique is used more for combustion processes, the use of catalysts with a role in improving the quality of the obtained products, in association with the reduction of pollutants, is a frequently considered goal in the field of biomass processing.

The mechanical durability of solid fuels obtained in thermo-chemical reactions is the ability to remain as close as possible to the initial state over long time periods. It can be improved by reducing the content of lignin, fat, and other extractives found in the catalysts [

38] and works in a complementary way with the variation of the reaction parameters [

39]. However, in our research study, the objective was to obtain rather a very airy and low-density solid product. The solid product was used for the restoration of marginal soils; therefore, it needed to allow the bacteria and fungi to hide and grow. In addition, a supply of carbon and minerals was provided to the degraded soil, which helped to reduce the deterioration of arable soils by applying regenerative ecological technologies [

40].

1.4. General Aim and Scope of the Paper

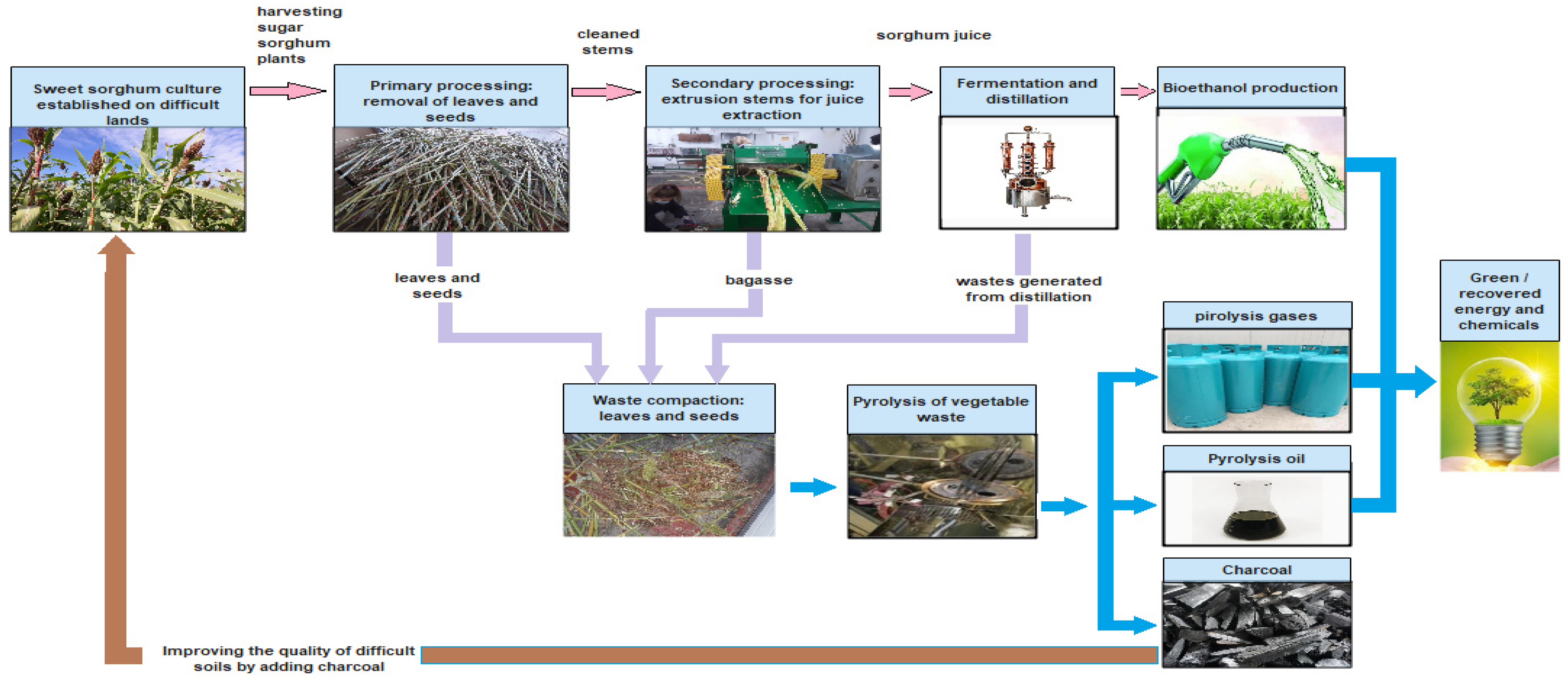

Considering sweet sorghum’s characteristics of adaptability and the opportunity for cultivation on poor and contaminated soils, an experimental culture was established on marginal lands to evaluate the potential for producing both juice and biomass. The juice obtained by extraction with extruding equipment was subjected to maceration and double distillation, obtaining bioethanol.

The vegetable mass resulting as waste, composed of the bagasse, seeds, and leaves of the sweet sorghum plant, was subjected to pyrolysis treatment in conditions that maximized the production of high-quality bio-oils (tar). The bio-oil has the potential to be used for the production of high-value chemicals or biofuels.

The compounds obtained by pyrolysis were subsequently analyzed and characterized, with the treatment regime being varied and optimized, to obtain the maximum quantities of the compounds of interest.

Following pyrolysis, solid by-products were obtained in the form of a biochar. This product has a high potential to be used as an amendment to improve the quality of degraded soil where the sweet sorghum plantation was established, improving the land capability classification over time.

To integrate marginal lands into the agricultural circuit, an approach designed to have beneficial effects on the ecosystem was assumed, stopping soil degradation processes and creating practical methods to improve the quality of fuels obtained from biomass waste. The general process diagram that illustrates the experimental activity described in the present paper is depicted in

Figure 1.

2. Materials and Methods

The experimental design comprised three main phases. The first phase dealt with assessing the productivity of the sweet sorghum crop when planted on marginal soils to evaluate the real output of biomass and juice, and the productivity of bioethanol obtained from sweet sorghum juice. The second phase envisaged the production and evaluation of the bio-oil product obtained by pyrolysis in relation to the thermo-chemical parameters. The third phase (which is not the subject of the current paper) involved evaluating the biochar’s ability to recondition marginal lands. According to the land capability classification (LCC) derived from the USDA-NRCS (2010) [

17], the marginal land analyzed was assigned to Class 6, with severe limitations that makes it generally unsuitable for cultivation and that restrict its use mainly to pasture, rangeland, forestland, or wildlife habitat.

Sweet sorghum tolerates drought and high-temperature stress better than many crops, but it does not grow well under low temperatures. Therefore, 15 May was chosen for the establishment of the culture, taking into account the local climatic specificities.

Sweet sorghum is an ideal candidate for difficult, contaminated, or marginal areas because it can be grown under reduced inputs (water, fertilizer) and responds more efficiently to stresses than other traditional crops. Therefore, after planting (performed according to the specifications of the seed producer), the crops were not irrigated and no additional treatments were applied. A locally resistant hybrid was tested in the experiment on two different areas (regular soil and marginal soil), each measuring 0.5 hectares. The main characteristics of the plant were stem thickness of 25–30 mm and height of 3.6–3.9 m, increased leaf size, cellulose content of 35–38%, amount of sugar in the juice of the stem of 14–19%; tolerance to soil salinization, and resistance to diseases and pests.

To establish the growing characteristics for the plants raised on different soil types, 20 different perimeters of 1 square meter each were harvested and associated with each culture. For the assessment, the randomized complete block design was used. The leaves were removed from the stem, then the panicles with seeds and all the components were weighed separately. The sweet sorghum cleaned stems were extruded using dedicated equipment in order to obtain the juice, and the fiber resulting from the process (bagasse) was weighed and evaluated in terms of humidity. The extracted juice was evaluated in terms of soluble dry matter and Brix degree, using a professional Abbe digital Brix refractometer.

Weather variables did not differ considerably during the sweet sorghum growing period, since the plantations were established at a distance of 1 km from each other.

2.1. Evaluation Phase of the Biomass Productivity Obtained from a Sweet Sorghum Crop and Planted on Marginal Lands (Degraded Soils)

Two experimental crops were established on normal and marginal lands, and the same agricultural works were carried out according to the specifications of the seed producer and the norms of good practices. The planting operations were performed, keeping 15 cm between plants and 60 cm between rows, and weed growth was controlled by mechanical weeding. Harvesting of the sweet sorghum was performed using automatic threshing equipment, which cut the stem from 2 cm above the ground when the plant reached maturity, and was carried out only when the Brix index exceeded the value of 18 Brix degrees. The plants were then plucked for leaf removal and pressed with stem extrusion equipment, as showed in

Figure 2.

Sweet sorghum productivity per hectare was evaluated by analyzing 20 perimeters of 1 square meter each for both cultures. In each perimeter the average plant dimensions (height and thickness), the vegetal mass of the plants grown per square meter, and the number of plants that managed to grow vigorously per square meter were determined. Then, each component of the plants (leaves, tops with seeds, and cleaned stems) was weighed separately for each representative area, and after extruding the stems, the juice and bagasse were weighed.

The obtained data allowed us to analyze the differences in productivity between the two crops, evaluating how the soil quality affects the production of juice and biomass. Knowing the amount of juice that can be obtained per hectare and measuring the Brix index with a professional refractometer ABBE KRUSS AR4, it was possible to determine the maximum amounts of sugars that can be obtained from the two crops of sweet sorghum, using Guigou et al. Equation (1), for the range of 12.2 to 18.6

oBrix [

41].

Sweet sorghum harvesting for both crops was performed after the Brix index reached the value of 18 oBrix; therefore, the refractometric analyses showed uniform values. Based on the sugar value found in the extracted juice, it was possible to determine the total amount of bioethanol obtained for the culture established in marginal soils in relation to the one established on regular soils.

Considering an average sugar content in the juice of 110 g/L and a theoretical yield of ethanol from sweet sorghum juice sugars of 0.51 g ethanol/g sugar, with an expected conversion ratio of 90%, the potential for bioethanol production for the two cultures was calculated.

2.2. Pyrolysis of Sweet Sorghum Vegetal Mass for Obtaining High-Quality Chemicals and Biofuels

The main goal of performing the thermal processing of biomass was to obtain highly calorific liquid fuel using the pyrolysis process. Pyrolysis offers advantages over other product-processing methods, as the treatment that maximizes the production of bio-oil with superior technical applications and having the potential to be used to produce several highly valuable chemicals. The pyrolysis unit consists of a cylindrical reactor and a liquid phase-condensing system, as shown in

Figure 3.

The main characteristics of the pyrolysis reactor used in the experiment are an inner diameter of 130 mm, a height of 330 mm, and a wall thickness of 2 mm. The wall is heated by electrical resistors with a total power of 5 kW, isolated with a thick layer from the outside environment. The maximum temperature that can be reached is 800 °C. The experiments were performed at the decomposition temperatures identified by thermo-gravimetric analysis, between 350 and 600 °C. The wall temperature is measured with an N-type thermocouple and is maintained by a proportional–integral–derivative controller (PID controller).

The vapors obtained by heating are condensed by a refrigerant and collected in a calibrated glass container that is immersed in ice to further increase the condensation rate.

Two series of experiments were performed for each sample to verify the accuracy of the data. To be sure all the phases would be detected (the first vapors, the first condensation drops, the peak of the condensable gas release), temperature levels of 2–3 min were used, starting with 150 °C from 50 to 50 °C and going up to a temperature of 500 °C. To obtain good-quality solid residue, the temperature of 500 °C was kept for 120 min.

The main components of the pyrolysis experimental setup are depicted in

Figure 4.

A mass of approximately 150 g of sample was introduced into the reactor without any process of crushing, drying, or pre-treatment, as shown in

Figure 5. Sweet sorghum plants were analyzed both before extrusion and after extrusion (bagasse) to identify the differences in the production potential of valuable chemical components. To accurately simulate the industrial pyrolysis of the sweet sorghum plants, the stem, leaves, and seeds were taken in the reference sample in the same percentages as produced by the plant.

2.3. Materials and Methods—Analysis and Characterization of Liquid and Solid Fuels Obtained from the Pyrolysis Process

The most important parameters affecting the generation of pyrolysis products are the pyrolizer design, biomass composition, and operating parameters such as heating rate, pyrolysis temperature, residence time in the reaction, and particle size of the substrate. Based on heating rate, pyrolysis can be classified as slow (heating rate of 0.1–0.8 °C/s) or fast (heating rate of 10–200 °C/s).

Thermogravimetric analysis was performed using thermogravimetric analyzer Setaram SETSYS Evolution TGA-DTG/DSC. Small pieces of 7 mg from each sample were pyrolyzed under a 20 mL/min N2 flow at a 20 °C/min heating rate, with the temperature varying from 50 to 600 °C. The nitrogen flow rate ensured an inert atmosphere during functioning.

The liquid fractions (bio-oils) were analyzed using gas chromatography with flame-ionized detector (FID), using a PERKIN ELMER XL Gas Chromatograph with Autosampler. The tar (bio-oil) was filtered using a glass filter for microsyringe (Filtstar GF) in order to remove impurities from the pyrolysis oil. Extraction and dilution of the components were performed using n-hexane as a solvent with a dilution of 1:50, stirring for 2 min with a shaker Vortex Velp-RX3. The sample was automatically introduced into the GC-MS using the autosampler. The column was VARIAN WCOT Fused Silica type (30 m length × 0.39 mm interior diameter, film thickness 0.25 mm). The injector temperature was 250 °C. The chromatograph program comprised 1 min at 45 °C followed by a ramp to 300 °C at a rate of 7 °C min

−1. The final temperature was held constant for 10 min. The equipment design allowed the split of the carrier gas flow to perform analyses using FID and MS detectors simultaneously. The mass spectrometer was operated at an electron impact ionization energy of 70 eV. The scan range was 30–450

m/

z and the individual compounds were identified from the GC/MS chromatograms using Library MS NIST [

42].

4. Discussion

Crop production on marginal lands is limited by the lack of infrastructure (considering that the lands can be located in inaccessible areas) and reduced soil fertility, resulting in higher costs for production than in typical crops.

Sweet sorghum cultivation on marginal lands has proven to record an acceptable level of productivity, given the difficult growing conditions (floodable and clayey soils). Establishing plantations on marginal lands characterized by low productivity for common crops may be an opportunity for sweet sorghum, as it can reintegrate some lands into the agricultural circuit. The development of the plants took place in good conditions, without carrying out expensive works such as irrigation, the addition of nutrients, or chemical treatment against weeds and diseases.

Regarding the biomass productivity obtained by sweet sorghum (

Sorghum bicolor [L.] Moench) crops in other studies, substantial differences have been reported in the literature, depending on the climate, the type of soil, and the agricultural works applied, with a major impact being produced by irrigation and fertilizer application. Some of the hybrids offered productivity of dry biomass between 18.65 and 19.01 t ha

−1 [

43], whereas the crops grown in a sub-humid climate and on saline land registered 12.2 t ha

−1 biomass and 3425 L ha

−1 theoretical ethanol production. A semi-arid climate and wasteland offered a productivity of 8.6 t ha

−1 biomass and 2091 L ha

−1 of alcohol [

44], whereas irrigated and intensively treated and processed crops exceeded values of 35 t ha

−1 of dry biomass [

45]. Comparing to the values obtained in the literature, the studied marginal land registered acceptable productivity values of 14.7 t ha

−1 dry biomass per hectare without applying expensive works such as irrigation or adding fertilizers. In these conditions the productivity reached 40% from the theoretical values; however, it should be noted that Romania’s warm climate with rainy springs offers benefits to sweet sorghum crops. The plantation was able to control weeds naturally (without the need for herbicide) due to the high growth of the plants. Plant pests were identified on the crops, the most important pest being from the aphid family, but they did not affect the economic damage threshold. However, the natural enemy of aphids,

Coccinella septempunctata, managed to keep the pest population under control naturally; therefore, the use of insecticides is not recommended for the cultivation of sweet sorghum on marginal lands [

46].

In addition, the application of biochar obtained by biomass pyrolysis on marginal lands can lead to quality improvement, given the high remedial properties of biochar.

However, a balanced attitude is needed in the use of marginal lands, given that some areas may raise concerns related to environmental impacts, ecosystem services, and sustainability. It is known that marginal lands can host some species of flora and fauna that would disappear due to intensive agriculture [

47,

48].

The biomass production on the marginal lands was rated to 40% of the production registered on optimal planting conditions of the envisaged hybrid. Analysis of the level of plant growth per square meter showed similar values regarding the biomass produced from the two crops, except that on the marginal lands the plants were smaller and thinner, and therefore had higher lignin content [

49].

The approach proposed in this paper to extract sweet sorghum juice to produce bioethanol by alcoholic fermentation and then use the vegetable waste obtained in the pyrolysis process for the manufacture of valuable chemical components (bio-oil), as well as an amendment for soil reconditioning (biochar), could bring benefits both financially and to the environment.

During thermal decomposition of the biomass under limited supply of oxygen and a temperature regime of up to 600 °C, the material underwent a series of fragmentation reactions as volatile matter evolved, resulting in the generation of tar (bio-oil) and bio-char.

The compounds identified in the largest amounts in bio-oil can be used in a wide variety of purposes, such as the synthesis of fine chemicals and pharmaceuticals (Acetylfuran-); inhibitors and flavoring agents (2-furaldehyde, 5-methyl-); the production of bactericides, disinfectants, or herbicides (phenol); use in the food industry to provide flavor to beverages such as whiskey and coffee (phenol, 2-methoxy-); pesticides such as fenitrothion and fenthion, synthetic vitamin E, antiseptics, and preservatives (m-cresol); the production of food supplements (1-butoxy-1isobutoxy- butane); and adhesives and sealants, lubricants, and hydraulic fluids (phenol, 4-ethyl-2-methoxy).

The resulting biochar was a porous high-carbon product mainly composed of aromatic compounds. Due to the high porosity and adsorption properties, biochar is generally recognized for its soil reconditioning efficiency, and it may be further improved or transformed into activated carbon by physical or chemical activation. It is important to note that the application of biochar on the marginal lands enhances microbial relationships, adds concentrated mineral content, and contributes to surface functional groups, which helps to restore the productive upper soil layers.

It was determined that in the pyrolysis treatment, bagasse can produce bio-oil more qualitatively than unprocessed sorghum stem, because the extrusion phase also removes a large amount of water. Therefore, extrusion for obtaining sweet sorghum juice can be considered a pre-processing phase for pyrolysis.

Considering the differences regarding the amount of cellulose, hemicellulose, and lignin found in sweet sorghum plants depending on the soil quality levels, both thermogravimetric analysis (TG) and derivative thermogravimetry (DTG) were performed for both core of the plant and for its outer shell. This is a useful tool to estimate pyrolysis processing temperatures for cases of severely affected crops (which will have a higher share of the total mass of the outer shell, and thus lignin).

The most important parameters determining pyrolysis product yields were tested using laboratory thermo-chemical treatment equipment (a pyrolizer). The fast pyrolysis technique was researched and the main operational parameters were determined, such as heating rate, pyrolysis temperature, and reaction residence time. For a better reflection of the results of industrial pyrolysis equipment, the sample was chosen to contain proportional amounts of leaves, seeds, and stem; no catalysts were used; and the plants were introduced without previous cutting or shredding.

The yield of components in the liquid products was influenced by temperature variations, since different reactions were favored, and therefore some components can be maximized by choosing the right temperature ramps. The identified bio-oil components were classified into the following main chemical groups: alkanes, alkenes, acids, furans, alcohols, phenolic compounds, nitrogen-containing compounds, benzene derivatives, ketones, and PAHs. Marginal soils can produce larger amounts of phenols from lignocellulosic biomass, since these compounds were generated by the decomposition of lignin at the temperature of around 550 °C.

The use of marginal or polluted lands for producing ethanol is a viable option to decrease any perceived competition between the production of food and bioenergy, even though the amount of fuel is lower than that obtained on very fertile lands. The use of marginal lands for bioenergy and chemical production by applying advanced management practices could potentially increase soil carbon sequestration, enhance soil, and water quality, and support ecosystem services.

Marginal land offers the opportunity to practice organic farming, as the soils have not been treated with insecticides, pesticides, or chemical fertilizers due to the low productivity. This would also help restore degraded or marginal arable soils by applying environmentally friendly regenerative technologies, which are equally oriented towards profit and recovery. However, depending on climatic and zonal conditions, it is necessary to assess whether the use of biomass in this way is financially profitable or not. Otherwise, biomass can be integrated into the soil for faster ecosystem regeneration.